Page 1

AR-LC1N

CODE: 00ZARLC1N/A1E

DIGITAL COPIER OPTION

LARGE-CAPACITY

PAPER FEED TRAY

MODEL AR-LC1N

CONTENTS

[Note]

This Service Manual describes only the differences from 00ZARLC1//A1E.

The items which are not described in this Manual are common with the

00ZARLC1//A1E.

[ 1 ] OUTLINE OF THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 2 ] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 3 ] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[ 4 ] EXTERNAL VIEW AND INTERNAL CONSTRUCTION . . . . . . . . . . . . 4-1

[ 5 ] OPERATING PRINCIPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[ 6 ] DISASSEMBLY AND REINSTALLATION . . . . . . . . . . . . . . . . . . . . . . 6-1

[ 7 ] ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[ 8 ] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[ 9 ] TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

[11] CIRCUIT DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

PARTS GUIDE

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

AR-LC1N

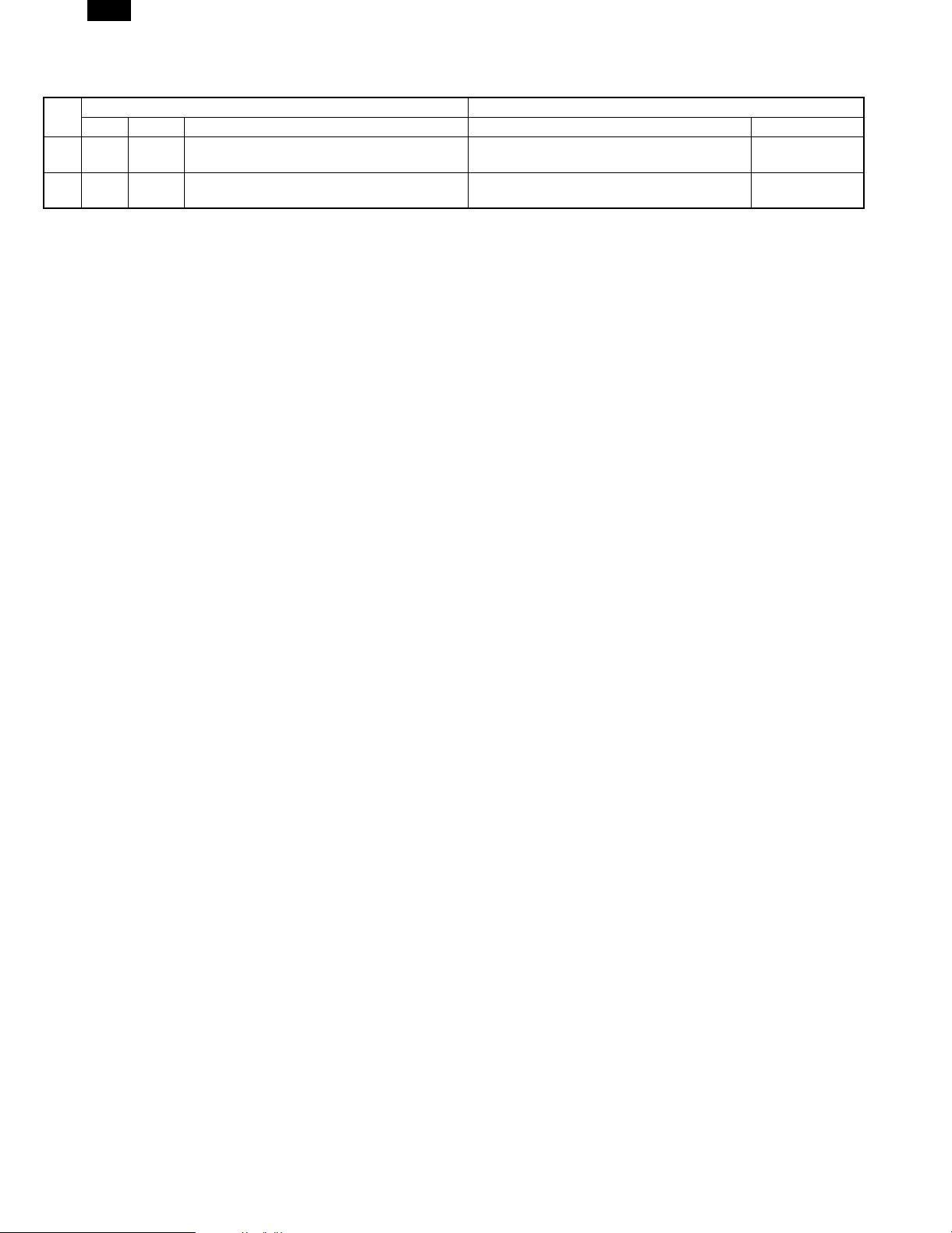

List of different points between the AR-LC1N and the AR-LC1

No.

Page Item Content Change Remark

1 1-1 [2]-9 Max. power consumption

about 17.6 W

2 11-1 [11] CIRCUIT DESCRIPTIONS Entirely changed. Refer to the

AR-LC1 AR-LC1N

Max. power consumption

Changed to about 25 W

attached page.

8/6/1999 – 1 –

Page 3

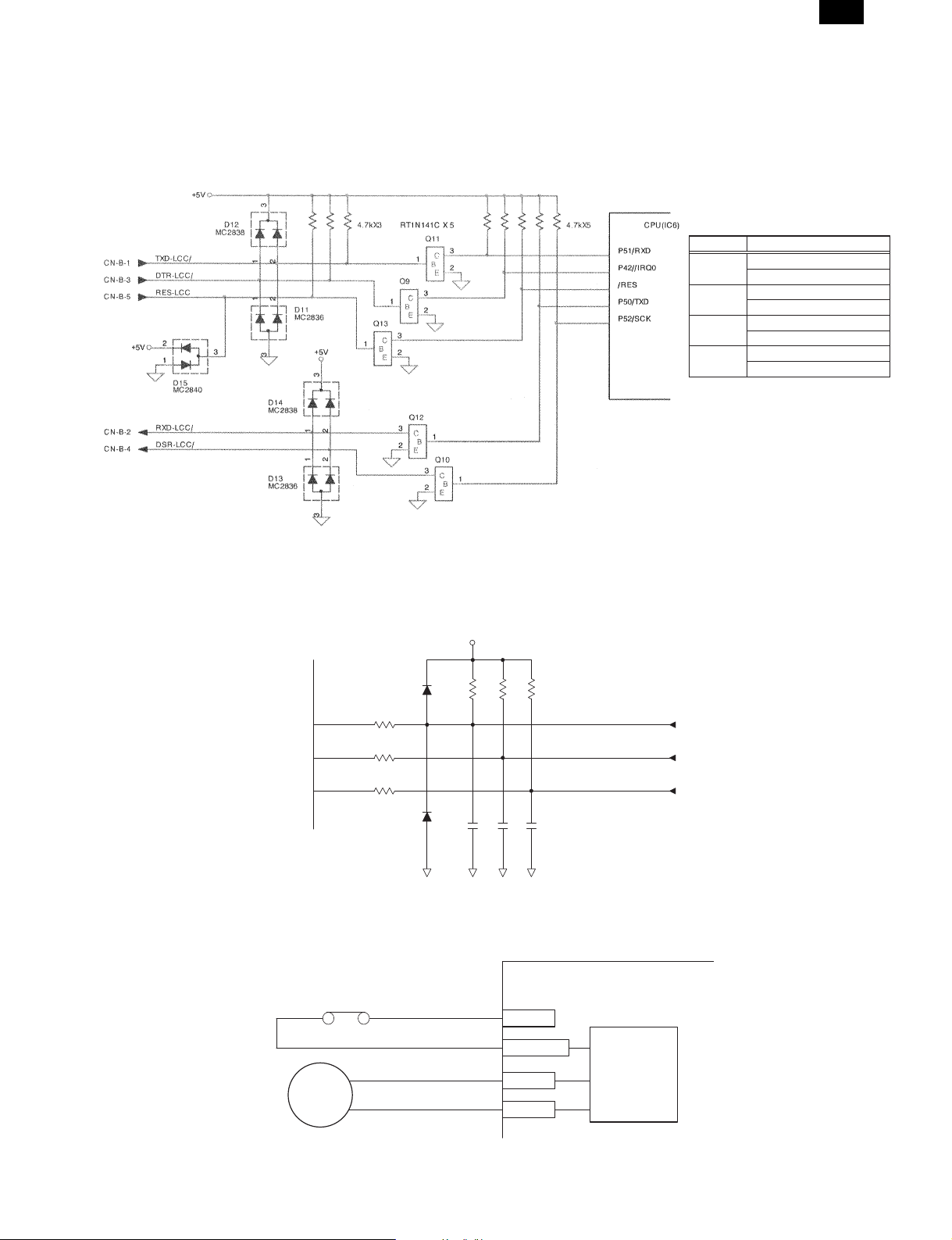

[11] CIRCUIT DESCRIPTIONS

1. Operation

(1) Communication buffer circuit

On the communication buffer circuit, signals are input and output by the transistor RT1N141C (Q9 – Q13).

AR-LC1N

Signal name Logic

DSR-LCC

DTR-LCC

TXD-LCC

RXD-LCC

H: Request for communication

L: No request for communication

H: Communication allowed

L: Communication inhibited

H: Normal

L: Start bit

H: Normal

L: Start bit

(2) Sensor input circuit

The sensor signals used by the LCC are connected directly to the input port of the IC6. LPFD and LCD are provided with a static electricity noise

protective diode which protects against static electricity from the paper transport section. The other sensors have the same circuit configuration as the

LPED.

+5V

CPU

(IC6)

P74/AN4

P73/AN3

P76/AN6

18 LPFD

17 LDD

21 LPED

MC2838

10K

10K

10K

MC2836

D9

D10

R16

R15

22K

22K

C12 C11 C10

BR1

4.7K

1000P x 3

LPFD

LDD

LPED

CN-A-17

CN-A-23

CN-A-12

(3) Upper limit switch

A limit switch is provided to protect the LCC If it fails to operate normally. If the tray exceeds the upper limit sensor (LUD) position, the switch is turned

off to shut off the power of the lift motor.

LCC control PWB

Upper limit switch

24V

Lift motor

24V(LLSW)

Lift motor

LLM+

LLM-

drive circuit

11 – 1 8/6/1999

Page 4

AR-LC1N

(4) Solenoid and clutch drive circuit

The solenoids and clutches are driven by a Darlington transistor array M63823P with 7-circuit clamp diode. LPFS is turned on wh en the CPU’s port

output is at H. LPFC has the same circuit.

IC2

M63823P

+24V

SOL

CPU(IC6)

P66/FTOB

/TMRI1

29 LPFS

10.5K

7.2K

3K

LPFS/

CN-A-8

(5) Lift motor drive circuit

The tray height is adjusted according to the size of the paper mounted on the paper feed tray. The lift motor controls the rotational direction

(CW/CCW) with the control signals (LLMU, LLMD) from the CPU. The circuit forms a bridge circuit with STA457C to allow the CW/CCW control.

A fuse (F1) is provided to protect the motor against shorting or overload.

1-E4

LLMU

LLMD

1-E4

Lift motor

Forward rotation (UP)

Forward rotation (DOWN)

IC2

314

IC2

413

CPU port

LLMD LLMU

L

H

L

H

L

LOFF

R21 1K

R22 1K

IC3

7

2

R20 1K

1

R18

1K

6

D3

D2

1SS133x2

STA457C

2

7

3

3

1

8

8

4

4

9

9

6

5

51010

R17

10K

R19

10K

F1

1.25A/120V

T1.0A/250V

R3

3.9K

(1/4W)

C13

0.1uF

LLM+

LLM-

+24V(LLSW)

CN-A-3

CN-A-4

Suppose that both LLMD and LLMU become H level at the above circuit. If LLMU becomes H first, t he STA457C pin 3 become H, IC04 pin 13

through IC07 pin 6 become H due to diode D20. Even if LLMU is at H and LLMD at H on the port, STA457C pin 1 is at L and pin 6 at H, thus no

conduction of STA457C is achieved.

(6) Transport motor drive circuit

U

V

W

HU

HV

HW

RE\

The motor drive circuit is composed of IC4 motor ICs (Q5 – 8 (transistor), IC2 and IC5). When the PWM signal output from the CPU made at H level,

the transistor inside the IC5 turns on to supply current to the motor to start the motor. As the motor is started, hole signals (Hu, Hv, Hw) in side the

motor switch the input of IC4, while the output switches the transistor inside IC5. The motor thus starts rotating under non-control state.

When the motor rotates, the speed si gnal (RE) is output from the motor. The signal is taken into the CPU. If the motor speed is slow, the RWM signal

On duty is increased to increase the speed; if the motor speed is high, the PWM signal On duty is decreased to maintain the required speed.

As the current flowing to the mot or becomes large, the input voltage at the minus side of the IC7 rises. If the voltage exceeds the plus-side input

voltage, output voltage at IC7 becomes at L level, leading in the PWM signal to t urn off the transistor of Q5 so t hat the current to the motor is cut of f.

(setting: 3A).

8/6/1999 11 – 2

Page 5

AR-LC1N

(7) 24V power detection line

The line monitors 24V power. If the 24V power fed from the copier is not 24V, the level becomes L and the 24V power error is sent to the copier.

24V

R11

22K

14

P70/AN0

R10

4.7K

(8) Cassette detection line

This line has the same circuit as each sensor. When the LCC cassette door is opened, the CPU level becomes H when the door is closed, the line is

connected to GND and the CPU level becomes L.

5V

5V

P26/A14

33

10K

(9) LED lighting circuit

This is the LED lighting circuit for the cassette door switch.

R7

4.7K

1000p

D9

MC2838

D10

MC2836

Drawer connector

When the CPU outputs the L signal, the LED comes on.

11 – 3 8/6/1999

Page 6

AR-LC1N

D

1/3

CN-A-15

LPFD

1

R2

220(1/4W)

BR4

10kX4

12

8

7567586

BR5

10kX4

44

2

1

33

+5V

2

IC1

1

8

2

7

3

3

R31

22k

65

4

BR8

10kX4

4

324

1

BR9

4.7kX4

R26

4.7k

758

6

5

24

A16

2

OE

D0

D1

D2

D3

D4

D5

D6

D7

LTRC

LRE

DTR-LCC

A15

3

A15

A16

IC6

A14

29

21

D7D5D3

A11

A12A2A10

A13

23

25

4

28

A11

A12

A13

A14

D4

D5

D6

D7

17

18

19

20

D6

D4

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

H8/3294FP-64A

C

CN-A-6

LPFC/

BR6

10kX4

11

22

33

44

75867586

BR7

10kX4

A5

A3

A7

A4

A6A0A8

A9

A1

12

11

10

9

8

7

6

5

27

26

A10

D3

15

D2

A9

D2

P30/D0

P31/D1

P32/D2

P33/D3

P34/D4

P35/D5

P36/D6

P37/D7

P45//AS

A8

D1

14

D1

P41//IRQ1

P42//IRQ0

P43//RD

P44//WR

P46/CLK

P47//WAIT

13

D0

A7

D0

A0

48

1

RXD-LCC

A6

32

VCC(+5V)

A1

47

P10/A0

P50/TXD

2

TXD-LCC

A1

A2

A3

A4

A5

CE

PGM

VPP

VCC

1

30

22

31

C7

0.1u

4

1

2

3

BR11

10kX4

A6

A5

A4

A3

A2

42

43

44

45

46

P15/A5

P14/A4

P13/A3

P12/A2

P11/A1

P40//ADTRG//IRG

VCC

/NMI

/RES

P52/SCK

P51/RXD

7

6

5

4

3

VCC(+5V)

RES-LCC

/NMI

DSR-LCC

/STBY

A0

GND

NC

16

VSS(SGND)

5867

A7

VSS(SGND)

40

41

P17/A7

P16/A6

VSS

/STBY

9

8

VSS(SGND)

XTAL

VSS

XTAL

27C010

A8

39

10

EXTAL

A9

38

P20/A8

EXTAL

11

MD1

P21/A9

MD1

A10

37

12

MD0

A12

A11

A13

35

36

P23/A11

P22/A10

AVSS

MD0

14

13

/24VM

VSS(SGND)

34

P25/A13

P24/A12

P71/AN1

P70/AN0

15

/LDSW

A14

33

16

LCD

P26/A14

P72/AN2

IC2B

32

P27/A15

31

VCC

30

P67/TMO1

29

P66/FTOB/TMRI1

28

P65/FTID/TMCI1

27

P64/FTIC/TMO0

26

P63/FTIB/TMRI0

25

P62/FTIA

24

P61/FTOA

23

P60/FTCI/TMCI0

22

AVCC

21

P77/AN7

20

P76/AN6

19

P75/AN5

18

P74/AN4

17

P73/AN3

15

2

LPFC

M63823P

A15

VCC(+5V)

LPFC

LPFS

LLED/

PWM/

DIR

RE

LLMU

LLMD

VCC(+5V)

LPED

LUD

LTOD

LPFD

LDD

B

CN-A-17

CN-A-23

22k

22k

2

1

BR1

4.7kX4

7586

R7

4.7k

LPFD

LPED

8

BR2

10kX4

2

CN-A-12

LDD

LPFD

LPED

2134

LDD

/LDSW

LTOD

LUD

LCD

657

758

6

314

2

431

CN-A-29

CN-A-8

LPFS/

LLED

IC2A

M63823P

1 16

LPFS

R1

220(1/4W)

R8

4.7k

C

R9

4.7k

2-C2

2-B2

2-B2

DIR

PWM/RELLMU

B

2-C2

+5V

R15

+5V

R16

D9

MC2838

3

+5V

E

10k

Q4

DTD114GK

2-C2

LLMD

A

CN-A-11

CN-A-18

CN-A-28

CN-A-27

LCD

LUD

LTOD

/LDSW

C5

C8C9 C6

1000pX7

C10C11

C12

2

3

1

D10

MC2836

R10

4.7k

1

2

3

R11

22k

+24V

/24VM

BR3

10kX4

4

5

6

Q14

RT1N141C

C

E

7

8

B

7586

4.7kX4

BR13

3

+5V

D12

MC2838

2. LCC MAIN PWB

4.7k

R32

C14

0.1u

R42

4.7k

BR12

4.7kX4

1

34

2

75 86

C22

1000p

C21

0.1u

Q13

Q11

E

RES-LCC/

CN-B-5

RT1N141C

B

0.1u

C25

0.1u

C24

2

3

1

D11

MC2836

Q9

RT1N141C

C

B

C

4

213

2

1

DTR-LCC/

TXD-LCC/

LRE/

CN-B-3

CN-B-1

CN-A-24

RT1N141C

E

C

E

B

3

D15

MC2840

1

2

D

+

C1

47u/35V

Q12

RT1N141C

C

D14

MC2838

2

3

+5V

1

RXD-LCC/

DSR-LCC/

CN-B-4

CN-B-2

C

R14

0J(JUMPER)

R13

10K

CPUMODESELLECTP ART

R12 10k

X1

8.00MHz

B

E

B

C

Q10

RT1N141C

D13

MC2836

2

3

1

or

+5V

0J(JUMPER)

L1

ACB20120M-150-T

VCC(+5V)

VSS(SGND)

L2

or

CN-A-5

CN-A-7

CN-A-1

0J(JUMPER)

ACB20120M-150-T

+24V

E

+24V

+24V

CN-B-09

CN-A-9

CN-A-10

+5V

C33

0.1u

C3

47u/35V

+

GND

JP1

GND1

CN-B-10

CN-A-16

+5V

CN-A-21

+5V

CN-B-7

C32

+

C4

CN-A-22

CPUMODESELLECTP ART

CN-C-1

0.1u

47u/35V

GND2

CN-B-8

B

INTER-ROM

0EUPWB0409

N31,32,41,42

OUTER-ROM

UNITCODE

CN-A-14

CN-A-13

CN-B-6

A

H

MODE(MODE3)

H

MODE(MODE1)

MD0

(12Pin)

CPU

CPUMODE

CN-A-19

CN-A-20

H

L

MD1

(11Pin)

PORT

LOGIC

CN-A-25

+24V(LLSW)

+24V(LLSW)

CN-A-2

R13

ASSEN-

CN-A-26

R14

BLE

PARTS

CN-C-6

6

7

8

8/6/1999 11 – 4

Page 7

AR-LC1N

D

C

B

A

2/3

1

+24V

C2

100U/35V

+

2

R33

R34

R43

3

4

CN-C-7

CN-C-8

CN-C-9

U

V

W

ISR124-400X3

0.1u

D6 D7 D8

10

7

3

1

OC

OB

OA

VCC

IA2

IB2

IC2

GND

GND

IC1

IB1

IA1

IC5

9

8

2

1k

1k

1k

2.2K

R25

R23 2.2K

R24 2.2K

12

M63823P

IC2E

5

Q8

RT1N141C

SLA6012

4

6

5

11

12

C18

C15

1k

R36

R35

R27

11

10

M63823P

IC2F

IC2G

6

7

Q7

RT1N141C

Q6

1k

1k

M63823P

RT1N141C

0.1uX3

R39 680

R38 680

R37 680

+10V

+5V

C19

C16

1

IC7A

BA10393

4

8

+

-

3

2

0.1u

C17

R30

2.4k

R28

Q5

200

RT1N141C

R40

R29

360

R4

0.22(1W)

C20

0.1u

10k

F1

IC2C

+24V(LLSW)

1.25A/120V

T1.0A/250V

IC3

STA457C

7

2

14

M63823P

3

CN-A-3

CN-A-4

LLM+

LLM-LLM-

0.1u

C13

R3

3.9k(1/4W)

R19

10k

9

4

8

3

8

3

7

2

1

1

1k

R20 1k

R22 1k

R21 1k

IC2D

R17

10k

9

4

10

10

5

5

6

6

R18

1SS133x2

D3

D2

13

M63823P

4

1

2

3

4

6

7

+10V

2.7k

R41

5

6

+5V

5

BR10

10kX4

234

9

7

16

15

14

13

12

11

GND

OUT1

OUT2

OUT4

OUT6

OUT3

OUT5

REVERSE

VREF

VCC

IN6

IN5

IN4

IN3

IN2

IN1

IC4

1

2

4

6

3

8

5

2.2kX4

4

3

21

10

+10V

2.2k

R45

2.2k

R44

+5V

BR14

876

5

7

7

6

5

BR15

1.2kX4

4

3

2

8

UPC1246C

0.1u

C23

C27 C29

C28 C26

R46

1000pX4

1-D2

PWM

LLMU

1-D2

LLMD

1-D2

1-D2

DIR

7

IC7B

BA10393

+

-

5

6

5

6

RE

1-D2

10k

R5

1k(1/4W)

+24V

FR1

100(1/4W)

R6

1k(1/4W)

Q1

2SC1472K

+10V

IC2

9

+24V

D5

RD18FB1

C30

0.1u

C31

0.1u

D4

RD11EB

8

7

8

LCC MAIN PWB

D

RE/

HWHVHU

CN-C-5

CN-C-2

CN-C-3

C

CN-C-4

B

A

11 – 5 8/6/1999

Page 8

AR-LC1N

D

C

B

A

3/3

1

2

3

1

2

3

4

5

6

7

8

9

1

2

3

CN-C(B9B-EH-A)

5V

RE/

HU

HV

HW

GND2

U

V

W

4

RXD-LCC

GND2

DSR-LCC

GND1

GND2

5

12

34

56

78

910

TXD-LCC

5V

RES-LCC

DTR-LCC

CN-B(B10B-PHDSS-B)

24V

6

24V(LLSW)

LLM-

LPFC/

LPFS/

5V(LPED)

LPED

GND2(LPED)

5V(LTOD)

LTOD

GND2(LTOD)

5V(LRE)

LRE/

GND2(LRE)

LCD

N.C.

2

4

6

87

12

14

109

1615

18

1

3

5

11

13

7

17

24

2019

28

21 22

23

27

29 30

25 26

4

5

6

7

24V(OUT)

LLM+

24V(LPFS)

5V(LUD)

LUD

GND2(LUD)

5V(LPFD)

LPFD

GND2(LPFD)

5V(LDD)

LDD

GND2(LDD)

/LDSW

CN-A(B30B-PHDSS-B)

24V(LPFC)

LLED

8

LCC MAIN PWB

D

8/6/1999 11 – 6

C

8

B

A

Page 9

CAUTION FOR BATTERY REPLACEMENT

(Danish) ADVARSEL !

Lithiumbatteri – Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandoren.

(English) Caution !

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according to manufacturer’s instructions.

(Finnish) VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

(French) ATTENTION

Il y a danger d’explosion s’ il y a remplacement incorrect

de la batterie. Remplacer uniquement avec une batterie du

même type ou d’un type équivalent recommandé par

le constructeur.

Mettre au rebut les batteries usagées conformément aux

instructions du fabricant.

(Swedish) VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent

typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

instruktion.

AR-LC1N

Page 10

AR-LC1N

All rights reserved.

Printed in Japan.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted,

in any form or by any means,

electronic; mechanical; photocopying; recording or otherwise

without prior written permission of the publisher.

SHARP CORPORATION

Digital Document Systems Group

Quality & Reliability Control Center

Yamatokoriyama, Nara 639-1186, Japan

1999 August Printed in Japan

Loading...

Loading...