Page 1

CONTENTS

CODE: 00ZARSP2//A1E

Digital copier

Single Pass Feeder

(SPF)

MODEL AR-SP2

[1] PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

[2] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

[3] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . 1

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE . . . . . . . . . . . . . 5

[5] OPERATIONAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

[6] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . 7

[7] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

[8] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Parts marked with "!" is important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

[1] PRODUCT OUTLINE

This unit is installed to the top of the copier to feed document automatically. Documents are automatically transported to the copier to

allow continuous copying.

[2] SPECIFICATIONS

[3] UNP ACKING AND

INSTALLATION

1. Unpacking

Document set

direction

Document set

position

Document transport

system

Document feed

sequence

Document size AB series: A3 ∼ A5

Document weight 56 ∼ 90g/cm

Document set

quantity

Dimensions 583mm (W) × 435mm (D) × 131mm (H)

Weight About 5.4 Kg

Power source Supplied from the copier.

Document size

detection

Detection size Japan: A3, B4, A4, A4R, B5, B5R

Multi copy Models without memory:

Document mixture Mixture paper feed:

Random paper feed Unavailable

Document reverse None

Display section

(LED)

Document

replacement speed

Face up

Center reference

Sheet through type

Top take\up

Inch series: 11 × 17 ∼ 8.5 × 5.5

30 sheets (30 sheets, 90 g/cm2)

Max. thickness 4mm

Document feed tray upper

Inch series: 11 × 17, 8.5 × 14, 8.5 × 11, 8.5 × 11R,

8.5 × 5.5

EX AB series: A3, B4, A4, A4R, A5

S → S unavailable S → D unavailable

Models with memory copy:

S → S allowed S → D unavailable

With the electronic sort board:

S → S allowed S → D allowed

Copy mode: Unavailable

FAX mode: Allowed (Same width)

None

S → S: 16-sheet machine

2

(Duplex copy model only)

(Duplex copy model only)

(Duplex copy model only)

16 sheets/min (Document replacement rate

100%)

20-sheet machine

18 sheets/min (Document replacement rate

90%)

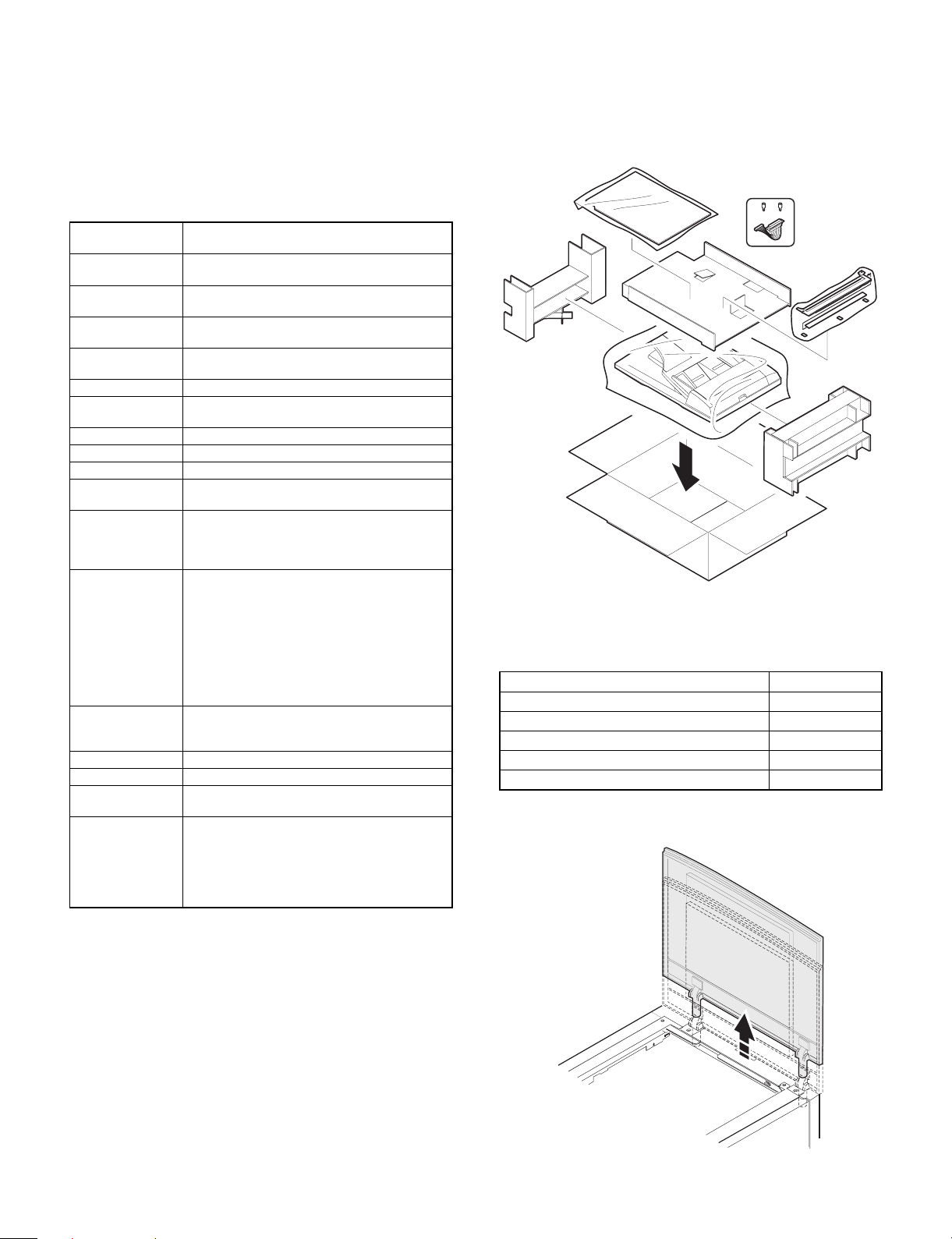

2. Installation

(1) Package contents

Name Quantity

OC matt 1

SPF glass holding cover 1

SPF harness 1

Step screw 2

Installation Manual 1

1) Remove the document cover.

Lift the document cover and remove it from the copier.

– 1 –

Page 3

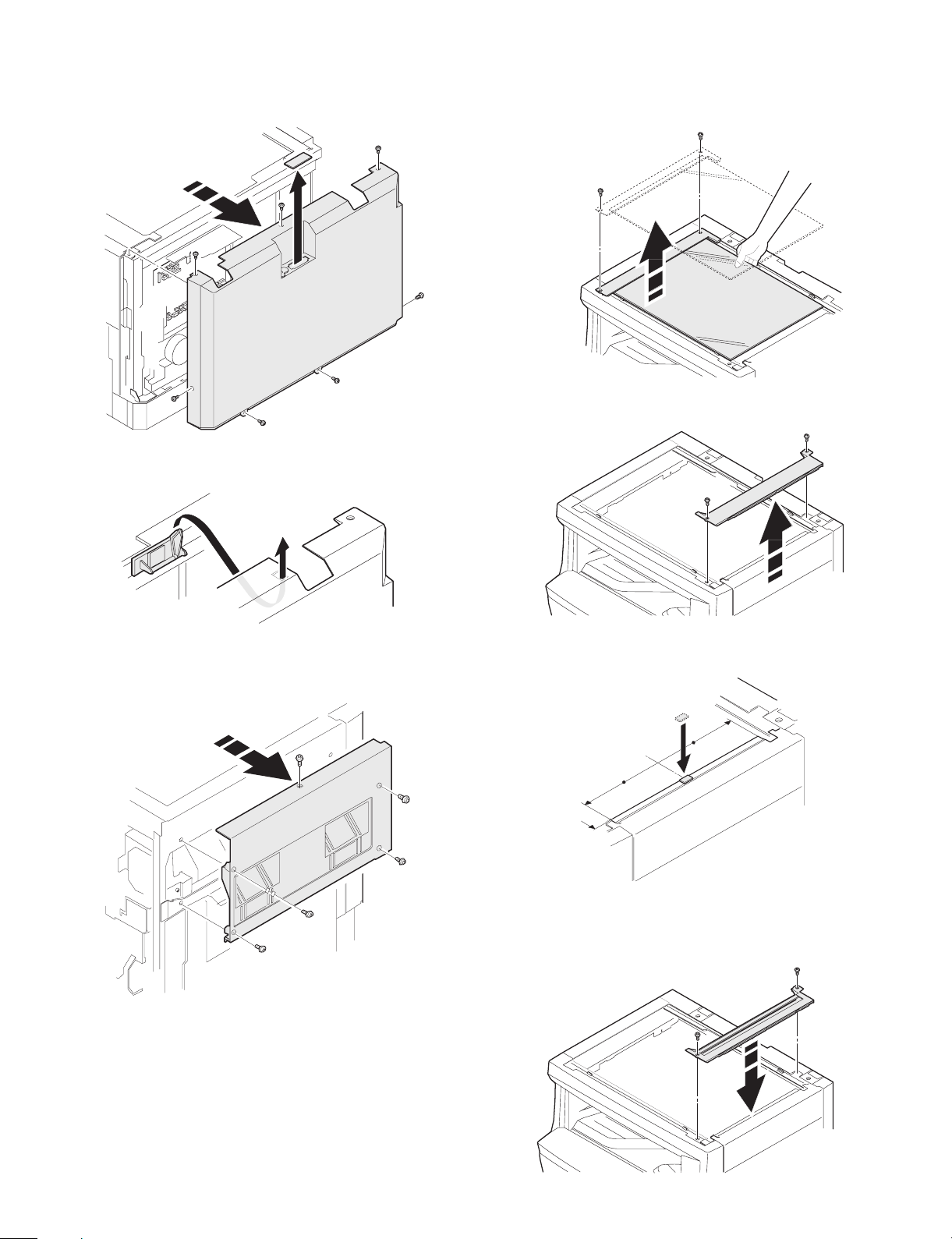

2) Remove the rear cabinet of the copier.

Remove the screws and remove the cabinet.

Remove the connector cover.

* If the open/close detection is attached, be careful not to break the

actuator.

4) Remove the document glass holder (left side) and the

document glass.

Remove the screws and carefully remove the document glass holder

(left side) and the document glass together.

5) Remove the document glass holder cover (right side).

Remove the screws.

3) Remove the right cabinet.

Remove the screws.

6) Attach the cushion.

* Attach the cushion so that it does not extend from the edge of the

plate.

7) Attach the SPF glass holder cover.

Attach the document glass holder (left side) and the document glass

in the reverse procedure of 3), and fix them with the screws which

were removed in procedure 4.

– 2 –

Page 4

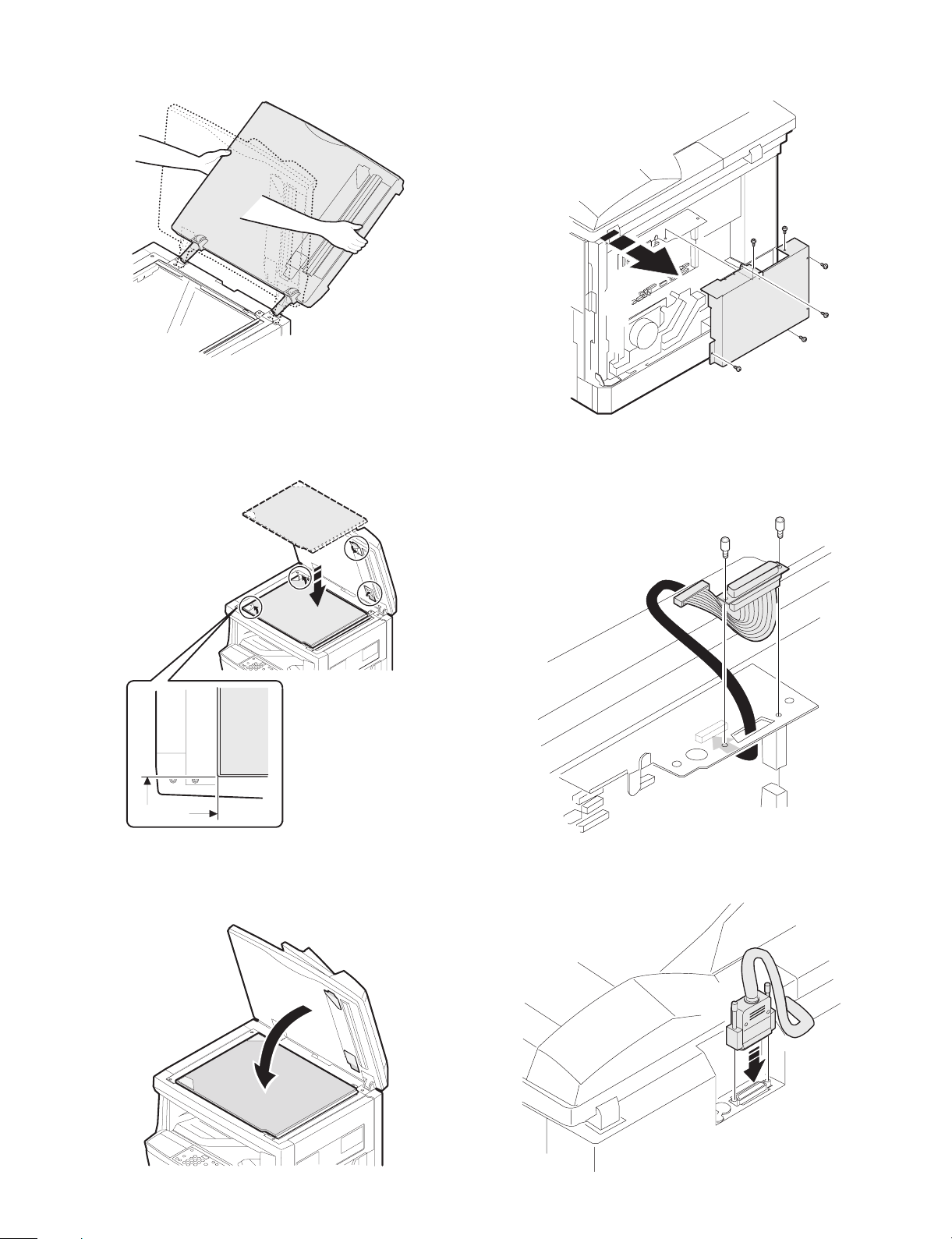

8) Install the SPF to the copier.

Tilt the SPF backward and insert into the hinge guide.

9) Set the document matt.

Remove the seals of the SPF side duplex tape.

Remove duplex tape seal of the document matt.

Set the document matt to the following reference position.

* The document matt must not cover the glass holder plate and the

front cabinet.

11) Remove the copier shield plate.

Remove the screws.

12) Install the SPF harness (Included together with the

unit).

Pass the harness through the plate hole from the above, and connect

it to the main PWB connector (CN11) inside the copier.

Fix it with the hex cap screws.

10) Fit and attach the SPF and the document matt

together.

Tilt the SPF and attach with duplex tape.

Be careful that the document matt must not be shifted.

13) Install the SPF connector.

Connect the interface harness extended from the SPF, and fix with

the hand screws.

– 3 –

Page 5

14) Remove the fixing tape.

Remove the fixing tape.

• When the set value is decreased, the image is shifted to the

front side.

Center line of image

Center line

of paper

Insert the power plug of the copier to the power outlet,

turn on the power switch, and perform the following

procedures.

15) Perform the magnification ratio adjustment.

Set a document on the automatic document feeder and make a copy.

Then set a document on the document glass and make a copy.

* If the copy magnification ratio of the copy made with the automatic

document feeder is shifted compared with the copy image made

with the document glass, perform the following procedure.

1. Execute SIM 48-5 with the key operations on the copier.

[Program key]

C

0 4 8 0 5

2. Enter the set value with the keys on the operation panel to per-

form the magnification ratio adjustment, and make a copy with the

automatic document feeder again to check that the magnification

ratio is proper.

After completion of the adjustment, press the key to cancel the

CA

mode.

16) Perform the center shift adjustment.

Set a document on the automatic document feeder and make a copy.

* If the center of the copy image is shifted, perform the following

procedure.

1. Execute SIM 50-16 with the key operations on the copier.

After completion of the adjustment, press the key to cancel the

CA

mode.

17) Perform the lead edge adjustment.

Set a document on the automatic document feeder and make a copy.

Then set document on the document glass and make a copy.

* If the lead edge of the copy image made with the automatic docu-

ment feeder is shifted from that made with the document glass,

perform the following adjustment.

1. Execute SIM 52-16 with the key operations on the copier.

[Program key]

C 6

0 5 2

1

2. Select the SPF item on the display with [↑] and [↓] keys.

3. Enter the set value with the keys on the operation panel to perform the lead edge adjustment, and make a copy to check that

the lead edge is not shifted.

• When the set value is increased, the copy image moves for-

ward.

• When the set value is decreased, the copy image moves back-

ward.

After completion of the adjustment, press the key to cancel the

mode.

CA

[Program key]

C 6

0 5 0

1

2. Enter the set value with the keys on the operation panel to perform the center shift adjustment, and make a copy again to check

that the center is not shifted.

• When the set value is increased, the image is shifted to the

rear side.

Center line of image

Center line

of paper

– 4 –

Page 6

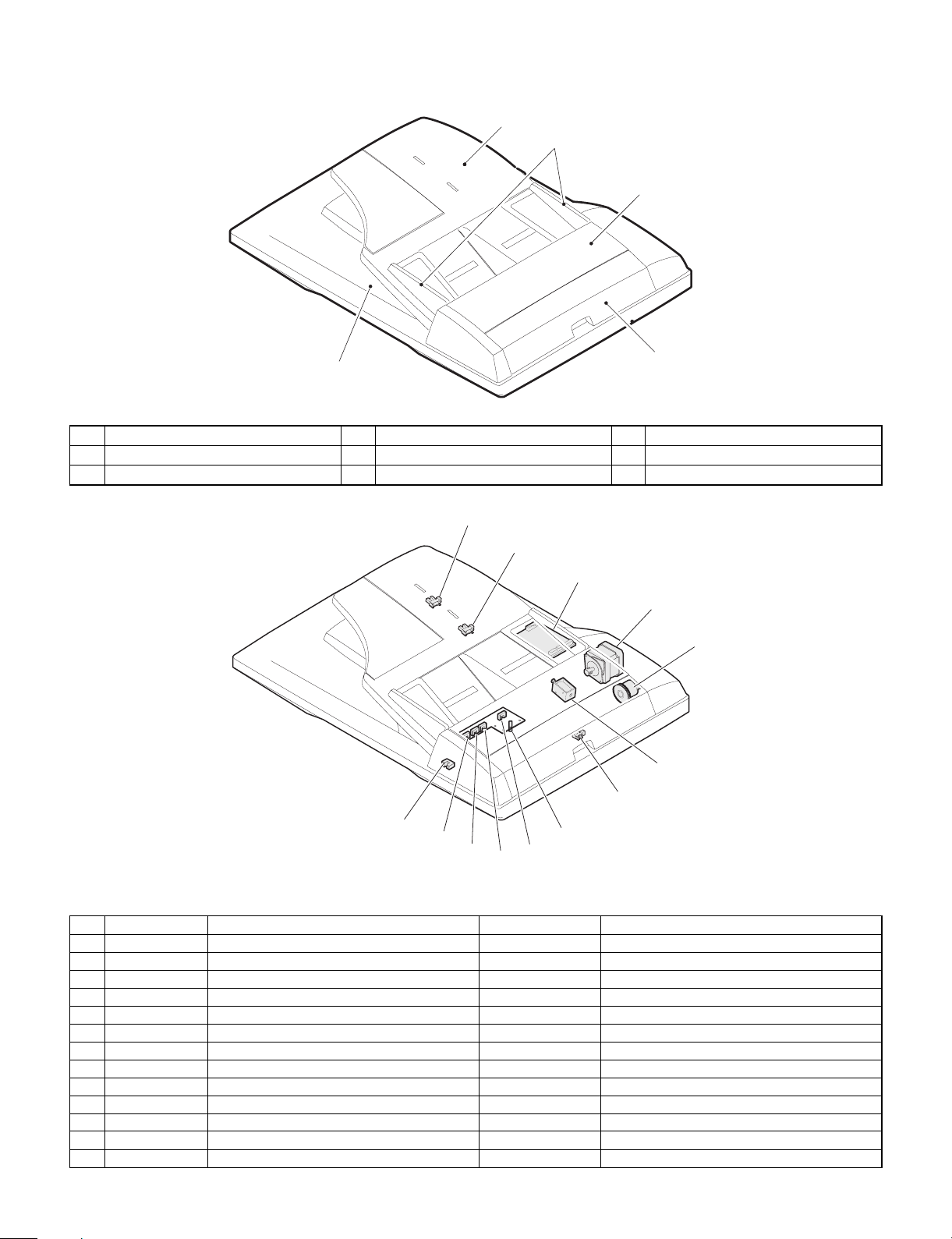

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE

1. External view

1

2

3

4

5

No. Name No. Name No. Name

1 Document set tray 2 Document guide 3 Document feed section cover

4 Document transport section cover 5 Document exit section

2. Internal structure

14

13

12

10

9

6

7

Sensors and detectors

No. Code Name Type Function, operation

1 W0 Document set sensor Photo transmission Document presence detection

2 COVER Open/close sensor Photo transmission Paper feed unit open/close detection

3 W1 Document sensor (A4R, LTR, A5) Photo transmission Tray document width detection

4 W2 Document width sensor (B4R, B5) Photo transmission Tray document width detection

5 W3 Document width sensor (WLTR, A5R, A4, LT) Photo transmission Tray document width detection

6 PSOL Pickup solenoid — —

7 PAPER Paper entry sensor Photo transmission Document presence detection

9 CLH Transport clutch — —

10 MOT SPF motor Stepping motor Tray paper feed, transport, paper exit roller drive

12 — Interface PWB — —

13 L1 Document length detection SW (Short) Photo transmission Tray document length detection

14 L2 Document length detection SW (Long) Photo transmission Tray document length detection

15 COVER OPEN Book sensor Photo transmission Detects SPF floating.

15

5

4

3

2

1

– 5 –

Page 7

[5] OPERATIONAL DESCRIPTION

1. Paper feed section major parts

1

2

13

No. Part name Operation

1 Document length

sensor (L2)

2 Document length

sensor (L1)

3 Document length

sensor (W0)

4 Document width sensor

(W1, W2, W3)

5 Pickup roller Picks up the document.

6 Paper feed roller Feed and transport the

7 Paper entry sensor

(PAPER)

8 PS roller Makes synchronization between

9 PS follower roller Makes synchronization between

10 Transport roller Transports the document.

11 Transport follower roller Transports the document.

12 Paper exit follower roller Discharges the document.

13 Paper exit roller Discharges the document.

Detects the document length on

the tray.

Detects the document length on

the tray.

Detects the presence of

document.

Detects the document width.

document.

Detects the document transport.

the document lead edge and the

image lead edge.

the document lead edge and the

image lead edge.

2. Brief descriptions of operations

1) Document set (Document set sensor ON)

2) Document size detection (The document width is detected

with document width sensors W1, W2, and W3, and the

document length is detected with document length sensors

L1 and L2.)

3) Copy start (Machine)

4) SPF motor ON

5) Pickup solenoid ON

6) Pickup roller rotation

7) Paper feed roller rotation

8) Paper entry sensor detects paper presence.

12

3,4

5

6

7

8

1011

9

3. Document size detection

Document size detection by document set tray

When a document is set on the document set tray in the auto mode

of paper/copy magnification ratio selection, the document size is

detected to perform the auto selection function of paper and the copy

magnification ratio according to the detected document size.

When documents of different sizes are mixed and set on the tray, the

max. size is detected. The document width is detected by the document width sensors (W1, W2, W3), and the document length is

detected by the document length sensors (L1, L2) to determine the

document size.

The document size judgment is made after a certain time from when

the document set sensor (W0) detects the document.

L2 L1

W0

W1

W2

W3

Document size

and set direction

A5 FDDDD

B5 FFDDD

A5R DDDDD

A4 FFFDD

AB

series

B5R DDDFD

A4R FDDFD

8.5" × 13" FDDFF

B4 FDDFF

A3 FFFFF

8.5" × 5.5" FDDDD

8.5" × 5.5"R DDDDD

11" × 8.5" FFFDD

Inch

11" × 8.5"R FDDFD

series

8.5" × 13" FDDFF

8.5" × 14" FDDFF

11" × 17" FFFFF

[Note] Sensor ON: F OFF: D

Document width

sensor

W1 W2 W3 L1 L2

Document

length sensor

9) PS roller rotation

10) Copy operation (Machine)

11) Transport roller rotation

12) Paper exit roller rotation

13) Document exit

YES

14) Next document

15) SPF motor OFF

NO

– 6 –

Page 8

[6] DISASSEMBLY AND ASSEMBLY

2) Document transport section cover

1. External fitting section

NOTE: Remove the pawl in the arrow direction.

2

2

1

1

2

1

3) Document feed section cover

2

2

3

2. Paper feed unit section

1) Paper feed unit

1

1

1

4) Sensor PWB

1

2

4

2

3

3

1

1

– 7 –

Page 9

5) Pickup solenoid

NOTE: Remove section A of the pickup solenoid from the solenoid

arm groove.

2

1

A

7) Pickup roller ass’y

NOTE: When setting the pickup roller ass’y 4, check that rib A is on

the solenoid arm rib.

A

1

2

4

6) Clutch gear ass’y

5

3

6

6

1

8) Pickup roller, paper feed roller

4

3

3

1

2

1

4

2

1

– 8 –

Page 10

3. Interface PWB

2

2) Rack cover

1

2

3) Document length detection SW

2

1

1

2

1

1

4. Document tray section

1) Document tray

2

5. Drive frame section

1) Drive frame unit

3

1

1

2

1

1

– 9 –

1

Page 11

2) Transport belt

6. Transport section

1) Clutch

NOTE: When assembling, check that the rib is in the clutch groove

A, and fix the E-ring.

3

1

3) Drive frame ass’y and drive belt

2

A

1

1

3

2

4) SPF motor

2

2) Transport roller gear

1

1

1

1

3

– 10 –

Page 12

3) Transport roller

6) Paper feed paper guide lower

2

1

1

1

4) PS roller

1

2

1

5) Paper feed paper guide upper

NOTE: When assembling, check that the paper feed paper guide

upper is set to rib A and boss B.

7) Paper exit roller

1

1

2

B

1

2

3

A

– 11 –

Page 13

[7] MAINTENANCE

1. Maintenance parts

No. Name Work item

(1) Pickup roller Cleaning F

(2) Separation pad Cleaning F

(3) Paper feed roller Cleaning F

(4) PS roller Cleaning F

(5) Transport roller Cleaning F

(6) Paper exit roller Cleaning F

When

service call

1

Remark

3

2

6

5

4

[Note] When performing maintenance, refer to [6] DISASSEMBLY

AND ASSEMBLY.

– 12 –

Page 14

[8] ELECTRICAL SECTION

D

C

B

A

1/1

12345678

SPF/RSPF UNIT

2 1

3

B/

COVER OPEN

5V2

PAPER

COVER

5V2

W1

W0L1W2

Senser PWB

W3

5V2

L2

SENSER

5V2

24V

24V

24V

CLH

RSOL

PSOL

RSPF ONLY

24V

GSOL

SOL./CLU.

RSPF ONLY

24V

MOT

AA/B

4

24V

24V

5V2

5V1

Data selector

5V1

PAPER

COVER

IC001

3

Y

24V

Driver array

IC003

5

SELA

SELB

SELB

CLH

RSOL

PSOL

PDOWN

INTERFACE PWB

Motor driver

IC002

4

MOTA

MOTB

MOTBN

GSOL

PDOWN

MOTAN

Copier body

1. BLOCK DIAGRAM

D

8 7 6 5 4

C

B

A

– 13 –

Page 15

D

C

B

A

12345678

L2

L1

1

OR

2

L1

5

3

2

1

5V

6

PHNR-6-H

Original Tray

DF3-3S-2C

PHNR-6-H

RSOL

CLH

PAPER

1

2

3

PHR-3

SMR-02V(N)

SMR-02V(B)

CLH/

24V1

1

RSOL/

24V1

1

2

2

GSOL

RSPF ONLY

2 1

3

MOT

SMP-02V(N)

SMP-02V(B)

3

6

5

1

2

4

PHR-6

Senser PWB

(PHR-7)

PAPER FEED UNIT

CN101

OR

BU7P-TR-P-H

COVER

5V

W1

W0

6

3

1

2

25V

3

1W0

6

W1

COVER

7

6

2

5

PSOL

W3

LGND

W2

5

4W2

7

GY

5

4

W2

4

2

7

PHNR-7-H

LGND

24V1

W3

1

3

1

BU2P-TR-P-H

PHNR-7-H

1

3

2

DF3-3S-2C

BL

LB

GY

OR

GY

1

PHNR-2-H

PSOL/

2

PHNR-2-H

3

5

4

6

LGND

L2

5V

LGND

1

2

4

3

BU6P-TR-P-H

2. ACTUAL WIRING DIAGRAM 1/1

OR

1

5V2

(PHDR-22VS)

CN002

Interface PWB

24V

(PHDR-24VS)

CN001

22

RD

24V

1

CL211-0211-6

PPC

OR

GY

LB

BL

OR

20

15

3

17

4

5V2

5V2

L2

LGND

L1

Y

SELA

SELC

SELB

COVER OPEN

PDOWN

COVER

10

11

BL

BR

BR

4

3

2

12

1

PL

LB

OR

BL

BR

5V1

7

GY

BR

PL

22

5

18

PAPER

LGND

LEDSPPD

5V2

9

INTERNAL SPF/DSPF

OR

RD

12

24V1

FG

RD

LB

6

CLH/

PK

14

24V1

RD

PL

1

8

RSOL/

EARTH

2

24V1

GSOL/

(PHR-2)

CN004

PLATE

PLATE

SPF FIXING

CN003

CN005

PL

1

B

(PHR-7)

(PHR-3)

1 COVER OPEN

2

PK

2

B/

2LGND

ORBRGY

1

BL

3

A

35V2

3

LB

RD

RD

6

7

24V1

A/ 4

N.C.

24V1 5

DF3-3S-2C

19

LGND

MOTA

18

BR

BL

GY

RD

10

24V1

MOTAN

MOTB

MOTBN

16

20

14

PL

BL

GY

2

PSOL/

PGND

21

GY

PGND

23

GY

LGND

5

GY

LGND

6

LB

21

LGND

PAPER

8

LB LB

BL BL

PL PL

PK PK

GY

BR BR

13

9

7

16

11

W1

W3

W0

COVER

CLH

PSOL

RSOL

24V

GSOL

15

24

13

17

19

PK

PL

BR

PL

RD

PL

COVER OPEN

GP1A71A1

24V

2

MOTA

GSOL

CLH

PSOL

3

MOTB

RSOL

6

8

5

7

4

LGND

MOTBN

PGND

PGND

MOTAN

9

LGND

14

11

13

10

12

Y

COVER

COVER OPEN

PAPER

PDOWN

17

16

15

19

18

5V2

5V1

SELC

SELB

SELA

23

20

22

24

21

FG

25 N.C.

SRA-21T-4

8 7 6 5 4

D

C

B

A

– 14 –

Page 16

D

C

B

A

1/1

12345678

CN002-2

CN002-6

CN002-8

CN004-2

PSOL/

CLH/

RSOL/

GSOL/

C001

47uF/35V

+

24V1

7

24V1

9

10

O116O215O314O413O512O611O7

COM

IC003

I11I22I33I44I55I66I7

GND

BA12003B

7

8

PSOL

CLH

RSOL

GSOL

PDOWN

CN001-19

CN001-17

CN001-15

CN001-13

CN001-11

5V1

12

VSA

IC002

TdA

2

9.1KJ

R005

47kJ

R009

47kJ

R008

VSB

TdB13RSA

9

R001

CN003-4

CN003-2

CN001-20

CN001-14

CN003-3

CN003-1

A/

B/

B

A

11

1

8

18

OUTB

OUTA

OUTA

OUTB

REFA

REFB

3

14

C007

2200pF

1.5J(1W)

C008

R007

2.4kJ

R006

2.4kJ

CN001-16

CN001-18

MOTAN

MOTB

MOTBN

MOTA

5

6

16

17

INA

INA

INB

INB

GA

GB

RSB

10

2200pF

R002

C004

R003

C006

C005

SLA7027M

4

15

1.5J(1W)

0.1uF

1.5KJ

470pF

470pF

5V1

5V1

R015

R014

R013

R012

R011

R010

CN001-10

CN001-12

COVER

PAPER

COVER OPEN

CN005-1

CN002-16

Y

D008

1SS133

5V1

6

W

IC001

D04D13D22D31D415D514D613D712A11B10C9G

R016

10kJ

CN001-8

W1

CN002-18

CN002-9W2CN002-13

CN001-3

D007

1SS133

D006

5V1

D005

D004

5

Y

7

C014

W0(Document Size Senser)

L2

W3

CN002-11

CN002-7

CN002-15L1CN002-17

CN001-1

CN001-4

CN001-2

SELA

SELC

SELB

C017

2200pFx3

C016

C015

1SS133x3

D002 D003

1SS133x3

D001

74HC151

2200pFx6

C013C009

C012

C011

C010

5V1

IC001

DSPF

C003

100000pF

16

8

2 1

3

74HC151AP

CN002-10

CN002-12

CN002-14

CN003-5

CN003-6

CN004-1

24V1

ICP001

ICP-N38

24V

24V

CN001-24

CN001-22

CN002-1

CN002-3

TO 5V1

5V1

5V2

PGND

PGND

CN001-21

CN001-23

CN002-4

CN002-5

CN005-3

CN002-19

CN002-20

CN002-21

CN002-22

CN005-2

LEDSPPD

220J(1/4W)

LED POWER

LGND

R004

C018

10uF/16V

+

C002

10uF/16V

+

LGND

LGND

1. INTERFACE PWB

3. CIRCUIT DIAGRAM

CN001-7

CN001-9

CN001-5

CN001-6

D

(PHDR-22VS)

CN002

(PHDR-24VS)

CN001

PSOL/

5V2

CLH/

RSOL/

246

8

5V2

LEDSPPDW0W2W3W1L1L2

5V2

13579

SELB

SELC

LGND

PAPER

SELAYLGND

5V1

123456789

C

24V1

24V1

24V1

COVER

PAPER

LGND

10121416182022

LGND

1113151721

19

COVER

MOTB

MOTBN

MOTA

MOTAN

COVER OPEN

10

12141618202224

CLH

5V2

PSOL

PDOWN

GSOL

RSOL

11131517192123

LGND

LGND

24V

PGND

24V

PGND

(PHR-3)

CN005

(PHR-2)

CN004

(PHR-6)

CN003

LGND

LED POWER

COVER OPEN

3

1

2

24V1

GSOL/

1

2

BB/AA/24V1

12345

CN001

CN005

(PHR-3)

CN003

(PHR-7)

W1W2W3

W0

L1

L2

SPF/ /RSPF

L

HL

LH

L

L

LLL

H

HH

LLH

HHH

HH

H

SELA

LL

24V1

6

SELB

7N.C.

L

SELC Y

MATRIX

Senser

B

(PHDR-24VS)

PARTS VIEW

CN002

CN004

(PHR-2)

(PHDR-22VS)

8 7 6 5 4

A

– 15 –

Page 17

D

C

B

A

1/1

12345678

CN101-5

GP1S58V

PT105

W3

R103

240J/ 1/4W

2 1

3

CN101-3

W1

R102

120J/ 1/4W

CN101-1

PT101

W0

R101

120J/ 1/4W

5V

PT103

GP1S58V

GP1S58V

C101

22000pF

CN101-4

W2

CN101-6

COVER

PT104

GP1S58V

PT102

GP1S58V

SGND

W05VW1W2W3

(PHR-7)

1234567

CN101

2. SENSOR PWB

D

COVER

SGND

CN102-2

CN101-7

8 7 6 5 4

C

B

– 16 –

A

Page 18

4. PARTS ARRANGEMENT

[PARTS SURFACE]

PSOL/

5V2

CLH/

RSOL/

24V1

24V1

24V1

COVER

PAPER

LGND

LGND

2

4

6

8

10

12

14

16

18

20

(PHDR-22VS)

CN002

22

LGND

21

LGND

19

5V2

LEDSPPD

W0

W2

W3

W1

L1

L2

3

5

7

9

11

13

15

17

5V2

1

(PHR-2)

CN004

24V1

GSOL/

1

2

N.C.

7

24V1

6

(PHR-6)

CN003

24V1

5

B

B/

A

A/

1

2

3

4

[SOLDER SURFACE]

(PHDR-24VS)

CN001

123456789

SELAYLGND

5V1

SELB

SELC

LGND

PAPER

11131517192123

5V2

10

COVER

CLH

PDOWN

GSOL

RSOL

12141618202224

MOTB

MOTBN

MOTA

COVER OPEN

PSOL

MOTAN

PGND

24V

PGND

24V

(PHR-3)

CN005

3

1

2

LGND

LED POWER

COVER OPEN

– 17 –

Page 19

q

COPYRIGHT C 1998 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted,

in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission of the publisher.

SHARP CORPORATION

Printing & Reprographic Systems Group

Quality & Reliability Control Center

Yamatokoriyama, Nara 639-1186, Japan

1998 November Printed in Japan K

Loading...

Loading...