Page 1

q

SERVICE MANUAL

Digital copier

MODEL

CONTENTS

CODE : 00Z

ARSP6//A1E

Reverse Single

Pass Feeder (RSPF)

Single Pass Feeder (SPF)

AR-RP6

AR-SP6

[1] PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

[2] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

[3] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . 1

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE . . . . . . . . . . . 4

[5] OPEREATIONAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . 5

[6] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

[7] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . 8

[8] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

[9] ELECTRICAL SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Parts marked with "!" are important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales servic e only.

The contents are subject to change without notice.

Page 2

Page 3

[1] PRODUCT OUTLINE

This machine is a duplex document auto feeder attached to a digital

copier.

It feeds originals automatically to allow continuous copying.

[2] SPECIFICATIONS

AR-RP6 AR-SP6

Document set direction Face up

Document set position Right/Center reference

Document transport

system

Document feed sequence Top take-up feed

Document size AB series: A3 ~ A5

Document weight 56 ~ 90g/m

Document set quantity Max. 40 sheets (Stack range: within 4mm)

Dimensions 583mm (W) x 435mm (D) x 133mm (H)

Weight About 5.4 kg About 5.0 kg

Power source S up p l i ed f r o m th e

Power consumption 26.4W 21W

Document size detection On the document feed tray

Detection size Japan: A3, B4, A4, A4R, B5, B5R,

Mixture of different

document sizes

Document reverse Allowed

Display section (LED) None

Document exchange

speed

Sheet through type

Inch series: 11 x 17 ~ 8.5 x 5.5

2

, 15 ~ 24lbs

2

: Set capacity = 30 sheets)

(90g/m

copier. (DC 24V)

Inch series: 11 x 17, 8.5 x 14, 8.5 x 11,

EX AB series: A3, B4, A4, A 4R, A 5 , B5,

Mixture paper feed: Not available

Random paper feed: Not available

(without 8.5 x 5.5)

S 3 S, 16 sheets/min (AR-160M)

S 3 S, 20 sheets/min (AR-200M)

Supplied from the

copier. (DC 24V, 5V)

A5

8.5 x 11R, 8.5 x 5.5

B5R, A5R

Not allowed

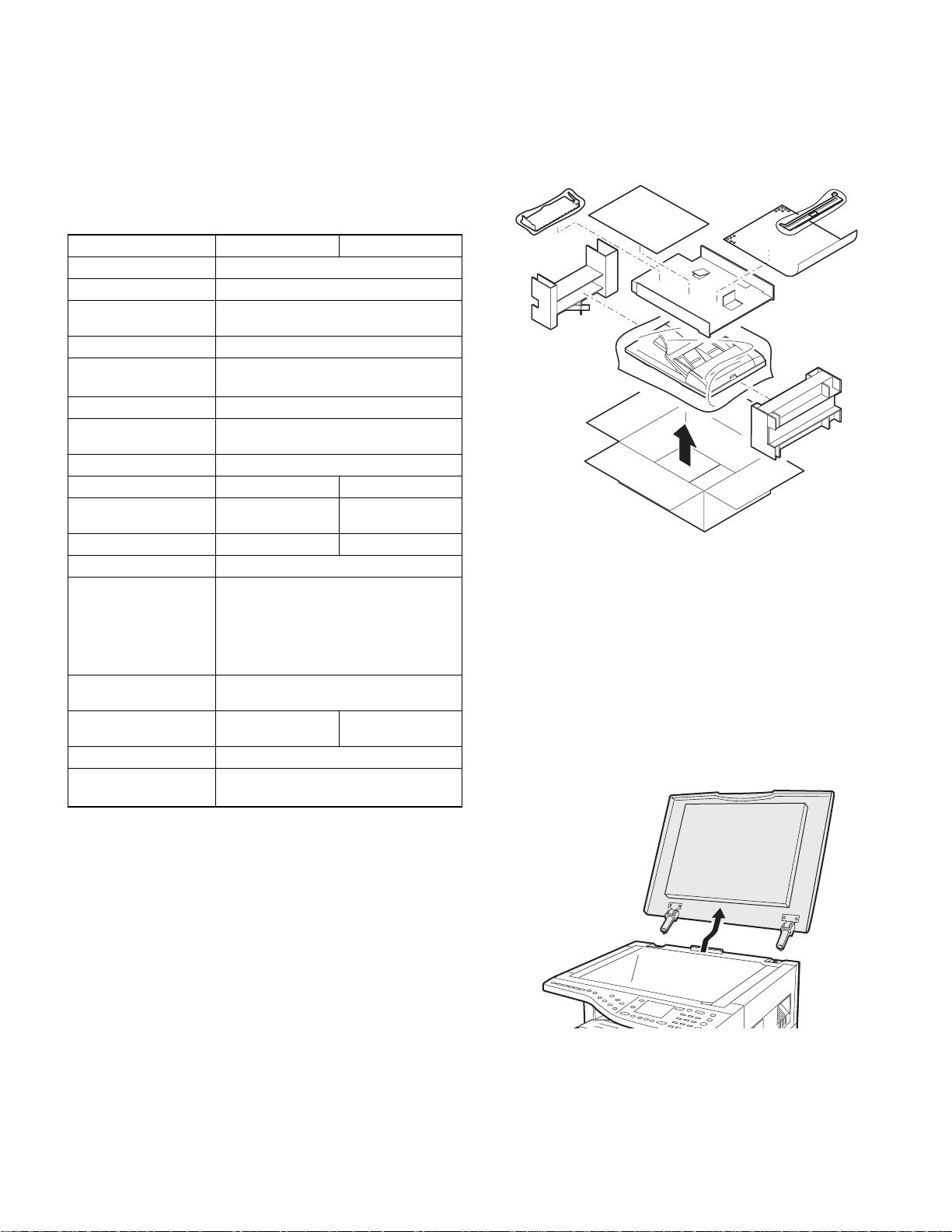

[3] UNPACKING AND INSTALLATION

1. Unpacking

For unpacking, refer to the figure below.

2. Installation

Turn the main switch of the copier to the “OFF” position and then

remove the power plug of the copier from the outlet.

1. Remove th e document cover.

Lift the document cover from the copier and tilt it to the rear side to

remove it.

AR-SP6/RP6 PRODUCT OUTLINE

– 1 –

Page 4

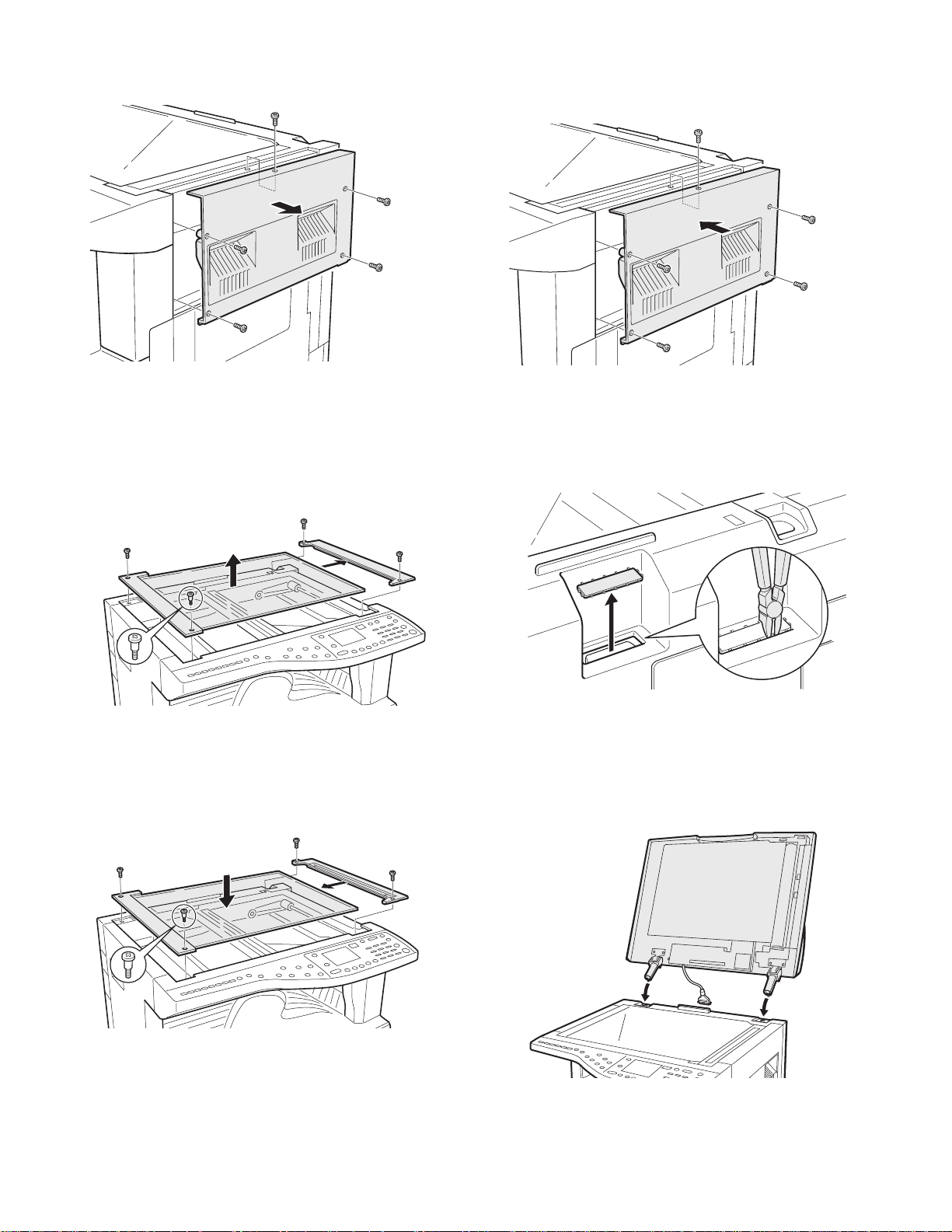

2. Remove the right cabinet.

Remove the screws and remove the right cabinet.

5. Attach the right cabinet.

Reattach the right cabinet to its original position and fix it with the

screws.

3. Remove the document glass and the right document

glass holder.

Remove the screws, remove the document glass from the copier, and

then remove the right document glass holder.

4. Attach the SPF glass holder.

Fit the SPF glass holder to the document glass.

Attach the document glass to the copier and fix it with the screws.

6. Cut out the cut-out portion.

Cut out the cut-out portion of the rear cabinet with nippers or the like.

At this time, be careful about the orientation of the nippers so that the

cut plane of the rear cabinet is flat.

7. Attach the automatic document feeder.

Insert the hinge portions of the document feeder into the mounting portions of the copier by holding the feeder at an angle toward the rear

side.

AR-SP6/RP6 UNPACKING AND INSTALLATION

– 2 –

Page 5

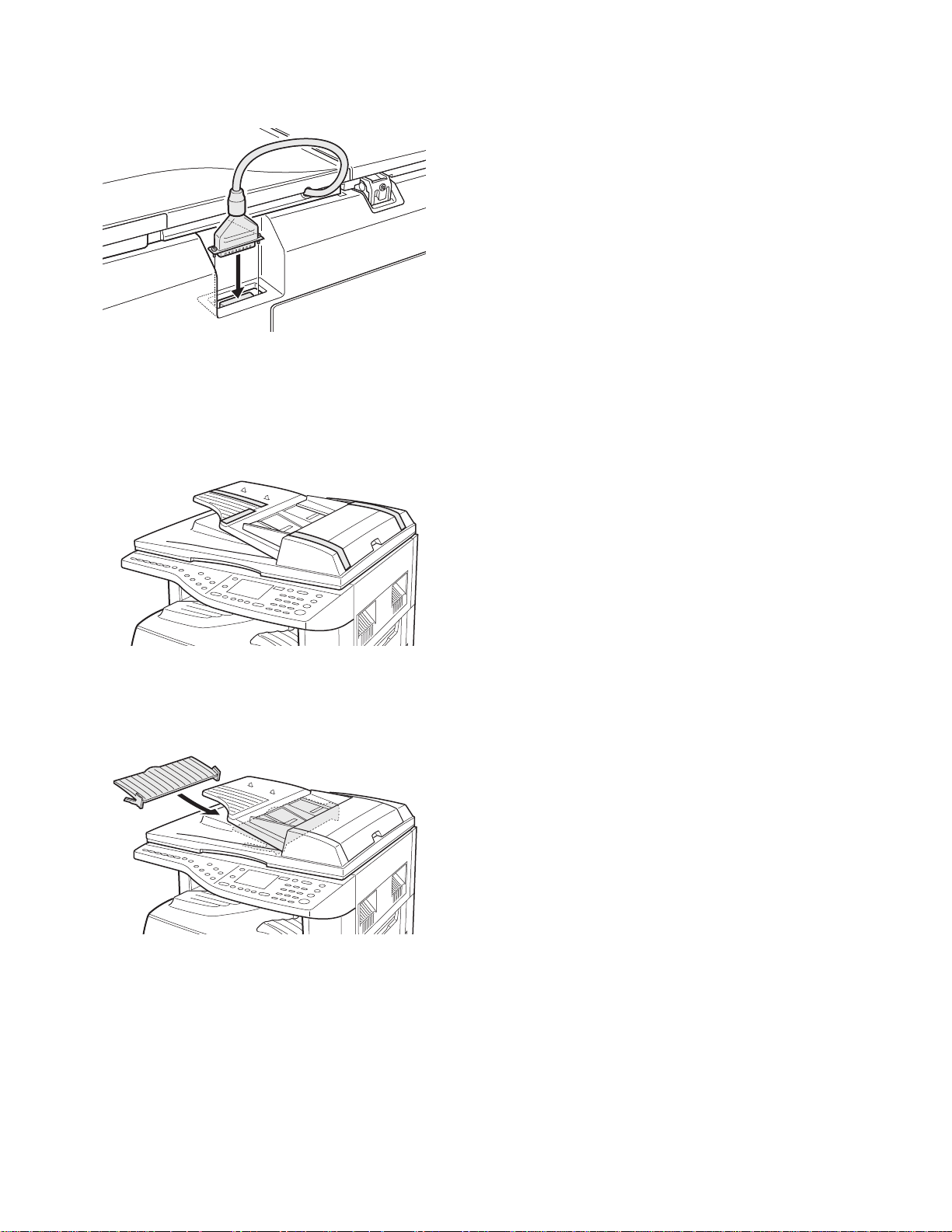

8. Connect the relay connector.

Connect the harness of the automatic document feeder to the connector of the copier and tighten the screws on the connector.

9. Remove the filament tape.

Remove the filament tape located in the positions shown in the illustration.

Insert the power plug of the copier to the outl et and turn on

the main switch of the copier.

11. Adjust the white compensation pixels.

• Open the automatic document feeder, execute simulation 63-7 referring to the service manual, and adjust the automatic white compensation pixels of the document feeder.

12. Check the copy magnification ratio.

• Set an original on the document glass and copy it.

Then, set an original in the document feeder tray and copy it.

• If the magnification ratio of the copy from the document feeder is different from that of the copy from the document glass, execute simulation 48-5 to carry out adjustment referring to the service manual.

13. Check the center displacement.

• Set an original on the document glass and copy it.

Then, set an original in the document feeder tray and copy it.

• If the center of the copy image from the document feeder is different

from that of the copy image from the document glass, execute simulation 50-12 to carry out adjustment referring to the service manual.

14. Check the top end position.

• Set an original on the document glass and copy it.

Then, set an original in the document feeder tray and copy it.

• If the top end position of the copy image from the document feeder is

different from that of the copy image from the document glass, execute simulation 50-06 to carry out adjustment referring to the service

manual.

10. Attach the intermediate tray. (AR-RP6 only)

Insert the intermediate tray all the way into the document feeder.

AR-SP6/RP6 UNPACKING AND INSTALLATION

– 3 –

Page 6

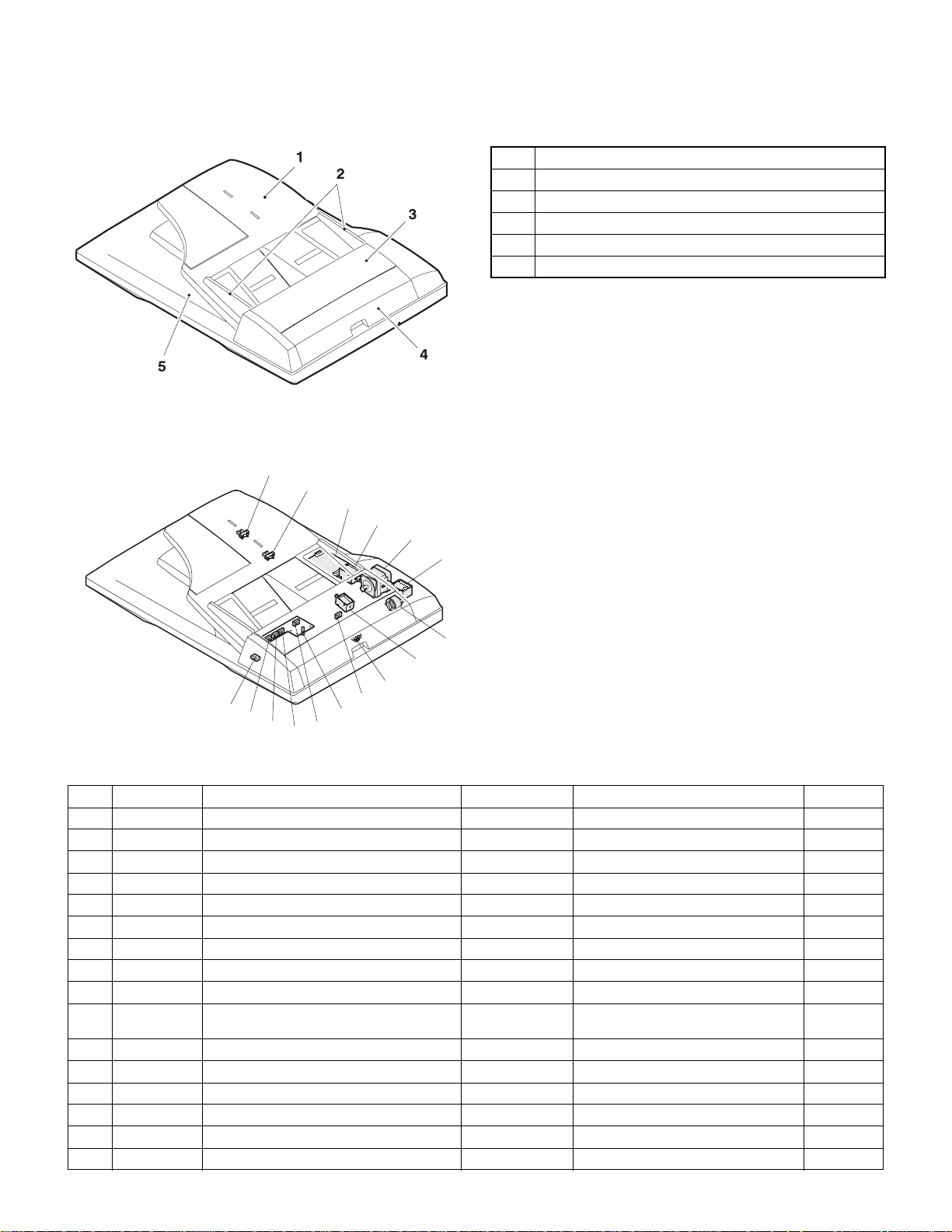

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE

1. External view

No. Name

1 Document set tray

2 Document guide

3 Document feed section cover

4 Document transport section cover

5 Document exit section

2. Internal structure

14

13

12

11

10

8

9

6

7

15

5

4

3

16

2

1

Sensor, detector, etc.

No. Code Name Type Function/Operation Note

1 W0 Document set sensor Photo transmission Detects presence of documents.

2 COVER Open/close sensor Photo transmission Detects open/close of the paper feed unit.

3 W1 Document width sensor (A4R, LTR, A5) Photo transmission Detects the document width on the tray.

4 W2 Document width sensor (B4, B5) Photo transmission Detects the document width on the tray.

5 W3 Document width sensor (WL, TR, A5R, A4, LT) Photo transmission Detects the document width on the tray.

6 PSOL Pickup solenoid — —

7 PAPER Paper entry sensor Photo transmission Detects presence of documents.

8 RSOL Pressure release solenoid — — AR-RP6 only

9 CLH Transport clutch — —

10 MOT SPF (RSPF) motor Stepping motor Drives document feed on the tray, trans-

11 GSOL Gate solenoid — — AR-RP6 only

12 — Interface PWB — —

13 L1 Document length detection SW (Short) Photo transmission Detects the document length on the tray.

14 L2 Document length detection SW (Long) Photo transmission Detects the document length on the tray.

15 COVER OPEN Book sensor Photo transmission Detects the SPF (RSPF) float.

16 PO Paper exit sensor Photo transmission Detects presence of documents.

port, and paper exit roller.

AR-SP6/RP6 EXTERNAL VIEW AND INTERNAL STRUCTURE

– 4 –

Page 7

[5] OPEREATIONAL DESCRIPTIONS

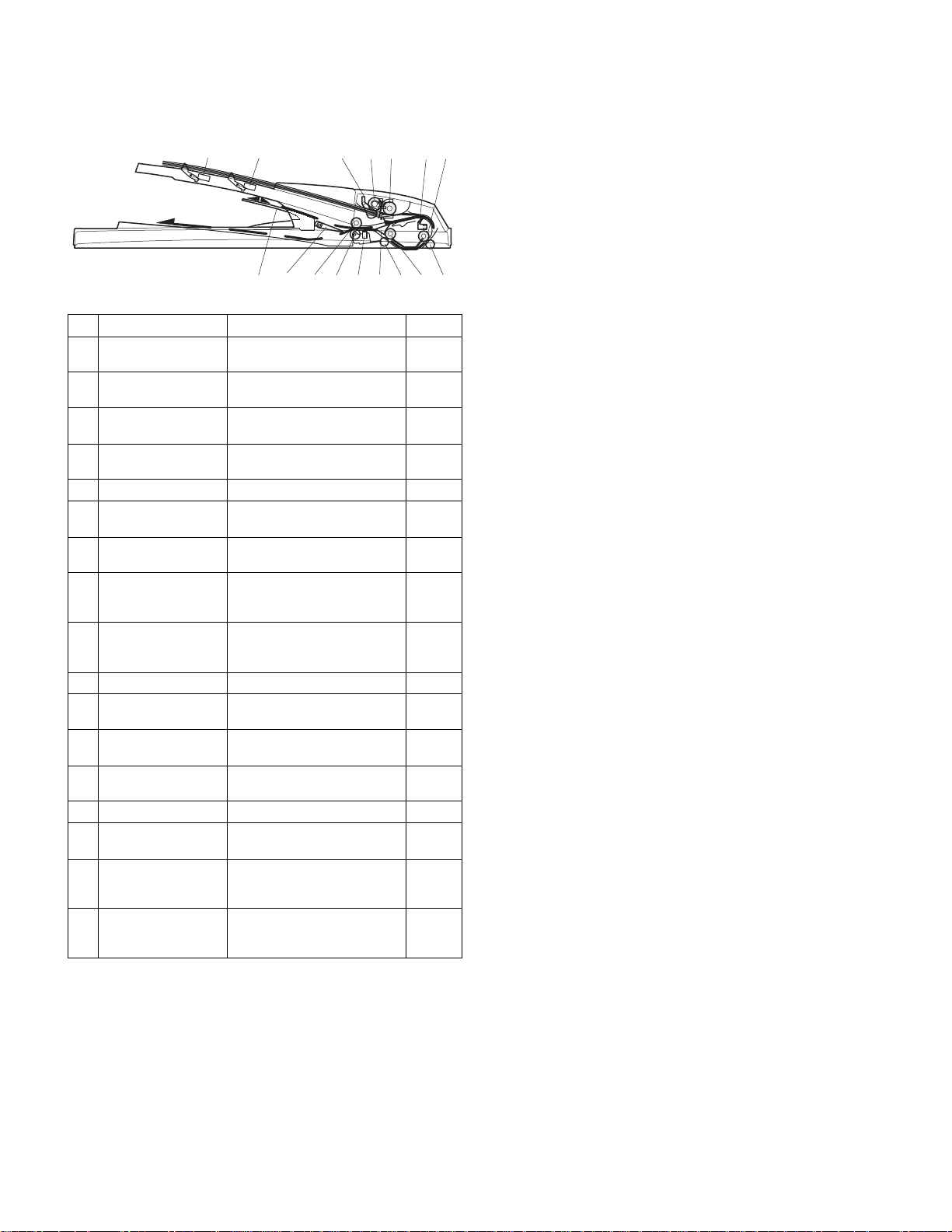

1. Major parts of the paper feed section 2. Out line of operations

1 2 3,4 5 6 7 8

12

No. Part name Operation Note

1 Document length

sensor (L2)

2 Document length

sensor (L1)

3 Document set

sensor (W0)

4 Document width

sensor (W1, W2, W3)

5 Pickup roller Picks up documents.

6 Paper feed roller Feeds and transports docu-

7 Paper entry sensor

(PAPER)

8 PS roller Makes synchronization

9 PS follower roller Makes synchronization

10 Transport roller Transports documents.

11 Transport follower

roller

12 Paper exit sensor

(PO)

13 Paper exit follower

roller

14 Paper exit roller Discharges documents.

15 Reverse gate Opens/closes the document

16 Paper exit gate Separate document exit to the

17 Intermediate tray Discharges documents to the

Detects the document length

on the tray.

Detects the document length

on the tray.

Detects presence of documents.

Detects the document width.

ments.

Detects transport of docu-

ments.

between the document lead

edge and the image lead edge.

between the document lead

edge and the image lead edge.

Transports documents.

Detects transport of documents.

Discharges documents.

reverse path.

intermediate or the paper exit

tray.

intermediate tray during document reverse.

AR-RP6

only

AR-RP6

only

910111314 151617

■AR-RP6 (RSPF)

[Duplex documents]

1) Document set (Document set sensor ON)

4

2) Document size detection (Document width sensors W1, W2, W3

detect the document width, and document length sensors L1, L2 detect the

document length.)

4

3) Copier COPY key ON

4

4) RSPF motor ON

4

5) Pickup solenoid ON

4

6) Pickup roller and paper feed roller rotation

4

7) Paper entry sensor detects the document presence.

4

8) PS roller rotation

4

9) Copying (Front surface of document)

4

10) Transport roller rotation

4

11) Paper exit roller rotation

4

12) Paper exit gate falls down.

(Documents are discharged to the intermediate tray.)

4

13) Reverse gate falls down.

4

14) Paper exit roller reverse rotation

(Documents are fed to the reverse path.)

4

15) Paper entry sensor detects document presence.

4

16) PS roller rotation

4

17) Copying (Back surface of document)

4

18) Transport roller rotation

4

19) Paper exit roller rotation

4

20) Paper exit gate falls down

(Documents are discharged to the intermediate tray.)

4

21) Reverse gate falls down.

4

22) Paper exit roller reverse rotation

(Documents are fed to the reverse path.)

4

23) Paper entry sensor detects document presence.

4

24) PS roller rotation

4

25) Paper exit roller rotation

4

26) Paper exit gate lifts up.

4

27) Documents are fed to the paper exit tray.

4

28) Next document 3 (YES) 3 Go to 4).

4 (NO)

29) RSPF motor OFF

AR-SP6/RP6 OPEREATIONAL DESCRIPTIONS

– 5 –

Page 8

■AR-SP6 (SPF)

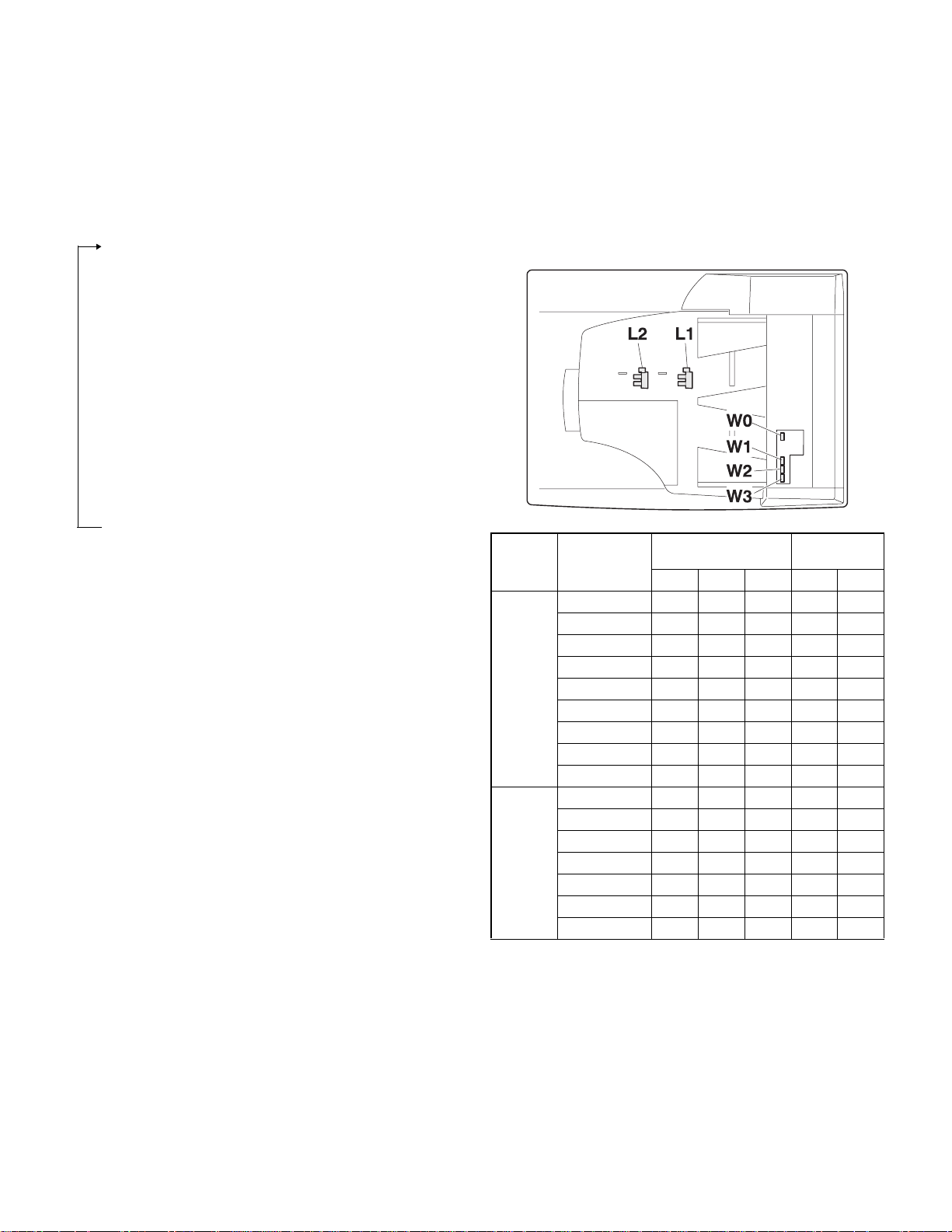

3. Document size detection

1) Document set (Document set sensor ON)

4

2) Document size detection (Document width sensors W1,

W2, W3 detect the document

width, and document length sensors L1, L2 detect the document

length.)

4

3) Copier COPY key ON

4

4) SPF motor ON

4

5) Pickup solenoid ON

4

6) Pickup roller and paper feed roller rotation

4

7) Paper entry sensor detects the document presence.

4

8) PS roller rotation

4

9) Copying (Front surface of document)

4

10) Transport roller rotation

4

11) Paper exit roller rotation

4

12) Documents are fed to the paper exit tray.

4

13) Next document 3 (YES) 3 Go to 4).

4 (NO)

14) SPF motor OFF

1) Document size detection with the document set tray

When documents are set on the document set tray in the auto selection

mode of paper/copy magnification ratio, the document size is detected

and paper and the copy magnification ratio are automatically selected.

When different sizes of documents are set, the max. size is detected.

The document width is detected by the document width sensors (W1,

W2, W3), and the document length is detected by the document length

sensors (L1, L2) to identify the document size. Judgement of the document size is made in a certain timing after detecting the document w ith

the document set sensor (W0).

Document

length sensor

AB series

Inch

series

Document set

size and set

direction

A5 onnnn

B5 oonnn

A5R nnnnn

A4 ooonn

B5R nnnon

A4R onnon

8.5” x 13” onnoo

B4 onnoo

A3 ooooo

8.5” x 5.5” onnnn

8.5” x 5.5”R nnnnn

11” x 8.5” ooonn

11” x 8.5”R onnon

8.5” x 13” onnoo

8.5” x 14” onnoo

11” x 17” ooooo

Document width sensor

W1 W2 W3 L1 L2

Note: Detection sensor ON: o, OFF: n

AR-SP6/RP6 OPEREATIONAL DESCRIPTIONS

– 6 –

Page 9

[6] ADJUSTMENTS

(1) Auto white correction pixel adjustment

[Function]

The white correction start pixel position is automatically adjusted.

This adjustment is performed after the lens unit is replaced.

[Operation]

Open the SPF (RSPF) unit and press the [OK] key.

7-segment indicates the order number of the pixel of the white sheet for SPF (RSPF)

exposure correction in the SPF (RSPF) position.

It will display on 7-segment, if values are 93-299, and data are written into the EEPROM.

It will display on 7-segment, it values are 0-92 or 230-999, and data are not written into

the EEPROM.

It will display "--" on 7-segment, it values is 1000 or larger, and data are not written into

the EEPROM..

[CA] key: Cancels the test command.

[Interruption] key: Shifts to the sub code entry menu.

The SPF white correction start pixel = Displayed pixel position - 34

Interruption is inhibited during execution.

If the simulation is executed with the SPF unit closed, an error is resulted.

During execution,"EXEC" is highlighted

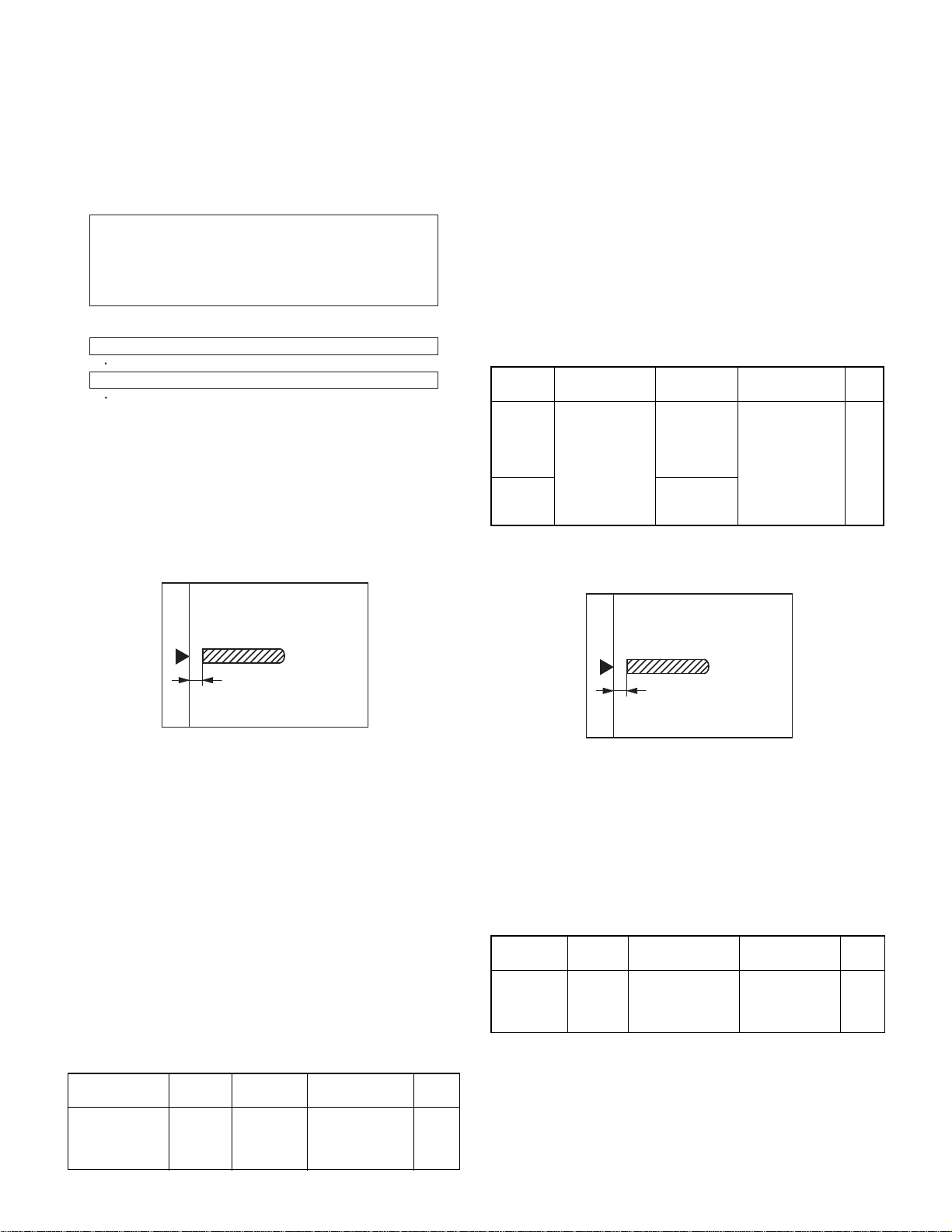

(2) Magnification ratio adjustment

Note: • When performing this adjustment, check that the CCD unit is

properly installed.

• When performing this adjustment, check that the OC mode

adjustment in copying is completed.

1) Place a scale on the document table as shown be low, and make a

normal copy to make a test chart.

(3) Document off center adjustment

Note: When performing this adjustment, check that the paper off-cen-

ter is properly adjusted.

1) Set the center position adjustment test chart (made by yourself) on

the SPF (RSPF).

<Adjustment specifications>

Draw a line in the center of paper. (In the scanning direction)

2) Make a normal copy from the manual feed tray, and co mpare the

copy and the test chart.

If an adjustment is required, perform the following procedures.

3) Execute SIM 50-12.

4) The current off-center adjustment value is displayed on the display

section in two digits.

5) Enter the set value and press the START key.

The entered correction value is started and a copy is made.

<Adjustment specifications>

Mode Specification SIM Set value

Document

off-center

(AR-RP6)

Document

off-center

(AR-SP6)

Simplex:

Center

Duplex:

Center

m

m

3.0mm

3.5mm

SIM 50-12

TEXT:

SPF surface

PHOTO:

SPF back

AE: Surface

TEXT: Back

Add 1:

0.1mm shifted to

R side.

Reduce 1:

0.1mm shifted to

L side.

Set

range

1 ~ 99

(4) Image lead edge position adjustme nt

1) Set a scale on the OC table as shown below.

Note: Since the printed paper is used as the test chart,

place the scale in parallel to both sides.

2) Set the test chart to the SPF (RSPF) and make a normal copy.

3) Compare the copy and the test chart.

If an adjustment is needed, perform the following procedures.

4) Execute SIM 48-5.

5) The current correction value is displayed on the display section in

two digits.

6) Enter the set value, and press the START key.

The entered correction value is stored and a copy is made.

7) Change the TEXT mode.

The TEXT lamp lights up, and the current correction value of the

back surface sub scanning direction magnification ratio is displayed

on the display section in two digits.

8) Enter the set value, and press the START key.

The entered correction value is stored and a copy is made.

<Adjustment specifications>

Mode Spec SIM Set value

Magnification

ratio adjustment

Normal:

m 1.0%

SIM 48-5

AE: Surface

TEXT: Back

Add 1:

Reduce 1:

0.1% increase

0.1% decrease

Set

range

1 ~ 99

Note: Since the printed paper is used as the test chart,

place the scale in parallel to both sides.

2) Make a copy, and use the copied paper as the document and make

a copy from SPF (RSPF) again.

3) Check the copied paper. If an adjustment is required, perform the

following procedures.

4) Execute SIM 50-6.

5) Set the SPF/RSPF lead edge position set value so that the image

similar to the adjusted image at the OC image lead edge position

described previously is printed.

<Adjustment specifications>

Adjustment

mode

Image

lead edge

position

SIM Set value Specification

SIM 50-6 1step: 0.1mm shift Lead edge void:

1 ~ 4mm

Image loss:

Set

range

1 ~ 99

3mm or less

AR-SP6/RP6 ADJUSTMENTS

– 7 –

Page 10

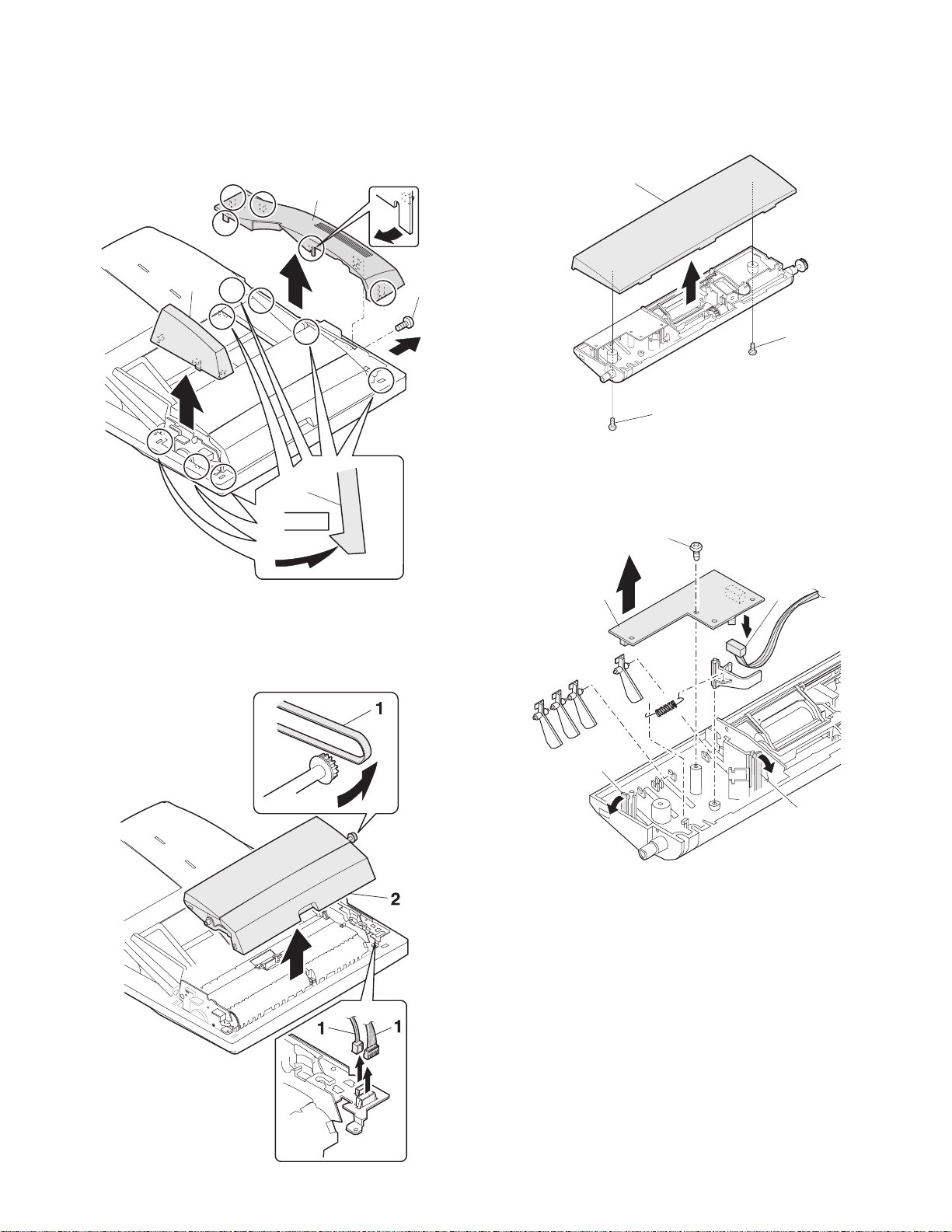

[7] DISASSEMBLY AND ASSEMBLY

1. External fitting section

Note: Turn the paw in the arrow direction.

3

2) Document feed section cover

2

2

1

1

1

2

3) Sensor PWB

1

2. Paper feed unit section

1) Paper feed unit

3

4

2

2

AR-SP6/RP6 DI SASSEMBLY AND ASSEMBLY

– 8 –

Page 11

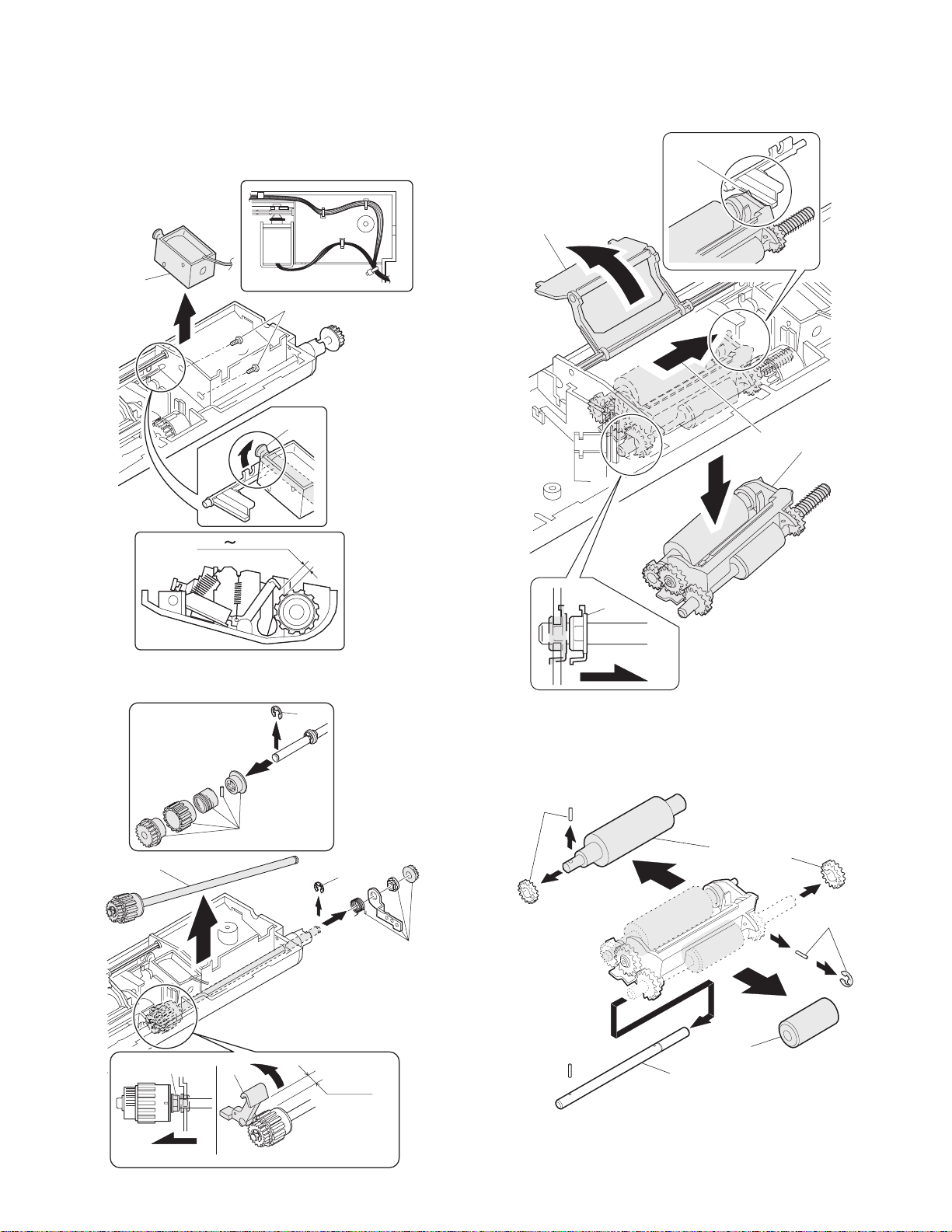

4) Pickup solenoid

Note: Remove section A of the pickup solenoid from the solenoid arm

groove.

When assembling, adjust the spacing between the clutch latch

and sleeve with the pick-up solenoid pulled. The size should be

the distance from the tip of the clutch latch and the root of the

clutch sleeve latch.

2

1

A

6) Pickup roller ass’y

Note: When assembling the pickup roller ass’y 4, check that rib A is on

the rib of the solenoid arm.

A

1

2

4

2.5 4.5mm

5) Clutch gear ass’y

5

3

6

7) Pick up roller, paper feed roller

4

6

1

2

3

1

1

3

4

From Edge pawl

2.5~4.0

1

AR-SP6/RP6 DI SASSEMBLY AND ASSEMBLY

– 9 –

2

Page 12

3. Interface PWB

5. Document tray section

1

1) Document tray

1

2

A

2

3

1

B

1

B

1

A

2) Rack cover

■■■■AR-RP6

1

1

1

4. Gate solenoid

■■■■AR-RP6 only

2

1

Bearing

■■■■AR-SP6

1

1

1

2

Note: When assembling, check that the paper exit gate hook is set in

the solenoid groove.

When assembling, the bearing D-cut surface shuold be faced

down.

AR-SP6/RP6 DI SASSEMBLY AND ASSEMBLY

– 10 –

Page 13

3) Document length sensor SW

2

1

2

1

2) Drive frame unit

1

1

1

2

1

6. Drive frame section

1) Book sensor

2

1

3) Drive frame ass’y and drive belt

3

1

2

3

4

AR-SP6/RP6 DI SASSEMBLY AND ASSEMBLY

– 11 –

Page 14

4) Pressure release solenoid

■■■■AR-RP6 only

Note: Make sure the spring pin A is inserted into the slot.

Make sure that the clearance between the position at which force

is applied and the sound deadening sponge is 0.5 ~ 2 mm when

the pressure release solenoid plunger is pulled toward the solenoid side.

0.5 2mm

7. Transport section

1) Clutch

Note: When assembling, check that the rib is in the clutch groove A

and fix it with E-ring.

2

A

A

2

5) RSPF motor / SPF motor

1

3

3

1

1

2) Transport roller gear

1

1

1

3) Reverse gate

■■■■AR-RP6 only

4

Note: When assembling the inversion gate, apply grease G-484 on the

area A.

1

1

2

A

AR-SP6/RP6 DI SASSEMBLY AND ASSEMBLY

– 12 –

3

A

A

2

1

Page 15

4) Transport roller

Note: Note that the spring will come off when removing.

■■■■AR-RP6

5) PS roller

1

1

1

■■■■AR-SP6

1

2

1

1

6) Paper feed paper guide lower

Note: When assembling, check that the paper feed paper guide lower

is securely set to rib A and boss B.

+

1mm

-

0 0.5mm

2

1

1

1

AR-SP6/RP6 DI SASSEMBLY AND ASSEMBLY

– 13 –

B

1

A

Page 16

7) Paper feed paper guide upper

[8] MAINTENANCE

1

8) Paper exit roller

2

1

1. Maintenance parts

No. Name Work item Service call Remark

1 Pickup roller Cleaning o

2-1 Separation unit Cleaning o Replace when

2-2 Front separation

sheet

3 Paper feed roller Cleaning o

4 PS roller Cleaning o

5 Transport roller Cleaning o

6 Paper exit roller Cleaning o

Cleaning o

1

worn down.

3

1

2

8. Hinge L

Note: When assembling the hinge L, reference is based on the mark of

base tray and the center line of the 5 lines of the hinge L

extended horizontally.

1

1

2

1

2-2

2-1

6

5

4

Note: When performing maintenance, refer to [7] DISASSEMBLY AND

ASSEMBLY.

AR-SP6/RP6 MAINTENANCE

– 14 –

Page 17

D

1

SENSOR

5V

C

B

SOL/CLU

A

RSPF ONLY

5V

5V

24V

24V

5V

24V

24V

24V

24V

24V

234

L2

L1

W0W1W2

SPF SENSOR PWB

W3

PAPER

/SPFOUT

SPFOPEN

/CLH

/PSOL

/RSOL

/GSOL

MOTOR

(A,B,/A,/B)

2 1

/SPFCOVER

3

5

DATA

SELECTOR

5V

TRANSISTOR

24V

ARRAY

MOTOR

DRIVER

5 4

SPF/RSPF INTERFACE PWB

678

7 6

[9] ELECTRICAL SECTION

1. Block diagram

PEGASUS

(MCU PWB)

D

YSPF

/SPFCOVER

SEL(A#,B#,C#)

C

AR-SP6/RP6 ELECTRICAL SECTION

PAPER

– 15 –

/SPFOUT

SPFOPEN

SPF(CLH,PSOL,RSOL,GSOL)

B

/MODA,/MODB)

SPF(MODA,MODB,

A

PDOWNA

PDOWNB

8

Page 18

D

C

B

A

12345678

DSPF ONLY

ORIGINAL TRAY

Sensor PWB

PAPER FEED UNIT

W0

5v

1

2

BL

OR

W2

W1

4

3

PLBRLB

W3

5

SPFCOVER

SGND7

6

GY

PK

SPFPSOL

L1

321

ORLBGY

L2

321

ORGYBL

PAPER

(Paper Entry Sensor)

213

GYBRPL

SPFRSOL

SPFGSOL

A

3

1

BLLBPK

/B2/A

PLUSE MOTOR

4B

PLRDRD

24V1624V1

5

2 1

PHR-7

BLORPLBRLBGYPK

2

3

5V

W1

W0 17

BU7P-TR-P-H

6

5

BLORPLBRLBGYPK

PHDR-20

BLORPLBRLBGYPK

7

1

5

5VW0W1

CN6

B20B-PHDSS

PHR-3

DF3-3S-2C

ORLBGY

PHNR-7-HPHNR-7-H

SGND 71

SPFCOVER 62

W3 53

W2 44

1

2

SPFPSOL

24V1

BU2P-TR-P-H

2

1

BL

RD

PHNR-2-H

BU6P-TR-P-H

2

L1

5V 16

5

ORLBGY

3

SGND

4

ORGYBL

5V 43

ORGYBL

PHNR-2-H

BL

RD

9

20314

SGND

W2

W3

SPFCOVER

11

/PSOL 6

24V1

ORLBGY

2

15

L1

5V

16

SGND

ORGYBL

45V

DF3-3S-2C

PHNR-6-HPHNR-6-H

SGND 61

L2 52

1

SPFRSOL

1

LB

2

SMR-02V-N(JST)

24V1

2

RD

SMP-02V-BC(JST)

GYBRPL

17SGND

L2 13

18SGND

pull up 8

LB

19PAPER

PHR-2

RD

CN4

B2B-PH-K-S

2/GSOL

24V1 1

1224V1

/RSOL 10

PHR-6

PHR-7

BLLBPK

CN3

B7B-PH-K-S

3

PL

RD

RD

3/B

2/A

5N.C.

4B

1A

624V1

724V1

2. Actual wiring diagram

PAPER

1

CN5

B26B-PHDSS

25

PAPER

MCU PWB Interface PWB

/SPFCOVER

SELA#

3

2

20

16

/SPFCOVER

SELA#

D

SPFMODB

SELB#

5

4

17

SPFMODB

SELB#

/SPFMODB

SELC#

3 7 6

/SPFMODB

SELC#

N.C.6SGND

SGND7YSPF

9108

12

13-18

N.C.

SGND

SGND

11

15

YSPF

SPFOPEN

5V

12

13

24

SPFOPEN

5V

SPFGSOL

SPFMODA

15

16

22

5

SPFGSOL

SPFMODA

/SPFMODA

SPFRSOL

181719

4 921

/SPFMODA

SPFRSOL

SPFCLH

SPFCLH

PDOWNA

PDOWNA

/SPFOUT

14

19

/SPFOUT

C

AR-SP6/RP6 ELECTRICAL SECTION

PDOWNB

SPFPSOL

212220

1023 8

PDOWNB

SPFPSOL

– 16 –

PGND

23

11

PGND

PGND

24

14

PGND

SPF0PEN2

SGND

N.C.2

24V1

24V

24V

25

26

CN7

1

B3B-PH-K-S

/CLH

3

CN1

BL

FG

PHR-3

SRA-21T-4

SRA-21T-4SRA-21T-4

BL BL

BL

1

2

26

FG

24V

24V

SPFCLH

5V

3

1

B3B-PH-K-R(RD)

GY

OR

BRBR

PHR-3(RD)

DF3-3S-2C

GY

OR

123

/SPFOUT2

SGND

1

CN2

B3B-PH-K-K(BK)

GR

GY

PHR-3(BK)

DF3-3S-2C

GYORGR

123

5V

3

OR

EARTH PLATE(SPF ONLY)

8 7 6 5 4

SPFOPEN

(Book Sensor)

B

/SPFOUT

(Paper Exit Sensor)

A

Page 19

D

CN2-6 (B3)

CN6-3 (B2)

CN2-10 (B3)

CN3-3 (A2)

C

B

A

12345678

/CLH

/RSOL

/GSOL

/PSOL

24V1

C115

0.047u/50V

C114

0.047u/50V

5V

1C2C3C4C5C6C7C

1B2B3B4B5B6B7B

IC2

SPFCLH

SPFPSOL

(A4) CN1-21

(A4) CN1-19

IC101

COM

GND

TD62003AP

SPFRSOL

SPFGSOL

(A4) CN1-17

(A4) CN1-15

CN1-11 (A4)

YSPF

ZD102

UDZ5.6

C120

0.1u/25V

Y

W

VCC

D0D1D2D3D4D5D6D7ABC

GND

CN7-4 (B2)

CN7-3 (A2)

CN7-2 (B3)

CN7-1 (B3)

CN7-6,7 (B3)

BA/B

/A

2 1

Pattern width: 0.5mm or above

C1

47u/35V

3

C104

R107

R101

C107

0.047u/50V

24V1

7.5KJ

C113

7.5KJ

2200pF/50V

2200pF/

50V

C110

C103

3300pF/50V

0.047u/50V

IC1

R104

C108

0.1uF/25V

1KJ

Vmm

CrA

CrB

R102 2.4k

OUT A

VsA

R1 1.5(1W)

OUT B

RsA

OUT /A

VrefA

NCNCNCNCNCNCPG

OUT /B

VrefB

RsB

VsB

In /A

In A

R105

R2 1.5(1W)

R106 2.4k

In /B

1KJ

C112

LG

PG

PG

In B

0.1uF/25V

C111

MTD1361

3300pF/50V

/SPFMODB

/SPFMODA

SPFMODA

(C4) CN1-6

(C4) CN1-16

(C4) CN1-18

Pattern width: 1.0mm or above

SPFMODB

(C4) CN1-4

CN1-5 (A4)

CN1-7 (A4)

CN1-3 (A4)

SELA#

SELC#

SELB#

C118

1000p/50V

C117

1000p/50V

C119

1000p/50V

ZD103

UDZ5.6

ZD101

UDZ5.6

ZD104

UDZ5.6

G

74HC151

R111

R113

R112

R115

R114

R117

R116

10K

10K

10K

10K

10K

10K

10K

Document size senser

(A3) CN2-9

(A3) CN2-3

(A3) CN2-7

W0W2W3W1L2

L1

(A3) CN2-5

(A3) CN2-15

(A3) CN2-13

5V

3-1. Interface PWB (1/2)

3. Circuit Diagram

D

C122

C121

C124

C123

C126

C125

/SPFDTC

1000pF/50V*7

JP1

DSPF

Y

W3

W2

W1

W0

/SPFDTC (L)

L2

L1

SPF(H)/DSPF(L)

LHLHLHL

SELA

L

SELB

LLL

SELC

Senser Mtorix

L

H

L

L

H

H

H

H

L

H

HHH

C

AR-SP6/RP6 ELECTRICAL SECTION

– 17 –

C2

$PIN0

C109

0.1u/25V

10k

PDOWNA

(C4) CN1-20

10u/16V

110F

R110

Q102

DTC114EK

10k

10k

Q101

DTC114EK

10k

PDOWNB

(C4) CN1-22

8 7 6 5 4

A

5V

R103

620F

TP103

$PIN0

R109

430F

$PIN0

TP102

R108

390F

1

TP101

B

Page 20

D

C

B

A

12345678

CN1-2 (C4)

(E4)

(D4)

/PSOL

/RSOL

8

1012141618

/SPFCOVER

20

R119

R118

470

470

246

5V

123

CN7

B3B-PH-K-S

24V1

/CLH

(E4)

2 1

1357911131517

CN6

5V

24V1

W3

(B3)

(B3)

CN4-2 (B2)

(C1)

CN2-20 (B3)

(B2) CN5-2

(C1)

/SPFOUT

SPFMODB

SPFOPEN

/SPFMODB

/SPFCOVERPAPER

W1W2W0

(B3)

(B3)

(C1)

(C1)

SPFMODA

/SPFMODA

L2

L1

(B3)

(B3)

(B1)

(B1)

PDOWNA

PDOWNB

19

PAPER

CN1-1 (A4)

24V1

F1

B20B-PHDSS

C127

0.1u/25V

ICP-N38

C105

0.047u

C106

0.047u

CN1-14 (C4)

C102

0.1u/25V

/SPFOUT

5V

123

CN2

B3B-PH-K-E(BL)

CN1-12 (C4)

C101

0.1u/25V

SPFOPEN

5V

123

CN1

B3B-PH-K-R(RD)

3

246

CN5

135791113151719212325

SELA#

CN2-19 (A3)

3-2. Interface PWB (2/2)

D

8

101214161820222426

SELB#

SELC#

YSPF

5V

(E3)

(E3)

(E3)

(E3)

SPFGSOL

SFPRSOL

SPFCLH

5V

(D4)

(D4)

(D4)

1

2

B26B-PHDSS

C116

0.1u/25V

+

C3

10u/16V

SPFPSOL

(D4)

C

CN4

B2B-PH-K-S

24V1

/GSOL

(E4)

CN3

24V1

1234567

B7B-PH-K-S

A/A/B

B

(E4)

(E4)

(E4)

(E4)

8 7 6 5 4

B

A

AR-SP6/RP6 ELECTRICAL SECTION

– 18 –

Page 21

D

C

B

A

12345678

2 1

3

3-3. Sensor PWB

D

C

AR-SP6/RP6 ELECTRICAL SECTION

– 19 –

8 7 6 5 4

B

A

Page 22

4. Parts arrangement

4-1. Interface PWB

a. Parts surface

CN3(B7B-PH-K-S)

1

2

3

4

5

6

7

CN4(B2B-PH-K-S)

1

2

CN6(B20B-PHDSS)

25V15V

45V3W3

6 /PSOL 5 W0

8 Pull up 7 W1

10 /RSOL 9 W2

12 24V1 11 24V1

14 SGND 13 L2

16 SGND 15 L1

18 SGND 17 SGND

20 SPFCOVER 19 PAPER

A

/A

/B

B

N.C.

24V1

24V1

24V1

/GSOL

CN7(B3B-PH-K-S)

1 24V1

2 N.C.

3 /CLH

CN1(B3B-PH-K-R RD)

1 SGND

2 SPFOPEN

35V

CN2(B3B-PH-K-E BK)

1 SGND

2 /SPFOUT

35V

CN5(B26B-PHDSS)

24V1

25

PGND

23

SPFPSOL

21

SPFCLH

19

SPFRSOL

17

SPFGSOL

15

13

11

5V

YSPF

SGND

9

SELC#

7

SELB#

5

SELA#

3

PAPER

1

24V1

26

PGND

24

PDOWNB

22

PDOWNA

20

/SPFMODA

18

SPFMODA

16

/SPFOUT

14

SPFOPEN

12

SGND

10

8

/SPFMODB

6

SPFMODB

4

/SPFCOVER

2

N.C.

b. Solder surface

4-2. Sensor PWB

AR-SP6/RP6 ELECTRICAL SECTION

– 20 –

Page 23

q

PARTS GUIDE

デジタル複合機オプション

デジタル複合機オプション

デジタル複合機オプションデジタル複合機オプション

原稿自動送り装置

原稿自動送り装置 (SPF)

原稿自動送り装置原稿自動送り装置

両面原稿自動送り装置

両面原稿自動送り装置 (RSPF)

両面原稿自動送り装置両面原稿自動送り装置

Digital Copier

Digital Copier

Digital CopierDigital Copier

Single Pass Feeder(SPF)

Single Pass Feeder(SPF)

Single Pass Feeder(SPF)Single Pass Feeder(SPF)

Reverse Pass Feeder(PSPF)

Reverse Pass Feeder(PSPF)

Reverse Pass Feeder(PSPF)Reverse Pass Feeder(PSPF)

AR-SP6

MODEL

AR-RP6

(SPF)

(SPF)(SPF)

(RSPF)

(RSPF)(RSPF)

EXCEPT

(

JAPAN

)

このパーツガイドに掲載されている表示価格ランクは消費税抜きです。

CONTENTS

1

外装部 (Exteriors)

2

給紙部 (Paper feed unit)

3

搬送部 (Transport unit)

4

梱包及び付属品 (Packing material & Accesories)

■

索引 (Index)

本書はサービス活動用に作成した資料です。

一部内容が製品の改良・改善等により予告

なしに変わることがあります。

SHARP CORPORATION

This document has been pub lished to be used for

after sales service only .

The contents are subject to change without notice.

Page 24

補修部品のランク付

市場における補修部品の在庫管理が、適正に運営出来る手助けとなることを、目的とします。

Aランク : メンテナンスパーツ、メンテナンスパーツには入っていないがメンテナンスパーツに近い消耗パーツ。

Bランク : 性能・機能パーツ(センサー、クラッチ等の電気パーツ)、消耗パーツ。

Eランク : 基板含むユニットパーツ。

Dランク : 整備パーツ(外装、パッキング、同梱パーツ)。

Cランク : 上記ランク以外のパーツ(基板の子部品を除いたもの)。

DEFINITION

Rank A : Maintenance parts, and consumable parts which are not included in but closely related to maintenance parts

Rank B : Performance/function parts (sensors, clutches, and other electrical parts), consumable parts

Rank E : Unit parts including PWB

Rank D : Preparation parts (External fitting, packing, parts packed together)

Rank C : Parts other than the above (excluding sub components of PWB)

安全性・信頼性確保のため部品は、必ず正規のものをご使用下さい。

! 印の商品は、安全上重要な部品です。交換をする時は、安全及び性能維持のため必ず指定の部品をご使用下さい。

Because parts marked with "!" is indispensable for the machine safety maintenance and operation, it must be replaced with

the parts specific to the product specification.

F

当モデルのサービス資料には、この資料以外にサービスマニュアル ( 回路図含む ) があります。合わせてご利用下さい。

F Other than this Parts Guide, please refer to documents Service Manual(including Circuit Diagram)of this model.

F Please use the 13 digit code described in the right hand corner of front cover of the document, when you place an order.

F For U.S. only-Use order codes provided in advertising literature. Do not order from parts department.

1

外装部 (Exteriors)

NO. PARTS CODE

1 LSOU-0015QSE3 AX FG N D

2 LSOU-0017QSE2 AP EQ D

3 LPLTP0107QSE1 AH DX N C

4 LPLTP0108QSE1 AH DX N C

5 NGERR0377FCZZ AD DJ C

6 XEPSD30P08X00 AA DD C

7 NGERH0193FCZZ AB DD C

8 MSPRP0059QSZZ AD DJ C

9 MLEVP0035QSE1 AC DJ C

10 VHPGP1A71A1-1 AG DX B

11 DHAI-0070QSZ1 AG DS N C

12 PCOVP0039QSE2 AQ EQ D

13 LSOU-0016QSEZ AP EQ D

14 CFRM-0029RS56 BK HG E

15 GCAB-0051QSZA AT EZ N D

16 GCAB-0022QSE2 AK DX N D

19 MHNG-0013QSZZ AX FG C

20 XEBSE40P12000 AA DD C

21 LSOU-0028QSZB BF GN N D

22 PCUSS0022QSZZ AW FG C

23 PSHEZ0077QSZ1 AE DJ C

24 XEBSE30P08000 AA DD C

25 PSHEZ0078QSZZ AF DS C

26 NROLP0011QSZZ AD DJ C

27 PSPO-0020QSZZ AB DJ C

28 NSFTZ0013QSZZ AF DS C

29 NBRGM0501FCZZ AB DJ C

30 PSHEZ0284QSZZ AB DJ C

31 LPLTM0110QSEZ AF DS C

32 XHBSD30P10000 AA DD C

33 MSPRD0267QSZ1 AC DJ C

34 MSPRD0268QSZ1 AC DJ C

NSFTZ0030QSZZ AL EB C

35

NSFTZ0035QSZ1 AP EQ C

36 NROLP0091GCAZ AE DS C

37 NSFTZ0009QSZZ AE DS C

38 MSPRP0123QSZZ AD DJ C

39 MSPRP0060QSZZ AD DJ C

40 LPLTM0109QSZ1 AG DS C

41 MHNG-0014QSZZ AX FG C

42 PSHEZ0268QSZZ AC DD C

43 PSHEZ0069QSZZ AE DJ C

MLEVF0040QSZZ AD DJ C

44

MLEVF0041QSZZ AD DJ C

45 LPLTM0111QSZZ AC DJ C

46 DHAI-0249QSZ1 BA FX C

CPWBF0084QSE3 BA FX N E

47

CPWBF0084QSE4 BA FX N E

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Original tray 原稿トレイ

Original tray S 原稿トレイ S

Regulation plate F 規制板 F

Regulation plate R 規制板 R

Manual feed rack 手差しラック

Screw(3×8) ビス

UC manual feed gear UC 手差しギヤ

Regulation plate spring 規制板スプリング

Original detect actu ator 原稿検知アクチュエーター

Photo sensor(GP1 A71A1) フォトセンサー

Original tray ha rness 原稿トレイハーネス

Rack cover ラックカバー

Middle tray [AR-RP 6] 中間トレイ

Paper feeding unit 給紙ユニット SPF

Rear exterior 後キャビネット

Front exterior 前キャビネット

SPF hinge L SPF ヒンジ L

Screw(4×12) ビス

Base tray R ベーストレイ R

OC mat OC マット

OC mat sheet F OC マットマイラー F

Screw(3×8) ビス

OC mat sheet R OC マットマイラー R

Paper exit roller 排紙従動ローラー

Sponge 蹴出しスポンジ

Paper exit roller shaft 排紙従動軸

Bearing(B-F6-7) 軸受

Pressure release lever silen ce sheet [AR-RP6] 圧解レバー消音シート

Release plate 圧力解除板

Screw(3×10) ビス

Paper exit spring F 排紙従動スプリング F

Paper exit spring R 排紙従動スプリング R

Pressure release shaft [AR-SP6] 圧力解除軸

Pressure release shaft [AR-RP6] 圧力解除軸

Transport roller 搬送従動ローラー

Transport shaft 搬送従動軸

Transport spring 搬送従動スプリング

Transport spring 搬送従動スプリング

Base tray reinforce plate ベーストレイ補強板

SPF hinge R SPFヒンジ R

PS support myl ar PS 従動マイラー

Base tray sheet ベーストレイマイラー

Pressure release lever [AR-SP6] 圧解レバー

Pressure release lever [A R-RP6] 圧解レバー

Reinforce plate earth 補強板アース

Interface harness 中継ハーネス

SPF interface PWB [AR-SP6] SPF 中継基板

RSPF interface PWB [AR-RP6] RSPF 中継基板

DESCRIPTION

– 1 –

Page 25

1

外装部 (Exteriors)

NO. PARTS CODE

PRICE RANK

Ex. Ja.

NEW

MARK

48 XWVSD40-05000 AA DD C

49 PSHEZ0285QSZZ AB DJ C

50 LX-BZ3008SC0M AA DD C

51 PSPO-0023QSZZ AB DJ C

52 MSPRD0212QSZZ AD DJ C

53 MSPRD0154QSZZ AD DJ C

54 XRESP50-06000 AA DD C

55 XEBSE40P14000 AA DD C

56 RCORF0026FCZZ AL EB C

58 PSHEZ0215QSZZ AD DJ C

59 MSPRD0211QSZZ AC DJ C

60 MLEVP0073QSZ1 AD DJ C

61 DHAI-0248QSZ1 AE DJ N C

62 NROLP0059GCZZ AC DJ C

63 LPLTP0117QSZZ AM EG C

64 MLEVP0036QSZZ AD DJ C

65 MSPRD0162QSZZ AC DJ C

66 PRNGP0090FCZZ AA DJ C

67 NBRGP0041GCZZ AD DJ C

68 RPLU-0011QSZ1 AQ EQ N B

69 PSPO-0004QSZZ AB DJ C

70 XBBSD30P05000 AA DD C

71 MSPRP0150QSZZ AC DJ C

72 PSPO-0003QSZZ AC DJ C

73 XRESP20-04000 AA DD C

74 XHBSE30P08000 AA DD C

77 MSPRC0274QSZZ AC DJ C

78 DHAI-0154QSZ1 AC DJ C

TLABH0267QSZZ AD DJ D

79

TLABH0461QSZZ AG DS N D

80 TLABH0323QSZZ AD DJ D

CSOU-0028RS54 BR LX E

501

CSOU-0028RS55 BS MJ E

502 CSOU-0015RS60 BF GN E

PART

RANK

DESCRIPTION

Washer ワッシャー

Delivery support silence s heet [AR-RP6] 排紙従動消音シート

Screw(3×8) ビス

Damper sponge [AR-RP6] 消音スポンジ

SPF earth spring PS 従動アーススプリング

Earth spring 排紙従動アーススプリング

E type ring E- リング

Screw(4×14) ビス

Core(TFC-16813) コア

Solenoid shee t 圧解ソレノイド放熱シート

Paper exit sensor ACT spring 排紙センサー ACT スプリング

Paper exit sensor AC T lever 排紙センサー ACT レバー

Paper exit sensor h arness 排紙センサーハーネス

Transport rol ler 1 搬送従動ローラー 1

Paper exit gate [AR-RP6] 排紙ゲート

Paper exit gate lever [AR-RP6] 排紙ゲートレバー

Paper exit gate spring [AR-RP6] 排紙ゲートスプリング

E type ring [AR-RP6] E リング

Bearing [AR-RP6] 軸受

Gate solenoid [AR-RP6] ゲートソレノイド

Gate sponge [AR-RP6] 排紙ゲート用スポンジ

Screw [AR-RP6] ビス

Lock spring [AR-RP6] 中間トレイロックスプリング

Gate sponge [AR-RP6] 圧解消音スポンジ

E type ring E- リング

Screw(3×8) ビス

Pressure release lever earth spring (Taiwan only) 圧解レバーアーススプリング

SPF ground wire [AR-SP6] SPFグランド線

Cleaning cautions label (Japan only) 清掃注意ラベル

Cleaning cautions label (U.S.A only) 清掃注意ラベル

Scanner direction direct ions label スキャナ方向指示ラベル

Base tray unit [AR-SP6] ベーストレイユニット

Base tray unit [AR-RP6] ベーストレイユニット

Original tray unit [AR-RP6] 原稿トレイユニット

1

外装部 (Exteriors)

502

71

24

2

3

9

10

9

10

6

12

6

24

13

22

1

6

23

24

6

7

8

71

24

48

48

20

21

63

27

26

73

4

80

79

5

16

20

55

11

19

25

28

72

49

29

31

34

54

33

50

14

20

48

56

66

24

49

74

45

47

67

43

42

75

73

26

27

37

35

38

62

53

36

24

24

15

24

20

32

46

58

70

68

64

69

65

44

42

75

75

54

38

61

10

59

60

48

29

48

20

62

36

62

39

52

37

39

24

24

24

501

51

50

30

78

77

24

41

20

24

40

PRP01632

– 2 –

Page 26

2

給紙部 (Paper feed unit)

NO. PARTS CODE

1 GCAB-0025QSE2 AN EG N D

2 PSPO-0002QSZZ AC DJ C

4 MARMP0003QSZ1 AD DJ C

5 LSTPP0001QSZZ AD DJ C

6 XEBSE30P08000 AA DD C

7 CPWBF0017QSE2 AR EQ N E

8 DHAI-0071QSZ1 AG DS N C

9 MLEVP0090QSZ1 AC DJ C

10 MLEVP0010QSZZ AE DJ C

11 RPLU-0004QSZ2 AQ EQ B

12 XBPSD30P06KS0 AA DD C

13 MARMP0002QSZZ AD DJ C

14 MSPRT0067QSZ1 AB DJ C

15 XRESP40-06000 AA DD C

16 NGERH0073QSZZ AE DS C

17 PPIPP0010QSZZ AD DJ C

18 MSPRC1316FCZ1 AE DS C

19 LBOSZ1508FCZZ AG DX C

20 LBSHZ0303FCZZ AC DJ C

21 NSFTZ0032QSZZ AH DX C

23 NPLYZ0010QSZZ AE DS C

24 XRESP30-06000 AA DD C

25 MSPRT0066QSZ1 AC DJ C

26 PTME-0019QSZZ AD DJ C

27 NROLP0024QSZZ AL EB C

28 NGERH0990FCZZ AB DJ C

29 XPSSP20-07000 AA DD C

30 NGERH0992FCZZ AB DJ C

31 NROLR1051FCZZ AT EZ C

32 NSFTZ0011QSZZ AG DX C

33 MSPRC0230QSZZ AC DJ C

34 MARMP0028QSZZ AE DJ C

35 LFRM-0029QSE1 AQ EQ C

36 MLEVP0037QSZZ AD DJ C

37 MSPRD0133QSZZ AC DJ C

41 MSPRD0132QSZZ AC DJ C

42 MARMM0013QSZZ AF DS C

43 XEBSE30P08000 AA DD C

44 MARMM0014QSZZ AE DS C

45 MSPRD0140QSZZ AC DJ C

46 PGIDM0047QSEZ AN EG C

47 GCAB-0024QSE2 AN EQ N D

48 NBRGP0015QSZZ AC DJ C

49 LBSHZ0006QSZZ AC DJ C

50 NBRGC2033SCZZ AC DJ C

52 LBNDJ2003SCZZ AA DD C

501 CCAB-0024RS52 AW FG E

502 CARMP0028RS51 AY FQ E

901 CFRM-0029RS56 BK HG E

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Open and shut e xterior 開閉キャビネット

Stopper sponge ストッパースポンジ

Stopper arm ストッパーアーム

Paper stopper ペーパーストッパー

Screw(3×8) ビス

Sensor PWB センサー基板

Sensor harness センサーハーネス

Set detect lever セット検知レバー

Open and shut d etect lever actuator 開閉検知アクチュエーター

PU solenoid PU ソレノイド

Screw(3×6KS) ビス

Solenoid arm ソレノイドアーム

Solenoid arm sp ring ソレノイドアームスプリング

E type ring E- リング

Clutch gear(20T) クラッチギヤ

Clutch sleeve R クラッチスリーブ R

MF clutch spring B 手差しクラッチスプリング B

Cam boss A2 カムボス A2

M bushing C Mブッシング C

Clutch shaft クラッチ軸

20MXL pulley 20MXLプーリー

E type ring E- リング

Clutch pawl spring クラッチ爪スプリング

Clutch pawl クラッチ爪

Pick up roller ピックアップローラー

Gear(16T) ギヤ

Spring pin(φ2-7) スプリングピン

Gear(20T) ギヤ

Manual feed roller 手差しローラー

Paper feeding shaft 給紙軸

Paper feeding spring ピックアップアームスプリング

Pick up arm ピックアップアーム

Paper feeding frame 給紙フレーム

Open and shut d etect lever 開閉検知レバー

Open and shut detect spring 開閉検知レバースプリング

JAM release spring JAM 解除スプリング

U-turn PG arm F U ターン PG アーム F

Screw(3×8) ビス

U-turn PG arm R U ターン PG アーム R

JAM release spring R JAM 解除スプリング R

U-turn paper guide U ターンペーパーガイド

U-turn PG exterior U ターン PG キャビネット

Bearing 軸受

Bearing 軸受

Bearing 軸受

Cable band(PLT1M ) ケーブルバンド

U-turn PG uint U ターン PG ユニット

Pick-up unit ピックアップユニット

(Unit)

Paper feeding unit 給紙ユニット SPF

DESCRIPTION

– 3 –

Page 27

2

給紙部 (Paper feed unit)

1

2

15

19

11

52

4

15

16

17

18

29

21

7

37

45

46

23

24

43

44

30

15

32

43

20

25

33

12

50

12

26

49

502

14

29

13

10

28

30

48

6

27

29

34

31

29

6

9

8

36

5

9

35

6

42

43

41

43

501

43

47

PRP01633

– 4 –

Page 28

3

搬送部 (Transport unit)

NO. PARTS CODE

1 PSHEZ2174FCZZ AB DD C

4 MSPRC0062QSZZ AC DJ C

5 PGIDM0045QSE5 AN EG C

6 NROLM0041QSZ1 AR EQ C

7 PBRSS0008QSZ1 AH DX B

8 PGIDH0046QSZ1 AK EB C

9 XEBSE30P08000 AA DD C

10 PSPO-0022QSZZ AB DJ C

DHAI-0250QSZ1 AP EQ N C

11

DHAI-0251QSZ1 AQ EQ N C

12 LBNDJ2003SCZZ AA DD C

13 RMOTP0020QSZZ BC GJ B

14 XBBSD30P05000 AA DD C

15 QCNCM1003FCZZ AD DJ C

16 QCNCM1004FCZZ AD DJ C

17 QCNCM0999FCZZ AC DJ C

18 LFRM-0030QSZ1 AG DX C

19 LHLDW1263FCZZ AC DJ C

20 XRESP50-06000 AA DD C

21 PSHEP3029FCZZ AA DD C

22 NBLTT0027QSZZ AF DS B

23 NGERH0116QSZ1 AD DJ C

24 XPSSP20-09000 AA DD C

25 NBRGM0501FCZZ AB DJ C

26 NGERH0079QSZZ AD DJ C

27 XRESP40-06000 AA DD C

28 NGERH0117QSZZ AK DX C

29 NBRGC0017QSZZ AC DJ C

31 LFRM-0028QSZ1 AD DJ C

32 MSPRP0065QSZZ AD DJ C

33 PGIDM0043QSE1 AQ EQ C

34 PTME-0015QSZZ AD DJ C

35 RDTCT0006QSZZ AL EB B

36 MSPRC0063QSZZ AB DJ C

39 JKNBZ0005QSZZ AE DJ C

40 NROLR0101QSZZ AS EQ N C

41 PGIDH0044QSZZ AK DX C

42 PSHEZ0397QSZZ AF DS C

43 NROLR0102QSZZ AS EZ N C

44 PSHEZ0071QSZZ AE DJ C

45 XHBSE30P08000 AA DD C

46 XEBSD30P10000 AA DD C

47 PTPE-0018QSZZ AC DJ C

50 LPLTP0131QSZZ AD DJ C

51 MLEVP0047QSE1 AD DJ N C

52 MSPRC0153QSZZ AB DJ C

53 VHPGP1A71A1-1 AG DX B

55 PSHEZ0252QSZZ AF DS C

56 JKNBZ0007QSZZ AD DJ C

57 NPLYZ0019QSZZ AE DJ C

58 PCLC-0013QSZZ AT EZ B

59 NBLTT0028QSZZ AF DS B

60 NPLYZ0018QSZZ AE DJ C

61 LPLTP0118QSZZ AK DX C

62 RPLU-0015QSZ1 AR EQ N B

63 PSPO-0004QSZZ AB DJ C

64 LBNDJ0043FCZ1 AA DJ C

66 NKOM-0008QSZZ AC DJ N C

67 LX-BZ7038XCZZ AB DD C

69 LX-WZ2011SCZZ AA DD C

72 LPINS0019QSZZ AA DJ C

73 MLEVP0078QSZZ AC DJ C

CGIDM0043RS59 BM HV N E

501

CGIDM0043RS60 BM HR N E

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Paper feeding sheet 給紙用シート

Pressure spring 圧着スプリング

PF paper guide upper 給紙ペーパーガイド 上

Paper exit roller 排紙ローラー

Discharge brush 除電ブラシ

PF paper guid e lower 給紙ペーパーガイド 下

Screw(3×8) ビス

Damper sponge [AR-RP6] 消音スポンジ

Separator harnes s [AR-SP6] 分岐ハーネス

Separator harnes s [AR-RP6] 分岐ハーネス

Cable band(PLT1M ) ケーブルバンド

SPF motor SPF モーター

Screw(3×5) ビス

Connector(BU06P-TR-PH) コネクター

Connector(BU07P-TR-PH) コネクター

Connector(BU02P-TR-PH) コネクター

Drive frame 駆動フレーム

Wire holder(EDS0607M) ワイヤーサドル

E type ring E- リング

Flange sheet フランジマイラー

Belt(B90MXL4.8) ベルト

Gear Gear(48T/ 25P) ギヤ

Spring pin(φ2-9) スプリングピン

Bearing(B-F6-7) 軸受

Gear(30T) ギヤ

E type ring E- リング

Gear(48T) ギヤ

Bearing R 軸受 R

Frame R フレーム R

Open and shut lock sp ring 開閉ロックスプリング

Transport pape r guide R 搬送ペーパーガイド R

U-turn PG lock pawl U ターン PG ロック爪

Inlet detect sensor 入紙検知センサー

Delivery PG spring 排紙 PG スプリング

JAM release knob(22P) JAM 解除ノブ

Transport roller 搬送ローラー

Paper exit guide R 排紙ペーパーガイド R

White sheet 白マイラー

PS roller PS ローラ -

Derively PG myler [AR-SP6] 排紙 PG マイラー

Screw(3×8) ビス

Screw(3×10) ビス

Motor earth tape モーターアーステープ

Book sensor fixing plate ブックセンサー取付板

Book sensor actuator ブックセンサーアクチュエーター

Book sensor spring ブツクセンサースプリング

Photo sensor(GP1 A71A1) フォトセンサー

Front separate sheet 前捌きシート

PS JAM release knob PS JAM 解除ノブ

PS pulley PS プーリー

PS clutch PS クラッチ SPF

Belt(B76MXL4.0) ベルト

PS cupling pulley PSカップリングプーリー

Reverse gate [AR-RP6] 反転ゲート

Pressure release solnoid [AR-RP6] 圧解ソレノイド

Gate sponge [AR-RP6] 排紙ゲート用スポンジ

Cable band ケーブルバンド

Tension roller テンションコロ

Screw ビス

Poly slider ポリスライダー

SP pin(2.5×9) SPピン

SPF lever [AR-SP6] SPF レバー

SPF Transport unit [AR-SP6] 搬送ユニット SPF

RSPF Transport un it [AR-RP6] 搬送ユニット RSPF

DESCRIPTION

– 5 –

Page 29

3

搬送部 (Transport unit)

55

11

1

5

32

3

4

6

7

8

32

9

33

12

45

73

45

14

14

25

13

18

23

24

14

47

15

22

26

502

12

34

21

28

31

10

63

62

12

12

45

19

20

21

69

60

17

27

68

66

65

16

72

58

67

20

57

20

20

29

9

59

25

9

20

46

53

64

PRP01634

20

39

74

25

20

75

51

50

52

45

25

9

24

56

76

45

44

501

25

34

36

40

44

35

44

61

36

42

41

43

– 6 –

Page 30

4

梱包及び付属品 (Packing material & Accesories)[AR-SP6]

NO. PARTS CODE

2 SPAKA0086QSZZ AS EQ D

3 SPAKA0087QSZ1 AV FG D

4 SPAKA0152QSZZ AG DX D

5 SSAKH3012KCZZ AD DJ D

6 SSAKZ0004QSZZ AA DD D

7 SPAKA0088QSZZ AE DS D

TCADZ0257QSZZ AG DS N D

8

TCADZ0251QSZZ AD DJ N D

9 TLABH0323QSZZ AD DJ D

10 LSOU-0016QSEZ AP EQ D

11 CFIX-0022RS51 AX FG N E

12 SSAKA1341QCZZ AA DD D

4

梱包及び付属品 (Packing material & Accesories)[AR-SP6]

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Add L アド L

Add R アド R

Top add 天パッド

Vinyl bag(790×740) ポリ袋

Vinyl bag(120×450) ポリ袋

Protect packing cushion 保護材

Inst. manual (Japan) 設置手順書

Inst. manual (except Japan) 設置手順書

Scanner direction direct ions label スキャナ方向指示ラベル

Middle tray [AR-RP 6] 中間トレイ

SPF grass fixing unit SPF ガラス固定ユニット

Vinyl bag(180×380) [AR-RP6] ポリ袋

DESCRIPTION

10

12

8

7

9

6

4

2

7

3

1

11

– 7 –

PRP01635

Page 31

■

索引 (Index)

PARTS CODE

[C]

CARMP0028RS51

CCAB-0024RS52

CFIX-0022RS51

CFRM-0029RS56

CGIDM0043RS59

CGIDM0043RS60

CPWBF0017QSE2

CPWBF0084QSE3

CPWBF0084QSE4

CSOU-0015RS60

CSOU-0028RS54

CSOU-0028RS55

DHAI-0070QSZ1

DHAI-0071QSZ1

DHAI-0154QSZ1

DHAI-0248QSZ1

DHAI-0249QSZ1

DHAI-0250QSZ1

DHAI-0251QSZ1

GCAB-0022QSE2

GCAB-0024QSE2

GCAB-0025QSE2

GCAB-0051QSZA

JKNBZ0005QSZZ

JKNBZ0007QSZZ

LBNDJ0043FCZ1

LBNDJ2003SCZZ

LBOSZ1508FCZZ

LBSHZ0006QSZZ

LBSHZ0303FCZZ

LFRM-0028QSZ1

LFRM-0029QSE1

LFRM-0030QSZ1

LHLDW1263FCZZ

LPINS0019QSZZ

LPLTM0109QSZ1

LPLTM0110QSEZ

LPLTM0111QSZZ

LPLTP0107QSE1

LPLTP0108QSE1

LPLTP0117QSZZ

LPLTP0118QSZZ

LPLTP0131QSZZ

LSOU-0015QSE3

LSOU-0016QSEZ

LSOU-0017QSE2

LSOU-0028QSZB

LSTPP0001QSZZ

LX-BZ3008SC0M

LX-BZ7038XCZZ

LX-WZ2011SCZZ

MARMM0013QSZZ

MARMM0014QSZZ

MARMP0002QSZZ

MARMP0003QSZ1

MARMP0028QSZZ

MHNG-0013QSZZ

MHNG-0014QSZZ

MLEVF0040QSZZ

MLEVF0041QSZZ

MLEVP0010QSZZ

MLEVP0035QSE1

MLEVP0036QSZZ

MLEVP0037QSZZ

MLEVP0047QSE1

MLEVP0073QSZ1

MLEVP0078QSZZ

MLEVP0090QSZ1

MSPRC0062QSZZ

MSPRC0063QSZZ

"

[D]

[G]

[J]

[L]

"

"

[M]

JAPAN ONLY

ORDER CODE

578 240 0103 2- 502 AY FQ E

578 107 0563 2- 501 AW FG E

578 211 0087 4- 11 AX FG N E

578 213 0475 1- 14 BK HG E

578 213 0475 2- 901 BK HG E

578 345 0453 3- 501 BM HV N E

578 345 0454 3- 501 BM HR N E

578 684 1119 2- 7 AR EQ N E

578 684 1120 1- 47 BA FX N E

578 684 1121 1- 47 BA FX N E

578 226 0243 1- 502 BF GN E

578 226 0244 1- 501 BR LX E

578 226 0245 1- 501 BS MJ E

578 542 0334 1- 11 AG DS N C

578 542 0335 2- 8 AG DS N C

578 542 0341 1- 78 AC DJ C

578 542 0336 1- 61 AE DJ N C

578 542 0337 1- 46 BA FX C

578 542 0346 3- 11 AP EQ N C

578 542 0338 3- 11 AQ EQ N C

578 107 0557 1- 16 AK DX N D

578 107 0558 2- 47 AN EQ N D

578 107 0562 2- 1 AN EG N D

578 107 0559 1- 15 AT EZ N D

572 174 0329 3- 39 AE DJ C

578 174 0155 3- 56 AD DJ C

572 201 0125 3- 64 AA DJ C

541 933 1001 2- 52 AA DD C

541 933 1001 3- 12 AA DD C

572 202 0378 2- 19 AG DX C

578 204 0017 2- 49 AC DJ C

572 204 0302 2- 20 AC DJ C

578 213 0297 3- 31 AD DJ C

578 213 0322 2- 35 AQ EQ C

578 213 0306 3- 18 AG DX C

572 214 1529 3- 19 AC DJ C

578 218 0049 3- 72 AA DJ C

578 221 0600 1- 40 AG DS C

578 221 0601 1- 31 AF DS C

572 221 7096 1- 45 AC DJ C

578 221 0777 1- 3 AH DX N C

578 221 0778 1- 4 AH DX N C

572 221 7095 1- 63 AM EG C

572 221 7097 3- 61 AK DX C

572 221 7142 3- 50 AD DJ C

578 226 0241 1- 1 AX FG N D

578 226 0121 1- 13 AP EQ D

578 226 0121 4- 10 AP EQ D

578 226 0145 1- 2 AP EQ D

578 226 0242 1- 21 BF GN N D

572 230 0494 2- 5 AD DJ C

572 970 0011 1- 50 AA DD C

569 970 0060 3- 67 AB DD C

595 990 0031 3- 69 AA DD C

572 240 0347 2- 42 AF DS C

572 240 0356 2- 44 AE DS C

572 240 0338 2- 13 AD DJ C

572 240 0358 2- 4 AD DJ C

578 240 0080 2- 34 AE DJ C

578 246 0024 1- 19 AX FG C

578 246 0025 1- 41 AX FG C

572 248 1134 1- 44 AD DJ C

572 248 1148 1- 44 AD DJ C

572 248 1136 2- 10 AE DJ C

572 248 1225 1- 9 AC DJ C

572 248 1158 1- 64 AD DJ C

572 248 1146 2- 36 AD DJ C

578 248 0259 3- 51 AD DJ N C

578 248 0256 1- 60 AD DJ C

578 248 0231 3- 73 AC DJ C

578 248 0262 2- 9 AC DJ C

572 258 3213 3- 4 AC DJ C

572 258 3214 3- 36 AB DJ C

NO.

PRICE R.

Ex. Ja.

NEW P/R

PARTS CODE

MSPRC0153QSZZ

MSPRC0230QSZZ

MSPRC0274QSZZ

MSPRC1316FCZ1

MSPRD0132QSZZ

MSPRD0133QSZZ

MSPRD0140QSZZ

MSPRD0154QSZZ

MSPRD0162QSZZ

MSPRD0211QSZZ

MSPRD0212QSZZ

MSPRD0267QSZ1

MSPRD0268QSZ1

MSPRP0059QSZZ

MSPRP0060QSZZ

MSPRP0065QSZZ

MSPRP0123QSZZ

MSPRP0150QSZZ

MSPRT0066QSZ1

MSPRT0067QSZ1

[N]

NBLTT0027QSZZ

NBLTT0028QSZZ

NBRGC0017QSZZ

NBRGC2033SCZZ

NBRGM0501FCZZ

"

NBRGP0015QSZZ

NBRGP0041GCZZ

NGERH0073QSZZ

NGERH0079QSZZ

NGERH0116QSZ1

NGERH0117QSZZ

NGERH0193FCZZ

NGERH0990FCZZ

NGERH0992FCZZ

NGERR0377FCZZ

NKOM-0008QSZZ

NPLYZ0010QSZZ

NPLYZ0018QSZZ

NPLYZ0019QSZZ

NROLM0041QSZ1

NROLP0011QSZZ

NROLP0024QSZZ

NROLP0059GCZZ

NROLP0091GCAZ

NROLR0101QSZZ

NROLR0102QSZZ

NROLR1051FCZZ

NSFTZ0009QSZZ

NSFTZ0011QSZZ

NSFTZ0013QSZZ

NSFTZ0030QSZZ

NSFTZ0032QSZZ

NSFTZ0035QSZ1

[P]

PBRSS0008QSZ1

PCLC-0013QSZZ

PCOVP0039QSE2

PCUSS0022QSZZ

PGIDH0044QSZZ

PGIDH0046QSZ1

PGIDM0043QSE1

PGIDM0045QSE5

PGIDM0047QSEZ

PPIPP0010QSZZ

PRNGP0090FCZZ

PSHEP3029FCZZ

PSHEZ0069QSZZ

PSHEZ0071QSZZ

PSHEZ0077QSZ1

PSHEZ0078QSZZ

PSHEZ0215QSZZ

PSHEZ0252QSZZ

PSHEZ0268QSZZ

PSHEZ0284QSZZ

PSHEZ0285QSZZ

PSHEZ0397QSZZ

PSHEZ2174FCZZ

PSPO-0002QSZZ

PSPO-0003QSZZ

JAPAN ONLY

ORDER CODE

572 258 3310 3- 52 AB DJ C

578 258 0625 2- 33 AC DJ C

578 258 0736 1- 77 AC DJ C

572 258 2132 2- 18 AE DS C

572 258 3258 2- 41 AC DJ C

572 258 3259 2- 37 AC DJ C

572 258 3263 2- 45 AC DJ C

572 258 3315 1- 53 AD DJ C

578 258 0550 1- 65 AC DJ C

578 258 0650 1- 59 AC DJ C

578 258 0651 1- 52 AD DJ C

578 258 0737 1- 33 AC DJ C

578 258 0738 1- 34 AC DJ C

572 258 3217 1- 8 AD DJ C

572 258 3227 1- 39 AD DJ C

572 258 3218 3- 32 AD DJ C

572 258 3232 1- 38 AD DJ C

572 258 3309 1- 71 AC DJ C

572 258 3293 2- 25 AC DJ C

572 258 3294 2- 14 AB DJ C

578 271 0063 3- 22 AF DS B

578 271 0064 3- 59 AF DS B

578 272 0127 3- 29 AC DJ C

574 272 0001 2- 50 AC DJ C

572 272 0461 1- 29 AB DJ C

572 272 0461 3- 25 AB DJ C

578 272 0135 2- 48 AC DJ C

578 272 0061 1- 67 AD DJ C

572 281 1803 2- 16 AE DS C

572 281 1804 3- 26 AD DJ C

578 281 0382 3- 23 AD DJ C

578 281 0363 3- 28 AK DX C

572 281 0318 1- 7 AB DD C

572 281 1125 2- 28 AB DJ C

572 281 1127 2- 30 AB DJ C

572 281 0271 1- 5 AD DJ C

578 273 0006 3- 66 AC DJ N C

572 284 0715 2- 23 AE DS C

578 284 0058 3- 60 AE DJ C

578 284 0059 3- 57 AE DJ C

578 287 0382 3- 6 AR EQ C

572 287 1880 1- 26 AD DJ C

572 287 1881 2- 27 AL EB C

578 287 0181 1- 62 AC DJ C

578 287 0214 1- 36 AE DS C

578 287 0403 3- 40 AS EQ N C

578 287 0404 3- 43 AS EZ N C

572 287 1365 2- 31 AT EZ C

572 290 2457 1- 37 AE DS C

572 290 2459 2- 32 AG DX C

572 290 2478 1- 28 AF DS C

572 290 2479 1- 35 AL EB C

572 290 2480 2- 21 AH DX C

578 290 0181 1- 35 AP EQ C

578 310 0062 3- 7 AH DX B

578 316 0040 3- 58 AT EZ B

578 323 0206 1- 12 AQ EQ D

578 326 0028 1- 22 AW FG C

572 345 3190 3- 41 AK DX C

578 345 0330 3- 8 AK EB C

578 345 0341 3- 33 AQ EQ C

578 345 0433 3- 5 AN EG C

578 345 0375 2- 46 AN EG C

572 395 0217 2- 17 AD DJ C

572 399 0186 1- 66 AA DJ C

572 403 1107 3- 21 AA DD C

572 403 4396 1- 43 AE DJ C

572 403 4398 3- 44 AE DJ C

572 403 4466 1- 23 AE DJ C

572 403 4400 1- 25 AF DS C

578 403 0622 1- 58 AD DJ C

578 403 0615 3- 55 AF DS C

578 403 0646 1- 42 AC DD C

578 403 0658 1- 30 AB DJ C

578 403 0659 1- 49 AB DJ C

578 403 0847 3- 42 AF DS C

572 403 2095 3- 1 AB DD C

572 415 0002 2- 2 AC DJ C

572 415 0003 1- 72 AC DJ C

NO.

PRICE R.

Ex. Ja.

NEW P/R

– 8 –

Page 32

PARTS CODE

PSPO-0004QSZZ

"

PSPO-0020QSZZ

PSPO-0022QSZZ

PSPO-0023QSZZ

PTME-0015QSZZ

PTME-0019QSZZ

PTPE-0018QSZZ

[Q]

QCNCM0999FCZZ

QCNCM1003FCZZ

QCNCM1004FCZZ

[R]

RCORF0026FCZZ

RDTCT0006QSZZ

RMOTP0020QSZZ

RPLU-0004QSZ2

RPLU-0011QSZ1

RPLU-0015QSZ1

[S]

SPAKA0086QSZZ

SPAKA0087QSZ1

SPAKA0088QSZZ

SPAKA0152QSZZ

SSAKA1341QCZZ

SSAKH3012KCZZ

SSAKZ0004QSZZ

[T]

TCADZ0251QSZZ

TCADZ0257QSZZ

TLABH0267QSZZ

TLABH0323QSZZ

"

TLABH0461QSZZ

[V]

VHPGP1A71A1-1

"

[X]

XBBSD30P05000

"

XBPSD30P06KS0

XEBSD30P10000

XEBSE30P08000

"

"

"

XEBSE40P12000

XEBSE40P14000

XEPSD30P08X00

XHBSD30P10000

XHBSE30P08000

"

XPSSP20-07000

XPSSP20-09000

XRESP20-04000

XRESP30-06000

XRESP40-06000

"

XRESP50-06000

"

XWVSD40-05000

JAPAN ONLY

ORDER CODE

572 415 0004 1- 69 AB DJ C

572 415 0004 3- 63 AB DJ C

578 415 0012 1- 27 AB DJ C

578 415 0015 3- 10 AB DJ C

578 415 0016 1- 51 AB DJ C

572 420 0305 3- 34 AD DJ C

578 420 0040 2- 26 AD DJ C

572 423 0224 3- 47 AC DJ C

572 510 1004 3- 17 AC DJ C

572 510 1053 3- 15 AD DJ C

572 510 1054 3- 16 AD DJ C

572 615 0040 1- 56 AL EB C

572 618 0138 3- 35 AL EB B

572 630 0969 3- 13 BC GJ B

578 647 0026 2- 11 AQ EQ B

578 647 0027 1- 68 AQ EQ N B

578 647 0028 3- 62 AR EQ N B

572 902 1479 4- 2 AS EQ D

572 902 1522 4- 3 AV FG D

572 902 1481 4- 7 AE DS D

572 902 1484 4- 4 AG DX D

572 906 0053 4- 12 AA DD D

588 906 0009 4- 5 AD DJ D

578 906 0017 4- 6 AA DD D

578 913 0290 4- 8 AD DJ N D

578 913 0292 4- 8 AG DS N D

578 917 0513 1- 79 AD DJ D

578 917 0587 1- 80 AD DJ D

578 917 0587 4- 9 AD DJ D

578 917 0619 1- 79 AG DS N D

572 574 0114 1- 10 AG DX B

572 574 0114 3- 53 AG DX B

596 970 0142 1- 70 AA DD C

596 970 0142 3- 14 AA DD C

541 970 0016 2- 12 AA DD C

578 970 0106 3- 46 AA DD C

595 970 0121 1- 24 AA DD C

595 970 0121 2- 43 AA DD C

595 970 0121 2- 6 AA DD C

595 970 0121 3- 9 AA DD C

572 970 1447 1- 20 AA DD C

572 970 1506 1- 55 AA DD C

595 970 0136 1- 6 AA DD C

572 970 0530 1- 32 AA DD C

595 970 0163 1- 74 AA DD C

595 970 0163 3- 45 AA DD C

572 218 0417 2- 29 AA DD C

572 218 0552 3- 24 AA DD C

507 399 5004 1- 73 AA DD C

541 399 5002 2- 24 AA DD C

509 399 5001 2- 15 AA DD C

509 399 5001 3- 27 AA DD C

572 399 0063 1- 54 AA DD C

572 399 0063 3- 20 AA DD C

572 990 0241 1- 48 AA DD C

NO.

PRICE R.

Ex. Ja.

NEW P/R

PARTS CODE

JAPAN ONLY

ORDER CODE

NO.

PRICE R.

Ex. Ja.

NEW P/R

– 9 –

Page 33

Page 34

Page 35

CAUTION FOR BATTERY REPLACEMENT

(Danish) ADVARSEL !

Lithiumbatteri - Eksplosionsfare ved fejlagtig håndtering.

(English) Caution !

Dispose of used batteries according to manufacturer's instructions.

(Finnish) VAROITUS

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

(French) ATTENTION

ll y a danger d'explosion s'il y a remplacement incor re ct

de la batterie. Remplacer uniquement avec une batterie du

Mettre au rébut les batteries usagées conformément aux

Udskiftning må kun ske med batteri

Levér det brugte batteri tilbage til leverandoren.

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

Paristo voi räjähtää,jos se on virheellisesti asennettu.

tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden

même type on d'un type équivalent recommandé par

af samme fabrikat og type.

recommended by the manufacturer.

mukaisesti.

le constructeur.

instructions du fabricant.

(Swedish) VARNING

(German) Achtung

Als Ersatzbatterien dürfen nur Batterien vom gleichen Typ oder

(For USA,CANADA)

Contains lithium-ion battery. Mu st be disposed of properly.

Remove the battery from the product and contact

agencies for information on recycling and disposal options.

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent

typ som rekornmenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

Explosionsgefahr bei Verwendung inkorrekter Batterien.

vom Hersteller empfohlene Batterien verwendet werden.

Entsorgung der gebrauchten Batterien nur nach den vom

Hersteller angegebenen Anwerisugen.

CAUTION FOR BATTERY DISPOSAL

Instruktion.

federal or state environmental

Page 36

q

COPYRIGHT

No part of this publication may be reproduced,

electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission of the publisher.

2003 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

stored in a retrieval system, or transmitted.

In any form or by any means,

SHARP CORPORATION

Digital Document Systems Group

Products Quality Assurance Department

Yamatokoriyama, Nara 639-1186, Japan

2003 June Printed in Japan t

Loading...

Loading...