Page 1

Date: Feb. 3, 1995

DUPLICATOR: SD-2060

1. PREVENTION OF MODE EXCHANGE GATE VIBRATION INSIDE FINISHER

2. CHANGE OF IC INSIDE OPERATION CONTROL PWB (TO IMPROVE PRODUCTIVITY)

3. COMMONLY USE OF PARTS DUE TO MODEL SD-2160 PRODUCTION

4. CHAN GE O F P USH RATCH ATTACH ME N T P O S IT IO N

No. : DTE-198

1. Prevention of mode exchange gate vibration inside finisher

1.Model name: SD-3062

2.General: We added a washer to prevent unstable in the mode exchange gate in Technical Report

DTE-180. However, we have changed the added washer thick from 1.0 mm to 0.5 mm

because the gate shook up and down in the non-staple mode.

3.Action: From mid-July 1994 production

2. Change of IC inside operation control PWB (to improve productivity)

1.Model name: SD-2060, 3062

2.General: We have changed manufactures of the IC (CG-ROM) used in the operation control

PWB to improve productivity . There is no change in the software contents. The new one

is compatible with the old one. Only the parts’ code has been changed.

3.Action: From the first unit of November 1994 production

3. Commonly use of parts due to change of model SD-2160 production

1.Model name: SD-2060, 3062

2.General: Part of the parts used in the models above has been used compatibly with the model

SD-2160 (only in Japan).

Green

C

SHARP CORPORATION Reprography Division

1/3

Page 2

3.Description: Changed parts

Operation base plate A (P/G 2 -46)

Operation panel A (P/G 1 -27, 2 -7)

LCD attachment plate (P/G 2 -26)

Change of screw (pointed by arrows in the

illustration shown in right)

Unpacking instruction manual (for domestic only)

The operation panel A is compatibly used between current and new. The operation

base plate A and the LCD attachment plate are compatibly used when you exchange it

a pair of current type or new type.

When you clump the screw shown in the illustration

above to attach the operation base plate after the

change, please cut ribs as shown right to fix it.

Cut ribs

4.Action: From mid-October 1994 production

LX-BZ0689FCZZ

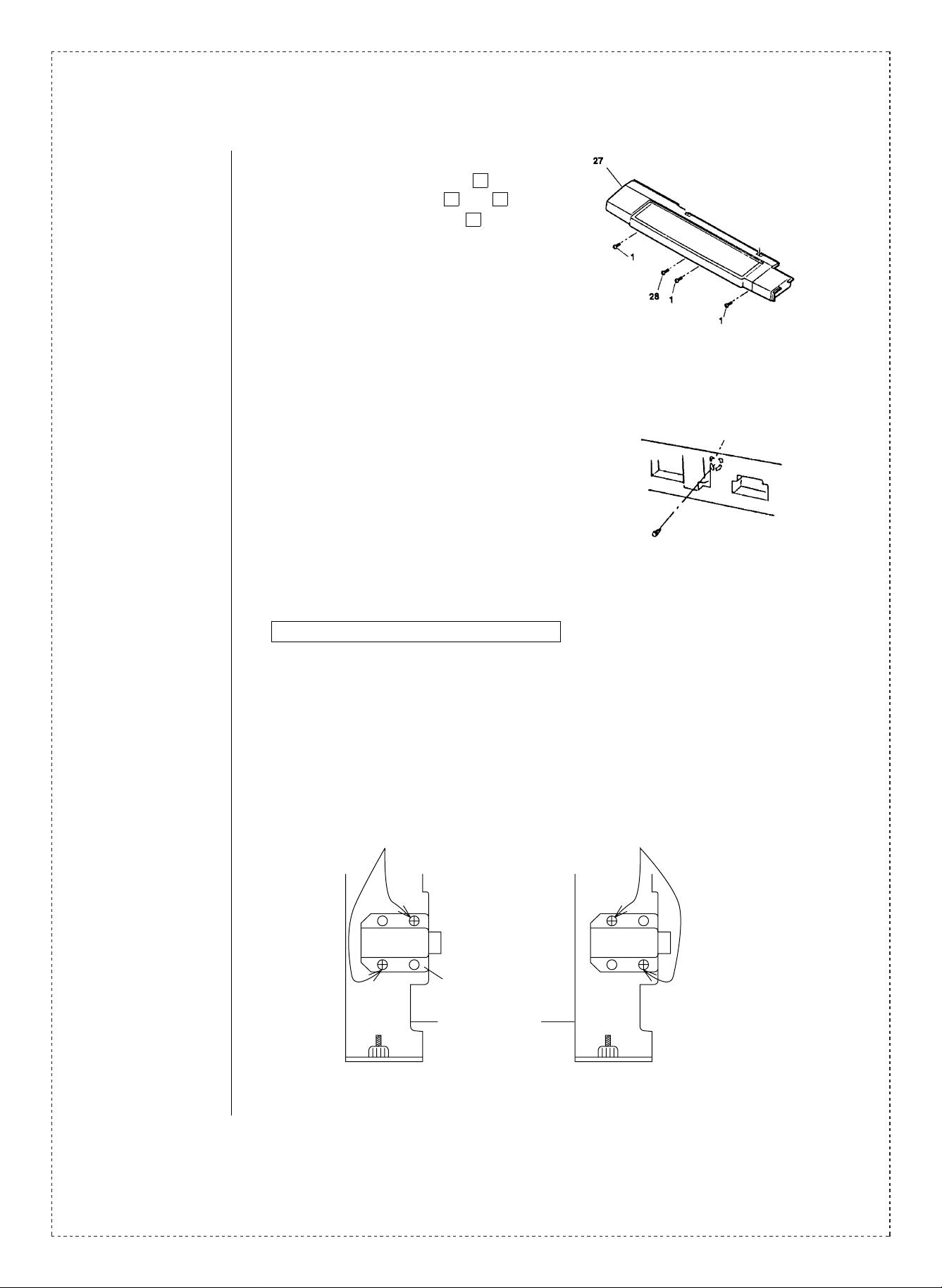

4. Change of push ratch attachment position

1.Model name: SD-2060, 3062

2.General: In some of the waste toner cover, positions of the hook section and the opposite side of

push ratch have not matched since their production. These covers cannot be closed or

opened perfectly and were difficult to correct them. Therefore we have made a new

screw hall on the push ratch fixing plate and changed the method to fix it as shown in

the illustration below.

Clump screws on these two points

and fix the push ratch

Add two screw halls to 1 mm upward from

the current halls. Fix it by screws at these

two points.

Push ratch

(LSTPZ0296FCZZ)

Push ratch

attachment plate

(LPLTM4441FCZZ)

3.Action: From the first unit of November 1994 production

2/3

Page 3

Ref.

Model

No.

1 SD-3062

2

SD-2060

SD-3062

3

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

sp eci fi e d on es fo r m ai n ta in i ng t he s a fe ty an d pe rformanc e o f th e s et .

name

Version P/G No.

53 LX-WZ0042FCZZ LX-WZ0017FCZZ AA Washer

8 -44

2 -46

All

1 -27

2-7

2 -26

1 -28

!

Current parts New parts

Parts code Parts code

VHITC531000CF VHILH531GP5-1 AR IC [IC430]

GDAI-0163FCZZ GDAI-0163FCZ1 BF

HPNLC0212FCZZ HPNLC0212FCZ1 BB Ope ra tion pane l A 1

LPLTM4212FCZ1 LPLTM4212FCZ2 AQ LCD fixing plate 5

XBBSD40P14000 LX-BZ0689FCZZ AA Screw 5

Price

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others .

Parts name

rank

Operat io n ba se

plate A

Effec-

tive

time

Mid-

’94/7

1st lot

’94/11

Mid-

’94/10

Inter-

change-

ability

3

1

5

Note

3/3

Loading...

Loading...