Page 1

CODE: 00ZARPX1//A1E

Printer I/F kit

AR-PX1

MODEL AR-PX2

AR-PX1

(for North &

South Amer ica)

CONTENTS

[1] OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

[2] SET UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

[3] BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

[4] ACTUAL WIRING CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

[5] CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

PARTS GUIDE

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

AR-PX1

AR-PX1/PX2 Installation Manual

FOR USE WITH COMPATIBLE SHARP COPIERS.

SEE SHARP COPIER INSTALLATION MANUAL TO DETERMINE SUITABILITY.

ACCESSORY

I.T.E.

9K11

[1] OUTLINE

This kit is used to connect the printer controller with the scanner and

the printer section in the machine.

1. Kit composition

This kit is composed of the following major parts:

• Printer I/F PWB

• Printer I/F connector unit

• Internal connection cable

• External connection cable

2. Outline of operations

(Printer mode)

Each color image data of 8bit of Y/M/C/K outputted from the print

controller is converted into the engine logic level in the printer I/F

PWB.

(Scanner mode)

Each color image data of 8bit of R/G/B scanned by the scanner is

inputted to the printer I/F PWB, and converted into the differential

output and sent to the print controller.

(Circuit system)

High-speed data transmission/reception is performed between the engine and the print controller. For that, the differential I/O system is

employed to increase the noise margin.

(Parts list)

No. Part name Quantity

1 Printer I/F PWB 1

2 Wake up signal harness (connected to the printer I/F PWB) 1

3 Printer I/F connector unit 1

4 Flat cable 1

5 Flat cable clip 1

6 Harness clip 1

7 Screw (M3) 4

8 Printer cable 1

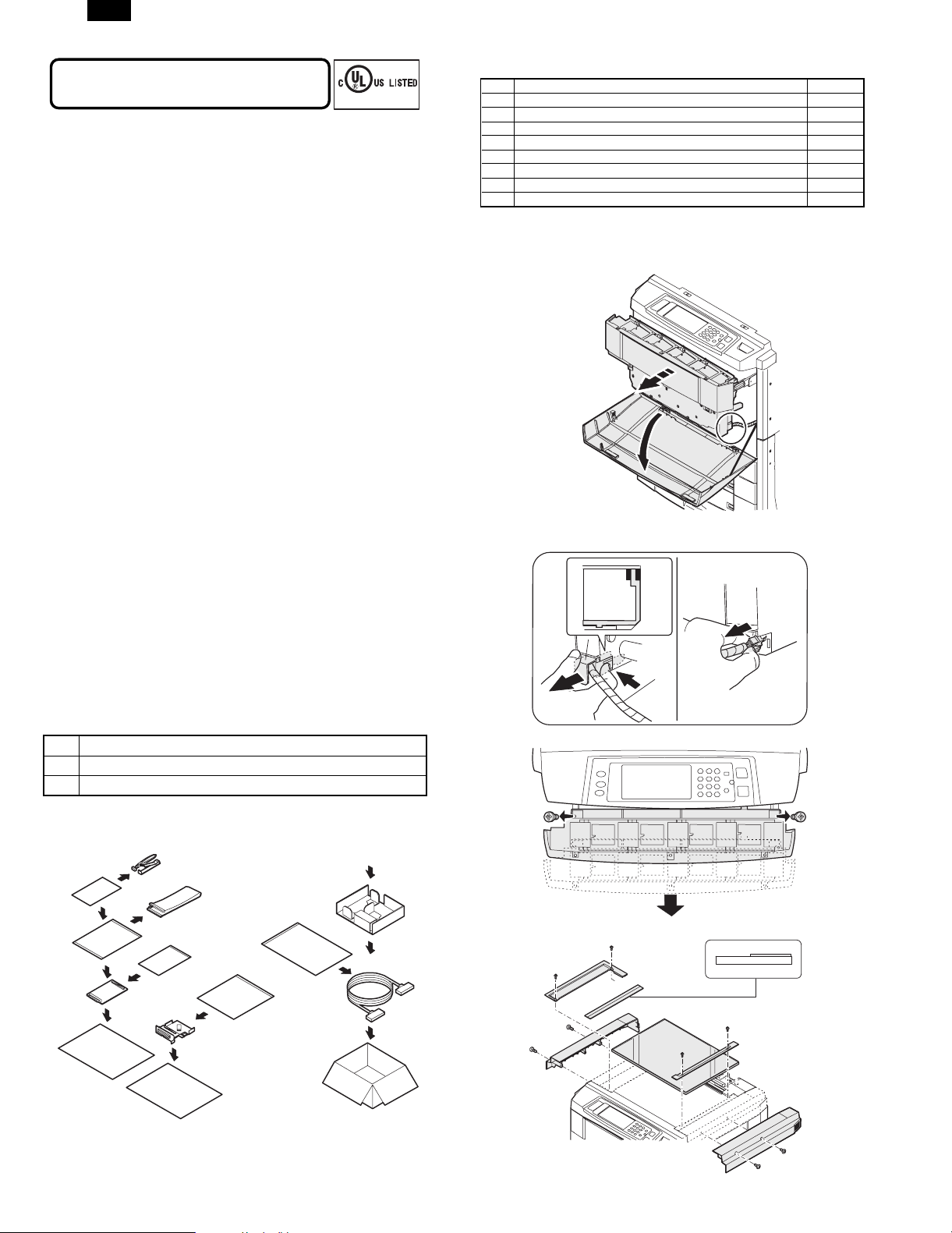

2. Parts assembly

1) Open the front cabinet, and pull out the toner hopper unit.

2) Remove the toner hopper connector cover, and remove the toner

hopper connector.

[2] SETUP

(Necessary tools)

1 Screwdriver

2 Short screwdriver

3 Nippers

1. Unpacking

3) Remove the toner hopper unit.

4) Remove the right upper cabinet.

– 1 –

Page 3

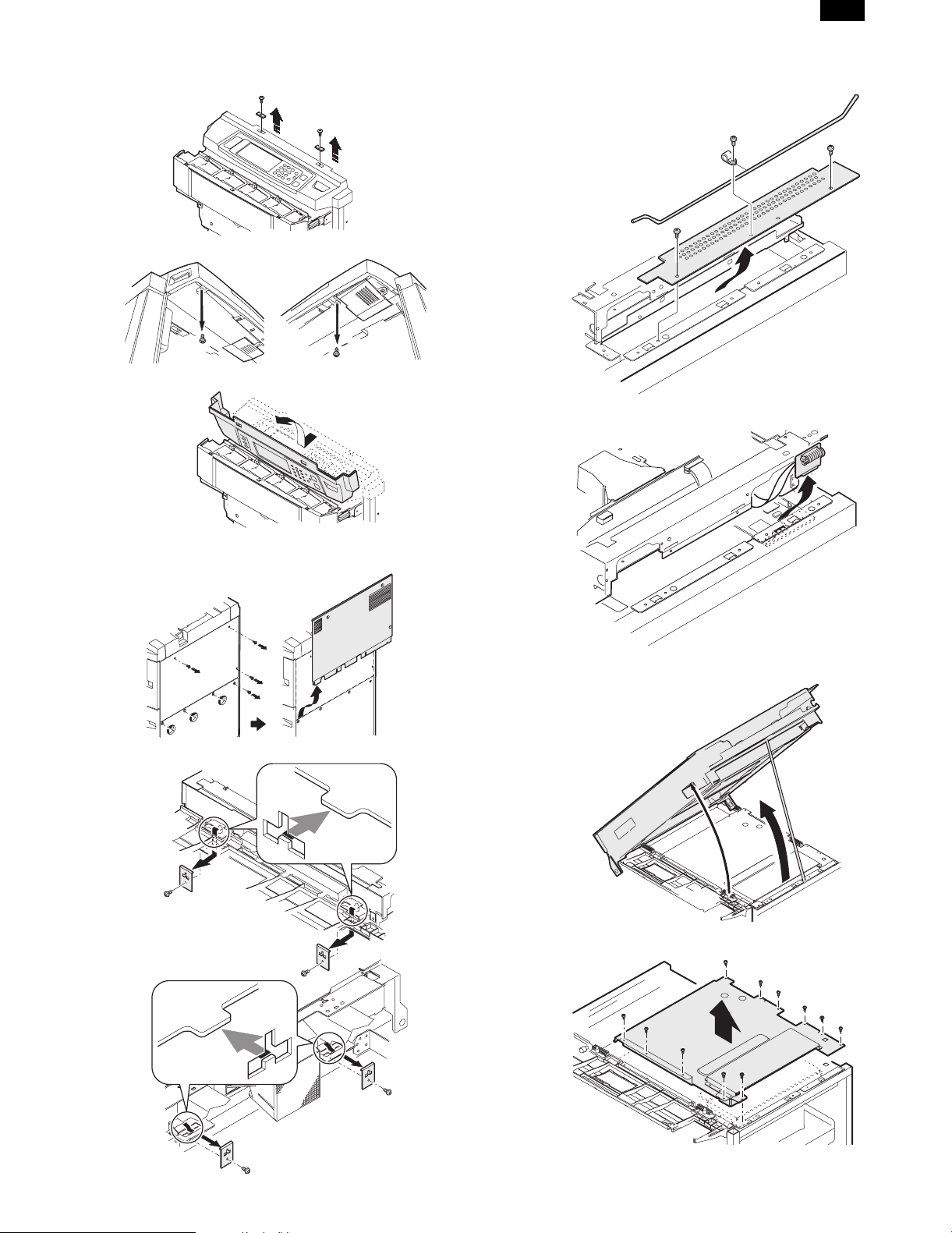

AR-PX1

5) Remove the left upper cabinet.

6) Remove the operation unit.

10) Remove the scanner (reading) unit hold shaft and the ICU PWB

shield plate.

11) Remove the CCD flat cable connector.

7) Remove the original table glass.

8) Remove the rear cabinet.

9) Remove the scanner (reading) unit fixing angle.

12) Open the scanner (reading) unit and fix it with the hold shaft.

13) Remove the ICU PWB cover.

– 2 –

Page 4

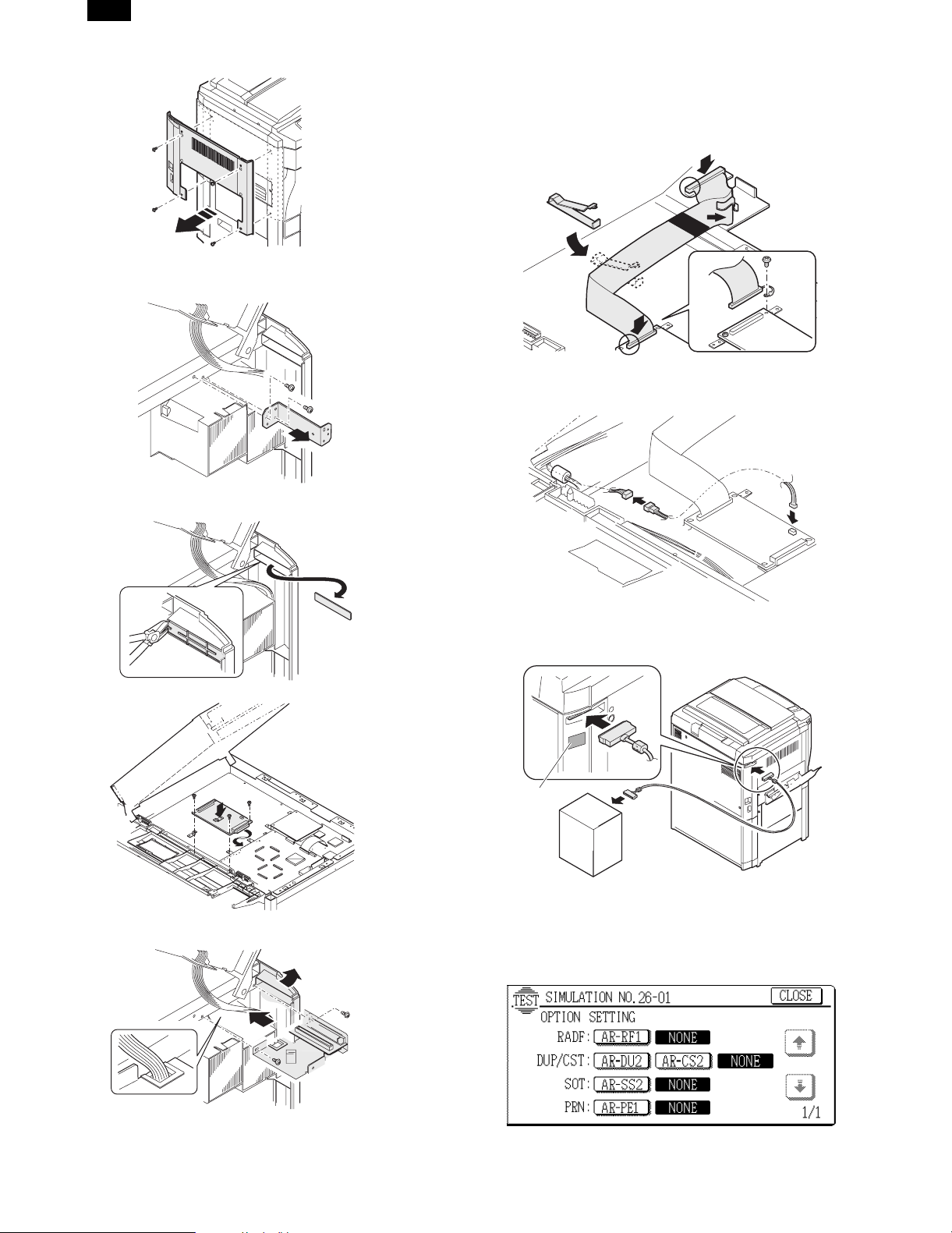

AR-PX1

14) Remove the left side cabinet.

15) Remove the cabinet angle. This angle is unnecessary when

removed. However, the screw which was fixing the angle is required to fix the printer I/F connector unit later.

16) Open the printer I/F connector window of the left rear cabinet.

(Cut the cabinet with nippers.)

19) Use the flat cable to connect the printer I/F PWB and the printer

I/F unit. At that time, be careful of the connector direction. Also

check that the flat cable protector section (black section) passes

through the chassis edge. Bend the flat cable at the right angle

in two positions. Fix the flat cable with the cable clamp of the

printer I/F unit section and the flat cable clip.

20) Connect the wake up signal harness connector to the printer I/F

PWB, and connect the other end to the main harness wake up

signal connector.

17) Attach the printer I/F PWB with the accessory screw.

18) Use the screw noted in procedure 15) and attach the printer I/F

connector unit.

21) Install all the parts that were removed to their original positions.

22) Connect the main unit and the printer controller with the printer

cable.

Caution label

23) Attach the caution label to the cabinet.

3. Setting

1) Turn on the power of the unit.

2) Enter the simulation 26-1 mode.

(NOTE)

When attaching the I/F connector mounting plate, be careful not to

apply an excessive stress to the connector which is passed under the

I/F connector mounting plate.

3) Press "PRN: AR-PE1" button. (Communication between the unit

and the printer controller is allowed.)

4) Cancel the simulation mode.

– 3 –

Page 5

AR-PX1

4. Other

A. Printing Documents from the Computer

In most cases, it is not necessary to use the operation panel when

printing documents from the computer. When a document is sent to

the printer from the computer, the printer will automatically print the

document. However, following the procedure specified below can

help ensure that documents are printed accurately. The procedure

assumes that the printer has been properly connected to a computer,

and that a printer driver has been installed.

1) Check the operation panel to confirm that the ON LINE indicator is

lit. If the ON LINE indicator is not lit, press the PRINT key to select

the printer mode and then press the "ONLINE" key on the touch

panel to set the printer to the on-line condition.

2) Check the paper tray(s) to ensure that the desired paper is

loaded.

3) Using the computer and any appropriate application software, load

the document to be printed, set any desired features using the

installed printer driver, and give the command to print the document. If necessary, refer to the documentation for the computer

and/or the application software for help on issuing the necessary

commands.

4) The printer will print the document.

(1) Selecting the Online Mode

If the printer is in the offline mode, printing cannot be performed. To

select the online mode, use the procedure below.

1) If the printer is in the copier mode, press the PRINT key to select

the printer mode.

The basic screen of the printer mode will appear.

2) Press the "ONLINE/OFFLINE" key on the touch panel to switch

the printer to the online mode.

3) To select the copier mode, press the COPY key.

B. Tray Select

(1) Tray Selection

The "PAPER SELECT" key on the touch panel can be used to

change paper trays when printing has stopped for one of the following

reasons.

• In ‘Auto Select’ paper source selection mode, all trays on the

printer configured for the requested paper size are out of paper or

no trays on the printer are configured for the requested paper size.

• If a paper source has been specified, the requested tray on the

printer has run out of paper.

In most cases it will be best to load or re-load the printer with the

appropriate paper size and continue printing. If it is preferable to

continue printing from a different tray (possibly containing a different

size paper than requested by the computer), follow the procedure

below.

Tray Change Procedure:

1) Press the "ONLINE/OFFLINE" key on the touch panel to set the

printer to an offline state.

2) Press the "PAPER SELECT" key to select the desired paper tray.

3) Press the "ONLINE/OFFLINE" key to return the printer to an online state. The printer will begin printing from the selected tray.

NOTES: Selecting a tray containing a different size or orientation of

paper than that specified by the computer may result in the

pages being clipped to fit the physical paper size.

Note that using the "PAPER SELECT" key to select a new

paper tray overrides any selection previously made using

the printer driver configuration menus.

To cancel the print, use the operation panel of the Printer

Controller.

C. Key Operator Programs

Four key operator programs are available which allow a key operator

to adjust certain printer operating conditions. These programs are

listed as below.

1 Enable Bypass-Tray

Size Detection

2 Enable Bypass-Tray

Type Detection

3 Prohibit Bypass-Tray

Selection

4 Prohibit Auto Tray

Switching

Key operator programs governing printer features and functions can

be called in the same manner as the key operator programs governing copier features.

For general information on accessing key operator programs, including registration of a key operator code number, refer to the Key

Operator’s Guide in the copier manual.

If the printer function kit has been expanded, the "PRINTER" key will

be displayed on the touch panel after the key operator code number

is entered. Press the "PRINTER" key to access the key operator

programs for the printer features.

Enables or disables paper size

detection for the bypass tray.

Enables or disables paper type

detection for the bypass tray.

Enables/disables bypass tray

selection in the ’Auto Tray

Switching’ mode.

Enables/disables automatic

switching between paper trays

during printing when paper runs out.

(1) Enable Bypass-Tray Size Detection

This program is used to enable or disable paper size detection of the

bypass tray in the printer mode. This setting does not affect the paper

size detection in the copier mode.

To enable paper size detection of the bypass tray in the printer mode,

press the "ENABLE BYPASS-TRAY SIZE DETECTION" box to display a check mark.

To disable paper size detection, press the checked box again to clear

the check mark.

NOTE: If size detection of the bypass tray is disabled, paper in the

bypass tray will always be treated as the largest allowable

size paper (either 11" x 17" or A3). If an image larger than

the paper in the bypass tray is printed, a malfunction may

occur. Be careful when disabling the size detection.

(2) Enable Bypass-Tray Type Detection

This program is used to check the paper type selection for the bypass

tray at the machine with that selected at the printer driver when

printing from the bypass tray.

• When the check mark is on, the paper type selections at the

machine and at the driver will be checked. If both do not match,

auto paper feed will not be activated. If they match and the other

conditions for the auto paper feed are satisfied, the auto paper

feed will be activated.

• When the check mark is off, the paper type selection for the

bypass tray at the machine will be disregarded. Even if the selection is made at the machine, the selection at the printer driver will

override it.

When using with the check mark off, be sure not to select wrong

paper type. If the wrong paper type is selected, a misfeed or a

malfunction may occur.

To enable paper type detection of the bypass tray, press the

"Enable Bypass-Tray Type Detection" check box to display a check

mark. To disable paper type detection, press the checked box

again to clear the check mark.

– 4 –

Page 6

AR-PX1

(3) Prohibit Bypass-Tray Selection

If this program is set, the bypass tray will not be selected for a print

job that specifies auto paper selection or during auto tray switching.

To prohibit bypass tray selection, press the "PROHIBIT BYPASSTRAY SELECTION" box to display a check mark.

To restore bypass tray selection, press the checked box again to

clear the check mark.

(4) Prohibit Auto Tray Switching

This program prevents automatic switching between paper trays in

print jobs. This program does not affect the auto tray switching function in the copier mode.

To prohibit automatic tray switching, press the "PROHIBIT AUTO

TRAY SWITCHING" box to display a check mark.

To restore automatic tray switching, press the checked box again to

clear the check mark.

D. General Operation Steps for the Scanner Use

To scan, process or edit images and documents by using the

machine as a scanner, a TWAIN application software (such as Adobe

PhotoShop) is required.

1) Install the required driver software in your computer in accordance

with the operation manual for the Printer Controller.

2) Press PRINTER key to display the printer mode screen.

3) Check the operation panel to confirm that the ONLINE Key is

selected. If not, touch the ONLINE key to be in the online status.

4) Place the original on the document glass or in the document

feeder (optional).

NOTE: Even if the multiple originals are set in the document feeder,

5) Acquire the image or the document using the application software.

6) Edit or store the scanned image or document. For the details,

the scanning is processed by one page at each operation

and it is required to repeat the below mentioned step 5) by

the numbers of the original pages.

For the details, refer to the operation manual supplied with the

application software.

refer to the operation manual supplied with the application

software.

– 5 –

Page 7

AR-PX1

[4] ACTUAL WIRING CHART

WAKE UP RELAY HARNESS

MAIN HARNESS R (3PIN)

OP PANEL

– 6 –

Page 8

AR-PX1

CN543-13

1/2

C/R DATA4A

C/R DATA4B

3

2

1Y

1A

IC107

1

3

Y1

A1

IC117

2

1

+3.3V +3.3V

CN543-17

CN543-18

CN543-15

CN543-16

CN543-19

CN543-20

CN543-14

C/R DATA6B

C/R DATA5A

C/R DATA5B

C/R DATA7B

C/R DATA7A

C/R DATA6A

100J

100J

100J

100J

R102

R103

R112

6

1Z

7

6

Y2

A2

B1

5

4

8

10

14

5

11

13

2Y

3Y

4Y

2Z

3Z

4Z

4A

3A

2A

G

9

4

15

7

11

8

Y4

Y3

GND

74LCX32

B413A4

VCC

B2

B3

A3

0.1uF

9

C136

12

14

10

2

1

GND

1A

G

12

16

1B

VCC

DS90LV031A

1Y

IC101

0.1uF

C119

3

+3.3V

R113

10KJ

+3.3V

R111

6

7

2A

2B

2Y

5

8

10

14

9

15

3A

4A

3B

4B

GND

VCC

G

4Y

3Y

G

DS90LV032A

4

12

16

13

11

0.1uF

C102

CN543-37

CN543-39

CN543-35

CN543-33

M/G DATA4A

M/G DATA4B

3

2

1Y

1A

IC125

1

+3.3V

3

Y1

A1

IC120

2

1

+3.3V

CN543-40

CN543-38

CN543-36

CN543-34

M/G DATA6A

M/G DATA7A

M/G DATA5A

M/G DATA7B

M/G DATA6B

M/G DATA5B

100J

100J

100J

100J

R142

R143

R154

6

2Y

1Z

2A

7

6

Y2

B2

A2

B1

5

4

8

10

14

5

11

13

3Y

4Y

2Z

3Z

4Z

GND

G

4A

3A

G

VCC

DS90LV031A

9

15

7

11

8

Y4

Y3

GND

74LCX32

VCC

B4

A4

B3

A3

9

C133

14

13

12

10

IC115

4

12

16

0.1uF

C117

+3.3V

R144

10KJ

+3.3V

0.1uF

R155

2

6

1

7

1A

2A

1B

2B

2Y

1Y

5

3

8

10

14

9

15

3A

4A

3B

4B

GND

VCC

G

4Y

3Y

G

DS90LV032A

4

16

12

13

11

0.1uF

C100

CN543-67

CN543-65

CN543-69

CN543-64

CN543-66

CN543-68

CN543-63

Y/B DATA4B

Y/B DATA4A

3

2

1Y

1A

IC106

1

+3.3V

3

Y1

A1

IC118

2

1

+3.3V

CN543-70

Y/B DATA6A

Y/B DATA5A

Y/B DATA7A

Y/B DATA5B

Y/B DATA6B

Y/B DATA7B

100J

100J

100J

100J

R108

R101

R109

DS90LV031A

C141

R100

2

6

10

14

1

7

9

15

1A

2A

3A

4A

1B

2B

3B

4B

G

4Y

3Y

2Y

1Y

IC100

0.1uF

3

+3.3V

R110

10KJ

+3.3V

4

5

12

13

11

6

10

14

8

5

11

13

2Y

3Y

4Y

1Z

2Z

3Z

4Z

GND

G

4A

3A

2A

G

VCC

9

7

4

15

12

16

7

11

8

6

Y4

Y3

Y2

GND

74LCX32

VCC

B413A4

B3

A3

B2

A2

B1

0.1uF

9

5

4

C135

14

12

10

CN543-83

CN543-89

CN543-84

CN543-85

CN543-86

CN543-87

CN543-88

CN543-90

K DATA4B

K DATA4B

K DATA5B

K DATA5B

K DATA6B

K DATA6B

K DATA7B

K DATA7B

100J

100J

100J

100J

R141

R140

R151

8

GND

VCC

G

DS90LV032A

IC114

16

0.1uF

C130

+3.3V

R153

10KJ

+3.3V

R152

2

6

1

7

1A

2A

1B

2B

2Y

1Y

5

3

8

10

14

9

15

3A

4A

3B

4B

GND

VCC

G

G

4Y

3Y

11

DS90LV032A

4

12

16

13

0.1uF

C129

*NR105

DR7

DR4

DR5

DR6

CN541-20

CN541-17

CN541-18

CN541-19

CN543-11

CN543-7

CN543-8

CN543-5

CN543-10

CN543-6

CN543-12

CN543-9

C/R DATA1B

C/R DATA0A

C/R DATA2B

C/R DATA0B

C/R DATA3B

C/R DATA2A

C/R DATA3A

C/R DATA1A

6

10

14

3

5

11

2

1Y

1A

IC109

1

3

Y1

A1

IC116

1

+3.3V +3.3V

*NR101

13

2Y

3Y

4Y

1Z

2Z

3Z

4Z

4A

3A

2A

9

7

15

7

11

8

6

Y4

Y3

Y2

GND

74LCX32

B4

A4

VCC

B2

A2

B3

B1

A3

5

4

C131

2

9

13

12

14

10

DR3

DR0

DR1

DR2

CN541-16

CN541-13

CN541-14

CN541-15

*NR102

BDC6

BDC7

BDC5

BDC4

CN541-52

CN541-53

CN541-51

CN541-50

100J

100J

100J

100J

R107

R118

R117

DS90LV031A

C120

R106

2

6

10

14

1

7

9

1A

1Y

IC103

0.1uF

3

+3.3V

R119

10KJ

+3.3V

*NR103

BDC0

CN541-46

15

2A

3A

4A

1B

2B

3B

4B

G

4Y

3Y

2Y

4

5

13

11

BDC2

BDC1

BDC3

CN541-48

CN541-47

CN541-49

8

GND

G

G

VCC

4

12

16

0.1uF

*NR109

DG5

DG4

DG6

DG7

CN541-27

CN541-28

CN541-26

CN541-25

CN543-26

CN543-30

CN543-28

CN543-31

CN543-27

CN543-29

CN543-25

M/G DATA0B

M/G DATA2B

M/G DATA0A

M/G DATA1B

M/G DATA3B

M/G DATA3A

M/G DATA1A

M/G DATA2A

6

10

14

3

5

11

2

8

1Y

GND

1A

IC123

VCC

G

DS90LV032A

1

12

16

0.1uF

C103

3

Y1

A1

IC119

1

+3.3V +3.3V

*NR107

13

2Y

3Y

4Y

1Z

2Z

3Z

4A

3A

2A

9

7

15

7

11

8

6

Y4

Y3

Y2

GND

74LCX32

B4

A4

VCC

B2

A2

B3

B1

A3

5

4

C132

2

9

13

12

14

10

DG3

DG0

DG2

DG1

CN541-24

CN541-21

CN541-23

CN541-22

*NR106

BDM4

BDM7

BDM5

BDM6

CN541-58

CN541-61

CN541-59

CN541-60

CN543-32

100J

100J

100J

100J

R138

R139

R149

8

2

4Z

G

G

4

12

0.1uF

1

GND

1A

1B

VCC

DS90LV031A

1Y

IC113

16

0.1uF

C118

3

+3.3V

R150

10KJ

+3.3V

*NR104

BDM2

BDM1

BDM0

CN541-55

CN541-54

R148

6

10

14

7

9

15

2A

3A

4A

2B

3B

4B

4Y

3Y

2Y

4

5

13

11

BDM3

CN541-56

CN541-57

*NR112

DB7

DB5

DB4

DB6

CN541-36

CN541-34

CN541-33

CN541-35

CN543-59

CN543-55

CN543-60

CN543-56

CN543-61

CN543-58

CN543-57

Y/B DATA1A

Y/B DATA2A

Y/B DATA0A

Y/B DATA2B

Y/B DATA0B

Y/B DATA3A

Y/B DATA3B

Y/B DATA1B

6

10

14

3

5

11

2

8

1Y

GND

1A

IC108

VCC

G

G

DS90LV032A

1

12

16

0.1uF

C101

3

Y1

A1

IC121

1

+3.3V +3.3V

*NR111

13

2Y

3Y

4Y

1Z

2Z

3Z

4A

3A

2A

9

7

15

7

11

8

6

Y4

Y3

Y2

GND

74LCX32

B4

A4

VCC

B2

A2

B3

B1

A3

5

4

C134

2

9

13

12

14

10

DB2

DB3

DB1

DB0

CN541-31

CN541-32

CN541-30

CN541-29

*NR110

BDY6

BDY4

BDY5

BDY7

CN541-66

CN541-67

CN541-69

CN541-68

CN543-62

100J

100J

100J

100J

R104

R105

8

4Z

GND

G

G

VCC

DS90LV031A

IC102

4

12

16

0.1uF

C139

+3.3V

R116

10KJ

+3.3V

0.1uF

*NR108

R115

2

6

10

14

1

7

9

15

1A

2A

3A

4A

1B

2B

3B

4B

4Y

3Y

2Y

1Y

5

3

13

11

BDY3

BDY2

BDY1

BDY0

CN541-65

CN541-64

CN541-63

CN541-62

*NR100

BDK6

BDK4

BDK7

BDK5

CN541-43

CN541-44

CN541-42

CN541-45

CN543-75

CN543-76

CN543-77

CN543-78

CN543-79

CN543-80

CN543-81

CN543-82

K DATA0B

K DATA0B

K DATA1B

K DATA1B

K DATA2B

K DATA2B

K DATA3B

K DATA3B

100J

100J

100J

100J

R145

R136

R146

R114

8

GND

VCC

G

G

DS90LV032A

4

12

16

0.1uF

C128

+3.3V

R137

2

6

1

7

1A

2A

1B

2B

2Y

1Y

IC112

5

3

+3.3V

R147

10KJ

*NR113

BDK0

BDK2

BDK3

BDK1

CN541-38

CN541-40

CN541-41

CN541-39

8

10

14

9

15

3A

4A

3B

4B

GND

VCC

G

4Y

3Y

G

DS90LV032A

4

12

16

13

11

0.1uF

C127

PRT-I/F P WB

[5] CIRCUIT DIAGRAM

CN543-4

CN543-2

CN543-1

CN543-3

CN543-42

CN543-41

ECLKB

ECLKA

HSYNCB

VSYNCB

VSYNCA

HSYNCA

6

10

14

2

3

5

11

13

2Y

3Y

4Y

1Y

1Z

2Z

3Z

4Z

4A

3A

2A

1A

IC104

1

+3.3V

+3.3V

R122

10KJ

*TP102

R120

680J

+3.3V

*R125

SCLKB6

CN541-10

G

9

7

4

15

3

Y1

B1

A1

IC105

2

1

+3.3V

R121

360J

560pF

C114

*TP100

*R127

PRT_P

CN541-6

/PRT_SB

PRT_PB

8

GND

DS90LV031A

G

VCC

12

16

0.1uF

C104

+3.3V

7

11

8

6

Y4

Y3

Y2

GND

74LCX32

B4

A4

VCC

B2

B3

A2

A3

0.1uF

5

4

9

C105

13

12

14

10

*TP101

*R126

/PRT_S

CN541-7

+3.3V

*C107 *C106

IC111

*R124

3

Y1

A1

2

1

SSYNCB6

CN541-11

7

11

8

6

Y4

Y3

Y2

GND

B413A4

VCC

B2

A2

B3

B1

A3

5

4

9

12

14

10

*R123

HSYNCB6

CN541-12

CN543-43

CN543-44

CN543-46

CN543-45

CN543-47

CN543-49

CN543-50

CN543-48

/CRDYA

/CRDYB

STA TUSA

STA TUSB

/CONTRESETA

/CONTRESETB

/ENGINEUPB

/ENGINEUPA

6

10

2

3

5

13

2Y

3Y

1Y

1Z

2Z

3Z114Y144Z

4A

3A

2A

1A

IC122

1

+3.3V

R160

10KJ

74VHC32

0.1uF

C122

*C116

*R134

*R129

*C115

/PRTE_RDY

CN541-8

G

9

7

4

15

12

*R132

*R130

/PRT_RTS

PRT_RXD

/PRTC_RES

CN541-4

CN541-1

CN541-2

CN543-91

CN543-92

CN543-97

CN543-98

CN543-100

CN543-99

CMDB

CMDA

CCLKA

CCLKB

/SRDYA

/SRDYB

100J

100J

100J

R156

R162

R161

2

8

GND

G

VCC

16

*C124 *C110

*C112 *C123

DS90LV031A

C138

6

1

7

1A

2A

1B

2B

2Y

1Y

IC124

5

3

0.1uF

R157

10KJ

+3.3V

*TP103

*R158

BPCLK

CN541-37

8

10

14

9

15

3A

4A

3B

4B

G

4Y

3Y

G

4

12

16

13

11

+3.3V

*C109

*C111

*R133

*R131

/PRT_CTS

PRT_TXD

CN541-3

CN541-5

CN543-96

CN543-95

/CONTUPA

/CONTUPB

100J

R128

5

4

3

2

1

NC

NC

1A

1B

GND

VCC

DS90LV032A

0.1uF

C140

IC126

+3.3V

GND

VCC

NC

1Y

IC110

DS90LV018A

8

6

7

5

9

4

2

1

B2

A3

A2

B1

A1

Y3

Y2

Y1

8

6

3

*R135

/PRTC_RDY

CN541-9

C121 0.1uF

*C126

7

13

12

10

B4

A4

B3

GND

74LV32A

VCC

Y4

0.1uF

C142

14

11

*C113

47uF

C143

+

C144

3

1SS133

22000pF

OUT

D100

GND

IN

NJU7200L33

IC127

1

2

22000pF

C145

+

B

C146

100uF

JP103

+5VS

Q100

NF102

+5VS

GND3

WAKEUP

CN542-1

CN542-2

DTC114EKA

10K

10K

E

C

*R159

*NF101

+3.3V

+3.3V

+3.3V

CN541-72

CN541-71

CN542-3

CN543-93

CN543-94

+3.3V

GNDA

GNDB

C108,C125,C137

470uFx3

+

NF100

+3.3V

JP102

GND

JP100

GND

+3.3V

GND

+3.3V

CN541-77

CN541-75

CN541-76

CN541-74

CN541-73

: Uninstalled

*

GND

JP105

GND

JP104

GND

JP101

GND

GND

GND

CN541-79

CN541-80

CN541-78

– 7 –

Page 9

AR-PX1

PRT-I/F P WB

VSYNCA

VSYNCB

HSYNCA

HSYNCB

C/R DATA0A

C/R DATA0B

C/R DATA1A

C/R DATA1B

C/R DATA2A

C/R DATA2B

C/R DATA3A

C/R DATA3B

C/R DATA4A

C/R DATA4B

C/R DATA5A

C/R DATA5B

C/R DATA6A

C/R DATA6B

C/R DATA7A

C/R DATA7B

M/G DATA0A

M/G DATA0B

M/G DATAA

M/G DATA1B

M/G DATA2A

M/G DATA2B

M/G DATA3A

M/G DATA3B

M/G DATA4A

M/G DATA4B

M/G DATA5A

M/G DATA5B

M/G DATA6A

M/G DATA6B

M/G DATA7A

M/G DATA7B

ECLKA

ECLKB

/CONTRESETA

/CONTRESETB

/ENGINEUPA

/ENGINEUPB

/CRDY A

/CRDYB

STATUSA

STATUSB

PRT-I/F PRT-CN

CN543

1

25152

3

53

4

54

5

55

6

56

7

57

8

58

9

59

10

60

11

61

12

62

13

63

14

64

15

65

16

66

17

67

18

68

19

69

20

70

21

71

22

72

23

73

24

74

25

75

26

76

77

27

78

28

79

29

80

30

81

31

82

32

83

33

84

34

85

35

86

36

87

37

88

38

89

39

90

40

91

41

92

42

93

43

94

44

95

45

96

46

97

47

98

48

99

49

100

50

8931E-100-178S(KEL)

Y/B DATA0A

Y/B DATA0B

Y/B DATA1A

Y/B DATA1B

Y/B DATA2A

Y/B DATA2B

Y/B DATA3A

Y/B DATA3B

Y/B DATA4A

Y/B DATA4B

Y/B DATA5A

Y/B DATA5B

Y/B DATA6A

Y/B DATA6B

Y/B DATA7A

Y/B DATA7B

K DATA0A

K DATAB

K DATA1A

K DATA1B

K DATA2A

K DATA2B

K DATA3A

K DATA3B

K DATA4A

K DATA4B

K DATA5A

K DATA5B

K DATA6A

K DATA6B

K DATA7A

K DATA7B

CCLKA

CCLKB

GNDA

GNDB

/CONTUPA

/CONTUPB

/SRDYA

/SRDYB

CMDA

CMDB

/PRTC_RES

PRT_RXD

PRT_TXD

/PRT_RTS

/PRT_CTS

PRT_P

/PRT_S

/PRTE_RDY

/PRTC_RDY

SCLKB6

SSYNCB6

HSYNCB6

DR0

DR1

DR2

DR3

DR4

DR5

DR6

DR7

DG0

DG1

DG2

DG3

DG4

DG5

DG6

DG7

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

BPCLK

BDK0

BDK1

BDK2

PRT-I/F ICU-IMG

CN541

41

1

2

42

43

3

44

4

45

5

46

6

47

7

48

8

49

9

50

10

51

11

52

12

53

13

54

14

55

15

56

16

57

17

58

18

59

19

60

20

61

21

62

22

63

23

64

24

65

25

66

26

67

27

68

28

69

29

70

30

71

31

32

72

33

73

34

74

35

75

36

76

37

77

38

78

39

79

40

80

52409-0801 (molex)

BDK3

BDK4

BDK5

BDK6

BDK7

BDC0

BDC1

BDC2

BDC3

BDC4

BDC5

BDC6

BDC7

BDM0

BDM1

BDM2

BDM3

BDM4

BDM5

BDM6

BDM7

BDY0

BDY1

BDY2

BDY3

BDY4

BDY5

BDY6

BDY7

+3.3V

+3.3V

+3.3V

+3.3V

+3.3V

GND

GND

GND

GND

GND

OPE PRT-I/F

+5VS

GND3

WAKEUP

2/2

CN542

1

2

3

B3B-PH-K-S (JST)

PRT-CN PWB

CN545

1

VSYNCA

2

VSYNCB

3

HSYNCA

4

HSYNCB

C/R DATA0A5Y/B DATA0A

C/R DATA0B6Y/B DATA0B

C/R DATA1A7Y/B DATA1A

C/R DATA1B8Y/B DATA1B

9

C/R DATA2A

C/R DATA2B10Y/B DATA2B

C/R DATA3A11Y/B DATA3A

C/R DATA3B12Y/B DATA3B

C/R DATA4A13Y/B DATA4A

C/R DATA4B14Y/B DATA4B

C/R DATA5A15Y/B DATA5A

C/R DATA5B16Y/B DATA5B

C/R DATA6A17Y/B DATA6A

C/R DATA6B18Y/B DATA6B

C/R DATA7A19Y/B DATA7A

C/R DATA7B20Y/B DATA7B

21

NC

22

NC

23

NC

24

NC

M/G DATA0A25K DATA0A

26

M/G DATA0B

27

M/G DATA1A

28

M/G DATA1B

29

M/G DATA2A

30

M/G DATA2B

31

M/G DATA3A

32

M/G DATA3B

33

M/G DATA4A

34

M/G DATA4B

35

M/G DATA5A

36

M/G DATA5B

37

M/G DATA6A

38

M/G DATA6B

39

M/G DATA7A

40

M/G DATA7B

41

ECLKA

42

ECLKB

43

/CONTRESETA

44

/CONTRESETB

45

/ENGINEUPA

46

/ENGINEUPB

47

/CRDYA

48

/CRDYB

49

STATUSA

50

STATUSB

DHA-RC100-R131N (DDK) 8931E-100-178S(KEL)

Y/B DATA2A

K DATA0B

K DATA1A

K DATA1B

K DATA2A

K DATA2B

K DATA3A

K DATA3B

K DATA4A

K DATA4B

K DATA5A

K DATA5B

K DATA6A

K DATA6B

K DATA7A

K DATA7B

CCLKA

CCLKB

GNDA

GNDB

/CONTUPA

/CONTUPB

/SRDYA

/SRDYB

CMDA

CMDB

51

NC

52

NC

53

NC

54

NC

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

NC

72

NC

73

NC

74

NC

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

CN544

1

VSYNCA

2

VSYNCB

3

HSYNCA

4

HSYNCB

C/R DATA0A5Y/B DATA0A

C/R DATA0B6Y/B DATA0B

C/R DATA1A7Y/B DATA1A

C/R DATA1B8Y/B DATA1B

9

C/R DATA2A

C/R DATA2B10Y/B DATA2B

C/R DATA3A11Y/B DATA3A

C/R DATA3B12Y/B DATA3B

C/R DATA4A13Y/B DATA4A

C/R DATA4B14Y/B DATA4B

C/R DATA5A15Y/B DATA5A

C/R DATA5B16Y/B DATA5B

C/R DATA6A17Y/B DATA6A

C/R DATA6B18Y/B DATA6B

C/R DATA7A19Y/B DATA7A

C/R DATA7B20Y/B DATA7B

21

NC

22

NC

23

NC

24

NC

M/G DATA0A25K DATA0A

26

M/G DATA0B

27

M/G DATA1A

28

M/G DATA1B

29

M/G DATA2A

30

M/G DATA2B

31

M/G DATA3A

32

M/G DATA3B

33

M/G DATA4A

34

M/G DATA4B

35

M/G DATA5A

36

M/G DATA5B

37

M/G DATA6A

38

M/G DATA6B

39

M/G DATA7A

40

M/G DATA7B

41

ECLKA

42

ECLKB

43

/CONTRESETA

44

/CONTRESETB

45

/ENGINEUPA

46

/ENGINEUPB

47

/CRDYA

48

/CRDYB

49

STATUSA

50

STATUSB

Y/B DATA2A

K DATA0B

K DATA1A

K DATA1B

K DATA2A

K DATA2B

K DATA3A

K DATA3B

K DATA4A

K DATA4B

K DATA5A

K DATA5B

K DATA6A

K DATA6B

K DATA7A

K DATA7B

CCLKA

CCLKB

GNDA

GNDB

/CONTUPA

/CONTUPB

/SRDYA

/SRDYB

CMDA

CMDB

1/1

51

NC

52

NC

53

NC

54

NC

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

NC

72

NC

73

NC

74

NC

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

– 8 –

Page 10

AR-PX1

PCU PWB

Synchronous S10

64K*8

SRAM

EEPROM

CPU

ICU-MAIN PWB

CPUC

Synchronous S10

LSU K

LSU Y

LSU M

LSU C

AR-PE1

K

FROM

*4

Synchronous

K

VCO

K

K

ASIC

Y

PWM

PWMK

Y

LSU

ASIC

Y

Y

M

IC

K

Color

correction

C

K

Y

IC

Synchronous

VCO

Color

C

Tandem memory

Y

ASIC

correction

M

IC

Differential

Y

IC

Synchronous

VCO

adjustment

Intermediate

ROM

M

ASIC

C

C

M

PWM

PWM

C

M

LSU

ASIC

M

C

M

Color

ASIC

correction

M

C

K

IC

IC

Synchronous

Synchronous

Asynchronous S10

C

Color

ASIC

correction

M

C

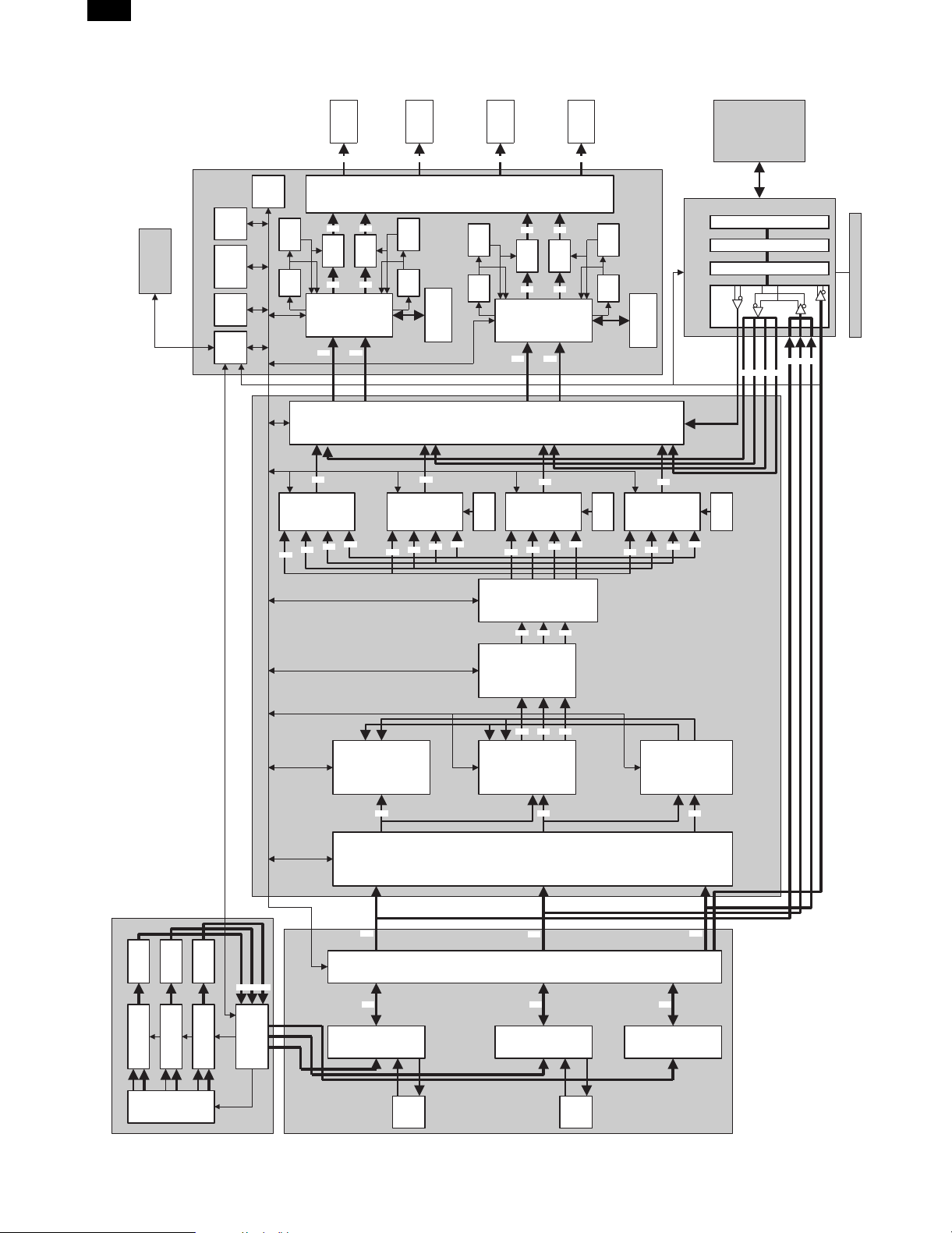

AR-PX1/PX2

Printer connection kit

CRESET

Y

VCO

Tandem memory

ROM

Y

K

Printer controller

External connection cable

Connector PWB

Printer I/F PWB

Printer

I/F PWB

KYM

CCLK

ROM

C

WAKE UP signal

Operation control PWB

RGB

ECLK, HSYNC, SSYNC

R ADC

R analog IC

G ADC

G analog IC

B ADC

B analog IC

R

CCD ASIC

ICU-IMG PWB

B

G

RGB

Area

R

R

R SCN

ASIC

separation A

C

ASIC

C

ASIC

Area

separation C

C

Area

separation B

Input

VIF

Black

generation

M

M

ASIC

M

processing

G

G

G SCN

ASIC

ASIC

ASIC

Y

Y

Area

ASIC

separation D

Y

B

B

ASIC

B SCN

[3] BLOCK DIAGRAM

1.Overall block diagram

CCD PWB

Color

3-line

CCD

ICU-SCN PWB

FMEM

FMEM

– 9 –

Page 11

2. Engine (machine)-to-controller

connection

VSYNC - SSYNCB6

HSYNC - HSYNCB6

C/R Data[0 - 7] - BDC[0 - 7]

DR[0 - 7]

AR-PX1

M/G Data[0 - 7] - BDM[0 - 7]

Y/B Data[0 - 7] -

Controller

K Data[0 - 7] -

ECLK CCLK -

/ CONTRESET - /PRTC RES

/ CONTUP -(WAKE UP)

GND GND

/ ENGINEUP - /PRTE RDY

/CRDY /PRT RTS -

STATUS - PRT RXD

/SRDY -

PRT P

DG[0 - 7]

BDY[0 - 7]

DB[0 - 7]

Engine

Controller

BDK[0 - 7]BDK[0 - 7]

SCLKB6

BPCLK

/PRTC RDY

/PRT CTS

PRT TXD CMD PRT P

/PRT S /PRT S

SIGNAL LIST

SIGNAL NAME

CONTROLLER SIDE ENGINE(COPIER) SIDE

VSYNC - SSYNCB6

HSYNC - HSYNCB6

OUTPUT FUNCTION

Print mode Page Sync Signal

E

Scanner mode Page Sync Signal

Print mode Line Sync Signal

E

Scanner mode Line Sync Signal

This signal is always output during power-on.

C/R Data[0 - 7] - BDC[0 - 7] C Print mode 8 bit Cyan data

DR[0 - 7] E Scanner mode 8 bit Red data

M/G Data[0 - 7] - BDM[0 - 7] C Print mode 8 bit Magenta data

DG[0 - 7] E Scanner mode 8 bit Green data

Y/B Data[0 - 7] - BDY[0 - 7] C Print mode 8 bit Yellow data

DB[0 - 7] E Scanner mode 8 bit Blue data

K Data[0 - 7] - BDK[0 - 7] C Print mode 8 bit Black data

ECLK - SCLKB6

21MHz Clock supplied by the Engine. Data is accepted by the Controller at this CLK

transitions to true. This CLK sends to Engine as the CCLK. This ECLK is transmitted

E

from the Engine to the Controller. Then, ECLK is generated into CCLK at the

Controller and transmitted to the Engine. This signal is always output during

power-on.

CCLK BPCLK

21MHz Clock supplied by the Controller. Data is accepted by Engine at this CLK

C

transitions to true. This signal is always output during power-on.

/ CONTRESET - /PRTC RES E Reserve

/ CONTUP -(WAKE UP) /PRTC RDY C Indicates Controller power is up and it is able to communicate. Engine start signal

GND GND E/C Ground

/ ENGINEUP - /PRTE RDY E Indicates the Print Engine is up and ready to communicate. Controller start signal

CMD - PRT TXD

/CRDY /PRT RTS -

STATUS PRT RXD

/SRDY /PRT CTS

Serial channel signal used to send serial command information from the controller to

C

the engine.

Serial channel signal indicating whether the Engine is ready to receive status

E

information over the serial channel.

Serial channel signal that is used to send serial status information from the Engine

E

to the Controller.

Serial channel signal indicating whether the Controller is ready to receive status

C

information over the serial channel.

PRT P PRT P E Operation mode switch signal (Printer operation mode)

/PRT S /PRT S E Operation mode switch signal (Scanner operation mode)

E: Engine

C: Controller

– 10 –

Page 12

AR-PX1

Page 13

PARTS GUIDE

PRINTER I/F KIT

AR-PX1

MODEL AR-PX2

AR-PX1

AR-PX2

For North and

(

South America

)

CONTENTS

1 Packing material & Accessories

2 Printer I/F PWB unit

■ Index

SHARP CORPORATION

This document has been published to be

used for after sales service only.

The contents are subject to change without

notice.

Page 14

AR-PX1

AR-PX2

DEFINITION

The definition of each Rank is as follows and also noted in the lis t

A : Parts necessary to be stocked as High usage parts.

B : Parts necessary to be stocked as Standard usage parts.

C : Low usage parts.

D : Parts necessary for refurbish.

E : Unit parts recommended to be stocked for efficient after sales service.

Please note that the lead time for the said parts may be longer than normal parts.

S : Consumable parts.

Please note that the following parts used in Copier under the same description are classi fied into A or B Rank depending

upon the place used.

Example : Gear made of Metal, Sprocket, Beari ng, Belt made of Rubber, Spring clutch mechanism.

A Rank : The parts which may be with the revolution or loading.

B Rank : Parts similar to A Rank parts, but are not included in Rank A.

Because parts marked with "!" is indispensable for the machine safety maintenance and operati on, it must be replaced with

the parts specific to the product specification.

F Other than thi s Parts Guide, please refer to documents Service Manual (including Circuit Diagram) of this model.

F Pl ease use the 13 digit code described in the right hand corner of front cover of the document, when you place an order.

F For U.S. onl y-Use order codes provided in advertising literature. Do not order from parts department.

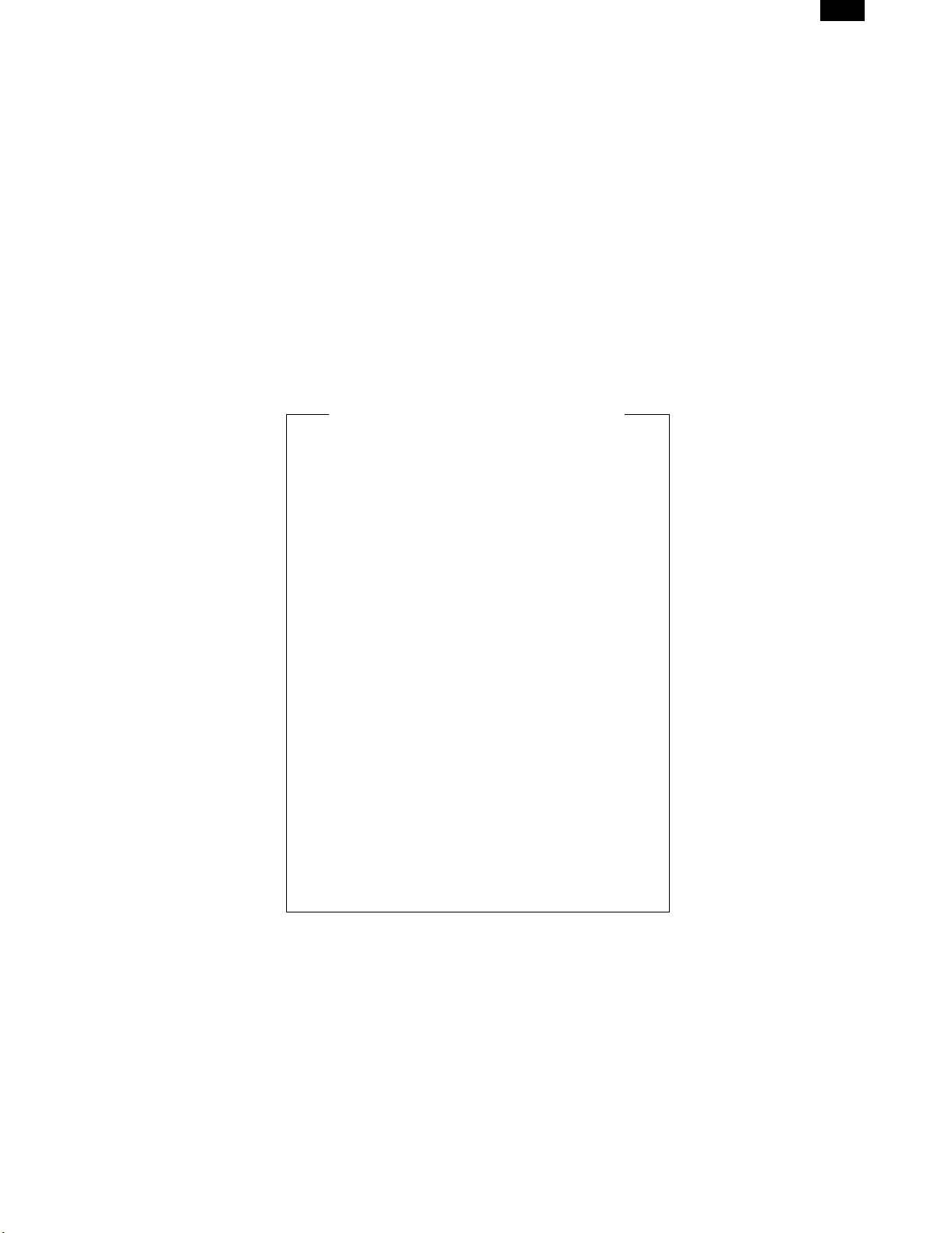

1 Packing material & Accessories

PRICE

NO. PARTS CODE

SPAKA6077FCZZ AH

1

SSAKA3440QCZZ AB

2

QCNW-0164FCZZ BX

3

SPAKC6076FC13 AN

SPAKC6076FCZZ AN

4

SPAKC6076FC12 AN

SPAKC6076FC11 AN

SPAKA0011YSZZ AD

5

CPLTM5607FC51 BD

6

CPWBN1384FC51 BD

7

CPWBN1382FC51 CD

8

SSAKA1241QCZZ AB

9

SPAKP2374ACZZ AD

10

SSAKA5003CCZZ AA

11

SSAKH3012CCZZ AA

12

QCNW-0163FCZZ BN

13

LHLDW1435FCZZ AF

14

DHAI-3131FCZZ AG

15

XBPSD30P06XS0 AA

101

TLABS3760FCZZ AC

102

TLABZ4173FCZZ AG

103

RANK

NEW

MARK

N D Spacer

N C Twist cable

N D Packing case (USA)

N D Packing case (Japan)

N D Packing case (Europe,U.Kingdom,Australia,New Zealand)

N D Packing case (Canada,other countries)

N D Protect sheet

N E Printer CN fixing plate U

N E Printer CN PWB unit

N E Printer I/F PWB unit

N C Flat cable

N C Flat cable holder

N C Wake up harness

PART

RANK

D Vinyl bag (300

D Vinyl bag (240

D Vinyl bag (240

D Vinyl bag (140

D Vinyl bag (80

CScrew (3

D CE mark label (Europe,U.Kingdom,Australia,New Zealand)

D Connector caution label (Europe,U.Kingdom,Australia,New Zealand)

´420mm)

´180mm)

´170mm)

´260mm)

´120mm)

´6XS)

DESCRIPTION

– 1 –

Page 15

1 Packing material & Accessories

15

AR-PX1

AR-PX2

11

12

14

1

13

2

10

3

9

8

6

7

4

5

5

2 Printer I/F PWB unit

NO. PARTS CODE

QCNCM1054FCZZ AS

1

QCNCM7014SC0C AA

2

QCNCW1053FCZZ AM

3

RFILN0041FCZZ AC

4

VCEAGA1AW107M AB

5

VCEAGU1AW476M AA

6

VCEAGA1AW477M AB

7

VCKYCY1EF104Z AA

8

VCKYCY1HB561K AA

9

VCKYCY1HF223Z AA

10

VHDDSS133//-1 AA

11

VHIDS90LV018A AQ

12

VHIDS90LV031A AY

13

VHIDS90LV032A AY

14

VHINJU7200L33 AF

15

VHI74LCX32MTC AE

16

VHI74LV32AT// AD

17

VHI74VHC32MTC AD

18

VRS-TS2AD101J AA

19

VRS-TS2AD101J AA

VRS-TS2AD103J AA

20

VRS-TS2AD361J AA

21

VRS-TS2AD681J AA

22

VSDTC114EK/-1 AB

23

(Unit)

CPWBN1382FC51 CD

901

PRICE

RANK

FCP04110

NEW

PART

MARK

RANK

N C Connector (100pin) [CN543]

C Connector (3pin) [CN542]

N C Connector (80pin) [CN541]

C EMI filter (ZJSR5101222) [NF100,102]

C Capacitor (10WV 100mF) [C146]

C Capacitor (10WV 47mF) [C143]

C Capacitor (10WV 470mF) [C108,125,137]

Capacitor (25WV 0.10mF)

C

C Capacitor (50WV 560PF) [C114]

C Capacitor (50WV 0.022mF) [C144,145]

B Diode (DSS133) [D100]

N B IC (DS90LV018A) [IC110]

N B IC (DS90LV031A) [IC104,106~109,122,123,125]

N B IC (DS90LV032A) [IC100~103,112~115,124]

N B IC (NJU7200L33) [IC127]

B IC (74LCX32MTC) [IC105,116~121]

B IC (74LV32AT) [IC126]

B IC (74VHC32MTC) [IC111]

Resistor (1/10W 100W

C

C Resistor (1/10W 100W

C Resistor (1/10W 10KW

C Resistor (1/10W 360W

C Resistor (1/10W 680W

B Transistor (DTC114EK) [Q100]

N E Printer I/F PWB unit

±5%)

±5%) [R145,146,148,149,151,152,154,155,156,161,162]

±5%) [R110,113,116,119,122,144,147,150,153,157,160]

±5%) [R121]

±5%) [R120]

DESCRIPTION

[C100~105,117~122,127~136,138~142]

[R100~109,111,112,114,115,117,118,128,136~143]

– 2 –

Page 16

AR-PX1

AR-PX2

■ Index

PARTS CODE NO.

[C]

CPLTM5607FC51

CPWBN1382FC51

"

CPWBN1384FC51

[D]

DHAI-3131FCZZ

[L]

LHLDW1435FCZZ

[Q]

QCNCM1054FCZZ

QCNCM7014SC0C

QCNCW1053FCZZ

QCNW-0163FCZZ

QCNW-0164FCZZ

[R]

RFILN0041FCZZ

[S]

SPAKA0011YSZZ

SPAKA6077FCZZ

SPAKC6076FC11

SPAKC6076FC12

SPAKC6076FC13

SPAKC6076FCZZ

SPAKP2374ACZZ

SSAKA1241QCZZ

SSAKA3440QCZZ

SSAKA5003CCZZ

SSAKH3012CCZZ

[T]

TLABS3760FCZZ

TLABZ4173FCZZ

[V]

VCEAGA1AW107M

VCEAGA1AW477M

VCEAGU1AW476M

VCKYCY1EF104Z

VCKYCY1HB561K

VCKYCY1HF223Z

VHDDSS133//-1

VHI74LCX32MTC

VHI74LV32AT//

VHI74VHC32MTC

VHIDS90LV018A

VHIDS90LV031A

VHIDS90LV032A

VHINJU7200L33

VRS-TS2AD101J

VRS-TS2AD103J

VRS-TS2AD361J

VRS-TS2AD681J

VSDTC114EK/-1

[X]

XBPSD30P06XS0

1- 6

1- 8

2-901

1- 7

1- 15

1- 14

2- 1

2- 2

2- 3

1- 13

1- 3

2- 4

1- 5

1- 1

1- 4

1- 4

1- 4

1- 4

1- 10

1- 9

1- 2

1- 11

1- 12

1-102

1-103

2- 5

2- 7

2- 6

2- 8

2- 9

2- 10

2- 11

2- 16

2- 17

2- 18

2- 12

2- 13

2- 14

2- 15

2- 19

2- 20

2- 21

2- 22

2- 23

1-101

PRICE

RANK

BD

CD

CD

BD

AG

AF

AS

AA

AM

BN

BX

AC

AD

AH

AN

AN

AN

AN

AD

AB

AB

AA

AA

AC

AG

AB

AB

AA

AA

AA

AA

AA

AE

AD

AD

AQ

AY

AY

AF

AA

AA

AA

AA

AB

AA

NEW

PART

MARK

RANK

NE

NE

NE

NE

NC

NC

NC

C

NC

NC

NC

C

ND

ND

ND

ND

ND

ND

D

D

D

D

D

D

D

C

C

C

C

C

C

B

B

B

B

NB

NB

NB

NB

C

C

C

C

B

C

PARTS CODE NO.

PRICE

RANK

NEW

MARK

PART

RANK

– 3 –

Page 17

CAUTION FOR BATTERY REPLACEMENT

(Danish) ADVARSEL !

Lithiumbatteri – Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandoren.

(English) Caution !

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according to manufacturer’s instructions.

(Finnish) VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

(French) ATTENTION

Il y a danger d’explosion s’ il y a remplacement incorrect

de la batterie. Remplacer uniquement avec une batterie du

même type ou d’un type équivalent recommandé par

le constructeur.

Mettre au rebut les batteries usagées conformément aux

instructions du fabricant.

(Swedish) VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent

typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

instruktion.

AR-PX1

Page 18

AR-PX1

All rights reserved.

Printed in Japan.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted,

in any form or by any means,

electronic; mechanical; photocopying; recording or otherwise

without prior written permission of the publisher.

SHARP CORPORATION

Digital Document Systems Group

Quality & Reliability Control Center

Yamatokoriyama, Nara 639-1186, Japan

1999 December Printed in Japan

Loading...

Loading...