Page 1

Date: May. 17, 1995

DUPLICATOR : SD-2060

1. CHANGE IN THE SHAPE OF THE LIQUID CRYSTAL ATTACHMENT PLA TE IN THE

OPERATION PANEL UNIT (TO IMPROVE PRODUCTIVITY).

2. PREVENTION OF THE READING SWITCH IN THE MANUAL PAPER FEEDING TRAY UNIT

FROM BECOMING DETACHED.

3. PREVENTION OF THE NO. 3 MIRROR FROM CRACKING.

4. EXPLANATION OF SUPPLEMENT TO T/R NO. DTE-200.

No. : DTE-205

1. Change in the shape of the liquid crystal attachment plate in the operation panel unit

(To improve productivity).

1.Model name: SD-2060/3062

2.General: During the assembly process of the SD-2160 model, which is shipped only to domestic

markets, difficulties in the attachment operations of the operation panel sometimes

occur when the liquid crystal attachment plate in the operation panel comes in contact

with the sensor attachment plate of the optical unit. T o alleviate this problem, the shape

of the liquid crystal attachment plate has been changed. [Note: While this change is

necessary only for the SD-2160 model, the SD-2060 and the SD-3062 models both use

the same liquid crystal attachment plates, and the changes have therefore also been

carried out on these models.]

3.Action: Running change from 1995 January production.

2. Prevention of the reading switch in the manual paper feeding tray unit from

becoming detached.

1.Model name: SD-2060/3062

2.General: The fixing screws of the reading switch on the inside surface of the manual paper

feeding tray are too shallow, and the switch sometimes becomes detached. To alleviate

this problem, the following changes have been carried out.

1/3

SHARP CORPORATION Reprography Division

Green

C

Page 2

3.Description:

Bit press fitting locations.

Changed screws

XEPSD30P06000

↓

XBPSD30P06KSO

4.Action: From the start of 1995 January production.

Bit press fitting locations.

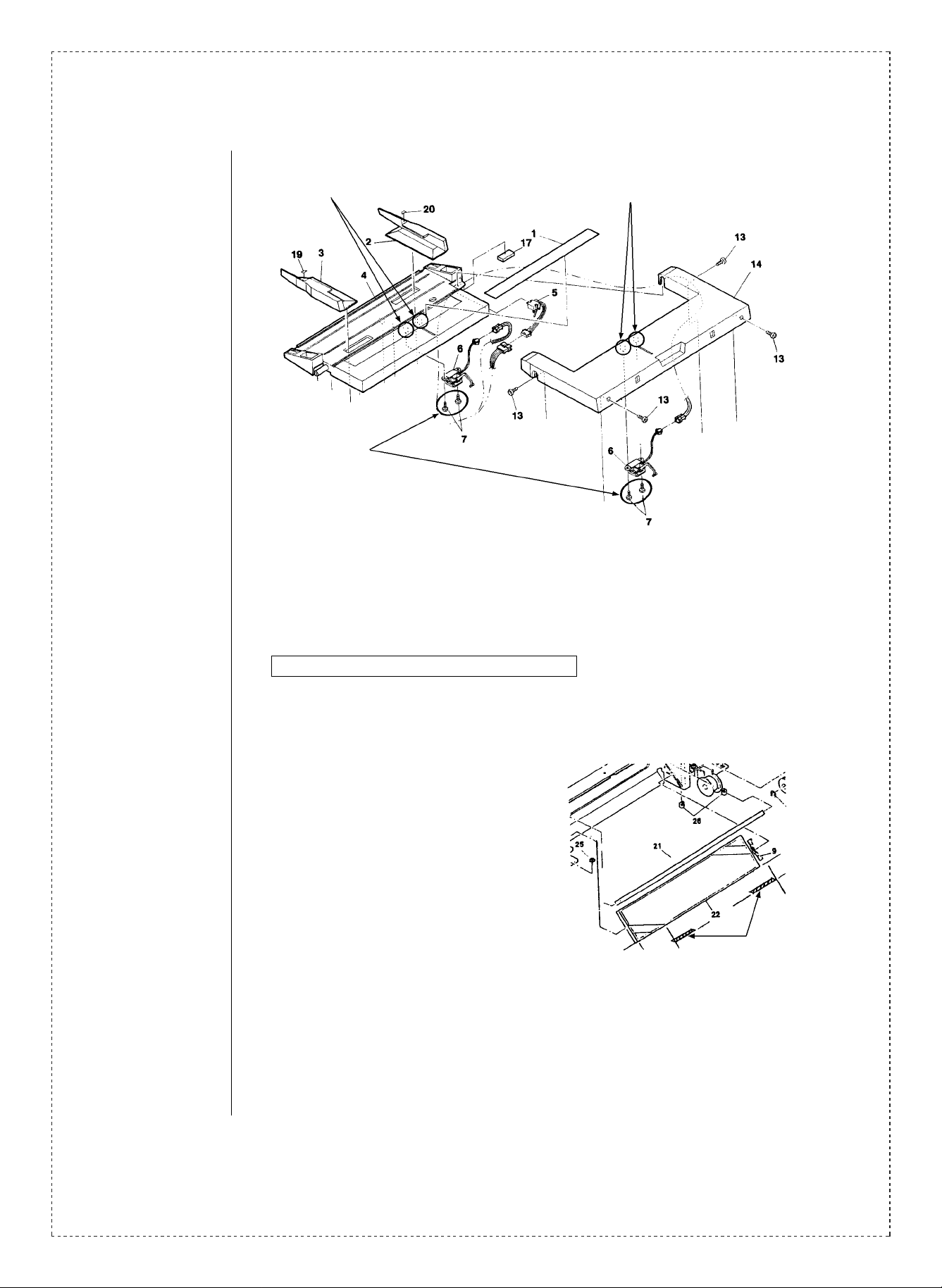

3. Prevention of the No. 3 mirror from cracking.

1.Model name: SD-2060/3062

2.General: According to reports from clients, the

No. 3 mirror sometimes cracks when

shipped. Cushions have therefore been

attached to the No. 2 and No. 3 mirror

attachment plate unit as a

countermeasure to prevent the No. 3

mirror from cracking during transport.

[Note: cushions do not need to be

added to machines already out on the

market which do not have them.]

3.Action: From the start of 1994 December production.

No. 3

mirror.

No. 3 mirror cushion.

2/3

Page 3

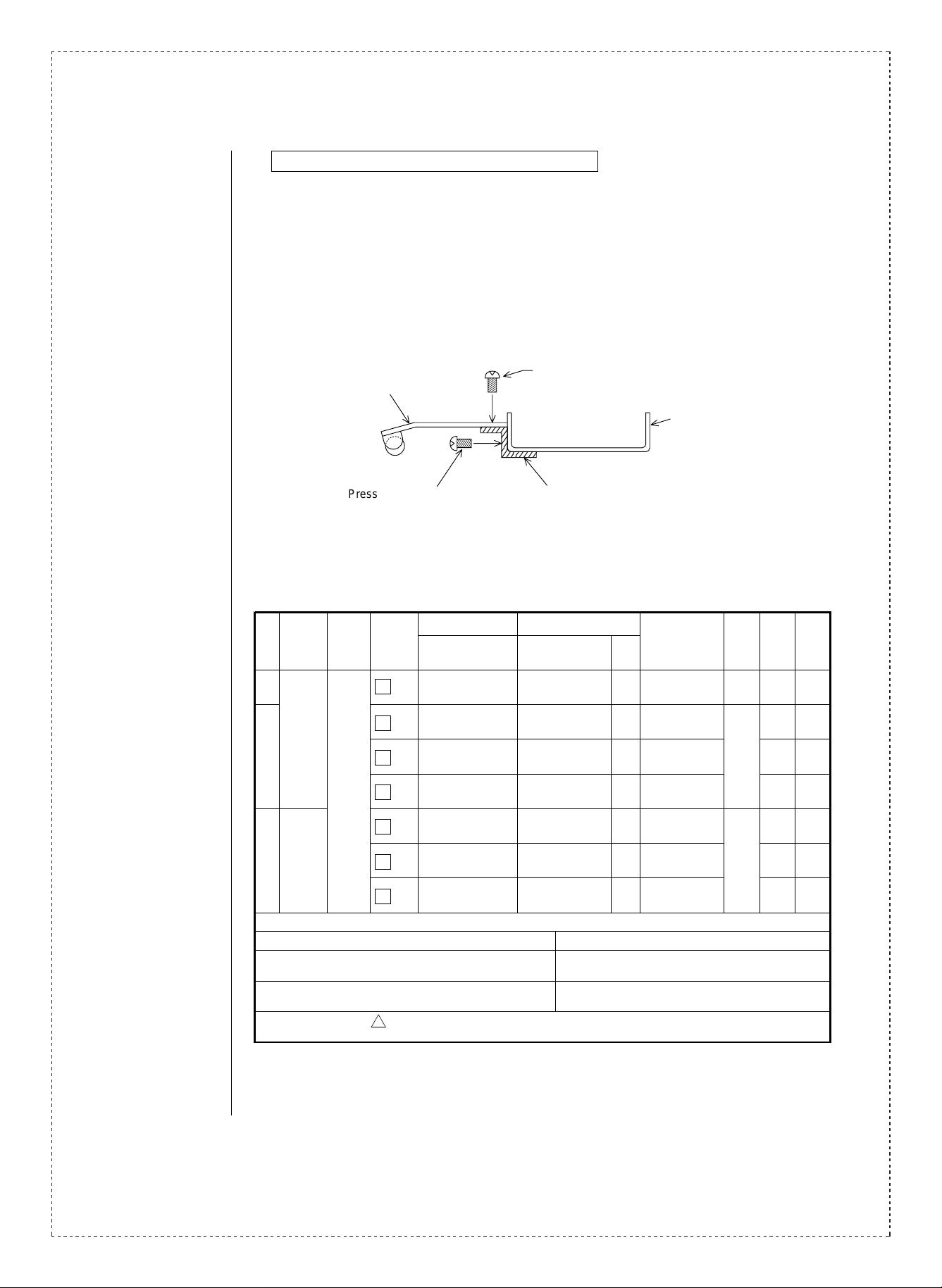

4.Explanation of supplement to T/R No. DTE-200.

1.Model name: SD-2060

2.General: In item No. (1) of T/R DTE-200 (concerning the measures taken for dirty transport

belts), it was stated that when the old type conveyor belt was replaced with the new

type, the pressure roller plate spring also needed to be changed to the new type.

However, when the old type conveyor belt is replaced, the 3 parts shown below also

need to be changed.

Pressure roller

plate spring 2

Pressure roller plate spring fixing screw

(0CW030040FZBI)

Pressure roller stay

Pressure plate spring fixing screw

(0CW030060FZTP)

Ref.

Model

No.

1

SD-2060

SD-3062

2

4 SD-2060

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

specified on es for m ain ta in i ng t he s a fe ty an d pe r fo rma nc e o f th e s et .

name

Version P/G No.

2 -26

38 -4 LSOU0107FCZZ LSOU-0107FCZ1 AY

38 -14 LSOU0108FCZZ LSOU-0108FCZZ AW

All

38 —

44 — 0CW2176P152A/ AH

44 —

44 —

!

Current parts New parts

Parts code Parts code

LPLTM4212FCZZ LPLTM4212FCZ3 AR LCD fixing plate

Pressure plate spring

(0CW2176P152A/)

XBPSD30P06KS0

(Q’ty: 4)

0CW030040FZBI

(Q’ty: 2)

0CW030060FZTP

(Q’ty: 2)

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others.

Price

Parts name

rank

Manual feed

tray 1

Manual feed

tray 2

AA Screw (M3 x 6) 5

Pressure plate

spring

AA Screw —

AA Screw —

Effec-

tive

time

See

text.

1st lot

’95/1

1st lot

’94/11

Inter-

change-

ability

3

5

5

—

Note

3/3

Loading...

Loading...