Page 1

Page 2

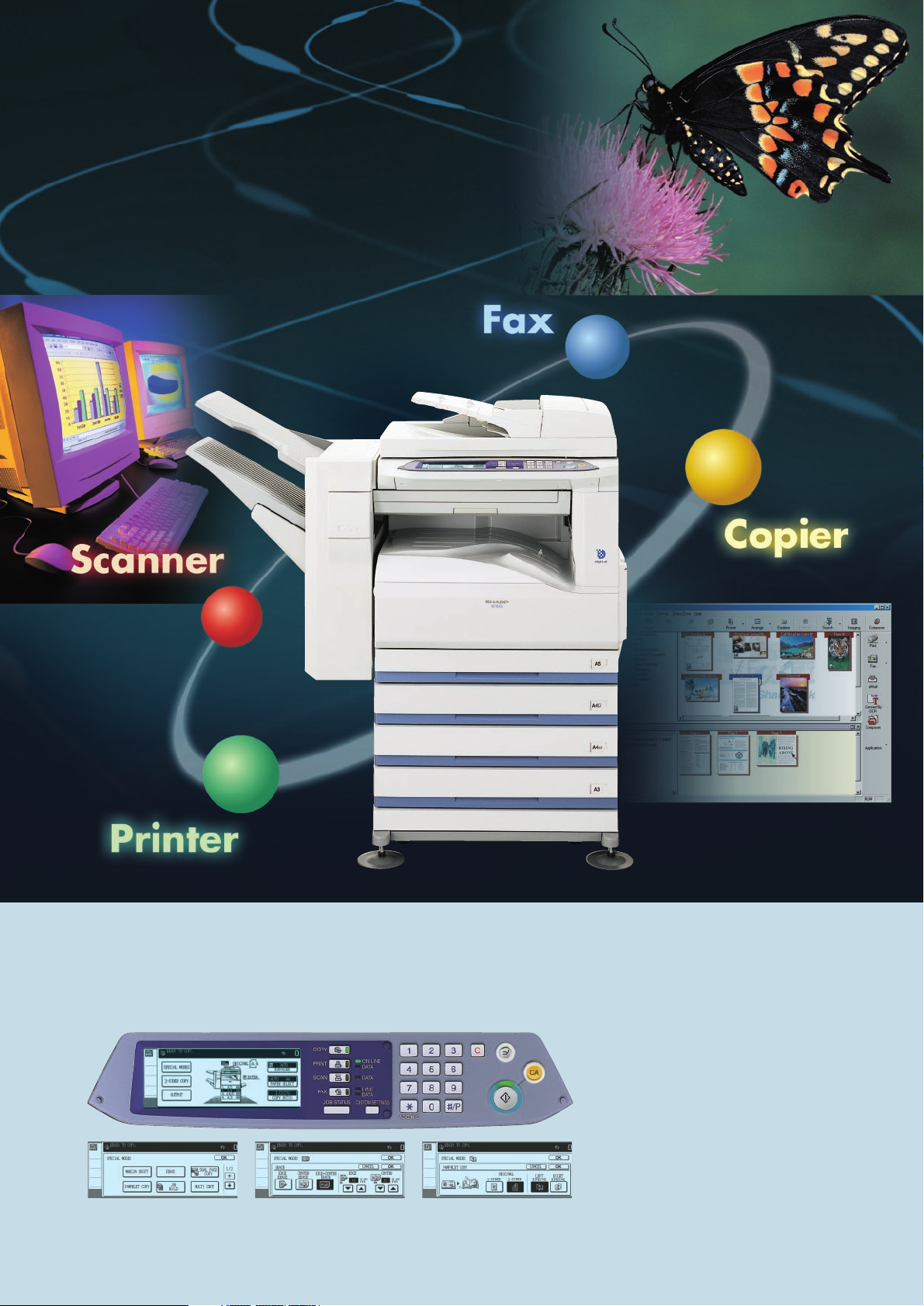

Combining advanced digital technology with powerful features, the AR-M276

Digital Multifunctional System offers high-performance copying and printing

functions for businesses of all sizes, helping you achieve professional results,

faster and easier than ever before. The saddle stitch finisher gives highly

efficient automatic job finishing, allowing you to make professional-looking

booklets. Network scanning and the Sharpdesk™ application contribute to

enhanced workflow in the office. And the universal design and user-friendly

touch-screen LCD control panel make it easy for anyone to harness the power

of this versatile multifunction machine.

The Multifunction that Grows with Your Business

Special modes Edge/centre erase Pamphlet copy

User-Friendly Touch-Screen LCD

The AR-M276’s logically designed control panel features a wide, clear touch-screen

LCD panel with easy-to-follow guidance. For example, when adjusting the edge/centre

erase function or, in the event of a paper jam, the LCD displays step-by-step instructions

to guide you through the necessary procedures.

User-Friendly Universal Design

Based on the concept of universal design,

the AR-M276 has features that make it

user-friendly for everyone from beginners

to the physically challenged.

• Optimum-height operation panel for

easy access

• Easy-to-press and -feel indented keys

• Notification sounds for default levels in

manual settings (zoom, exposure, etc.)

• Delayed response setting gives enough

time to cancel operation

Page 3

Speedy Copying and Quick First Copy Time

The AR-M276 has a quick first copy time of 4.8 seconds to save

valuable time when performing

multiple short-run jobs. And with a

continuous copy rate of up to 27

cpm* (A4 size), you can do more

copy jobs in less time.

*13.5 cpm at 1,200 dpi.

Built-in Stackless Duplex Module

The AR-M276 can automatically produce duplex copies from

one- or two-sided originals. This reduces paper costs and helps

save filing space. Duplex copying is even more productive

when used together with the optional RSPF (reversing single

pass feeder), which

efficiently feeds in up to

100 pages of either

one- or two-sided

originals. Plus, the

duplex module’s short

paper path keeps paper

jams to a minimum.

Electronic Sorting and Offset Stacking

When working with the

optional 100-sheet

RSPF, the Electronic

Sorting function does

one scan of multiplepage documents and

stores them in memory

for making up to 999

copies of each page.

The AR-M276

automatically collates

multiple sets of copies in

page order without the

aid of a sorter and can

also stack each set

slightly shifted apart

from the previous (offset

stacking) for easy

retrieval. All this adds up to speedy copying that boosts

productivity even for large-volume documents.

Automated Job Finishing

The AR-M276 makes it easy to create professional-looking

booklets automatically. Working together with the efficient

Electronic Sorting function and highly productive stackless

duplex module, the optional Saddle Stitch Finisher* folds and

staples sets of documents to make completed booklets. A Punch

Module allows you to punch holes in documents for easy filing.

And a Finisher is also available for jobs that require only simple

sorting and stapling.

*To be available at a later date.

Job Build for Large-Volume Scanning

With optional extra memory installed, the AR-M276 easily

handles copy jobs exceeding the RSPF capacity of 100

pages*. The AR-M276 automatically stores large-volume

documents of up to 2,970 pages** in memory so that users

can print all documents at once at a later time.

*A4 size

**Standard A4 pages. The actual storage limit depends on the amount of

memory installed.

Large Paper Capacity

The AR-M276 comes standard with two

500-sheet drawers and a 100-sheet

multi-bypass feeder for a total paper

capacity of 1,100 sheets. For largevolume jobs and a wider selection

of available paper sizes, the

AR-M276 can accommodate two

types of extra paper drawers for

a total paper capacity of up to

2,100 sheets. When a tray runs

out of paper, the Auto Tray

Switching function automatically

switches to another paper tray filled with the same size paper.

This allows you to do extra-large volume jobs without worrying

about running out of paper.

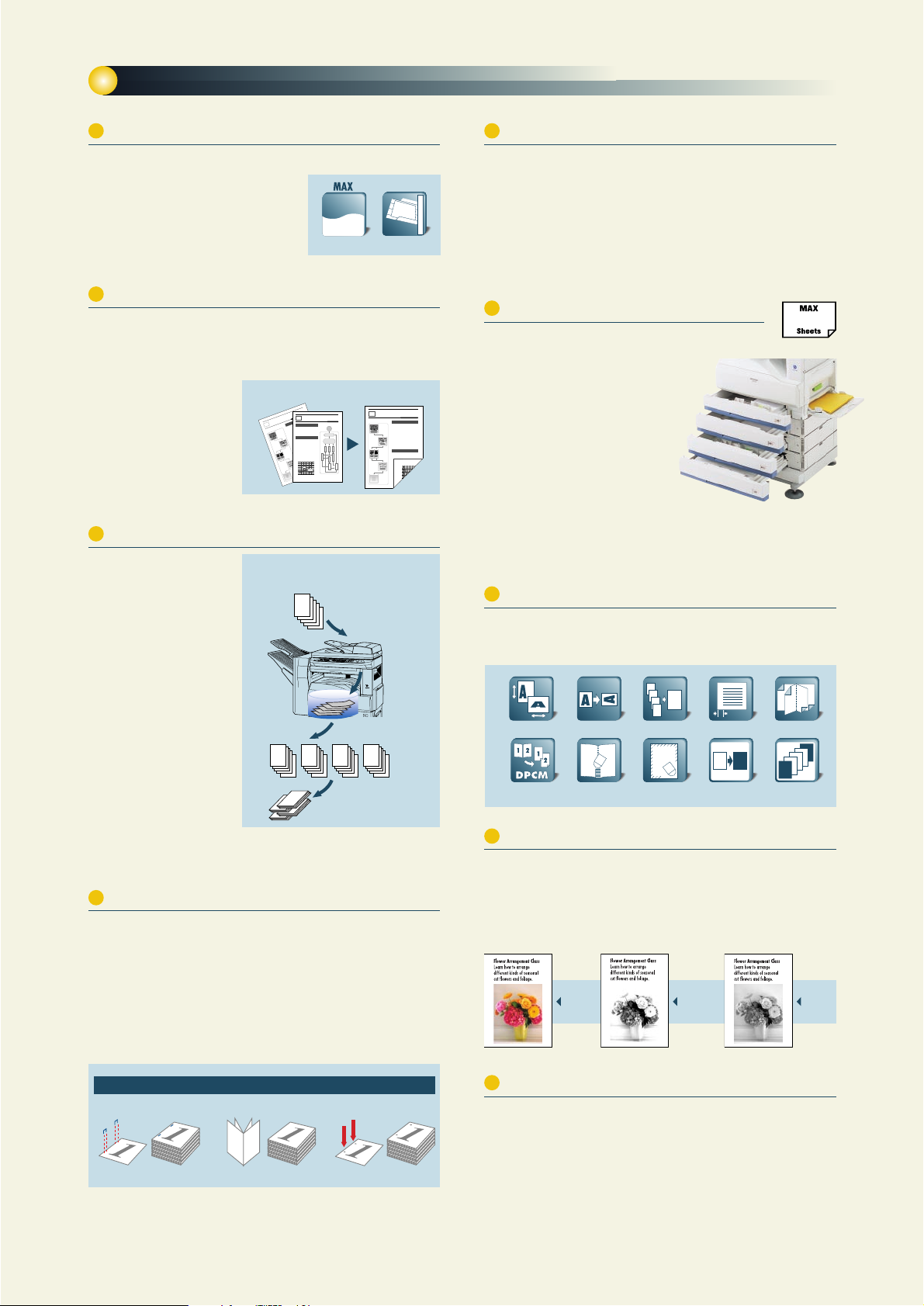

Versatile Editing Functions

Along with conventional editing functions such as B&W Reverse

and XY Zoom, the AR-M276 gives you advanced editing

functions made possible by digital technology.

Superb Image Quality

The Digital Automatic Exposure Control function lets you copy

documents at the optimum exposure level. In Super Photo mode,

the 1,200-dpi laser engine reproduces the finest details of the

original to give you impressive, professional-looking copies.

The Text/Photo mode automatically adjusts the contrast to the

optimum level for an original that includes text and photos.

OTHER KEY FEATURES

• Wide zoom range from 25 to 400% with preset copy ratios

• Automatic paper/magnification selection

• Can handle heavy paper stock up to 200 g/m

2

• Copy auditing (100 accounts)

• Pre-Heat and Auto Power Shut-Off modes

Analogue

AE

Original

Digital

AE

Stapled documents Booklets

Electronic Sorting and Offset

Stacking

.....

1515151

5

1

5

Document is

scanned...

Multi-page

original

stored in

memory...

Copies

electronically sorted...

and stacked offset

during output.

Duplex Copying

Purifying Water with Bio-Power

Naturally purifying waste with a fluidized treatment system

Special Edition

1

Waste fluid treatment system at Fukuyama site

Microorganism

treatment

Populous

microorganism cultures

decompose main

components

Bincho charcoal/

bio-activated

charcoal treatment

Microorganisms

decompose as they are

absorbed by charcoal

Reuse of treated

water

Treated water is

reused in other

drainage treatment

processes

Oyster shell

treatment

Oyster shells

neutralize the

fluid

Monitoring by fish

Sensitive to

environmental

changes, roaches are

used to monitor safety

levels

Oyster shells

Bincho

charcoal

Activated

charcoal

Freshwater fish

Large amounts of

microorganisms

Fluidized waste treatment system

using natural purification

At the Fukuyama site where ICs are manufactured, we used to

hire a subcontractor to incinerate spent developer, which

makes up 70% of all our industrial waste. This method placed a

significant burden on the environment, including the energy

used for incineration and exhaust gas from the vehicles

transporting the waste. Treatment costs swelled as production

increased. It was a challenging issue for us, from both an

environmental and managerial standpoint.

We at the Fukuyama site had been pursuing in-house

treatment for spent developer, and we finally completed a

fluidized waste treatment system using natural purification in

1996.

This system is based on a concept of purifying spent

developer by natural processes. Built according to our

proprietary design, it is a state-of-the-art system that produces

no hazardous sludge during the treatment process.

Microorganisms Purify Water, Sustain

Monitoring by Fish

In-House Treatment of Used Developer

to Produce No Polluted Mud

Sharp’s system makes the maximum use of materials existing

in nature. In the microorganism treatment process,

microorganisms cultured to high levels of density are used to

decompose most of the main components in spent developer

that have strong alkalinity.

In the oyster shell treatment process, neutralizing treatment is

carried out using a film of microorganisms that forms on the

surface of oyster shells to decompose other organic

substances.

In the Bincho charcoal/bio-activated charcoal treatment

process, charcoal agents absorb a slight amount of the

remaining organic substances. The charcoal is cleansed

automatically, as the absorbed organic substances are treated

by microorganisms growing on the surface of the charcoal.

In the fish monitoring process, in addition to measuring

instruments, water safety is monitored with freshwater fish,

such as roaches and Japanese bitterlings, which are sensitive

to environmental changes.

Purifying Water with Bio-Power

N

a

tu

r

a

ll

y

p

ur

ify

in

g

w

as

te

w

it

h a

fl

ui

di

z

e

d

tre

at

m

en

t

sy

ste

m

S

pe

c

i

a

l E

d

iti

o

n

1

W

a

s

t

e

fl

u

id

t

re

a

t

m

e

n

t

s

y

s

t

em

a

t

F

u

k

u

y

a

m

a

s

it

e

M

icr

o

o

rga

n

is

m

tr

ea

tm

ent

P

o

p

u

l

o

u

s

m

i

c

r

o

o

r

g

a

n

i

s

m

c

u

ltu

re

s

d

e

co

m

p

o

s

e

m

a

in

c

o

m

p

o

n

e

n

t

s

Binch

o

cha

rcoa

l/

b

io-ac

tiv

ated

char

c

oal

treatm

e

nt

Mi

cro

orga

ni

sms

de

comp

ose

as they

are

abso

r

bed

by cha

rc

oal

Re

us

e o

f tr

ea

ted

w

a

te

r

T

r

e

a

te

d

w

a

te

r

i

s

r

e

u

s

e

d

in

o

th

e

r

d

r

a

in

a

g

e

tr

e

a

t

m

e

n

t

p

r

o

c

e

s

s

e

s

O

y

s

ter

sh

ell

t

re

atm

ent

O

y

s

t

e

r

s

h

e

l

ls

n

e

u

tr

a

l

ize

th

e

flu

i

d

M

o

n

i

to

ri

n

g

b

y

f

is

h

S

e

n

s

it

iv

e

t

o

e

n

v

i

r

o

n

m

e

n

t

a

l

c

h

a

n

g

e

s

,

ro

a

ch

e

s

a

r

e

u

s

e

d

t

o

m

o

n

i

to

r

s

a

fe

t

y

le

v

e

ls

O

y

ster

sh

ells

B

incho

ch

ar

c

o

al

Activat

ed

ch

ar

c

o

al

Fre

s

h

wat

er f

is

h

Large

am

ounts

o

f

m

icr

o

o

rgan

is

ms

Flu

idized

was

te trea

tment sys

tem

u

sing

natural purificatio

n

A

t

th

e F

u

ku

y

am

a

s

ite

w

h

er

e

IC

s ar

e m

an

ufa

c

ture

d

, w

e

u

sed

to

h

ir

e a

su

b

co

n

tra

cto

r to

in

ci

n

e

rat

e sp

e

nt

de

v

elo

p

er,

w

hi

ch

m

ak

e

s u

p

70

%

o

f a

ll o

u

r i

nd

us

trial

w

aste

.

T

h

is m

e

th

od

p

la

ced

a

s

ign

ifica

n

t

b

ur

d

en

o

n

the

en

v

ir

on

m

e

n

t, in

c

lu

di

n

g

the

en

erg

y

u

s

ed

fo

r

in

cin

er

atio

n

an

d

e

xh

a

us

t g

as fr

om

th

e

ve

h

ic

l

es

tra

ns

p

o

rtin

g

the

w

a

ste

.

T

re

at

m

en

t

co

s

t

s

sw

e

lle

d

a

s

p

r

od

u

c

tio

n

in

cre

as

e

d.

It

w

as

a c

h

a

lle

n

gin

g

iss

ue

fo

r u

s,

fro

m

bo

th

a

n

e

nv

iro

n

m

en

ta

l a

n

d

m

an

a

ge

ri

a

l s

ta

nd

p

o

in

t.

W

e

a

t

th

e F

u

ku

ya

m

a

s

it

e

h

a

d b

e

en

p

u

rs

u

in

g

in-

h

ou

s

e

tre

atm

e

n

t

for

sp

e

nt d

e

ve

l

op

er

,

an

d

we

fin

al

ly co

m

p

le

ted

a

fluid

ize

d

w

as

te

tr

ea

tm

en

t s

ys

tem

usi

n

g

n

atu

r

al

p

ur

ific

a

tio

n

in

1

9

96

.

T

h

i

s s

yst

em

is b

a

sed

o

n

a c

o

nc

e

pt o

f p

u

rify

in

g

sp

e

n

t

d

e

ve

l

o

p

er

b

y

n

atu

ra

l

pr

o

ces

s

es.

B

u

ilt

a

cc

o

rd

i

ng

to

o

u

r

p

ro

p

r

ieta

ry

d

esig

n

,

it is a

sta

te-

o

f-th

e-a

rt

sy

s

tem

th

a

t p

r

od

u

c

es

n

o

h

a

za

rd

o

u

s s

lud

g

e

d

u

rin

g

th

e tr

ea

tm

en

t p

ro

ce

s

s.

M

ic

r

o

o

rg

a

ni

sm

s

P

u

ri

fy

W

a

t

er,

S

u

s

t

ai

n

M

o

n

it

o

rin

g

b

y

F

i

s

h

In

-H

o

us

e

T

rea

t

m

e

n

t o

f U

s

e

d

D

e

v

e

lo

p

e

r

to

P

r

o

d

u

c

e

N

o

Po

l

lu

t

e

d

M

ud

S

h

ar

p’

s s

yst

em

m

a

k

e

s

th

e

m

a

x

im

u

m

u

se

o

f m

at

e

ri

als

e

x

is

tin

g

in

n

atu

re

.

In

th

e

mi

c

ro

o

r

g

an

ism

tre

a

tm

en

t p

ro

c

es

s

,

mic

ro

o

rg

an

i

sm

s

cu

ltu

re

d to

h

ig

h le

ve

ls o

f de

n

sity

ar

e u

se

d

to

d

ec

om

po

s

e

m

o

st

o

f t

h

e

m

a

i

n

co

m

p

on

e

n

ts i

n

sp

en

t d

e

ve

l

o

pe

r

th

a

t h

a

ve

str

o

ng

a

lk

a

lin

ity

.

In

th

e

o

y

ste

r

sh

e

ll tre

a

tme

n

t p

ro

ce

ss

,

ne

u

tra

liz

in

g

tr

ea

tm

en

t i

s

car

rie

d o

u

t u

si

n

g

a fil

m

o

f m

icro

o

rg

a

n

is

m

s

th

a

t fo

rm

s o

n

the

su

rfa

ce

o

f o

y

ste

r

sh

el

ls to

d

ec

o

m

p

o

s

e

o

th

e

r o

r

ga

n

i

c

su

b

s

tan

c

es.

In

the

B

in

ch

o

c

ha

rc

o

al

/b

i

o-a

c

tiva

te

d

c

h

a

rco

a

l t

rea

tm

e

nt

p

r

oc

es

s,

c

ha

rc

o

al

a

ge

n

ts a

b

so

rb

a

s

lig

h

t

a

m

o

un

t o

f th

e

r

em

a

inin

g

o

rg

an

ic

su

b

s

tan

c

es

.

T

h

e

c

h

ar

co

al i

s

c

le

a

n

sed

au

to

m

a

tica

lly

, a

s th

e

a

b

so

r

be

d

or

ga

n

ic su

b

s

tan

c

es

a

re

tre

ate

d

b

y

m

i

cr

o

org

a

n

is

m

s g

ro

w

in

g

o

n

th

e su

r

fa

c

e o

f

th

e

c

h

ar

co

a

l.

In

th

e

fish

m

o

n

itor

ing

p

ro

ce

ss

,

in

a

dd

iti

o

n

to

m

e

a

su

rin

g

in

st

ru

m

en

ts,

w

ate

r sa

fet

y

is m

o

n

i

tore

d

wi

th

fre

sh

w

a

ter

fis

h

,

su

c

h

a

s

ro

a

ch

e

s

a

nd

J

ap

a

ne

s

e

b

itter

lin

g

s,

w

hic

h

are

se

n

sitiv

e

to

e

nv

iro

n

m

en

ta

l c

h

an

g

e

s.

Effective use of water at Mie site

Making the Most Effective Use of Water Resources

Recovery effluents with a reuse rate of 92%

Special Edition

2

Our Mie plant is located 10 km southeast of Matsuzaka City in

Mie prefecture. The nearby Kushida River is the source of

drinking water for Matsuzaka citizens and is also used for local

agricultural irrigation. Since LCD manufacturing requires a lot

of water, drainage treatment is an important factor in

environmental preservation in the neighborhood.

Effluent Treatment Facility Ensures

Reuse Rate of 92%

Clear Concept for Environmental

Preservation

Pure water used in the production process is classified into

inorganic, organic and neutral effluents* before being

discharged and recovered in a closed system for later reuse.

When we began operations in 1995, we mainly recovered and

reused inorganic effluent, which was believed to have a

negative effect on the environment with a recovery rate of

30%. We had repeatedly evaluated treatment processes to

recover and reuse organic and neutral effluents until 1996

when we introduced a new treatment process. This process

utilizes microorganisms for the organic effluent and

ultraviolet-ray oxidation treatment technology for the neutral

effluent. This raised the recovery rate to 69%.

Ion exchange treatment

Reverse osmosis

film treatment

Ultraviolet-ray

oxidation treatment

Vacuum evaporator

Neutral effluent

Organic effluent

Bio-treatment

Inorganic effluent

Supplied

water

Production process

*1 Inorganic effluent: effluent containing acid, alkali

*2 Organic effluent: effluent containing alcohol, etc.

*3 Neutral effluent: effluent containing microscopic dust and dirt

Pure water

facility

*1*2*3

Closed system for water treatment

(Amount of supplied

water: 1,000 tons)

(LCD output growth: 1996 = 1)

0

1000

2000

3000

4000

5000

6000

7000

8000

9000

0

1

2

3

4

5

6

7

8

9

(Fiscal year)

19971996 19981999 20002001

8.9

1470

Amount of

supplied water

Output

Annual changes in amount of

supplied water and LCD output growth

(Amount of supplied

water: 1,000 tons)

(LCD output growth: 1996 = 1)

0

1000

2000

3000

4000

5000

6000

7000

8000

9000

012345678

9

(Fiscal year)

19971996 19981999 20002001

8.9

1470

Amount of

supplied water

Output

Annual changes in amount of

supplied water and LCD output growth

Various Types of Job Finishing with the Saddle Stitch Finisher

or

Punched documents

or

COPYING

27

CPM

(at 600 dpi)

1st.

4.8

sec.

First copy time

2,100

7

1

5

3

8

2

6

4

Pamphlet Copy

3

2

1

Cover Insertion

XY Zoom

Dual Page Copy Mode

A

ACB

B

C

D

D

Rotation Copy

2-in-1/4-in-1 Copy Margin Shift

A A

Centre Erase B&W Reverse

Edge Erase

8

1

Page 4

Speedy Printing with Sharp Technology

The AR-M276 is a high-performance printer incorporating

Sharp Printer Language with Compression (SPLC) technology.

SPLC effectively reduces the data size of print jobs, speeding

up the data transfer time and printing process while improving

overall throughput. Also, the Rip Once/Print Many function

saves print data in the AR-M276’s internal memory and

transfers it to output at an amazing rate of 27 ppm in 600-dpi

resolution. Both IEEE 1284 parallel and USB 2.0 (full speed

mode) ports are provided as standard.

PCL6 and PostScript 3 Emulation

When equipped with the optional AR-P17 Printer Expansion Kit,

the AR-M276 supports PCL5e and PCL6 printer languages.

For compatibility with more fonts and better graphics handling,

PostScript 3 is available with the AR-PK1N PS3 Expansion Kit.

Note: The optional AR-NC5J is also required for PostScript printing in the

Macintosh OS.

Razor-Sharp 1,200-dpi Printing

The AR-M276’s 600-dpi print engine provides enhanced

1,200-dpi print quality. This can be upgraded to true 1,200-dpi

printing for ultra-clear image quality with the optional AR-P17.

Job Offset and Job Separator

The AR-M276 ensures your documents will stay neatly

organised even when others are using the machine at the same

time. To make it easier to locate and retrieve your documents

from the tray, the AR-M276’s Job Offset function stacks each

print job slightly shifted apart from one another. In addition, a

convenient Job Separator* outputs copied documents onto a

separate tray, preventing them from getting mixed in with

printouts and faxes.

*Requires optional AR-TR3.

Document Finishing

Choose the optional Finisher or Saddle Stitch Finisher to

automate time-consuming tasks such as sorting and stapling.

The Saddle Stitch Finisher* automatically arranges your

document in the proper page layout and makes booklets. A Punch

Module is also available to make hole-punched documents.

*To be available at a later date.

Network Printing

The AR-M276 works as a network printer when equipped with

the optional AR-P17, giving it TCP/IP support and allowing

printing in a Windows®network environment. By adding the

optional AR-NC5J Print Server Card, the AR-M276 becomes

compatible with most of today’s available network operating

systems and protocols and can be used in mixed network

environments as well. You can easily integrate the AR-M276 into

your existing network and enjoy its powerful network printing via

100Base-TX and 10Base-T Ethernet standards in various network

protocols including Novell IPX/SPX, TCP/IP and NetBEUI for

Windows and UNIX, and Macintosh EtherTalk*.

*Requires optional AR-PK1N.

Network Utility Software

Sharp’s original Printer

Administration Utility software

makes printer networks easier to

manage by allowing network

administrators to customise

monitored items and view settings

such as the IP address directly from

their PC. Printer Status Windows

conveniently allow you to monitor

important printer information on

your PC, including on-line/off-line

status, name of the active print job,

and machine conditions such as

amount of paper or toner.

Various Printing Functions

• Proof Printing allows you to check a trial set before

printing out entire multiple-page documents in order to avoid

printing mistakes and wasted paper and time.

• Carbon Copy Printing prints out the same page of a

document onto up to three*1different kinds of paper from

separate, multiple trays.

• Direct Printing without Printer Driver prints out PDF*

2

or TIFF*3files without opening applications or using printer

drivers. Plus, this function enables e-mail printing, which

automatically prints out the attached files when the

AR-M276 receives e-mail.

*1: Optional paper feed unit required.

*2: Direct PDF printing requires optional AR-PK1N.

*3: Certain types of TIFF and PDF files may not print out this way.

OTHER KEY FEATURES

• Duplex printing, Pamphlet Style printing

• N-up, Fit-to-Page, Watermarks, Mirror Image

• Barcode font compatibility, form/font download

Compress print data, reduce transfer time

Data is com-

pressed

Decompressing

Transfer

Transfer time reduced by

nearly half (vs. GDI)

Fast printing of text and graphics

SPLC (Sharp Printer Language with Compression) Printing

Host-based

print data

Macintosh

Windows

®

95/98/Me

Windows

®

2000

Ethernet

(10Base-T/100Base-TX)

TCP/IP

IPX/SPX

IPP, etc.

TCP/IP

IPX/SPX

IPP, etc.

EtherTalk

Print

Windows® XP

Windows NT

®

4.0

UNIX

TCP/IP

With optional AR-P17

and AR-NC5J installed

Copier output

Job Offset

Job Separator

Won’t get

mixed!

Printer/fax output

Printer Administration Utility screen

NETWORK PRINTING

(option)

Printer Status Window

in it’s

ga

nce a

O

ine taste-

tion.

time for our annual

er w

summ

testing celebra

l

ur annua

nce again it’s

O

ine taste-

e for o

tim

er w

summ

testing celebration.

Page 5

A3 Network Scanning

The optional AR-NS2

Network Scanner Expansion

Kit turns the AR-M276 into a

convenient monochrome

network scanner. With the

touch of a few buttons, you

can choose one of three

ways to distribute your

scanned documents.

Scan to E-mail allows you

to send documents as an

attachment to any e-mail address over the Internet. Additionally,

an “ad hoc” feature allows you to conveniently enter an e-mail

subject title or file name from the touch-screen LCD.

Scan to FTP Server lets you scan a

document directly to an FTP server for

special applications such as company-wide

posting or archiving. Scan to Desktop

enables you to send scanned documents

directly to your desktop computer. And with

Sharpdesk™, Sharp’s powerful but easy-touse document management software (see

below), editing and managing scanned

documents is easier than ever.

Sharpdesk™ for Total Document Management

Sharpdesk™ is an original,

intuitive application that provides

integrated desktop management

of documents regardless of the

format. Once you scan

documents and images, or dragand-drop existing files

on your PC into

Sharpdesk™, you can

view their thumbnail

images and organise,

edit, search and

distribute your

documents in over

200 file formats for

maximum productivity.

VIEW & SEARCH

Sharpdesk’s built-in Search

engine displays results

clearly and logically, making it fast and easy to find

and retrieve scanned documents or any electronic file

on your PC. You can also

view files in their native

format by dragging and

dropping them onto

Sharpdesk’s View/Work

area, where they will be displayed as easy-to-recognise thumbnail images. Sharpdesk supports over 200 kinds of file formats,

including Excel, Word, TIFF, JPEG and BMP.

EDIT & PROOFREAD

Sharpdesk Composer lets you

combine different types of files

into a single document through

simple drag-and-drop operation.

Image Editor provides a range

of useful annotation tools such as

labels, stamps and marks,

allowing network users to check

and proofread documents without

overwriting the original files

and without having to print out

a hard copy.

CONVERT & OUTPUT

Output your scanned documents by dragging them onto the

desired icon in the Output zone. You can archive, print, e-mail

or fax files, or open them in your favourite application.

Sharpdesk can convert documents to PDF format for

sending as easy-to-open e-mail attachments. It can also convert

scanned documents to editable text using OCR (optical

character recognition).

LDAP Compatibility for Network Scanning

Built-in LDAP (lightweight directory access protocol) support

eliminates the need to enter or register an entire e-mail address

from the LCD control panel. Simply enter the first few letters of

the recipient’s name and the AR-M276 displays a list of

possible matches from

names and e-mail

addresses on your

company’s LDAP server.

This feature saves

precious time and lets you

avoid errors when typing

e-mail addresses.

Print

Sharpdesk™ 3.0 screen

Annotation function

Scan

Internet

Scan to e-mail

Document

File server Client PCs

Send as e-mail

attachment

Scan to FTP server

Store and share

as digital data

Scan to desktop

Send to

designated PC

Folder window View/work area

Output zone

Composer

Fax E-mail

Convert

by OCR

Composer

NETWORK SCANNING

(option)

Image Editor

Search screen

_ _ _ _ _ _ _ _ _ _ _________ _ _ __ _ _ _ _ _ _ _ _ _ _______

_ _ _ _ _ _ _ _ _ _ _________ _ _ __ _ _ _ _ _ _ _ _ _ _______

_ _ _ _ _ _ _ _ _ _ _________ _ _ __ _ _ _ _ _ _ _ _ _ _______

Page 6

High-Speed Operation

The AR-FX7 Fax Expansion Kit turns the AR-M276

into a Super G3 fax machine featuring a fast

modem speed of 33.6 Kbps. Using JBIG data

compression, the AR-M276 can send an A4 size page in under

3 seconds*. Working together with the machine’s 1.5-second

scanning, this function greatly enhances the efficiency of your

faxing jobs.

*Based on ITU-T test chart No. 1 at standard resolution.

Duplex Transmission and Reception

With the optional RSPF, the AR-M276 scans both pages of twosided documents and sorts them in memory. The pages are then

transmitted in the proper order. Thanks to the standard duplex

module, the AR-M276 can also print incoming faxes onto both

sides of paper, thus saving you paper costs.

Quick On-Line Transmission

The AR-M276 starts dialling and transmitting a multi-page

document as soon as the first page is scanned into memory.

This greatly reduces the overall time it takes to send the

document.

500-Number Auto Dialling

Register up to 500 numbers

into the customisable

directory of one-touch autodial keys, listed in

alphabetical order for easy

searches of specific

numbers.

F-Code Communication

Conforming to the ITU-T F-Code (sub-address and passcode)

standard, the AR-M276 is capable of F-Code confidential

communication, F-Code relay request transmission and F-Code

memory polling with other fax machines regardless of the

manufacturer or model.

Ultra Fine Mode

You can set the AR-M276 to this ultra-high resolution to give

the recipient crisp, clear reproduction of detailed images and

fine text.

FAXING

(option)

OTHER KEY FEATURES

• Automatic Print Reduction automatically reduces the

size of received faxes to fit the size of the printing paper

•

Memory Transmission stores documents in memory,

allowing the originals to be returned to the user quickly

•

Memory Reception saves incoming faxes in memory

if the AR-M276 runs out of paper or toner

•

Timer Transmission enables unattended after-hours

operation when reduced phone rates are in effect

•

Polling allows the user to retrieve a document left in the

feeder of a remote fax machine

•

Programme keys (up to 8 keys) are available to set up

frequently used transmissions for instant recall

•

Long originals (up to 1,000 mm long) can be sent using

the RSPF (Note: Not possible for A3-wide paper or in Ultra

Fine mode)

•

Dual Page Scan allows faxing of pages from an open

book or documents placed side by side

•

Job Separator separates incoming faxes from copier jobs

•

Offset Stacking slightly shifts individual faxes as they

arrive for easy retrieval

•

Broadcast Faxing to up to 200 destinations

•

Anti-Junk Fax blocks unwanted faxes from up to 50

specified fax numbers

Multi Access

You get two different functions simultaneously; for example, you

can scan documents into memory for transmission while you

receive an incoming fax.

PC-Fax

A PC-Fax function allows you to directly send a document

created on your PC to a recipient’s fax machine via the

AR-M276. Since all faxing procedures are done on your PC

without printing to paper, this function saves times, increases

faxing productivity, and retains original document quality.

Conventional Memory Transmission

Scan All

Send

Saves Time

Scan

Quick On-Line Transmission (AR-M276)

Dial

Send

Dial

“Send Fax”

command from PC

Conventional faxing

Fax is sent to recipient

fax machine

3 steps!

Fax documentOutput document“Print” command

(AR-M276)

PC-Fax

Select printer or

PC-fax driver

“Send” command

1 step!

Greatly reduces time

required for faxing

Page 7

AR-M276

(Base Unit)

USB 2.0 (full speed)

IEEE 1284 (parallel)

AR-P17

10Base-T/100Base-TX

USB 2.0 (full speed)

IEEE 1284 (parallel)

AR-NC5J

AR-NS2

COPY

Max. 27 cpm

True 1,200 dpi*

1

Electronic sorting

Duplex copying

–

–

–

–

–

PRINT

SPLC printing

Max. 27 ppm (ROPM)

Duplex printing

PCL6/5e printing

Network printing (TCP/IP)*

2

True 1,200 dpi printing

Direct TIFF*

3

printing

PAU & status monitor

PS3 printing

Direct PDF*

3

printing

Barcode font support

Font & form download

Network printing (multi protocol)

–

SCAN

–

–

–

–

–

Network scanning

Sharpdesk™ 3.0

Sharp’s Layered Security Approach Protects Your Business at Every Level

The AR-M276 has multiple levels of network and data security to restrict access to your electronic documents and ensure that

unauthorised personnel cannot get hold of valuable data. Users get peace of mind knowing they can safely copy, print, scan

and fax digital documents in any business environment, thanks to Sharp, the leader in office equipment security.

and

stored on

memory

Set PIN on your PC.

Data is sent from PC...

User enters PIN on

operation panel.

Confidential printouts won’t be read

by others.

Confidential Print

AR-PK1 N

AR-PF1/PF2

Super G3 & G3 fax, PC-fax (with AR-P17)AR-FX7

*1: Max. 13.5 cpm at 1,200 dpi resolution. *2: In Windows environment only. *3: Certain types of TIFF and PDF files may not print out this way.

Data erase (copy/print/scan/fax)AR-FR12

SECURITY

Copy auditor

Confidential printing (with PIN)

–

IP/MAC address filtering

Protocol selection

Scan user authentication

IP/MAC Address Filtering

The optional AR-NC5J Print Server Card and the AR-P17 Printer

Expansion Kit provide the AR-M276 with highly secure printing

and scanning capabilities by restricting access to the AR-M276

on your office network.

Only PCs that have either

or both their IP address

or MAC (media access

control) address

registered are allowed to

use the AR-M276.

Attempted access from

an unknown IP or MAC

address will be denied,

preventing unauthorised

use.

Data Security

Digital copier/printers or multifunction products can retain

hundreds of pages of confidential information from previous

jobs on their internal memory. To prevent these sensitive records

from being recovered by

unauthorised persons, the

AR-M276 can be

equipped with the

optional AR-FR12 Data

Security Kit*, which

completely erases the

data generated for each

job.

*To be available at a later

date.

DOCUMENT SECURITY

Confidential Print

With the optional AR-P17, the AR-M276 provides confidential

printing. To keep others from seeing confidential documents as

they are being printed out, the AR-M276’s Confidential Print

function requires the user to enter in a PIN (personal

identification number) at the machine before printing can begin.

User Authentication for Network Scanning

To prevent unauthorised use of network scanning, the AR-M276

supports user authentication, which requires users to log in to

the machine before performing any network scanning

operations.

Note: Available with optional AR-P17 and AR-NS2.

Auditing Mode

An auditing mode built into the AR-M276 requires users to enter

a five-digit PIN code to gain access to the operation panel. This

feature also restricts users from printing to the AR-M276.

Software Options to Expand the AR-M276’s Key Features

Data Security SystemIP/MAC Address Filtering

OK

Copy Data Print Data

Scan Data Fax Data

Unknown IP or MAC addresses

will be denied access

NO!

TOP SECRET

Prevents data leak

Data Erase

The data generated for each

job is automatically erased

once that job is finished

Page 8

©SHARP CORP. Printed in Australia

Type

Engine speed (copy/print)

(A4 size)

Paper size

Paper capacity

Memory

First copy time*

1

Warm-up time*

2

Power requirements

Power consumption

Dimensions (W x D x H)

Weight

Desktop

600 dpi: Max. 27 cpm/ppm

1,200 dpi: Max. 13.5 cpm/ppm

Max. A3, min. A5

1,100 sheets (500 x 2 + 100), max. 2,100 sheets with option

32MB, upgradeable to 1,056MB

4.8 seconds

23 seconds

230 ~ 240V AC ±10%, 50/60 Hz

Max. 1.4 kW, 1.1W or less in Sleep mode

623 x 609.5 x 640.5 mm

Approx. 46 kg

*1: When feeding A4 sheets from 1st paper tray, A4 original scanned on document glass

in Auto Exposure mode.

*2: At rated voltage, 25°C, 65% RH.

*3: Optional AR-P17 Printer Expansion Kit required for some features.

*4: AR-PK1

N PS3 Expansion Kit required.

*5: Available only in PS3.

*6: Certain types of PDF and TIFF files may not print out this way.

*7: AR-PF1 Barcode Font Kit required.

*8: AR-P17 provides TCP/IP network connectivity in a Windows environment; adding the AR-NC5J

Print Server Card gives network connectivity with other operating systems and protocols.

*9: Optional AR-NS2 Network Scanner Expansion Kit, AR-P17 and memory required.

*10: Resolutions higher than 400 dpi are interpolated.

*11: Optional AR-FX7 Fax Expansion Kit required.

*12: Based on ITU-T test chart no.1 at standard resolution in Super G3 mode, 33,600 bps,

JBIG compression.

• Design and specifications are subject to change without prior notice. Colour variations to

products may occur due to printing.

• Windows and Windows NT are either registered trademarks or trademarks of Microsoft

Corporation in the United States and/or other countries. All other brand names and

product names may be trademarks or registered trademarks of their respective owners.

•

Some options may not be available in some areas.

Resolution*

10

Compatibility

File format

Features

Original paper size

Continuous copy

Resolution

Gradation

Zoom range

Features

Max. A3

Max. 999 copies

Scan: 400 dpi

Print: 600 dpi, 1,200 dpi (Super Photo mode)

Scan: 256 levels

Print: 2 levels

25 to 400% (1,200 dpi: 50 to 200%) in 1% increments with

10 preset ratios (5R + 5E) in metric system

• Scan once/print many • Electronic sorting • Offset function

• Duplex copy • Dual page copy • B&W reverse • XY zoom

• Multi shot (2-in-1/4-in-1) • Rotation copy • Edge/centre erase

• Margin shift • Auto paper/magnification selection

• Job programme • Job build • Pre-heat/auto power shut-off modes

• Copy auditing (100 accounts) • Pamphlet copy • Cover insertion

Compression method

Communication protocol

Transmission time

Modem speed

Scanning resolution

Memory

Grayscale levels

Features

JBIG/MMR/MR/MH

Super G3/G3

Less than 3 seconds*

12

33,600 bps to 2,400 bps with automatic fallback

Standard: 8 dots x 3.85 lines/mm up to 16 dots x 15.4 lines/mm

2MB, upgradeable to 10MB with options

256 levels

• Duplex transmission/reception • PC-fax transmission

• Quick on-line transmission • F-Code compatibility

• 500 rapid dials • Confidential communication

• Anti-junk fax reception • Memory transmission

• Group dials (up to 50 groups & 200 destinations)

• Broadcasting (up to 200 destinations) • 8 programmes

• Department control (100 profiles)

Hardware interface

Supported platforms

Network protocols

Printing protocols

Feature

10Base-T, 100Base-TX (RJ-45 Ethernet connection)

Windows

®

95/98/Me, Windows NT® 4.0, Windows® 2000/XP,

Novell NetWare 3.x/4.x/5.x/6.0, UNIX, Linux, Macintosh system

8.6 to 9.x and 10.1 or later

TCP/IP for Windows and UNIX environments,

IPX/SPX for Novell environments, EtherTalk for Macintosh

environments, NetBEUI for Windows environments

LPR, Raw TCP (port 9100), POP3 (e-mail printing), HTTP,

Novell Printserver application with NDS and Bindery,

FTP for downloading print files, EtherTalk printing, IPP

Network security with IP/MAC address filtering

Resolution

Memory

Interface

Supported OS

PDL emulation

Available fonts

Features [Standard]

[Option]

Standard: 600 dpi (enhanced 1,200 dpi)

Option: 1,200 dpi

Standard: Shared

Option: 64MB, upgradeable to 320MB

Standard: IEEE 1284, USB 2.0

Option: 10Base-T/100Base-TX

Standard: Windows NT

®

4.0, Windows® 2000/XP,

Windows

®

95/98/Me

Option: Macintosh 8.6 to 9.x and 10.1 or later*

4

Standard: SPLC (Sharp Printer Language with Compression)

Option: PCL 6/5e, PS3*

4

Standard: Host-based

Option: 80 fonts for HP PCL, 136 fonts for PS3*

4

• Duplex print • N-up (2/4) • Paper/output tray selection

• Smoothing • RIP once/print many • Fit to page • Image adjust

• Print with stapling • Watermarks

• Pamphlet style • Binding edge • N-up (2/4/8/16)

• Cover insertion (front & back) • Transparency insertion

• Negative image*5 • Mirror image*5 • Carbon copy print • Overlay

• Print auditor • Job retention (confidential print, proof print)

• Direct printing of PDF*4*6 and TIFF*6 files • E-mail print

• Barcode font compatibility*7 • Font/form download

Optical: 400 dpi (setting range: 200, 300, 600)

Output: 200, 300, 600 dpi

TWAIN compliant (push out method)

TIFF, PDF

• Sharpdesk™ 3.0 • Scan to e-mail/FTP server/desktop PC

(with Sharpdesk) • LDAP for easy e-mail address browsing

and ad hoc e-mail/file name entry from control panel

AR-M276 Digital Multifunctional System

Specifications

General

Copier

Printer*

3

Network Support*

8

(option)

Scanner*

9

Facsimile*

11

Distributed by:

Shown with options.

Options

AR-D21

500-Sheet Paper

Feed Unit

AR-M276

AR-D22

Dual 500-Sheet

Paper Feed Unit

AR-FN5 N

Finisher

AR-F14

Saddle Stitch

Finisher

(to be available

at a later date)

AR-TR3

Job Separator

Tray Kit

AR-FX7

Fax Expansion Kit

AR-P17

Printer Expansion Kit

AR-PN1A/B/C/D Punch Module

AR-NC5J Print Server Card

AR-PK1

N PS3 Expansion Kit

AR-PF1 Barcode Font Kit

AR-PF2 Flash ROM Kit

for downloaded fonts

AR-NS2 Network Scanner Expansion Kit

(with 10 Sharpdesk™ licenses)

AR-MM9 8MB Fax Memory

AR-SM5 256MB Memory

AR-SM6 512MB Memory

AR-FR12 Data Security Kit

(to be available at a later date)

AR-RP7

100-Sheet Reversing

Single Pass Feeder

AR-VR6

Document Cover

930.7 mm

1,100 mm

609.5 mm

623 mm

1,097 mm

474 mm

SHARP CORPORATION OF AUSTRALIA PTY LTD

ABN 40 003 039 405

1 Huntingwood Drive, Huntingwood NSW 2148

PO Box 827 Blacktown NSW 2148

Tel: (02) 9830 4600 Fax: (02) 9672 1208

www.sharp.net.au

Loading...

Loading...