Page 1

Date: Dec. 1, 1994

DUPLICATOR: SD-3062

No. : DTE-195

UDH PARTS CHANGE INFORMATION

1.Model name: SD-3062

2.General: This technical report tells you a collective information concerning UDH parts change.

3.Items: 1. Improvement of interference between the disposed paper opening and closing

cabinet (P/G 68-16) and the moving cabinet (P/G 68-27)

Improvement of interference between the moving paper guide upper AS (P/G 68-27)

and the moving guide opening and closing shaft upper attachment plate (P/G 64-62)

Improvement of the disposed paper opening and closing unit not to be able to be closed

by deforming of the fulcrum section in the moving paper guide

2. Improvement of the irregular noise from the absorber (P/G 68-37)

3. Improvement of the moving drive belt skipping (P/G 64-24)

4. Prevention removal of the coupling Z for the belt drive roller (P/G 67-9)

5. Discontinuance of the tapping hall in the frame support plate (P/G 59-84) to improve

productivity

6. Improvement of irregular noise from the paper feeding roller shaft L (P/G 59-6)

7. Improvement of malfunction of return of the edge stopper (P/G 72-7)

8. Improvement of irregular noise by contact between the belt frame F-R (P/G 67-10, 37)

and the belt UN fixed plate F-R AS (P/G 67-1, 39)

4.Description: 1. Improvement of interference between the disposed paper opening and closing

cabinet (P/G 68-16) and the moving cabinet (P/G 68-33)

Improvement of interference between the moving paper guide upper AS (P/G 68-27)

and the moving guide opening and closing shaft upper attachment plate (P/G 64-62)

Improvement of the disposed paper opening and closing unit not to be able to be

closed by deforming of the fulcrum section in the moving paper guide

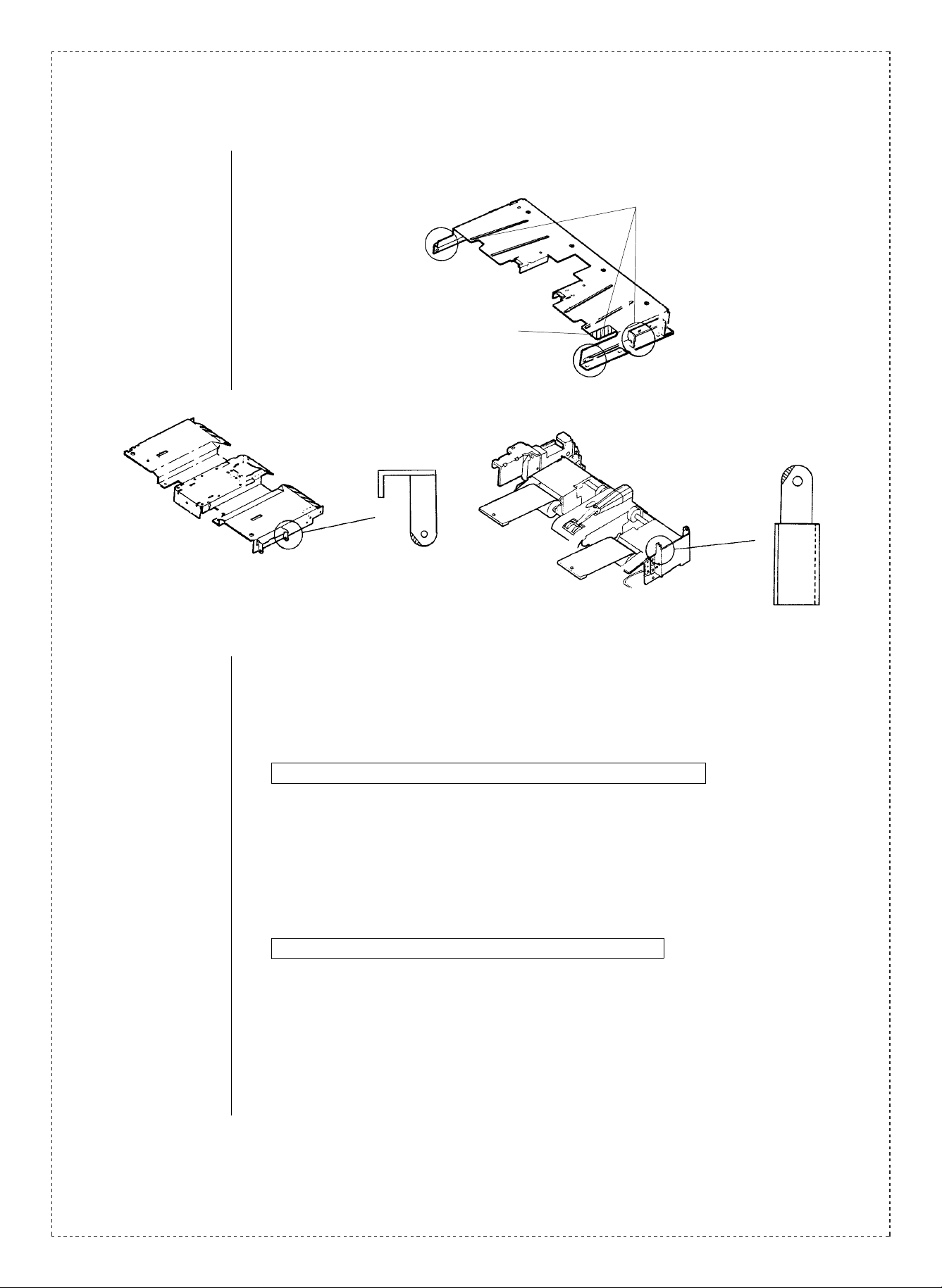

➀ We have changed the folding angle and the form (cut the shading part) of steel plate

of the disposing exit PGM-AS to improve interference between the disposed paper

opening and closing cabinet and the moving cabinet. (See Fig. 1)

➁ We have changed the form (cut the shading part) of the moving paper guide upper

AS and the moving guide opening and closing shaft upper attachment plate to improve

interference between them. (See Fig. 2 and 3)

Green

C

SHARP CORPORATION Reprography Division

1/4

Page 2

➂ We have changed the plate thick to improve deform of the fulcrum section in the

moving paper guide upper. (See Fig. 2)

Folding angle change

Cut shading part

(Fig. 1) Disposing exit PGU-AS

Cut the shaded part

• Cut shading part above

• Change thick (t 1.2 → t1.6)

(Fig. 3) Moving opening shaft attachment plate lower(Fig. 2) Moving paper guide upper AS

(Action) ➀ From June 1994

➁,➂From mid-May 1994

2. Improvement of the irregular noise from the absorber (P/ G 68-37)

Change of the opening shaft diameter of absorber and improvement of the irregular

noise due to elimination of the internal gears

(Action) From June 1994

3. Improvement of the moving drive belt skipping (P/G 64-24)

Irregular noise and paper jam occurred on rare occasion. These were due to the

moving drive belt skipping caused by inconsistency in parts quality of the discharge

paper motor attachment plate (P/G 64-38). We have improved this by enlarging the

motor attachment hall of this part. ( φ17

+0.05

+0.02

→φ18)

2/4

(Action) From April 1994

Page 3

4. Prevention removal of the coupling Z for the belt drive roller (P/G 67-9)

We have changed the coupling position at the time of changing forms of the belt unit

fixing plate F , R A/S . This was to improve the condition that the coupling Z for the belt

drive roller was detached due to overload.

(Action) From mid-May 1994

5. Discontinuance of the tapping hall in the frame support plate (P/G 59-84) to improve

productivity

We have discontinued the M4 tapping hall (unused) of the frame support plate.

(Action) From mid-June 1994

6. Improvement of irregular noise from the paper feeding roller shaft L (P/G 59-6)

The shaft D cut part and the projected part of

Rolling UL tube

the paper guide outside (P/G 59-7) crashed by

rolling and reversing the paper feeding roller L.

It caused irregular noise. We have added the

rolling UL tube (2) to prevent this. (Newer

paper roller shaft L has a wider D cut part.)

(Action) From June 1994

Out side paper guide

Paper feeding

roller shaft L

7. Improvement of malfunction of return of the edge stopper (P/G 72-7)

Malfunction of return of the edge stopper (narrow margin) occurred because of curving

of the separate duct (P/G 72-3) and the separate duct cover (P/G 72-19). We have

added the belt spacer to the duct to prevent this.

Standard

Belt spacer

* Attach to center

(Action) From mid-May 1994

Separate duct

3/4

Page 4

8. Improvement of irregular noise by contact between the belt frame F-R (P/G 67-10,

37) and the belt UN fixed plate F-R AS (P/G 67-1, 39)

When the transport belt UN moves up and down, irregular noise occurred by contact

between the belt frame F-R (P/G 67-10, 37) and the belt UN fixed plate F-R AS (P/G

67-1, 39). We have attached the belt UN mylar to the belt frame F, R to prevent this.

(Quantity 2 for each of the front and the rear side)

Belt UN mylar

Belt frame F.R

(Action) June 1994

Ref.

Model

No.

1

2 68-37 0EUABS0301D01 0EUABS0302D02 BA Absorber AS ’94/6 1

3 64-38 0EUFRM0311D11 0EUFRM0311DZ1 AM

SD-3062 All

4

5 59-84 0EUANG0328D// 0EUANG0328DZ1 AN

6

7 — 0EUSHE0335D// AG Belt spacer

8 — 0EUANG0313D// AK Belt UN mylar ’94/6 Q’ty: 4

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

speci fied ones fo r m ain taining t he s a fe ty and pe r fo r ma nce o f th e s et .

name

Version P/G No.

68-5 0EUGID0356D01 0EUGID0356D02 BB

68-27 0EUGID0363D01 0EUGID0363D04 BC

64-62 0EUANG0313D// 0EUANG0313DZ1 AK

67-39 0EUFRM0307D01 0EUFRM0307D02 AS

67-1 0EUFRM0308D01 0EUFRM0308D02 AS

59-6 0EUSFT0306D// 0EUSFT0306DZ1 AU

!

Current parts New parts

Parts code Parts code

— 0EUTUB0301D// AB Rolling UL tube Q’ty: 2

Price

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others .

Parts name

rank

Disposing exit

PGU-AS

Moving paper

guide upper AS

Moving opening

shaft attachment

plate lower

Discharge paper

motor attachment

plate

Belt unit fixing

plate F A/S

Belt unit fixing

plate R A/S

Frame support

plate

Paper feeding

roller shaft L

Effec-

tive

change-

time

’94/6 3

’94/5 3

Mid-

’94/5

’94/4 3

Mid-

’94/5

Mid-

’94/6

’94/6

Mid-

’94/5

Inter-

Note

ability

3

3

3

1

3

Q’ty:

3 → 4

4/4

Loading...

Loading...