Page 1

Date: Mar. 11, 1997

DUPLICATOR : SD-4085

1.MEASURE TO ALLEVIATE PROBLEMS OF FAULTY CLEANING.

2.MEASURE TO PREVENT PROBLEMS OF DISLODGING OF THE UPPER FUSING FAN.

3.MEASURE TO ALLEVIATE PROBLEMS OF FOLDED CORNERS OF THE COPY PAPER IN

THE FUSING SECTION.

4.MEASURE TO ALLEVIATE PROBLEMS OF BLURRING OF THE LEADING EDGE OF COPIES.

No. : DTE-266

1. Measure to alleviate problems of faulty cleaning.

1.Model Name: SD-3075/3076

2.General: There have been problems of the supplementary CL roller in the fusing unit warping

due to heat, causing a danger of faulting cleaning. As a measure to alleviate this

problem a change has been carried out in the finishing of the surface of the boss of the

supplementary CL roller.

3.Description: (Old) Non-electrolytic nickel plating CROLI0884FC33

↓

(New) Phosphoric acid manganese processing CROLP1178FC31

4.Action: From 1996 September production.

2. Measure to prevent problems of dislodging of the upper fusing fan.

1.Model Name: SD-4085

2.General: There have been problems in the cleaning fan inside the chassis unit of the models

listed above. There have been cases of the fan becoming dislodged from the rotor due

to heat from the fusing unit. As a measure to alleviate this problem, a change has been

carried out in the glue used to adhere the fan. In accordance with this change a change

has also been carried out in the part code.

3.Action: From 1996 July production.

SHARP CORPORATION Reprography Division

1/3

Green

C

Page 2

3. Measure to alleviate problems of folded corners of the copy paper in the fusing

section.

1.Model Name: SD-2075/3075/3076

2.General: There have been problems of folded corners sometimes occurring in copies caused by

the paper guide section in the fusing unit. As a measure to alleviate this problem, a

change in the shape of the paper guide section has been carried out as described in

the figure shown below.

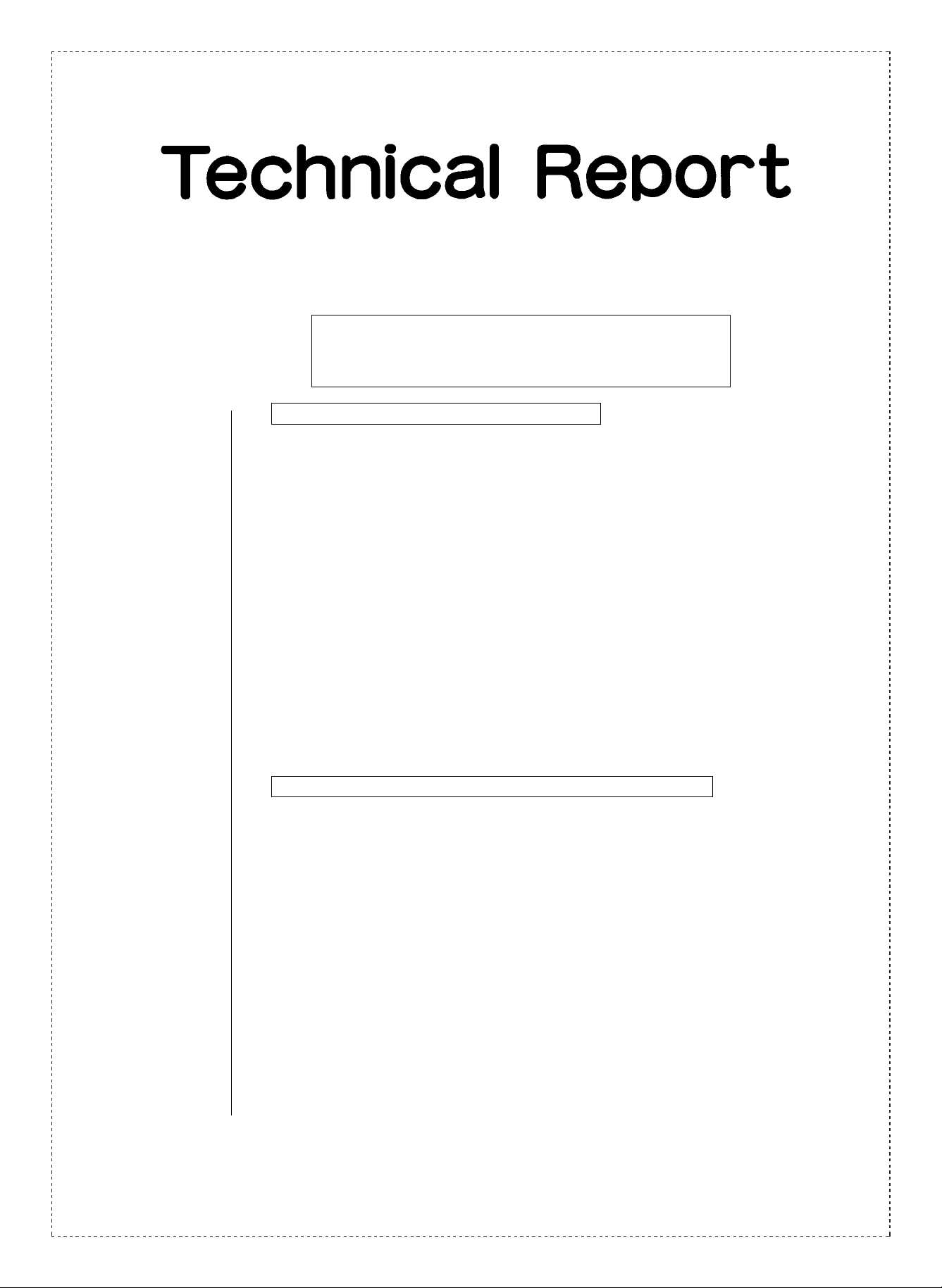

3.Description:

CGIDH1171FC03

The shaded sections (2) have

been cut away and discontinued.

4.Action: From 1996 October production.

4. Measure to alleviate problems of blurring of the leading edge of copies.

1.Model Name: SD-4085

2.General: When copy operations are carried out from the second copy paper tray with A3

(W-Letter) sized copy paper in OC mode and a magnification ratio of 64-99%,

101-144% in the models listed above, The transport clutch is turned ON at the same

time only when RRC, TBC2, TRC1 and TRC2 paper feeding operations are carried out.

As a result a sudden change in load occurs, and the revolutions of the main motor 1

(MM1) temporarily decrease, and problems of blurring sometimes occur approximately

60 mm from the leading edge of the copy paper. As a measure to alleviate this problem

a change has been carried out in the main motor to increase its power .

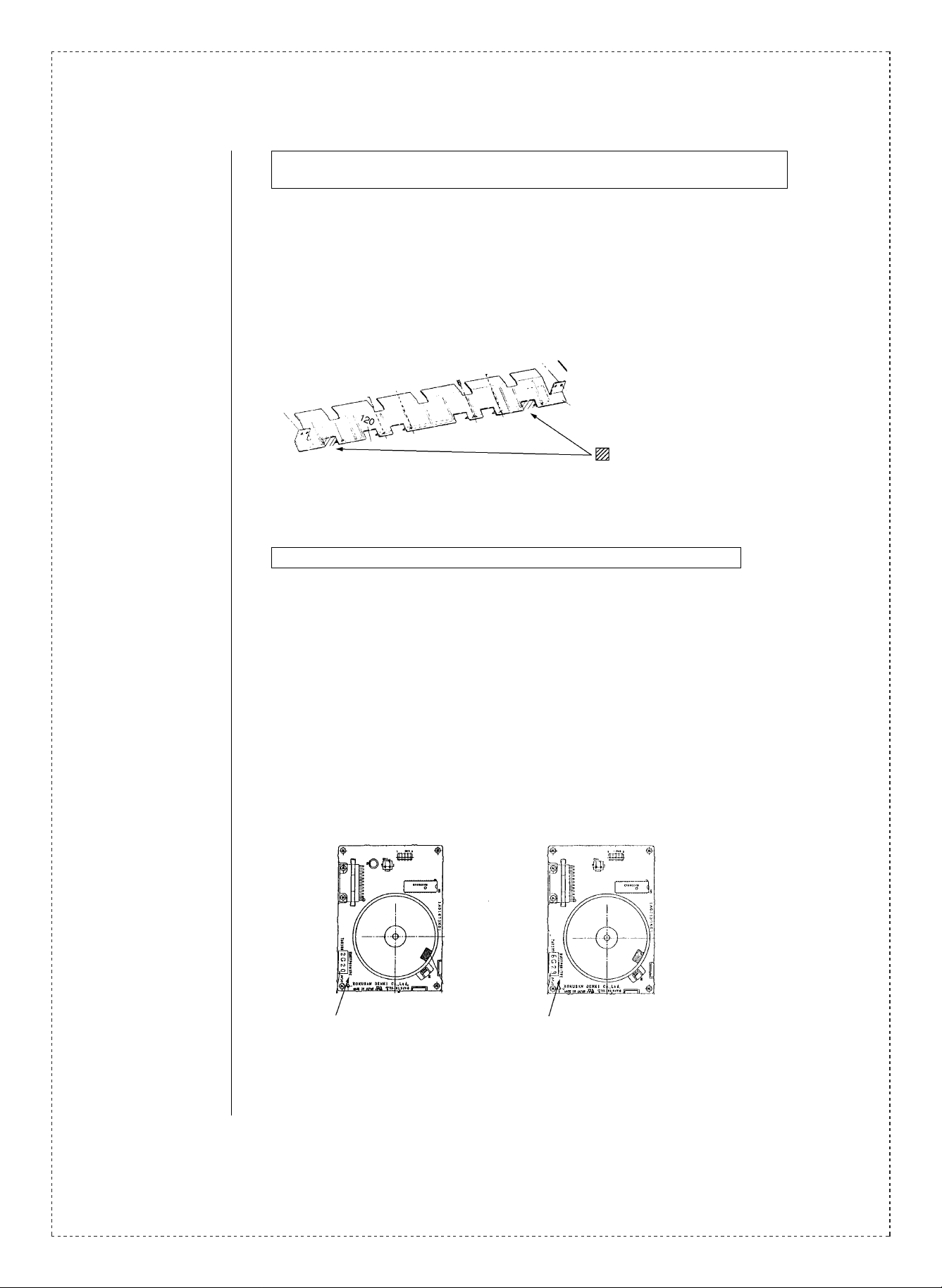

3.Description:

[ Old: C6 ] [ New: Eagle units only ]

Part code:RMOTP0703FC

White characters on the substrate

silk-screening

4.Action: From 1996 August production.

2/3

Part code:RMOTP0817FC

Green characters on the substrate

silk-screening

Page 3

Ref.

Model

No.

name

SD-3076 AB series

1

SD-3075 Inch series

2 SD-4085

SD-2075

3

SD-3075

SD-3076

4 SD-4085

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. Curr e nt t y pe c a n be u s ed in place of n ew type.

New ty pe cann ot be us ed i n place of curr ent type .

3. Curr ent type cannot be use d in plac e of ne w typ e.

New t y pe c a n be u sed in plac e of c u rr en t ty p e.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

Version P/G No.

25 -44 CROLI0884FC33 CROLP1178FC31 BQ Supplementary CL roller

35 -4 RMOTP0595FCZZ RMOTP0595FCZ1 BF Upper fusing fan

All

25 -118 CGIDH1171FC02 CGIDH1171FC03 AZ Paper guide FB As

31 -31 RMOTP0703FCZZ RMOTP0817FCZZ BY Main motor 1

!

Current parts New parts

Parts code Parts code

5. In te rc ha ng ea bl e if r ep l ace d wi th s a m e typ es of

relate d pa r ts in use.

6. Others.

Price

rank

Parts name

Effec-

tive

time

1st lot

’96/9

1st lot

’96/7

1st lot

’96/10

1st lot

’96/8

Inter-

change-

ability

3

1

Note

3/3

Loading...

Loading...