Page 1

Date: Jan. 20, 1994

COPIER : CX-7700

No. : CCT-84

CX-7700 PARTS CHANGES IN COMPLIANCE

WITH SAFETY STANDARDS.

1.General: Var ious parts of the 200 V series of model CX-7700 have been changed in compliance

with safety standard demands.

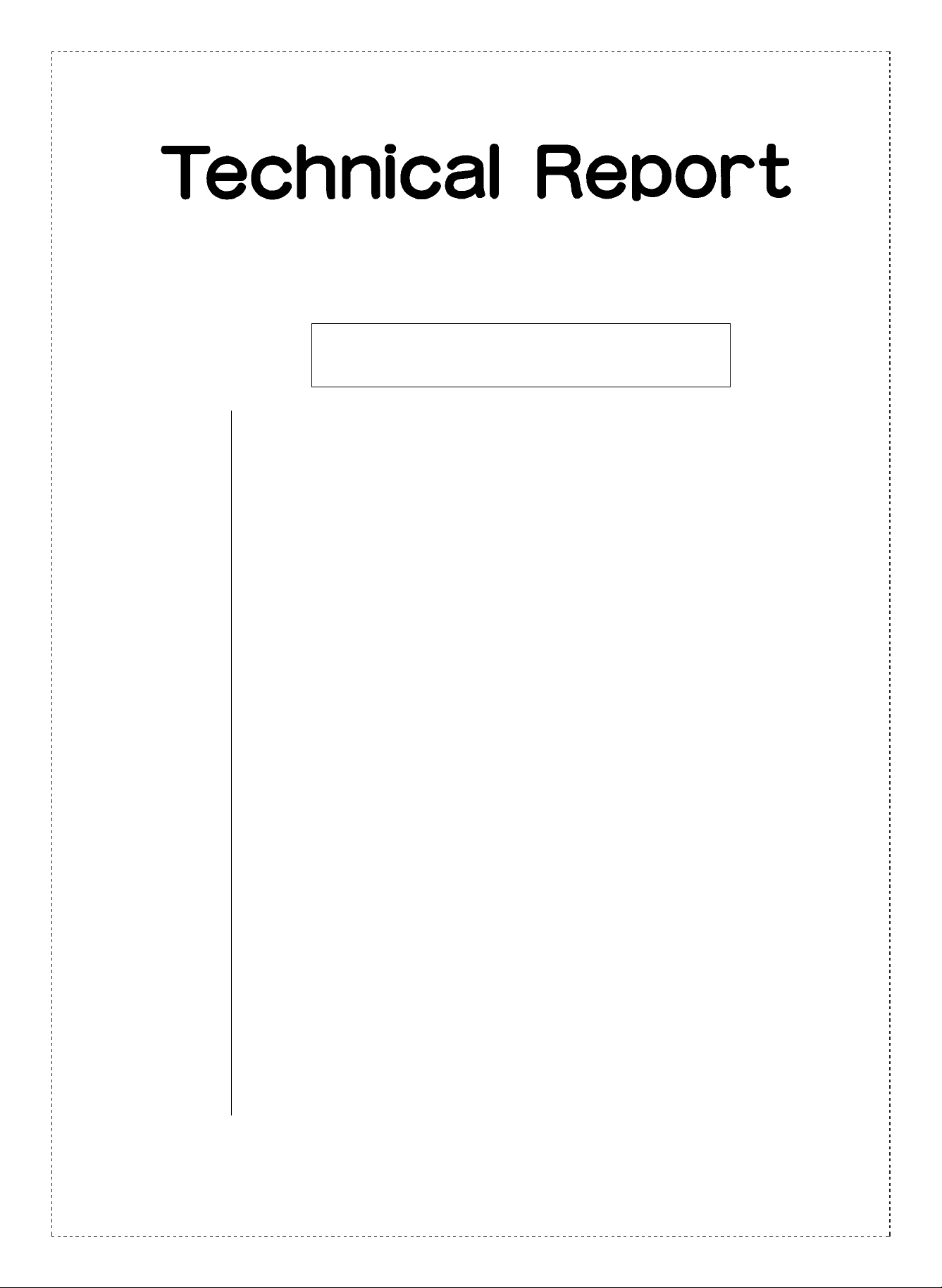

2.Description: 1. Copy lamp unit.

Heat reducing tubes (4 locations) have been added to the terminal area (Fig. 1).

Mylar tape has been attached to the edge of the wiring path (Fig. 2).

2. Zoom lens unit.

A reducing tube has been added to the drying heater terminal (Fig. 3.)

3. Drive unit.

Edge bushings (4 locations) have been added to the upper surface of the drive unit

frame (Fig. 4).

4. Rear frame.

An edge bushing has been added to the attachment plate angle of the slave circuit

board (Fig. 5).

An edge bushing has been added to the attachment plate of the slave circuit board

(Fig. 6 ).

An edge bushing has been added to the holding plate of the main circuit board (Fig. 7).

5. Lower frame.

An edge bushing has been added to the right fulcrum angle (Fig. 8).

A bushing has been added to the suction fan attachment angle (Fig. 9).

6. DV motor.

A protection sheet has been added to the motor lead (Fig. 10).

7. Fixing unit.

Edging has been added to the oil tank holding plate area (Fig. 11 and 12).

A protection sheet has been added to the oil tank holding plate area (Fig. 11, 13 and

14).

A protection sheet has been added to the thermostat attachment plate (Fig. 15).

The fixing unit harness has been changed (Fig. 16).

SHARP CORPORATION Reprography Division

1/7

Green

C

Page 2

An edge protection coil has been added (Fig. 16).

A heat resistant clamp has been added (Fig. 16).

The screws have been changed (Fig. 16).

1. Copy lamp unit.

Added heat reducing tube.

Fig. 1

2. Zoom lens unit.

Edge mylar tape attac hed

to the shaded areas.

Fig. 2

Drying heater.

Reducing tube.

Fig. 3

2/7

Page 3

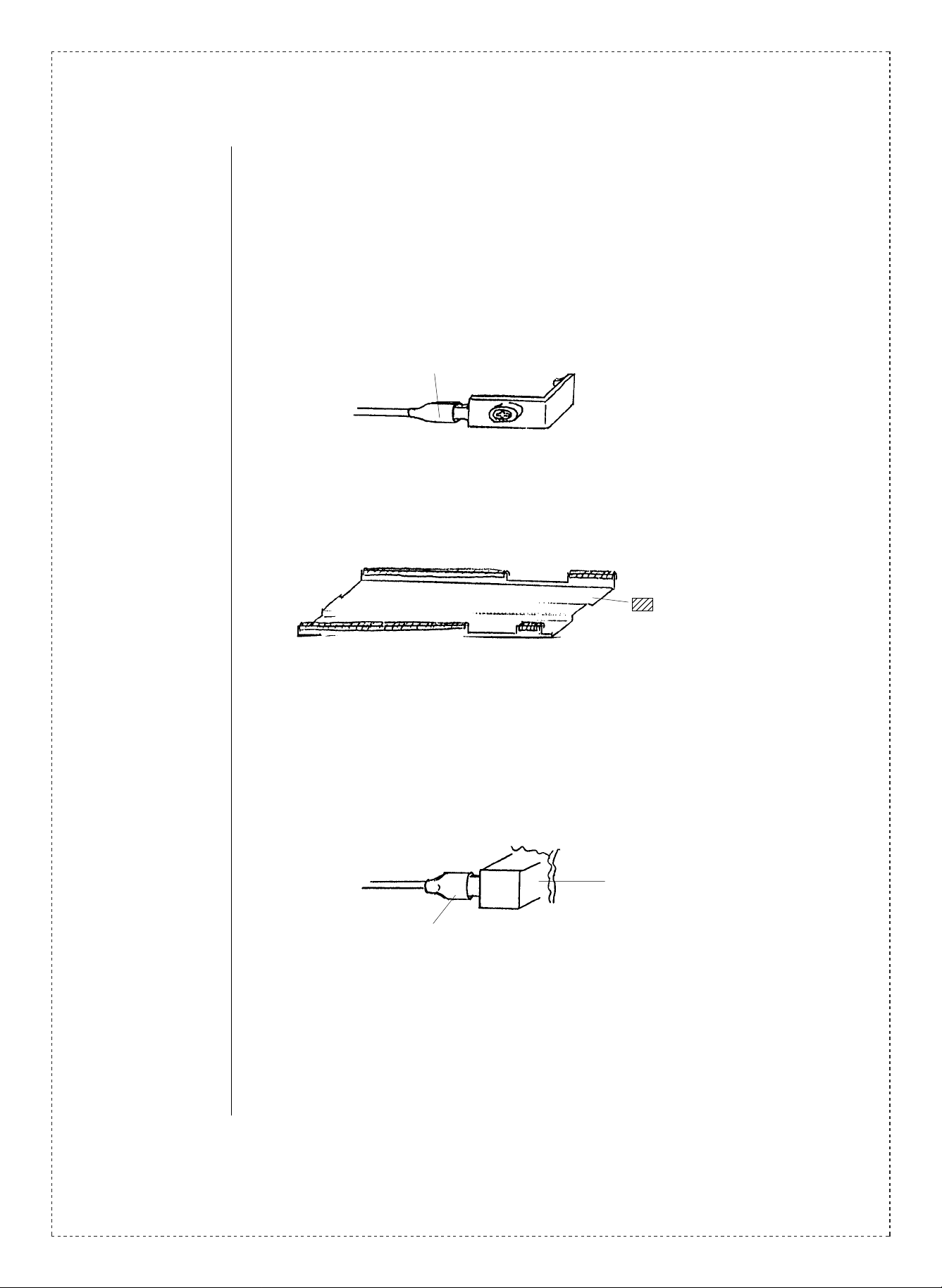

3. Drive unit.

4. Rear frame.

Edge bushing CE-016.

Drive unit 220 (V).

CFRM-0526FC

Fig. 4

PHOG-7003XCZZ

Fastened with instantaneous adhesion glue.

.

**

Slave circuit board

attachment plate.

Fig. 5

Slave circuit board

attachment plate.

(LPLTM2811FCZZ)

PHOG-1007HCZZ

Fig. 6

Main circuit board holding plate.

(LPLTM2749FCZZ)

PHOG-2029SCZZ

Fastened with instantaneous adhesion glue.

Fig. 7

3/7

Page 4

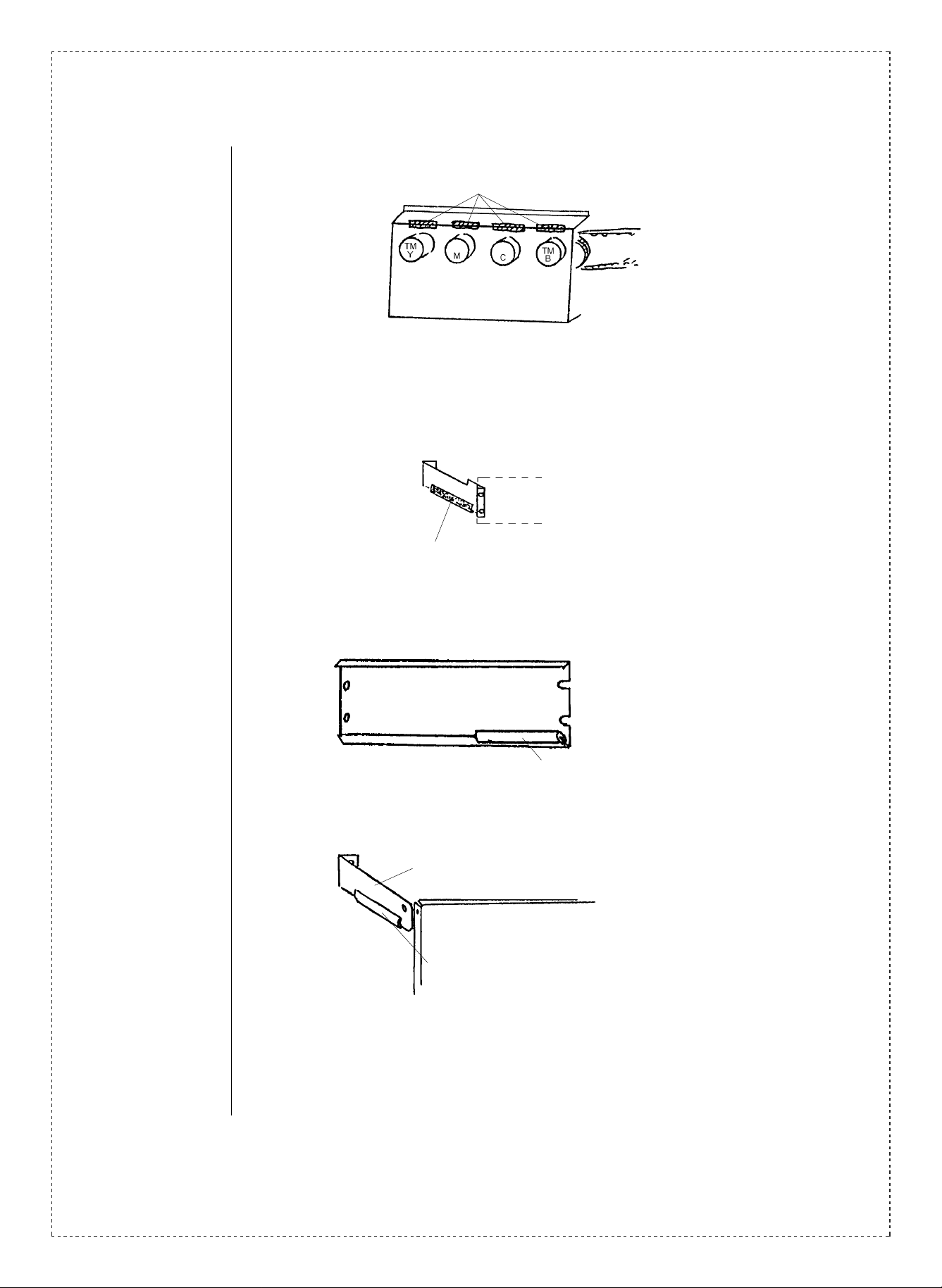

5. Lower frame.

Rear frame angle (CANGT1249FC2)

LBSHC0282FCZZ

Standard installment of bottom surface.

Fig. 8

Added.

LBSHC7004SCZZ

6. DV motor.

Rear frame.

Fig. 9

PSHEP3083FCZZ

DV motor.

Fixed by inserting into the motor screw area.

Fig. 10

4/7

Page 5

7. Fixing unit.

Fig. 11

Section A of the left diagram.

LBSHC0281FCZZ x2

=17mm

CE024

LBSHZ7004GCZZ x1

@=3.00

Fig. 12

Section B and section B’ of the left diagram.

Held in position by the

lead wire after inserting.

Lead wire.

Section C of the diagram above.

Bottle-neck holder.

Lead wire.

Fig. 14

PSHEZ3082FCZZ (Protection sheet FU3.)

Fig. 13

PSHEZ3081FCZZ

Protection sheet FU2.

Fixing unit rear frame.

Tightened.

5/7

Page 6

M3 x 6 S/SW

Rear.

Fixing unit front frame.

M3 x 6 S/SW

Insert under the metal plate.

PSHEZ3080FCZZ

Fig. 15

Front.

Thermostat attachment plate.

PSHEZ3080FCZZ

Added edge protection coil.

Added heat resistant clamp.

Changed screw.

M4 x 6 with SW

M4 x 6 with S/SW.

Changed tightening screw.

M4 x 6 with SW

M4 x 8 with S/SW.

Changed fixing unit

harness ?????.

Electrode holder.

Heater.

Fig. 16

6/7

Page 7

Ref.

No.

1

Model

name

Version P/G No.

200V

11 -501 CREFL0130FC37 CREFL0131FC38 BW Copy lamp unit

series

Current parts New parts

Parts code Parts code

Price

rank

Parts name

Effec-

tive

time

Inter-

change-

ability

1

Note

2

3

4

5 220V

6

CX-7700

7

220V

SEEG

only

ALL

SEEG

only

ALL 20 -6 DHAI-1559FCZZ DHAI-1559FC12 AH

SEEG

only

12 —3 CR-WZ0247FC04 CR-WZ0247FC10 AV Drying heater 1

19 — PHOG-7001SCZZ AV

4

4

8

23 — LBSHC0282FCZZ AV —

23 — LBSHC7004SCZZ AB Bushing —

8

20 — LBSHC0281FCZZ AB

20

20

20 — PSHEZ3081FCZZ AL

20

20 — XBPSD30P06KSD AA Screws (M3 x 6) —

20 — MSPRC1991FCZZ AA

20 — LHLDW0433FCZZ AD

20 -B48 XBPSD40P06K00 XBPSD40P06KSD AA Screw (M4 x 8) 1

— PHOG-7003XCZZ AV —

— PHOG-1007HCZZ AV —

— PHOG-2029SCZZ AV —

— PSHEP3083FCZZ AD Protection sheet —

— LBSHC7004GCZZ AB — Q’ty: 1

— PSHEZ3082FCZZ AL

— PSHEZ3080FCZZ AG

Edge bushing

Edge bushing

Protection sheet

FU 3

Protection sheet

FU 2

Protection sheet

FU 1

Fixing unit

harness

Edge protection

coil

Heat resistant

clamp

92/12

— Q’ty: 4

Q’ty: 1

— Q’ty: 2

— Q’ty: 2

— Q’ty: 1

—

Q’ty: 2

1

—

Q’ty: 1

—

20 -B48

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. C urr e nt t y pe c a n be u s ed i n place of n ew type.

New ty pe cann ot be us ed in place of curr ent type .

3. C urr e nt type cannot b e us e d in p l ac e o f ne w ty p e.

New t y pe c a n be u s ed i n pl a ce of curr en t ty p e.

Parts m ar ke d wi th “ ” is imp or t an t fo r mai n ta in ing t he s a fe ty of t he se t. Be sur e t o rep l ac e t he se pa r ts wi th

specified ones for maintaining the safety and performance of the set.

!

XBPSD40P06K00 XBPSD40P08K00 AA Screw (M4 x 8) 1

5. Interc ha ng ea ble i f r ep l ace d wi th s a m e typ es of

relate d pa r ts in use.

6. Others.

7/7

Loading...

Loading...