Page 1

Date: Feb. 28, 1997

DUPLICATOR : SD-3062

MEASURES CARRIED OUT TO PREVENT COPY PAPER

JAMS AND DOUBLE FEEDING IN THE CENTER TRAY.

This action was previously reported and explained in T/R DTE-230. A claim was

received, however, to the effect that the explanation concerning the measure carried out

to prevent copy paper jams in the center tray was difficult to understand, and the action

is hereby once again reported and explained.

No. : DTE-278

1.Model Name: SD-2060/3062

2.General: There were reports of some problems of folded corners on the leading edge of the copy

paper and copy paper jams which occurred in the center tray in cases of large copy

paper curls during back side copy operations. There were also reports of some

problems of double feeding of copy paper due to the effects of static electricity. As a

measure to alleviate these problems, the action described below has been carried out.

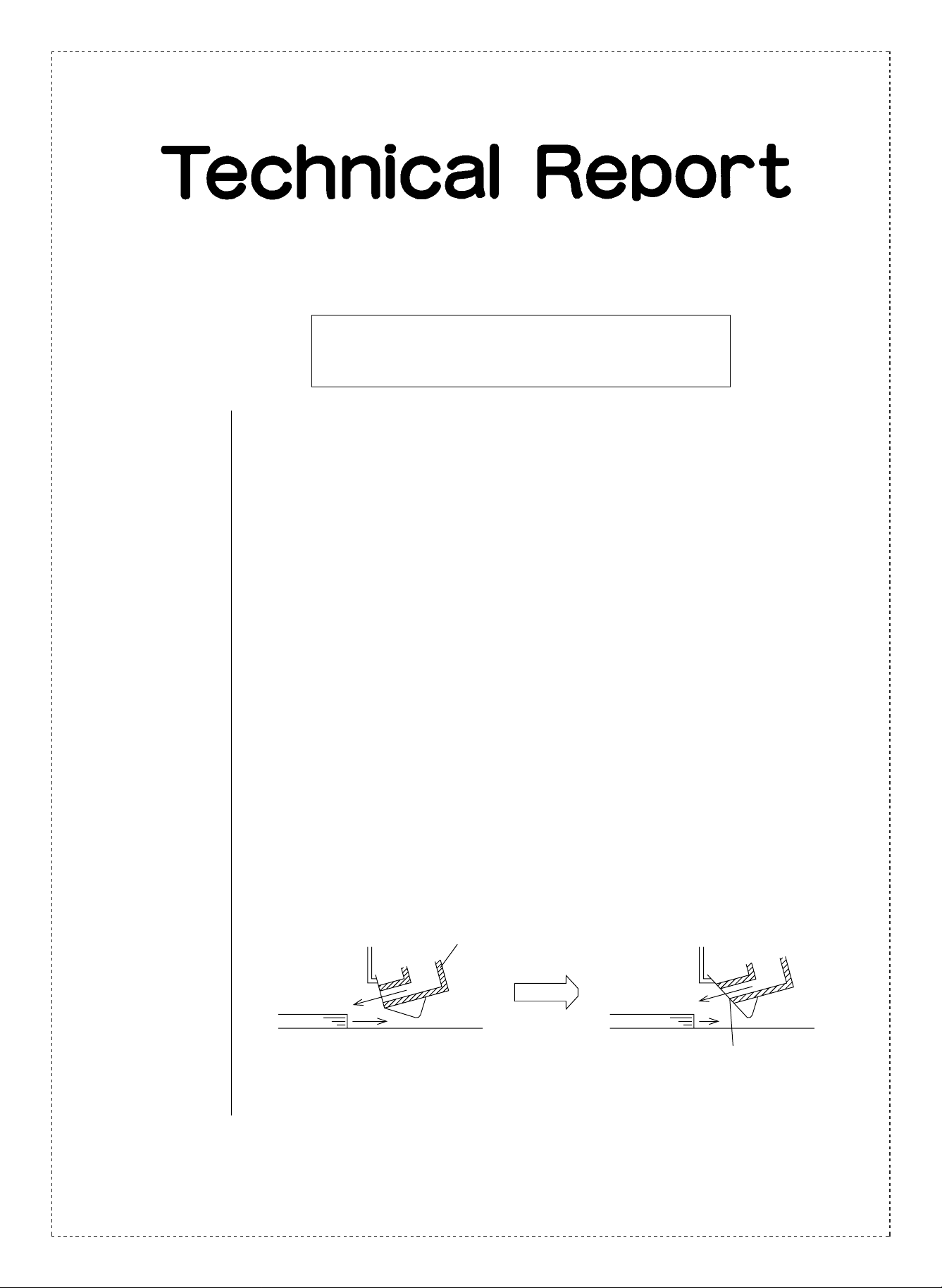

3.Description: (1) As described in figure-1 shown below, the end portion of the blow duct is positioned

so that the air is split on the paper guide from behind. When upward curling copy paper

is fed, however, the copy paper sometimes gets caught on the blow duct causing folded

corners on the leading edge of the copy paper which results in copy paper jams. As a

measure to alleviate the problem described above, a change in the shape of the blow

duct has been carried out so that the copy paper does not become caught on it. In

accordance with the change in shape that was carried out on the blow duct, a change

has also been carried out on the shape of the blow duct mylar sheet.

Figure-1: The performance of the machine concerning upward curling copy paper has

been improved by enlarging the taper on the bottom portion of the blow duct.

Blow duct

Air

Change

Direction of copy paper feed

The taper of this portion has been enlarged.

Please refer to the parts list for information concerning the change that was carried out

on the blow duct mylar sheet.

SHARP CORPORATION Reprography Division

1/4

Green

C

Page 2

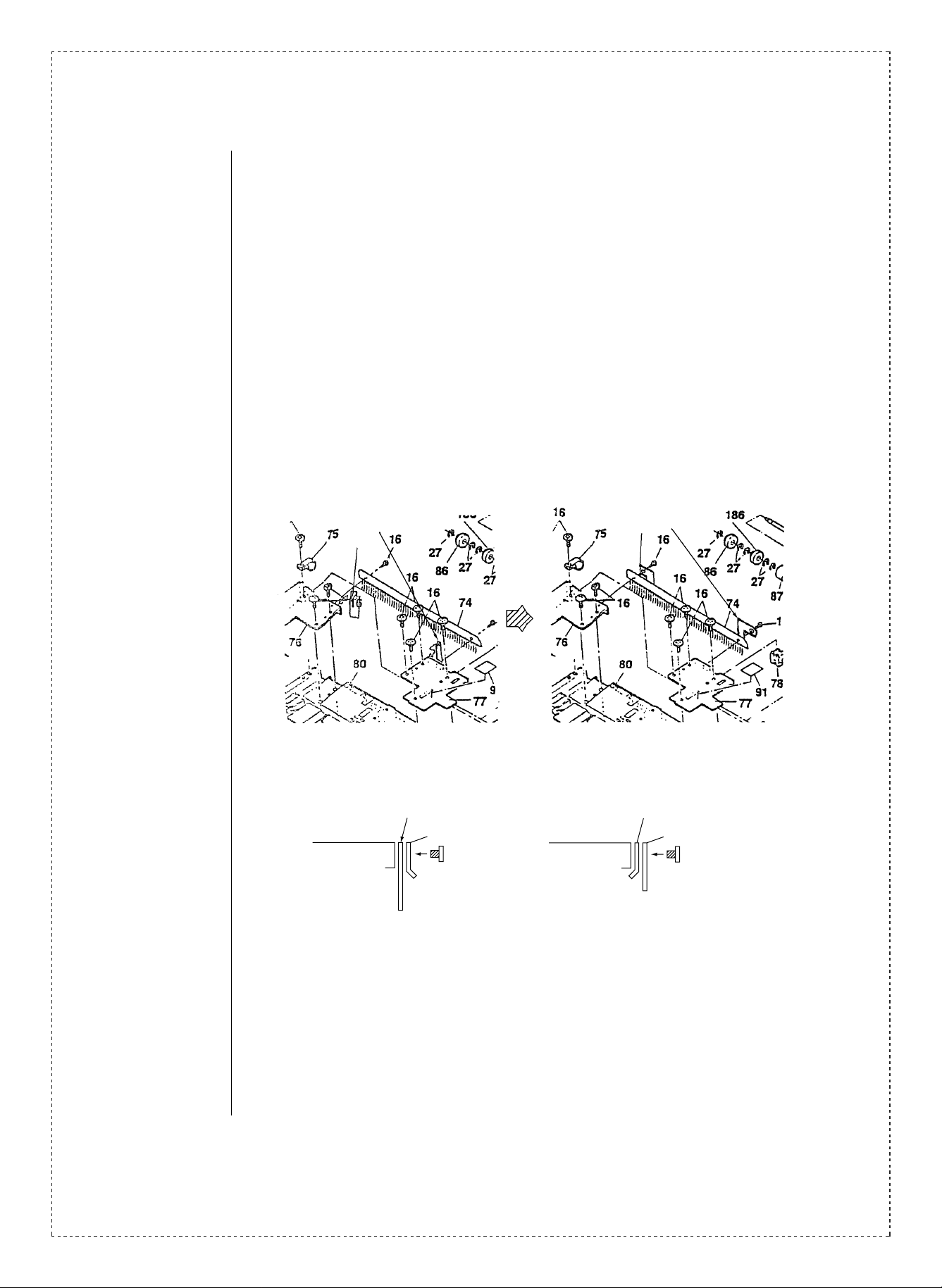

(2)-A

• A change has been carried out in the contact angle of the discharge brush and the

copy paper. As an effect of this change the discharge of static electricity is facilitated,

which results in the alleviation of problems of copy paper double feeding.

• A change in the method of attaching the discharge brush will result in the hairs of the

brush coming in contact with the FN and RN of the rear end sheet. A change in the

attachment method of the FN and RN of the rear end sheet has therefore been carried

out.

• A s a result of the change in the method of attachment of the FN and RN of the rear

end sheet, the ground cannot be reached between the frame and the FN and RN of the

rear end sheet. As a measure carried out to alleviate this problem, a change has been

carried out in the shape of the FN and RN of the rear end sheet so that it can be

tightened simultaneously with the discharge brush, which allows the ground between

the frame and the FN and RN of the rear end sheet to be reached.

(The FN and RN of the rear end sheet is an electrically conductive mylar sheet.)

Discontinued

FN and RN of the

rear end sheet.

Added (Z1 part)

2/4

FN and RN of the rear end sheet

(ZZ part)

Discharge brush

Discharge brush

FN and RN of the

rear end sheet.

(Z1 part)

Page 3

(2)-B

• A discharge sheet fixing plate and a lift bearing discharge sheet has been added to

the F/R section of the lift slide plate. This change has been carried out as a measure to

diminish the charge of static electricity on the copy paper.

Discharge sheet

fixing plate

Lift bearing discharge sheet

Attachment standard

0~1mm

4.Action: (1) From the start of 1996 March production.

(2)-A From 1995 mid-December production.

(2)-B From 1996 mid-June production.

Discharge sheet fixing plate

0~1mm0~1mm

Lift bearing discharge

sheet

3/4

Page 4

Ref.

No.

Model

name

Version P/G No.

Current parts New parts

Parts code Parts code

Price

rank

Parts name

Effec-

tive

time

Inter-

change-

ability

Note

15 -44

15 -45 PDUC-0081FCZZ PDUC-0123FCZZ AN Blow duct lower

(1)

SD-2060

SD-3062

(2)

-A

(2)

-B

<Inter chan ge>

1. Interchangeable. 4. Not interchangeable.

2. C urr e nt t y pe c a n be u s ed i n p la ce of new t y pe .

New ty pe cann ot be us ed i n place of curr ent type .

3. C urre nt ty pe cann ot be used i n place of new ty pe.

New t y pe c a n be u sed in p la c e of c u rr en t ty p e.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

15 -77 PSHEP3427FCZZ Discontinued — Sheet

15 -75 PSHEP3501FCZZ PSHEP3501FCZ1

15 -74 PSHEP3502FCZZ PSHEP3502FCZ1 Duct sheet R

All

31

31

!

PDUC-0080FCZZ PDUC-0122FCZZ AP Blow duct upper

Duct sheet F

AD

PSHEP4027FCZZ PSHEP4027FCZ1

PSHEP4028FCZZ PSHEP4028FCZ1

— LPLTM5286FCZZ

— PSHEZ4231FCZZ

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others .

Rear end sheet

FN

AG

Rear end sheet

RN

Discharge sheet

fixing plate

AH

Lift bearing

discharge sheet

1st lot

’96/3

Mid-

’95/12

Mid-

’96/6

3

3

6

4/4

Loading...

Loading...