Page 1

DUPLICATOR : SD-4085

Date

:

Jul. 11, 1997

1. MEASURE TO ALLEVIATE PROBLEMS OF CRACKING OF THE EXPOSURE PAPER GUIDE IN THE RDH.

2. MEASURE TO IMPROVE THE PAPER FEEDING PERFORMANCE OF THE LOWER CURL ORIGINAL

DOCUMENTS IN THE RDH.

3. MEASURE TO ALLEVIATE PROBLEMS OF IMAGE MISALIGNMENT DUE TO THE DRIVE IN THE RDH.

4. MEASURE TO ALLEVIATE PROBLEMS OF COPY PAPER BECOMING CAUGHT IN THE ORIGINAL

DOCUMENT TRAY IN THE RDH.

No. : DTE-303

1. Measure to alleviate problems of cracking of the exposure paper guide in the RDH.

1.Model Name: SD-4085

2.General: There were some problems of the fixing screws which secure the No. 1 exposure paper

guide and the No. 2 exposure paper guide the frame F and frame R in the exposure

frame unit in the RDH being too long, causing the paper guide to have a tendency to be

pulled, and resulting in damage to the paper guides. As a measure to alleviate this

problem, the measures described below have been carried out.

3.Description: The 8 fixing screws of the No. 1 exposure paper guide and the No. 2 exposure paper

guide have been changed to shorter screws.

No. 1 exposure paper guide (P/G [56]-25)

No. 2 exposure paper guide (P/G [55]-20)

4.Action: From the start of 1997 June production.

(As a temporary measure, washers have been added to units produced in April and May.)

2. Measure to improve the paper feeding performance of the lower curl original

documents in the RDH.

1.Model Name: SD-4085 (only for machines bound for the U.S.A. market)

2.General: The following changes described below have been carried out in the searing unit of the

RDH. These changes have been carried out as a measure to improve the paper feeding

performance of the lower curl original documents.

SHARP CORPORATION Reprography Division

1/4

Green

C

Page 2

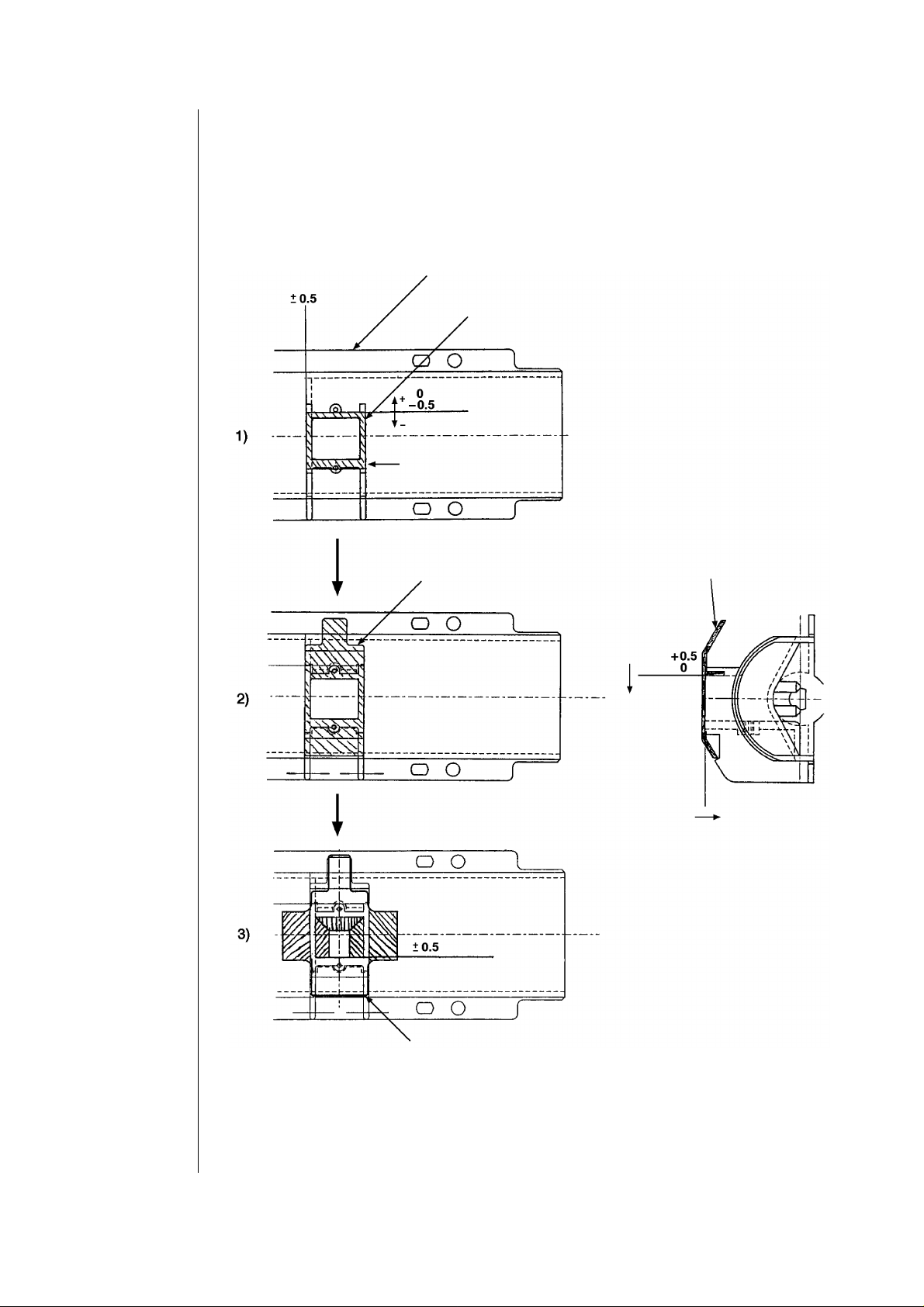

3.Description: • The nozzle spacer has been discontinued.

• The addition of a nozzle sheet and nozzle tape has been carried out.

• A change in the shape of the nozzle S has been carried out.

(Please refer to the figures described below for details concerning the method of

attachment and the attachment procedures.)

Searing Lower

Attachment standard

Nozzle tape

(PTPE-0240FCZZ)

Attachment

standard

<Market action>

For machines already out on

the market, nozzle S and the

nozzle spacer should be

detached before carrying out

operations.

The portion with the

greater width.

The attachment

surface should be

Nozzle N

(PDUC-0139FCZ1)

wiped clean with

alcohol.

The shaded portion should be

bent, and aligned with the sealing

lower side surface when

attaching.

Attachment standard

Attach with the left and right sides

averaged out in relationship to

the nozzle N.

Nozzle sheet:

(PSHEZ0699FCZZ)

4.Action: From the start of 1997 March production.

The fixing screws which

secure nozzle S have been

discontinued.

Nozzle N

(PDUC-0139FCZ1)

Attachment standard

Align and attach

Align and attach

Note:

Caution must be exercised to insure

that the copy paper suction section of

the nozzle N does not lift up, and that

there are no air bubbles. Before

folding the nozzle tape, the

attachment of the suction section

should be carefully checked.

2/4

Page 3

3. Measure to alleviate problems of image misalignment due to the drive in the RDH.

1.Model Name: SD-4085

2.General: The following changes described below have been carried out as a measure to alleviate

problems of image misalignment due to the drive.

3.Description: <1>A change has been carried out in the pulley and the gears of the drive section as a

measure to improve the precision of the parts.

<2>A change has been carried out in the tension spring of the drive unit. The new spring

has a greater load (an increase of approx. 50%).

Discontinued E-ring

Pulley 24T2GTN

(NPLYZ0334FCZZ)

WP M3 x 4

(LX-BZ0826FCZZ)

RDH tension spring

(MSPRT2600FCZZ)

E-ring

The RDH tension spring should be

placed in position, after which the

belt 412-2GT(NBLTH0272FCZZ)

should be turned several times.

After the position has become

stabilized, the fixing screws should

be tightened.

Discontinued E-ring

36-48T

Gear pulley N

WP M3 x 4

(LX-BZ0827FCZZ)

The gear should be aligned in

the direction indicated by the

arrows and then attached.

Belt tension pulley 24 N AS

Exposure BLT tension plate

(CPLTM5174FC01)

4.Action: From the start of 1997 April production.

3/4

Page 4

4. Measure to alleviate problems of copy paper becoming caught in the original

document tray in the RDH.

1.Model Name: SD-4085

2.General: There have been problems of the original document copy paper becoming caught on the

belt when an original document is put into the original document tray unit of the RDH. As

a measure to alleviate this problem, the belt has been changed to a belt which will allow

operations to run more smoothly.

3.Action: From the start of 1997 June production.

Ref.

Model

No.

1

2

SD-4085

3

4 48 -6 NBLTH0271FCZ1 NBLTH0271FCZ2 BA Belt ’97/6

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. Current type can be used in place of new type.

3. Current type cannot be used in place of new type.

Parts marked with ‘‘ ’’ is important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

Version P/G No.

name

55

All

56

46 -5 PDUC-0139FCZZ PDUC-0139FCZ1 AG Nozzle N

U.S.A.

Only

46

55 -35

55 ---- LX-BZ0826FCZZ AH Screw (M3×4) 6

55 -46

All

55 ---- LX-BZ0827FCZZ AG Screw (M3×10) 6

55 -51 CPLYZ0318FC01 CPLYZ0332FC01 AQ Tension Pulley (24T)

55 -49

New type cannot be used in place of current type.

New type can be used in place of current type.

Current parts New parts

Parts code Parts code

LX-BZ0656FCZZ LX-BZ0825FCZZ AC Washer

PSPAZ0699FCZZ

(Q’ty 2)

----

NPLYZ0319FCZZ NPLYZ0334FCZZ AS Pulley (24-2GT)

NPLYZ0320FCZZ NPLYZ0333FCZZ AY Gear Pulley (36-48T) 3

MSPRT1199FCZZ MSPRT2600FCZZ AE RDH tension spring

Discontinued ---- Nozzle spacer

PSHEZ4507FCZZ AD Nozzle sheet

PTPE-0240FCZZ AC Nozzle tape

Price

rank

5. Interchangeable if replaced with same types of

related parts in use.

6. Others.

Parts name

Effec-

tive

time

1st lot

’97/4

1st lot

’97/3

1st lot

’97/4

Inter-

change-

ability

6 Q’ty 4

3 Q’ty 2

6

3

3

Note

Q’ty 2

4/4

Loading...

Loading...