Page 1

Date: Jan. 10, 1997

DUPLICATOR : SD-2060

1.TROUBLE SHOOTING FOLDED CORNERS OF THE A4R/LTR COPY PAPER.

2.MEASURE TO IMPRO VE THE LIFE SPAN OF THE UPPER HEAT ROLLER BEARING.

3.ADDITION OF A VACUUM SHEET.

4.TROUBLE SHOOTING PROBLEMS OF PAPER JAMS AND ABNORMAL NOISE IN THE CENTER TRAY UNIT.

5.TRO UBLE SHOOTING MEASURE TO PREVENT CRACKING OF THE FU LEVER HOLDER.

6.MEASURE TO PREVENT THE PROCE S S HAR NE SS FROM BEING CUT.

No. : DTE-255

1. Trouble shooting folded corners of the A4R/LTR copy paper.

1.Model Name: SD-2060/3062

2.General: Problems sometimes occurred with the corners of the copy papers folding over due to

their becoming caught on the PG assistant plates of the paper guides immediately after

the fusing heat roller when making copies using A4R/LTR copy paper. As a trouble

shooting measure to alleviate this problem the following change was carried out.

3.Description: Improvement measures were carried out by enlarging the discharge flow hole by 1.2

mm in the heat roller side of the PG assistant plate.

Furthermore, because there was a danger of the PG assistant plate coming in contact

with the heat roller when removing the paper guide during this trouble shooting

measure, a change has been carried out in the shape of the rotational axis section of

the paper guide FB so that the paper guide FB will come in contact with the bearing

before the paper guide assistant plate comes in contact with the heat roller.

(Description)

The surface of the rotational axis section of the paper guide FB in the location

indicated by the arrow to the left.

Paper guide FB

Upper heat roller

Lower heat roller

(Reason)

The degree of extension of the paper guide assistant

plate. When attaching the paper guide assistant plate

there is a danger of the paper guide assistant plate

coming in contact with the heat roller, and by building

up the surface area of the paper guide FB the raised

section of the paper guide FB will come in contact with

the heat roller bearing before the heat roller and the

paper guide assistant plate come in contact, thus

preventing the heat roller from becoming damaged.

When replacing the paper guide assistant plate the paper guide FBA should always be

replaced at the same time.

4.Action: From the start of 1996 October production.

SHARP CORPORATION Reprography Division

1/4

Green

C

Page 2

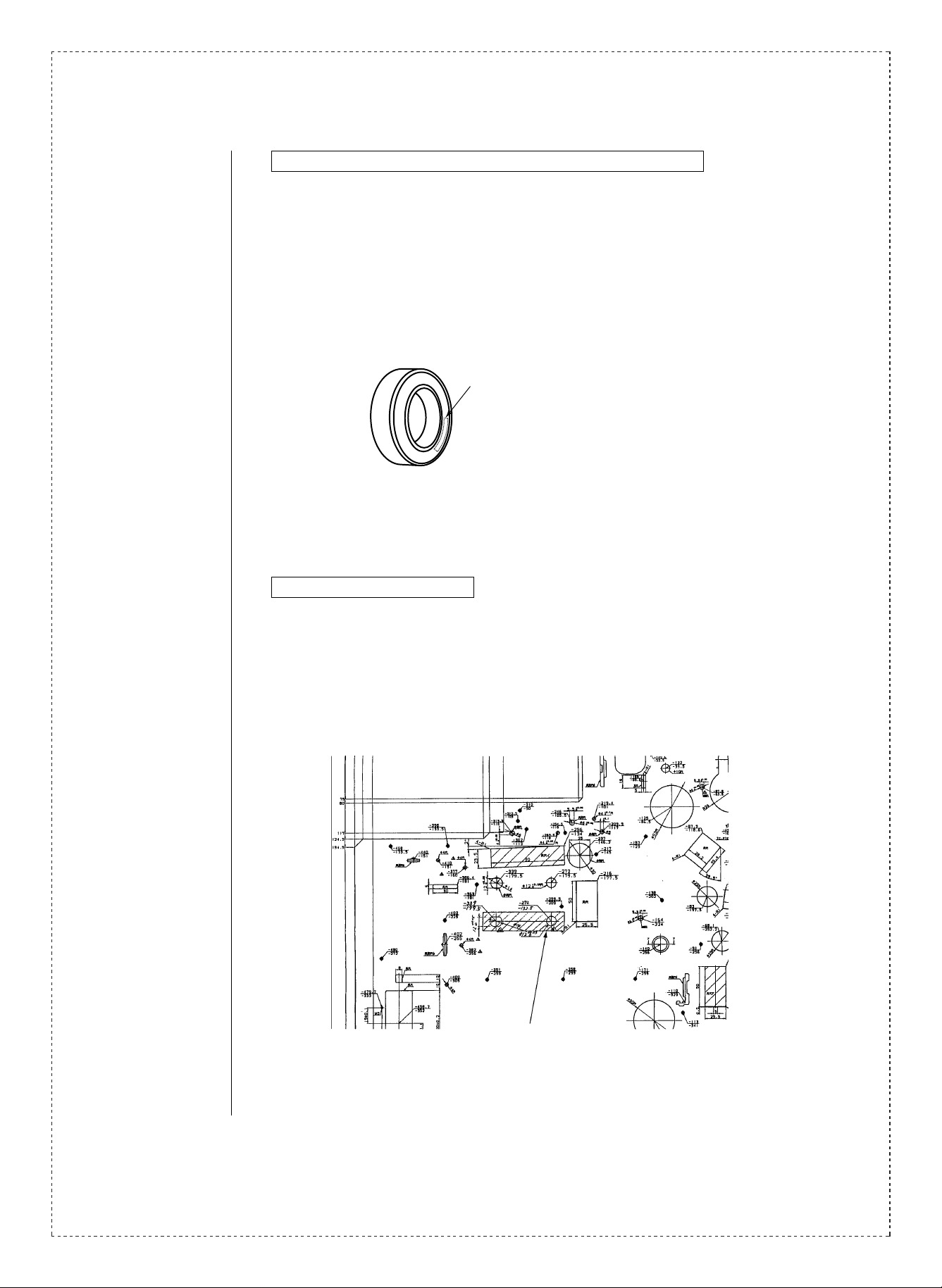

2. Measure to improve the life span of the upper heat roller bearing.

1.Model Name: SD-2060/3062

2.General: The grease used in the inner surface of the bearing has been changed from one with a

temperature resistance of 150C° to one that is resistant to temperatures of up to 230C° as a

measure to improve the life span of the upper heat roller bearing used in the fusing unit.

The lettering of the stamp on the shield for both

New and Old is as shown below.

(Old) 6008ZL → (New) 6008ZLC4 (added)

3.Action: From the start of 1996 October production.

3. Addition of a vacuum sheet.

1.Model Name: SD-2060/3062

2.General: Some unnecessary holes were added in the rear frame of the models listed above.

These holes have been covered up by the addition of vacuum sheets, in order to

establish interchangeability between the chassis and new models.

Upper side of the rear frame left

3.Action: From the start of 1996 October production.

2/4

Vacuum sheet (added)

Page 3

4. Trouble shooting problems of paper jams and abnormal noise in the center tray unit.

1.Model Name: SD-2060/3062

2.General: Copy paper sometimes becomes caught in the convex section of the upper surface of

the copy paper tray causing problems of paper jamming in the center tray unit. As a

trouble shooting measure to alleviate this problem, a sheet has been added to guide

the copy paper across the convex section of the upper surface of the copy paper tray.

Also, problems of abnormal noise occurring in the pulley plate link section of the

transfer paper guide unit section when movement of the plate occurs after the rear

edge of the copy paper passes. As a trouble shooting measure to alleviate this problem,

MOLYKOTE has been applied to the pulley plate.

3.Description:

Copy paper tray

29 -53

Copy paper holding sheet

Pulley plate A and the joint section.

Convex section

MOLYKOTE has been applied

(approx. one half droplet).

Pulley plate B. AS

31 -153

4.Action: From the start of 1996 September production.

5. Trouble shooting measure to prevent cracking of the FU lever holder.

1.Model Name: SD-2060/3062

2.General: Problems of cracking in the FU lever holder have occurred when tightening the screws

of the FU lever holder used to attach the door switch of the fusing unit. As a trouble

shooting measure to alleviate this problem a change has been carried out in the

screws, and also a change has been carried out in the screw fixing section of the FU

lever holder so that it is secured by a bit insert.

3.Action: From the start of 1996 November production.

3/4

Page 4

6. Measure to prevent the process harness from being cut.

1.Model Name: SD-2060/3062

2.General: The edge of the chassis and the harness sometimes come in contact due to frequent

insertion and extraction of the process unit, which can cause the harness to become

damaged or cut. As a trouble shooting measure to alleviate this problem, a tube has

been added to the harness to protect it.

Note: The wrapping of tape around the harness has been carried out as a temporary

trouble shooting measure.

Added tube

Rear frame side of the processing unit.

Drawer connector section.

3.Action: Temporary measure → From the start of 1996 October production.

(Permanent measures will be carried through running change

in accordance with the depletion of supplies for the temporary

measure.)

Ref.

Model

No.

1

2

SD-2060

3

SD-3062

4

5

6

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i n te r cha ng ea bl e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts m a r ked w it h “ ” i s imp or t an t fo r m ai n ta ini ng t he s a fe ty of the s e t. B e sur e t o rep l ac e t he se pa r ts with

s p eci fi e d on es fo r m ai n ta in i ng t he s a fe ty an d pe rf o rma nc e o f th e s et .

name

Version P/G No.

12 -77 PGIDH1418FCZ1 PGIDH1418FCZ2 AT Paper guide FB

12 -85 LPLTM5251FCZZ LPLTM5251FCZ1 AF PG assistant plate

12 -112 NBRGY0479FCZZ NBRGY0479FCZ1 BA Upper heat roller bearing 1

9 -43

All

29 — PSHEP4358FCZZ Copy paper holding sheet

12 -5

12 -3 XUPSD30P16000 XBBSD30P16000 AA Screw (M3 x 16)

10 -11 DHAI-2157FCZZ DHAI-2157FC11 BA Process harness 3

!

Current parts New parts

Parts code Parts code

PSHEP3420FCZZ Q’ty: 3 → 4

LHLDZ1127FCZ1 LHLDZ1127FCZ2 AU FU lever holder

Price

rank

AC

5. Interchangeable if replaced with same types of

related parts in use.

6. Others .

Parts name

Vacuum sheet

Effec-

tive

time

1st lot

’96/10

Inter-

change-

ability

3

6

5

Note

Q’ty: 2

4/4

Loading...

Loading...