Page 1

SERVICE MANUAL

CODE: 00ZARLC1//A1E

DIGITAL COPIER OPTION

LARGE-CAPACITY

PAPER FEED TRAY

MODEL AR-LC1

CONTENTS

[ 1 ] OUTLINE OF THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 2 ] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 3 ] UNPACKING AND INSTALLATI ON . . . . . . . . . . . . . . . . . . . . . . 3-1

[ 4 ] EXTERNAL VIEW AND INTERNAL CONSTRUCTION . . . . . . 4-1

[ 5 ] OPERATING PRINCIPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[ 6 ] DISASSEMBLY AND REINSTALLATION . . . . . . . . . . . . . . . . . 6-1

[ 7 ] ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[ 8 ] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[ 9 ] TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

[11] EXPLANATION OF THE CIRCUITS . . . . . . . . . . . . . . . . . . . . 11-1

PARTS GUIDE

Parts marked with "!" is important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

CAUTION FOR BATTERY REPLACEMENT

(Danish) ADVARSEL !

Lithiumbatteri – Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandoren.

(English) Caution !

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according to manufacturer’s instructions.

(Finnish) VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

(French) ATTENTION

Il y a danger d’explosion s’ il y a remplacement incorrect

de la batterie. Remplacer uniquement avec une batterie du

même type ou d’un type équivalent recommandé par

Mettre au rebut les batteries usagées conformément aux

(Swedish) VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent

typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

le constructeur.

instructions du fabricant.

instruktion.

Page 3

[1] OUTLINE OF THE PRODUCT

This paper feed unit stores about 3300 sheets of A4- or B5-size

paper to save the trouble of adding paper when a large amount of

copies is to be taken.

Note: If this large-capacity paper feed unit is to be installed, it is

required to install an optional single-stage paper feed desk

(AR-DE1) or special desk (AR-DD1).

AR-DE2 AR-LC1

[2] SPECIFICATIONS

(1) Paper feed capacity

Paper feed capacity 3300 sheets (64 g/m2 or equivalent)

(2) Amount detection

Paper amount detection Provided (5-stage sensors including

empty detection)

Detector 0% (empty), ∼ 25%, ∼ 50%, ∼ 75%,

∼ 100%

Paper size detection None

(3) Paper size

Paper size A4/B5

Paper weight 56 ∼ 105 g/m2 (14 ∼ 28 lbs) (Same as

the copier’s paper feed section)

(4) Size switching

Switching to be performed by service personnel

(6) Dehumidifying heater

Yes/No Yes

ON/OFF switch ON/OFF by dehumidification heater

switch on the copier

(7) Factory setting

Factory setting paper

size

Plate display A4

A4

(8) Power supply

Power supply supplied by the copier

(DC 5 V, DC 24 V)

(9) Power consumption

Max. power consumption about 17.6 W

At stand-by about 1.2 W

(5) Size detection

Size detection Setting by simulation

(10) External view

External dimensions 325 (wide) × 536 (deep) × 572 (high)

mm

Weight about 32 kg

Case color Frosty gray

1 – 1

Page 4

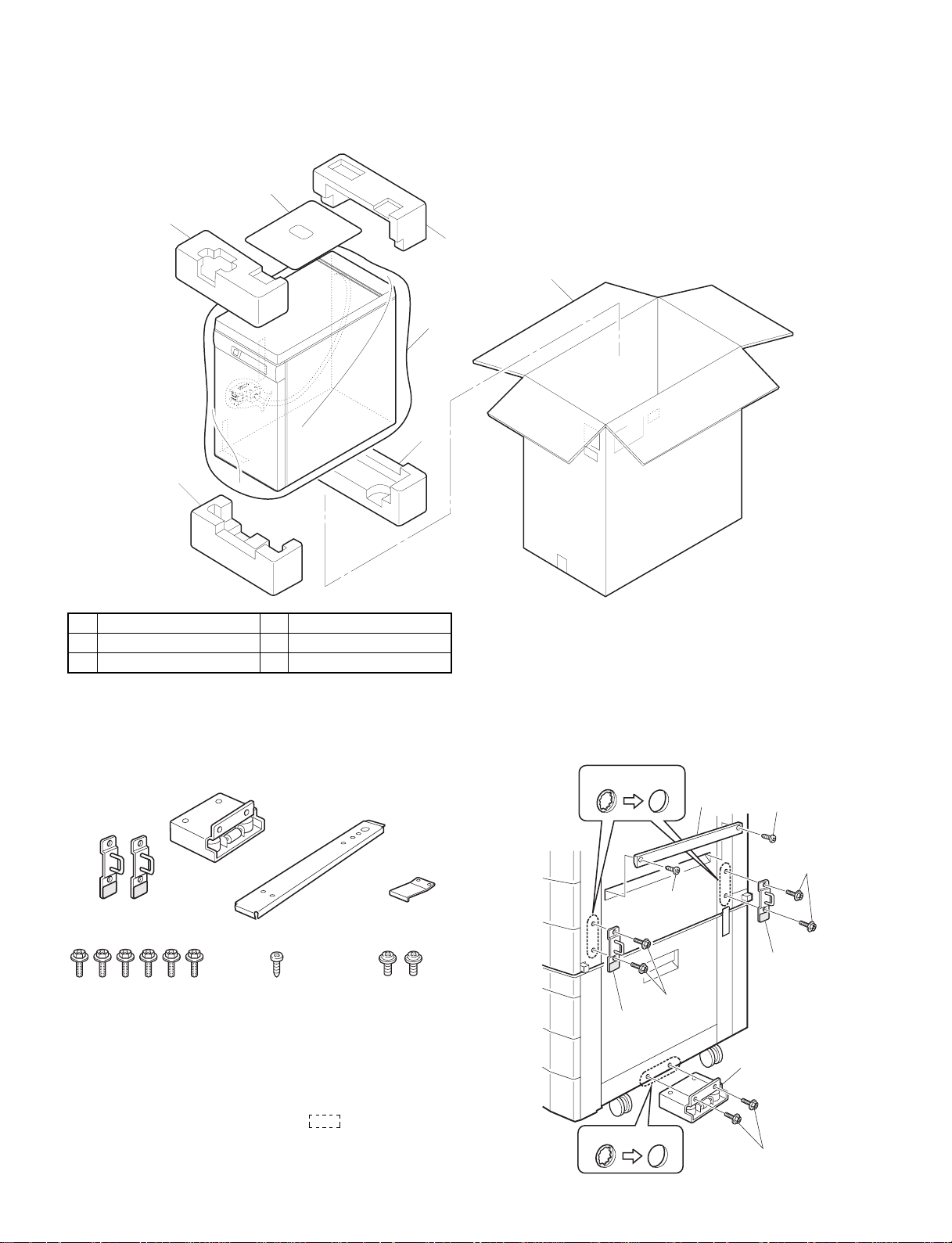

[3] UPACKING AND INSTALLATION

1. Unpacking

2

1

4

4

1

5

3

1 Upper cushion 2 Installation manual

3 LCC 4 Lower cushion

5 Packing case

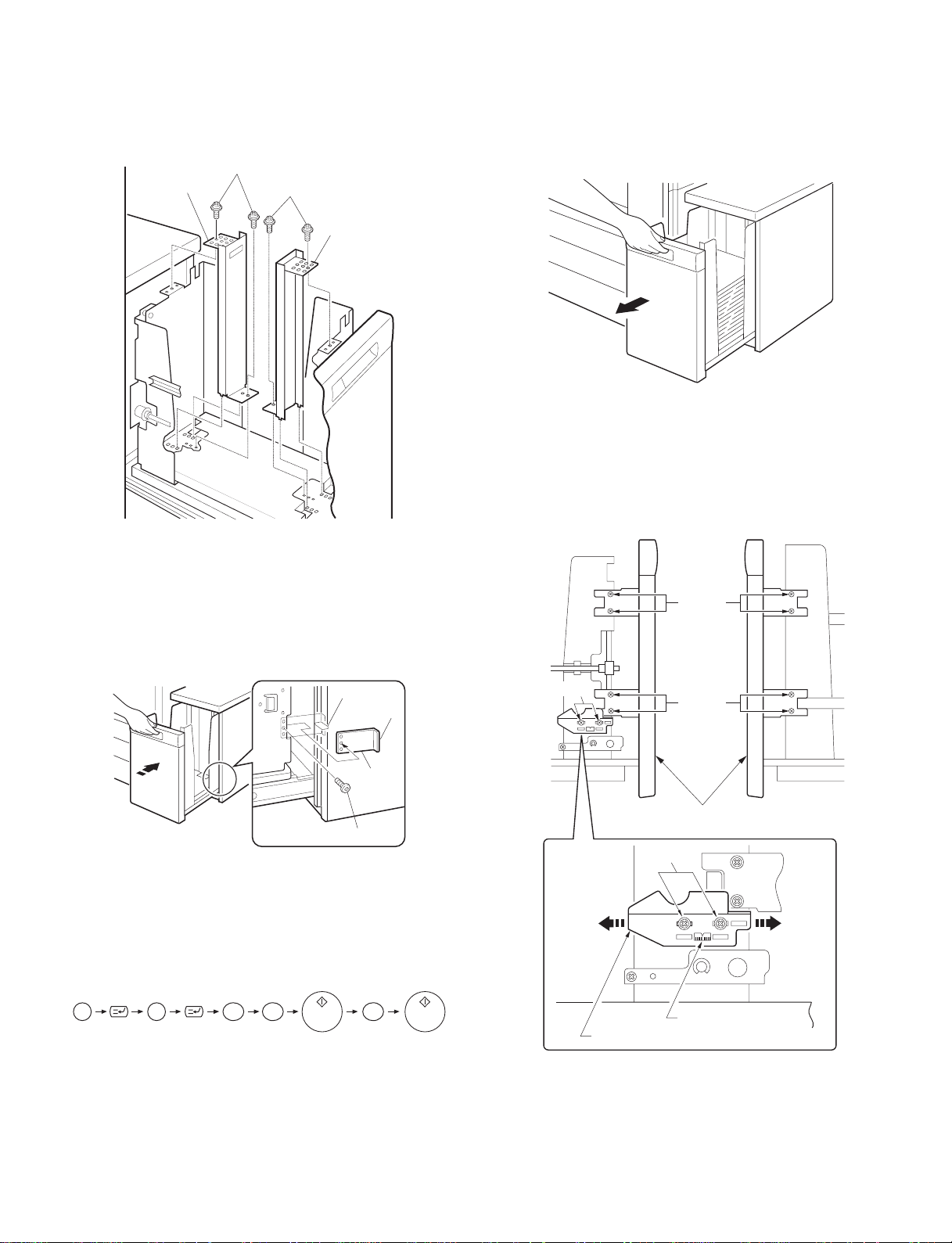

2. Installation procedure

Parts included

Mounting plate

(1 pc.)

Upper mounting plates

(2 pcs.)

Screws A (6 pcs.)

Remove the power cord from the copier and then

perform the following procedure.

1. Mount the upper mounting plates and the mounting

plate.

Make 6 holes for mounting (indicated with ) on the copier and

lower part of the stand using a Phillips screwdriver, etc. and remove

burs using a flat-blade screwdriver, etc.Mount the upper mounting

plates using screws A (two for each plate).

Connecting plate

(1 pc.)

Screw B (1 pc.) Screws C (2 pcs.)

Securing plate

(1 pc.)

Then remove 2 screws from the LCC cover on the copier and remove

the LCC cover.

Hole for mounting

LCC cover

Screw

Screws A

Upper

mounting plate

Hole for mounting

Screw

Screws A

Upper

mounting plate

Mounting plate

Screws A

3 – 1

Page 5

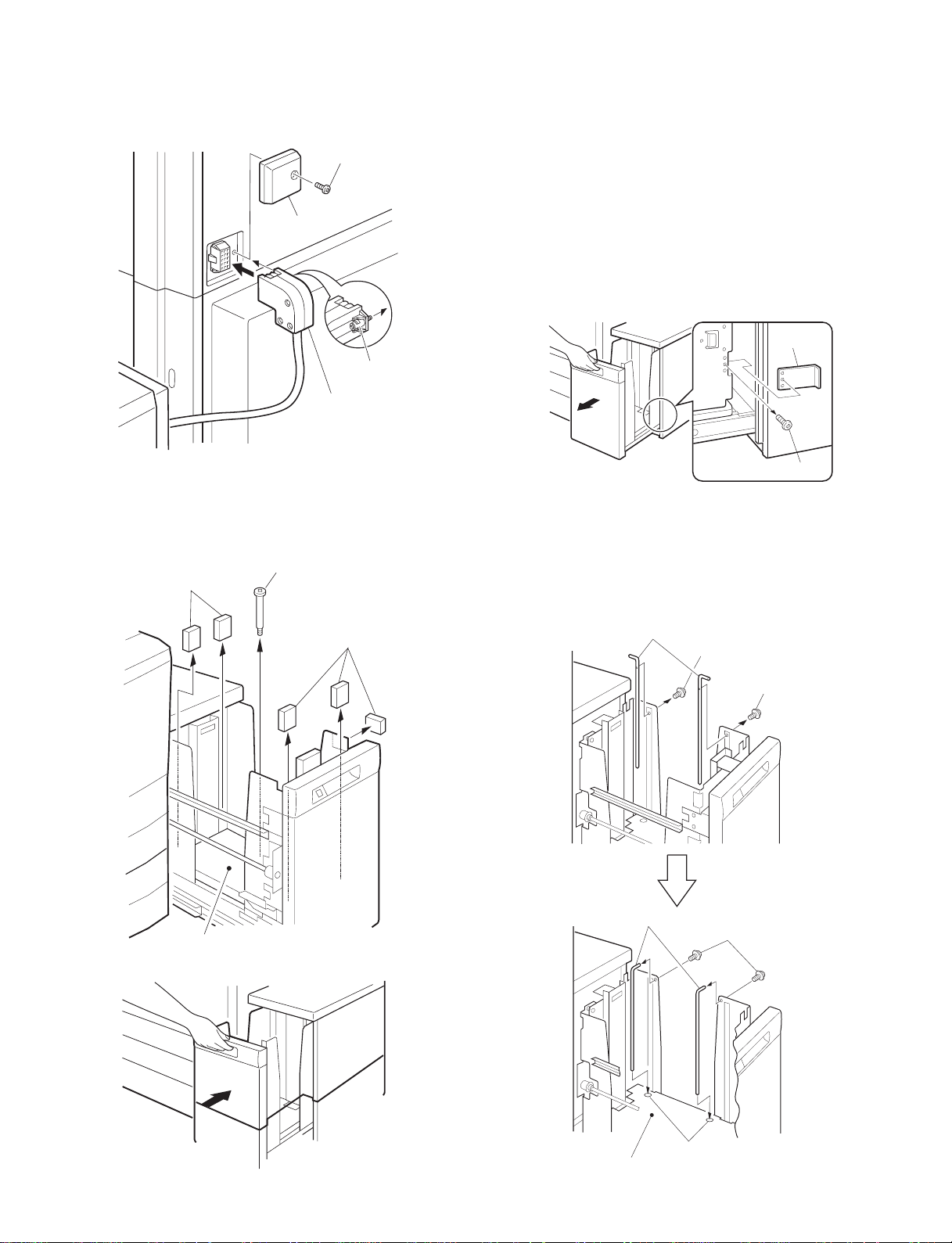

2. Mount the connecting plate to the large capacity tray.

Note: Before mounting the connecting plate to the large capacity

tray, be sure to remove the 2 step screws for securing the

bottom plate.

Fit the connecting plate to the lower part of the large capacity tray

and mount the plate to the position indicated with A using screw B.

Screw B

• If the axis is flush with the rib:

Push the large capacity tray toward the copier.

Top view

Axis

Rib

Step screws

‚a

‚`

‚a

‚`

Connecting plate

3. Fit the connecting plate of the large capacity tray to

the mounting plate of the stand.

Insert the connecting plate into the mounting plate of the stand while

lifting the large capacity tray a little.

After insertion, move the large capacity tray away from the copier to

check that the tray is locked.While the tray is locked, mount the

securing plate using 2 screws C.

Connecting plate

• If the axis is not flush with the rib:

Loosen the 2 screws of the installation adjuster mounting plate located at the lower part of the large capacity tray and adjust as follows:

★ If the rib is to the right of the axis

Turn the knob clockwise to adjust.

After adjustment, tighten the 2 screws of the installation adjuster

mounting plate.

Top view

Axis

Rib

Screw

Mounting plate

Securing plate

1 2

Screws C

4. Check and adjust the height of the large capacity tray.

Move the large capacity tray toward the copier and adjust the tray

and check it so that the rib of the large capacity tray is flush with the

axis of the mounting plate which has been mounted to the copier as

shown in the figure.

★ If the rib is to the left of the axis

Turn the knob counterclockwise to adjust.

After adjustment, tighten the 2 screws of the installation adjuster

mounting plate.

3 – 2

Axis

Knob

Top view

Rib

Screw

Knob

Page 6

5. Connect the connector of the large capacity tray.

Remove the connector cover securing screw for connection of the

large capacity tray relay harness connector and remove the connector cover.Then connect the large capacity tray relay harness connector to the connector of the copier and tighten the screw on the connector to secure the connector.

Securing screw

Connector cover

Screw

Connector

To use the large capacity tray without changing the paper size from

the factory default setting:

★Proceed to step 12 of this installation manual.

At this time, insert the power plug of the copier to an outlet and turn

the power switch to the "ON" position.

★Factory default setting: A4 size

The paper size can be switched only to the B5 size.

To use the large capacity tray after changing the paper size from the

factory default setting:

7. Remove the stopper from the paper tray.

Pull out gently the paper tray until it stops and remove the stopper

securing screw located on the lower part of the right side to remove

the stopper.

Then pull out again the paper tray until it stops.

Stopper

6. Remove the feed table securing screw and securing

materials.

Pull out gently the paper tray of the large capacity tray until it

stops.Remove the feed table securing screw and 5 securing materials

which secure the feed table of the large capacity tray.

Feed table securing screw

Securing materials

Securing materials

Feed table

Push back gently the paper tray to its original position.

Securing screw

8. Switch the rear end shaft.

Remove each rear end shaft securing screw (blue) which secures the

rear end shaft to the right side in the paper tray and remove the 2

rear end shafts.

Then fit the lower part of each removed rear end shaft to the mounting hole of the feed table of the paper tray and secure the upper part

to the position with B5 indication using a securing screw (blue).

Rear end shafts

Securing screw (blue)

Securing screw (blue)

Rear end shafts

Securing screw (blue)

3 – 3

Feed table

Mounting holes

Page 7

9. Switch the size of side plates F and R

Remove the screws which secure the upper and lower parts of side

plates F and R and remove side plates F and R.

Then fit the lower parts of side plates F and R to the position with B5

indication, position also the upper parts to the B5 size position, and

secure the plates using two screws (blue) for each plate.

Screws (blue)

Side plate R

Screws (blue)

Side plate F

12. Adjust the center position.

Since adjustment has been made at shipment, adjustment is basically

not needed. However, if the center should be displaced, adjust it

using the procedure below.

Make a copy. If the center is displaced as shown in Fig. 1 or Fig. 2,

pull out gently the paper tray until it stops.

Then, loosen the 2 screws at portion a which secure the tray lock

plate and the 8 screws at portion b (right and left sides) which secure

the tray cover unit to the frame and adjust the center position using

the procedure below.

10. Mount the stopper of the paper tray.

Push in the paper tray a little, mount the stopper which has been

removed in step 9, and secure it using the screw. At this time, check

that the pawl of the stopper is caught by the stopper block of the large

capacity tray.

Then push back gently the paper tray to its original position.

Paper size switching is complete here.

Stopper block

Pawl

Stopper

Screw

Insert the power plug of the copier to an outlet,

turn the power switch to the "ON" position and

then perform the following procedure.

11. Register the paper size.

• Register the paper size with the key operation of the copier.

Portion a

Direction A

Left side

Right side

Portion b

Portion b

Tray cover unit

Portion a

Direction B

P

2 6 2C

The LCC size selection window will be displayed in the message

display with the operation above.

Select the number of the size to be registered in the message display, enter the number using the keys on the operation panel and

press the OK key to register it.

Then turn the power switch to the "OFF" position and then to the

"ON" position again.

Scale (pitch in mm)

Tray lock plate

3 – 4

Page 8

• In case of Fig. 1:

Move the tray lock plate in direction A by the length of displacement,

tighten the 2 screws at portion a and then the 8 screws at portion b,

and make a copy again to check that the center is not displaced.

Fig. 1

Center line of paper

Center of image (first image)

• In case of Fig. 2:

Move the tray lock plate in direction B by the length of displacement,

tighten the 2 screws at portion a and then the 8 screws at portion b,

and make a copy again to check that the center is not displaced.

Fig. 2

Center line of paper

Center of image (first image)

3 – 5

Page 9

[4] EXTERNAL VIEW AND INTERNAL CONSTRUCTION

1. External view

1

1. Tray down button/lamp

The tray can be opened by pressing the button. Use this button when adding paper or paper jam occurs.

2. Main parts

123

4

5

6

7

8

9

No. Name No. Name

1 Transport roller 2 Paper feed roller

3 Hitching roller 4 Reversion roller

5 Tray 6 Lift-up unit

7 Encoder 8 Height adjustment unit

9 Caster

4 – 1

Page 10

PWB location

1

No Name Function and operation

1 Control PWB Controlling LCC

2 Tray switch PWB Tray lifting switch

2

Motor, clutch, solenoid, motor

3 LPFC

4 LPFS

1 LPFM

2 LLM

5 HT

Motor

No. Symbol Name Function and operation

1 LPFM Paper feed and transport motor Driving paper feed and transport systems

2 LLM Lift-up motor Driving tray lifting up

Clutch and solenoid

No. Symbol Name Function and operation

3 LPFC Paper clutch Driving paper clutch

4 LPFS Pick-up solenoid Operating pick-up roller

Motor

No. Symbol Name Function and operation

5 HT Dehumidifying motor Dehumidifying paper and preventing condensation of dew.

4 – 2

Page 11

Sensor, detector location

2 LLSW

4 LUD

3 LPED

1 LPFD

7 LTOD

5 LRES

6 LDD

No. Symbol Name Function and operation

1 LPFD Transport detector Detecting paper discharge

2 LLSW Upper limit lock switch Detecting tray upper limit lock (Shutting off motor as a safety device.)

3 LPED Paper detector Detecting the presence of paper

4 LUD Upper limit detector Detecting tray upper limit position

5 LRES Encoder sensor Controlling lifting up

6 LDD Lower limit detector Detecting tray lower limit position

7 LTOD Copier connection detector Detecting connection to copier

4 – 3

Page 12

[5] OPERATING PRINCIPLE

Lifting (no paper, descending from top to bottom)

Descending starts

1. Lift-up operation

When the copier is powered up, the main circuit checks the detection

state of each sensor. If the upper limit detector (LUD) is OFF, the

lift-up motor is turned on to elevate the tray till the position which

allows paper feed (upper limit detector ON).

1,2

3

4

LLMD

LLMU

LDD

30msec

LUD

100msec

3. Paper feeding

When copying is started, the transport motor (LPFM) starts. Then, the

pick-up solenoid (LPFS) and paper feed clutch (LPFC) turn on. When

the solenoid is turned on, the paper hitching roller is lowered to

contact the paper.

When the clutch is turned on, both the paper feed roller and the

hitching roller rotate to start paper feeding. The paper is sent through

the transport sensor (D) to the copier.

4

2

1 Upper limit detector (LUD)

2 Paper detector (LPED)

3 Paper tray

4 Lower limit detector (LDD)

Lifting (no paper, lifting from bottom to top)

Elevation starts

LLMD

LLMU

LDD

About 100 msec

LUD

Reversion starts

5msec

30msec

2. Lift-down op eration

If no paper is present after paper feed, the main circuit detects the

ON condition of the paper detector (LPED) and turns on the lift-up

motor to descend the tray till the position at which the lower limit

detector (LDD) turns on (the tray can be drawn out).

The tray switch PWB indication LED blinks while the tray is lifting or

descending.

1

3

1 Paper feed roller clutch (LPFC)

2 Paper hitching roller

3 Paper feed roller

4 Pick-up solenoid (LPFS)

Paper feed (Letter size, A4, B5)

Paper feed start signal reception

Job start signal reception

LPFM

LPFC

LPFS

3

2

4

Paper feed finish

signal transmission

Job END signal

reception

5 – 1

LPFD

Page 13

[6] DISASSEMBLY AND ASSEMBLY

1. Transport section (Paper feed roller) 2. Paper feed section

A. Paper feed unit

1)

2)

2)

3)

4)

2)

2)

6)

5)

2)

7)

5)

1)

1)

1)

2)

2)

1)

3)

1)

6 – 1

Page 14

B. Paper feed roller, take-up roller

2

C. Reverse roller

2)

1)

3)

2)

1)

3. Control PWB

1

rib

2)

3)

6)

4)

1)

5)

Note 1: When installing the paper feed roller, be careful of the install-

ing direction. … *1

Note 2: When installing the paper feed clutch, check that the clutch

stopper is caught by the pawl. … *2

6)

6 – 2

Page 15

4. Paper feed/transport motor

3)

2)

1)

5. Lift-up motor

2)

2)

1)

3)

2)

6 – 3

Page 16

[7] ADJUSTMENT

Lift-up motor (LLM) installing position adjustment

Install the motor so that the lift-up motor shaft comes to the center of

the insertion port of the lift-up motor installing plate shaft.

7 – 1

Page 17

[8] MAINTENANCE

Make sure to disconnect the phone line/communication cable from the copier before performing maintenance, because receiving the signal during

maintenance is dangerous.

1. Maintenance system tabl e

F: cleaning ★: lubricat ion ×: checking (cleaning, replacement or adjustment as required)

Unit name Name 80K 160K 240K 320K Remarks

Driving section Paper feed and transport gear ★★★★

Lift-up gear ★★★★

Transport section Transport roller FFFF

Paper guide FFFF

Paper feed section Paper feed roller ××××Replacement period (80K or 2 years)

Reversion roller ××××Replacement period (80K or 2 years)

Hitching roller ××××Replacement period (80K or 2 years)

Torque limiter ××××

2. Details of mainte na nc e

A. Driving section

1

2

No. Name Operation Cycle Remarks

1 Paper feed and transport gear Lubrication 80K

2 Lift-up gear Lubrication 80K

8 – 1

Page 18

B. Paper feed and transport section

1

2

1

5

3

6

4

No. Name Operation Cycle Remarks

1 Transport roller Cleaning 80K

2 Paper feed guide Cleaning 80K

3 Paper feed roller Check * 80K Replacement period (80K or 2 years)

4 Reversion roller Check * 80K Replacement period (80K or 2 years)

5 Hitching roller Check * 80K Replacement period (80K or 2 years)

6 Torque limiter Check * 80K Replacement period (80K or 2 years)

8 – 2

Page 19

[9] TROUBLESHOOTING

If a trouble occurs, check the cause of the trouble using the following

flow charts.

N: No Y: Yes

1. Troubl e code l ist

Trouble

code

U6 09 LCC lift motor trouble — LCC

20 LCC communication trouble — PCU

21 LCC transport motor trouble — LCC

22 LCC 24V power trouble — LCC

Trouble Remarks

2. Self-diagn ostics

Trouble

code

U6 09 Content LCC lift motor trouble

Detail LCC lift motor trouble

Cause Sensor defective

LCC control PWB defective

Gear broken

Lift motor defective

Check and

remedy

Check sensor operation with SIM4-2.

Check lift motor operation with

SIM4-3.

20 Content LCC communication trouble

Detail Communication trouble with LCC

Error at communication line test

when power is turned on or leaving

SIM.

Cause Connector: Defective connection of

harness or broken wire

LCC control PWB defective

Control PWB (PCU) defective

Control PWB (PCU) defective

Malfunction due to noise

Check and

remedy

Can be reset by turning on and off

power supply.

Check communication line connector

and harness.

21 Content LCC transport motor trouble

Detail LCC transport motor operation

trouble

Cause Motor lock

Motor speed error

Overcurrent to motor

LCC control PWB defective

Check and

remedy

Check transport motor operation with

SIM4-3.

22 Content LCC24V power supply error

Detail No power supply (24V) to LCC

Cause Connector: Harness connection

defective or broken wire

LCC control PWB defective

Power supply unit defective

Check and

remedy

Check power supply line connector

and harness.

Check for 24V at power supply unit

and LCC control PWB

* Displayed on the control panel of the copier

Details of trouble

Trouble

detection

A. LCC does not operate

A

Is interface

harness properly

connected?

Y

+5V between

CN-B-7 and 8 of

control PWB?

Y

+24V between

CN-B9 and 10 of

control PWB?

Y

Ready state after

setting paper?

Y

N

N

N

N

DB

Connect properly.

Check and if necessary

replace harness.

Check and if necessary

replace harness.

F

9 – 1

Page 20

B. Lift motor error C. Transport motor error

B

Is fuse blown out?

Y

Is load on motor

shaft normal?

Y

Is upper limit

sw on paper feed

UN turned on?

Y

Is harness

connected properly?

N

N

Replace fuse.

Check mechanical load

and driving system, and

remove any foreign matter.

N

Lower tray until upper

limit switch turns off.

Connect harness properly.

N

Check harness and if

necessary replace.

C

Is load on motor

shaft normal?

Y

Is harness

connected properly?

Y

Does motor rotate

even slightly?

Y

Check mechanical load

N

and driving system, and

remove any foreign matter.

Connect harness properly.

N

Check and if necessary

replace harness.

N

Is voltage applied to

motor connector?

N

Y

Y

Does motor rotate

even slightly?

Y

Is motor

encoder sensor

output normal?

Y

N

Check and if necessary

N

D

Check and if necessary

replace control PWB.

Is voltage

applied to motor

connector?

Y

replace motor.

Is motor encoder

output normal?

N

Y

N

Check and if necessary

Check and if necessary

replace control PWB.

replace motor.

D. Sensor error

D

Check for

sensor mounting.

Is harness connected

properly?

Y

Replace control PWB.

N

Check mounting and if

necessary replace harness.

9 – 2

Page 21

E. Clutch and solenoid error

F. No paper is fed

Is each load

properly installed?

Conductivity

between coils of

each load?

Conductivity

between connectors

and terminals?

Replace control PWB.

G. Paper jam

G

Y

Is improper

paper used?

Y

E

N

Check mounting and if

necessary replace.

Y

N

Replace clutch or solenoid.

Y

N

Check and if necessary

replace harness.

Y

F

Is paper feed

rollers contaminated

with paper dust?

Y

Does roller rotate?

Y

Does pick-up

roller drop at paper

feeding?

Y

Check mechanical load and

N

driving system. Remove any

foreign matter and clean.

N

C

N

E

Does

pick-up roller

rotate in paper feed

direction at paper

N

E

feeding?

Y

N

Use specified paper.

N

Is improper

paper used?

Use specified

paper.

Y

Replace control PWB.

Foreign matter

in paper path?

Y

Is transfer

sensor normal?

Y

Sheets are fed

one by one?

Y

Replace

control PWB.

N

Remove foreign

matter.

N

D

N

roller contaminated

separation roller.

Is paper feed

unit properly

assembled?

Y

Is separation

with paper

dust?

Y

Replace

N

feed unit and if

N

Check paper

necessary

replace.

Clean.

9 – 3

Page 22

[10] WIRING DIAGRAM

Copier

LRE

LDD

TRAY SW

PWB

LIFT

MOTO

CN-11

1

2

3

CN-12

1

2

3

BL

BR

GY

BL

PL

GY

CN-13

GY

3

LB

2

BR

1

CN-14

RD

1

GY

2

PK

3

G8

GY GY

G4 G3

CN-RL

WH

CN-HT

WH

CN-DT 12pin

1

2

6

11

3

7

8

9

10

4

5

12

12

12

LHT

WH

WH

CN-A

BL

22 5V(LRE)

BR

24 LRE/

GY

26 GND2(LRE)

BL

21 5V(LDD)

PL

23 LDD

GY

25 GND2(LDD)

PK

28 LCD/

LB

27 LDSW/

BR

29 LLED

RD

3LLM+

PK

4LLM-

G1

LCC

CONTROL

PWB

83

BR

1

PLLBBR

2

4

TXD-LCC

RXD-LCC

DSR-LCC

CN-B

PKRDGY

3

5

DTR-LCC

RES-LCC

91051112467

BL

GY

75V8

9

10

24V

GND2

GND1

CN-A

CN-C

BL

95V(LUD)

BR

11LUD/

GY

13GND2(LUD)

BL

105V(LPED)

PL

12LPED/

GY

14GND2(LPED)

RD

124Vout

RD

224V(LLSW)

RD

524V(LPFC)

PK

6LPFC/

RD

724V(LPFS)

LB

8LPFS/

BL

155V(LPFD)

BR

17LPFD/

GY

19GND2(LPFD)

BL

165V(LTOD)

BR

18LTOD/

GY

20GND2(LTO)

BL

15V

BR

2RE

PL

3HU

LB

4HV

PK

5HW

GY

6GND1

PL

7U

LB

8V

PK

9W

1

2

3

4

5

6

7

8

9

10

11

12

CN-FT 3pin

1

2

3

CN-3CN-KT 12pin

3

2

LUD

1

CN-4

3

LPED

2

1

LLSW

CN-1 CN-2

CN-5

1

2

CN-6

1

2

CN-7

1

3

2

CN-8

1

2

3

LPFC

LPFS

LPFD

LTOD

CN-10

4

6

3

2

1

5

9

8

7

LPFM

10 – 1

Page 23

Control circuit

Block diagram

Copier

VCC

GND2

+24V

GND1

FG

RXDTXDDSRDTRRES-

Communication

buffer circuit

8MHz

Xtal

Power supply

monitoring unit

24V

Power supply

10 V circuit

10V

CPU(H8/3294)

Operation unit

Large-capacity tray control PWB

Large-capacity tray

24V

Lift motor drive

circuit

Solenoid drive

circuit

LED lighting circuit

Sensor input

circuit

Transfer motor

drive circuit

10V

Upper limit sw (LLSW)

Lift motor (LLM)

Paper amount detection

sensor (LRE)

Paper feed clutch (LPFC)

Paper feed solenoid (LPFS)

LLED

Cassette detection line (LCD)

Upper limit detection sensor (LUD)

Lower limit detection sensor (LDD)

Paper detection sensor (LPED)

Paper delivery detection sensor

(LPFD)

Copier connection sensor

Door open switch (LDSW)

Transfer motor (LPFM)

10 – 2

Page 24

[1 1] EXPLANATION OF THE CIRCUITS

1. Operation

(1) Communication buffer circuit

On the communication buffer circuit, signals are input and output by the transistor array TD62504 (IC02).

+5V

CN-B-1

CN-B-3

CN-B2

CN-B-4

TXD-LCC

DTR-LCC/

RXD-LCC/

DSR-LCC/

D01 D02 D07 D08

1SS133 x 4

D04 D05 D09 D10

1SS133 x 4

4.7K x 2

4.7K x 4

IC02C

314

TD62504F

IC02B

215

TD62504F

IC02E

12 5

TD62504F

IC02G

10 7

TD62504F

CPU(IC01)

2

P51/RXD

6

P46/CLK

1

P50/TXD

3

P52/SCK

Signal name Logic

DSR-LCC

DTR-LCC

TXD-LCC

RXD-LCC

H: Request for communication

L: No request for communication

H: Communication allowed

L: Communication inhibited

H: Normal

L: Start bit

H: Normal

L: Start bit

(2) Sensor input circuit

The sensor signals used by LCC are connected directly to the input port of the IC02. LPFD is provided with a static electricity noise protective diode

which protects against static electricity from the paper transport section. The other sensors has the same circuit configuration as the LPED.

+5V

CPU

(IC01)

P21/A9

P22/A10

P20/A8

38 LPFD

37 LDD

39 LPED

1SS133

R79

10K

R80

10K

R78

10K

1SS133

D23

D24

R94

R95

22K

22K

C14 C15 C16

BR04

4.7K

1000P x 3

LPFD

LDD

LPED

CN-A-17

CN-A-23

CN-A-12

(3) Upper limit switch

A limit switch is provided to protect the LCC If it fails to operate normally. If the tray exceeds the upper limit sensor (LUD) position, the switch is

turned on to shut off the power of the lift motor.

LCC control PWB

Upper limit switch

Lift motor

11 – 1

24V

24V(LLSW)

LLM+

LLM-

Lift motor

drive circuit

Page 25

(4) Solenoid and clutch drive circuit

The solenoids and clutches are driven by a Darlington transistor array TD62004AP with 7-circuit clamp diode. LPFS is turned on when the CPU’s

port output is at H. LPFC has the same circuit.

+24V

9A12004B

SOL

CPU(IC01)

P10/A0

48 LPFS

10.5K

LPFS/

CN-A-8

7.2K

3K

(5) Lift motor drive circuit

The tray height is adjusted according to the size of the paper mounted on the paper feed tray. The lift motor controls the rotational direction

(CW/CCW) with the control signals (LLMU, LLMD) from the CPU. The circuit forms a bridge circuit with STA457C to allow the CW/CCW control.

A fuse (F01) is provided to protect the motor against shorting or overload.

IC04C

314

ULN2004A

IC04D

413

ULN2004A

CPU port

LLMU

LLMD

Lift motor

1-E4

1-E4

LLMD LLMU

Forward rotation (UP) L H

Forward rotation (DOWN) H L

OFF L L

R34 1K

R35 1K

D20

R36 1K

R37

D21

1SS133x2

IC07

7

2

STA457C

1

2

7

3

3

1

8

1K

8

4

4

6

9

9

6

5

51010

R38

R39

10K

10K

F01

1.25A/120V

T1.0A/250V

R40

3.9K

(1/4W)

C31

0.1uF

LLM+

LLM-

+24V(LLSW)

CN-A-3

CN-A-4

Suppose that both LLMD and LLMU become H level at the above circuit. If LLMU becomes H first, the STA457C pin 3 become H, IC04 pin 13

through IC07 pin 6 become H due to diode D20. Even if LLMU is at H and LLMD at H on the port, STA457C pin 1 is at L and pin 6 at H, thus no

conduction of STA457C is achieved.

(6) Transport motor drive circuit

+10V

R19

CN-C-3

CN-C-4

CN-C-5

CN-C-2

IC12A

2.7K

116

TD62504F

IC12B

215

TD62504F

IC12C

314

TD62504F

+5V

R15

D25

RD18FB1

R14

2.2K

2.2K

IC05

1

2

4

3

5

6

8

+10V

10

C21

0.1U

RE

1-D2

+10V

IN1

IN2

IN3

IN4

IN5

IN6

VCC

VREF

UPC1246C

OUT1

OUT3

OUT5

OUT6

OUT4

OUT2

REVERSE

DIR

11

12

13

14

15

16

7

9

GND

1-D2

10K

R16

10K

R17

10K

R18

IC12D

R77

10K

413

TD62504F

PWM

1-D2

R86

+5V

1.2K

+24V

R90

1K(1/4W)

R32

1K(1/4W)

D22

RD11EB

R87

R88

1.2K

C29

0.1U

1.2K

+24V

+5V

R85

2.2K

FR01

100(1/4W)

Q02

2SC1472K

C30

0.1U

2

3

4

BR15

2.2K X 3

R76

10K

HU

HV

HW

RE/

C17 C19

C18 C20

1000P X4

IC04E

12

5

ULN2004A

IC04F

11

6

ULN2004A

IC04G

710

ULN2004A

BR07

R20

R21

R22

R23

R24

R25

2

2.2K

3

2.2K

4

2.2K

1K x3

BR08

4

680

3

680

2

680

C22 C23 C24

1K x3

0.1U X3

C26

0.1U

IC06

2

IA1

8

IB1

9

IC1

1

VCC

3

OA

7

OB

10

OC

5

GND

12

GND

11

IC2

6

IB2

4

IA2

SLA6012

+10V

+5V

R27

2.4K

R28

200

R29

R26

360

0.22

/1W

8

IC09A

3

+

1

2

LM393

4

C27

0.1U

The motor drive circuit is composed of IC05 motor ICs (IC12, IC04 and IC06). When the PWM signal output from the CPU made at H level, the

transistor inside the IC06 turns on to supply current to the motor to start the motor. As the motor is started, hole signals (Hu, Hv, Hw) inside the

motor switch the input of IC05, while the output switches the transistor inside IC06. The motor thus starts rotating under non-control state.

When the motor rotates, the speed signal (RE) is output from the motor. The signal is taken into the CPU. If the motor speed is slow, the RWM

signal On duty is increased to increase the speed; if the motor speed is high, the PWM signal On duty is decreased to maintain the required speed.

As the current flowing to the motor becomes large, the input voltage at the minus side of the IC09 rises. If the voltage exceeds the plus-side input

voltage, output voltage at IC09 becomes at L level, leading in the PWM signal to turn off the transistor of IC07 so that the current to the motor is cut

off. (setting: 3A).

11 – 2

C34

0.1U

+

C25

100U/35V

D17 D18 D19

+24V

ISR124-400 X3

U

CN-C-7

V

CN-C-8

W

CN-C-9

Page 26

(7) 24V power detection line

The line monitors 24V power. If the 24V power fed from the copier is not 24V, the level becomes L and the 24V power error is sent to the copier.

24V

R04

22K

55

P36/D6

R05

4.7K

(8) Cassette detection line

This line has the same circuit as each sensor. When the LCC cassette door is opened, the CPU becomes at H level; when the door is closed, the

line is connected to GND and the CPU becomes at L level.

5V

P26/A14

33

R84

10K

(9) LED lighting circuit

This is the LED lighting circuit for the cassette door switch.

5V

BR04

2.2K

P27/A15

32

IC12E

TD62504F

BR04

4.7K

1000p

R03

220(1/4W)

Drawer connector

LED

When the CPU outputs the L signal, the LED comes on.

11 – 3

Page 27

12345678

11 – 4

COUGAR - LCC MAIN PWB

D

+5V

D01 D02 D03

+24V

GND1

+5V

GND2

1SS133x6

C01

C03

D04 D06

+

C02

47U/35V

+

C04

47U/35V

C05

D05

+24OUT

+24V

0.1U

+5V

0.1U

+24V(LLSW)

TXD-LCC

CN-B-1

DTR-LCC/

CN-B-3

RES-LCC/

CN-B-5

LRE/

CN-A-24

C

CN-B-2

CN-B-4

RXD-LCC/

DSR-LCC/

B

+24V

CN-B-09

GND1

CN-B-10

+5V

CN-B-7

CN-B-8

GND2

CN-B-6

A

CN-A-2

+24V(LLSW)

0.1U

CN-A-1

C35

1SS133x2

CN-C-6

0.1U

+5V

D07 D08

D09

D10

+24V

+5V

BR01

4.7KX7

1SS133x2

+5V

6

7

8

5

2

4

3

IC02

3

O3

I3

2

O2

I2

1

O1

I1

4

O4

I4

7

O7

I7

5

I5

O5

6

I6

O6

GND8NC

TD62504F

X1 8.00MHz

CN-A-5

CN-A-7

CN-A-9

CN-A-10

CN-A-16

CN-A-22

CN-C-1

CN-A-13

CN-A-14

CN-A-19

CN-A-20

CN-A-25

CN-A-26

+24V

R04

R91

22K

22K

R05

R92

4.7K

4.7K

+5V

14

6

15

7

16

8

13

5

10

2

12

11

9

BR02

4.7KX7

C09

4

3

C07

+

+5V

0.1U

RXD-LCC

TXD-LCC

DSR-LCC

4.7K X 3

R41

R42

R43

RES-LCC

C08

47U

0.1U

R01

10K

IC01

H8/3294 FP-64A

1

2

3

4

/NMI

5

VCC

6

7

/STBY

8

9

XTAL

10

EXTAL

MD1

11

MD0

12

AVSS

13

N.C

14

15

N.C

16

N.C

R93

R89

P50/TXD

P51/RXD

P52/SCK

/RES

/NMI

VCC

/STBY

VSS

XTAL

EXTAL

MD1

MD0

AVSS

P70/AN0

P71/AN1

P72/AN2

4.7K X 10

10K

10K

DTR-LCCDTR-LCC

/24VM

LCD2

YOBI

LRELRE

N.C

N.C

N.C

N.C

N.C

N.C

64

63

P47//WAIT

P60/FTCI/TMCI0

P63/FTIB/TMRI0

P64/FTIC/TMO0

P61/FTOA

P62/FTIA

P73/AN3

P74/AN4

P75/AN5

P76/AN6

P77/AN7

AVCC

173218192021222324252627282930

SW1-2

SW1-1

SW1-4

SW1-3

PWM/

SW2

N.C

DIR

N.C

RE

VCC

R45RR46

R47

R48

R49

R50

R44

+5V

BR04

4.7K X 5

IC04A

16

1

ULN2004A

IC04B

15

2

ULN2004A

+5V

R94

R95

22K

22K

C15

C14

1000P X2

6

5

4

3

2

C12C10 C11

+5V

R03

220(1/4W)

+5V

R96

R97

LPFSLPFS

LPFC

LPFC

R66

R65

R64

R63

R62

R61

R59

R58

R57

R56

R55

N.C

P66/FTOB/TMRI1

P65/FTID/TMCI1

N.C

R75

4.7K X 11

N.C

N.C

N.C

N.C

49

P30/D0

P31/D150P32/D251P33/D352P34/D453P35/D554P36/D655P37/D756P40//ADTRG//IRG57P41//IRQ158P42//IRQ059P43//RD60P44//WR61P45//AS62P46/CLK

LPFS

48

P10/A0

LPFC

47

P11/A1

N.C

46

P12/A2

45

P13/A3

44

P14/A4

43

P15/A5

42

P16/A6

41

P17/A7

40

VSS

39

P20/A8

38

P21/A9

37

P22/A10

36

P23/A11

35

P24/A12

P67/TMO1

N.C

R51

34

P25/A13

33

P27/A15

P26/A14

VCC

31

N.C

LLED/

VCC

R52

+5V

R

=

4.7K

LLMU

LLMD

N.C

N.C

N.C

LPED

LPFD

LDD

LUD

LDSW

LTOD

LCD1

R72

R73

R74

4.7K X 4

R54

PWM/

2-C2

DIR

2-B2

2-B2

RE

+5V

IC12F

6

TD62504F

IC12G

7

TD62504F

R79

10K

R80

10K

R78

10K

R81

10K

R82

10K

R83

10K

R84

10K

+5V

R02

IC12E

2.2K

512

TD62504F

11

10

D23

D24

C13

220(1/4W)

220(1/4W)

1SS133

1SS133

C16

LCD2

LPFS/

LPFC/

LLMU

LLMD

1000P X5

LPFD

LDD

LPED

LUD

LDSW

LTOD

LCD1

LLED

2-C2

2-C2

CN-A-30

D

CN-A-8

CN-A-6

LLMU

LLMD

CN-A-17

CN-A-23

C

CN-A-12

CN-A-11

CN-A-27

CN-A-18

CN-A-28

B

CN-A-29

CN-A-15

CN-A-21

A

8 7 6 5 4

3

2 1

Page 28

COUGAR - LCC MAIN PWB

12345678

11 – 5

D

+10V

R19

IC12A

2.7K

116

TD62504F

IC12B

215

TD62504F

IC12C

R77

10K

IC04C

IC04D

ULN2004A

ULN2004A

314

TD62504F

IC12D

413

TD62504F

R34 1K

R35 1K

C

D25

RD18FB1

+5V

1-D2

R86

R90

1K(1/4W)

R32

1K(1/4W)

D22

RD11EB

C29

0.1U

R87

R88

1.2K

HU

CN-C-3

HV

CN-C-4

HW

CN-C-5

RE/

CN-C-2

C18 C20

C17 C19

1000P X4

+24V

B

1.2K

1.2K

+24V

+5V

R85

2.2K

FR01

100(1/4W)

Q02

2SC1472K

C30

0.1U

+5V

2

3

4

BR15

2.2K X 3

R76

10K

+10V

+10V

RE

2.2K

R15

R14

2.2K

IC05

1

IN1

2

IN2

4

IN3

3

IN4

5

IN5

6

IN6

8

VCC

10

VREF

C21

UPC1246C

0.1U

OUT1

OUT3

OUT5

OUT6

OUT4

OUT2

REVERSE

GND

DIR

1-D2

LLMU

LLMD

11

12

13

14

15

16

7

9

1-E4

1-E4

10K

R16

10K

R17

10K

R18

PWM

1-D2

314

413

D20

D21

IC04E

512

ULN2004A

IC04F

611

ULN2004A

IC04G

10

7

ULN2004A

2

R36 1K

1

2

7

1

R37

1K

6

6

5

51010

1SS133x2

7

3

8

4

9

R20

R21

R22

R23

R24

R25

IC07

STA457C

3

8

4

9

R40

3.9K

(1/4W)

2.4K

F01

IC06

2

IA1

8

IB1

9

IC1

1

VCC

3

OA

7

OB

10

OC

5

GND

12

GND

11

IC2

6

IB2

4

IA2

SLA6012

+10V

+5V

R27

R29

360

C31

0.1uF

0.1U

8

IC09A

3

+

1

2

LM393

C34

4

C27

LLM+

LLM-

0.1U

+24V(LLSW)

CN-A-3

CN-A-4

BR07

2

2.2K

3

2.2K

4

2.2K

1K x3

BR08

4

680

3

680

2

680

C22 C23 C24

1K x3

0.1U X3

R28

200

R26

C26

0.1U

R38

10K

0.22

/1W

1.25A/120V

T1.0A/250V

R39

10K

+

C25

100U/35V

D17 D18 D19

+24V

ISR124-400 X3

U

CN-C-7

V

CN-C-8

W

CN-C-9

D

C

B

+24V

IC04

9

A

8

8 7 6 5 4

IC12

9

N.C

8

IC09B

5

+

7

6

LM393

3

2 1

A

Page 29

COUGAR - LCC MAIN PWB

12345678

11 – 6

D

CN-A (B30B-PHDSS) CN-B (B10B-PHDSS)

1

2

10

4

6

8

RXD-LCC

DSR-LCC

GND2

GND2

GND1

2

24V(OUT)

LLM+

24V(LPFC)

24V(LPFS)

5V(LUD)

LUD/

GND2(LUD)

5V(LPFD)

C

LPFD/

GND2(LPFD)

5V(LDD)

LDD/

GND2(LDD)

LDSW/

LLED/

1

34

11

13 14

17 18

21 22

25 26

29 30

65

87

109

12

1615

2019

2423

2827

24V(LLSW)

LLMLPFC/

LPFS/

5V(LPED)

LPED/

GND2(LPED)

5V(LTOD)

LTOD/

GND2(LTOD)

5V(LRE)

LRE/

GND2(LRE)

LCD1/

LCD2/

TXD-LCC

DTR-LCC

RES-LCC

5V

24V

3

5

7

9

CN-C (B9B-EH-A)

5V

RE/

HU

HV

HW

GND2

U

V

W

1

2

3

4

5

6

7

8

9

B

D

C

B

A

8 7 6 5 4

3

2 1

A

Page 30

q

COPYRIGHT C 1998 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted,

in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission of the publisher.

SHARP CORPORATION

Printing & Reprographic Systems Group

Quality & Reliability Control Center

Yamatokoriyama, Nara 639-1186, Japan

1998 May Printed in Japan S

Loading...

Loading...