Page 1

TopPage

BD-HP21U

SERVICE MANUAL

No. S88M8BDHP21U/

BLU-RAY DISC PLAYER

MODEL

In the interests of user-safety (Required by safety regulation in so me countries) the set sh ould be restored to its

original condition and only parts identical to those specified should be used.

BD-HP21U

CONTENTS

SAFETY PRECAUTION

IMPORTANT SERVICE NOTES.........................i

Precautions for using lead-free solder ..............iii

CHAPTER 1. SPECIFICATIONS

[1] SPECIFICATIONS .........................................1-1

CHAPTER 2. OPERATION MANUAL

[1] PARTS NAMES.............................................. 2-1

CHAPTER 3. REMOVING OF MAJOR PARTS

[1] REMOVING OF MAJOR PARTS ................... 3-1

[2] EXTENSION CABLE CONNECTION DIA-

GRAM ............................................................3-4

[3] IMPORTANT SERVICE NOTICE...................3-6

[4] UPGRADING .................................................3-6

CHAPTER 4. BLOCK DIAGRAM

[1] MAIN BLOCK DIAGRAM ............................... 4-1

[2] ANALOG/LCD/OPERATION BLOCK DIA-

GRAM ............................................................4-2

CHAPTER 5. SCHEMATIC DIAGRAMS

[1] MAIN (1) CIRCUIT SCHEMATIC DIA-

GRAM ............................................................5-1

[2] MAIN (2) CIRCUIT SCHEMATIC DIA-

GRAM ............................................................5-2

[3] MAIN (3) CIRCUIT SCHEMATIC DIA-

GRAM ............................................................5-3

[4] MAIN (4) CIRCUIT SCHEMATIC DIA-

GRAM ............................................................5-4

[5] MAIN (5) CIRCUIT SCHEMATIC DIA-

GRAM ............................................................5-5

[6] MAIN (6) CIRCUIT SCHEMATIC DIA-

GRAM ............................................................5-6

[7] MAIN (7) CIRCUIT SCHEMATIC DIA-

GRAM............................................................5-7

[8] MAIN (8) CIRCUIT SCHEMATIC DIA-

GRAM............................................................5-8

[9] MAIN (9) CIRCUIT SCHEMATIC DIA-

GRAM............................................................5-9

[10] MAIN (10) CIRCUIT SCHEMATIC DIA-

GRAM..........................................................5-10

[11] ANALOG CIRCUIT SCHEMATIC DIA-

GRAM..........................................................5-11

[12] POWER (1) CIRCUIT SCHEMATIC DIA-

GRAM..........................................................5-12

[13] POWER (2) CIRCUIT SCHEMATIC DIA-

GRAM..........................................................5-13

[14] POWER (3) CIRCUIT SCHEMATIC DIA-

GRAM..........................................................5-14

[15] OPERATON CIRCUIT SCHEMATIC DIA-

GRAM..........................................................5-15

[16] LCD CIRCUIT SCHEMATIC DIAGRAM......5-17

CHAPTER 6. PRINTED WIRING BOARD ASSEMBLIES

[1] MAIN PWB ....................................................6-1

[2] ANALOG PWB ..............................................6-5

[3] POWER PWB................................................6-7

[4] OPERATION-L PWB .....................................6-9

[5] OPERATION-R PWB...................................6-10

[6] LCD PWB ....................................................6-11

[7] SPACER PWB.............................................6-12

Parts Guide

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

BD-HP21U

BDHP21U

SAFETY PRECAUTION

IMPORTANT SERVICE NOTES

IMPORTANT SERVICE NOTES

ServiceManual

Note:

This unit can be used only where the power

supply is AC 120V, 60Hz.

It cannot be used elsewhere.

CAUTION:

USE OF CONTROLS OR ADJUSTMENTS OR

PERFORMANCE OF PROCEDURES OTHER

THAN THOSE SPECIFIED HEREIN MAY RESULT

IN HAZARDOUS RADIATION EXPOSURE.

DO NOT STARE INTO THE LASER BEAM OR

VIEW WITH OPTICAL INSTRUMENT.

WARNING:

TO REDUCE THE RISK OF FIRE OR ELECTRIC

SHOCK, DO NOT EXPOSE THIS EQUIPMENT TO

RAIN OR MOISTURE.

TO REDUCE THE RISK OF FIRE OR ELECTRIC

SHOCK, AND ANNOYING INTERFERENCE, USE

THE RECOMMENDED ACCESSORIES ONLY.

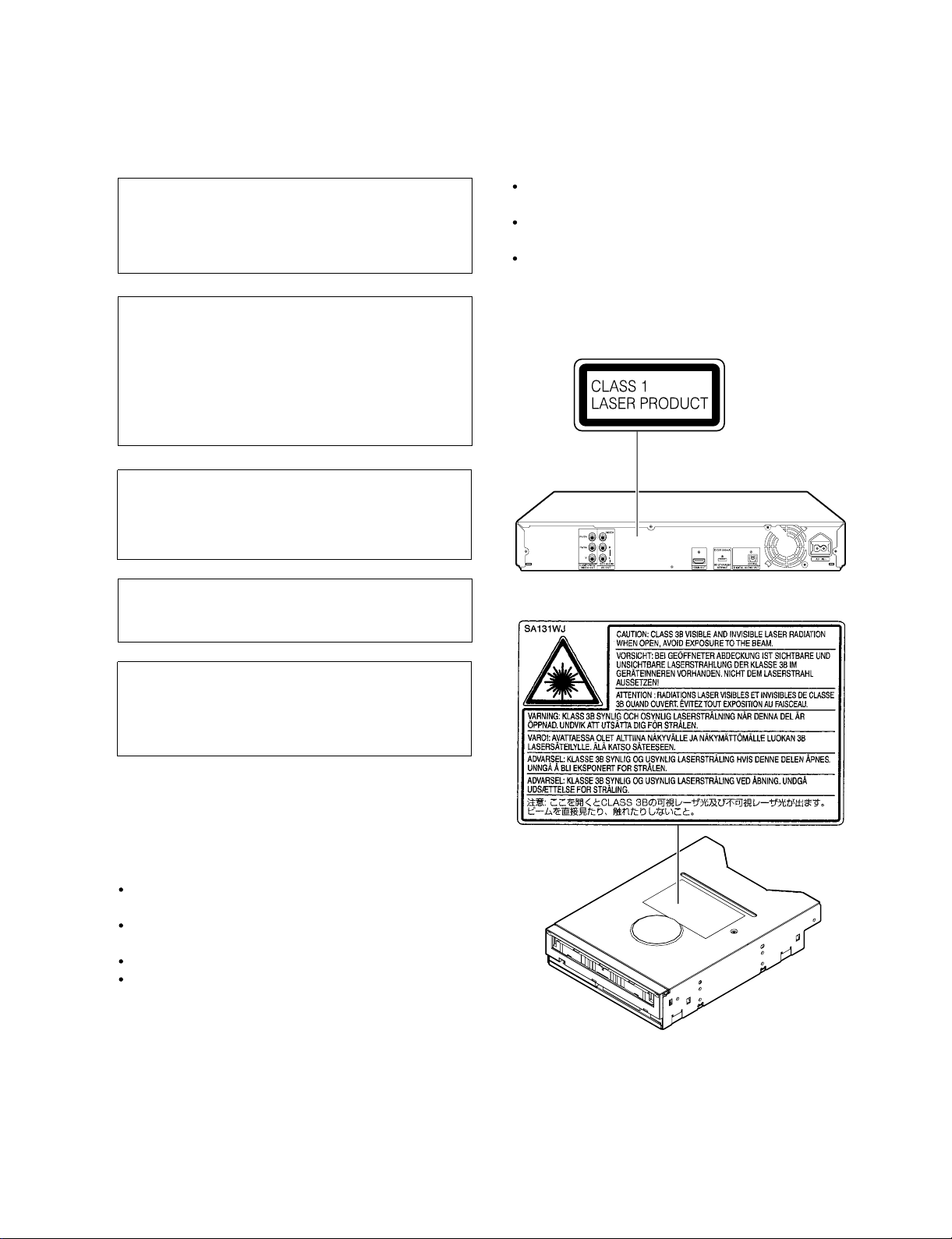

This Unit is classified as a CLASS 1 LASER

product.

The CLASS 1 LASER PRODUCT label is located

on the rear cover.

This product contains a low power laser device.

To ensure continued safety do not remove any

cover or attempt to gain access to the inside of

the product. Refer all servicing to qualified

personnel.

(Rear of product)

Laser Diode Properties

Material: AlGaInP

Wave length: 650 nm

Emission Duration: Continuous

Laser output: Max. 0.7 mW

Power Cord Protection

To avoid any malfunctions of the unit, and to protect

against electric shock, fire or personal injury, please

observe the following.

Hold the plug firmly when connecting or

disconnecting the AC power cord.

Keep the AC power cord away from heating

appliances.

Never put any heavy object on the AC power cord.

Do not attempt to repair or reconstruct the AC

power cord in any way.

VARO! AVATTAESSA OLET A LTTIINA LASERS ÄTEILYLLE.

ÄLÄ TUIJOTA SÄTEESEEN ÄLÄKÄ KATSO SITÄ OPTISEN LAITTEEN LÄPI.

VARNING - LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD.

STIRRA EJ IN STRÅLEN OCH BETRAKTA EJ STRÅLEN GENOM OPTISKT

INSTRUMENT.

i

Page 3

IMPORTANT SERVICE SAFETY PRECAUTION

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the

servicing guidelines which follow:

BD-HP21U

WARNING

1. For continued safety, no modification of any circuit should be

attempted.

2. Disconnect AC power before servicing.

CAUTION: FO R CON TIN UE D PROTECTION

AGAINST A RISK OF FIRE REPLACE ONLY WITH

SAME TYPE FUSE.

F901 (125V 3A)

Use an AC voltmeter having with 5000 ohm per volt, or higher, sensitivity or measure the AC voltage drop across the resistor.

Connect the resistor connection to all exposed metal parts having a

return to the chassis (antenna, metal cabinet, screw heads, knobs

and control shafts, escutcheon, etc.) and measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC cord plug connection

reversed. (If necessary, a nonpolarized adaptor plug must be used

only for the purpose of completing these checks.)

Any reading of 0.75 Vrms (this corresponds to 0.5 mA rms AC.) or

more is excessive and indicates a potential shock hazard which

must be corrected before returning the monitor to the owner.

DVM

BEFORE RETURNING THE BD PLAYER (Fire &

Shock Hazard)

Before returning the BD player to the user, perform the following

safety checks:

3. Inspect all lead dress to make certain that leads are not pinched,

and check that hardware is not lodged between the chassis and

other metal parts in the receiver.

4. Inspect all protective devices such as non-metallic control knobs,

insulation materials, cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacitor networks, mechanical

insulators, etc.

5. To be sure that no shock hazard exists, check for leakage current in

the following manner.

Plug the AC cord directly into a 120 volt AC outlet.

Using two clip leads, connect a 1.5k ohm, 10 watt resistor paral-

leled by a 0.15

parts and a known earth grou nd, such as electrical conduit or electrical ground connected to an earth ground.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

F capacitor in series with all exposed metal cabinet

TO EXPOSED

METAL PARTS

AC SCALE

1.5k ohm

10W

0.15µF

TEST PROBE

CONNECT TO

KNOWN EARTH

GROUND

SAFETY NOTICE

Many electrical and mechanical parts in BD player television have

special safety-related characteristics.

These characteristics are often not evident from visual inspection, nor

can protection afforded by them be necessarily increased by using

replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are

identified in this manual; electrical components having such features

are identified by " " and shaded areas in the Replacement Parts List

and Schematic Diagrams.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

For continued protection, replacement parts must be identical to those

used in the original circuit.

The use of a substitute replacement parts which do not have the same

safety characteristics as the factory recommended replacement parts

shown in this service manual, may create shock, fire or other hazards.

ii

Page 4

BD-HP21U

Precautions for using lead-free solder

Employing lead-free solder

• “All PWBs” of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs and service manuals.

The alphabetical character following LF shows the type of lead-free solder.

Example:

L Fa

Indicates lead-free solder of tin, silver and copper.

Indicates lead-free solder of tin, silver and copper.

L F a/a

Using lead-free wire solder

• When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 °C, we recommend you to use a dedicated soldering

bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering

• As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 °C which is higher than the conventional lead solder by 40 °C, and as it has poor

solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of time. However, Since the land may be

peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the

steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit as

required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

• Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No. Description Code

ZHNDAi123250E J φ0.3mm 250g (1roll) BL

ZHNDAi126500E J φ0.6mm 500g (1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg (1roll) BM

iii

Page 5

BDHP21U

CHAPTER 1. SPECIFICATIONS

ServiceManual

[1] SPECIFICATIONS

General

Power supply AC 120V, 60Hz

Power consumption (Normal) 23 W

Power consumption (Standby) 0.4 W (When "QUICK START" is set to "NO")

Dimensions

Weight Approx. 8.8 lbs. (4.0 kg)

Operating temperature 41°F to 95°F (5°C to 35°C)

Storage temperature -4°F to 131°F (-20°C to 55°C)

Operating humidity 10 % to 80 % (no condensation)

TV systems NTSC system

Approx. 16

Approx. 430 mm x 68 mm x 335 mm (W x H x D)

59

/64x211/16x133/16inch (W x H x D)

Playback

BD-HP21U

Playable discs BD-ROM, BD-RE Dual Layer (BDMV format), BD-R Dual Layer (BDMV format),

DVD Video, DVD+RW/+R/-RW/-R/-R Dual Layer (Video/VR format),

Audio CD (CD-DA), CD-RW/R (CD-DA, JPEG file format)

Input/Output

HDMI HDMI 19-pin standard connector (1080p 24Hz output)

Component video output Output level:

Video output Output level: 1 Vp-p (75 ohms)

Digital audio optical output Terminal: Square Optical terminal

Audio output Output level: 2 V rms (Output impedance: 1K ohms)

USB input USB 2.0 correspondence (for Local storage/Software update)

Specifications are subject to change without notice.

TM

HDMI

Jacks: RCA jack

Jack: RCA-pin jack

Jacks: RCA jack

(V.1.3 with x.v.Color, Dolby TrueHD, DTS-HD Advanced Digital Out )

Y: 1 Vp-p (75 ohms)

B/CB,PR/CR

P

: 0.7 Vp-p (75 ohms)

1 – 1

Page 6

BD-HP21U

BDHP21U

CHAPTER 2. OPERATION MANUAL

[1] PARTS NAMES

1. MAIN Unit

Main Unit (Front)

1 43

2

58

ServiceManual

1

2

3

4

5

6

7

8

POWER

Remote control sensor

Disc tray

OPEN/CLOSE

ON indicator

STANDBY indicator

Front panel display

BD/DVD/CD mode indicator

6

Main Unit (Rear)

1 2

3

7

COMPONENT VIDEO OUT jacks

1

VIDEO output jack

2

3

2CH AUDIO output jacks

4

HDMI OUT terminal

5

BD STORAGE/SERVICE terminal

BD STORAGE

SERVICE for software

DIGITAL AUDIO OUT OPTICAL

7

8

6

terminal

Cooling fan

7

The cooling fan operates while the

power to the Player is on.

AC IN terminal

8

64 5

2 – 1

Page 7

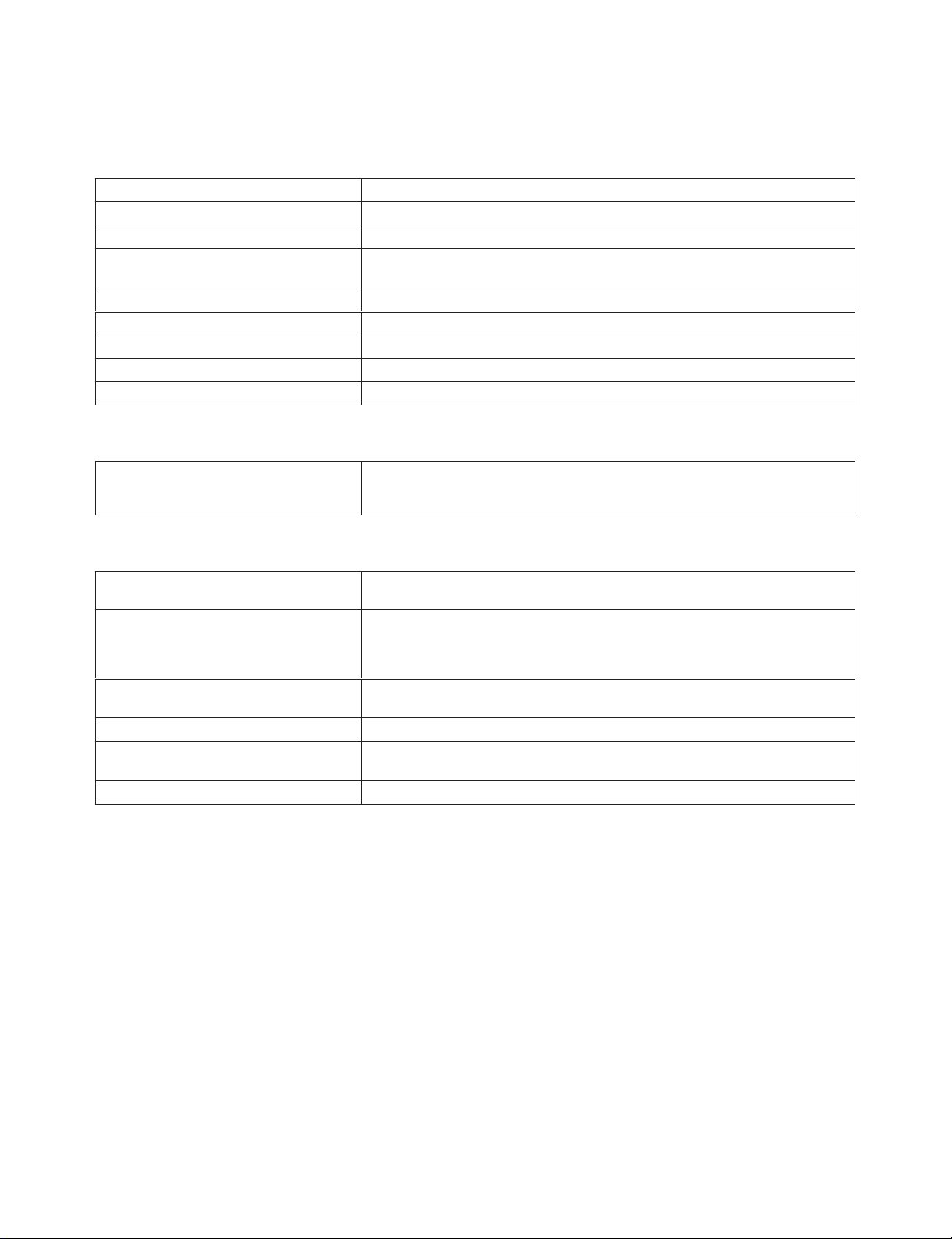

2. Remote Control Unit

Remote Control Unit

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

POWER

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

OPEN/CLOSE

AUDIO, SUBTITLE

Number buttons

REPEAT

SKIP/

SKIP/

PAU S E

PLAY

TOP MENU/TITLE LIST

Cursor buttons ( / / / ), ENTER

EXIT

A (Red), B (Green), C (Blue), D (Yellow)

(Lock) (See below.)

COMPONENT RESET

DISPLAY

TV CONTROL buttons

FUNCTION

FWD

REV

STOP

POP-UP MENU

RETURN

HDMI

SETUP

BD-HP21U

Keylock function

You can set the keylock to prevent accidental operations.

This function allows TVs compatible with AQUOS LINK to

also perform a Key Lock on the player.

Press and hold

Each time you perform this operation, the function is activated

•

or deactivated.

If you try to operate the Player while the keylock function is

•

set, “Hold” blinks on the front display panel to indicate that the

keylock function is set.

(Lock) for more than 5 seconds.

2 – 2

Page 8

BD-HP21U

BDHP21U

CHAPTER 3. REMOVING OF MAJOR PARTS

ServiceManual

[1] REMOVING OF MAJOR PARTS

1. Removing the tray cover

1. Eject the tray by inserting a pin into the compulsory eject hole, then remove the tray cover.

Insert

a pin

Tray cover

2. Removing the cabinet and the panel

1. Remove two screws and three screws from the top cabinet.

2. Unhook claws of the front panel and remover the front panel.

Top cabinet

1

2

1

Front panel

3 – 1

Page 9

3. Removing the BD drive

1. Disconnect the SATA cable and power cable.

2. Remove four screws and remove the BD unit (with the angle) upward.

3. Remove four screws and remove the BD unit.

BD-HP21U

Power cable

3

4

BD drive

angle (Left)

3

BD

drive

4

4. Removing the front PWB

1. Disconnect the LCD FFC between the LCD PWB and power PWB.

2. Disconnect the Connecting cord (Operation-R-Power) and Connecting cord (Power-Analog).

SATA cable

3

BD drive

angle

(Right)

3. Remove three screws .

4. Remove one screw .

5. Remove the operation PWB angles (left and right).

Operation PWB

angle (Left)

Oreration PWB

(Left)

5

5

LCD

PWB

Oreration PWB

(Right)

6

LCD FFC

Operation PWB

angle (Right)

Connecting cord

(Power-Analog)

5

Spacer

PWB

Connecting cord

(Operation-R-Power)

3 – 2

Page 10

BD-HP21U

5. Removing the fan and the rear terminal board

1. Remove two screws .

2. Remove six screws .

3. Disconnect the fan cable connector and remove the fan.

Fan

8

7

8

Rear terminal board

6. Removing each PWB

1. Disconnect the board to board connectors from each PWB.

2. Disconnect the board to board connectors (two) from the main PWB and analog PWB, then remove one screw .

Disconnect the board to board connector (two) between the main PWB and power PWB.

3. Remove two screws .

4. Remove three screws .

5. Remove the insulation sheet.

11

Power PWB

Main PWB

10

Analog PWB

Insulation sheet

9

3 – 3

Page 11

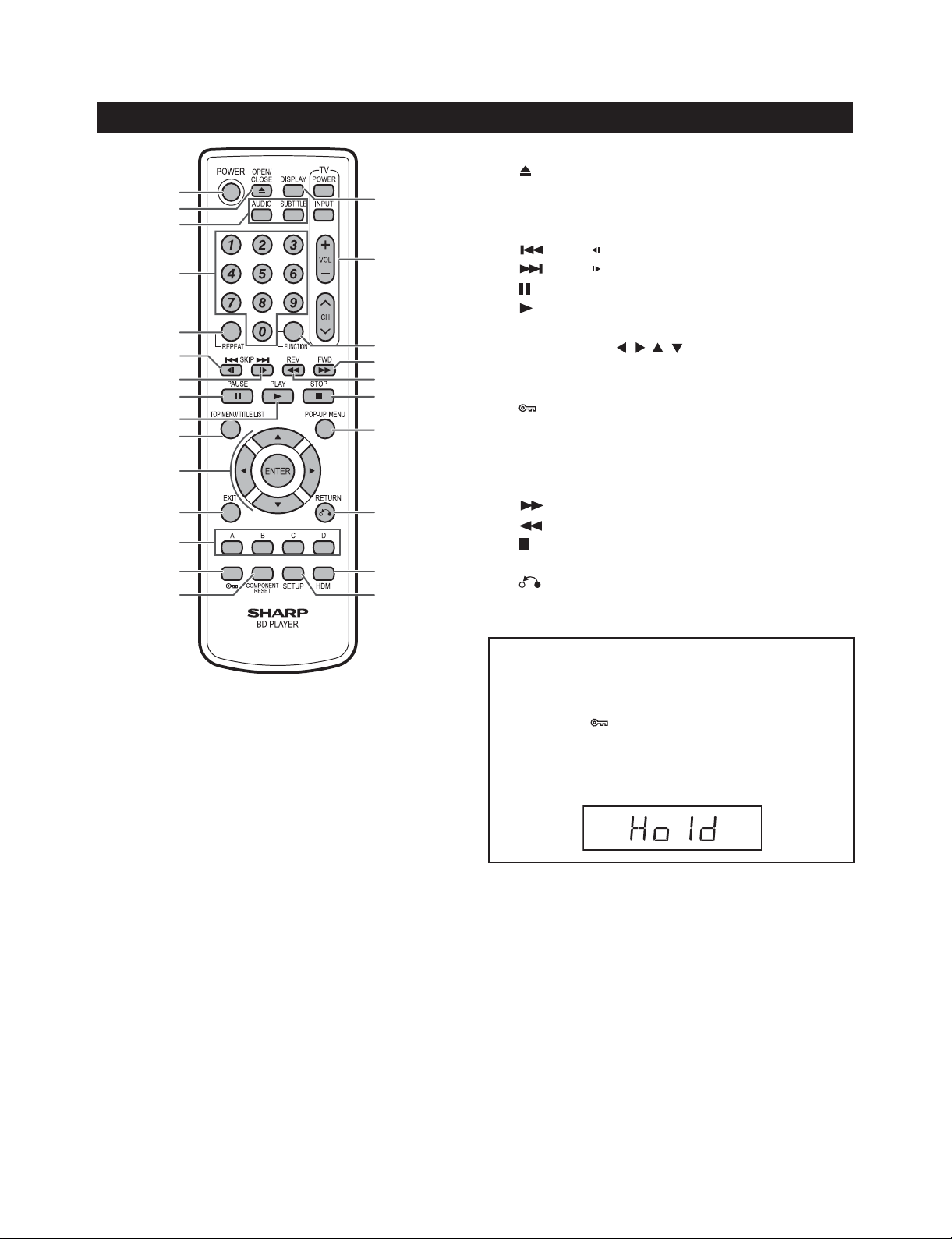

[2] EXTENSION CABLE CONNECTION DIAGRAM

BD-HP21U

㪪㪚㪐㪇㪈

㪧㪦㪮㪜㪩

㪧㪮㪙

㪝㪘㪥

㪚㪥㪐㪇㪉

㪚㪥㪏㪈㪇㪉

㪤㪘㪠㪥

㪧㪮㪙

㪪㪚㪐㪇㪇㪈 㪪㪚㪌㪍㪇㪋

㪚㪥㪐㪌㪇㪉 㪚㪥㪉㪌㪇㪈

㪜

㪙㪛

㪛㪩㪠㪭㪜

㪛

㪘㪭

㪧㪮㪙

㪪㪚㪌㪍㪇㪈

㪙

㪚㪥㪌㪍㪇㪈

㪚

㪘㪙

㪧㪉㪌㪇㪉

㪚㪥㪉㪊㪇㪈 㪚㪥㪉㪊㪇㪉

㪧㪉㪊㪇㪈

㪧㪉㪌㪇㪊

㪧㪉㪌㪇㪈

㪧㪈㪊㪇㪈

㪦㪧㪜㪄㪩

㪪㪚㪉㪌㪇㪈

㪚㪥㪐㪇㪈

㪚㪥㪉㪌㪇㪉

㪧㪮㪙

㪦㪧㪜㪄㪣

㪧㪮㪙

Parts Code Price Code Name/Description Pin

A

QCNW-E227WJPZ CL CN5601 <=> CN2301 23

B

QCNW-E229WJPZ DG SC5601 <=> CN2302, SC9001 <=> CN9502 15

C

QCNW-E231WJPZ DB SC5604 <=> CN2501 9

D

QCNW-E573WJPZ AP

E

- - SATA Cable ( Commercially available ) CN8102 <=> BD DRIVE 7

㪪㪚㪈㪈㪇㪈

㪣㪚㪛

㪧㪮㪙

CN901 <=> BD DRIVE 4

3 – 4

Page 12

BD-HP21U

㪨㪚㪥㪮㪄㪜㪉㪉㪎㪮㪡㪧㪱

㪘

㪚㪥㪌㪍㪇㪈㹤㪚㪥㪉㪊㪇㪈

㪬㫊㪼㪻㩷㫀㫅㩷㫋㪿㪼㩷㪸㫍㫆㪹㪼

㫆㫅㪼㩷㫇㫀㪼㪺㪼㪅㩷㩿㪉㪊㪧㫀㫅㪀

㪍㪇㪇

㪨㪚㪥㪮㪄㪜㪉㪉㪐㪮㪡㪧㪱

㪙

㪪㪚㪌㪍㪇㪈㹤㪚㪥㪉㪊㪇㪉

㪪㪚㪐㪇㪇㪈㹤㪚㪥㪐㪌㪇㪉

㪬㫊㪼㪻㩷㫀㫅㩷㫋㪿㪼㩷㪸㫍㫆㪹㪼

㫋㫎㫆㩷㫇㫀㪼㪺㪼㫊㪅㩷㩿㪈㪌㪧㫀㫅㪀

㪨㪚㪥㪮㪄㪜㪉㪊㪈㪮㪡㪧㪱

㪚

㪪㪚㪌㪍㪇㪋㹤㪚㪥㪉㪌㪇㪈

㪬㫊㪼㪻㩷㫀㫅㩷㫋㪿㪼㩷㪸㫍㫆㪹㪼

㫆㫅㪼㩷㫇㫀㪼㪺㪼㪅㩷㩿㪐㪧㫀㫅㪀

㪛

㪨㪚㪥㪮㪄㪜㪌㪎㪊㪮㪡㪧㪱

㪚㪥㪐㪇㪈㹤㪙㪛㩷㪛㪩㪠㪭㪜

㪬㫊㪼㪻㩷㫀㫅㩷㫋㪿㪼㩷㪸㫍㫆㪹㪼

㫆㫅㪼㩷㫇㫀㪼㪺㪼㪅㩷㩿㪋㪧㫀㫅㪀

㪪㪘㪫㪘㩷㪚㪸㪹㫃㪼㩷㩿㪚㫆㫄㫄㪼㫉㪺㫀㪸㫃㫃㫐㩷㪸㫍㪸㫀㫃㪸㪹㫃㪼㪀

㪜

㪍㪇㪇

㪍㪇㪇

㪌㪇㪇

㪚㪥㪏㪈㪇㪉㹤㪙㪛㩷㪛㪩㪠㪭㪜

㪬㫊㪼㪻㩷㫀㫅㩷㫋㪿㪼㩷㪸㫍㫆㪹㪼

㫆㫅㪼㩷㫇㫀㪼㪺㪼㪅㩷㩿㪎㪧㫀㫅㪀

3 – 5

Page 13

BD-HP21U

[3] IMPORTANT SERVICE NOTICE

1. To replace the Main CBA, perform the items 9 - 12 of [4] Upgrading and confirm the version: it is necessary to upgrade with a disc to the latest version if the CBA version is old.

2. The IC 7201 and IC8505 cannot be replaced because they have the BD-playback key already written. Accor dingly, the IC8502 that has the software written together with the IC8505 cannot be replaced either. Keep also in mind that the IC8503 cannot be replaced either because of the

model information on it.

3. After replacing the E2PROM for front-end software (IC2505), perform Menu - Miscellaneous Settings - Reset Settings.

4. The SPACE PWB (DUNTKE844TEV1) is used to adjust the drive height. In disassembling the set for overhauling or the like, be careful not to lose

it.

[4] UPGRADING

Consult with your Services Company as we cannot provide the upgrading software.

1. Press [Power] button to turn the switch on, then wait till the BD_LED changes from blinking to lit.

2. Press [Tray Open/Close] button to open the Tray, put the upgrade disc on the tray and close the tray.

3. The power automatically turns off. Then it turns on again and the upgrading with the disc will start.

4. During the upgrading, the mode indicator stays blinking in white as "V-up" message keeps blinking on LCD.

"NOW UPDATING DO NOT UNPLUG AC CORD" appears on the monitor screen.

And the version updating progress is expressed in %.

5. When upgrading with the disc is completed, the Tray automatically opens.

* If the front-end software was upgraded, the standby LED lights up halfway as well as the mode indicator starts blinking alternately in white and

blue.; the Tray will open after the upgrading is completed and the power will turn off. (Go to step 8.)

6. When the upgrading is completed, the following appears on the monitor screen.:

"SOFTWARE UPDATE IS COMPLETE"

If the version updating fails, "FAILED TO COMPLETE UPDATE RETRY SOFTWARE UPDATE" is displayed. Take out the disc, turn off the power

and take the procedure again starting from [1] above.

7. Remove the disc from the Tray and press any other button of the Main Unit than [Power], then the Tray will close and the power will automatically

turn off. (Confirm the power-off by stop of the Cooling Fan.)

* If [Power] button is pressed, the power will turn off with the Tray open.

8. Press [Power] button to turn the power on, then wait till the MODE INDICATOR changes from blinking to lit.

9. Press the [SETUP] button on the remote controller, and the menu screen shows up (if the wallpaper screen is used).

* There is no need to take this step, because just after the power is turned on, the menu screen shows up.

10.Select [SETTINGS] first and then [VERSION]. (Press the ENTER button.)

11.The version of the currently installed software appears on the monitor screen. Compare with the version of this updated software, make sure the

version is just the same. If the version id not updated, take the procedure again from Step [2].

12.Press [Power] button to turn the power off. (Confirm the power-off by stop of the cooling fan.)

NOTE: Do not unplug the AC cord during version updating.

3 – 6

Page 14

BD-HP21U

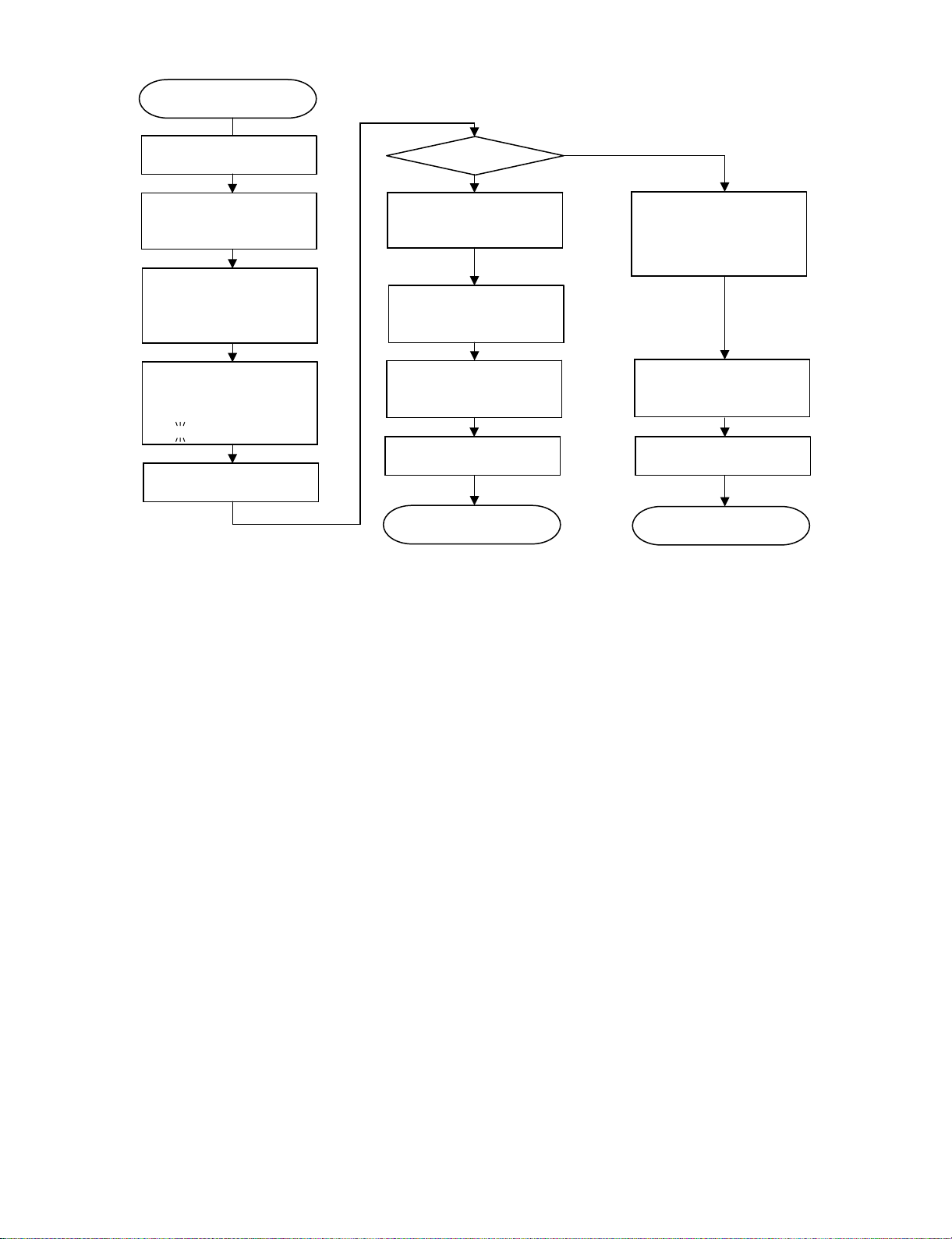

Start

Turn the power on.

Open the tray,

put the upgrade disc and

close the tray

The power automatically

turns off. Then, the power

turns on automatically and

the upgrading starts.

Monitor:

"NOW UPDATING

DO NOT UNPLUG AC CORD"

ex.

غغغع

غغ20%

The tray opens

automatically.

* The version updating cannot be made on the menu screen. Make the wallpaper onscreen.

Monitor: "CANNOT UPDATE. FINISH PLAYBACK OR EDIT AND SET A DISC"

Upgrading completed

Yes

Monitor:

"SOFTWARE UPDATE IS

COMPLETE"

Remove the disc and turn

the power off.

Turn the power on and

confirm the version.

Upgrading successful. Upgrading unsuccessful.

End

No

Monitor:

"FAILED TO COMPLETE

UPDATE

RETRY SOFTWARE

UPDATE"

Remove the disc and turn

the power off.

Restart

3 – 7

Page 15

BDHP21U

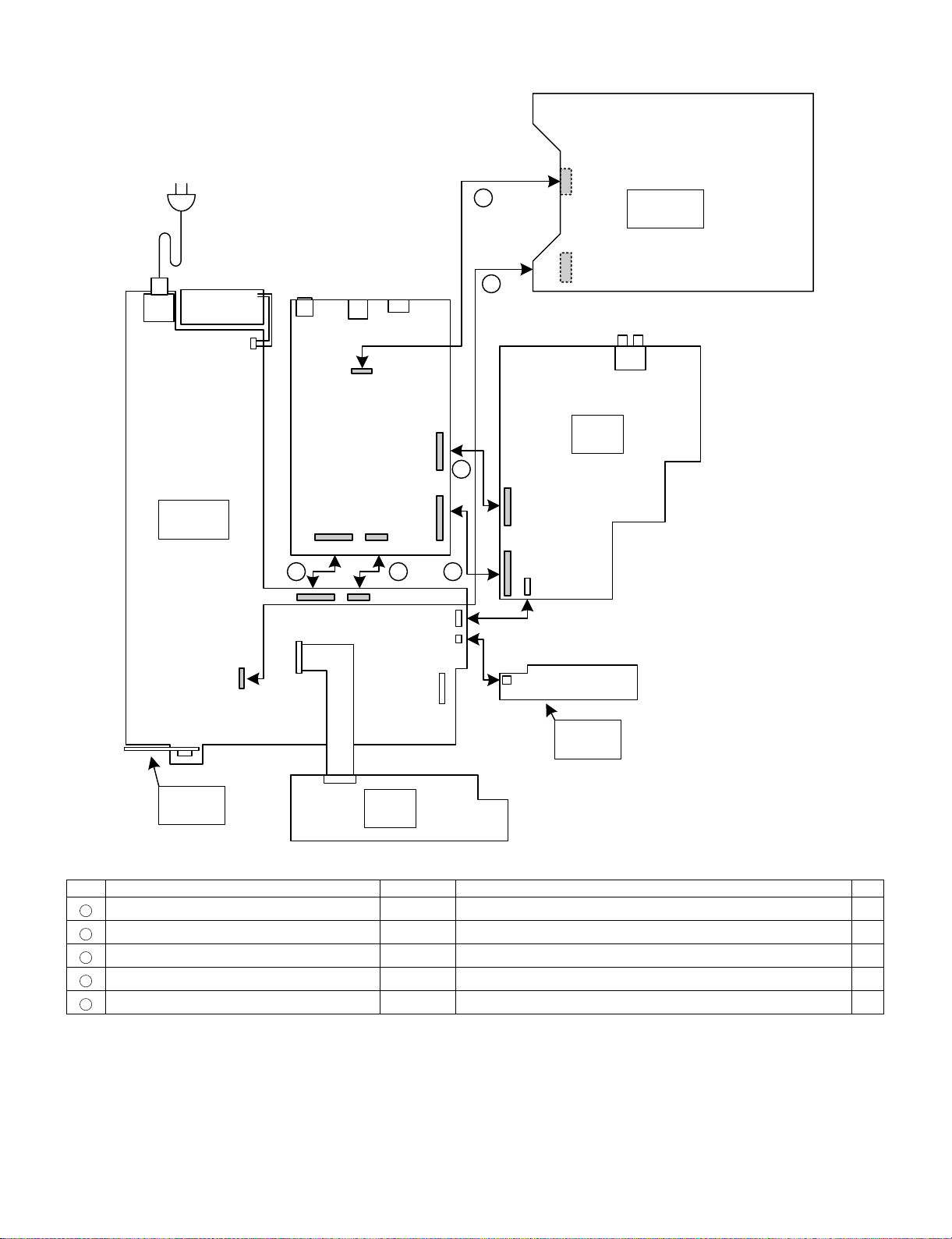

CHAPTER 4. BLOCK DIAGRAM

[1] MAIN BLOCK DIAGRAM

ServiceManual

㪚㪥㪌㪍㪇㪉

㪪㪧㪛㪠㪝㩷㪦㪬㪫

㪭㪟㪧㪞㪧㪈㪝㪌㪌㪫㪢㪭㪰

BD-HP21U

㪧㪩㪠㪤㪘㪩㪰

㪚㪦㪥㪫㪩㪦㪣

㪚㪠㪩㪚㪬㪠㪫

㪠㪚㪐㪇㪈

㪤㪩㪋㪇㪉㪇

㪦㪭㪜㪩㪭㪦㪣㪫㪘㪞㪜

㪧㪩㪦㪫㪜㪚㪫㪜㪩

㪪㪮

㪫㪩㪘㪥㪪

㪫㪐㪇㪈

㪮㪘㪉㪏㪈㪮㪡

㪝㪜㪜㪛㩷㪙㪘㪚㪢

㪚㪠㪩㪚㪬㪠㪫

㪪㪫㪘㪥㪛㪙㪰㩷㪚㪫㪣

㪚㪠㪩㪚㪬㪠㪫

㪝㪘㪥㩷㪩㪜㪞

㪦㪭㪧

㪘㪫㪶㪈㪋㪭

㪩㪜㪚㪫㪠㪝㪠㪜㪩

㪘㪫㪶㪐㪭

㪩㪜㪚㪫㪠㪝㪠㪜㪩

㪘㪫㪶㪌㪭

㪩㪜㪚㪫㪠㪝㪠㪜㪩

㪘㪫㪶㪄㪈㪉㪭

㪩㪜㪚㪫㪠㪝㪠㪜㪩

㪨㪐㪇㪈

㪉㪪㪛㪋㪍㪏

㪙㪛㪶㪈㪉㪭㩷㪩㪜㪞

㪨㪐㪇㪋

㪉㪪㪙㪈㪊㪋㪉

㪘㪫㪶㪐㪭㩷㩿㪫㫆㩷㪤㪘㪠㪥㩷㪧㪚㪙㪀

㪙㪛㪶㪌㪭㩷㪪㪮

㪨㪐㪈㪊

㪩㪪㪪㪇㪋㪇㪧

㪪㪬㪙㪶㪧㪚㪶㪌㪭㩷㪪㪮

㪨㪐㪌㪇㪈

㪩㪨㪇㪊㪌㪧

㪣㪦㪮㪶㪧㪦㪮㪜㪩㪶㪚㪫㪣

㪪㪬㪙㪶㪧㪚㪶㪄㪏㪭㩷㪪㪮

㪨㪐㪌㪇㪊

㪉㪪㪙㪈㪈㪊㪉㪨

㪧㫆㫎㪼㫉㩷㪙㪣㪦㪚㪢

㪫㫆㩷㪝㪘㪥㩷

㪚㪥㪐㪇㪉

㪝㪘㪥㪶㪎㪅㪌㪭

㪙㪛㪶㪈㪉㪭

㪙㪛㪶㪌㪭

㪪㪬㪙㪶㪧㪚㪶㪌㪭㩷㩿㪫㫆㩷㪤㪘㪠㪥㩷㪧㪚㪙㪀

㪪㪬㪙㪶㪧㪚㪶㪌㪭㩷㩿㪫㫆㩷㪘㪥㪘㪣㪦㪞㩷㪧㪚㪙㪀

㪘㪫㪶㪌㪭㩷㩿㪫㫆㩷㪤㪘㪠㪥㩷㪧㪚㪙㪀

㪘㪫㪶㪌㪭㩷㩿㪫㫆㩷㪘㪥㪘㪣㪦㪞㩷㪧㪚㪙㪀

㪪㪬㪙㪶㪧㪚㪶㪄㪏㪭㩷㩿㪫㫆㩷㪤㪘㪠㪥㩷㪧㪚㪙㪀

㪚㪥㪐㪇㪈

㪫㫆㩷㪙㪛㩷㪛㪩㪠㪭㪜

㪤㪸㫀㫅㩷㪙㫆㪸㫉㪻

㪠㪚㪏㪌㪇㪊

㪍㪋㪢 㪜㪉㪧

㪤㪉㪋㪚㪍㪋㪮㪥

㪠㪉㪚㪤㪶㪪㪚㪣㪃㩷㪠㪉㪚㪤㪶㪪㪛㪘

㪤㪘㪠㪥㪶㪰㪦㪬㪫

㪤㪘㪠㪥㪶㪧㪙㪦㪬㪫

㪤㪘㪠㪥㪶㪧㪩㪦㪬㪫

㪪㪬㪙㪶㪰㪦㪬㪫

㪪㪬㪙㪶㪚㪦㪬㪫

㪘㪬㪛㪠㪦

㪘㪬㪛㪠㪦

㪶㪌㪭

㪶㪄㪌㪭

㪠㪚㪌㪍㪇㪍

㪉㪺㪿㩷㪘㫌㪻㫀㫆㩷㪛㪘㪚

㪘㪢㪋㪊㪋㪇㪜㪫㩷

㪣㪆㪩

㪧㪚㪤

㪪㪚㪋㪉㪇㪈

㪘㪫㪶㪌㪭

㪨㪋㪉㪇㪈㪃㪋㪉㪇㪉

㪣㪜㪭㪜㪣㪚㪟㪘㪥㪞㪜

㪉㪪㪢㪌㪊㪍

㪠㪉㪚㪤㪶㪪㪚㪣㪃㩷㪠㪉㪚㪤㪶㪪㪛㪘

㪛㪛㪚

㪫㫏

㪟㪛㪤㪠㩷㪦㫌㫋

㪨㪪㪦㪚㪱㪘㪇㪎㪉㪮㪡㪱㪱㪨

㪠㪚㪋㪉㪇㪌

㪣㪚㪯㪈㪉㪌㪝㪫

㪘㪶㪌㪭

㪠㪚㪋㪉㪇㪍

㪧㪨㪈㪣㪘㪯㪐㪌

㪧㪤㪬㪫㪜㪈

㪧㪤㪬㪫㪜㪉

㪘㪬㪛㪤㪘㪠㪥㪤㪬㪫㪜

㪝㪠㪣㪶㪪㪜㪣

㪚㪪㪥

㪚㪚㪣㪢

㪚㪛㪫㪈

㪚㪪㪠

㪝㪄㫌㪚㪦㪥

㪩㪟㪄㪠㪯㪚㪈㪏㪉㪮㪡㪨㪈㪨

㪧㫆㫎㪼㫉㩷㪧㪮㪙

㪝㪩㪶㪚㪜㪚㪠㪥㪃㪝㪩㪶㪚㪜㪚㪦㪬㪫

㪧㪦㪮㪜㪩㪶㪝㪘㪠㪣

㪚㪙㪦㪦㪫

㪝㪣㪶㪙㪬㪪㪰

㪚㪦㪣㪛㪶㪩㪪㪫㩺

㪝㪩㪶㪫㪯㪛㪃㩷㪝㪩㪶㪩㪯㪛

㪛㪼㪹㫌㪾

㪪㪼㫉㫀㪸㫃

㪈㪋㪅㪊㪈㪏㪈㪏㪤㪟㫑

㪠㪚㪏㪎㪇㪉

㪚㫃㫆㪺㫂㩷㪞㪼㫅㪼㫉㪸㫋㫆㫉

㪧㪠㪍㪚㪋㪈㪇㪤

㪩㪟㪄㪠㪯㪚㪌㪈㪇㪮㪡㪨㪱㪰

㪠㪚㪎㪏㪇㪉㪃㪊

㪛㪛㪩㪉㩷㪪㪛㪩㪘㪤

㪈㪞㪹㫀㫋㪲㪍㪋㪤㬍㪈㪍㪹㫀㫋㪴

㪩㪟㪄㪠㪯㪚㪌㪍㪎㪮㪡㪨㪱㪨

㪛㪶㪈㪅㪏㪭

㪈㪇㪇㪤㪟㫑

㪪㪘㪚㪩㪜㪝㪧

㪆㪪㪘㪚㪩㪜㪝㪥

㪊㪊㪤㪟㫑

㪛㪶㪊㪅㪊㪭

㪬㪘㪩㪫㪇

㪬㪘㪩㪫㪈

㪜㪫㪟㪜㪩㪥㪜㪫

㪪㪘㪫㪘 㪚㪣㪢

㪧㪚㪠㩷㪚㪣㪢

㫉㪼㫊㪼㫋

㪉㪎㪤㪟㫑

㪠㪚㪎㪉㪇㪈

㪙㪛㩷㪧㫃㪸㫐㪼㫉㩷㪙㪜

㪜㪤㪤㪘㪊㪧

㪠㪯㪚㪋㪍㪎㪮㪡㪨㪱

㪞㪧㪠㪦

㪛㪛㪩㪉㩷㪪㪛㪩㪘㪤

㪈㪞㪹㫀㫋㪲㪍㪋㪤㬍㪈㪍㪹㫀㫋㪴

㪩㪟㪄㪠㪯㪚㪌㪍㪎㪮㪡㪨㪱㪨

㪛㪶㪈㪅㪏㪭

㪠㪚㪎㪏㪇㪋㪃㪌

㪠㪉㪚

㪟㪛㪤㪠

㪠㪉㪪

㪪㪧㪛㪠㪝

㪪㪘㪫㪘㪇

㪰㪆㪧㪹㪆㪧㫉

㪰㪆㪚

㪧㪚㪠

㪩㪦㪤㪆㪞㪠㪦

㪪㪙㪩㪪㪫

㪠㪚㪏㪌㪇㪌

㪥㪘㪥㪛 㪝㫃㪸㫊㪿

㪌㪈㪉㪤㪹㫀㫋㪲㪍㪋㪤㬍㪏㪹㫀㫋㪴

㪩㪟㪄㪠㪯㪚㪈㪋㪎㪮㪡㪨㪱㪨

㪛㪶㪊㪅㪊㪭 㪛㪶㪊㪅㪊㪭

㪮㪧

㪪㪙㪩㪪㪫

㪠㪚㪏㪌㪇㪉

㪥㫆㫉㩷㪝㫃㪸㫊㪿

㪈㪉㪏㪤㪹㫀㫋㪲㪈㪍㪤㬍㪏㪹㫀㫋㪴

㪭㪟㪠㪪㪉㪐㪞㪈㪉㪏㪧㪄㪈㪨

㪘㫅㪸㫃㫆㪾㩷㪙㫆㪸㫉㪻

㪙㪛㪆㪛㪭㪛㩷㪛㫉㫀㫍㪼㩷㪬㫅㫀㫋

㪚㪥㪏㪈㪇㪉

㪊㪇㪤㪟㫑

㪚㪥㪋㪏㪇㪉

㪠㪚㪋㪏㪇㪉

㪬㪪㪙㩷㪙㫉㫀㪻㪾㪼㩿㪉㪅㪇㪀

㪧㪛㪎㪉㪇㪈㪇㪉

㪧㪚㪠

㪛㪶㪊㪅㪊㪭

㪊㪊㪤㪟㫑

㪮㪧

㪬㪪㪙㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉

4 – 1

Page 16

BD-HP21U

[2] ANALOG/LCD/OPERATION BLOCK DIAGRAM

㪦㫍㪼㫉㩷㪭㫆㫃㫋㪸㪾㪼㩷㪧㫉㫆㫋㪼㪺㫋㪼㫉

㪧㫉㫀㫄㪸㫉㫐

㪚㫆㫅㫋㫉㫆㫃

㪠㪚㪐㪇㪈

㪤㪩㪋㪇㪉㪇

㪪㫎㫀㫋㪺㪿㫀㫅㪾

㪫㫉㪸㫅㫊㪽㫆㫉㫄㪼㫉

㪮㪘㪉㪏㪈㪮㪡

㪝㪜㪜㪛㩷㪙㪘㪚㪢

㪪㪫㪘㪥㪛㪙㪰㩷㪚㪫㪣

㪧㪦㪮㪜㪩㩷㪧㪮㪙

㪘㪫㪶㪈㪋㪭

㪩㪼㪺㫋㫀㪽㫀㪼㫉

㪘㪫㪶㪐㪭

㪩㪼㪺㫋㫀㪽㫀㪼㫉

㪘㪫㪶㪌㪭

㪩㪼㪺㫋㫀㪽㫀㪼㫉

㪘㪫㪶㪄㪈㪉㪭

㪩㪼㪺㫋㫀㪽㫀㪼㫉

㪦㪭㪧

㪝㪘㪥㩷㪩㪜㪞

㪝㪘㪥㪶㪎㪅㪌㪭

㪨㪐㪇㪈

㪉㪪㪛㪋㪍㪏

㪨㪐㪇㪋

㪨㪐㪈㪊

㪨㪐㪌㪇㪈

㪩㪨㪇㪊㪌㪧

㪨㪐㪌㪇㪊

㪙㪛㪶㪈㪉㪭

㪙㪛㪶㪌㪭

㪙㪛㪶㪈㪉㪭㩷㪩㪜㪞

㪉㪪㪙㪈㪊㪋㪉

㪘㪫㪶㪐㪭㩷㩿㪫㫆㩷㪤㪘㪠㪥㩷㪧㪚㪙㪀

㪙㪛㪶㪌㪭㩷㪪㪮

㪩㪪㪪㪇㪋㪇㪧

㪪㪬㪙㪶㪧㪚㪶㪌㪭㩷㪪㪮

㪣㪦㪮㪶㪧㪦㪮㪜㪩㪶㪚㪫㪣

㪪㪬㪙㪶㪧㪚㪶㪄㪏㪭㩷㪪㪮

㪉㪪㪙㪈㪈㪊㪉㪨

㪫㫆㩷㪝㪘㪥㩷

㪫㪦

㪧㪦㪮㪜㪩㩷㪚㪠㪩㪚㪬㪠㪫

㪙㪣㪦㪚㪢

㪚㪥㪐㪇㪈

㪚㪥㪐㪇㪉

㪪㪬㪙㪶㪧㪚㪶㪌㪭㩷㩿㪫㫆㩷㪤㪘㪠㪥㩷㪧㪚㪙㪀

㪪㪬㪙㪶㪧㪚㪶㪌㪭㩷㩿㪫㫆㩷㪘㪥㪘㪣㪦㪞㩷㪧㪚㪙㪀

㪘㪫㪶㪌㪭㩷㩿㪫㫆㩷㪤㪘㪠㪥㩷㪧㪚㪙㪀

㪘㪫㪶㪌㪭㩷㩿㪫㫆㩷㪘㪥㪘㪣㪦㪞㩷㪧㪚㪙㪀

㪪㪬㪙㪶㪧㪚㪶㪄㪏㪭㩷㩿㪫㫆㩷㪤㪘㪠㪥㩷㪧㪚㪙㪀

㪫㫆㩷㪙㪛㩷㪛㪩㪠㪭㪜

㪈㪌㪧㪠㪥

㪙㩷㫋㫆㩷㪙

㪚㪥㪐㪌㪇㪉

㪤㪘㪠㪥㪶㪧㪄㪚㪦㪥㩿㪟㪀

㪛㪩㪠㪭㪜㪶㪧㪄㪚㪦㪥㩿㪟㪀

㪪㪬㪙㪶㪧㪚㪶㩿㪟㪀

㪝㪘㪥㪶㪛㪜㪫

㪣㪦㪮㪶㪧㪦㪮㪜㪩㪶㪚㪫㪣

㪪㪬㪙㪶㪪㪟㪦㪩㪫㪶㪛㪜㪫

㪤㪘㪠㪥㩷㪧㪮㪙

㪈㪌㪧㪠㪥

㪙㩷㫋㫆㩷㪙

㪪㪚㪐㪇㪇㪈

㪤㪘㪠㪥㪶㪧㪶㪚㪦㪥

㪦㪭㪧

㪘㪫㪶㪐㪭

㪘㪫㪶㪌㪭

㪪㪬㪙㪶㪧㪚㪶㪄㪏㪭

㪪㪬㪙㪶㪧㪚㪶㪌㪭

㪉㪊㪧㪠㪥

㪙㩷㫋㫆㩷㪙

㪚㪥㪉㪊㪇㪈

㪢㪜㪰㪶㪪㪫㪙㪰

㪝㪩㪶㪚㪜㪚㪶㪠㪥

㪝㪩㪶㪚㪜㪚㪶㪦㪬㪫㩷

㪛㪶㪞㪥㪛

㪝㪩㪦㪥㪫㪶㪩㪯㪛

㪝㪩㪦㪥㪫㪶㪫㪯㪛

㪚㪦㪣㪛㪶㪩㪪㪫㩷

㪝㪣㪶㪙㪬㪪㪰

㪧㪦㪮㪜㪩㪶㪝㪘㪠㪣

㪚㪙㪦㪦㪫

㪧㪦㪮㪜㪩㪶㪝㪘㪠㪣

㪠㪚㪉㪌㪇㪏

㪩㪜㪪㪜㪫

㪙㪬㪋㪏㪋㪍

㪠㪚㪉㪌㪇㪉

㪩㪜㪪㪜㪫

㪧㪪㪫㪊㪉㪉㪇

㪠㪚㪉㪌㪇㪍

㪘㪥㪛

㪫㪎㪪㪜㪫㪇㪏㪝

㪠㪚㪉㪌㪇㪉

㪜㪉㪧㪩㪦㪤㩷

㪙㪩㪉㪋㪣㪈㪍㪝

㪠㪚㪉㪌㪇㪈

㪩㪜㪪㪜㪫

㪙㪛㪌㪉㪊㪈

㪠㪉㪚

㪝㪩㪶㪚㪜㪚㪶㪦㪬㪫

㪝㪩㪶㪚㪜㪚㪶㪠㪥

㪝㪩㪦㪥㪫㪶㪩㪯㪛

㪝㪩㪦㪥㪫㪶㪫㪯㪛

㪚㪦㪣㪛㪶㪩㪪㪫

㪝㪣㪶㪙㪬㪪㪰

㪧㪦㪮㪜㪩㪶㪝㪘㪠㪣

㪚㪙㪦㪦㪫

㪠㪠㪚㪶㪪㪛㪘

㪠㪠㪚㪶㪪㪚㪣

㪤㪘㪠㪥㪶㪧㪦㪮

㪛㪩㪶㪧㪦㪮

㪪㪬㪙㪶㪧㪚㪶㩿㪟㪀

㪧㪦㪮㪜㪩㪶㪝㪘㪠㪣

㪝㪘㪥㪶㪛㪜㪫

㪣㪦㪮㪶㪧㪦㪮㪜㪩㪶㪚㪫㪣

㪪㪬㪙㪶㪪㪟㪦㪩㪫㪶㪛㪜㪫

㪩㪜㪪㪜㪫

㪩㪆㪚㪶㪧㪬㪣㪪㪜

㪢㪜㪰㪶㪪㪫㪙㪰

㪝㪩㪦㪥㪫㪶㪤㪠㪚㪦㪥

㪠㪯㪙㪏㪍㪎㪮㪡㪨㪱㪨

㪣㪚㪛㪶㪛㪘㪫㪘

㪣㪚㪛㪶㪚㪣㪢

㪣㪚㪛㪶㪚㪪

㪣㪚㪛㪶㪩㪪㪫

㪠㪚㪉㪌㪇㪋

㪙㪣㪶㪣㪜㪛

㪣㪜㪛㪶㪧㪦㪥

㪛㪶㪞㪥㪛

㪝㪠㪣㪶㪪㪜㪣

㪧㪤㪬㪫㪜㪉

㪣㪶㪦㪬㪫

㪩㪶㪦㪬㪫

㪝㪠㪣㪶㪪㪜㪣

㪧㪤㪬㪫㪜㪈

䌓䌙

䌓䌃

䌃䌖

㪤㪬㪫

㪭㪠㪛㪜㪦㩷㪙㫌㪽㪽㪼㫉

䌙

䌐䌂

䌐䌒

㪝㪠㪣

㪘㪬㪛㪤㪘㪠㪥㪤㪬㪫㪜

㪤㪬㪫

㪠㪚㪉㪉㪇㪋

㪟㪛㪆㪪㪛

㫎㫀㫋㪿㩷㪣㪧㪝

㪤㪤㪈㪎㪌㪎㪙㪟

㪘㪬㪛㪠㪦

㪤㪬㪫㪜

㪝㪶㪤㪬㪫㪜

䌓䌙

䌓䌃

䌃䌖

䌙

䌐䌂

䌐䌒

㪘㪶㪌㪭

㪡㪉㪋㪇㪈㪶㪉

㪨㪡㪘㪢㪣㪘㪇㪊㪐㪮㪡㪧㪱

㪡㪉㪋㪇㪈㪶㪈

㪨㪡㪘㪢㪣㪘㪇㪊㪐㪮㪡㪧㪱

㪈㪌㪧㪠㪥

㪙㩷㫋㫆㩷㪙

㪚㪥㪉㪊㪇㪉

㪝㪠㪣㪶㪪㪜㪣

㪛㪶㪞㪥㪛

㪧㪤㪬㪫㪜㪉

㪧㪤㪬㪫㪜㪈

㪘㪬㪛㪤㪘㪠㪥

㪤㪬㪫㪜

㪘㪶㪞㪥㪛

㪪㪬㪙㪶㪰㪦㪬㪫

㪘㪶㪞㪥㪛

㪪㪬㪙㪶㪚㪦㪬㪫

㪘㪶㪞㪥㪛

㪤㪘㪠㪥㪶㪰㪦㪬㪫

㪘㪶㪞㪥㪛

㪤㪘㪠㪥㪶㪧㪙㪦㪬㪫

㪘㪶㪞㪥㪛

㪤㪘㪠㪥㪶㪧㪩㪦㪬㪫

㪘㪶㪞㪥㪛

㪘㪬㪛㪶㪤㪘㪠㪥㪶㪣

㪘㪬㪛㪠㪦㪶㪞㪥㪛

㪘㪬㪛㪶㪤㪘㪠㪥㪶㪩

㪘㪬㪛㪠㪦㪶㪞㪥㪛

㪘㪭㩷㪧㪮㪙

㪧㪉㪊㪇㪈

㪌㪧㪠㪥

㪧㪣㪬㪞

㪧㪉㪌㪇㪉

㪘㪫㪶㪌㪭

㪝㪶㪤㪬㪫㪜

㪣㪜㪛㪶㪪㪫㪙㪰

㪣㪜㪛㪶㪛㪭㪛㪶㪧㪣㪘㪰

㪢㪜㪰㪶㪜㪡㪜㪚㪫

㪣㪜㪛㪶㪛㪭㪛㪶㪤㪦㪛㪜

㪣㪜㪛㪶㪙㪛㪶㪧㪣㪘㪰

㪣㪜㪛㪶㪙㪛㪶㪤㪦㪛㪜

㪪㪬㪙㪶㪧㪚㪌㪭

㪚㪥㪉㪌㪇㪉

㪋㪧㪠㪥

㪙㫋㫆㪙

㪚㪥㪈㪉㪇㪈

㪦㪧㪜㪩㪘㪫㪠㪦㪥㩿㪣㪜㪝㪫㪀㩷㪧㪮㪙

㪢㪜㪰㪶㪪㪫㪙㪰

㪧㪦㪮㪜㪩

㪩㪆㪚㪶㪧㪬㪣㪪㪜

㪢㪜㪰㪶㪪㪫㪙㪰

㪘㪫㪶㪌㪭

㪣㪚㪛㩷㪧㪮㪙

㪙㪣㪶㪣㪜㪛

㪩㪆㪚㪶㪧㪬㪣㪪㪜

㩿㪮㪟㪠㪫㪜㪀

㪚㪥㪉㪌㪇㪉

㪉㪈㪧㪠㪥㪝㪝㪚

㪪㪚㪈㪈㪇㪈

㪣㪚㪛㪶㪚㪣㪢

㪣㪚㪛㪶㪚㪪

㪣㪚㪛㪶㪛㪘㪫㪘

㪠㪚㪈㪈㪇㪈

㪣㪚㪛㩷㪛㪩㪠㪭㪜㪩

㪧㪫㪍㪌㪐㪍

㪣㪚㪛㪶㪩㪪㪫

㪪㪜㪞㪶㪈䌾㪈㪎

㪚㪦㪤㪈䌾㪊

㪘㪫㪶㪌㪭

㪣㪚㪛㪈㪈㪇㪈

㪣㪚㪛

㪩㪣㪚㪛㪛㪘㪇㪊㪐㪮㪡㪧㪱

㪦㪧㪜㪩㪘㪫㪠㪦㪥㩿㪩㪠㪞㪟㪫㪀㩷㪧㪮㪙

㪣㪜㪛㪶㪧㪦㪥

㪣㪜㪛㪶㪪㪫㪙㪰

㪣㪜㪛㪶㪙㪛㪶㪧㪣㪘㪰㩷㩿㪙㫃㫌㪼㪀

㪣㪜㪛㪶㪙㪛㪶㪤㪦㪛㪜㩷㩿㪮㪿㫀㫋㪼㪀

㪧㪉㪌㪇㪈

㪉㪧㪠㪥

㪧㪣㪬㪞

㪪㪚㪈㪊㪇㪈

㪢㪜㪰㪶㪜㪡㪚㪫

㪜㪡㪜㪚㪫

4 – 2

Page 17

BDHP21U

CHAPTER 5. SCHEMATIC DIAGRAMS

[1] MAIN (1) CIRCUIT SCHEMATIC DIAGRAM

J

I

H

BD-HP21U

ServiceManual

G

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

5 – 1

Page 18

BD-HP21U

[2] MAIN (2) CIRCUIT SCHEMATIC DIAGRAM

J

I

H

G

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

5 – 2

Page 19

[3] MAIN (3) CIRCUIT SCHEMATIC DIAGRAM

J

I

H

G

BD-HP21U

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

5 – 3

Page 20

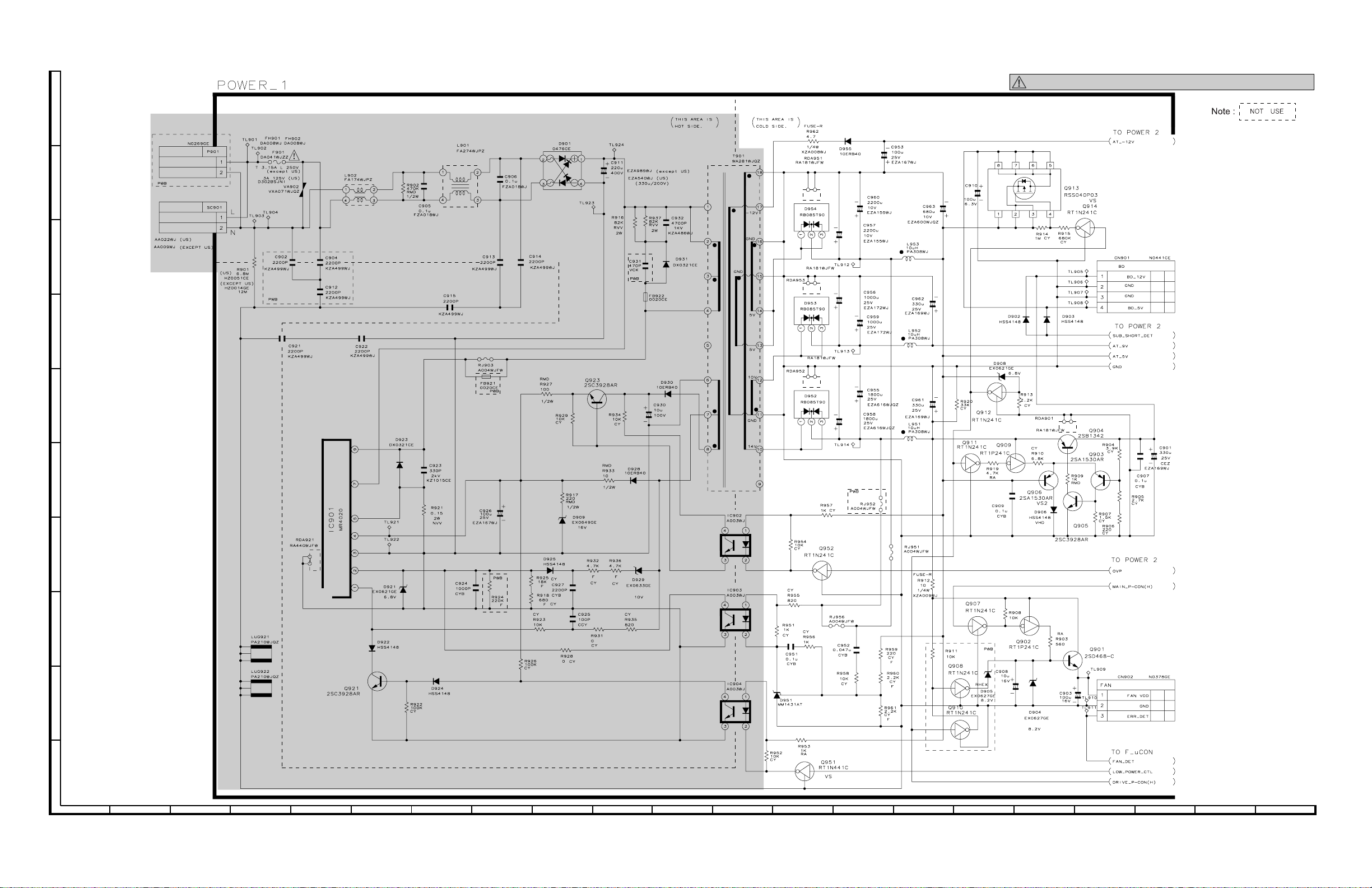

BD-HP21U

[4] MAIN (4) CIRCUIT SCHEMATIC DIAGRAM

J

I

H

G

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

5 – 4

Page 21

[5] MAIN (5) CIRCUIT SCHEMATIC DIAGRAM

J

I

H

G

BD-HP21U

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

5 – 5

Page 22

BD-HP21U

[6] MAIN (6) CIRCUIT SCHEMATIC DIAGRAM

J

I

H

G

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

5 – 6

Page 23

[7] MAIN (7) CIRCUIT SCHEMATIC DIAGRAM

J

I

H

G

BD-HP21U

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

5 – 7

Page 24

BD-HP21U

[8] MAIN (8) CIRCUIT SCHEMATIC DIAGRAM

J

I

H

G

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

5 – 8

Page 25

[9] MAIN (9) CIRCUIT SCHEMATIC DIAGRAM

J

I

H

G

BD-HP21U

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

5 – 9

Page 26

BD-HP21U

[10] MAIN (10) CIRCUIT SCHEMATIC DIAGRAM

J

I

H

G

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

5 – 10

Page 27

[1 1] ANALOG CIRCUIT SCHEMATIC DIAGRAM

J

I

H

G

BD-HP21U

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

5 – 11

Page 28

BD-HP21U

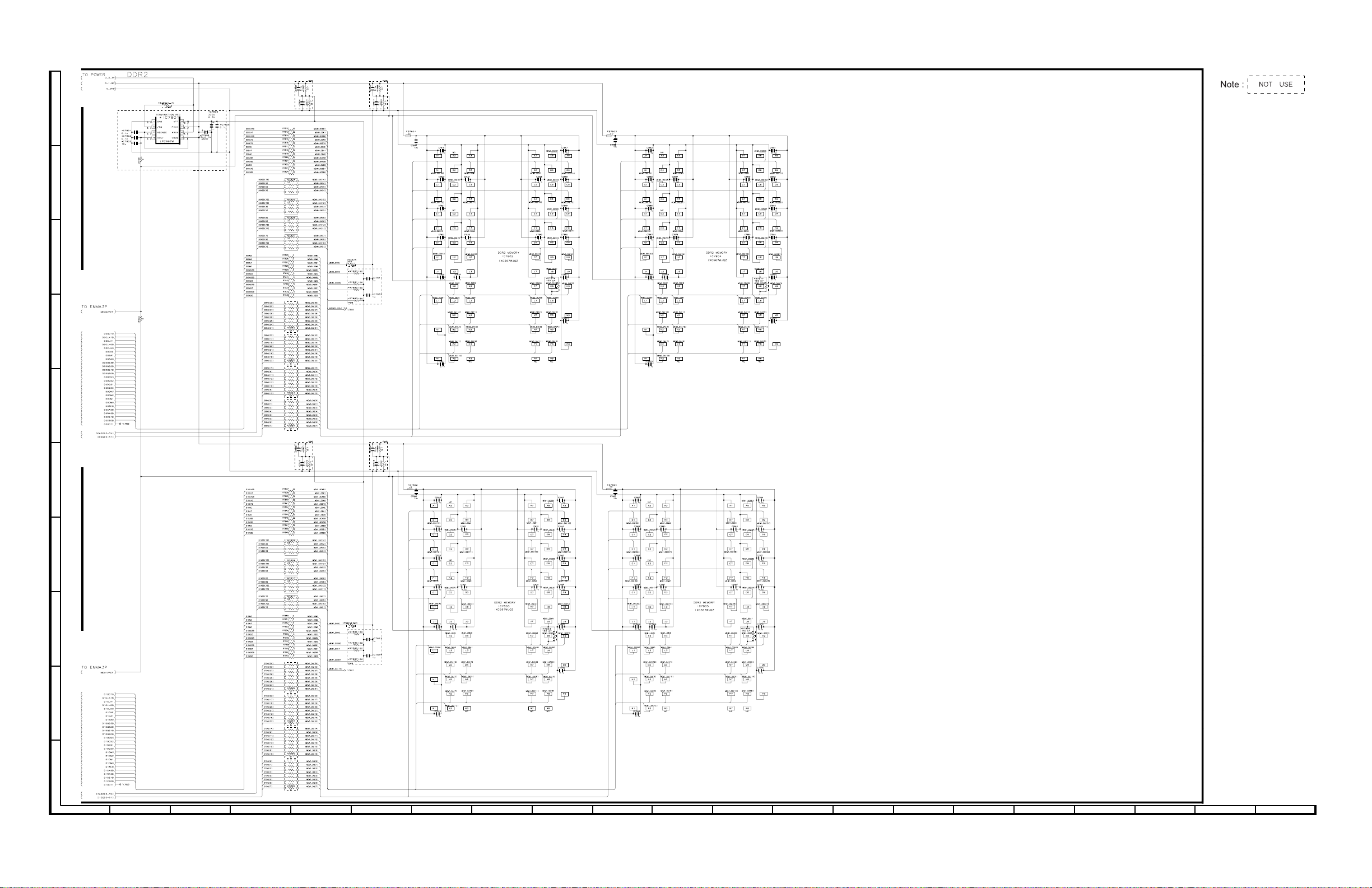

[12] POWER (1) CIRCUIT SCHEMATIC DIAGRAM

J

I

H

G

AND SHADED COMPONENTS=SAFETY RELATED PARTS

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

5 – 12

Page 29

[13] POWER (2) CIRCUIT SCHEMATIC DIAGRAM

J

I

H

G

BD-HP21U

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

5 – 13

Page 30

BD-HP21U

[14] POWER (3) CIRCUIT SCHEMATIC DIAGRAM

J

I

H

G

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

5 – 14

Page 31

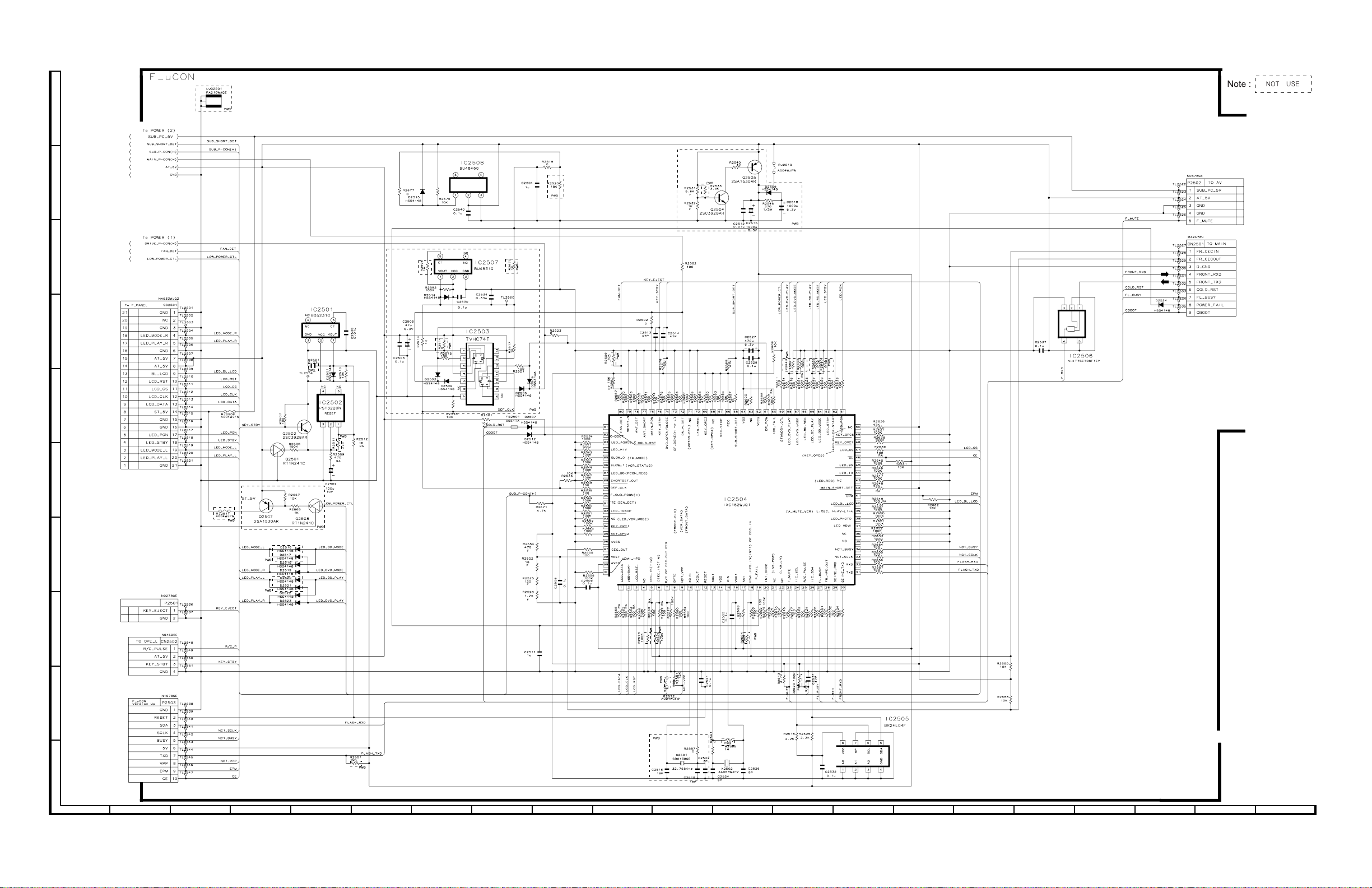

[15] OPERATON CIRCUIT SCHEMATIC DIAGRAM

J

I

H

G

BD-HP21U

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

5 – 15

Page 32

BD-HP21U

J

I

H

G

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

5 – 16

Page 33

[16] LCD CIRCUIT SCHEMATIC DIAGRAM

J

I

H

G

BD-HP21U

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

5 – 17

Page 34

BD-HP21U

BDHP21U

CHAPTER 6. PRINTED WIRING BOARD ASSEMBLIES

[1] MAIN PWB

Side-A Symbol

J

I

H

ServiceManual

G

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

6 – 1

Page 35

Side-A

J

I

H

G

BD-HP21U

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

6 – 2

Page 36

BD-HP21U

Side-B Symbol

J

I

H

G

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

6 – 3

Page 37

Side-B

J

I

H

G

BD-HP21U

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

6 – 4

Page 38

BD-HP21U

[2] ANALOG PWB

Side-A

J

I

H

G

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

6 – 5

Page 39

J

I

H

G

BD-HP21U

Side-B

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

6 – 6

Page 40

BD-HP21U

[3] POWER PWB

Side-A

J

I

H

G

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

6 – 7

Page 41

J

I

H

G

BD-HP21U

Side-B

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

6 – 8

Page 42

BD-HP21U

[4] OPERATION-L PWB

J

Side-A Side-B

I

H

G

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

6 – 9

Page 43

[5] OPERATION-R PWB

Side-A

J

I

H

G

BD-HP21U

F

Side-B

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

6 – 10

Page 44

BD-HP21U

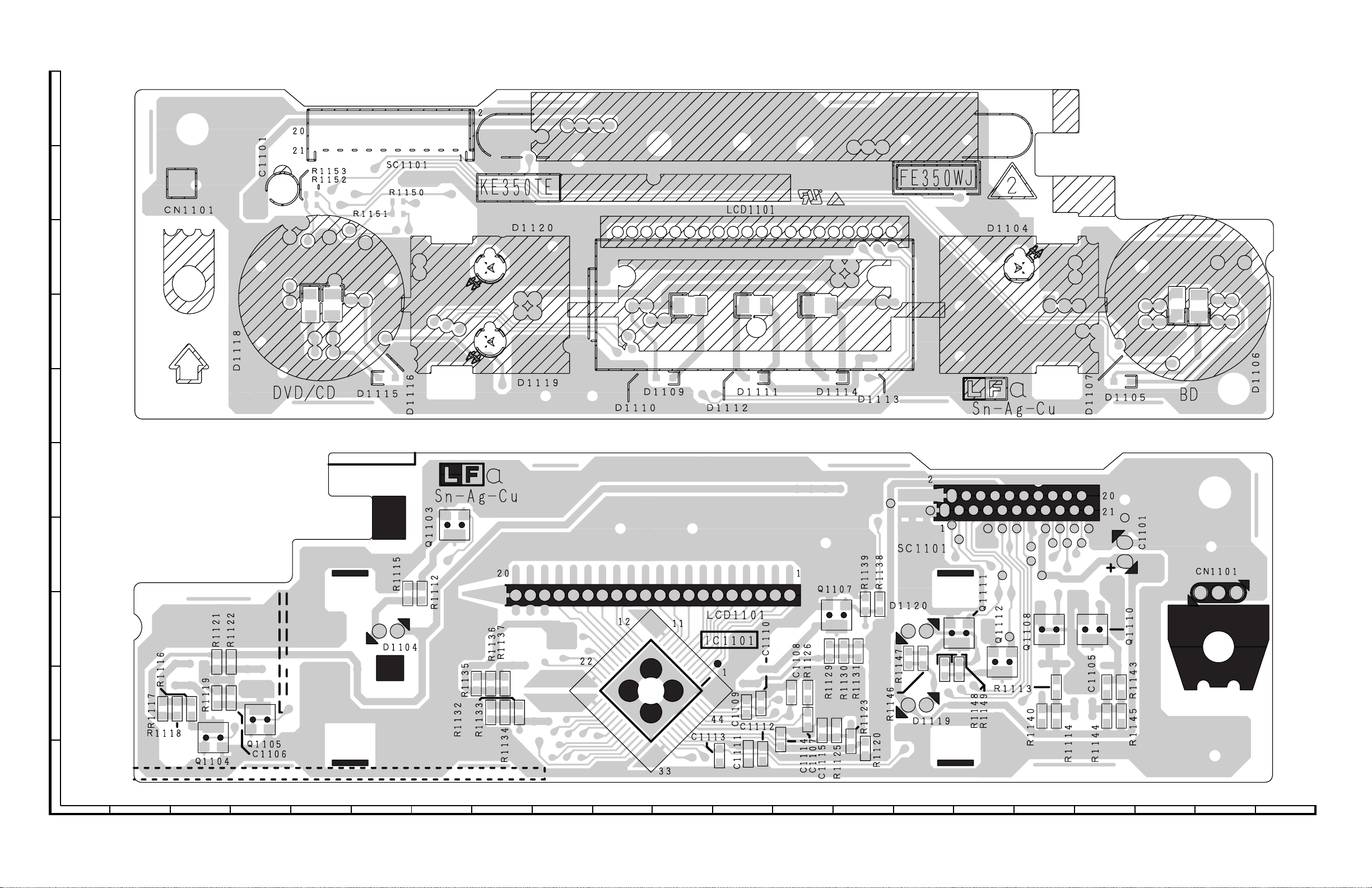

[6] LCD PWB

J

I

H

G

Side-A

F

Side-B

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

6 – 11

Page 45

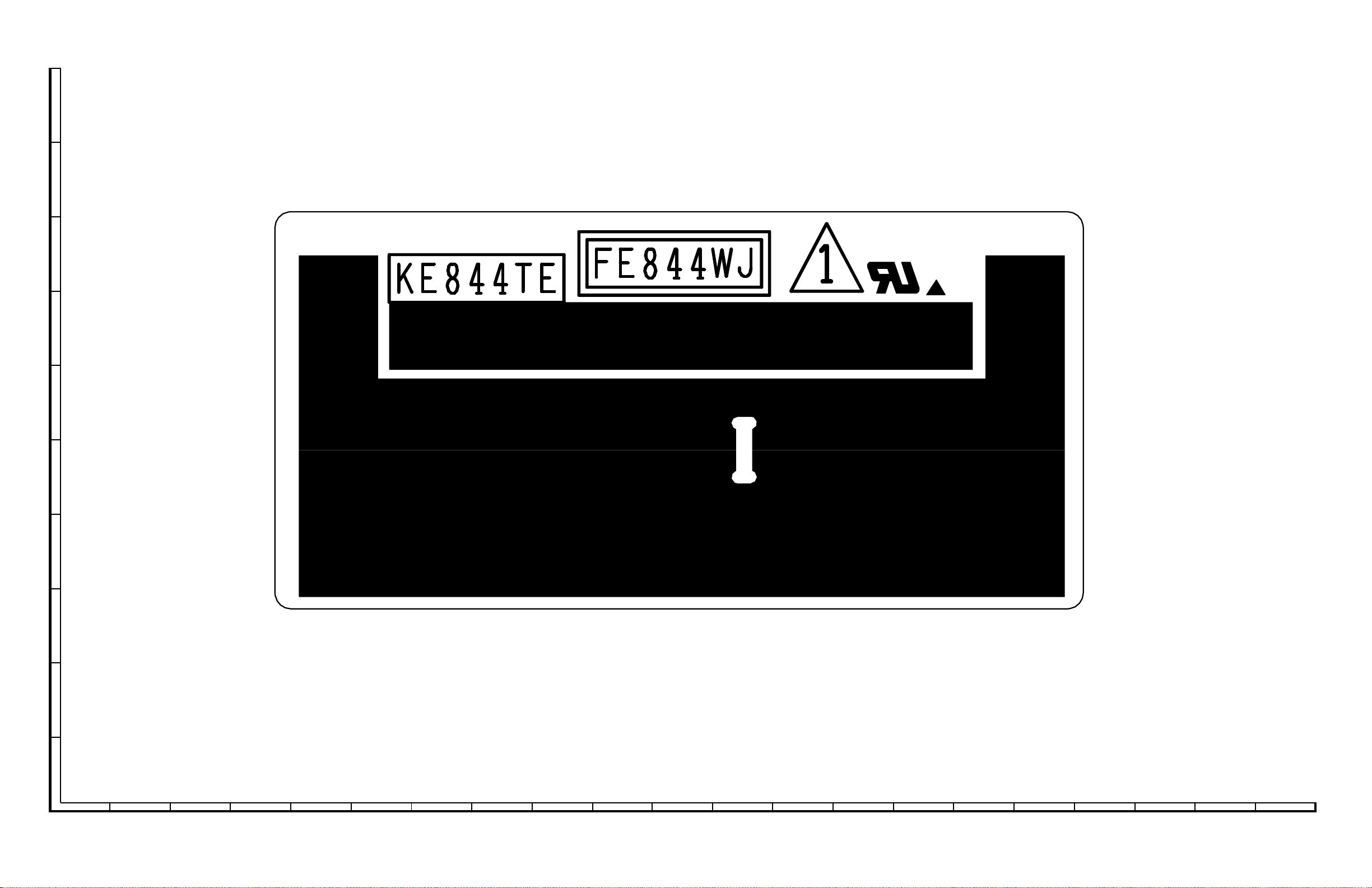

[7] SPACER PWB

J

I

H

G

BD-HP21U

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

6 – 12

Page 46

BD-HP21U

- MEMO -

6 – 13

Page 47

PartsGuide

BD-HP21U

PARTS GUIDE

No. S88M8BDHP21U/

BLU-RAY DISC PLAYER

CONTENTS

[1] PRINTED WIRING BOARD

ASSEMBLIES

[2] DSETV0192TEZM (MAIN Unit)

[3] DUNTKE841TEV1 (ANALOG Unit)

[4] DUNTKE840TEV1 (POWER Unit)

[5] DUNTKE842TEV1 (OPERATION-L

Unit)

[6] DUNTKE843TEV1 (OPERATION-R

Unit)

MODEL

[7] DUNTKE350TE6D (LCD Unit)

[8] CABINET PARTS

[9] FRONT PANEL PARTS

[10] PACKING PARTS (NOT

[11] SUPPLIED ACCESSORIES

[12] SERVICE JIG

BD-HP21U

REPLACEMENT ITEM)

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these

parts with specified ones for maintaining the safety and performance of the set.

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 48

BD-HP21U

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PART

DELIVERY

[1] PRINTED WIRING BOARD ASSEMBLIES

N DMECDA012TEV1 CH N V BD-RH2 Drive Unit

N DSETV0192TEZM CA N V MAIN Unit

N DUNTKE841TEV1 AT N V ANALOG Unit

N DUNTKE840TEV1 BK N V POWER Unit

N DUNTKE842TEV1 AL N V OPERATION-L Unit

N DUNTKE843TEV1 AH N V OPERATION-R Unit

N DUNTKE844TEV1 AH N V SPACER Unit

N DUNTKE350TE6D BE N V LCD Unit

[2] DSETV0192TEZM (MAIN Unit)

C4201 VCKYCY1AB105KY AB V 1 10V Ceramic

C4202 VCKYCY1AB105KY AB V 1 10V Ceramic

C4212 RC-KZA117WJZZY AC V CAPACITOR

C4222 VCKYCY1HB103KY AA V 0.01 50V Ceramic

C4223 VCKYCY1AB105KY AB V 1 10V Ceramic

C4224 VCKYCY1HB103KY AA V 0.01 50V Ceramic

C4225 VCKYCY1AB105KY AB V 1 10V Ceramic

C4226 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C4232 VCKYCY1AB105KY AB V 1 10V Ceramic

C4801 VCKYCY1HB102KY AA V 1000p 50V Ceramic

C4802 RC-KZA110WJZZY AD V CAPACITOR

C4803 RC-KZA214WJZZY AD V CAPACITOR

C4805 VCCCCY1HH471JY AA V 470p 50V Ceramic

C4806 VCCCCY1HH101JY AA V 100p 50V Ceramic

C4808 RC-KZA343WJPZY AB V CAPACITOR

C4809 RC-KZA195WJZZY AB V CAPACITOR

C4810 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C4811 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C4812 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C4813 RC-KZA195WJZZY AB V CAPACITOR

C4814 RC-KZA195WJZZY AB V CAPACITOR

C4815 VCKYCY1HB103KY AA V 0.01 50V Ceramic

C4816 RC-KZA195WJZZY AB V CAPACITOR

C4817 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C4818 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C4821 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C4823 VCCCCY1HH8R0DY AA V 80p 50V Ceramic

C4824 VCCCCY1HH8R0DY AA V 80p 50V Ceramic

C4825 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C4826 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C4827 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C4828 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C4829 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C4830 VCKYCY1CB104KY AB V

C4831 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C4832 RC-KZA195WJZZY AB V CAPACITOR

C4833 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C4834 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C4835 VCKYCY1AB105KY AB V 1 10V Ceramic

C4836 VCKYCY1HB104KY AA V 0.1 50V Ceramic

C4837 VCEASH0JN227MY AC V 220 6.3V Electrolytic

C5608 RC-KZA117WJZZY AC V CAPACITOR

C5609 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C5611 RC-KZA117WJZZY AC V CAPACITOR

C5613 VCKYCY1HB103KY AA V 0.01 50V Ceramic

C5614 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C5618 VCEAPF1CW106MY AB V 10 16V Electrolytic

C5619 VCEAPF1CW106MY AB V 10 16V Electrolytic

C5620 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C5621 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C5622 VCEAPF0JW107MY AC V 100 6.3V Electrolytic

C5626 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C5630 VCCCCY1HH330JY AA V 33p 50V Ceramic

C7201 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C7202 VCCCCY1HH330JY AA V 33p 50V Ceramic

C7203 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C7204 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7205 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7206 RC-KZA195WJZZY AB V CAPACITOR

C7207 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C7209 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7210 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C7211 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7212 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C7213 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7215 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7216 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7218

C7220 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7222 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7224 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7225 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7228 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7229 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7230 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

VCKYCZ1AB104KY AB V 0.1 10V Ceramic

0.1 16V Ceramic

DESCRIPTION

2

Page 49

BD-HP21U

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PART

DELIVERY

[2] DSETV0192TEZM (MAIN Unit)

C7233 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7234 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7235 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7236 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C7237 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7238 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7239 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C7240 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7241 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7242 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7243 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C7244 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C7245 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7246 VCCCCY1HH330JY AA V 33p 50V Ceramic

C7247 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7249 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7250 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7252 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7253 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7254 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C7255 VCCCCY1HH330JY AA V 33p 50V Ceramic

C7256 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7257 VCKYCY1AB105KY AB V 1 10V Ceramic

C7258 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C7259 VCKYCY1AB105KY AB V 1 10V Ceramic

C7260 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C7262 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7263 VCKYCY1AB105KY AB V 1 10V Ceramic

C7265 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7267 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7268 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7269 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7270 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7271 VCKYCZ1AB104KY AB V

C7272 VCAAPE0JJ227MY AE V 220 6.3V Electrolytic

C7273 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C7274 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C7278 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7279 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7281 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7282 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7283 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7284 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7285 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7287 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7288 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7289 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7290 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7292 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7293 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7294 RC-KZA195WJZZY AB V CAPACITOR

C7295 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7296 RC-KZA195WJZZY AB V CAPACITOR

C7297 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7298 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7299 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7300 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7301 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7303 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7304 VCKYCY1AB105KY AB V 1 10V Ceramic

C7305 VCKYCY1AB105KY AB V 1 10V Ceramic

C7306 RC-KZA195WJZZY AB V CAPACITOR

C7307 VCCCCY1HH4R0CY AA V 40p 50V Ceramic

C7308 VCCCCY1HH4R0CY AA V 40p 50V Ceramic

C7309 VCKYCY1AB105KY AB V 1 10V Ceramic

C7310 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7311 RC-KZA195WJZZY AB V CAPACITOR

C7312

C7317 VCKYCY1AB105KY AB V 1 10V Ceramic

C7318 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7319 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7320 VCKYCY1AB105KY AB V 1 10V Ceramic

C7322 RC-KZA195WJZZY AB V CAPACITOR

C7323 RC-KZA195WJZZY AB V CAPACITOR

C7324 RC-KZA195WJZZY AB V CAPACITOR

C7325 RC-KZA195WJZZY AB V CAPACITOR

C7326 VCKYCY1AB105KY AB V 1 10V Ceramic

C7327 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7328 RC-KZA195WJZZY AB V CAPACITOR

C7329 RC-KZA195WJZZY AB V CAPACITOR

C7330 VCKYCY1AB105KY AB V 1 10V Ceramic

C7333 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7336 VCKYCY1AB105KY AB V 1 10V Ceramic

C7337 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7339 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

VCKYCY1AB105KY AB V 1 10V Ceramic

0.1 10V Ceramic

DESCRIPTION

3

Page 50

BD-HP21U

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PART

DELIVERY

[2] DSETV0192TEZM (MAIN Unit)

C7340 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7341 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7342 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7343 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7344 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7345 RC-KZA195WJZZY AB V CAPACITOR

C7346 RC-KZA195WJZZY AB V CAPACITOR

C7347 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C7348 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C7349 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C7350 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C7351 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C7352 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C7353 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C7354 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7355 VCKYCZ1AB104KY AB V 0.1 10V Ceramic

C7356 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C7357 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C7358 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C7359 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C7360 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C7361 VCKYCY1AB105KY AB V 1 10V Ceramic

C7819 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7820 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7821 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7822 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7823 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7824 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7825 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7826 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7827 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7828 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7829 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7830 VCKYCY1CB104KY AB V

C7831 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7832 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7833 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7834 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7835 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7836 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7837 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7838 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7839 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7840 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7841 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7842 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7843 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7844 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7845 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7846 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7847 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7848 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7849 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7850 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7851 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7852 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7853 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7854 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7855 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7856 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7857 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7858 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7859 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7860 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7861 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7862 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7863 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7864

C7865 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7866 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7867 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7868 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7869 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7870 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7871 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7872 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7873 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7874 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7875 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7876 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7877 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7878 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7879 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7880 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7881 VCKYCY1CB104KY AB V 0.1 16V Ceramic

VCKYCY1CB104KY AB V 0.1 16V Ceramic

0.1 16V Ceramic

DESCRIPTION

4

Page 51

BD-HP21U

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PART

DELIVERY

[2] DSETV0192TEZM (MAIN Unit)

C7882 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7883 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7884 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7885 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7886 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C7897 RC-KZA195WJZZY AB V CAPACITOR

C7898 RC-KZA195WJZZY AB V CAPACITOR

C7899 RC-KZA195WJZZY AB V CAPACITOR

C7900 RC-KZA195WJZZY AB V CAPACITOR

C8108 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C8111 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C8112 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C8115 VCKYCZ1EB103KY AA V 0.01 25V Ceramic

C8503 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C8504 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C8506 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C8507 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C8508 VCCCCY1HH330JY AA V 33p 50V Ceramic

C8509 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C8701 VCKYCY1AB105KY AB V 1 10V Ceramic

C8702 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C8703 VCKYCY1AB105KY AB V 1 10V Ceramic

C8704 VCKYCY1AB105KY AB V 1 10V Ceramic

C8709 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C8710 VCCCCY1HH100DY AA V 10p 50V Ceramic

C8711 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C8712 VCCCCY1HH100DY AA V 10p 50V Ceramic

C8713 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C8714 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C8715 VCEASH0JN227MY AC V 220 6.3V Electrolytic

C8716 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C8717 VCKYCY1AB105KY AB V 1 10V Ceramic

C8718 RC-KZA117WJZZY AC V CAPACITOR

C8719 VCKYCY1CB104KY AB V

C8720 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C8721 VCKYCY1CB104KY AB V 0.1 16V Ceramic

C9001 RC-KZA110WJZZY AD V CAPACITOR

C9003 VCKYCY1HB102KY AA V 1000p 50V Ceramic

C9004 RC-KZA214WJZZY AD V CAPACITOR

C9005 RC-KZA214WJZZY AD V CAPACITOR

C9007 VCKYCY1HB222KY AA V 2200p 50V Ceramic

C9008 VCKYCY1HB561KY AA V 560p 50V Ceramic

C9009 RC-KZA110WJZZY AD V CAPACITOR

C9011 VCKYCY1HB102KY AA V 1000p 50V Ceramic

C9012 RC-KZA214WJZZY AD V CAPACITOR

C9013 RC-KZA214WJZZY AD V CAPACITOR

C9014 VCCCCY1HH101JY AA V 100p 50V Ceramic

C9015 VCKYCY1HB102KY AA V 1000p 50V Ceramic

C9016 VCCCCY1HH101JY AA V 100p 50V Ceramic

C9017 RC-KZA110WJZZY AD V CAPACITOR

C9019 VCKYCY1HB223KY AA V 0.022 50V Ceramic

C9020 RC-KZA214WJZZY AD V CAPACITOR

C9021 RC-KZA214WJZZY AD V CAPACITOR

C9023 VCKYCY1HB822KY AB V 8200p 50V Ceramic

C9033 RC-KZA067WJZZY AB V CAPACITOR

C9034 RC-KZA510WJPZY AB V CAPACITOR

C9035 VCKYCY1AB105KY AB V 1 10V Ceramic

C9036 VCKYCY1HB103KY AA V 0.01 50V Ceramic

C9037 RC-KZ0083TAZZY AC V CAPACITOR

C9038 VCKYCY1HB103KY AA V 0.01 50V Ceramic

CN4802 QSOCZA133WJQZ AK V SOCKET

CN5601 QCNCWA251WJZZY AH V CONNECTOR

CN5602 VHPGP1F55TKVY AF V PHOTODIODE

CN7203 QPLGN0054CEZZY AD V PLUG

CN8102 QCNCWA571WJQZQ AF V CONNECTOR

D4201 VHDMA111G++-1Y AA V MA2J1110GL

D4202 VHDMA111G++-1Y AA V MA2J1110GL

D4203

D4204 VHDMA111G++-1Y AA V MA2J1110GL

D4801 VHDMA2S111/-1Y AC V MA2S11100L

D4802 RH-EXA526WJZZY AB V MAZ8062GML

D5601 VHDMA111G++-1Y AA V MA2J1110GL

D9001 RH-EXA510WJZZY AA V MAZ8036GHL

D9002 VHDMA2S111/-1Y AC V MA2S11100L

D9003 RH-EXA517WJZZY AA V MAZ8047GML

D9004 VHDMA2S111/-1Y AC V MA2S11100L

D9006 RH-EXA510WJZZY AA V MAZ8036GHL

D9007 VHDMA2S111/-1Y AC V MA2S11100L

FB4801 RBLN-A018WJZZY AA V BALUN

FB4802 RBLN-A018WJZZY AA V BALUN

FB4803 RBLN-A018WJZZY AA V BALUN

FB4804 RBLN-A018WJZZY AA V BALUN

FB5605 RBLN-A021WJZZY AA V BALUN

FB7201 RBLN-A021WJZZY AA V BALUN

FB7202 RBLN-A018WJZZY AA V BALUN

VHDMA111G++-1Y AA V MA2J1110GL

0.1 16V Ceramic

DESCRIPTION

5

Page 52

BD-HP21U

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PART

DELIVERY

[2] DSETV0192TEZM (MAIN Unit)

FB7203 RBLN-A021WJZZY AA V BALUN

FB7204 RBLN-A021WJZZY AA V BALUN

FB7205 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

FB7206 RBLN-A410WJQZY AB N V BALUN

FB7207 RBLN-A021WJZZY AA V BALUN

FB7208 RBLN-A021WJZZY AA V BALUN

FB7209 RBLN-A410WJQZY AB N V BALUN

FB7211 RBLN-A021WJZZY AA V BALUN

FB7212 RBLN-A021WJZZY AA V BALUN

FB7213 RBLN-A021WJZZY AA V BALUN

FB7214 RBLN-A021WJZZY AA V BALUN

FB7215 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

FB7216 RBLN-A021WJZZY AA V BALUN

FB7217 RBLN-A021WJZZY AA V BALUN

FB7801 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

FB7802 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

FB7803 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

FB7804 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

FB8701 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

FB8703 RBLN-A410WJQZY AB N V BALUN

FB8705 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

FB8707 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

FB8708 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

FB9001 RBLN-A018WJZZY AA V BALUN

FB9002 RBLN-A018WJZZY AA V BALUN

FB9003 RBLN-A018WJZZY AA V BALUN

FB9004 RBLN-A018WJZZY AA V BALUN

FB9005 RBLN-A018WJZZY AA V BALUN

FB9006 RBLN-A018WJZZY AA V BALUN

FL7201 RFILNA118WJZZY AC V FILTER

IC4201 VHIBD10KA5W-1Y AF N V BD10KA5WF-E2

IC4203 VHIPQ1LA503-1Y AD V PQ1LA503MSPQ

IC4205 VHILCX125FT-1Y AD V TC74LCX125FT(EL,K)

IC4206 VHIPQ1LAX95-1Y AD V

IC4801 VHIAOZ1016+-1Y AF V AOZ1016AI

IC4802 VHIPD720102-1Q AV V UPD720102GC-YEB-A

IC4804 VHISTMP2151-1Y AE N V IC

IC5602 VHIPQ1LA503-1Y AD V PQ1LA503MSPQ

IC5606 VHIAK4340ET-1Y AH V AK4340ET

IC7201 RH-IXC467WJQZQ BQ N V IC

Note

IC7802 RH-IXC567WJQZQ AW N V IC

IC7803 RH-IXC567WJQZQ AW N V IC

IC7804 RH-IXC567WJQZQ AW N V IC

IC7805 RH-IXC567WJQZQ AW N V IC

IC8502 CHIS-9G12WJV7 AU N V IC

Note

IC8503 VHIM24C64WN-1Y AL V M24C64-WMN6TP

Note

IC8505 CH-IXC147WJV3 AS N V IC

Note

IC8702 RH-IXC510WJQZY AM N V IC

IC9001 VHIAOZ1024D-1Y AK N V AOZ1024DI

IC9002 VHIAOZ1016+-1Y AF V AOZ1016AI

IC9003 VHIMP2303A+-1Y AF V MP2303ADN-LF-Z

IC9005 VHIPQ1LA185-1Y AD V PQ1LA185MSPQ

L4801 RCILPA886WJZZY AD V COIL

L4803 RCILFA112WJZZY AC V COIL

L5601 VPCUN100KR42NY AB V Peaking 10µH

L9001 RCILPA787WJQZY AD V COIL

L9002 RCILCA029WJZZY AD V COIL

L9003 RCILPA787WJQZY AD V COIL

LUG9001 QLUGHA006WJZZY AC V LUG

LUG9002 QLUGHA006WJZZY AC V LUG

Q4201 VS2SK536///-1Y AE V 2SK536-TB-E

Q4202 VS2SK536///-1Y AE V 2SK536-TB-E

Q4203 VSUMH1N++++-1Y AB V UMH1NTN

Q5601 VS2SA1530ARS1Y AC V 2SA1530A-T112-1R

Q5602 VS2SA1530ARS1Y AC V 2SA1530A-T112-1R

Q5603 VS2SA1530ARS1Y AC V 2SA1530A-T112-1R

Q5604 VS2SA1530ARS1Y AC V 2SA1530A-T112-1R

Q5605 VS2SA1530ARS1Y AC V 2SA1530A-T112-1R

Q5606 VSRT1N241C/-1Y AB V RT1N241C-T112-1

Q5607 VS2SA1530ARS1Y AC V 2SA1530A-T112-1R

Q5610 VSUMH1N++++-1Y AB V UMH1NTN

Q9001 VSDTC124EE/-1Y AA V DTC124EETL

Q9002 VS2SC3928AR-1Y AB V 2SC3928A-T112-1R

Q9003 VSDTC124EE/-1Y AA V DTC124EETL

Q9004 VSDTC144EE/-1Y AA V DTC144EETL

Q9005 VS2SC3928AR-1Y AB V 2SC3928A-T112-1R

Q9011 VSDTC124EE/-1Y AA V DTC124EETL

R4201 VRS-CY1JF182JY AA V 1.8k 1/16W Metal Oxide

R4202 VRS-CY1JF182JY AA V 1.8k 1/16W Metal Oxide

R4204 VRS-CY1JF473JY AA V 47k 1/16W Metal Oxide

R4205 VRS-TV1JD000JY AA V 0 1/16W Metal Oxide

PQ1LAX95MSPQ

This IC cannot do an individual exchange. The relevant PWB must be entirely replaced with new one.

This IC cannot do an individual exchange. The relevant PWB must be entirely replaced with new one.

This IC cannot do an individual exchange. The relevant PWB must be entirely replaced with new one.

This IC cannot do an individual exchange. The relevant PWB must be entirely replaced with new one.

DESCRIPTION

6

Page 53

BD-HP21U

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PART

DELIVERY

[2] DSETV0192TEZM (MAIN Unit)

R4207 VRS-CZ1JF000JY AA V 0 1/16W Metal Oxide

R4208 VRS-CZ1JF000JY AA V 0 1/16W Metal Oxide

R4209 VRS-CZ1JF000JY AA V 0 1/16W Metal Oxide

R4210 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R4211 VRS-CZ1JF000JY AA V 0 1/16W Metal Oxide

R4212 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R4214 VRS-CZ1JF000JY AA V 0 1/16W Metal Oxide

R4215 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R4216 VRS-CZ1JF000JY AA V 0 1/16W Metal Oxide

R4217 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R4218 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R4219 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R4221 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R4222 VRS-CZ1JF000JY AA V 0 1/16W Metal Oxide

R4223 VRS-CZ1JF000JY AA V 0 1/16W Metal Oxide

R4225 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R4238 VRS-CY1JF221JY AA V 220 1/16W Metal Oxide

R4240 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R4241 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R4242 VRS-CY1JF273FY AA V 27k 1/16W Metal Oxide

R4248 VRS-CY1JF103FY AA V 10k 1/16W Metal Oxide

R4249 VRS-CY1JF562FY AA V 5.6k 1/16W Metal Oxide

R4250 VRS-CY1JF123FY AA V 12k 1/16W Metal Oxide

R4251 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R4252 VRS-CY1JF472JY AA V 4.7k 1/16W Metal Oxide

R4253 VRS-CY1JF472JY AA V 4.7k 1/16W Metal Oxide

R4255 VRS-CH1JF000JY AA V 0 1/16W Metal Oxide

R4256 VRS-CH1JF000JY AA V 0 1/16W Metal Oxide

R4801 VRS-CY1JF152JY AA V 1.5k 1/16W Metal Oxide

R4802 VRS-CY1JF152JY AA V 1.5k 1/16W Metal Oxide

R4804 VRS-CY1JF162FY AA V 1.6k 1/16W Metal Oxide

R4805 VRS-CY1JF103FY AA V 10k 1/16W Metal Oxide

R4806 VRS-CY1JF103FY AA V 10k 1/16W Metal Oxide

R4807 VRS-CY1JF152JY AA V

R4808 VRS-CY1JF103FY AA V 10k 1/16W Metal Oxide

R4809 VRS-CY1JF221JY AA V 220 1/16W Metal Oxide

R4810 VRS-CY1JF274JY AA V 270k 1/16W Metal Oxide

R4811 VRS-CY1JF103FY AA V 10k 1/16W Metal Oxide

R4812 VRS-CY1JF682FY AA V 6.8k 1/16W Metal Oxide

R4813 VRS-CY1JF473FY AA V 47k 1/16W Metal Oxide

R4814 VRS-CY1JF101JY AA V 100 1/16W Metal Oxide

R4815 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R4818 VRS-CY1JF152JY AA V 1.5k 1/16W Metal Oxide

R4819 VRS-CY1JF103FY AA V 10k 1/16W Metal Oxide

R4824 VRS-CY1JF331JY AA V 330 1/16W Metal Oxide

R5604 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R5605 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R5606 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R5612 VRS-CY1JF682JY AA V 6.8k 1/16W Metal Oxide

R5615 VRS-CY1JF101JY AA V 100 1/16W Metal Oxide

R5616 VRS-CY1JF181FY AA V 180 1/16W Metal Oxide

R5617 VRS-CY1JF181FY AA V 180 1/16W Metal Oxide

R5618 VRS-CY1JF181FY AA V 180 1/16W Metal Oxide

R5619 VRS-CY1JF181FY AA V 180 1/16W Metal Oxide

R5626 VRS-CY1JF222JY AA V 2.2k 1/16W Metal Oxide

R5627 VRS-CY1JF181FY AA V 180 1/16W Metal Oxide

R5628 VRS-CY1JF222JY AA V 2.2k 1/16W Metal Oxide

R5629 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R5633 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R5635 VRS-CY1JF122FY AA V 1.2k 1/16W Metal Oxide

R5636 VRS-CY1JF122FY AA V 1.2k 1/16W Metal Oxide

R5638 VRS-CY1JF473JY AA V 47k 1/16W Metal Oxide

R5640 VRS-TV1JD000JY AA V 0 1/16W Metal Oxide

R5641 VRS-TV1JD000JY AA V 0 1/16W Metal Oxide

R5645 VRS-TV1JD000JY AA V 0 1/16W Metal Oxide

R5646 VRS-TV1JD000JY AA V 0 1/16W Metal Oxide

R5647 VRS-TV1JD000JY AA V 0 1/16W Metal Oxide

R5648

R5649 VRS-CY1JF122FY AA V 1.2k 1/16W Metal Oxide

R5655 VRS-CY1JF681JY AA V 680 1/16W Metal Oxide

R5656 VRS-CY1JF681JY AA V 680 1/16W Metal Oxide

R5657 VRS-CY1JF681JY AA V 680 1/16W Metal Oxide

R5658 VRS-CY1JF681JY AA V 680 1/16W Metal Oxide

R5659 VRS-CY1JF681JY AA V 680 1/16W Metal Oxide

R5660 VRS-TV1JD000JY AA V 0 1/16W Metal Oxide

R5661 VRS-CY1JF331JY AA V 330 1/16W Metal Oxide

R5662 VRS-CY1JF331JY AA V 330 1/16W Metal Oxide

R5663 VRS-CY1JF331JY AA V 330 1/16W Metal Oxide

R5664 VRS-CY1JF331JY AA V 330 1/16W Metal Oxide

R5665 VRS-CY1JF331JY AA V 330 1/16W Metal Oxide

R5666 VRS-TV1JD000JY AA V 0 1/16W Metal Oxide

R5667 VRS-CY1JF102JY AA V 1k 1/16W Metal Oxide

R5668 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R5669 VRS-CY1JF101JY AA V 100 1/16W Metal Oxide

R5680 VRS-CY1JF122FY AA V 1.2k 1/16W Metal Oxide

VRS-TV1JD000JY AA V 0 1/16W Metal Oxide

1.5k 1/16W Metal Oxide

DESCRIPTION

7

Page 54

BD-HP21U

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PART

DELIVERY

[2] DSETV0192TEZM (MAIN Unit)

R5683 VRS-CY1JF122FY AA V 1.2k 1/16W Metal Oxide

R5698 VRS-CY1JF222JY AA V 2.2k 1/16W Metal Oxide

R5711 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R5712 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R5713 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R5714 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R5715 VRS-CY1JF473JY AA V 47k 1/16W Metal Oxide

R5717 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R5721 VRS-CY1JF222JY AA V 2.2k 1/16W Metal Oxide

R5723 VRS-CY1JF473JY AA V 47k 1/16W Metal Oxide

R5724 VRS-CY1JF473JY AA V 47k 1/16W Metal Oxide

R5725 VRS-CY1JF473JY AA V 47k 1/16W Metal Oxide

R7203 VRS-CY1JF473JY AA V 47k 1/16W Metal Oxide

R7204 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7207 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7209 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7210 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7211 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7213 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7214 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7215 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7216 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R7217 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R7218 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R7220 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7221 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7222 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7223 VRS-CY1JF101JY AA V 100 1/16W Metal Oxide

R7224 VRS-CY1JF151FY AA V 150 1/16W Metal Oxide

R7225 VRS-CY1JF151FY AA V 150 1/16W Metal Oxide

R7226 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R7227 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R7228 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R7229 VRS-CK1JF103JY AB V

R7230 VRS-CK1JF103JY AB V 10k 1/16W Metal Oxide

R7231 VRS-CK1JF103JY AB V 10k 1/16W Metal Oxide

R7232 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7233 VRS-CK1JF103JY AB V 10k 1/16W Metal Oxide

R7234 VRS-CK1JF103JY AB V 10k 1/16W Metal Oxide

R7235 VRS-CK1JF103JY AB V 10k 1/16W Metal Oxide

R7236 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R7237 VRS-CH1JF103JY AA V 10k 1/16W Metal Oxide

R7238 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R7240 VRS-CY1JF101JY AA V 100 1/16W Metal Oxide

R7241 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7242 VRS-CY1JF681FY AA V 680 1/16W Metal Oxide

R7243 VRS-CY1JF101JY AA V 100 1/16W Metal Oxide

R7244 VRS-CY1JF471FY AA V 470 1/16W Metal Oxide

R7245 VRS-CY1JF102FY AA V 1k 1/16W Metal Oxide

R7246 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7247 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7248 VRS-CY1JF221FY AA V 220 1/16W Metal Oxide

R7249 VRS-CY1JF221FY AA V 220 1/16W Metal Oxide

R7250 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7251 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R7252 VRS-CY1JF151FY AA V 150 1/16W Metal Oxide

R7254 VRS-CY1JF151FY AA V 150 1/16W Metal Oxide

R7256 VRS-CK1JF470JY AB V 47 1/16W Metal Oxide

R7257 VRS-CK1JF470JY AB V 47 1/16W Metal Oxide

R7258 VRS-CK1JF470JY AB V 47 1/16W Metal Oxide

R7259 VRS-CK1JF470JY AB V 47 1/16W Metal Oxide

R7260 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7261 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7262 VRS-CY1JF221JY AA V 220 1/16W Metal Oxide

R7263 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7265 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7266 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7267

R7268 VRS-CK1JF000JY AA V 0 1/16W Metal Oxide

R7269 VRS-CK1JF000JY AA V 0 1/16W Metal Oxide

R7270 VRS-CK1JF000JY AA V 0 1/16W Metal Oxide

R7271 VRS-CK1JF000JY AA V 0 1/16W Metal Oxide

R7275 VRS-CY1JF222JY AA V 2.2k 1/16W Metal Oxide

R7276 VRS-CY1JF222JY AA V 2.2k 1/16W Metal Oxide

R7277 VRS-CY1JF222JY AA V 2.2k 1/16W Metal Oxide

R7278 VRS-CY1JF222JY AA V 2.2k 1/16W Metal Oxide

R7279 VRS-CK1JF332JY AA V 3.3k 1/16W Metal Oxide

R7280 VRS-CK1JF332JY AA V 3.3k 1/16W Metal Oxide

R7281 VRS-CK1JF332JY AA V 3.3k 1/16W Metal Oxide

R7282 VRS-CK1JF332JY AA V 3.3k 1/16W Metal Oxide

R7283 VRS-CK1JF470JY AB V 47 1/16W Metal Oxide

R7284 VRS-CK1JF470JY AB V 47 1/16W Metal Oxide

R7286 VRS-CY1JF332JY AA V 3.3k 1/16W Metal Oxide

R7287 VRS-CY1JF332JY AA V 3.3k 1/16W Metal Oxide

R7288 VRS-CY1JF332JY AA V 3.3k 1/16W Metal Oxide

VRS-CK1JF000JY AA V 0 1/16W Metal Oxide

10k 1/16W Metal Oxide

DESCRIPTION

8

Page 55

BD-HP21U

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PART

DELIVERY

[2] DSETV0192TEZM (MAIN Unit)

R7290 VRS-CY1JF332JY AA V 3.3k 1/16W Metal Oxide

R7291 VRS-CY1JF332JY AA V 3.3k 1/16W Metal Oxide

R7292 VRS-CY1JF332JY AA V 3.3k 1/16W Metal Oxide

R7293 VRS-CY1JF332JY AA V 3.3k 1/16W Metal Oxide

R7294 VRS-CY1JF332JY AA V 3.3k 1/16W Metal Oxide

R7295 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R7296 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R7299 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7300 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7301 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7302 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7303 VRS-CY1JF105JY AA V 1M 1/16W Metal Oxide

R7304 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7305 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7306 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7307 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7308 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7309 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7310 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7311 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7312 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7313 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7314 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7315 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7316 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7317 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7324 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7325 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R7326 VRS-CY1JF821FY AA V 820 1/16W Metal Oxide

R7328 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7329 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7330 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7331 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7332 VRS-CY1JF000JY AA V

R7333 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7334 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7335 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7336 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7337 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7338 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7339 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7340 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7341 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R7342 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R7343 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R7352 RR-SZA015WJZZY AA V RESISTOR

R7353 VRS-CY1JF473JY AA V 47k 1/16W Metal Oxide

R7354 VRS-CY1JF473JY AA V 47k 1/16W Metal Oxide

R7355 VRS-CY1JF473JY AA V 47k 1/16W Metal Oxide

R7357 VRS-CY1JF473JY AA V 47k 1/16W Metal Oxide

R7359 VRS-CY1JF473JY AA V 47k 1/16W Metal Oxide

R7360 VRS-CY1JF473JY AA V 47k 1/16W Metal Oxide

R7361 VRS-CY1JF473JY AA V 47k 1/16W Metal Oxide

R7362 VRS-CY1JF473JY AA V 47k 1/16W Metal Oxide

R7363 VRS-CY1JF473JY AA V 47k 1/16W Metal Oxide

R7364 VRS-CY1JF473JY AA V 47k 1/16W Metal Oxide

R7365 VRS-CY1JF473JY AA V 47k 1/16W Metal Oxide

R7366 VRS-CY1JF473JY AA V 47k 1/16W Metal Oxide

R7369 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7370 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7371 VRS-CY1JF102FY AA V 1k 1/16W Metal Oxide

R7372 VRS-CY1JF102FY AA V 1k 1/16W Metal Oxide

R7373 VRS-CY1JF102FY AA V 1k 1/16W Metal Oxide

R7374 VRS-CY1JF102FY AA V 1k 1/16W Metal Oxide

R7375 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R7376 VRS-CY1JF332JY AA V 3.3k 1/16W Metal Oxide

R7377 VRS-CY1JF332JY AA V 3.3k 1/16W Metal Oxide

R7378

R7380 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R7384 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R7385 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R7386 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R7387 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R7391 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7392 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7393 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7394 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7395 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7396 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7804 VRS-CH1JF220JY AA V 22 1/16W Metal Oxide

R7805 VRS-CH1JF220JY AA V 22 1/16W Metal Oxide

R7806 VRS-CH1JF220JY AA V 22 1/16W Metal Oxide

R7807 VRS-CH1JF220JY AA V 22 1/16W Metal Oxide

R7808 VRS-CH1JF220JY AA V 22 1/16W Metal Oxide

R7809 VRS-CH1JF220JY AA V 22 1/16W Metal Oxide

VRS-CY1JF332JY AA V 3.3k 1/16W Metal Oxide

0 1/16W Metal Oxide

DESCRIPTION

9

Page 56

BD-HP21U

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PART

DELIVERY

[2] DSETV0192TEZM (MAIN Unit)

R7810 VRS-CH1JF220JY AA V 22 1/16W Metal Oxide

R7811 VRS-CH1JF220JY AA V 22 1/16W Metal Oxide

R7812 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7813 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7814 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7815 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7816 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7817 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7818 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7819 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7820 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7821 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7822 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7823 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7824 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7825 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7826 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7827 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7828 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7829 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7830 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7831 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7832 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7833 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7834 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7835 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7836 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7837 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7838 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7839 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7840 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7841 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7842 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7843 VRS-CY1JF220JY AA V

R7844 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7845 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7846 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7847 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7848 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7849 VRS-CY1JF220JY AA V 22 1/16W Metal Oxide

R7850 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7851 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7852 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7853 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7854 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7855 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7856 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7857 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7858 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7859 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7860 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7861 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R7862 VRS-CK1JF000JY AA V 0 1/16W Metal Oxide

R7863 VRS-CK1JF000JY AA V 0 1/16W Metal Oxide

R7864 VRS-CK1JF000JY AA V 0 1/16W Metal Oxide

R7865 VRS-CK1JF000JY AA V 0 1/16W Metal Oxide

R7866 VRS-CK1JF000JY AA V 0 1/16W Metal Oxide

R7867 VRS-CK1JF000JY AA V 0 1/16W Metal Oxide

R7868 VRS-CK1JF000JY AA V 0 1/16W Metal Oxide

R7869 VRS-CK1JF000JY AA V 0 1/16W Metal Oxide

R7876 VRS-CY1JF151JY AA V 150 1/16W Metal Oxide

R7877 VRS-CY1JF151JY AA V 150 1/16W Metal Oxide

R7893 VRS-CY1JF151JY AA V 150 1/16W Metal Oxide

R7895 VRS-CY1JF151JY AA V 150 1/16W Metal Oxide

R8187 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R8188 VRS-CY1JF000JY AA V 0 1/16W Metal Oxide

R8503 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R8504

R8505 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R8506 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R8507 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R8508 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R8511 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R8512 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R8516 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R8519 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R8520 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R8523 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R8524 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R8525 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R8526 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R8528 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R8530 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R8532 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R8533 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

22 1/16W Metal Oxide

DESCRIPTION

10

Page 57

BD-HP21U

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PART

DELIVERY

[2] DSETV0192TEZM (MAIN Unit)

R8535 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R8537 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R8539 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide

R8541 VRS-CY1JF103JY AA V 10k 1/16W Metal Oxide