Page 1

Date: Jul. 19, 1995

DUPLICATOR: SD-2060

1. CHANGE IN THE METHOD OF SIGNAL COUNTING FOR THE SF-EA11 ATTACHMENT OPERATIONS.

2. MEASURES TO PREVENT CONTACT OF THE 1000 TRAY SIZE GUIDE TO IMPROVE PRODUCTIVITY.

3. MEASURES TO PREVENT THE FIXING SCRAPER FROM WARPING DUE TO THERMAL EXPANSION.

4. MEASURES TO PREVENT STACKING DURING OFFSET MODE OPER ATIONS.

5. CHANGE IN THE MATERIAL USED FOR THE WASTE TONER BOTTLE.

No. : DTE-206

1. Change in the method of signal counting for the SF-EA11 attachment operations.

1.Model name: SD-3062

2.General: In order to carry out the change of the signal counting method during SF-EA11

(card-type section management counter) attachment operations, the program content of

the ROM program of the IC in the operations control PWB has been changed.

3.Description: ROM Version no.: V4.01 → V4.02

4.Action: From the start of 1995 January production.

2. Measures to prevent contact of the 1000 tray size guide to improve productivity.

1.Model name: SD-2060/3062

2.General: There is insufficient room between the connector for the sensor attached underneath

the air paper feeder unit and the R size guide in the 1000 tray unit, and therefore there

is a danger of the two coming in contact with each other. To alleviate this problem, the

shape of the R size guide has been changed.

3.Description: Change to prevent contact:

(1) Change in the shape of the 1000 R size guide.

Change to improve productivity:

(2) Change of the 1000 F size guide.

(3) Discontiuence of the SG spacer boss.

(4) Change in the attachment screws of the 1000 FN size guide.

(5) Change in the 1000 F size guide (Changed to the same item as the 1000 R size

guide).

4.Action: From the start of 1995 January production.

SHARP CORPORATION Reprography Division

1/4

Green

C

Page 2

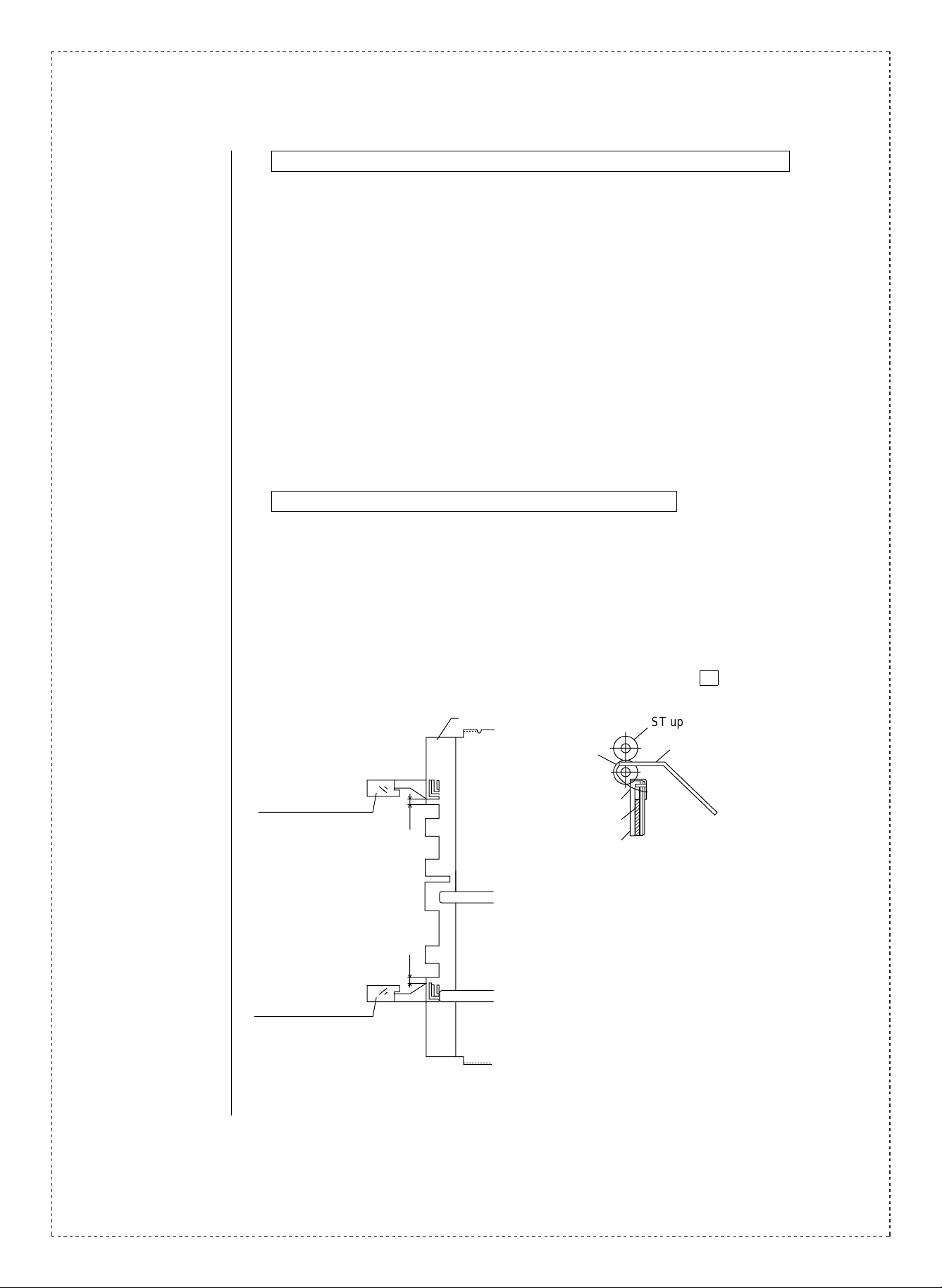

3. Measures to prevent the fixing scraper from warping due to thermal expansion.

1.Model name: SD-2060/3062

2.General: The supplementary CL scraper in the fusing unit sometimes warps due to thermal

expansion, causing the center portion of the scraper to raise up slightly. To alleviate

this problem, the following measures have been taken.

3.Description: To disperse the thermal expansion effects, the method of attachment has been changed

by changing the attachment holes (screw holes) of the supplementary CL scraper to

long holes, and changing the screws to step screws.

4.Action: From 1995 Mid-February production.

4. Measures to prevent stacking during offset mode operations.

1.Model name: SD-3062

2.General: When high humidity adsorption copy paper is used and copy operations are carried out

in the offset mode, stacking does not always occur as efficiently as it should.

To improve this problem, the following measures have been taken.

3.Description: (1) A shift roller sheet has been attached to the staple tray (P/G no. 52 -45).

P

(New design)

Shift roller sheet RN

(New design)

Shift roller sheet FN

Staple tray

Paper exit

drive roller FIN

Shift roller sheet N

±1

7

±1

7

Elevator frame cover

Shift roller

Caution:

1. Be sure to wipe the attachment surface of the

sheet with alcohol before attaching the sheet.

2. The sheet should be attached so that the vertical

direction attachment standard for the F/R N shift

roller is 7±1 from the cutaway of the metal plate,

and the horizontal direction standard should be

such that the riding surface is aligned with P.

3. After assembly, the F/R N shift roller should be

used by collecting the edge of the sheet in the

elevator frame cover as shown in the figure above.

ST upper paper exit drive roller

Staple tray

2/4

In accordance with the changes described above the previously attached shift roller

sheet (as shown in the figure to the right) has been discontinued.

Page 3

Shift roller sheetStaple tray

R side

±0.5

5

(2) A gate dropping sheet has been attached to the mode switching gate.

Gate dropping sheet.

Mode switching gate.

Material display.

The gate dropping sheet has been attached to the ABS material display side of the

mode switching gate. The vertical attachment standard 1+0.5 from the standard shown

in the figure above, and the horizontal attachment standard is aligned to the ribs in the

two locations.

(3) The attachment screws for L/R S roller holder have been changed from M4 x 6

capped screws to M4 x 6 flat screws.

Changed screws.

4.Action: From the start of 1995 May production.

3/4

Page 4

5. Change in the material used for the waste toner bottle.

1.Model name: SD-2060/3062

2.General: The material used for the waste toner bottles in the models listed above has been

changed so that they can be recycled. In accordance with this change the parts codes

have also been changed.

3.Action: From the start of 1995 July production.

Ref.

Model

No.

1 SD-2062

2

(1)

2

(2)

2

(3)

SD-2060

2

SD-3062

(4)

2

(5)

3

4

(1)

SD-3062

4

(2)

4

(3)

SD-2060

5

SD-3062

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

speci fied ones fo r mai n ta in i ng t he s a fe ty an d pe rf o rma nc e o f th e s et .

name

Version P/G No.

80 -51 VHI27C51229FC VHI27C51269FC AX IC [IC424]

20 -35

20 -45 PGIDM1448FCZ1 PGIDM1517FCZ2 AQ

20 -103

20 -34

20 -37

All

12 -149 LPLTM4461FCZZ LPLTM4461FCZ1 AK

12 -71

52 PSHEP3722FCZZ (Discontinued) — Shift roller sheet

52

52 — PSHEP3981FCZZ AE

53

51

86 -22

!

Current parts New parts

Parts code Parts code

PGIDM1448FCZZ PGIDM1448FCZ2 AL

LBOSZ1515FCZZ

(Q’ty: 4)

LX-BZ0222FCZZ

(Q’ty: 4)

CGIDH1459FC02 CGIDH1459FC03 AX

XBPSD30P05KS0

(Q’ty: 5)

— PSHEP3980FCZZ AE

—

LX-BZ0502FCZZ

(Q’ty: 4)

CYOK-0040FC01 CYOK-0040FC03 AX

(Discontinued) — SG spacer boss

XBTSF40P06000

(Q’ty: 4)

LX-BZ0761FCZZ

(Q’ty: 5)

PSHEP3979FCZZ

(Q’ty: 2)

LX-BZ0465FCZZ

(Q’ty: 4)

Price

rank

AA Screw

AC Screw

AD

AA Screw

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others.

Parts name

1000 R size

guide

1000 FN size

guide

1000 F size

guide

Supplementary

CL scraper

Shift roller sheetFN1st lot

Shift roller sheetFR1st lot

Gate dropping

sheet

Waste toner

bottel

Effec-

tive

time

1st lot

’95/1

1st lot

’95/1

1st lot

’95/1

1st lot

’95/1

1st lot

’95/1

1st lot

’95/1

Mid-

’95/2

Mid-

’95/2

1st lot

’95/5

’95/5

’95/5

1st lot

’95/5

1st lot

’95/5

1st lot

’95/7

Inter-

change-

ability

3

3

4

4

4

4

3

3

3

3

3

3

3

1

Note

4/4

Loading...

Loading...