Page 1

Date: Jun. 2, 1995

DUPLICATOR : SD-2060

1. PREVENTION OF DAMAGE TO THE IC IN THE MAIN PWB.

2. DIAGONAL FEEDING COUNTERMEASURES FOR THE 1000 TRAY UNIT .

3. CHANGE IN PARTS CODES IN ACCORDANCE WITH A CHANGE IN CLIENTS.

4. COUNTERMEASURES FOR OPERATION MALFUNCTI ONS OF TH E TRANSPORT A CC.

No. : DTE-204

1. Prevention of damage to the IC in the main PWB.

1.Model name: SD-2060/3062

2.General: There was a possibility of damage occurring to IC 133 caused by the shape of the

heads of the fixing screws previously used for the heat sink of the IC. To alleviate this

problem, the screws have been changed.

3.Description:

M3 x 10 changed M3 x 12

(with SW) → (3 point type)

XBPSD30P10K00 → XBPSD30P12KS0

The parts codes

are unclear in the fax that I have

received, and cannot be read.

4.Action: From the start of 1995 January production.

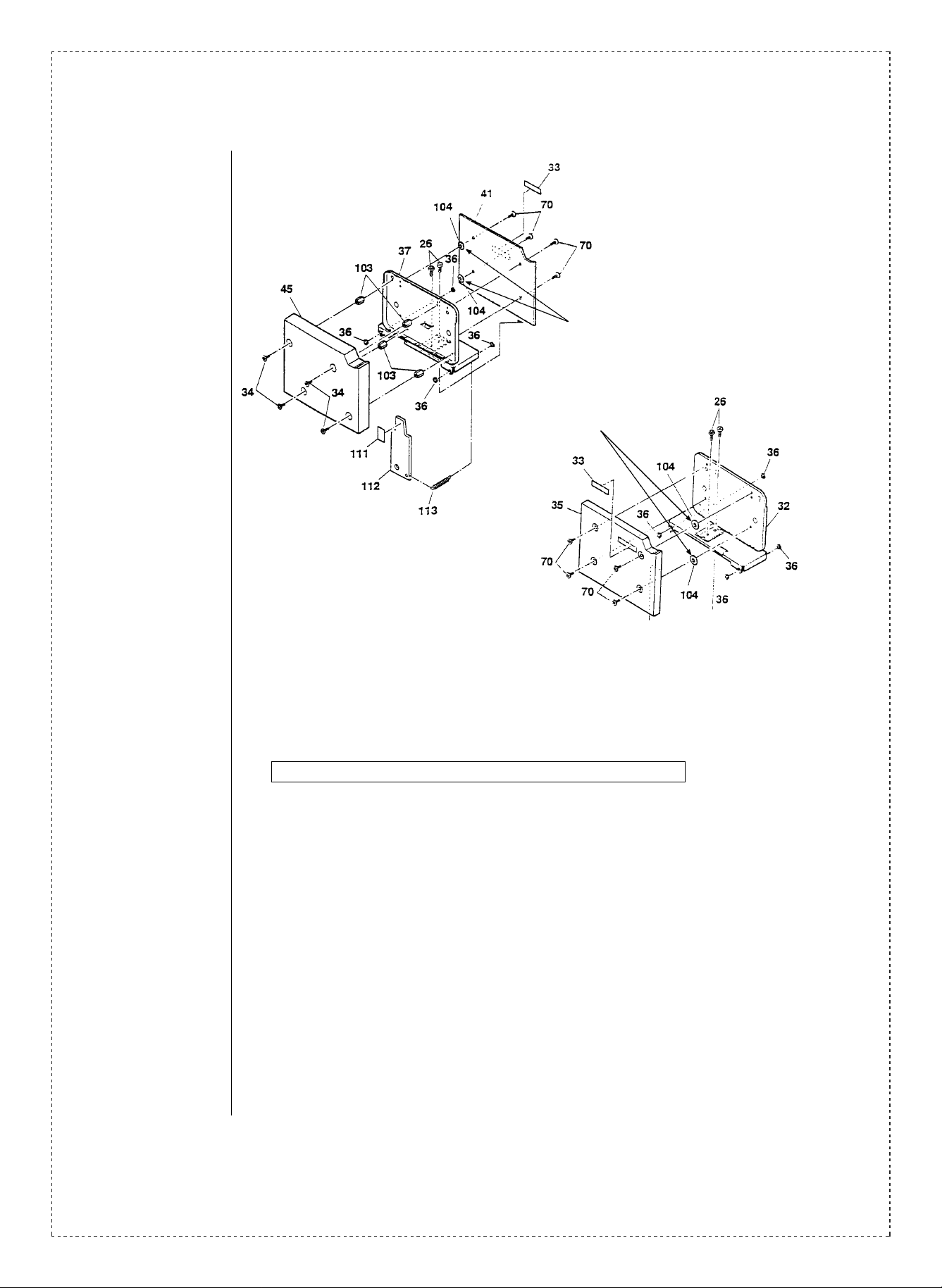

2. Diagonal feeding countermeasures for the 1000 tray unit.

1.Model name: SD-2060/3062

Heat sink

IC

2.General: Spacers have been added in the F-side R-side size guides to alleviate the problem of

diagonal paper feeding from the 1000 tray unit. By carrying out this change, the paper

is delivered horizontally, preventing diagonal paper feeding.

Green

C

SHARP CORPORATION Reprography Division

1/4

Page 2

3.Description:

F Side size guide

Added spacers

R Side size guide

Added spacers

4.Action: From the start of 1994 November production.

3. Change in parts codes in accordance with a change in clients.

1.Model name: SD-2060/3062

2.General: The clients and the parts codes of each of the units used in the models listed above

have been changed in accordance with the transfer of control of the assembly process

to overseas.

3.Description: Please refer to the parts list for details concerning the changed parts. [Note: No

changes have been carried out in the shapes of the parts or in the materials used in

their construction.]

4.Action: From the start of 1995 February production.

2/4

Page 3

4. Countermeasures for operation malfunctions of the transport ACC.

1.Model name: SD-2060/3062

2.General: The ends of the fixing screws which attach the switch-back unit to the main frame of the

machine sometimes rub against the transport ACC, causing the running operation to

become slow and heavy. To alleviate this problem, the screws have been changed so

that they do not rub against the transport ACC.

3.Description:

Changed screws

Switch-back unit

4.Action: From the start of 1994 December production.

Changed screws

3/4

Page 4

Ref.

No.

1

2

Model

name

Version P/G No.

77 -139

20 -104 —

26 -26 LHLDW2047SCZZ LHLDW1279FCZZ AB Wire holder

Current parts New parts

Parts code Parts code

XBPSD30P10K00

(Q’ty: 2)

XBPSD30P12KS0

(Q’ty: 2)

PSPAZ0631FCZZ

(Q’ty: 4)

Price

Parts name

rank

AA Screw (M3 x 12)

AB φ5 spacer

Effec-

tive

time

1st lot

’95/1

1st lot

’94/11

1st lot

’95/2

Inter-

change-

ability

3

—

1

Note

26 -27 LHLDW7075SCZZ LHLDW1280FCZZ AC Wire band

26 -31 PHOG-2023SCZZ PHOG-0389FCZZ AC Protector 1

26 -34 MSPRC0760FCZZ MSPRC0760FCZ1 AC DR spring 1

23 -23 LBNDJ0043FCZZ LBNDJ0043FCZ1 AA Snap band 1

SD-2060

SD-3062

3

4 25 -4

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

specifie d on es for mai n ta in i ng t he s a fe ty and pe rf o rma nc e o f th e s et .

All

23 -6

23 -24 PHOG-1007HCZZ PHOG-0390FCZZ AC Bushing 1

23 -26

23 -28

23 -1 MSPRT1199FCZZ MSPRT1199FCZ1 AC Wire spring 1

23

24 -4

25 -4 MSPRC1534FCZZ MSPRC1534FCZ1 AB DV dri ve spring 1

!

LHLDW2106SCZZ

(Q’ty: 2)

LHLDW1159FCZZ

(Q’ty: 2)

LBSHC0164FCZZ LBSHC0164FCZ1 AA Edge bush B 1

MSPRC2231FCZZ

(Q’ty: 2)

MSPRC1534FCZZ

(Q’ty: 2)

LX-BZ0689FCZZ

(Q’ty: 4)

LHLDW1281FCZZ

(Q’ty: 2)

LHLDW1159FCZ1

(Q’ty: 2)

MSPRC2231FCZ1

(Q’ty: 2)

MSPRC1534FCZ1

(Q’ty: 2)

XHBSE40P06000

(Q’ty: 4)

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others.

AC Wire holder 1

1st lot

’95/2

AB Wire holder 1

Drive brake

AD

spring

AB DV drive spring 1

AA Screw (M4 x 6)

1st lot

’94/12

1

1 *

3

4/4

* Supplemented in T/R No. DTE-170.

Loading...

Loading...