Page 1

AR-PB2A

CODE: 00ZARPB2A//1E

DIGITAL COPIER OPTION

PRINTER UNIT

MODEL AR-PB2A

CONTENTS

[ 1 ] SYSTEM CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 2 ] SPECIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[ 3 ] SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[ 4 ] SETTING AND ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . 4-1

[ 5 ] CONFIGURATION REPORT AND TEST PAGE . . . . . . . . . . . . 5-1

[ 6 ] FIRMWARE VERSION UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[ 7 ] FUNCTION AND OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

CIRCUIT DIAGRAM (Refer to the AR-PB2 Service Manual)

PARTS GUIDE

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

AR-PB2A

CONTENTS

[ 1 ] SYSTEM CONFIGURATION . . . . . . . . . . . . . . . . . . . . .1-1

1. Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

A. Main Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

B. System Elements . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

C. Input/Output Device Options . . . . . . . . . . . . . . . . . . .1-1

D. Accessory and Options . . . . . . . . . . . . . . . . . . . . . . .1-2

E. List of the Applicable Models for the AR-PB2A

Printer Expansion Kit . . . . . . . . . . . . . . . . . . . . . . . .1-2

2. Software Configuration . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

[ 2 ] SPECIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

1. General Specification . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

A. PS Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

B. Printer Driver Compatibility . . . . . . . . . . . . . . . . . . . .2-1

2. Printing Function Specification . . . . . . . . . . . . . . . . . . . .2-2

A. Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

B. Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

[ 3 ] SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

1. Parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

2. Preliminary work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3. Hardware setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

A. Common work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

B. Stand-alone environment

(Printer (parallel) cable connection) . . . . . . . . . . . . .3-3

C. Network environment

(Network card installation) . . . . . . . . . . . . . . . . . . . . .3-4

4. Setup on the copier side . . . . . . . . . . . . . . . . . . . . . . . . .3-4

A. Setup by simulation . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

B. Setup by key operator program . . . . . . . . . . . . . . . . .3-4

5. Software installation and setup . . . . . . . . . . . . . . . . . . . .3-4

6. Setup under network environment . . . . . . . . . . . . . . . . .3-4

A. Outline of the NW Setup . . . . . . . . . . . . . . . . . . . . . .3-4

B. Checking the Hardware and Software

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

C. Confidential Print . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

D. Tandem Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

7. Web Page Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

A. Password Setting . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

B. E-mail Setup and Network Scanning Setup . . . . . . .3-5

[ 4 ] SETUP AND ADJUSTMENTS . . . . . . . . . . . . . . . . . . . .4-1

1. Configuration setting . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

A. Printer setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

B. Interface Settings . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

C. Network Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

D. Print Test Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

E. Initialization and/or Storage Setting . . . . . . . . . . . . . 4-3

2. Key operator programs . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

3. Hardware setup and adjustments . . . . . . . . . . . . . . . . . .4-4

A. Flash Memory write protect setting . . . . . . . . . . . . . . 4-4

B. Laser power setup . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

C. Centro interface adjustment . . . . . . . . . . . . . . . . . . .4-4

D. NVRAM clear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

E. Network card check . . . . . . . . . . . . . . . . . . . . . . . . .4-4

[ 5 ] Configuration Report and Test Page . . . . . . . . . . . . . 5-1

1. Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

2. Description of Each contents . . . . . . . . . . . . . . . . . . . . .5-1

A. Hardware Status . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

B. Software Information . . . . . . . . . . . . . . . . . . . . . . . . .5-3

[ 6 ] FIRMWARE VERSION UP . . . . . . . . . . . . . . . . . . . . . . .6-1

1. Printer controll PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

A. Cases where flash memory rewriting is required . . .6-1

B. Necessary tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

C. Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

2. Network card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

A. Check the version number of the network card. . . . .6-1

B. Upgrade of network card The upgrade tool is

included in the PRINTER UTILITIES CD-ROM. . . . .6-1

[ 7 ] FUNCTION AND OPERATION . . . . . . . . . . . . . . . . . . .7-1

1. Multi Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

2. Printer Operation / Message Display . . . . . . . . . . . . . . .7-2

3. Emulation Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

4. Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

5. Font . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

A. Downloadable Font Types . . . . . . . . . . . . . . . . . . . . 7-3

B. Location of Font Data . . . . . . . . . . . . . . . . . . . . . . . .7-3

6. Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

A. Language Selection . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

B. Job, control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7. Host I/O Port Selection . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

13. Memory Configuration . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

14. Printer control PWB switch (short pin) and

LED display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

15. Confidential Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

16. Tandem Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

(Error Messages)

• PARTS GUIDE

Page 3

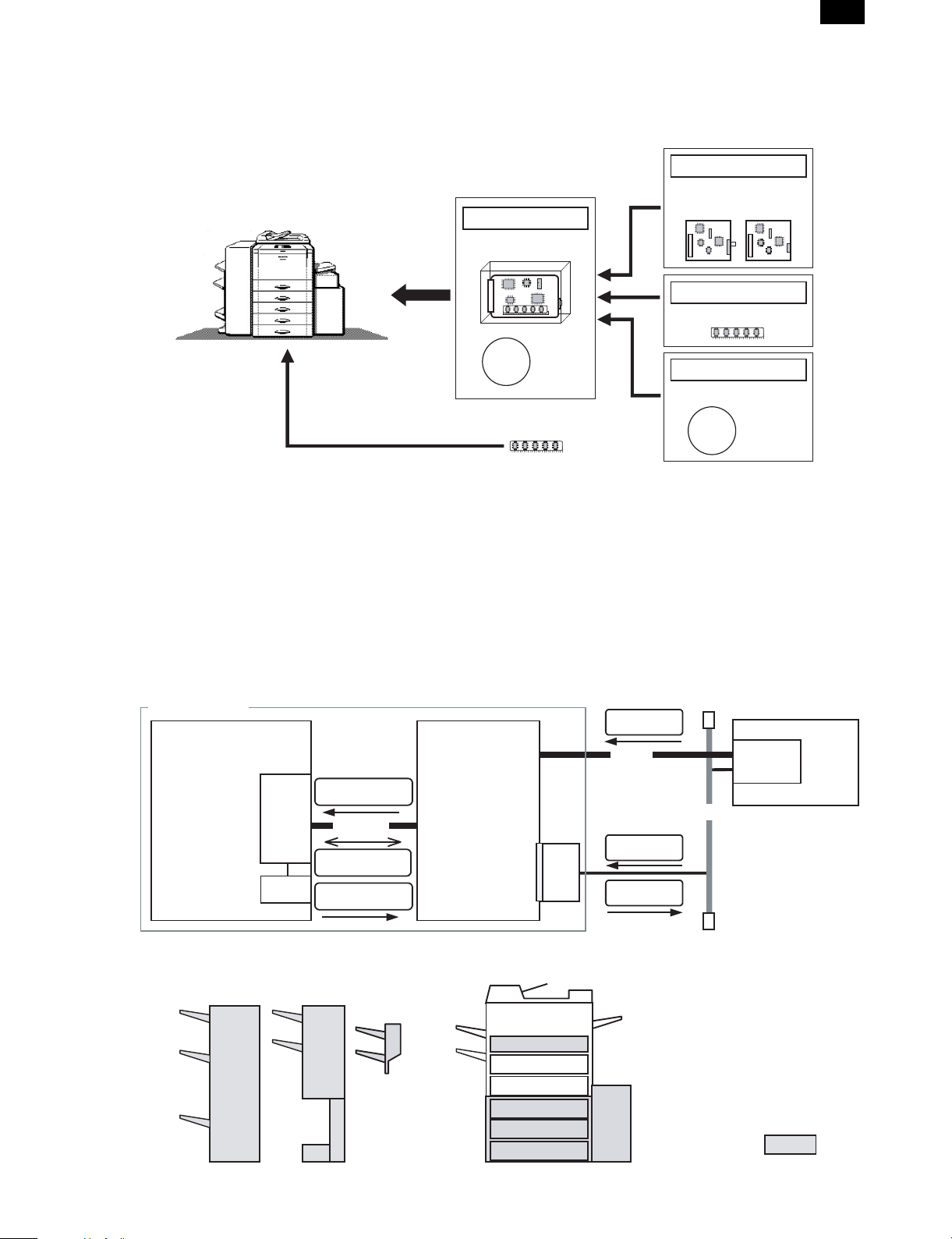

[1] SYSTEM CONFIGURATION

(BT)

1. Hardware

A. Main Unit

Printer Expansion kit

AR-PB2A

AR-PB2A

Print Server Card

AR-NC3D

(10Base-T / 100Base-TX)

Expansion Memory

AR-SM1

(1) Print Controller Hardware and Options

Controller Hardware

Hardware configuration is as follows:

• ProcessorR 4700

• Base Memory 16 MB

• Flash Memory 1 slot with 8 MB

• Memory Expansion 2 Standard 72 pin SIMM slots

• Parallel Interface 1 IEEE 1284 compatible Type B

• Network Expansion Slot 1 Internal slot

B. System Elements

AR-PB2A printer

Copier Printer Controller

Bitmap data

ICU

eRDH

SCSI I/F

command/status

Bitmap data

CD-ROM

SDRAM

Scanner Expansion Kit

AR-NS1

CD-ROM

(2) Options

DRAM

The system can optionally be configured with up to 64-MB optional

DRAM Using industry standard, 16 or 32 Mb72 pin SIMMs.

Network Server Card

AR-PB2 Printing system can optionally be configured with Network

Server Card of supporting 10Base-T and 100Base-TX.

Print data/

Setting data

P1284

Windows PC

Own

Printer

Driver

Ethernet

Print data/

Setting data

Scan data

DPO I/F

NIC

(DPI)

C. Input/Output Device Options

3Tray

Finisher

Finisher

2Tray

2Tray

Output

STD Output

(1Tray) or

(2Tray)

Tray5

1 – 1

ADU

Tray1

Tray2

Tray3

Tray4

(Only Japan

Domestic)

Bypass Tray

LCC

Option

Page 4

AR-PB2A

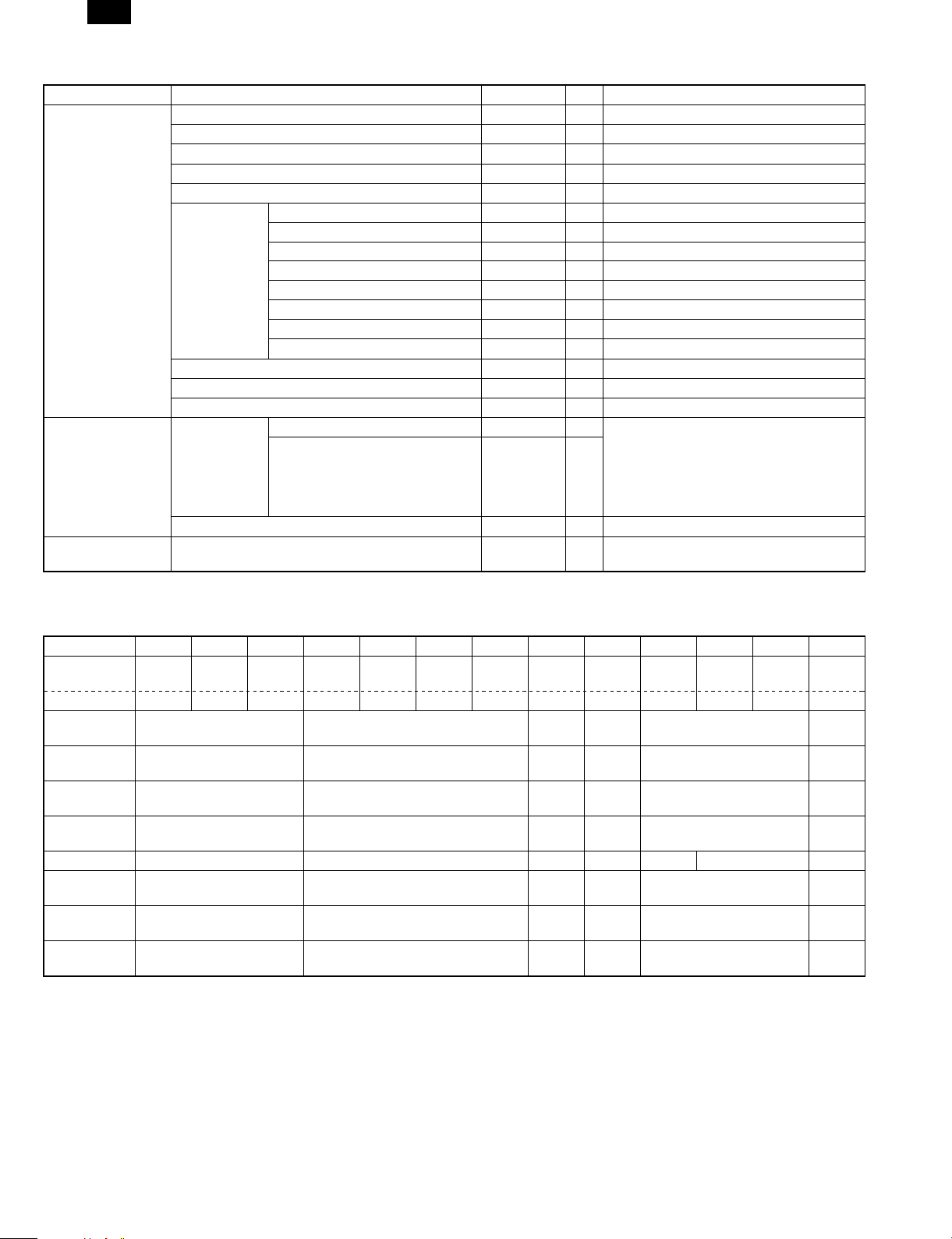

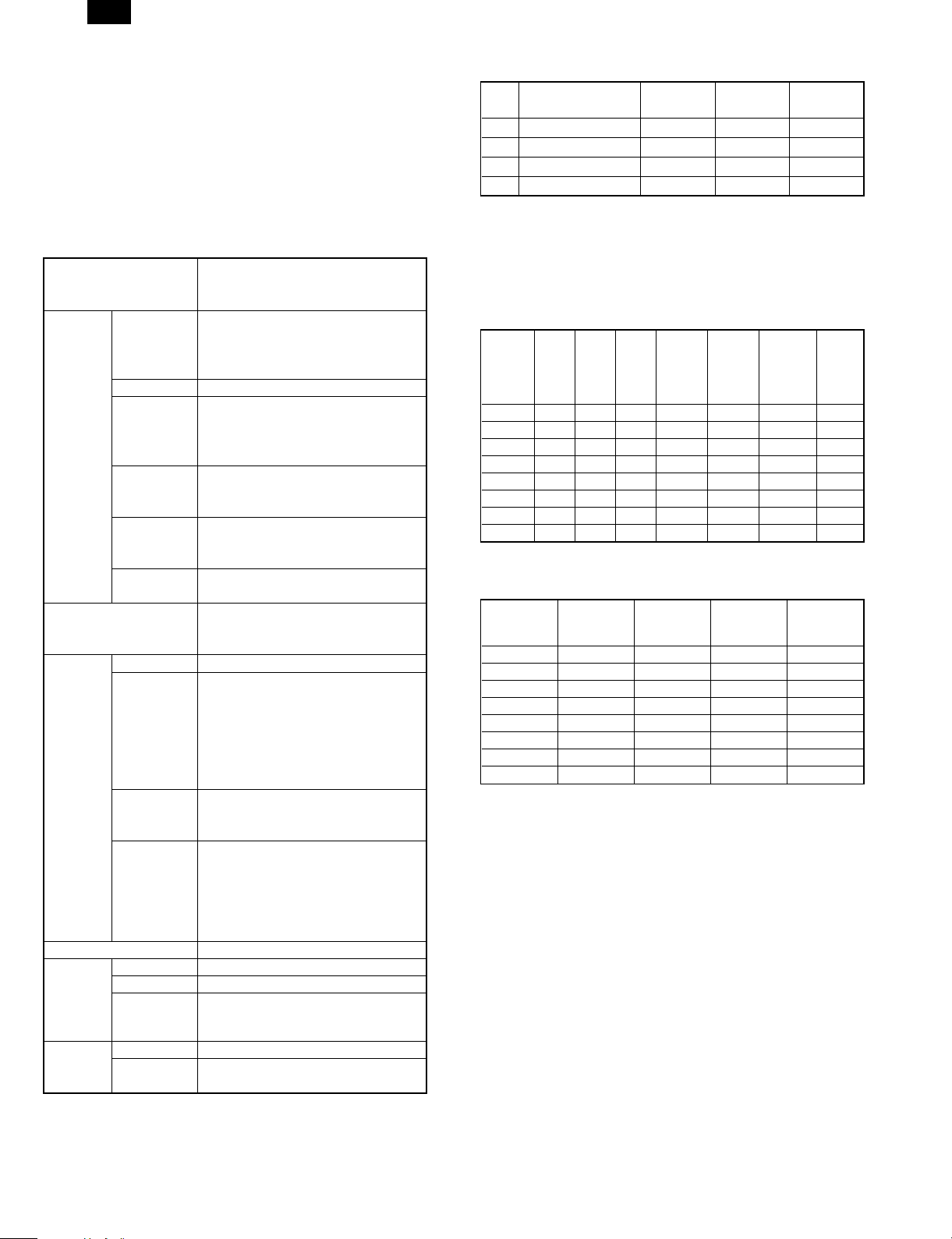

D. Accessory and Options

Part name Model Q’ty Note

Accessories SCSI cable 1

Wire saddle 1

Band 1

Printer box installing screw 5

Printer control PWB 1 With frame

Printer driver Printer Driver (including PPD File) 1

Screen Font 1

Resident-FontData Install Utility 1

Printer Administration Utility ver.2.x 1

NWsetup 1

Printer Status Monitor ver.2.0 1

Integrated Installer 1

Makedisk Utility 1

Installation manual 1

Operation Manual 1

Label 1 Only for Sweden and Norway

Option SIMM memory 16MB ED0 type/Without parity/70ns or above

32MB

Network card AR-NC3D 1 10Base-T / 100Base-TX

Separate purchase

Printer (parallel) cable Necessary when the copier is used as a

(User purchase)

The copier ICU PWB requires the total

memory of 16MB(20MB) or more.

The printer control PWB has two expansion

slots to which 16MB or 32MB memory can

be additionally installed. (16MB onboard)

stand-alone machine.

E. List of the Applicable Models for the AR-PB2A Printer Expansion Kit

The details of the specifications, features, and options of the printer may vary with the printer models. Some features described in this manual may

not be available depending on the printer drivers.

Model Name AR-280 AR-285 AR-335 AR-250 AR-281 AR-286 AR-336 AR-405 AR-505 AR-287 AR-337 AR-407 AR-507

Hard disk

drive

Capacity 2GB

Reverse

order printing

Photo

enhancement

Toner save/

smoothing

Confidential

print

Yes Yes Yes No

2

*

2GB

2

*

2GB

2

*

Yes Yes Yes No Yes No

No No No Yes Yes Yes

No Yes Yes Yes Yes Yes

No No No No Yes Yes

Tandem print No No No No No Yes Yes

Status/alert

by E-mail

Account

control

Network

scanner

*

3

No No No No Yes Yes

No No No No Yes Yes

No No No No Yes Yes

*1 Optional

*2 Some units of the models may come with a 1 GB hard disk drive.

*3 Optional AR-NS1 is needed.

AR-PB1 A and AR-PB2 A are available for following models however, the available functions can vary with the copier models installed.

1

*

Yes Yes Yes Yes Yes Yes Yes Yes Yes

1GB 2GB 2GB 2GB 2GB 2GB 4.3GB 4.3GB 4.3GB 4.3GB

1 – 2

Page 5

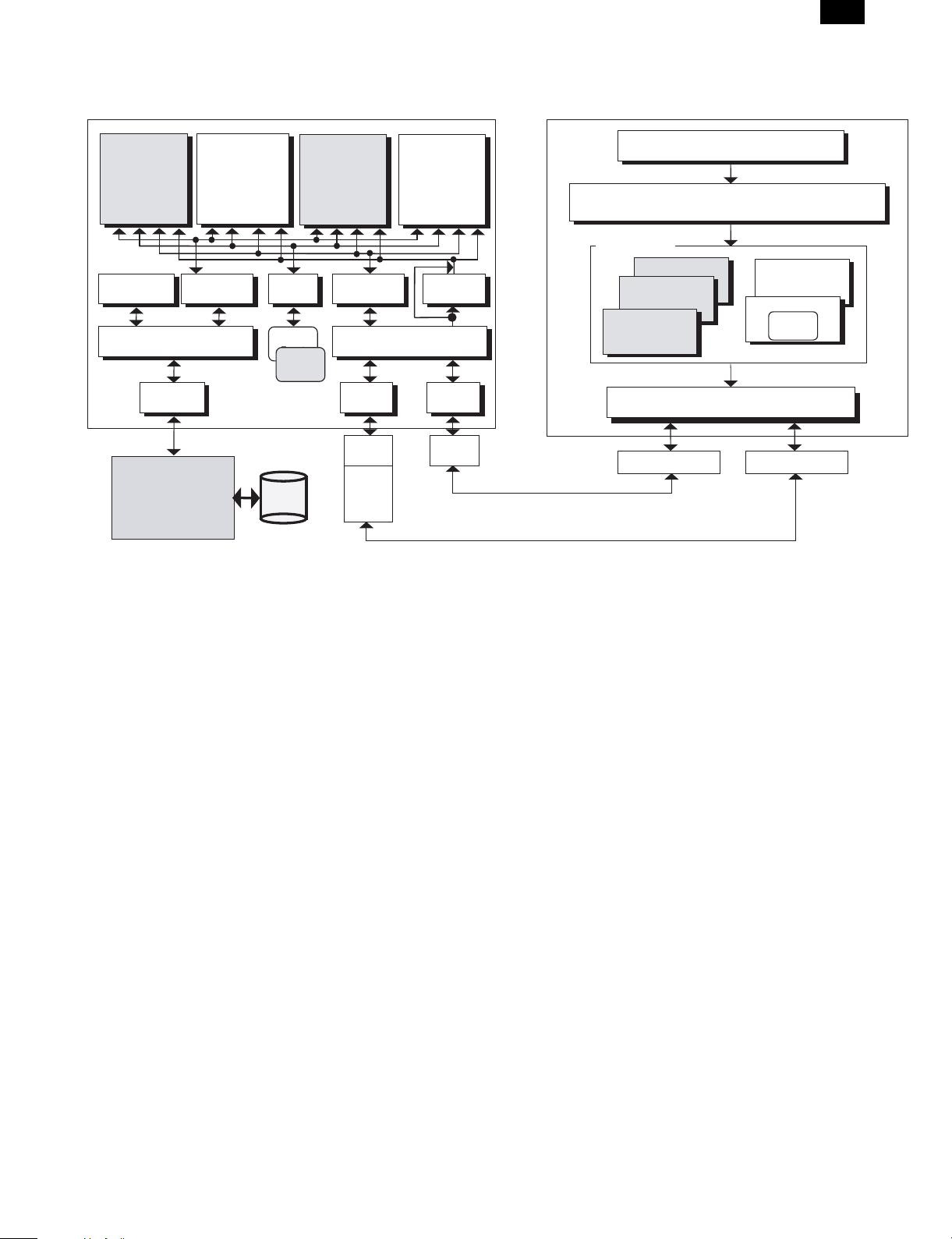

2. Software Configuration

AR-PB2A

ESC/P Super

ESC/P

(Japan only)

Front Panel

Control

Engine I/F Manager

SCSI-2 I/F

Driver

Print

Engine

PostScript L2

Print Queue

Manager

Font

Manager

Roman

Font

Kanji

(Japan only)

eRDH

PCL5e

(SPDL)

PJL

Host I/O Manager

DPO

Driver

DPO

Port

NIC

Firmware

PCL6

(EX only)

AUTO

Switching

1284

Driver

1284

Port

Application

GDI (Graphic Module)

Printer Driver

PostScript

PCL

(SPDL)

PCL6

(EX only)

Print Spooler

1284 Port Ethernet Port

Win3.1x/Win95/WinNT4.0

Others

PostScript

PPD

(Japan only)

1 – 3

Page 6

AR-PB2A

[2] SPECIFICATION

New function provided by combination use with AR-287/337/407/507

• Confidential Print

• Tandem Print

• E-mail Status/E-mail Alerts

• Potential to enhance the Network Document Scanner

1. General Specification

A. Specification

Platform *1 IBM PC/AT (Include compatible machine)

Macintosh (680 x 0)

Power Macintosh, iMac

Support OS

(Printer

Driver)

PDL PCL5e emulation

Network 1 Interface 10/100Base-T (AR-NC3D)

CPU R4700 (64bit RISC / 150MHz)

Memory Standard EDO RAM 16 MB

Resident

Fonts

Custom PS Windows 3.1/WfW3.11

Windows 95/98

Windows NT 4.0

Windows 2000

Custom SPDL N/A

Custom PCL5e Windows 3.1/WfW3.11

Windows 95/98

Windows NT4.0

Windows 2000

Custom PCL6 Windows 95/98

Windows NT4.0

Windows 2000

Windows PPD Windows 95/98

Windows NT 4.0

Windows 2000

Macintosh PPD MacOS 7.6 – 8.6

MacOS9

PCL6 emulation

PostScript Level 2 emulation

Support OS UNIX

Windows 3.1/95/98

Windows NT3.51/4.0

Windows 2000

Novell NetWare 3.x / 4.x / NetWare 5

Macintosh System 7.x / MacOS 7.5.x /

MacOS 8.x / MacOS 9

Base Protocols IPX/SPX for Novell

TCP/IP for Windows and UNIX

EtherTalk for Macintosh

Printing

Protocols

Max 80 MB

Slot 2 Slots

For PS 80 fonts (Same 80 fonts as PCL)

For PCL5e,

PCL6, SPDL

PSERVER for NDS or bindery environment

with Novell

LPR / LPD

EtherTalk

FTP

TCP Raw Socket (Direct Dump)

EDO type 72pin standard SIMM 16MB or

32MB

80 fonts (Same 80 fonts as PS)

Line Printer

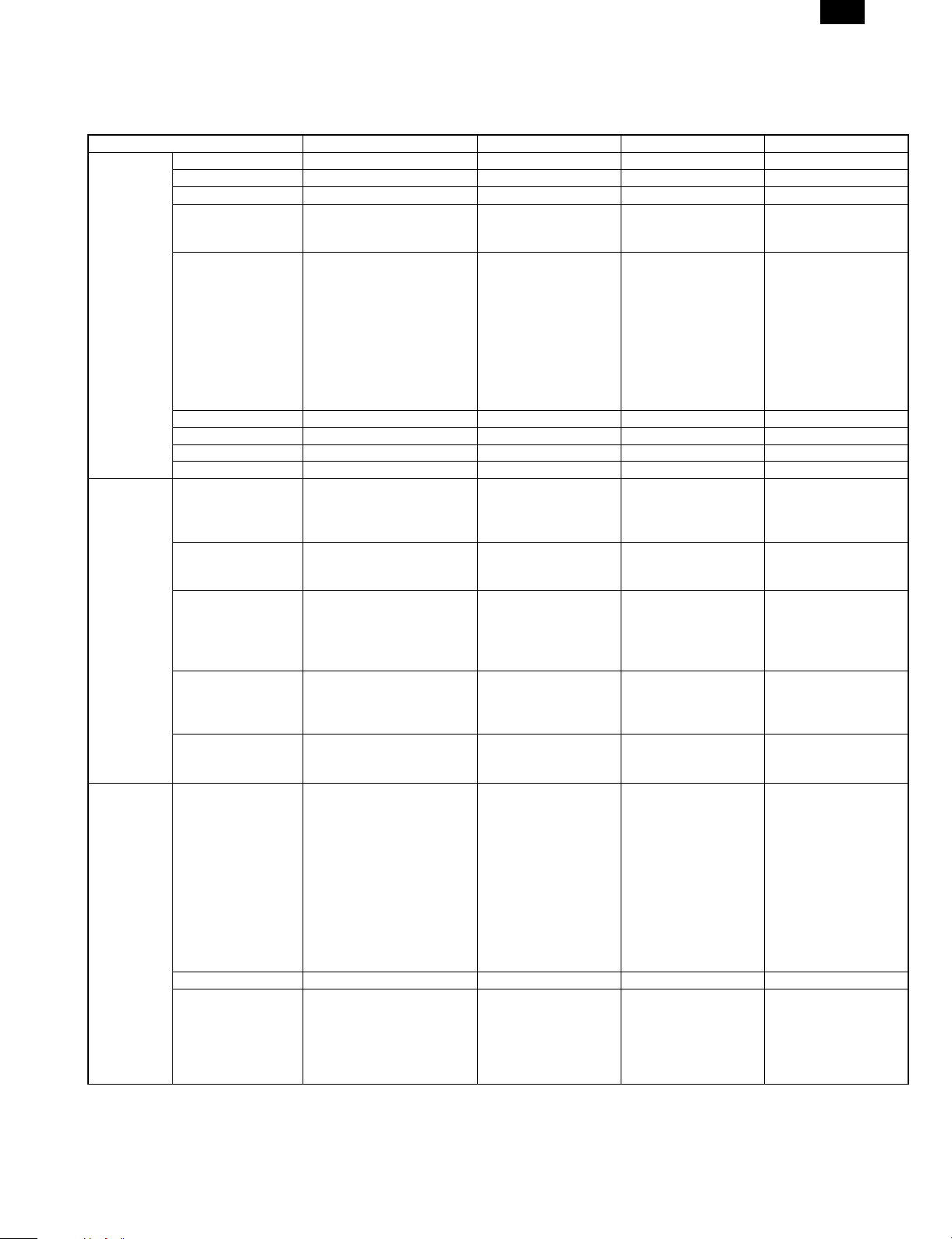

B. Printer Driver Compatibility

NO. PRINTER DRIVER WIN 3.1

1 Windows PS ✕✕✕

2 Windows PPD ✕✕

3 Windows PCL5e ✕✕✕

4 Windows PCL6 ✕✕

NOTE: Users of Windows will obtain maximum functionality and bet-

ter output quality by installing the Windows PostScript

Printer driver. Alternatively, the Windows PCL5e driver will

provide the best print speed.

WIN 95/

WIN 98

WIN NT

Language Localization

The description of the driver including the help file, front panel menu

and print text must be provided in various languages as follows:

Printer

Front

Panel

Demo

Pages

Integrated

Installer

PCL5e

Language

English ❍❍ ❍ ❍ ❍ ❍

German ❍❍ ❍ ❍ ❍ ❍

French ❍❍ ❍ ❍ ❍ ❍

Italian ❍❍ ❍ ❍ ❍ ❍

Spanish ❍❍ ❍ ❍ ❍ ❍

Dutch ❍❍ ❍ ❍ ❍ ❍

Swedish ❍❍ ❍ ❍ ❍ ❍

Japanese ❍❍ ❍ ❍ ❍

driver

PCL6

driver

SPDL

driver

Windows

PS2

driver

Windows

PPD

Macintosh

PPD

"Localization" includes changing default paper selection etc. to meet

the needs of each market.

The following is language-application matrix.

Language

English ❍❍❍❍

German ❍❍❍❍

French ❍❍❍❍

Italian ❍❍❍❍

Spanish ❍❍❍❍

Dutch ❍❍❍❍

Swedish ❍❍❍❍

Japanese ❍❍❍❍

Printer

Administration

Utility

Printer Status

Monitor

NW Setup

2 – 1

Page 7

AR-PB2A

2. Printing Function Specification

A. Outline

(1) Windows

Function PCL5e custom driver PCL6 custom driver PS custom driver PPD file *1

General Copies 1-999 ←←←

Orientation Portrait Landscape ←←←

Reverse Order Yes / No ←←←

Duplex 1-Sided

2-Sided

(Left /Top/Right Binding)

Booklet Invoice on Letter

Letter on Ledger

A5 on A4

A4 on A3

B5 on B4

Binding Edge Left / Top / Right ←←Long / Short

N-up N/A 2/4/6/8/9/16 ← 2/4 *2

N-up Order N/A Z ←←

N-up Border N/A Yes / No ← Always Yes

Paper Input Paper Size A3 / B4 / A4 / B5 / A5 / A6 /

Japanese Postcard / Ledger /

Legal / Foolscap / Letter /

Executive / Invoice

Custom Paper Size 1 size ← 1 size 3 sizes (0 sizes for

Source Selection Automatic

Bypass-Tray

Bypass-Tray(Manu.)

Tray 1/2/3/4

Large Capacity Tray

Different 1st Page Yes / No

It is possible to select

whether print back-side of

first paper with duplex

Transparency Inserts No

Yes (Blank)

Yes (Printed)

Paper Output Output Tray Selection 1 Exit Tray

Not Selectable

2 Exit Trays

Top Tray

Second Tray

2 Tray Finisher

Top Tray

Offset Tray

3 Tray Finisher

Top Tray

Second Tray

Offset Tray

Face-up/down Yes / No ←←←

Staple 2 Tray Finisher

Yes / No

3 Tray Finisher

No staple

1 staple

2 staples

←←1-Sided

Invoice on Letter

Letter on Ledger

A5 on A4

A4 on A3

B5 on B4

Letter on Letter

Ledger on Ledger

A4 on A4

A3 on A3

B4 on B4

←←←

←←←

←←N/A

←←

←←←

←←←

← N/A

2-Sided

(Long/Short Binding)

WindowsNT and

Windows2000)

Yes

2 – 2

Page 8

AR-PB2A

Function PCL5e custom driver PCL6 custom driver PS custom driver PPD file *1

Graphic Resolution Setting 600dpi ←←←

Halftone Setting N/A Photo image

Line image

Scan image

Graphics Mode Raster

HP-GL2

Smoothing Yes / No ←←←

Toner save Yes / No ←←←

Photo Enhancement N/A N/A Yes / No N/A

Negative Image N/A ← Yes / No ←

Mirror Image N/A ← Horizontal

Zoom N/A ← N/A 25-400%

Fit to Page Yes ←←N/A

Font Resident Font 80 fonts

Category 1, 3 and 4

In font chapter

Download Font Bitmap

TrueType

Graphics

Others Configuration Setting Yes ←←←

Watermark Yes ←←N/A

Form Overlay Yes ← N/A ←

Confidential Print Yes ←←N/A

Print Accounting Yes ←←N/A

Tandem Print Yes ←←←

Job End Notification Yes ←←N/A

*1...This file is required for printing on the Cougar using Adobe PS driver (V4.0)

*2...Windows NT does not support N-up printing. All Windows but NT support 2-up and 4-up only.

Raster

Vector

←←←

← Bitmap

Screen Frequency

8.0 to 360.0

in 0.1 steps

Screen angle

0.0 to 360.0

in 0.1 steps

N/A ←

Vertical

Type1

TrueType

←

Horizontal

←

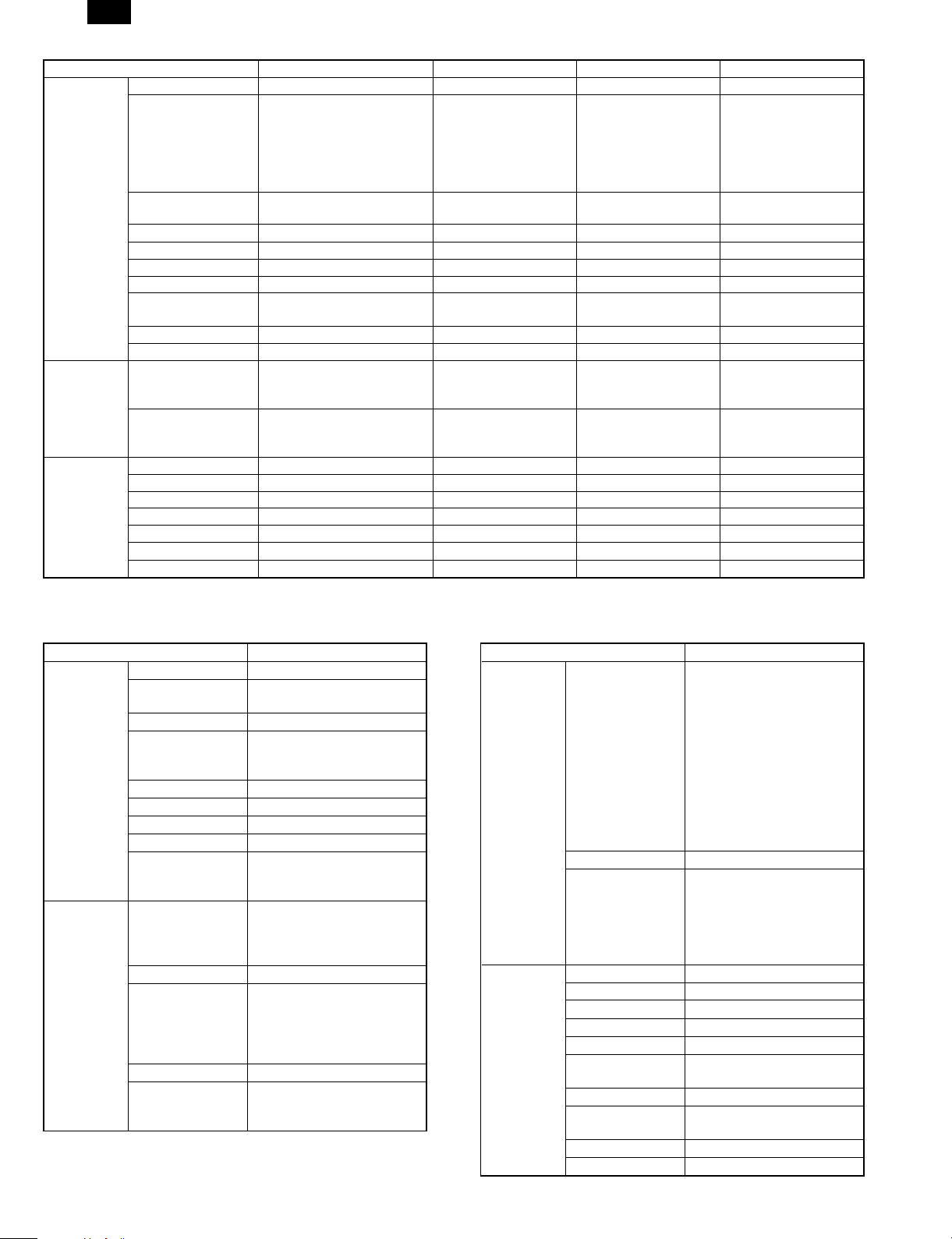

(2) Macintosh

Function Macintosh PPD file

General Copies 1-999

Orientation Portrait

Landscape

Reverse Order Yes / No

Duplex 1-Sided

Booklet N/A

Binding Edge Long / Short

N-up 2/4/6/9/16

N-up Order Z / reversed Z

N-up Border None / Single Hairline / Single

Paper Input Paper Size A3 / B4 / A4 / B5 / A5 / A6 /

Custom Paper Size N/A

Source Selection Automatic

Different 1st Page Yes / No

Transparency

Inserts

2-Sided

(Left /Top/ Right Binding)

Thinline / Double Hairline /

Double Thinline

Japanese Postcard /

Ledger / Legal / Foolscap /

Letter / Executive / Invoice

Bypass-Tray

Bypass-Tray(Manu.)

Tray 1/2/3/4

Large Capacity Tray

No

Yes (Blank)

Yes (Printed)

Paper Output Output Tray

Graphic Resolution Setting 600dpi

Function Macintosh PPD file

1 Exit Tray

Selection

Face-up/down Yes / No

Staple 2 Tray Finisher

Halftone Setting N/A

Graphics Mode N/A

Smoothing Yes / No

Toner save Yes / No

Photo

Enhancement

Negative Image Yes / No

Mirror Image Horizontal

Zoom 25-400%

Fit to Page N/A

Not Selectable

2 Exit Trays

Top Tray

Second Tray

2 Tray Finisher

Top Tray

Offset Tray

3 Tray Finisher

Top Tray

Second Tray

Offset Tray

Yes / No

3 Tray Finisher

No staple

1 staple

2 staples

N/A

Vertical

2 – 3

Page 9

AR-PB2A

Function Macintosh PPD file

Font Resident Font 35 fonts

Category 1

In font chapter

Download Font N/A

Others Configuration

Yes

Setting

Watermark N/A

Form Overlay N/A

Confidential Print Yes

(PIN selection)

Print Accounting Yes

Tandem Print Yes

Job End Notification N/A

NOTE: When the AR-PB2A is installed in AR-505/507/407/337/287,

the Printer Administration Utility is fully functional; however, if

the AR-PB2A is installed in other models, its functionality is

limited as follows:

AR-505/507/407/

All functionality is supported.

337/287

AR-405/336/286/

281/250

Printing Settings tab and Resources

tab are not displayed.

AR-335/285/280 Printing Settings tab and Resources

tab are not displayed. Some

information display may be limited.

B. Details

(1) Connectivity

a. Direct Connection

The Cougar print system supports IEEE 1284 (parallel)-connection.

Direct Connection Type Properties

IEEE 1284 • IEEE 1284 Compliant

• Compatible

• Connector: 1 (Type B)

b. Internal Network Connection

The Cougar print system supports an internal network connection.

Installing either of the following print server cards allows the system to

connect to the network.

Model Name Network Type

AR-NC3D 10Base-T / 100Base-TX

c. Network Print Channel

The Cougar printing system supports the following network print

channels.

• PSERVER for NetWare Environment

• LPR / LPD

• EtherTalk (AppleTalk)

• FTP

• TCP Raw Socket

(2) Printer Controller

a. Hardware

CPU: R4700 150MHz(64Bits RISC)

Peripheral ASIC: Galileo-Technology GT-64010A

DRAM Controller

DMA-4 ch (SCSI, P1284, IDE, Option I/F)

ROM:

Flash ROM 8 MB

(Boot (Sim)&Main Program/ Roman Font)*1

EEPROM 8 KB

RAM:

DRAM 16 MB (EDO)

SIMM 2 slots: 16/32 MB (Max. 32x2 + 16 = 80 MB)

Host I/O:

P1284 1ch: B connector (CL-CD1283)

16bits bus DMA

External I/O 1ch: DPO Type2 for DPI (HBM) NIC (optional)

Engine I/F:

SCSI-2 1ch: Asynchronous and Synchronous/16bits

bus DMA

b. Firmware

Job Control: PJL(PJL is used in emulations other than

PCL5e.)

Emulation: PCL5e

PostScript

Emulation Switching AUTO, PS, PCL

Resident Fonts:

PCL5e (SPDL) 80 Fonts (HP8000 Typeface compatible)

Lineprinter

PostScript

Roman 80 Fonts (Adobe PS Printer Typeface com-

patible)

PCL6 80 Fonts

Host I/O:

P1284

Compatible, Nibble for PnP

External I/O DPO Type2 for DPI (HBM) NIC

I/O Switching AUTO, P1284, NIC

Engine I/F:

SCSI-2 Asynchronous and Synchronous /DMA transfer

c. Emulation

Automatic (PCL5e ↔ PS ↔ PCL6)

PCL (fixed)

PostScript (fixed)

SPDL (fixed)

Emulation switching is performed in the following manner.

PJL Command

for Specifying

an Emulation

No OK Uses the

Yes Yes Uses the emulation

Specified

Emulation

Automatic

Sensing

NG Uses PCL

specified.

No Uses PCL Uses a default

Emulation Setting

Automatic Fixed

emulation

automatically

selected.

Uses a default

emulation.

Uses the

emulation

specified.

emulation.

In the automatic emulation sensing mode, for print data without the

PJL command, the emulation is automatically switched either to PostScript, PCL5e based on data sensed. In other words, automatic

emulation sensing (switching) is available only between PostScript

and PCL5e. For print data with the PJL command, the emulation is

automatically switched to the specified one without sensing the data.

When print data without the PJL command fails to be sensed, or

when the print data is given the PJL command but the specified

emulation is not present, the data is handled in the PCL emulation.

In the fixed emulation mode, for print data without the PJL command,

the fixed emulation is used to handle the print data. Print data with the

PJL command is switched to the specified emulation. When print data

is given the PJL command but the specified emulation is not present,

the data is processed by the default emulation.

The PJL Enter command specifies PostScript and PCL5e.

2 – 4

Page 10

AR-PB2A

(3) Engine Spec.

Maximum Paper Size A3, 11" x 17"

Print Resolution 600 x 600 dpi

Smoothing Yes

Toner Save Print Yes

Photo Enhancement Yes

Engine Speed 28ppm: AR-287

33ppm: AR-337

40ppm: AR-407

50ppm: AR-507

(8.5" x 11 continuous printing of same page)

Print Speed 28ppm: AR-287

33ppm: AR-337

40ppm: AR-407

50ppm: AR-507

(Tested by continuous printing of

4Kcharacter/Page text data)

Input Paper Trays Standard: Tray 1 / Tray 2 / Bypass Tray

Option: Tray 3 / Tray 4 / LCC

Support Paper Sizes A6, A5, A4, A3, B5, B4, Japanese Postcard

(148 x 100mm), 5.5" x 8.5"(Invoice), 7.25" x

10.5"(Executive), 8.5" x 11"(Letter), 8.5" x

13"(Foolscap), 8.5" x 14"(Legal), 11" x

17"(Ledger)

Custom (Max;297 × 432_Min;100 × 148)

Output Devices 1 Exit Tray

2 Exit Trays (for AR-287 / AR-337 / AR-407)

2-Tray Finisher (for AR-287 / AR-337 /

AR-407)

Face-up 3-Tray Finisher (for AR-287 /

AR-337 / AR-407)

Face-down 3-Tray Finisher (for AR-507)

Electric Collation Support By E-RDH

(Software collation will not be supported.)

Duplex Printing Yes with duplex option

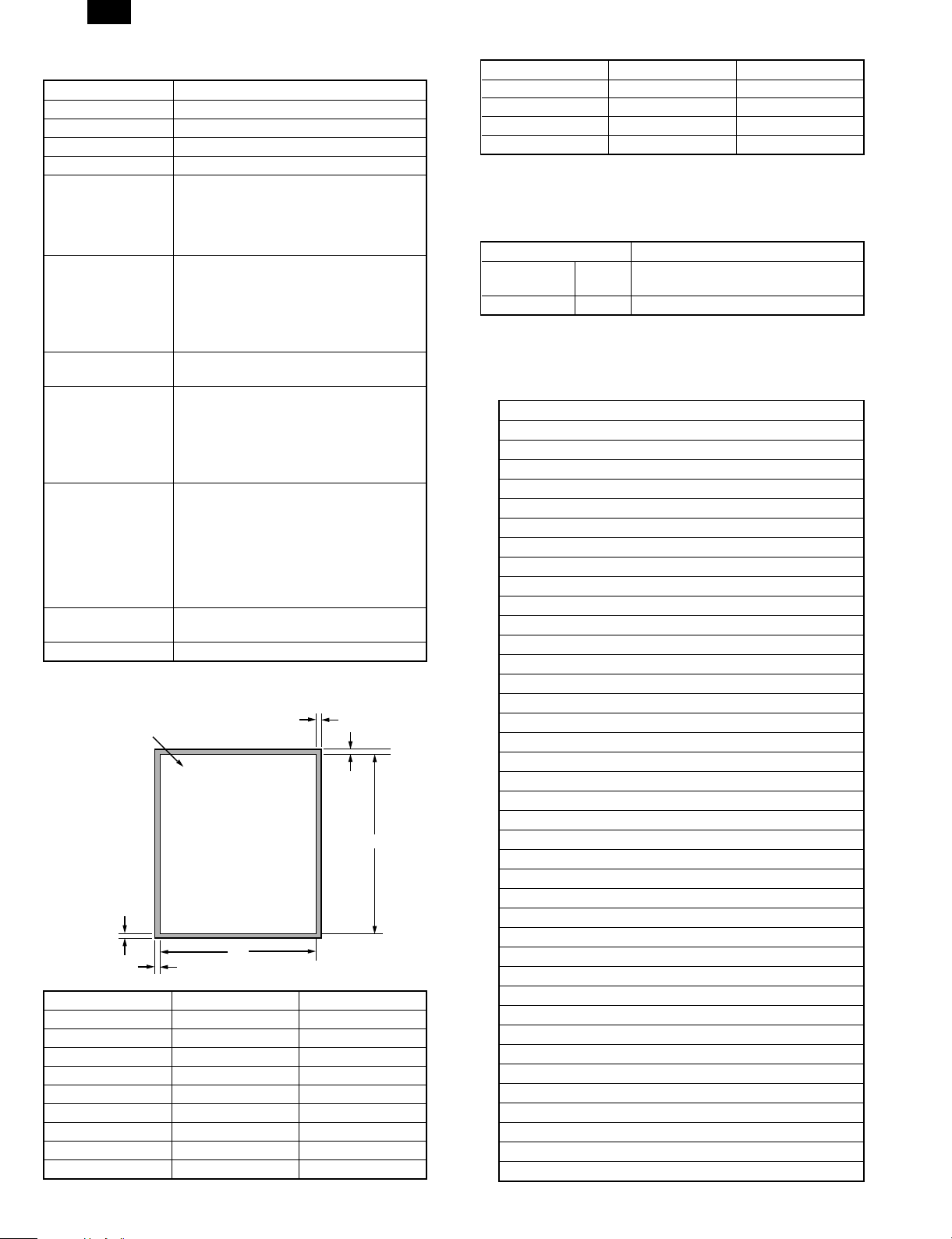

(5) Print Area

2.7mm (7/64")

Printable area

2.7mm (7/64")

X

2.7mm (7/64")

Paper size X Y

A3 6912 9824

B4 5952 8480

A4 6912 4864

B5 5952 4192

A5 4864 3392

A6 2368 3392

Ledger 6464 10080

Letter 6464 4992

Legal 4992 8288

2.7mm (7/64")

Y

Paper size X Y

Invoice 4992 3168

Executive 4224 6176

Foolscap 4992 7680

Japanese Postcard 2240 3392

(dots in 600 dpi)

(6) Font

a. Resident Font

Resident Fonts

Emulation Resident Font

PCL5e

PCL6

PostScript Roman 80 Fonts (Bitstream)

1) PCL5e Roman fonts

Font format: (80 fonts), Bitmap(1 font)

Font data size: Approx. 1.9MB

Font supplier: Bitstream

Dutch™ 801 SWC

Dutch 801 Italic SWC

Dutch 801 Bold SWC

Dutch 801 Bold Italic SWC

Swiss™ 742 SWC

Swiss 742 Italic SWC

Swiss 742 Bold SWC

Swiss 742 Bold Italic SWC

Swiss 742 Condensed SWC

Swiss 742 Condensed Italic SWC

Swiss 742 Condensed Bold SWC

Swiss 742 Condensed Bold Italic SWC

Incised 901 SWC

Incised 901 Italic SWC

Incised 901 Bold SWC

Zapf Humanist 601 SWC

Zapf Humanist 601 Italic SWC

Zapf Humanist 601 Bold SWC

Zapf Humanist 601 Bold Italic SWC

Aldine 430 Original Garamond SWC

Aldine 430 Original Garamond Italic SWC

Aldine 430 Original Garamond Bold SWC

Aldine 430 Original Garamond Bold Italic SWC

Fixed Pitch 810 Courier Roman SWC

Fixed Pitch 810 Courier Italic SWC

Fixed Pitch 810 Courier Bold SWC

Fixed Pitch 810 Courier Bold Italic SWC

Fixed Pitch 850 Letter Gothic 12 pitch/text SWC

Fixed Pitch 850 Letter Gothic Bold 12 pitch/text SWC

Fixed Pitch 850 Letter Gothic Bold Italic 12 pitch/text SWC

Flareserif 821 SWC

Flareserif 821 Extra Bold SWC

Clarendon 701 Clarendon Condensed SWC

Ribbon 131 SWC

Audrey Two SWC

Swiss 721 SWM

Swiss 721 Oblique SWM

Swiss 721 Bold SWM

Swiss 721 Bold Oblique SWM

Roman 80 Fonts (Bitstream)

1 Font-Bitmap (Bitstream)

Font name

*1

*1

*1

*1

2 – 5

Page 11

AR-PB2A

Dutch 801 SWM

Dutch 801 Italic SWM

Dutch 801 Bold SWM

Dutch 801 Bold Italic SWM

*1

*1

*1

*1

Symbol SWA

Wingbats SWM

Line Printer

*2

Dutch 801™ SWA

Dutch 801 Italic SWA

Dutch 801 Bold SWA

Dutch 801 Bold Italic SWA

Swiss™ 721 SWA

Swiss 721 Oblique SWA

Swiss 721 Bold SWA

Swiss 721 Bold Oblique SWA

Fixed Pitch 810 Courier® SWA

Fixed Pitch 810 Courier Italic SWA

Fixed Pitch 810 Courier Bold SWA

Fixed Pitch 810 Courier Bold Italic SWA

Symbol SWA (PS)

Zapf Calligraphic 801 SWA

Zapf Calligraphic 801 Italic SWA

Zapf Calligraphic 801 Bold SWA

Zapf Calligraphic 801 Bold Italic SWA

Revival 711 ITC Bookman® Light SWA

Revival 711 ITC Bookman Italic SWA

Revival 711 ITC Bookman Demi SWA

Revival 711 ITC Bookman Demi Italic SWA

Swiss 721 Narrow SWA

Swiss 721 Narrow Oblique SWA

Swiss 721 Narrow Bold SWA

Swiss 721 Narrow Bold Oblique SWA

Century 702 Century Schoolbook SWA

Century 702 Century Schoolbook Italic SWA

Century 702 Century Schoolbook Bold SWA

Century 702 Century Schoolbook Bold Italic SWA

Geometric 711 ITC Avant Garde Gothic® Book SWA

Geometric 711 ITC Avant Garde Gothic Book Oblique SWA

Geometric 711 ITC Avant Garde Gothic Demi SWA

Geometric 711 ITC Avant Garde Gothic Demi Oblique SWA

Chancery 801 ITC Zapf Chancery® Medium Italic SWA

ITC Zapf Dingbats® SWA

All above resident fonts in the column are licensed from Bitstream

Inc. Dutch and Swiss are trademarks of Bitstream Inc. All other

trademarks and copyrights are the property of their respective

owners.

*1: These fonts cann ot be used with the PS driver.

*2: For Line Printer in the above table, display font is not supplied.

2) PS2 Roman fonts

Number of fonts: 80

Font format: (All of the 80 fonts)

Font data size: Approx. 0.9MB

Font supplier: Bitstream

Font name

ITC Avant Garde Gothic® Book

ITC Avant Garde Gothic Book Oblique

ITC Avant Garde Gothic

ITC Avant Garde Gothic Demi Oblique

Font name

ITC Bookman® Demi

ITC Bookman Demi Italic

ITC Bookman Light

ITC Bookman Light Italic

810 Courier®

810 Courier Bold

810 Courier Bold Italic

810 Courier Italic

Swiss 721 Normal

Swiss 721 Bold

Swiss 721 Bold Oblique

Swiss 721 Oblique

Swiss 721 Narrow

Swiss 721 Narrow Bold

Swiss 721 Narrow Bold Oblique

Swiss 721 Narrow Oblique

Century Schoolbook Bold

Century Schoolbook Bold Italic

Century Schoolbook Italic

Century Schoolbook Roman

Zapf Calligraphic 801

Zapf Calligraphic 801 Bold

Zapf Calligraphic 801 Bold Italic

Zapf Calligraphic 801 Italic

Symbol Set

Dutch( 801 Bold

Dutch 801 Bold Italic

Dutch 801 Italic

Dutch 801 Normal

ITC Zapf Chancery® Medium Italic

ITC Zapf Dingbats®

b. Download Fonts

Data formats of download fonts in each emulation are in the table

below.

Emulation Download Font

PCL5e Roman Bitmap

TrueType

Intellifont

Kanji N/A

PostScript Roman Bitmap

Type 1

Type 42

Kanji N/A

(7) Interface Specification

The printing system supports IEEE 1284 compliant connections

Properties

IEEE 1284 • IEEE 1284 Compliant

• Compatible

• Connector: 1 (Type B)

(8) Network Specification

Interface Support OS

DPI_NIC 10Base-T

100Base-TX

NetWare,

Windows NT

Support

Protocol

IPX/SPX,

TCP/IP,

EtherTalk,

Peer to Peer

(IPX/SPX)

Area

JPN, North

America

(USA/

CANADA),

Europe, EX

2 – 6

Page 12

AR-PB2A

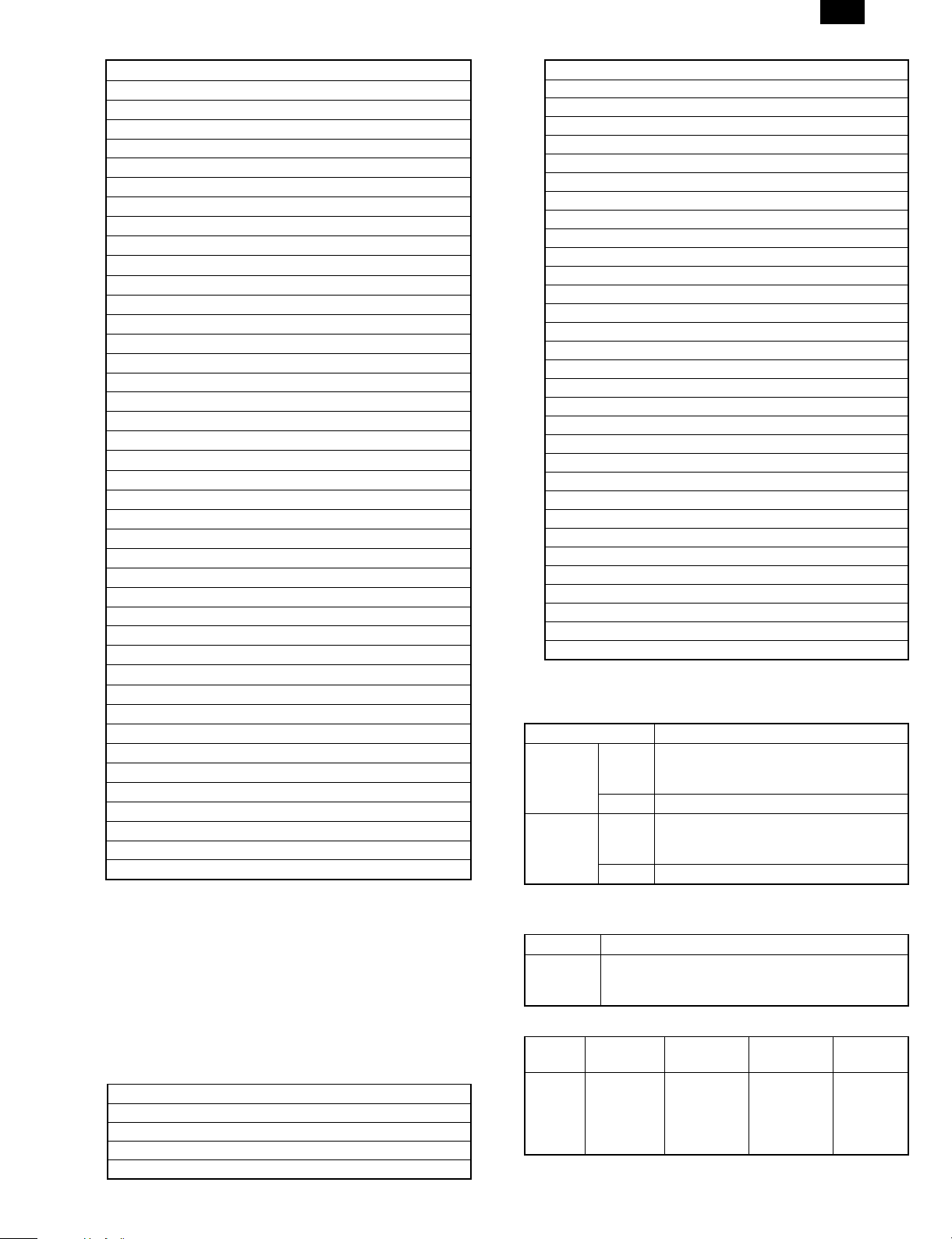

[3] SETUP

1. Parts list

Before installing the printer kit, check that all the following items are prepared.

Be careful that the necessary parts depend on the environment of the copier (model and unit installation).

Part name Model Q’ty Note

Accessories SCSI cable 1

Wire saddle 1

Band 1

Printer box installing screw 5

Printer control PWB 1 With frame

Printer driver Printer Driver (including PPD File) 1

Screen Font 1

Resident-FontData Install Utility 1

Printer Administration Utility ver.2.x 1

NWsetup 1

Printer Status Monitor ver.2.0 1

Integrated Installer 1

Makedisk Utility 1

Installation manual 1

Operation Manual 1

Label 1 Only for Sweden and Norway

Option Expansion board AR-EB1 1 The expansion board is necessary to

install the printer kit to the AR-S280.

SIMM memory 16MB ED0 type/Without parity/70ns or above

The copier ICU PWB requires the total

memory of 16MB(20MB) or more.

The printer control PWB has two

expansion slots to which 16MB or 32MB

memory can be additionally installed.

(16MB onboard)

stand-alone machine.

Separate purchase

(User purchase)

32MB

Network card AR-NC3D 1 10Base-T / 100Base-TX

Printer (parallel) cable Necessary when the copier is used as a

2. Preliminary work

If the version of the three kinds of flash memory installed to the copier

is older than the following, upgrade is required.

Check version number, and perform the upgrade if necessary. (For

the procedure, refer to the Technical Report.)

3. Hardware setup

A. Common work

(1) Printer unit installation

1) Turn "OFF" the main switch located on the left-hand side on the

main copier unit.

Next, unplug the power plug of the main copier unit from the

outlet.

Main switch

"OFF"

2) Removing the rear cover of the main copier unit.

If equipped with the RADF/ADF/SPF, loosen the securing screws

which the hold the RADF/ADF/SPF connector and remove the

connector from the main copier unit.

Connector

Screw

If the rear cabinet is a box type, remove the connector cover in

advance.

Remove the five securing screws which hold the rear cover of

main copier unit, then remove the rear cover.

Next, loosen the upper central one of four securing screws which

hold the rear lower cover, then remove the rest three screws, and

then remove the rear lower cover.

• If the rear cabinet is a box type:

Rear

cover

Rear

lower cover

Loosen

Securing

screw

Securing screws

Rear cover

Loosen

Rear

lower cover

Securing

screw

Connector

cover

Securing screws

3 – 1

Page 13

• The installation work after this step varies with the shape

of the rear cabinet.

• If the rear cabinet is a box type, proceed to step 9.

• If the rear cabinet is not a box type, proceed to step 3.

3) Cut out the central one of three notches of upper rear cover with a

nipper.

Notches

Binding

band

AR-PB2A

Ribs

A notch

4) Remove the three securing screws which hold the flywheel and

remove the flywheel.

Flywheel

Securing

screw

5) Remove the two securing screws which hold the shield line guide

to the main drive frame and remove the shield line guide.

Shield line

guide

Securing screws

Binding

band

Printer relay cable

Shield line guide

Cut away the surplus

8) Reinstall the flywheel (which was removed in the step 4) onto the

main drive shaft while slipping inside the exterior. Use the three

securing screws to secure it.

Make sure the arrow mark on flywheel faces toward you.

Caution

Flywheel

Engraved

arrow mark

Securing screws

6) Plug the printer relay cable connector into the most right hand port

on the ICU board.

Port on the ICU board

Printer relay cable

7) Place the printer relay cable into the central notch of shield line

guide (the location with a letter P) and attach it temporarily with a

binding band as shown in the illustration.

Next, insert the two ribs on the main drive frame through the

positioning holes of shield line guide, then use the two securing

screws to secure it.

Place the printer relay cable as shown in the illustration, then

tighten the binding band and cut away the excess.

Securing

screw

<Caution> Do not turn the flywheel with hands after installation

since it may cause damage to the gears.

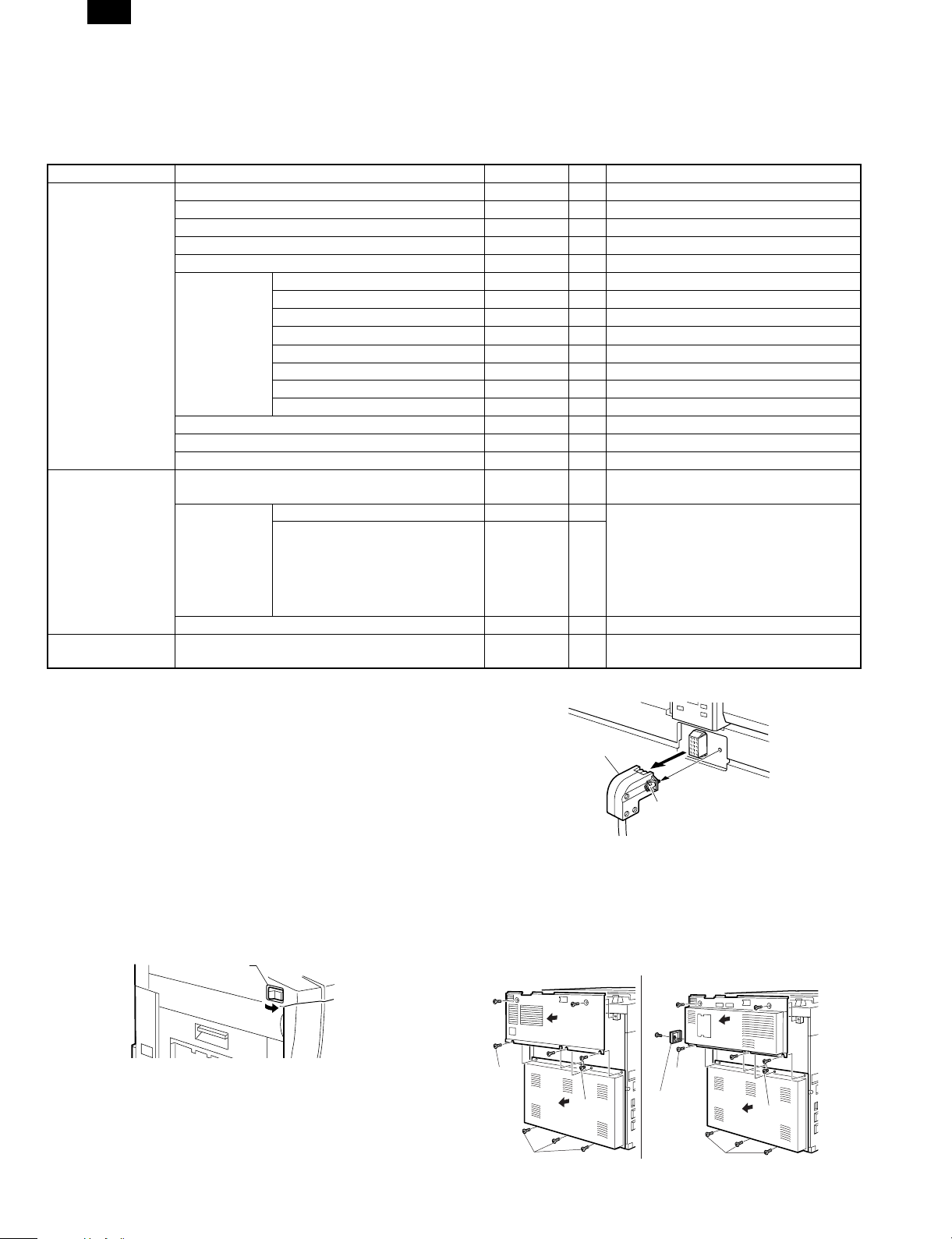

9) Connect the power connector of printer box unit to the power

supply port on the main copier unit, then attach the printer box unit

on the holes of F/P box mounting plate using the hooks.

Using the 5 pri nter bo x secu ring sc rews, at tach t he pr inter bo x to

the mounting plate.

Hook

Power connector

Printer box unit

Printer box securing screw

3 – 2

Page 14

AR-PB2A

10) Remove the securing screws holding the P side OP cover in the

rear lower cover which was removed in the step 2, then remove

the P side OP cover.

Next, paste an attached label at the position only for Sweden

and Norway as shown in the illustration.

P side OP cover

Label

Securing

screws

11) Hook the rear lower cover on the securing screw ➃ which was

loosened in the step 2 as shown in the illustration.

Next, tighten the securing screws ➀, ➁ and ➂ temporarily, which

were removed in the step 2 and tighten the securing screw ➃

which was loosened, then tighten the securing screws ➄, ➅ and

➆.

Reinstall the rear cover which was removed in the step 2 to the

original position by putting it onto the securing screws ➀, ➁ and

➂ which temporarily secure the rear cover, then tighten the

securing screws ➀, ➁ and ➂ after tightening the securing screws

➇ and ➈.

If the rear cabinet is a box type, attach the connector cover.

•

Securing screw

Rear cover

Securing

screws

Loosened

screw

Rear lower

cover

If the rear cabinet is a box type:

Securing screw

Rear

cover

Connector

cover

Securing

screws

Loosened

screw

Rear lower

cover

12) If the rear cabinet is a box type:

Insert the printer relay cable connector to the rightmost connec-

tor of the ICU PWB to connect it.

If an option has been already connected to the right SCSI con-

nector of the copier, however, connect the cable to the left connector.

Screw

Connector

1. Connect the printer relay cable to the connector of printer

box.

2. Attach the supplied wire saddles to the printer relay cable.

3. Insert and fix the wire saddle at the position of rear lower

cover as shown in the illustration.

•

Wire saddle (1 pc.)

Printer relay cable

Printer relay cable

If the rear cabinet is a box type:

Wire saddles (2 pcs.)

(2) Expansion memory installation

a. Memory expansion in the printer control PWB

Normally there is no need for memory expansion. However,

memory expansion will increase the printer performance.

When printing graphics or complex data, memory expansion will

increase printing speed.

Memory of 16MB or 32MB can be installed to the two slots. (16MB

onboard)

Different capacity of memory can be installed to the two slots.

The total memory after expansion may be 32, 48, 64, or 80MB.

After the above procedure, select VM Option menu and set the

total memory capacity.

b. ICU PWB memory expansion

The copier ICU PWB requires total memory capacity of 16 (20)MB

or more.

Memory of 16MB or 32MB can be installed to the two slots. (4MB

onboard)

Different capacity of memory can be installed to the two slots.

B. Stand-alone environment (Printer (parallel)

cable connection)

Plug the connector of the Centronics cable (sold separately) into the

Centronics port on the printer box base.Plug the other connector into

the laser printer port on a personal computer.

13) If the copier is equipped with an automatic document feeder,

connect the connector that has been removed in step 2 to its

original position of the copier and secure the connector with the

attached screw.

3 – 3

Connector going to the

laser printer port on the

personal computer

Centronics cable

(sold separately)

Page 15

AR-PB2A

C. Network environment (Network card installation)

1) Insert the network card into the network card slot on the printer

control PWB. and fix it with screws.

4. Setup on the copier side

A. Setup by simulation

Setup the followin g items. For parallel I/ F, se tup, if the re is no trouble

in operations, there is no need to change any settings.

Content Simulation No. Set value

System configuration setup 26-44 1

Print counter count mode setup 26-05

Parallel I/F timing adjustment 67-03

Parallel I/F select IN signal timing 67-11

B. Setup by key operator program

Refer to the section of the key operator program and make setting

according to the user environment.

5. Software installation and setup

Checking the Hardware and Software Requirements

You will need the following hardware and software in order to install

the printer driver.

(Windows)

Computer Type • IBM PC/AT or compatible computer

equipped with a bi-directional parallel

interface

Operating System • Windows 3.1x, Windows 95, Windows 98,

Windows 2000, Windows NT 4.0

CPU • Windows 3.1/Windows 95: 486SX or better

• Windows 98: 486DX/66 MHz or better

(Pentium or better is recommended.)

• Windows NT4.0: 486/25MHz or better

RAM • Windows 3.1/Windows 95: 8 MB or more

(12 MB or more is recommended.)

• Windows 98/Windows 2000: 16 MB or more

(32 MB or more is recommended.)

• Windows NT 4.0: 16 MB or more

(Macintosh)

Operating system • Mac OS 7.6 to 9.0

CPU • MC 68040 or PowerPC microprocessor

RAM • 16 MB or more for PowerPC microprocessor

machine

• 12 MB or more for MC 68040 machine

Printer driver • LaserWriter 8 version 8.4.1 or later

To use the printer with a Macintosh computer, an optional network

interface card (Print Server Card) is needed. Also the Macintosh computer must be equipped with an Ethernet port. If your computer is not

equipped with an Ethernet port, install an Ethernet interface.

2) Install the printer control PWB to the copier.

3) Connect the network cable to the network card connector.

6. Setup under network environment

Check the user environment and make setup according to the Operation Manual attached to the network card.

A. Outline of the NW Setup

The NW Setup is a setup tool for using a SHARP printer with a

network card installed in a Novell NetWare environment. Registration

of printers to a NetWare server and parameter settings for a network

card can be performed by using a procedure with wizards.

For using the NW Setup, a Novell Client supplied by Novell must

have been installed. Also before starting the NW Setup, you must log

in the NetWare server with the ’Administrator’ privileges.

3 – 4

Page 16

AR-PB2A

B. Checking the Hardware and Software

Requirements

To use the NW Setup, the following hardware and software are

needed.

NetWare server: IntranetWare (NetWare 4.x)

NetWare client: Novell Client 4.5 for Windows NT

Novell Client v3.0 for Windows 95/98/2000

Client PC operating

system:

Printer: SHARP printer with a Print Server Card

Windows 95, Windows 98, Windows 2000,

Windows NT 4.0

(AR-NC3D) installed

7. Web Page Setting

This copier/printer is equipped with web page features that allow

some network-related functions such as the network scanner function

and the Status & Alert by E-mail function to be set and used with a

web browser. (An optional Network Scanner Expansion Kit AR-NS1 is

required to use the network scanner function.)

The web page feature includes the following three types.

1. Password Setting

Setting up the administrator’s and user’s passwords.

The administrator of this software can set the passwords (for ad-

ministrator and user) to authorize the access to the E-mail Setup

Web page for the security of the settings on the page. If such a

security measure is not required, the Password Setting procedure

can be skipped. This will leave Web access settings open to all

users.

2. E-mail Setup and Network Scanning Setup

Configuration of the network scanning system and status/alert by

E-mail.

3. Scanning Destination Setup

Setting the default scanning parameters on the device to send the

scanned image or data as Destinations. (An optional Network

Scanner Expansion Kit AR-NS1 is required for this setup.)

First, assign an IP address to the copier/printer.

A. Password Setting

The administrator should exclusively do the setting of the password of

two levels: User and Admin when setting up network scanning system

security. A User password is required to create, change, and delete

destinations. An Admin Password lets you access to the same functions as the User password but is also required to set system configuration settings such as:

• Password Setup page

• Setup Status & Alerts by E-mail pages

• E-mail/Network Scanning Setup page

When you first install your network scanning system, both password

functions are disabled. To set a User and/or Admin password.

Name Definition

Enable Password

Protection of This

Web Site

User Access in

Destination List

Confirm Password Enter the User password again to confirm it.

Admin Control for

E-mail/Scanning

Confirm Password Enter the Admin password again to confirm it.

To enable password protection, check the

box and click the ‘Submit’ button. To disable

it, clear the check mark in the box and click

the ‘Submit’ button.

Enter a User password within 10 characters.

Enter an Admin password within 10

characters.

B. E-mail Setup and Network Scanning Setup

In the "Status/Alert by E-mail" function, SMTP (Simple Mail Transport

Protocol) protocol is used to send the e-mails. This section describes

how to set up the basic status of the e-mail sending including the

definition of the file names for the image data to be attached and so

on. Such settings must be effected by the system administrator who

has the special network related backgrounds.

(1) E-mail Setup

Item Description

Name Enter a unique name for the machine within 50

characters.

Machine Code This is not used. This field can be used to input

Machine

Location

Primary

E-mail Server

Secondary

E-mail Server

E-mail Time

Out

Reply Address Enter an e-mail address to which the machine

Time Zone Select the time zone of the place to use this

some machine related information. Some dealers

may use this field to identify the machine.

Enter a unique entry for the machine location

within 100 characters.

Enter an IP address for the primary e-mail server

or a host name.

Enter an IP address for the secondary e-mail

server or a host name. No need to enter if

secondary e-mail server is not set up.

Enter a time out period, from 0 to 60 seconds,

that the system will wait for as it attempts to

connect to the primary server. The default is 20

seconds. If no connection is made, the system

will then look for the secondary server if it has

been set up. If not, the system will stop

attempting to connect.

returns an unsuccessful delivery message when

the distribution has failed. Only 1 e-mail address

can be entered.

Network Scanning System. A specific time zone

is set after the selection.

3 – 5

Page 17

AR-PB2A

[4] SETTING AND ADJUSTMENT

1. Configuration setting

(Accessing the Printer Configuration Menu)

To access the printer configuration menu, follow the

steps below.

1. Press the PRINT key to select the printer mode. Make sure the

PRINT indicator lights up and the basic screen is displayed on the

touch panel.

2. Press the "ONLINE" key on the touch panel to select the OFFLINE

mode and press the "MENU" key.

The printer configuration menu screen will appear on the touch panel.

The main menu items are: PRINTER SETTINGS, INTERFACE SETTINGS, NETWORK SETTINGS, PRINT TEST PAGE, and INITIALIZE

AND/OR STORE SETTINGS. Use the UP/DOWN arrow (▲, ▼) keys

to scroll the screen.

NOTES: If any printing data remains in the memory, the printer con-

figuration menu will not appear. In this case, access the

printer configuration menu after printing is complete or

press the CLEAR () key to cancel printing and then continue to access the menu.

If conflicting settings are made with the printer driver and

the configuration menu, the printer driver will have priority.

PRINTER SETTINGS

SMOOTHING

TONER SAVE MODE

COPIES

ORIENTATION

STANDARD INPUT PAPER

SIZE

STANDARD OUTPUT TRAY

PRINT PS ERRORS

PCL SYMBOL SET SETTING

INTERFACE SETTINGS

HEXADECIMAL DUMP MODE

PARALLEL PORT

EMULATION SWITCHING

NETWORK PORT

EMULATION SWITCHING

I/O TIMEOUT

PORT SWITCHING METHOD

(Using the Printer Configuration Menu)

Use steps 1 and 2 above to access the printer

configuration menu.

3. Select the desired main menu item on the touch panel.

4. If a sub-menu appears, select the desired function. To scroll the

touch panel screen, use the UP/DOWN arrow (▲, ▼) keys.

5. Turn the setting of a function on or off by pressing its corresponding check box in front of the function name. For functions without a

check box, adjust the settings on each function setting screen.

6. To exit the configuration menu, return to the main menu by pressing the "OK" key and then press the "ONLINE/OFFLINE" key to

return to the online mode.

If a test print has been selected, once complete, the printer will

automatically return to the online mode.

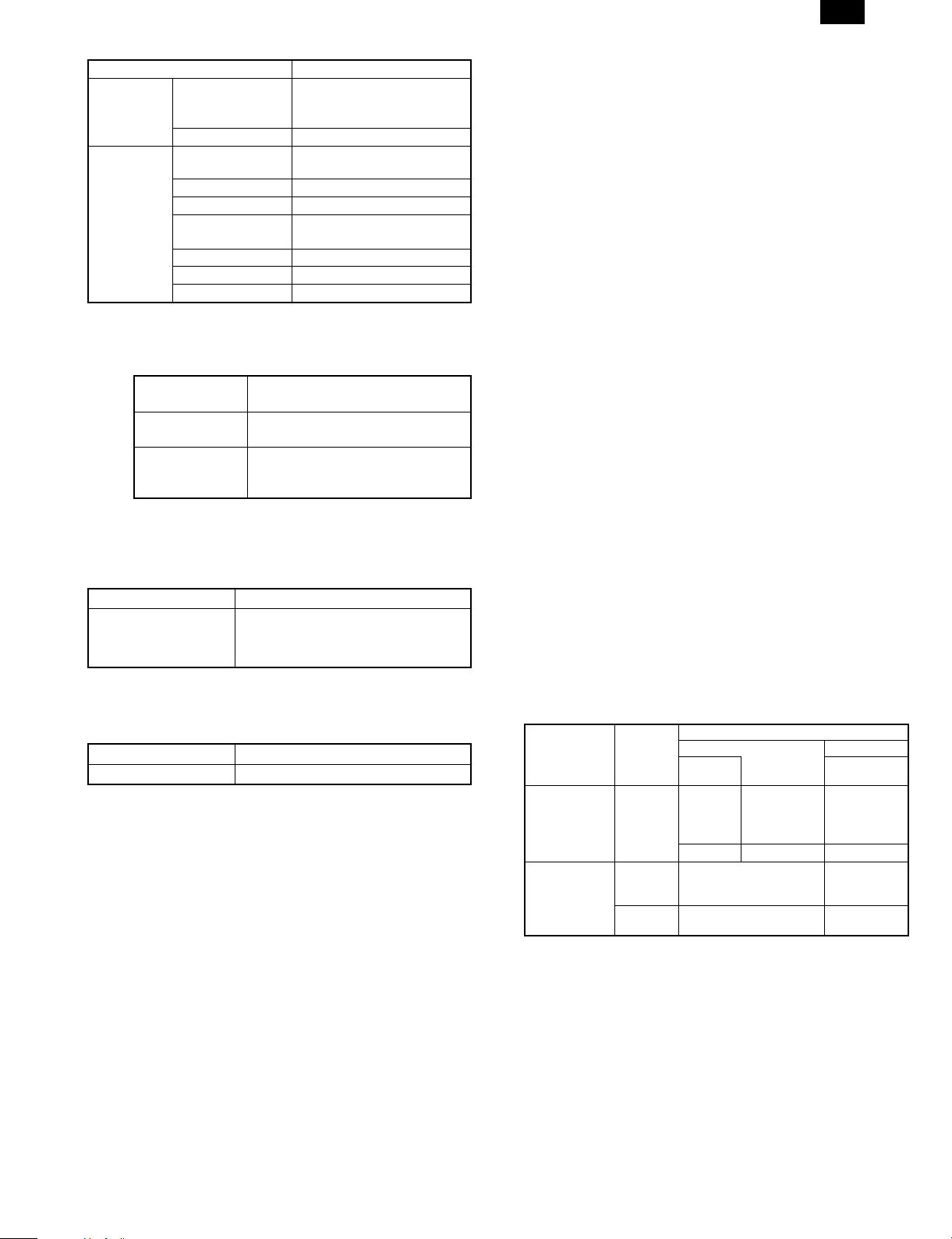

Printer Configuration Menus

A flow chart of the printer configuration menu is shown. The menu

structure changes depending on whether a network interface card is

present in the copier/printer or not. The menus inside the gray area

are for a copier/printer with a network interface card (Print Server

Card) installed.

NOTE: Depending on the particular printer, some functions of the

printer configuration menu cannot be set, for example,

smoothing and toner save mode.

COPIES (1* to 999)

ORIENTATION

PORTRAIT*

LANDSCAPE

STANDARD INPUT PAPER SIZE

A3 B4 A4* B5 A5 A6

11 x 17 8-1/2 x 14 8-1/2 x 13

8-1/2 x 11*

5-1/2 x 8-1/2 7-1/2 x 10-1/2

STANDARD OUTPUT TRAY

TOP TRA Y

SECOND TRAY*

Main Menu

PRINTER SETTINGS

INTERFACE SETTINGS

NETWORK SETTINGS

PRINT TEST PAGE

INITIALIZE AND/OR STORE

SETTINGS

NETWORK SETTINGS

ENABLE TCP/IP

IP ADDRESS SETTING

ENABLE NetWare

ENABLE EtherTalk

(TokenTalk)

PRINT NIC PAGE AT

POWER ON

PRINT TEST PAGE

PRINT CONFIGURATION

PAGE

PRINT RESIDENT FONT

LIST

PRINT DEMO PAGE

PRINT NIC PAGE

PRINT PCL SYMBOL

SET LIST

INITIALIZE AND/OR STORE

SETTINGS

RESTORE FACTORY

DEFAULT

STORE CURRENT

CONFIGURATION

RESTORE CONFIGURATION

RESET THE NIC

NOTES: The menus inside the gray area are for a printer with the

network interface card option installed.

* Denotes the default setting.

• The default setting of STANDARD INPUT PAPER SIZE

depends on the countries or regions.

PARALLEL PORT EMULATION

SWITCHING

AUTOMATIC*

PostScript

PCL

NETWORK PORT EMULATION

SWITCHING

AUTOMATIC*

PostScript

PCL

I/O TIMEOUT (1 to 999, 20*)

PORT SWITCHING METHOD

SWITCH AT END OF JOB*

SWITCH AFTER I/O TIMEOUT

DISABLE PARALLEL PORT

DISABLE NETWORK PORT

IP ADDRESS SETTING

IP ADDRESS (192 168 0 1)

IP SUBNET MASK (255 255 255 0)

IP GATEWAY (192 168 0 1)

• The default setting of STANDARD OUTPUT TRAY

depends on installation of optional finisher.

• The values indicated with IP ADDRESS are examples.

4 – 1

Page 18

AR-PB2A

A. Printer Settings

Use the printer settings when printing without the proper printer driver

installed (for example, printing from an MS-DOS application, printing

from a computer without the printer driver installed, etc.). This menu

allows detailed print conditions to be set.

SMOOTHING Enables or disables the smoothing function.

This setting is enabled in the default setting.

TONER SAVE

MODE

COPIES Number of copies to print can be set. 1 to

ORIENTATION Selects the default page orientation: portrait

STANDARD INPUT

PAPER SIZE

STANDARD

OUTPUT TRAY

PRINT PS ERRORS Determines whether or not PostScript®

PCL SYMBOL SET

SETTING

No. Symbol set No. Symbol set

1 Roman-8 19 Math-8

2 ISO 8859-1 Latin 1 20 PS Math

3 PC-8 21 Pi Font

4 PC-8 Danish/Norwegian 22 ISO 8859-2 Latin 2

5 PC-850 23 ISO 8859-9 Latin 5

6 ISO 6 ASCII 24 ISO 8859-10 Latin 6

7 Legal 25 PC-852

8 ISO 21 German 26 PC-775

9 ISO 17 Spanish 27 PC-Turkish

10 ISO 69 French 28 MC Text

11 ISO 15 Italian 29 Windows 3.1 Latin 1

12 ISO 60 Norwegian v1 30 Windows 3.1 Latin 2

13 ISO 4 United Kingdom 31 Windows 3.1 Latin 5

14 ISO 11 Swedish: names 32 Windows Baltic (not 3.1)

15 PC-1004 (OS/2) 33 Windows 3.0 Latin 1

16 DeskTop 34 Symbol

17 PS Text 35 Wingdings

18 Microsoft Publishing — —

Sets or cancels the toner save mode. The

toner save mode reduces toner

consumption. Printed images will be lighter

but still adequate for general use. This

setting is disabled in the default setting.

999 can be entered.

or landscape.

Specifies a default input paper size. One of

the following sizes can be selected: A3, B4,

A4, B5, A5, A6, 11 x 17, 8-1/2 x 14, 8-1/2 x

13, 8-1/2 x 11, 5-1/2 x 8-1/2, 7-1/4 x 10-1/2

Specifies a default output tray. Top tray,

second tray or offset tray can be selected.

The offset tray cannot be selected when no

optional finisher is installed. The second

tray cannot be selected when an optional

2-tray finisher is installed. Face up or face

down can also be selected for certain trays

in this menu.

error information will be printed. This setting

is disabled in the default setting.

Specifies a PCL symbol set. (The symbol

set is used to assign a part of character

codes to characters of a country.) The

factory default setting is 1 (Roman-8).

B. Interface Settings

Use the interface settings to configure the printer’s parallel and network interfaces.

HEXADECIMAL

DUMP MODE

PARALLEL PORT

EMULATION

SWITCHING

NETWORK PORT

EMULATION

SWITCHING

I/O TIMEOUT Use this function to set the amount of time to

PORT SWITCHING

METHOD

* If "AUTO" is set, the printer language will switch automatically in

accordance with the data from the computer. It is recommended to

set "AUTO" unless an error due to this setting occurs frequently.

If this function is set, the print job will be

output in the hex dump format. This setting is

disabled in the default setting.

Specifies a printer language to emulate for

printing when the printer is connected to the

computer through a parallel port. "AUTO"*,

"PostScript" or "PCL" can be set.

Specifies a printer language to emulate for

printing when the printer is connected to the

computer through network. "AUTO"*,

"PostScript" or "PCL" can be set.

wait after end of data stream before ending

print job. This time can be entered using the

UP/DOWN arrow (▲, ▼) keys. The allowable

range of the time is 1 to 999 seconds.

Determines which switching method to use

for the interface port. "SWITCH AT END OF

JOB", "SWITCH AFTER I/O TIMEOUT",

"DISABLE PARALLEL PORT" or "DISABLE

NETWORK PORT" can be selected.

C. Network Settings

Use the network settings when using this printer as a network printer.

If an optional network interface card (Print Server Card) is not installed, these settings will not appear on the touch panel.

ENABLE TCP/IP Enables or disables the TCP/IP protocol. This

setting is enabled in the default setting. To use

the printer with the TCP/IP protocol, set the IP

address in the next function.

IP ADDRESS

SETTING

ENABLE NetWare Enables or disables the NetWare protocol. This

ENABLE

EtherTalk

(TokenTalk)

PRINT NIC PAGE

AT POWER ON

NOTE: When the enable or disable setting of protocols (ENABLE

TCP/IP, ENABLE NetWare, and ENABLE EtherTalk) is

changed, the new setting will be effective after resetting the

printer. For resetting, follow the message by pressing "OK",

turning the printer off and then back on after waiting a few

seconds.

IP ADDRESS: Manually set the printer’s IP

address. Note that no number can exceed 254.

First digit of the number cannot be 0. Each

item can be selected directly with the touch

key. The value can be input using the 10-key

pad.

IP SUBNET MASK: Manually set the printer’s

IP subnet mask. Note that no number can

exceed 255. First digit of the number cannot be

0. Each item can be selected directly with the

touch key. The value can be input using the

10-key pad.

IP GATEWAY: Manually set the printer’s IP

gateway. Note that no number can exceed

254. First digit of the number cannot be 0.

Each item can be selected directly with the

touch key. The value can be input using the

10-key pad.

setting is enabled in the default setting.

Enables or disables the EtherTalk (TokenTalk

if TokenRing network is connected) protocol.

This setting is enabled in the default setting.

If this function is set, the printer will print the

NIC (Network Interface Card) configuration

page when power is turned on. This setting is

enabled in the default setting.

4 – 2

Page 19

AR-PB2A

D. Print Test Page

Printing a test page verifies that the printer operates properly. Also

you can check the configuration settings, built-in fonts etc. When

printing is complete, the printer will exit the printer configuration menu

and return to online mode.

PRINT

CONFIGURATION

PAGE

PRINT RESIDENT

FONT LIST

PRINT DEMO PAGE If this key is pressed, the printer will return

PRINT NIC PAGE If this key is pressed, the printer will return

PRINT PCL

SYMBOL SET LIST

If this key is pressed, the printer will return

to the online mode and print the

configuration list.

If this key is pressed, the printer will return

to the online mode and print the resident

font list.

to the online mode and print a

demonstration page.

to the online mode and print the NIC

(Network Interface Card) configuration

page. If an optional network interface card

(Print Server Card) is not installed, this

function will not appear on the touch panel.

If this key is pressed, the printer will return

to the online mode and print the PCL

symbol set list.

E. Initialize and/or Store Settings

Use these functions to initialize or store printer settings.

RESTORE

FACTORY

DEFAULTS

STORE CURRENT

CONFIGURATION

RESTORE

CONFIGURATION

RESET THE NIC When this key is pressed, a confirmation

NOTES: If configuration settings are protected using key operator

programs (Prohibit Changes to Printer Settings and Prohibit

Changes to Interface Settings), the settings cannot return

to the factory default setting and stored settings cannot be

recalled.

Use the key operator programs to cancel protection mode.

If the setting of functions of enabling protocols (ENABLE

TCP/IP, ENABLE NetWare, and ENABLE EtherTalk) is

changed by using the function "RESTORE FACTORY

DEFAULTS" or "RESTORE CONFIGURATION", the new

setting will be effective after resetting the printer. To reset

the printer, turn off the printer and then turn it on after a few

seconds.

The "Restore Factory Defaults" setting does not restore

network settings. To return the network settings to the factory default settings, use the "RESET THE NIC" function.

When this key is pressed, a confirmation

window will appear. If the "YES" key is

pressed, all the printer configuration

settings will return to the factory default

settings.

When this key is pressed, a confirmation

window will appear. If the "YES" key is

pressed, the current printer configuration

settings will be stored in the printer’s

nonvolatile memory.

When this key is pressed, a confirmation

window will appear. If the "YES" key is

pressed, the printer configuration settings

that have been stored in the printer’s

nonvolatile memory with the "STORE

CURRENT CONFIGURATION" function will

be recalled.

window will appear. If the "YES" key is

pressed, the settings of the optional

network interface card will return to the

factory default settings.

2. Key operator programs

(1) List

PROGRAM NAME FUNCTION

Printer Exposure Level Lightens or darkens printouts.

Memory Reserved for

Printer

Output Method When

Memory Is Full

Set the Number of

Confidential Print Jobs to

Be Stored

Enable Bypass-Tray Size

Detection

Give Priority to Print

Speed in Staple Mode

Prohibit Notice Page

Printing

Prohibit Rotated Output Enables/disables rotation of print

Prohibit Bypass-Tray

Selection

Prohibit Auto Tray

Switching

Prohibit Test Page

Printing

Prohibit Changes to

Printer Settings

Prohibit Changes to

Interface Settings

Prohibit Changes to

Network Settings

Record Copy and Print

per Account

Specifies percentage of document

memory allocated to storage of printer

jobs.

(AR-250 (1GB hard disk model) only)

Specifies whether one set or multiple

sets will be printed when the printer

memory becomes full.

Specifies the maximum number of

confidential print jobs that can be

stored in the printer and the maximum

number of pages in a job.

Enables or disables paper size

detection for the bypass tray.

Specifies an image processing method

for printing with stapling.

(AR-505/507 only)

Specifies whether a notice page will be

printed when the printer memory

becomes full and divided printing is

performed.

image for printing onto A4R or 8-1/2" x

11"R paper.

Enables/disables bypass tray selection

in the ‘Auto Tray Switching’ mode.

Enables/disables automatic switching

between paper trays during printing

when paper runs out.

Enables/disables test page printing

from the printer configuration menu.

Prohibits modification of basic printer

settings in the printer configuration

menu.

Prohibits modification of interface

settings in the printer configuration

menu.

Prohibits modification of network

settings in the printer configuration

menu.

Enables or disables the printer auditing

mode, which controls access to printer.

4 – 3

Page 20

AR-PB2A

3. Hardware setup and adjustments

A. Flash Memory write protect setting

Flash memory write protect setup (JP109)

Used to setup write protect YES/NO of flash memory.

JP109 JP109

1133

Write protect condition

(Default)

When making version up of the flash memory or when rewriting the

flash memory, short pins 2-3. In normal cases, short pins 1-2 (write

protect).

When shipping, the DIP switch is set to the following value.

JP109 1-2 Flash memory write protect

Write condition

B. Laser power setup

Enter SIM 61-4 and set the setup value to 16 (default).

If set to another value, normal print density may not be obtained.

C. Centro interface adjustment

(1) Centro interface timing adjustment

Enter SIM 67-3 and set the ACK signal width.

If communication between PC and the copier is not normally performed with the set value st to 10 (default), check the environment of

PC and change the set value.

Adjustment range: 0 ~ 255

(2) SELECT IN signal setup

Enter SIM 67-11 and set SELECT IN signal YES/NO.

The relationship between the set value (0 or 1) and SELECT IN

signal is as follows:

Set value SELECT IN signal

0 YES

1NO

If communication between PC and the copier is nor performed normally, check the environment of PC and change the set value.

D. NVRAM clear

Use SIM 67-17.

This is used to clear various setup data relating to the printer opera-

tions stored in NVRAM on the printer control PWB.

Execute this procedure to set all the setup data to default.

E. Network card check

After installing the network card, execute SIM 67-16, and the operation of the network card is displayed as NG or OK.

4 – 4

Page 21

[5] Configuration Report and Test Page

1. Samples

AR-PB2A

2. Description of Each contents

This section defines the meaning of each item. These items are basically used in configuration pages, but some contents are not used

depending on language.

A. Hardware Status

Machine Information

a. Resolution

Value: 600 dpi

Example: 600 dpi

Default: 600 dpi

Description: It is always 600 dpi.

b. Language

Value: (English) | Deutsch (German) | Francais (French) |

Italiano (Italian) | Nederlands (Dutch) | Espanol

(Spanish) | Svenska (Swedish)

Example: English

Default: Depends on copier language

Description: AR-PB2 includes seven language messages originally.

AR-PB2 decides the display language depending on the

language code sent from MAIN (MAIN sends the lan-

guage code based on its language ROM). This value

indicates the language that sent by MAIN to PRT.

5 – 1

Page 22

AR-PB2A

Hardware Specs

a. Base Memory

Value: 16 MB

Example: 16 MB

Default: 16 MB

Description: It indicates base memory quantity of the printer board.

Basically, this is fixed at 16 MB and it cannot be

changed.

b. Optional Memory

Value: (0|16|32|48|64) MB

Example: 0MB

Default: 0MB

Description: It indicates the printer board’s optional memory quantity.

The customer (serviceman) could extend the memory

by attaching 72pin-SIMM. 0MB means optional memory

is not attached. 16MB or 32MB SIMM can be used to

this purpose.

c. Total Memory

Value: (16|32|48|64|80) MB

Example: 16MB

Default: 16MB

Description: It indicates the printer board’s total memory quantity. In

other words, it is summation of Base Memory and Option Memory.

d. Copier HDD

Value: 4GB

Version Information

a. PRT

Value: #.##

Example: 2.00

Default: Depends on printer firmware version

Description: This number should be same as the PRT-PRG ROM

version number seen on serviceman simulation 22-5.

b. BOOT

Value: #.##

Example: 2.00

Default: Depends on printer firmware version

c. ICU

Value: #.##

Example: 2.00

Default: Depends on printer firmware version

Description: This number should be same as the ICU ROM version

number seen on serviceman simulation 22-5.

Installed Device

a. Duplex Module

Value: (Yes | No)

Example: Yes

Default: Depends on the Machine configuration

Description: It indicates that duplex unit is attached or not.It depends

on hardware configuration.

b. Output Device

Value: (Standard 1 Tray | Standard 2 Trays | 3 Tray Finisher|2

Tray Finisher)

Example: 3 Tray Finisher

Default: Depends on the Machine configuration

Description: It indicates attached output device.. It depends on

hardware configuration.

c. Paper Input Trays

Value: (2 trays | 3 trays | 4 trays)

Example: 2 trays

Default: Depends on the Machine configuration

Description: It indicates the number of standard input trays.It

d. Large Capacity Tray

Value: (Yes | No)

Example: Installed

Default: Depends on the Machine configuration

Description: It indicates that large capacity paper input tray(Large

e. Interface Board

Value: (None | Ethernet | TokenRing)

Example: Ethernet

Default: Depends on the Machine configuration

Description: It indicates the kind of installed network card option to

depends on hardware configuration.

Capacity Tray) is attached or not. It depends on

hardware configuration.

the slot. 10Base-T/2 and 10/100Base-T are not identified. Those two will be reported as Ethernet.

TokenRing would not be supported for AR-PB1 (ARPB2) for Japan domestic.

Available Paper Size

Appearance on

Configuration Page

Letter (81/2x11) Letter / Long Edge Feed

Letter (81/2x11R) Letter / Short Edge Feed

Legal (81/2x14) Legal / Short Edge Feed

Ledger (11x17) Ledger / Short Edge Feed

Executive (7 1/4x101/2) Executive / Short Edge Feed

Invoice (5 1/2x81/2) Invoice / Long Edge Feed

Foolscap (81/2x13) Foolscap / Short Edge Feed1

A4 A4 / Long Edge Feed

A4R A4 / Short Edge Feed

B5 B5 / Long Edge Feed

B5R B5 / Short Edge Feed

B4 B4 / Short Edge Feed

A3 A3 / Short Edge Feed

A5 A5 / Long Edge Feed

A6 A6 / Short Edge Feed

Japanese Postcard Japanese Postcard / Short Edge Feed

(Unknown) Other size (EXTRA)

(No Paper) No paper available on this tray.

(No Tray) There is a problem with this tray.

(Tray Open)

a. Tray 1 / Tray 2 / Tray 3 / Tray 4

Value: [Appropriate Paper Size]

Example: Letter (81/2x11)

Default: Depends on paper tray configuration.

Description: It indicates paper size configuration of Tray 1 /2 / 3 / 4 /

5. It depends on hardware configuration, not software

condition.

(Unknown) means paper size cannot be identified. (Tray

configuration is "EXTRA".)

This line is not printed for unavailable tray.

This tray is opened (except Bypass-Tray)

Description

or Tray is lifting up.

5 – 2

Page 23

AR-PB2A

b. Large Capacity Tray

Value: [Appropriate Paper Size]

Example: Letter (81/2x11)

Default: Depends on paper tray configuration.

Description: It indicates paper size configuration of Large Capacity

Tray. It depends on hardware configuration, not

software condition. When tray is opened, nothing is

printed at here.

This line is not printed when Large Capacity Tray is not

attached.

c. Bypass-Tray

Value: [Appropriate Paper Size]

Example: Letter (81/2x11)

Default: Depends on the paper size set on Bypass Tray.

Description: It indicates paper size of set on Bypass Tray. It depends

on detection of Bypass Tray paper size. (Unknown)

means paper size cannot be detected.

B. Software Information

PostScript Emulation

a. Job Time-out

Value: # (variable length digit)

Example: 0

Default: 0

Description: This value indicates PostScript Job Time-out length

(seconds). If this time will pass from receiving the job

then PostScript interpreter will give up to print the job

and cancel.

b. Manual Feed Time-out

Value: # (variable length digit)

Example: 0

Default: 0

Description: This value indicates PostScript Manual Feed Time-out

length (seconds). If the print data break off during printing and this time will pass, then PostScript interpreter

will cancel the print job. 0 means never time out.

c. Wait Time-out

Value: # (variable length digit)

Example: 300

Default: 300

Description: This value indicates PostScript Wait Time-out length

(seconds). If the print data break off during printing and

this time will pass, then PostScript interpreter will cancel

the print job. 0 means never time out.

PCL5e Emulation

This section tells PCL5e information. This section would not appear

on AR-PB1 (Siam) for Japan domestic.

a. Font Source

Value: (Resident | Download)

Example: Resident

Default: Resident

Description: Current font source to print characters in PCL mode.

b. Font Number

Value: 0 to 45

Example: 0

Default: 0

Description: This is the current default font number used for plain

PCL job stream.

c. Font

Value: (PCL font name)

Example: Courier

Default: Courier

Description: Current default font for PCL printing.

d. Pitch Size

Value: # (variable length digit)

Example: 0.44 to 99.99 in 0.01 steps

Default: 10.00

Description: This is the current default pitch size for plain PCL job

stream.

e. Point Size

Value: # (variable length digit)

Example: 4.00 to 999.75 in 0.25 steps

Default: 12.00

Description: This is the current default point size for plain PCL job

stream.

f. Symbol Set

Value: (PCL symbol set name)

Example: Roman-8

Default: Roman-8

Description: This is the current default symbol set for plain PCL job

stream.

Network Information

a. NIC Serial Number

Value: ######

Example: 123456

Default: Depends on NIC.

Description: It indicates the NIC’s serial number. This value is written

in NIC’s ROM (or flush ROM).

b. NIC Firmware Version

Value: ######

Example: 123456

Default: Depends on NIC.

Description: It indicates the NIC’s serial number. This value is written

in NIC’s ROM (or flush ROM).

c. NetWare Print Server Name

Value: [User Definable]

Example: SHARP_990792

Default: SHARP_[NIC card serial number]

Description: This value must reflect the printer name for IPX/SPX

(NetWare).

5 – 3

Page 24

AR-PB2A

[6] FIRMWARE VERSION UP

1. Printer controll PWB

A. Cases where flash memory rewriting is required

In the following cases, the program in the printer control PWB flash

memory must be rewritten.

1) When a bug or other error is found

2) Data stored in the flash memory is destroyed or deleted.

3) When the flash memory is replaced.

B. Necessary tools

1) Computer (PC)

2) Parallel cable

3) Program data file (xxx.hex)

C. Procedure

1) Print the setup list to check the firmware version.

Use the operation panel of the copier to perform the following

procedure.

Offline → Environment setup → Test page print → Test page

output