Page 1

Date: Nov. 5, 1996

DUPLICATOR : SD-2060

1. CHANGE IN THE MSDS CARD.

2. MEASURE TO ALLEVIATE PROBLEMS OF ABNORMAL NOISE IN THE PAPER DELIVERY UNIT.

3. MEASURE TO IMPROVE THE PAPER DELIVER Y STACKING PERFORMANCE.

4. MEASURE TO ALLEVIATE PROBLEMS OF CRACKING OF THE FU LEVER HOLDER IN THE

FUSING UNIT.

No. : DTE-240

1. Change in the MSDS card.

1.Model Name: SD-2060/3062 (only for machines bound for the U.S.A. Canada, and the U.K.).

2.General: A change has been carried out in the content of the MSDS card in accordance with a

change in standards.

3.Action: From 1996 September production.

2. Measure to alleviate problems of abnormal noise in the paper delivery unit.

1.Model Name: SD-2060

2.General: Problems have occurred of abnormal noise resulting from the contact surfac es of the

bearing and the delivery roller inside the paper delivery unit. To alleviate these

problems, the delivery roller core finish has been changed.

3.Action: From 1996 September production.

SHARP CORPORATION Reprography Division

1/3

Green

C

Page 2

3. Measure to improve the paper delivery stacking performance.

1.Model Name: SD-2060

2.General: Problems of curling of the delivered paper in the paper delivery tray have occurred

during paper delivery operations when the machine is operated in environmental

conditions of high temperature and high humidity, which causes poor stacking

performance of the paper. To alleviate these problems, the angle of the paper delivery

tray has been changed.

3.Description: The shape of the tray support plate has been changed.

4.Action: From 1996 September production.

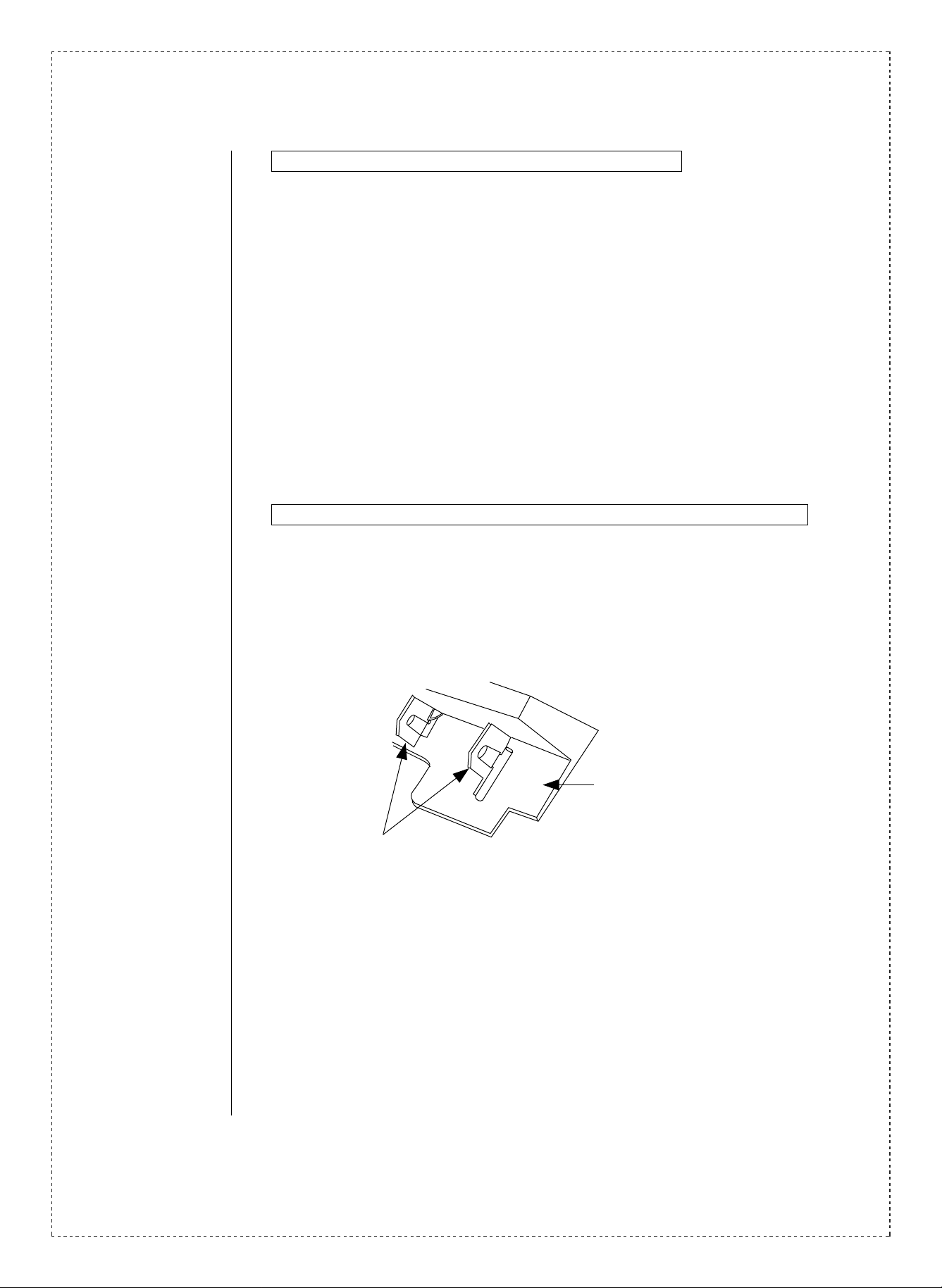

4. Measure to alleviate problems of cracking of the FU lever holder in the fusing unit.

1.Model Name: SD-2060/3062

2.General: Problems of damage to the FU lever holder in the fusing unit have occurred. To

alleviate these problems additional volume has been added to the ribs to reinforce the

FU lever holder.

A

Two ribs to which additional volume

as been added on both sides.

Reinforced parts have

been marked with an "A".

3.Action: From 1996 September production.

2/3

Page 3

Ref.

No.

1

Model

name

SD-2060

SD-3062

Version P/G No.

U.S.A.

Canada

86 -33 TCADZ1076FCZ1 TCADZ1076FCZ2 AE MSDS card

UK

16 -19 NROLR0959FCZZ NROLR0959FCZ1 AV Delivery roller S

Current parts New parts

Parts code Parts code

Price

rank

Parts name

Effec-

tive

time

Inter-

change-

ability

3

Note

2 SD-2060

3 SD-2060

SD-2060

4

SD-3062

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. C urr e nt t y pe c a n be u s ed i n p la ce of new ty pe .

New ty pe cann ot be us ed i n place of curr ent type .

3. C urre nt ty pe cann ot be used i n place of new ty pe.

New t y pe c a n be u sed in pla c e of c u rr en t ty p e.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

16 -20 NROLR0960FCZZ NROLR0960FCZ1 AX Delivery roller W

16 -21 NROLR0982FCZZ NROLR0982FCZ1 AV Delivery roller S2

All

16 -17

12 -5 LHLDZ1127FCZZ LHLDZ1127FCZ1 AU

!

LPLTM1828FCZ4 LPLTM1828FCZ5 AN

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others.

Tray support

plate

Fusing lever

holder

1st lot

’96/9

∗ When making arrangements for a new FU lever holder, arrangements for a fusing

lever (MLEVP0729FCZZ) should also be made at the same time. (The parts are

interchangeable in an assembled form.)

1

3

6 ∗

3/3

Loading...

Loading...