Page 1

AR-LC2

CODE : 00ZARLC2//A1E

Color Digital Copier Option

Large Capacity Paper Feed Tray

MODEL AR-LC2

CONTENTS

This model is the large capacity tray of the full color digital copier,

AR-C150.

This Service Manual describes only the different points from the AR-LC1.

Please refer to the AR-LC1 Service Manual for the common items.

[1] OUTLINE OF THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[3] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . 1-1

[4] EXTERNAL VIEW AND INTERNAL CONSTRUCTION . . . . . . . . 4-1

[6] DISASSEMBLY AND REINSTALLATION . . . . . . . . . . . . . . . . . . 6-1

[10] WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

[11] EXPLANATION OF THE CIRCUITS . . . . . . . . . . . . . . . . . . . . 11-1

■ PARTS GUIDE

Parts marked with “ ” are important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

AR-LC2

[1] OUTLINE OF THE PRODUCT

This paper feed unit stores about 3,300 sheets of A4 or letter size paper

to save the trouble of adding paper when a large amount of copies is to

be mode.

[3] UNPACKING AND INSTALLATION

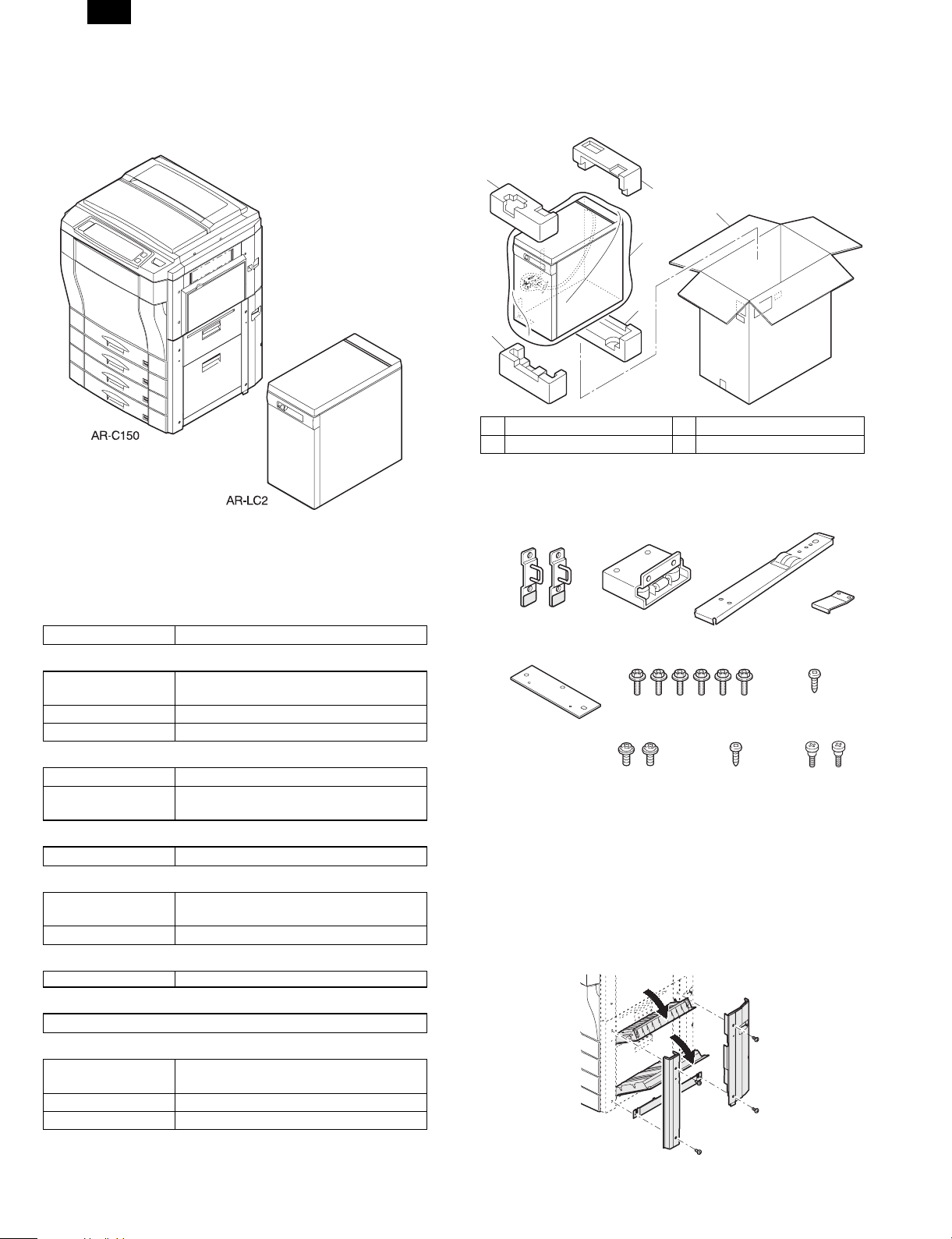

1. Unpacking

1

1

4

2

3

3

1 Upper cushion 2 LCC

3 Lower cushion 4 Packing case

2. Installation procedure

Parts included

[2] SPECIFICATIONS

(1) Paper feed capacity

Paper feed capacity 3,300 sheets (64g/m2 or equivalent)

(2) Amount detection

Paper amount

detection

Detector 0% (empty), - 25%, - 50%, - 75%, - 100%

Paper size detection None

(3) Paper size

Paper size A4/Letter

Paper weight 60 to 105 g/m2 (14 to 28 lbs) (Same as the

(4) Size detection

Size detection Setting by simulation

(5) Factory setting

Factory setting paper

size

Plate display A4/Letter

(6) Power supply

Power supply supplied by the copier (DC5V, DC24V)

(7) Power consum pt i on

Not more than 30 W

(8) Externa l view

External dimensions 325 (Width) x 536 (Depth) x 595 (Height)

Weight about 32 kg

Case color Frosty gray

Provided (5-stage sensors including empty

detection)

copier’s paper feed section)

A4/Letter

mm

Upper mounting plates

(2 pcs.)

Option mounting plate

(1 pc.)

Mounting plate

(1 pc.)

Securing screws A

Securing screws C

(2 pcs.)

Connecting plate

(6 pcs.)

Securing screw D

(1 pc.)

(1 pc.)

Securing plate

(1 pc.)

Securing screw B

(1 pc.)

Step screws

(2 pcs.)

Unplug the power cord from the copier and then

follow the procedure below.

1. Remo ve the right cover.

1) Open the upper right door unit and the lower right door unit.

2) Unscrew the front right lower door.

3) Unscrew the rear right lower door, and remove the right lower

door.

1 – 1

Page 3

AR-LC2

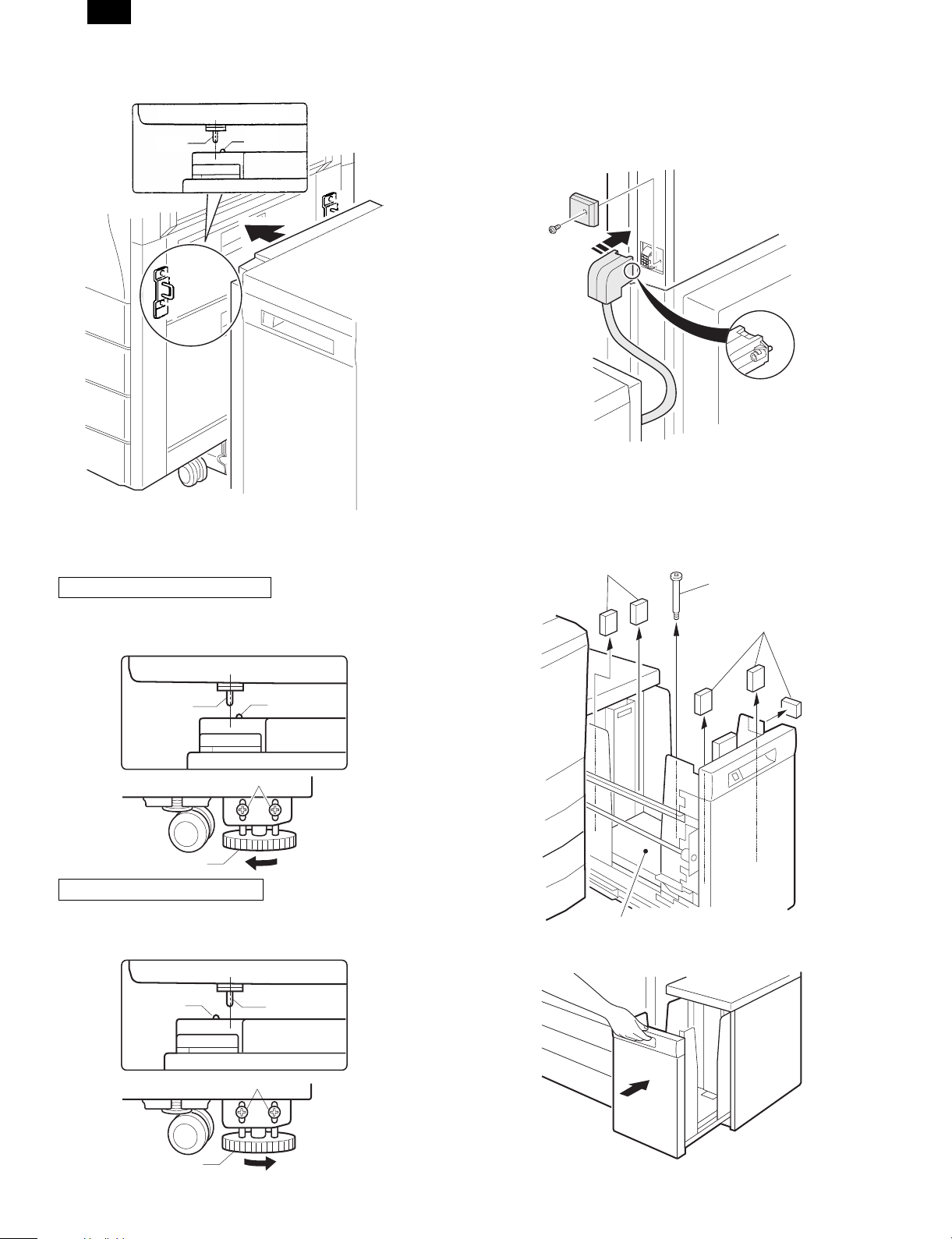

2. Instal l the option mounting plat e.

1) Install the option mounti ng plate.

2) Attach the right cabinet.

The convex side

is inside.

Step screws

Securing

screws D

Step screws

3. Install the upper mounting plates and the mounting

plate.

Make mounting holes with a driver, etc.

3) Remove the two pawls on the LCC cover, and detach the LCC

cover.

4. Mount the connecting plate to the larg e capacity tray.

NOTE: Before mounting the connecting plate to the large capacity tray,

be sure to remove the 2 step screws for securing the bottom plate.

Fit the connecting plate to the lower part of the large capacity tray and

mount the plate to the position indicated with A using screw B.

Securing screws B

Step screws

The spring is

provided only

for 200 series

models.

Connection

plate

Fit screws in hole A

5. Fit the connecting plate of the large capacity tray to

the mounting plate of the stand.

Insert the connecting plate into the mounting plate of the stand slightly

while lifting the large capacity tray.

After insertion, move the large capacity tray away from the copier to

check that the tray is locked.

While the tray is locked, mount the securing plate using screws C (2).

Securing

screws A

Rubber is attached

to the lower side.

Securing

screws A

1) Fit the upper mounting plates with the securing screws A (two for

each).

2) Fit the mounting plate to the lower part of the stand with the two

securing screws A.

Mounting plate

1

Securing

plate

Connecting

plate

2

Securing

plate

screw C

6. Check and adjust the heigh t of the large capacity tra y.

Move the large capacity tray toward the copier and adjust the tray and

check it so that the rib of the large capacity tray is flush with the axis of

the mounting plate which has been mounted to the copier as shown in

the figure.

LCC cover

3 – 1

Page 4

AR-LC2

•

When the axis is flush with the rib:

Push the large capacity tray toward the copier.

Top view

RibAxis

•

When the axis is not flush with the rib:

Loosen the two screws of the installation adjuster mounting plate located

at the lower part of the large capacity tray and adjust as follows:

★ When the rib is to the right of the axis

Turn the knob clockwise to adjust.

After adjustment, tighten the two screws of the installation adjuster

mounting plate.

Top view

7. Connect the connector of the large cap acity tray.

Remove the connector cover securing screw for connection of the large

capacity tray relay harness connector and remove the connector cover.

Then connect the large capacity tray relay harness connector to the

connector of the copier and tighten the screw on the connector to secure

the connector.

8. Remove the feed table securing screw and securing

materials.

Pull out gently the paper tray of the large capacity tray until it stops.

Remove the feed table securing screw and 5 securing materials which

secure the feed table of the large capacity tray.

Securing materials

Feed table

securing

screw

Securing materials

RibAxis

Securing screws

Knob

★ When the rib is to the left of the axis

Turn the knob counterclockwise to adjust.

After adjustment, tighten the two screws of the installation adjuster

mounting plate.

Top view

AxisRib

Securing screws

Feed table

Push back gently the paper tray to its original position.

Knob

3 – 2

Page 5

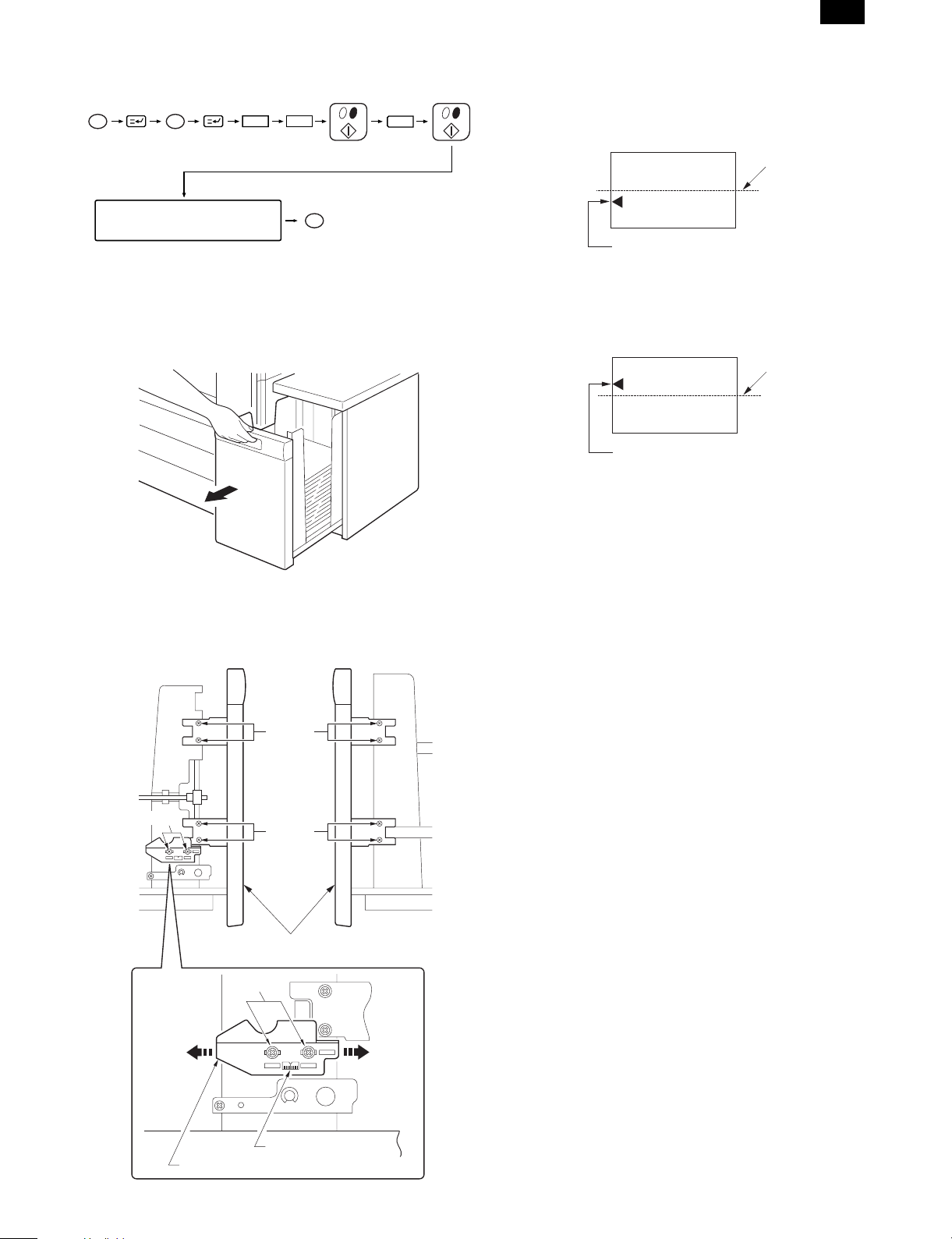

9. Set the mode.

•

Set the mode with the key operation of the copier.

PC

Clear

26

AR-LC2

•

In case of Fig. 1:

Move the tray lock plate in direction A by the length of displacement,

tighten the 2 screws at portion a and then the 8 screws at portion b, and

1

make a copy again to check that the center is not displaced.

Fig. 1

Center line of paper

Press the corresponding

operation key on the display.

CA

The mode is set with the

above operations.

10. Adjust the center position.

Since adjustment has been made at shipment, adjustment is basically

not needed. However, if the center should be displaced, adjust it using

the procedure below.

Make a copy. If the center is displaced as shown in Fig. 1 or Fig. 2, pull

out gently the paper tray until it stops.

Then, loosen the 2 screws at portion a which secure the tray lock plate

and the 8 screws at portion b (right and left sides) which secure the tray

cover unit to the frame and adjust the center position using the procedure

below.

Left side

Right side

Center of image (first image)

•

In case of Fig. 2:

Move the tray lock plate in direction B by the length of displacement,

tighten the 2 screws at portion a and then the 8 screws at portion b, and

make a copy again to check that the center is not displaced.

Fig. 2

Center line of paper

Center of image (first image)

Portion a

Direction A

Portion b

Portion b

Tray cover unit

Portion a

Direction B

Scale (pitch in mm)

Tray lock plate

3 – 3

Page 6

AR-LC2

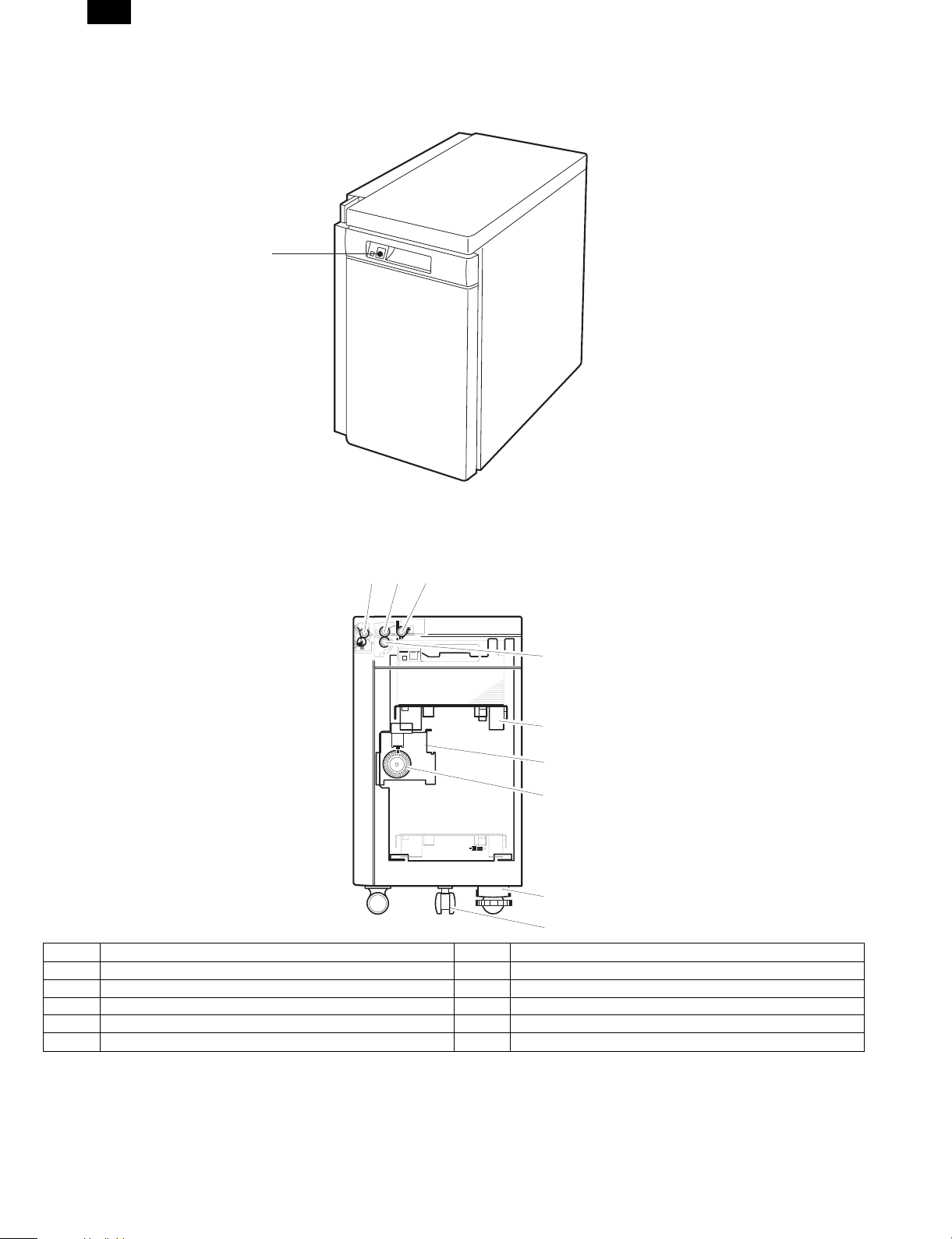

[4] EXTERNAL VIEW AND INTERNAL CONSTRUCTION

1. External view

1

1. Tray down/button/lamp

The tray can be opened by pressing the button. Use this button when adding paper or when a paper jam occurs.

2. Main parts

123

4

5

6

7

8

9

No. Name No. Name

1 Transport roller 6 Lift-up unit

2 Paper feed roller 7 Encoder

3 Pick-up roller 8 Height adjustment unit

4 Reversion roller 9 Caster

5 Tray

4 – 1

Page 7

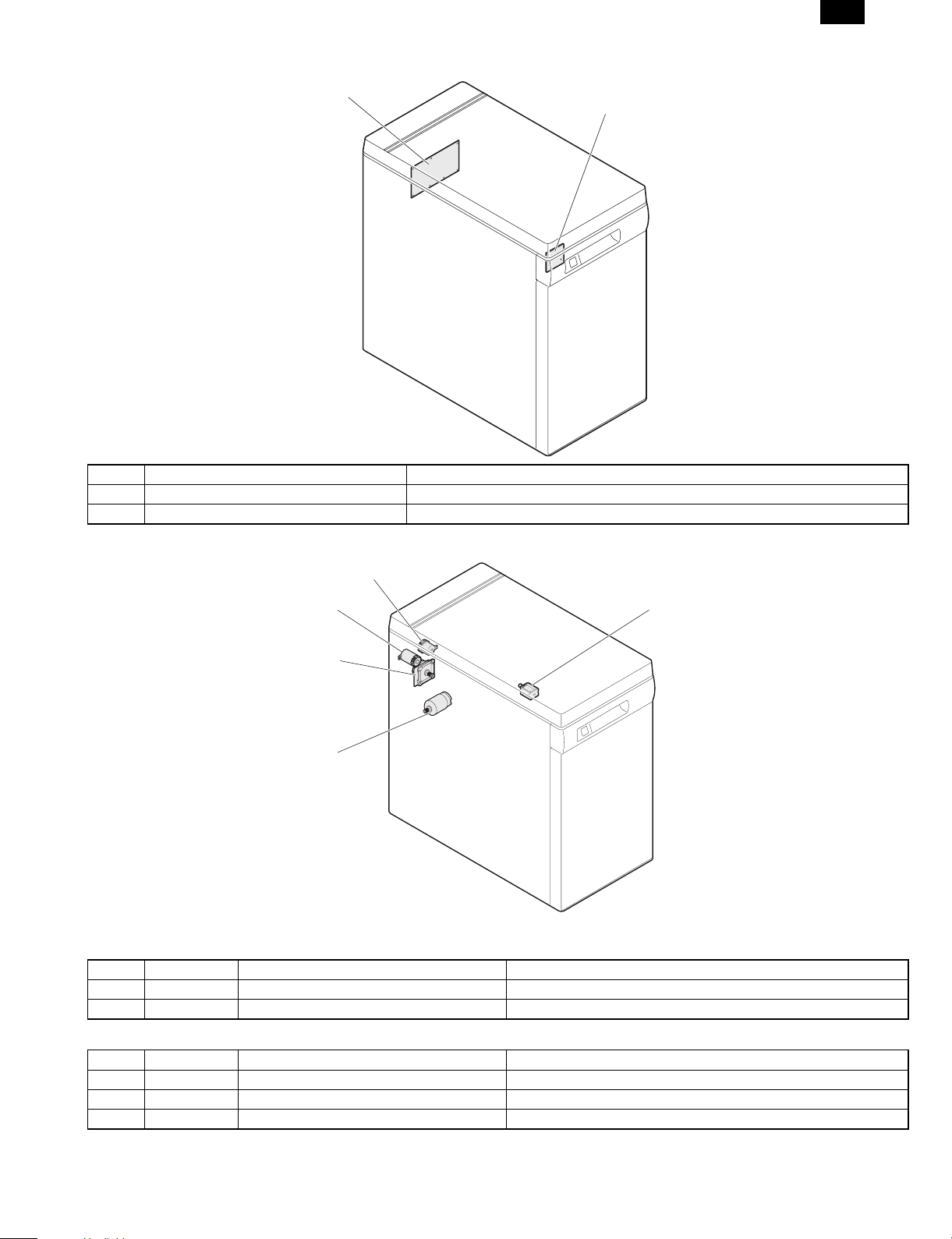

PWB location

AR-LC2

1

No. Name Function and operation

1 Control PWB Controlling LCC

2 Tray switch PWB Tray lifting switch

2

Motor, clutch, solenoid

3 LPFC

5 LTRC

4 LPFS

1 LPFM

2 LLM

Motor

No. Symbol Name Function and operation

1 LPFM Paper feed and transport motor Driving paper feed and transport systems

2 LLM Lift-up motor Driving tray lifting up

Clutch and solenoid

No. Symbol Name Function and operation

3 LPFC Paper clutch Driving paper clutch

4 LPFS Pick-up solenoid Operating pick-up roller

5 LTRC Paper feed clutch Driving paper clutch

4 – 2

Page 8

AR-LC2

Sensor, detector location

2 LLSW

4 LUD

3 LPED

1 LPFD

7 LTOD

5 LRES

6 LDD

No. Symbol Name Function and operation

1 LPFD Transport detector Detecting paper discharge

2 LLSW Upper limit lock switch Detecting tray upper limit lock (Shutting off motor as a safety device.)

3 LPED Paper detector Detecting the presence of paper

4 LUD Upper limit detector Detecting tray upper limit position

5 LRES Encoder sensor Controlling lifting up

6 LDD Lower limit detector Detecting tray lower limit position

7 LTOD Copier connection detector Detecting connection to copier

4 – 3

Page 9

AR-LC2

[6] DISASSEMBLY AND ASSEMBLY

1. Transport section (Paper feed roller)

2)

3)

4)

6)

5)

2)

7)

5)

1)

1)

2. P aper feed section

A. Paper feed unit

2)

1)

2)

2)

3)

1)

2)

6 – 1

Page 10

AR-LC2

B. Paper feed roller, take-up roller

2

2)

1)

C. Reverse roller

2)

3)

1)

1

[ a ]

3)

6)

4)

5)

NOTE: 1. When installing the paper feed roller , take car e of the

installing direction.*1

(The rib o f the pa per feed roller must be set toward th e rear

frame.)

2. When install ing the paper feed clutch , check that the cl utch

stopper is caught by the pawl.*2

6)

3. Control PWB

6 – 2

Page 11

AR-LC2

4. Paper feed/transport motor

3)

2)

5. Lift-up motor

6. Clutch

1)

2)

2)

1)

3)

2)

6 – 3

Page 12

AR-LC2

[10] WIRING DIAGRAM

Copier

LRE

LDD

TRAY SW

PWB

LIFT

MOTO

CN-11

1

2

3

CN-12

1

2

3

BL

BR

GY

BL

PL

GY

CN-13

GY

3

LB

2

BR

1

CN-14

RD

1

GY

2

PK

3

G8

GY GY

G4 G3

CN-15

LTRC

CN-RL

WH

CN-HT

WH

CN-DT 12pin

1

2

6

11

3

7

8

9

10

4

5

12

2

1

12

12

LHT

WH

WH

CN-A

BL

22 5V(LRE)

BR

24 LRE/

GY

26 GND2(LRE)

BL

21 5V(LDD)

PL

23 LDD

GY

25 GND2(LDD)

PK

28 LCD/

LB

27 LDSW/

BR

29 LLED

RD

3 LLM+

PK

4 LLM-

CN-D

RD

1 24V(LTRC)

BR

2 LTRC/

G1

LCC

CONTROL

PWB

83

BR

1

PLLBBR

2

4

TXD-LCC

RXD-LCC

DSR-LCC

CN-B

PKRDGY

3

5

DTR-LCC

RES-LCC

91051112467

BL

GY

75V8

9

10

24V

GND2

GND1

CN-A

CN-C

BL

95V(LUD)

BR

11LUD/

GY

13GND2(LUD)

BL

105V(LPED)

PL

12LPED/

GY

14GND2(LPED)

RD

124Vout

RD

224V(LLSW)

RD

524V(LPFC)

PK

6LPFC/

RD

724V(LPFS)

LB

8LPFS/

BL

155V(LPFD)

BR

17LPFD/

GY

19GND2(LPFD)

BL

165V(LTOD)

BR

18LTOD/

GY

20GND2(LTO)

BL

15V

BR

2RE

PL

3HU

LB

4HV

PK

5HW

GY

6GND1

PL

7U

LB

8V

PK

9W

1

2

3

4

5

6

7

8

9

10

11

12

CN-FT 3pin

1

2

3

CN-3CN-KT 12pin

3

2

LUD

1

CN-4

3

2

LPED

1

LLSW

CN-1 CN-2

CN-5

1

2

CN-6

1

2

CN-7

1

3

2

CN-8

1

2

3

LPFC

LPFS

LPFD

LTOD

CN-10

4

6

3

2

1

5

9

8

7

LPFM

10 – 1

Page 13

Control circuit

Block diagram

AR-LC2

Copier

VCC

GND2

+24V

GND1

FG

RXDTXDDSRDTRRES-

Communication

buffer circuit

8MHz

Xtal

Power supply

monitoring unit

24V

Power supply

10 V circuit

10V

CPU(H8/3294)

Operation unit

Large-capacity tray control PWB

Large-capacity tray

24V

Lift motor drive

circuit

Clutch solenoid

drive circuit

LED lighting circuit

Sensor input

circuit

Transfer motor

drive circuit

10V

Upper limit sw (LLSW)

Lift motor (LLM)

Paper amount detection

sensor (LRE)

Paper feed clutch (LPFC)

Transport clutch (LTRC)

Paper feed solenoid (LPFS)

LLED

Cassette detection line (LCD)

Upper limit detection sensor (LUD)

Lower limit detection sensor (LDD)

Paper detection sensor (LPED)

Paper delivery detection sensor

(LPFD)

Copier connection sensor

Door open switch (LDSW)

Transfer motor (LPFM)

10 – 2

Page 14

AR-LC2

[11] EXPLANATION OF THE CIRCUITS

A

CN-A-21

220(1/4W)

220(1/4W)

R97

2 1

11

10

IC12F

IC12G

TD62504F

6

TD62504F

7

R

4.7K

+5V

=

R

3

C16

C13

C12C10 C11

LLED/

VCC

N.C

N.C

N.C

PWM/

DIR

RE

N.C

SW2

VCC

N.C

SW1-4

SW1-3

SW1-2

SW1-1

1000P X5

B

CN-A-29

LLED

R03

220(1/4W)

+5V

IC12E

TD62504F

512

R02

2.2K

+5V

2-C2

2-B2

2-B2

PWM/

DIR

RE

+5V

R52

R51

R75

R50

R49

R48

R47

R46

R45

R44

4.7K X 10

CN-A-15

R96

+5V

D

CN-A-6

Q2

DTD114GK

R91

R04

CN-A-8

LPFS/

LPFC/

16

15

ULN2004A

E

IC04A

IC04B

1

2

LPFC

LPFC

LPFSLPFS

10K

10K

R89

R93

22K

22K

R92

4.7K

R05

4.7K

CN-D-2

LTRC/

12345678

+24V

D1

1SS133

Q3

C

B

DTD114EK

C

10k

B

E

+24V

LLMD

LLMU

2-C2

2-C2

LLMD

LLMU

ULN2004A

+5V

R61

R63

R66

R65

R64

R62

C

CN-A-28

CN-A-11

CN-A-18

CN-A-27

1000P X2

+5V

R78

4.7K X 4

R54

R74

R73

R72

LPFC

N.C

N.C

LLMU

LPFS

N.C

LLMD

N.C

48

40

47

P10/A0

P17/A741P16/A642P15/A543P14/A444P13/A345P12/A246P11/A1

P50/TXD

P51/RXD2P52/SCK3/RES4/NMI5VCC6/STBY7VSS8XTAL9EXTAL10MD111MD012AVSS13P70/AN014P71/AN1

1

/NMI

VCC

XTAL

/STBY

TXD-LCC

RES-LCC

DSR-LCC

RXD-LCC

CN-A-12

LUD

LDSW

LPED

65432

BR04

10K

10K

R81

R82

LDSW

LPFD

LDD

LCD1

LTO D

LUD

LPED

33

37

39

VSS

P21/A938P20/A8

P25/A1334P24/A1235P23/A1136P22/A10

P67/TMO1

P66/FTOB/TMRI1

P65/FTID/TMCI1

P64/FTIC/TMO0

P63/FTIB/TMRI0

P62/FTIA

P61/FTOA

P60/FTCI/TMCI0

P77/AN7

P76/AN6

P75/AN5

P74/AN4

P73/AN3

16

15

N.C

N.C

N.C

MD1

MD0

AVSS

EXTAL

R41

R42

R43

LTO D

4.7K X 5

10K

R83

P26/A14

P27/A15

AVCC

P72/AN2

VCC

4.7K X 3

LCD1

10K

10K

R84

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

CN-A-17

CN-A-23

LDD

LPFD

1SS133

D23

R95

22K

22K

R94

R79

R59

R58

R57

R56

R55

LCD2

/24VM

DTR-LCCDTR-LCC

YOB I

10K

R80

4.7K X 11

N.C

N.C

N.C

N.C

N.C

N.C

N.C

LRELRE

N.C

N.C

N.C

N.C

D24

C15

C14

10K

49

P30/D0

50

P31/D1

51

P32/D2

52

P33/D3

53

P34/D4

54

P35/D5

55

P36/D6

56

P37/D7

57

P40//ADTRG//IRG

58

P41//IRQ1

59

P42//IRQ0

60

P43//RD

61

P44//WR

62

P45//AS

63

P46/CLK

64

P47//WAIT

IC01

H8/3294 FP-64A

1SS133

MAIN PWB

0.1U

C09

6785243

+5V

+5V

D01 D02 D03

+5V

D

O314O215O116O413O710O512O6

I33I22I11I44I77I55I6

IC02

6785243

1SS133x6

TXD-LCC

CN-B-1

BR02

4.7KX7

11

9

NC

GND

TD62504F

6

8

BR01

4.7KX7

+5V

D07 D08

0.1U

C35

0.1U

C05

D05

D04 D06

DTR-LCC/

LRE/

RES-LCC/

CN-B-3

CN-B-5

CN-A-24

C

0.1U

10K

R01

C08

47U

+

C07

+5V

CN-C-1

CN-A-13

CN-A-19

CN-A-5

CN-A-7

CN-A-9

CN-A-10

CN-A-16

X1 8.00MHz

1SS133x2

D10

D09

1SS133x2

DSR-LCC/

RXD-LCC/

CN-B-2

CN-B-4

+24V

CN-A-1

+24V

+24OUT

+24V

+24V

CN-B-09

CN-A-22

+5V

+5V

0.1U

C02

47U/35V

+

C01

GND1

+5V

+5V

GND1

CN-B-7

CN-B-10

B

CN-A-20

CN-A-25

CN-A-14

CN-A-26

CN-C-6

0.1U

C04

+

47U/35V

C03

GND2

GND2

CN-B-8

+24V(LLSW)

+24V(LLSW)

CN-A-2

CN-B-6

8 7 6 5 4

A

11 – 1

Page 15

AR-LC2

D

C

B

A

12345678

CN-C-7

CN-C-8

CN-C-9

V

U

W

1OA3OB7

VCC

9

1K x3

2.2K

ULN2004A

IC04F

D17 D18 D19

10

OC

GND5GND12IC211IB26IA2

BR08

ULN2004A

611

432

680

R23

ISR124-400 X3

0.1U

C34

1

IC09A

LM393

8

4

+

-

+10V

3

SLA6012

4

C22 C23 C24

0.1U X3

1K x3

680

680

R24

R25

10

ULN2004A

IC04G

7

2

C27

+5V

R27

2.4K

0.1U

360

R29

200

R28

/1W

R26

0.22

C26

0.1U

+24V(LLSW)

CN-A-3

CN-A-4

LLM+

LLM-

0.1uF

C31

F01

1.25A/120V

T1.0A/250V

IC07

STA457C

7

2

R36 1K

3

7

2

116

(1/4W)

R40

3.9K

R39

10K

R38

10K

9944883

10

10

5

5

6

1K

R37

1SS133x2

D21

D20

2 1

3

+24V

+

IC06

BR07

IC04E

C25

100U/35V

IA12IB18IC1

234

2.2K

2.2K

R20

R21

R22

512

TD62504F

TD62504F

215

IC12C

314

TD62504F

+5V

R15

R14

2.2K

2.2K

+5V

R86

10K

10K

10K

R16

R17

R18

OUT111OUT312OUT513OUT614OUT415OUT2

IN11IN22IN34IN43IN55IN66VCC8VREF

IC05

234

1.2K

1.2K

R88

R87

16

BR15

+5V

1.2K

7

9

GND

REVERSE

10

+10V

2.2K X 3

DIR

UPC1246C

0.1U

C21

RE

R76

R85

2.2K

1000P X4

IC12D

1-D2

1-D2

10K

413

R77

PWM

TD62504F

10K

1-D2

+24V

+24V

R90

1K(1/4W)

IC12A

IC12B

116

+10V

R19

2.7K

FR01

R32

IC04C

1-E4

100(1/4W)

1K(1/4W)

R34 1K

ULN2004A

314

LLMU

Q02

2SC1472K

R35 1K

IC04D

413

+10V

C30

C29

D22

RD11EB

LLMD

D25

0.1U

0.1U

ULN2004A

1-E4

RD18FB1

7

IC09B

LM393

+

-

5

6

IC12

IC04

9

+24V

8

9

N.C

8

MAIN PWB

D

C18 C20

C17 C19

8 7 6 5 4

HV

HU

RE/

HW

CN-C-3

CN-C-4

CN-C-5

CN-C-2

C

B

11 – 2

A

Page 16

AR-LC2

D

C

B

A

12345678

1

2

24V

LTRC/

CN-D (B2B-PH-K-S)

1

2

3

4

5

6

7

8

9

2 1

3

5V

RE/HUHVHWGND2UV

CN-C (B9B-EH-A)

W

RXD-LCC

DSR-LCC

GND2

GND2

123456789

TXD-LCC

DTR-LCC

RES-LCC5V24V

24V(LLSW)

LLM-

LPFC/

LPFS/

2

65

87

1

34

GND1

10

5V(LPED)

LPED/

109

12

11

GND2(LPED)

5V(LTOD)

LTOD/

GND2(LTOD)

5V(LRE)

LRE/

GND2(LRE)

LCD1/

LCD2/

1615

2019

2423

2827

13 14

17 18

21 22

25 26

29 30

CN-A (B30B-PHDSS) CN-B (B10B-PHDSS)

MAIN PWB

D

24V(OUT)

LLM+

24V(LPFC)

24V(LPFS)

5V(LUD)

LUD/

GND2(LUD)

5V(LPFD)

LPFD/

GND2(LPFD)

5V(LDD)

LDD/

GND2(LDD)

LDSW/

LLED/

C

B

A

8 7 6 5 4

11 – 3

Page 17

[Note]

The AR-LC2 Parts guide describes only the

different points from the AR-LC1. Please

refer to the AR-LC1 Parts guide as well.

AR-LC2

PARTS GUIDE

MODEL AR-LC2

CONTENTS

1 Exteriors

2 Frame 1

3 Frame 2

4 Frame 3

5 Paper feeding section(Refer to the AR-LC1 Parts guide)

6 Drive section(Refer to the AR-LC1 Parts guide)

7 Transport section

8 Packing materials & Accessories

SHARP CORPORATION

This document has been published to be

used for after sales service only.

The contents are subject to change without

notice.

Page 18

AR-LC2

DEFINITION

The definition of each Rank is as follows and also noted in the lis t

A : Parts necessary to be stocked as High usage parts.

B : Parts necessary to be stocked as Standard usage parts.

C : Low usage parts.

D : Parts necessary for refurbish.

E : Unit parts recommended to be stocked for efficient after sales service.

Please note that the lead time for the said parts may be longer than normal parts.

S : Consumable parts.

Please note that the following parts used in Copier under the same description are classi fied into A or B Rank depending

upon the place used.

Example : Gear made of Metal, Sprocket, Beari ng, Belt made of Rubber, Spring clutch mechanism.

A Rank : The parts which may be with the revolution or loadi ng.

B Rank : Parts similar to A Rank parts, but are not included in Rank A.

Because parts marked with "!" is indispensable for the machine safety maintenance and operati on, it must be replaced with

the parts specific to the product specification.

F Other than this Parts Guide, please refer to documents Service Manual (including Circuit Diagram) of this model.

F Please use the 13 digit code described in the right hand corner of front cover of the document, when you place an order.

F For U.S. only-Use order codes provided in advertising literature. Do not order from parts department.

1Exteriors

PRICE

NEW

NO. PARTS CODE

0EUCOV0402E22 BA

3

RANK

PART

MARK

RANK

N C Tray cabinet

DESCRIPTION

2 Frame 1

NO. PARTS CODE

0EUSLI0601K// BA

11

0EUPLT0472N// AG

26

0EUPLT0473N// AG

27

0EUSFT0480N// AN

29

0EUSTY0416K02 BC

33

0EUANG0459N// AM

34

XHBSE40P08000 AA

45

3 Frame 2

NO. PARTS CODE

0EUSTY0405E03 BG

18

0EUANG0458N// AK

37

0EUPWB0409N31 BS

42

0EUPWB0409N32 BS

0EUHAI0450N// BA

43

0EUANG0457N// AL

67

0EUSFT0481N// AL

68

PCLC-0270FCZZ AW

69

NGERH0853FCZZ AE

70

NGERH1174FCZZ AQ

71

0EUHAI0451N// AG

72

XHBSE40P08000 AA

73

LPINS0155FCZZ AA

74

NBRGC0504FCZZ AC

75

XBBSD40P08000 AA

76

PRICE

RANK

PRICE

RANK

NEW

PART

MARK

RANK

N C Slide rail

N C Adjust guide plate F

N C Adjust guide plate R

N C Adjust screw

N C Caster plate

N C Caster

CScrew (4´8)

NEW

PART

MARK

RANK

N C Stay

N C Drive plate

N E LCC Main PWB unit 100V

N E LCC Main PWB unit 200V

N C I/F harness

N C CL plate

N C CL shaft

C Electromagnetic cluch (22T)

C Gear (32T)

C One way gear (17/22T)

N C CL I/F harness

CScrew (4´8)

C Pin (3-10)

C Bearing (F8-12-5)

CScrew (4´8)

DESCRIPTION

DESCRIPTION

4 Frame 3

NO. PARTS CODE

0EUSFT0482N// AW

18

0EULEG0606N// AT

46

0EUNZ-0603J// AE

51

XWHSD80-16180 AA

52

XBBSD30P08000 AA

53

7 Transport section

NO. PARTS CODE

0EUROL0360N// AV

4

0EUSPR0476N// AD

6

0EUGER0423N01 AN

9

PRICE

RANK

PRICE

RANK

NEW

PART

MARK

RANK

N C LCC rear edge guide

N C Caster

CNut M8

C Washer

CScrew (3´8)

NEW

PART

MARK

RANK

N C Transfer roller

N C Transfer spring 2

N C Gear 18T

– 1 –

DESCRIPTION

DESCRIPTION

Page 19

8 Packing materials & Accessories

PRICE

NEW

NO. PARTS CODE

0EUPKC0675N// AY

8

LPLTM5517FCZZ AE

17

LX-BZ0408FCZZ AB

18

XHBSE40P08000 AA

19

RANK

PART

MARK

RANK

N C Packing case

N C Option fixing plate

CScrew

CScrew (4´8)

2 Frame 1 3 Frame 2

AR-LC2

DESCRIPTION

34

4 Frame 3

45

45

33

53

53

73

53

67

74

18

75

68

31

44

69

4

33

5

4

44

71

44

34

33

44

36

4

5

35

76

70

4

37

73

4

33

5

36

42

64

41

18

44

44

51

52

45

46

8 Packing materials & Accessories

17

18

19

FCP03704

– 2 –

Page 20

AR-LC2

Page 21

CAUTION FOR BATTERY REPLACEMENT

(Danish)

Lithiumbatteri – Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri

Levér det brugte batteri tilbage til leverandoren.

(English)

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according to manufacturer’s instructions.

(Finnish)

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden

(French)

Il y a danger d’explosion s’ il y a remplacement incorrect

de la batterie. Remplacer uniquement avec une batterie du

même type ou d’un type équivalent recommandé par

Mettre au rebut les batteries usagées conformément aux

(Swedish)

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent

typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

ADVARSEL !

af samme fabrikat og type.

Caution !

VAROITUS

mukaisesti.

ATTENTION

le constructeur.

instructions du fabricant.

VARNING

instruktion.

AR-LC2

Page 22

AR-LC2

All rights reserved.

Printed in Japan.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted,

in any form or by any means,

electronic; mechanical; photocopying; recording or otherwise

without prior written permission of the publisher.

SHARP CORPORATION

Digital Document Systems Group

Quality & Reliability Control Center

Yamatokoriyama, Nara 639-1186, Japan

1999 September Printed in Japan

Loading...

Loading...