Page 1

SERVICE MANUAL

Digital copier option

Staple sorter

MODEL AR-FN5

CONTENTS

[ 1 ] SPECIFICATIONS ............ ............................ .............................. ............ 1

[ 2 ] UNPACKING AND INSTALLATION ....................................................... 2

[ 3 ] EXTERNAL VIEW AND INTERNAL STRUCTURE................................ 5

[ 4 ] OPERATIONAL DESCRIPTIONS ........ .................................................. 8

[ 5 ] DISASSEMBLY AND SSEMBLY ........ .................................... .............. 13

[ 6 ] ADJUSTMENTS ................................................................................... 20

[ 7 ] MAINTENANCE............ .................. .................. .................. .................. 22

[ 8 ] TROUBLESHOOTING.......................................................................... 23

[ 9 ] CIRCUIT DESCRIPTIONS ........... .................... ...................... .............. 25

[10] OUTLINE MAP ............................................................... ...................... 35

[11] ELECTRICAL SECTION....................................................................... 36

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

[1] SPECIFICATIONS

1. Type

Installation-to-the-copier type

2. Tray

Number of trays: 2

Type: Upper tray, normal type

Lower tray, lift-up type (with the offset function)

Capacity: Upper tray, 100 pages

Lower tray, 1,000 pages (500 pages for A4/Letter

or greater)

3. Paper transport

Center reference

4. Paper exit syst e m

Face down

5. Paper exit size

9. Paper exit job

Machine tray: Printer, FAX, and copy output

Finisher upper tray: FAX output and interruption output

Note: The factory default is 1. Setup to 2, 3, 4 is made

by the user.

When a COPY/FAX model is set to the default

(1), an interrupt copy to the top tray is inhibited.

Finisher lower tray: Copy, printer output

10. Staple secti on

Staple allowed: Lower tray

Binding capacity: M ax. 30 pages (80g/u or less)

Paper size: AB series: A3, B4, A4, A4R, B5

Inch series: 11x17, 8.5x14, 8.5x13, 8.5x11, 8.5x11R

For Mainland China: A3, B4, A4, A4R, B5, 16k, 8k

Binding reference: Parallel binding at one position

Staple supply: Cartridge-type (3,000 pcs. or more)

Detection: Staple empty detection, no cartridge detec-

tion

Manual stapling: Not provided.

Upper tray: A4 / A4R / A5 / A5R / B4 / B5 / B5R / A5 / 11x17 /

8.5x14 / 8.5x13 / 8.5x11 / 8.5x11R / INV / FC / OHP /

Label sheet / Second original / 16k / 16kR / 8k

Lower tray: A3 / A4 / A4R / B4 / B5 / B5R / 11x17 / 8.5x14 / 8.5x13 /

8.5x11 / 8.5x11R / FC / 16k / 16kR / 8k

6. Paper weight

52 ~ 128g/m2 (Upper/lower trays)

7. Paper exit full detection

Provided (Upper/lower trays)

8. Offset

Offset allowed: Lower tray

Offset quantity: 27mm

1 1. Power source

Supplied from the copier. 24V/5V/3.3V

12. Power consumption

63W (Max.)

13. External dimensions

Finisher paper exit section: 173.5(W) x 511(D) x 540(H) mm (Except

for the tray)

Compiler section: 562(W) x 444(D) x 109(H) mm

14. Weight

About 19kg (Finisher body 11kg, compiler section 7kg)

Note: The finisher cannot be used with the manual paper feed tray.

Page 3

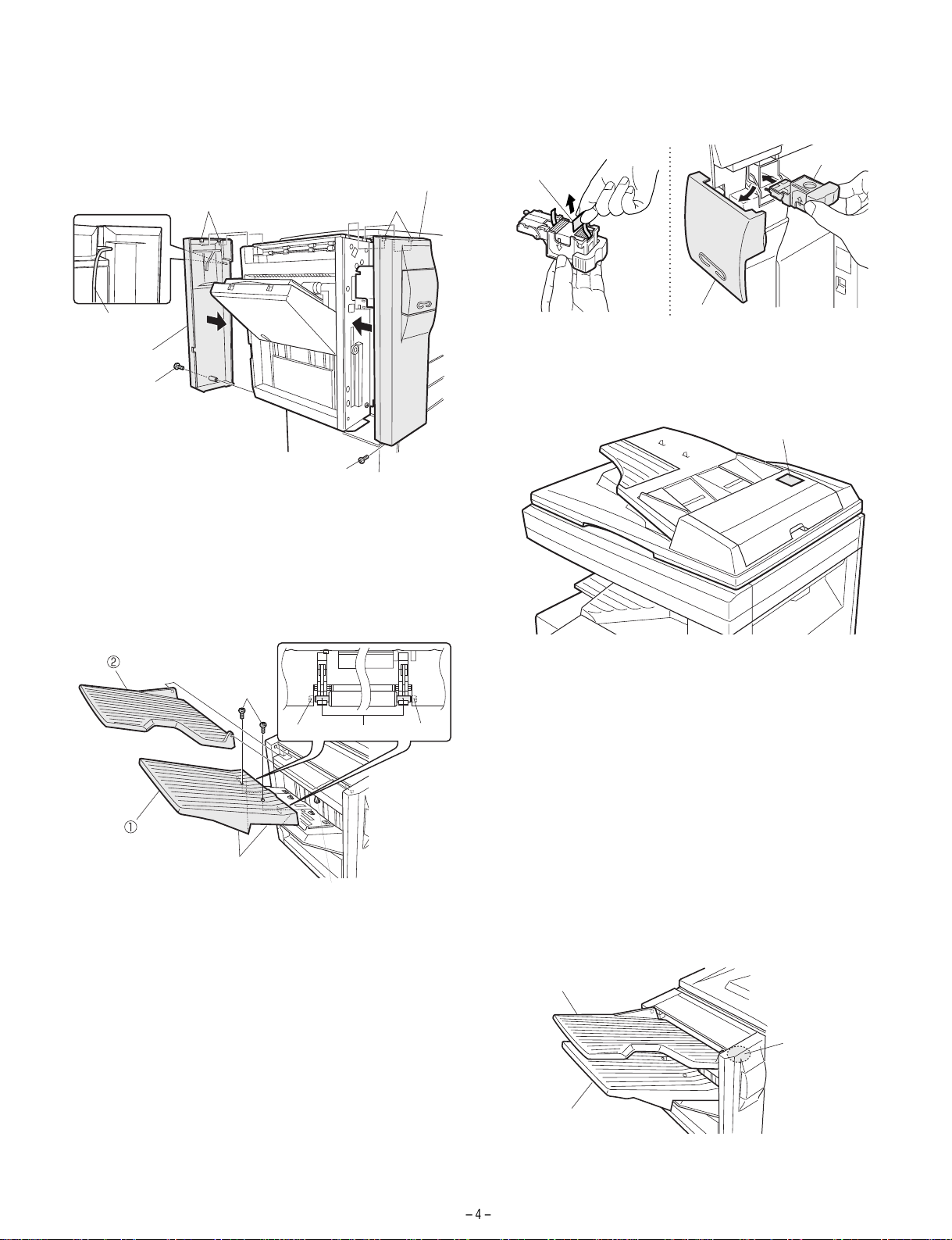

[2] UNPACKING AND INSTALLATION

1. Unpacking

2. Installation

If this unit is installed together with AR-SP4/RP3 or DM-SP2/RP1,

install AR-SP4/RP3 or DM-SP2/RP1 before installing this unit.

For improvement of workability, part of the description in this manual

may be modified without prior notice. In this case, refer to the service

manual.

Turn off the main switch of the co pi er an d the n r emove

the power plug of the copier from the outlet.

1. Remove the inner cabinet from the copier.

< 1 > Pull the lock lever to the right and then pull out the rail dummy

cover to remove it.

<2> Remove the pawl from the exit dummy cover and remove the exit

dummy cover.

Lock lever

Rail dummy cover

Pawl

Exit dummy cover

<3> Remove the screw and remove the rear exit cover.

<4> If this unit is installed together with AR-SP4/RP3 or DM-

SP2/RP1, install AR-SP4/ RP3 or DM-SP2/RP1 before installi ng

this unit.

Top tray: 1 pc.

Harness cover: 1 pc.

Screws (M4 x 10): 10 pcs.

Offset tray unit: 1 pc.

Staple cartridge: 1 pc.

Mounting fixtures: 2 pcs.

Staple position label

: 1 sheet

Installation manual

: 1 sheet

Remove all pieces of fixing tape and fixing materials from

the finisher.

· < 1 >, to < 2 >, < 3 >, < 4 >, < 5 >, < 7 >, and < 8 > indicate tape.

· < 6 >, < 9 >, and < 10 > indicate fixing material.

Paper pressure rollers

Rear exit cover

Screw (M3 x 10)

2. Fit the mounting fix ture s.

Cut and remove the two cut-out portions from the right cabinet of the

copier using a tool such as nippers.

(Be careful about the direction of the tool so that the cut surface is

flat.)

Fix the two mounting fixtures using two screws (M4 x 10) respectively.

Cut-out portions

Screws (M4 x 10)

Tape (wire handling)

Tape

Metal fitting

Screws (M4 x 10)

Metal fitting

Page 4

3. Remove the front and rear cabinets.

Remove the screw for each cabinet and remove the front and rear

cabinets.

Rear cabinet

Screw (M4 x 10)

Screw (M4 x 10)

Front cabinet

4. Attach the exit unit.

Lower the exit unit from above the mounting fixtures so that the right

and left positioning bosses are placed into the U-shaped grooves of

the fixtures. Then, fix the front side and the rear side using a screw

(M4 x 10) respectively.

5. Attach the alignment unit.

Place the rails of the alignment unit on the guide of the copier and

push it until it stops. Then, attach it using two screws (M4 x 10).

Guide

Rail

Harness

Pass the harness here.

Copier guide

Alignment unit

Screw (M4 x 10)

Right rail of

alignment unit

Screw (M4 x 10)

6. Connect each connector

< 1 > Connect the two harnesses of the alignment unit and the stapl e

connector to the exit unit relay harness on the front side.

< 2 > Pull out the harnesses of the alignment unit through the hole of

the copier rear frame and connect them to the three connectors

of the finisher PWB.

Front side Rear side

Rear side

Bosses

Mounting fixtures

U-shaped groove

U-shaped groove

<3> Connect the harness to the connector of the copier and fix it

using the screws.

Screws

Harness

7. Attach the harn es s co ve r .

Insert the rib of the harness cover into the left inner cabinet and then

hang the pawl on the right frame.

Screw (M4 x 10)

(Top view)

Screw (M4 x 10)

Rib

Pawl

Harness cover

Page 5

8. Attach the front and rear cabinets.

After hanging the ribs of the front and rear covers on the frames,

attach the front and rear cabinets using a screw (M4 x 10) respectively.

At this time, paste the connection harness to the rear cabinet as

shown in the illustration.

Front cabinet

Ribs

Ribs

10. Mount the staple cartridge.

Remove protective paper from the cartridge.

Open the staple cover, insert the staple cartridge to the staple unit

until it clicks, and then close the staple cover.

Staple cartridge

Protective paper

Connection

harness

Rear cabinet

Screw (M4 x 10)

Screw (M4 x 10)

9. Attach the trays.

< 1> Raise the paper holder lever, insert the two pawls on the rear

side of the offset tray unit to the mounting positions, and fix the

tray using the two screws (M4 x 10).

< 2> Insert the bosses of the escape exit tray into the mounting holes

shown in the illustration and attach the tray.

Top tray

Screw

(M4 x 10)

Roller shaft

Offset tray unit

pawls

Paper holder lever

[CAUTION]

When attaching the offset tray, make sure that part of the roller shaft

of the offset tray is not on the offset tray.

NGNG

Staple cover

11. Paste the staple po si tio n la be l.

Paste the staple position label to the document feeder.

staple position label

Insert the power plug of the copier to the outlet and turn

on the main switch of the copier. Then, carry out the

following procedure.

12. Check for stapl in g op er a tio n.

Make three copies in the staple sort mode.

Check to see if stapling has been performed properly.

13. Check for paper delivery to the top tray.

Deliver two copies to the top tray.

If this equipment is installed together with a printer expansion kit or a

facsimile expansion kit, check the appendix of each operation manual

(key operator programs and index list output and setting).

14. Check for paper delivery to the offs et tray .

Deliver three sets from two originals to the offset tray.

Check to see if copies have been offset stacked properly.

Escape exit tray

Offset tray

Installation of staple sorter is now complete.

Stapling position

Page 6

[3] EXTERNAL VIEW AND INTERNAL STRUCTURE

1. External view

1

2

3

No. Name

1 Upper tray

2 Lower tray

3 Alignment unit

Page 7

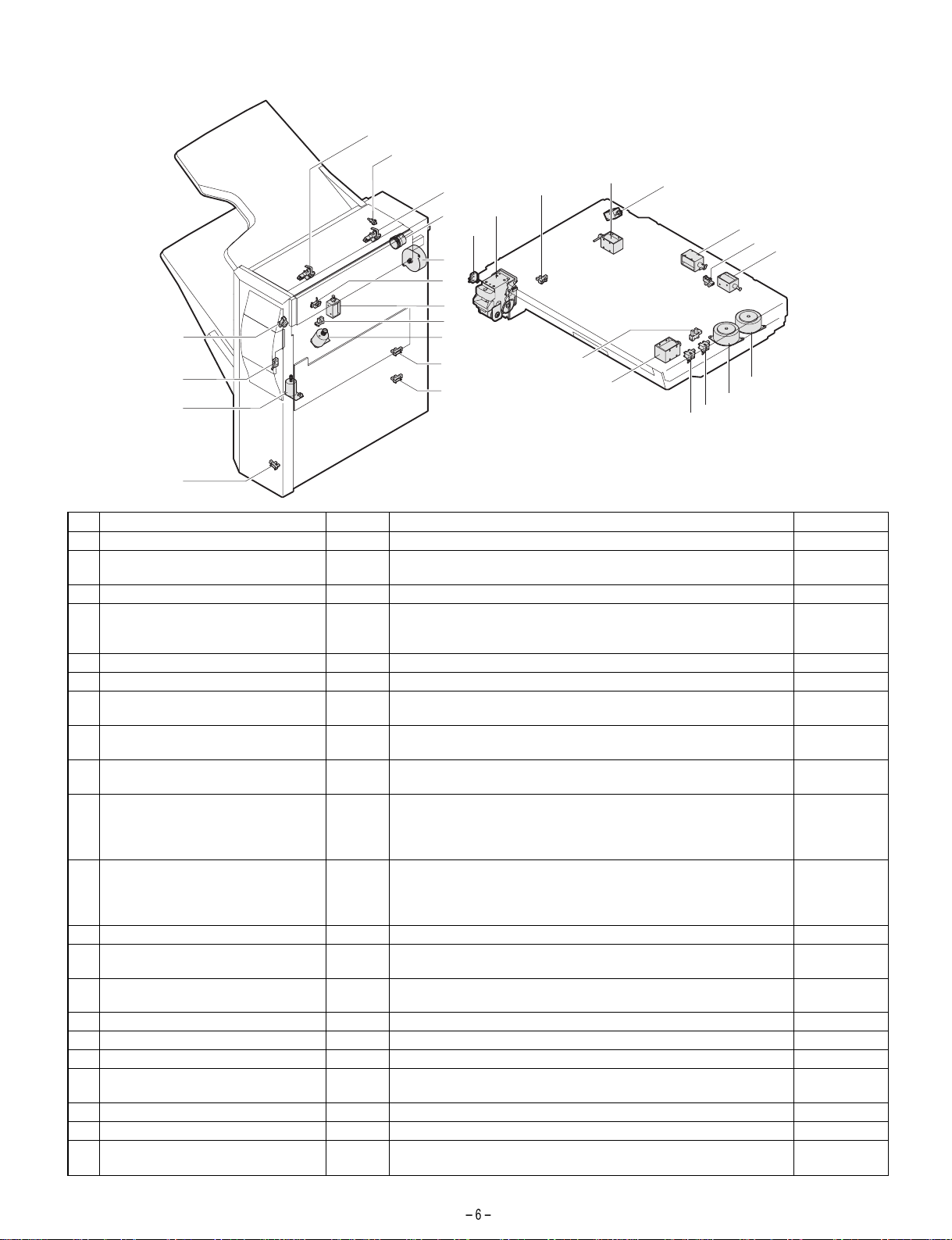

2. Sensors, motors, solenoids, etc.

1

2

3

4

29

17

16

5

6

7

8

18

12

13

9

10

11

28

27

14

15

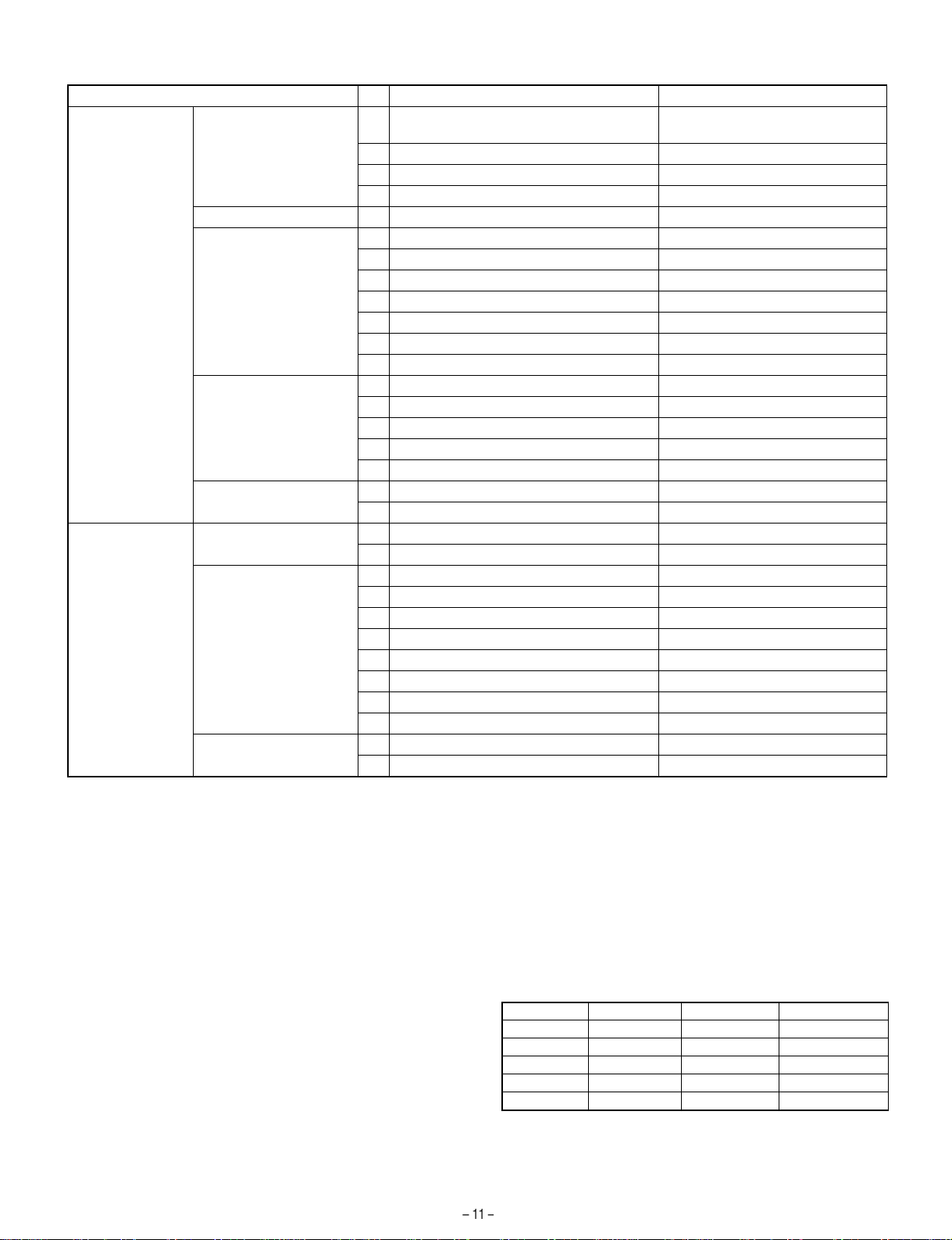

No. Part name Code Function/Operation Type

1 Upper tray paper exit sensor T10D Counts down the output page, detects JAM. Photo sensor

2 JAM process PG open/close detection

switch

3 Escape full sensor T1PD Detects paper full in the upper stage tray (ESC tray). Photo sensor

4 Paper exit roller rotation control clutch ORCLD Used to select whether to slow the speed of the paper exit roller upper

5 Main drive motor FMM Drives the rollers for paper transport. Pulse motor

6 Lower tray paper exit sensor /T20D Counts down the output page, detects JAM. Photo sensor

7 Paper hold solenoid OFSLD Presses paper onto the paper shift prevention lever of the lower stage

8 Paper position sensor /T2PD Detects the top surface of discharged paper, and detects the upper

9 Tray offset drive motor OFM

10 Tray position sensor (Upper) T2UP Detects the lift-up tray position in combination with the tray position

11 Tray position sensor (Lower) T2DN Detects the lift-up tray position in combination with the tray position

12 Offset home position sensor OFHP Detects the standby position of the offset tray. Photo sensor

13 Staple supply cover open/close

detection switch

14 Lift-up motor LUM

15 Lift-up drive control sensor LUEN Reads the encoder for control of the DC motor rotation. Photo sensor

16 Stapler unit

17 Tray paper empty sensor ATPD Detects paper presence or empty on the alignment tray. Photo sensor

18 Shutter drive solenoid STSLD When discharging a bundle of paper, shift the lead edge reference

19 Upper alignment plate drive solenoid AJSLD Holds paper on the alignment tray. Solenoid

20 Side guide plate home position sensor SDHP Detects the home position of the width alignment members. Photo sensor

21 Transport switch gate solenoid Right GRSLD Drive to sort paper into the escape transport section and the alignment

TCSW Interlocks when the open/close PG of the transport section in front of

(+, –)

SCSW Detects the staple supply cover open/close. When open, interlocks. Micro switch

(+, –)

the upper stage tray is open.

for the speed of the paper exit roller lower or to make it as a normal

follower roller.

tray upper.

standby position of the lift-up tray.

Supplies drive power to separate paper and shift the tray to the front

and the rear.

sensor (lower). (Upper limit detection in the case of erroneous detection

by the paper position sensor, intermediate position detection, and full

detection)

sensor (upper). (Upper limit detection in the case of erroneous

detection by the paper position sensor, intermediate position detection,

and full detection)

Drives the lift-up tray up and down. DC motor

plate in the paper transport direction.

tray.

22

26

25

24

19

23

20

21

Micro switch

Electromagnetic

clutch

Solenoid

Photo sensor

DC motor

Photo sensor

Photo sensor

Solenoid

Solenoid

Page 8

No. Part name Code Function/Operation Type

22 Transport switch gate solenoid Left GLSL Drive to sort paper into the escape paper exit port and the li ft -up tray

paper exit port.

23 Side guide plate alignment motor SDM Aligns paper vertically to the paper transport direction. Pulse motor

24 Reciprocating alignment motor BKM Aligns paper in the paper transport direction. Pulse motor

25 Paper entry sensor INPD Detects paper entry in the finisher and detects JAM. Switch trigger of

the transport switch gate right.

26 Paper width sensor WDPD Make a distinction between A4 and A5R, LT and INVR. If the paper

entry sensor is ON and this sensor is OFF, it is A5R or INVR.

27 Rear edge plate drive solenoid BKSLD Drives the rear edge plate. Solenoid

28 Rear edge plate home position sensor BKHP Detects the home position of the rear edge alignment members. Photo sensor

29 Tray JAM process detection switch PGSW Interlocks when the alignment tray is opened downward in a JAM

process.

Solenoid

Photo sensor

Photo sensor

Micro switch

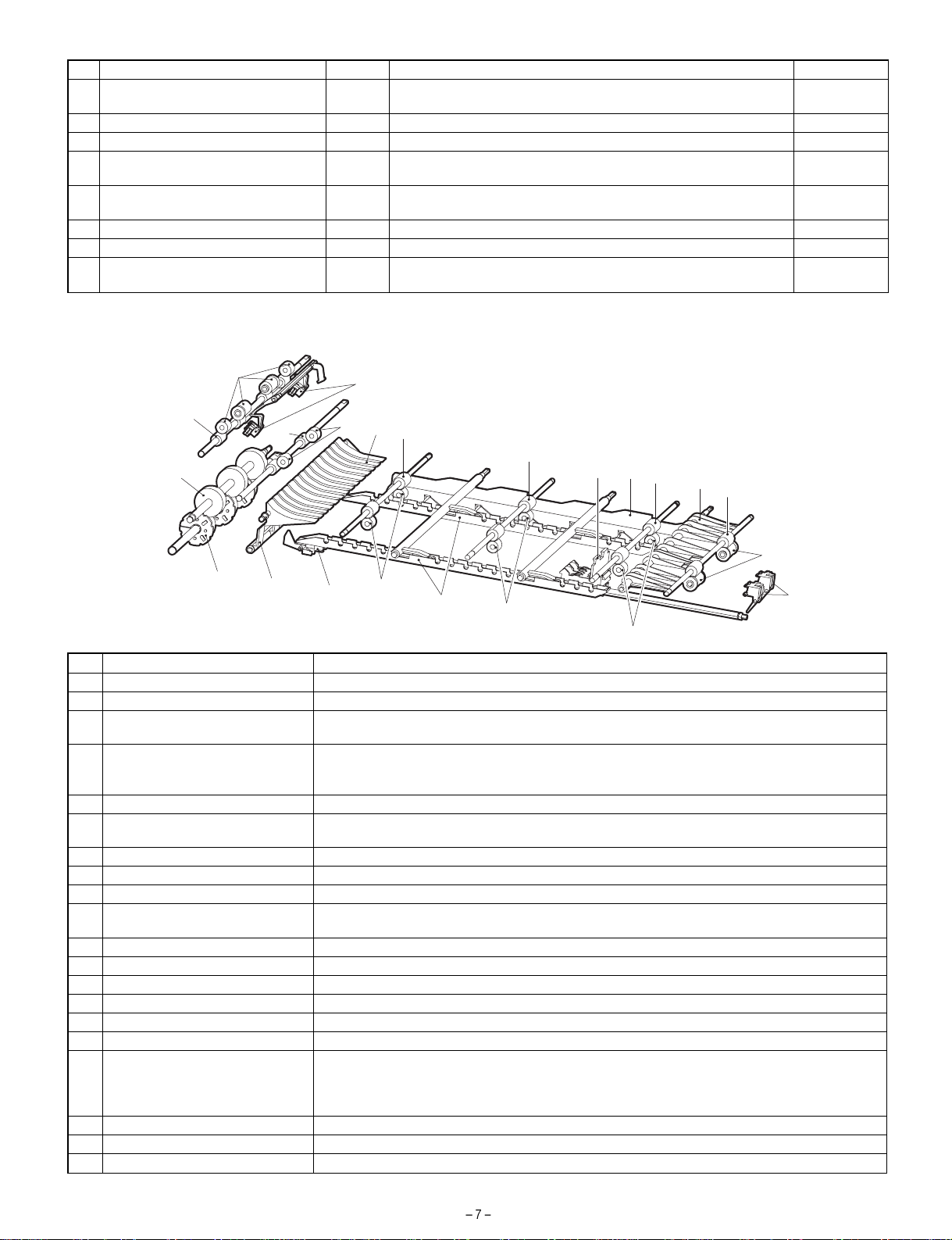

3. Rollers, gates, etc.

15

16

13

17

12

14

11

19

2

7

5

2

4

20

3

18

10

9

8

6

8

1

8

No. Name Function

1 Paper entry sensor Detects paper transported from the machine.

2 Transport roller fin Transports paper in combination with No. 8 roller.

3 Paper entry follower roller (Kick-out

sponge)

4 Transport switch gate right Selects between the escape transport (non-staple mode) and the alignment tray transport (staple

5 Side guide plate Aligns paper vertically to the paper transport direction.

6 Upper alignment hold plate Knocks paper when paper (5th page or later) comes on the alignment tray removing air or adjusting

7 Rear edge plate Aligns paper in the paper transport direction.

8 PS upper roller (Common part) Transports paper in combination with No. 2, 19, 20 rol lers.

9 Paper empty sensor (1A71A) Detects paper empty on the alignment tray.

10 Shutter Serves as the paper lead edge reference for alignment of paper, and opens to allow a bundle of

11 Transport switch gate left Selects between the escape tray transport and the offset tray transport.

12 PS upper roller (Common part) Transports paper in combination with No. 13 roller.

13 Escape transport roller Transports paper in combination with No. 12 (No. 8) roller.

14 Escape paper exit sensor Detects paper transport to the escape tray.

15 Transports paper in combination with No. 16 roller.

16 Escape paper exit roller Transports paper in combination with No. 15 roller.

17 Paper exit roller upper Transports paper in combination with No. 18 roller. This roll er normally follows No. 18 roller. When

18 Paper exit roller lower Transports (discharges) paper in combi nation with No. 17 roller.

19 Transport drive roller fin Transports paper in combination with No. 8 roller.

20 Paper entry roller fin Transports paper in combination with No. 8 roller.

Transports paper in combination with No. 2 roller.

mode).

When selecting the alignment transport (staple mode), this gate drops t he rear edge of paper.

curls.

paper to be transported to the paper exit port after stapling.

discharging a stapled bundle of paper, the electromagnetic clutch turns on to make this roller a drive

roller. The bundle of paper is bent by the difference between thi s roller speed and the No. 18 roller

speed so that it is not caught by the preceding bundle staple.

Page 9

[4] OPERATIONAL DESCRIPTIONS

1. Paper transport path

a. Tray 1 paper exit

b. Tray 2 paper exit (Offset function selectable)

c. Tray 2 staple paper exit

3. Paper exit of a stapled bundle

·

In the case of A3, WL

a. When paper is discharged from t he machine, the finisher raises

the direction switch gate right to pass the paper to the alignment

tray. When the read edge of paper passes the paper entry sensor,

the operation is triggered. That is, when the rear edge of paper

passes the direction switch gate right, the gate i s lowered to store

the rear edge of paper completely in the alignment tray.

2. Operational descriptions

1. Paper exit to the top tray

When paper is discharged from the machine, the finisher lowers the

direction switch gate right to pass the paper to the upper transport

path (escape transport section) and lowers the direction switch gate

left to discharge the paper to the top tray. The direction switch gate

right is triggered by the finisher paper entry sensor and operated only

when the paper lead edge passes through it.

2. Paper exit to the offset tray

When paper is discharged from the machine, the finisher lowers the

direction switch gate right to pass the paper to the upper transport

path, and lowers the direction switch gate left to discharge the paper

to the offset tray. The direction switch gate right is triggered by the

finisher paper entry sensor and operated only when the paper lead

edge passes through it.

b. The rear edge plate and the side guide plate are moved in the

paper alignment direction to lower the upper alignment plate, performing alignment. After alignment, stapling is performed by the

staple unit.

c. After alignment and stapling, the side guide plate is loosened and

the shutter is lowered to discharge paper to the paper exit roller by

the rear edge plate. The bundle of paper is discharged to the offset

tray by the paper exit roller.

· In the case of small size

a. The rear edge plate is moved to the center and the direction switch

gate right is raises to pass the paper to the alignment tray. When

the read edge of paper passes the paper entry sensor, the operation is triggered. That is, when the rear edge of paper passes the

direction switch gate right, the gate is lowered to store the rear

edge of paper completely in the alignment tray.

Page 10

b. When the second last paper is passed, the rear edge plate (1) is

lowered and passed under the paper bundle (2) to the rear edge of

the paper bundle (3). Then the rear edge plate is raised. (HP

position)

e. The rear edge plate and the side guide plate are moved in the

paper guiding direction and the upper guide plate is lowered to

perform the last alignment. Then stapling is performed by the staple unit.

f. After alignment and stapling by the stapler unit, the side guide

plate is loosened and the shutter is lowered. The paper is moved

to the paper exit roller by the rear edge plate, and discharged to

the offset tray by the paper exit roller.

(1) (2) (3)

c. When the last paper from the machine passes the direction switch

gate right, it lowers the gate.

d. The paper bundle is moved in the paper exit direction by the rear

edge plate.

3. Descriptions on each section

This machine is composed of the paper exit unit and the alignment

unit. The paper exit unit includes the paper exit tray 1 and 2. The

paper exit tray 2 is provided with the offset function and the lift-up

function.

The alignment unit includes the paper transport section used f or the

non-staple mode, the paper alignment section for the staple mode,

and the staple unit.

a. Paper exit unit section

(1) Paper transport (Main motor)

By rotating the main drive motor, the paper exit unit and the all transport rollers of the alignment unit are driven.

(2) Tray 1 full detection

The top of paper bundle on the tray is detected by t he combination of

the lever and the photo sensor to judge paper full on Tray 1.

(3) Lift-up section

· Lift-up motor

In order to discharge paper always at a fixed posi tion regardl ess of

paper load on the tray 2, the lift-up motor is driven, the pulley is

rotated normally or in reverse, and the timing belt is driven to move

the tray 2 up and down.

Page 11

· Full detection

Paper full on the tray 2 is detected in combination between the

lower limit sensor ON and detection of the top of paper bundle on

the tray by the paper exit actuator.

(4) Offset tray section

· Offset motor

The offset motor moves the offset tray vertically to the paper exit

direction so that each bundle of paper discharged to the offset tray

is separately grouped.

· Paper exit clutch

This clutch is turned on when a stapled bundle of paper is discharged so that the bundle of paper is warped by the difference

between the speeds of the upper and the lower paper exit rollers,

preventing the bundle from being caught by the preceding bundle’s

staple.

b. Alignment unit section

(1) Transport switch gate right (gate right solenoid)

Selection between the transport section and the alignment section

in the alignment unit is made by the transport switch gate right.

This gate drops the rear edge of paper entering the alignment

section so that the rear edge is completely transported.

(2) Rear edge plate uni t

· Rear edge plate motor

The motor is turned on at the timing when paper enters the alignment tray to drive the rear edge plate unit. Paper of A3 or WLT is

aligned to the shutter, and paper of a smaller size is aligned to the

right side of the alignment tray in the transport direction.

· Rear edge plate solenoid

After provisional alignment of small size paper, this solenoid puts

down the rear edge plate of the rear edge unit to pass it under the

aligned paper. After returning to the home position, it is turned off

and the rear edge plate is put back and paper is transported to the

shutter.

(3) Side guide plate (Guide plate motor)

When paper enters the alignment tray, this plate is driven to align

paper vertically to the paper transport direction toward the fixed

wall of the alignment tray front side.

(4) Shutter (Shutter soleno id )

The shutter solenoid drives the shutter which stops the lead edge

of paper for alignment. After stapling, the shutter is put down to

transport paper to the paper exit roller.

(5) Transport switch gate left (Gate left solenoid)

Paper passed through the escape transport path is sent to the tray

1 or to the tray 2.

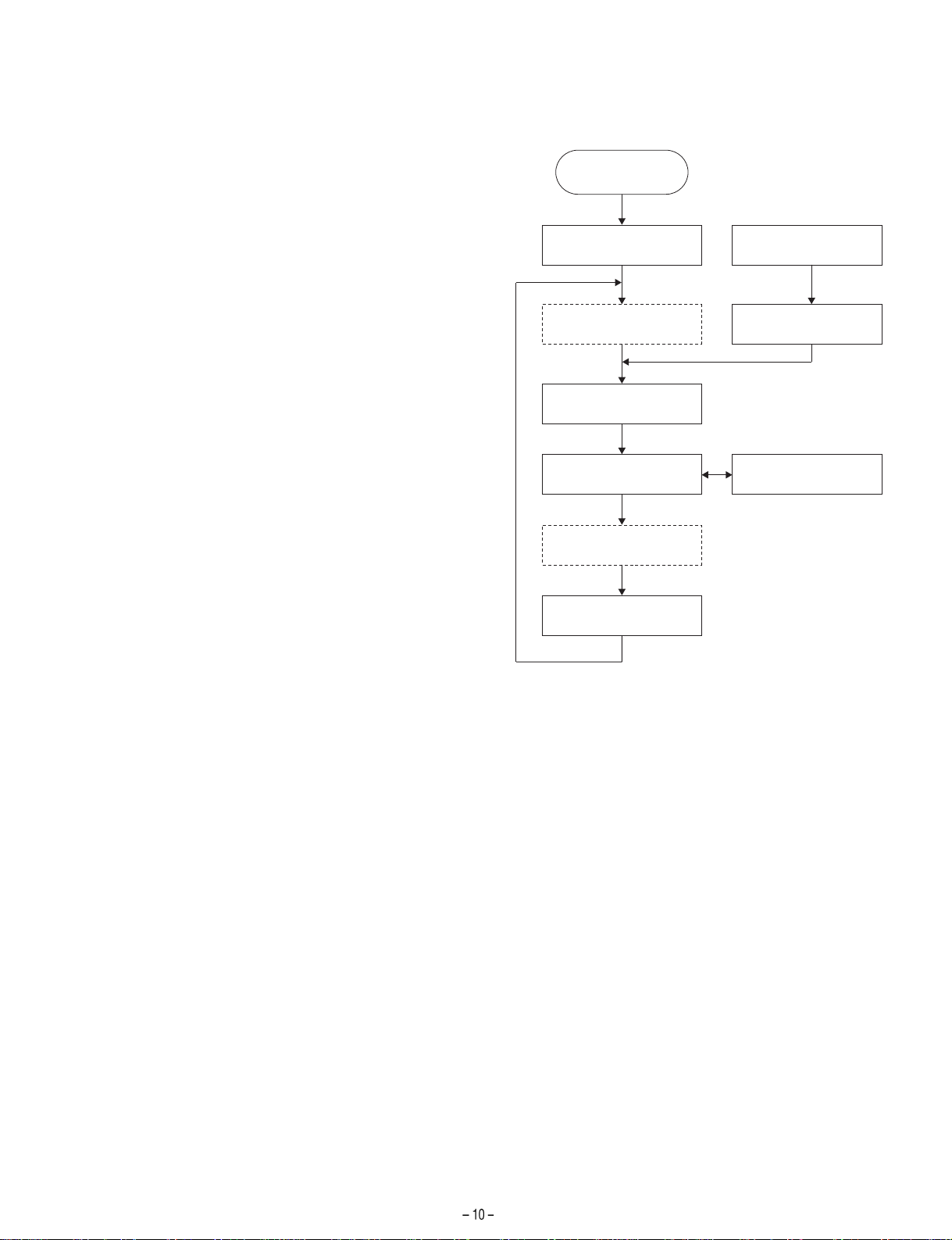

4. Basic operations

A. Flowchart of basic operations

Power ON

Initializing at power ON

Individual printing

operation (Offset tray)

Job start operation

Transport operation

Offset paper exit operation

Job end operation

The initialization (home positioning of each motor) is performed at the

following timing:

1) When the power is turned on.

2) When the staple section door on the upper side of the finisher

paper exit unit is opened or closed.

3) When the alignment unit is opened or closed.

4) When the copy start key is pressed (JOB_START): Recovery operation

5) When copying is completed (JOB_END).

6) When a jam occurs: Jogger saving

Operation in case

of an error

Operation when the

door is closed

Stapling operation

Page 12

B. Operations of each section when the power it turned on

Unit No. Operation Remark

Alignment unit Escape transport upper unit 1 Finisher paper entry detection OP: Paper provided. JAM display

CL: Paper empty. Go to READY

2 Paper width detection

3 Transport switch gate right drive

4 Transport switch gate left drive

Escape transport lower unit 5 Upper alignment plate drive

Alignment tray unit 6 Side guide plate alignment drive

7 Rear edge plate alignment drive

8 Rear edge plate drive

9 Side guide plate home position

10 Rear edge plate unit home position

11 Shutter drive

12 Tray paper empty detection

Staple unit 13 Staple empty detection

14 Cartridge empty detection

15 Stapling operation

16 Home position detection

17 Self priming

Others 18 Staple supply cover open/close detection

19 Tray JAM process detection

Paper exit tray unit Escape tray 20 No. 1 tray paper exit detection

21 JAM process PG open/close detection

Lift-up tray 22 No. 2 tray paper exit detection

23 Lift-up drive

24 Lift-up drive rotation control

25 Tray position detection (upper)

26 Paper position detection

27 Tray position detection (lower)

28 Tray offset drive

29 Offset home position

Main drive system 30 Main rotation drive

31 Paper exit roller rotation control

5. Operational specifications of each section

(1) Operational specifications of side guide plate

Pulse motor specifications and control

· 1 step = 7.5 degrees

· 1-2 phase drive 1200pps

· Reduction ratio 15P ® 40P = 24P (MXL tooth shape)

· Side guide plate shift for an input of 1 pulse: 0.1905mm / pulse

· Slow up/down control for tuning:

Basic operations of side guide plate

1. Moving to the standby position

· The side guide plate is moved from the home position to the

standby position according to the paper size information supplied

by the main body.

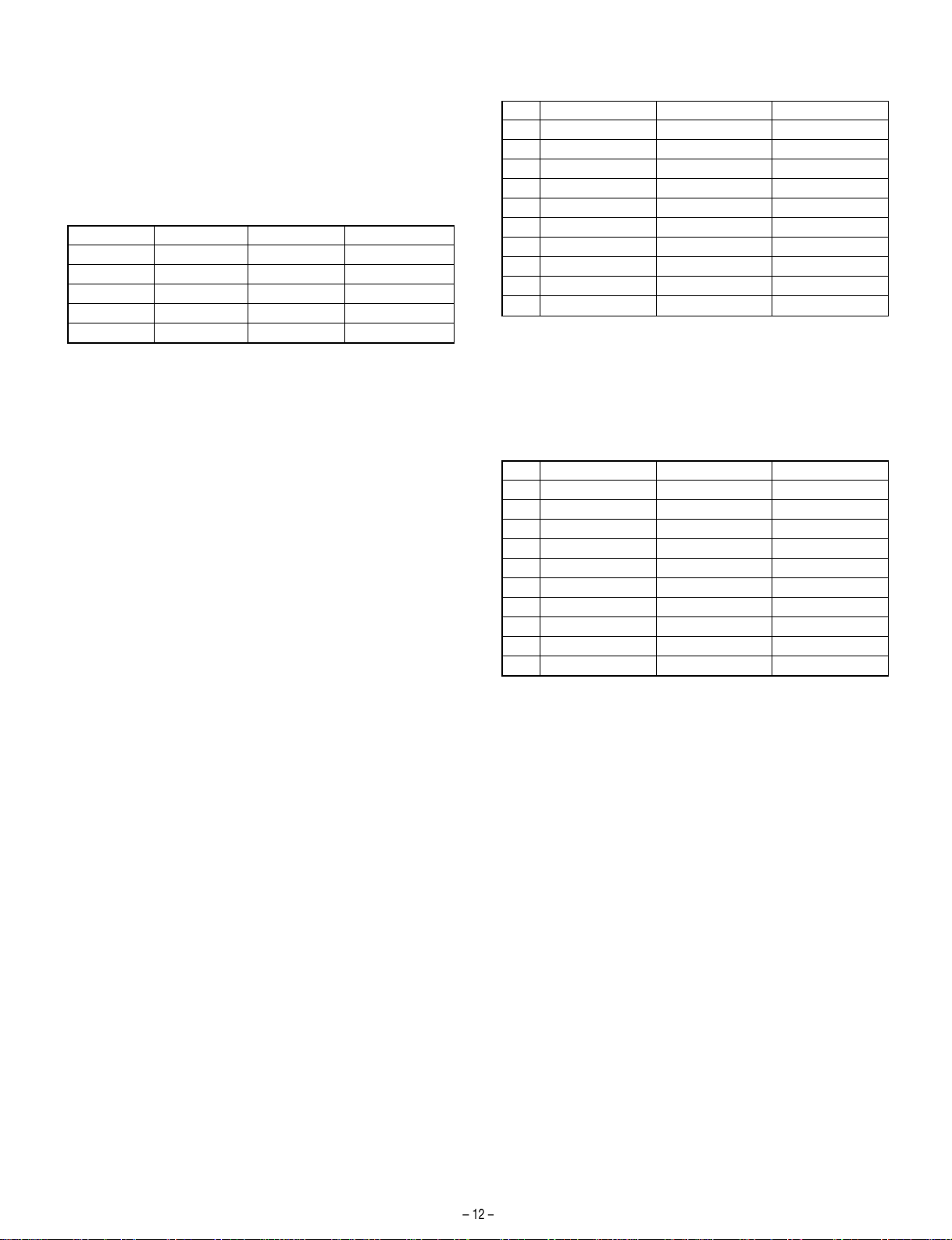

Paper width (mm) Shift quantity (mm) Pulse number (pluse)

A3, A4 297 0 0

B4, B5 257 22.1 116

A4R 210 45.5 239

WLT, LT 279.4 12.4 65

RG, LTR,GLG 215.9 42.7 224

Page 13

· The pulse number is rounded at the first digit below the decimal

point.

2. Alignment operation start

· Alignment operation is started at timer control after the paper

entry sensor is turned OFF.

¯

Timer time = 59.6(mm) / 122(mm/s) + a = About 0.7

3. Shift quantity in alignment

Paper width (mm) Shift quantity (mm) Pulse number (pluse)

A3, A4 297 27.4 144

B4, B5 257 45.3 238

A4R 210 69.0 362

WLT, LT 279.4 32.0 168

RG, LTR,GLG 215.9 65.9 346

· The pulse number is rounded at the first digit below the decimal

point.

4. Alignment operation

· Reciprocating operations in the above shift quantity are per-

formed. At the last page, the plate stops at a position about 2mm

from the edge. ® Staple process

¯

The last return is made by the pushing quantity (2).

· For provisonal alignment paper (B4 or less), the rear edge plate

passes under a bundle of paper to reach the home position, and

stands by at a position slightly wider than the paper width (about

2mm) until the final alignment is performed toward the shutter.

After completion of the final alignment, the plate stops at a position about 2mm from the edge similarly to the above, and stapling

is performed.

5. Paper exit operation

· When a bundle of paper is discharged after stapling, the side

guide plate moves to a position so as not to interfere discharging

and to prevent against skew feeding of the bundle.

¯

Paper width 12pulse (about 2.3mm)

6. Next job

· The rear edge plate pushes paper by specified distance, and

returns to the home position. The above procedures are repeated

for the next job.

· If the operation is completed wi th one job, the plate ret urns to the

home position.

(2) Operational descriptions of rear edge plate

Pulse motor specifications and control

· 1 step = 7.5 degrees

· 1-2 phase drive 847pps (600pps when discharging a paper bun-

dle)

· Reduction ratio 15P ® 20P = 26P

· Side guide plate shift for an input of 1 pulse: 0.141275mm / pulse

· Slow up/down control for tuning

Basic operations of side guide plate

1. Moving to the standby position

The side guide plate is moved from the home position to the

standby position according to the paper size information supplied

by the main body.

The standby position and the alignment operations differ depending on the following two size groups:

A3, WLT

B4, LG, FC, A 4 , B5, A4R, LT, LTR

Paper width (mm) Shift quantity (mm) Pulse number (pluse)

WLT 431.8 24.8 60

A3 420 24.8 60

B4 384 395.0 957

RG 355.6 393.8 954

GLG 330.2 368.6 893

A4R 297 335.2 812

LTR 279.4 317.8 770

LT 215.9 254.3 616

A4 210 248.5 602

B5 182 220.4 534

2. Alignment operation start

Alignment operation is started at timer control after the paper

entry sensor is turned OFF.

¯

Timer time = 59.6(mm) / 122(mm/s) + a = About 0.7

3. Shift quantity in alignment

Paper width (mm) Shift quantity (mm) Pulse number (pluse)

WLT 431.8 9.9 24

A3 420 20.6 50

B4 384 1.7 4

RG 355.6 7.4 18

GLG 330.2 8.3 20

A4R 297 8.3 20

LTR 279.4 8.3 20

LT 215.9 8.3 20

A4 210 8.3 20

B5 182 8.3 20

· The pulse number is rounded at the first digit below the decimal

point.

4. Alignment operation

· A3, WLT

Reciprocating alignment operation in the above shift quantity is

performed toward the shutter. At the last page, the plate stops at a

position about 2mm from the edge. ® Stapling process

· B4 or less

Reciprocating alignment operation in the above shift quantity is

performed toward the provisional alignment reference wall. After

the last page is aligned, the rear edge is put down, and t he unit

returns to the home position. After detection of the home position,

the rear edge plate is raised and the bundle of paper is transported

to the shutter. After completion of the final page alignment, the

plate stops at the paper edge. ® Stapling process

5. Paper exit operation

The stapled bundle of paper is lifted up by the rear edge plate and

pushed to the paper exit roller.

6. Next job

· The pushing distance of a paper bundle is a little bit greater than

the distance (71.6mm) between the shutter and the paper exit

roller. After pushing, moves toward the home position without

putting down the rear edge plate. The next job paper which is in

stand-by in front of PS is fed, and the above procedures are

repeated.

If the operation is completed with one job, the paper bundle is

Page 14

discharged and the plate returns to the home position.

[5] DISASSEMBLY AND ASSEMBLY

(3) Paper size detection

1. Body Paper-In sensor

Detects the paper size by the ON time.

¯

The following sizes cannot be judged only with the length.

A4 and A5R

A5 and postcard

LT and INVR

Some kinds of envelopes

2. Width detection of paper before discharging from the body

· No. 1 tray (escape tray) output inhibition size

¯

Postcards, envelopes

· No. 2 tray (list-up tray) output inhibition size

¯

A5, A5R, INV. INVR, postcards, envelopes

· Staple inhibition size

¯

B5R, above uncertain sizes

For disassembly, follow the sequence of the illustration numbers. For

assembly, reverse the disassembly procedures.

For disassembly and assembly of parts which are not described in this

manual, refer to the Parts Guide.

1. Finisher

A. Alignment plate unit

1-A-1

2)

4)

3)

1)

1-A-2

1-A-3

1-A-4

1)

3)

2)

4)

2)

1)

3)

Page 15

1-A-5

1)

B. Paper exit unit

1) Remove the alignment unit.

1)

2)

3. Paper exit unit and each roller

Move down the offset tray unit to the bottom, and remove the paper

exit unit from the copier.

Then remove the rollers from the paper exit unit.

Procedures to move down the offset tray unit to the bottom

2)

1)

1-B-1

1-B-2

3)

When turning on the power, lift the paper holding lever which

detects the top of the tray with your fingers.

When the tray reaches the bottom, turn off the power. (When

the lever moves about half of the moving distance, you may

release your fingers, and the tray will fall to the bottom.)

3-1

2. Stapler unit

1) Remove the alignment unit.

2-1

3-2

1)

2)

Page 16

3-3

1)

3-7

2)

3-4

3-5

2)

1)

3)

2)

3-8

1)

1)

1)

2)

2)

3)

3-6

1)

1)

1)

1)

2)

1)

3-9

3-10

2)

3)

2)

1)

1)

2)

Page 17

3-11

2)

A. ESC paper exit roller

B. ESC transport roller

C. Upper paper exit roller

3-A-1

1)

2)

3-12

3-13

2)

2)

1)

1)

2)

3)

3)

1)

2)

2)

2)

3-A-2

1)

3-A-3

1)

5)

2)

2)

2)

1)

1)

3)

3)

2)

1)

4)

3-A-4

1)

1)

2)

3)

4)

4)

1)

2)

3)

Page 18

4. Paper exit unit motor

A. Main drive motor

4-A-1

C. Lift-up motor

Note: Perform this procedure after removing the right cabinet (Step

3-5).

Refer to Fig.(3-1) to (3-6).

4-C-1

4-A-2

2)

1)

3)

4)

2)

1)

3)

4-C-2

1)

3)

1)

2)

3)

2)

1)

B. Offset tray drive motor

Refer to Fig.(3-1) to (3-4).

2)

4-B-1

3)

1)

5. Paper exit unit solenoid

Refer to Fig.(3-1) to (3-6).

5-1

1)

2)

3)

Page 19

5-2

2)

6-2

3)

1)

2)

1)

3)

4)

2)

5-3

1)

6. Alignment unit roller

6-1

2)

1)

6-3

6-4

1)

2)

2)

1)

3)

4)

6)

5)

4)

Page 20

7. Alignment unit motor

Refer to Fig.(6-1) to (6-2).

7-1

7-4

1)

3)

1)

7-2

1)

1)

1)

2)

2)

3)

3)

2)

4)

4)

5)

5)

8. Alignment unit sol enoid

Refer to Fig.(7-1) to (7-2).

A. Upper alignment plate drive solenoid

8-1

1)

7-3

1)

2)

1)

2)

B. Transport switch gate solenoid right

8-2

2)

2)

1)

Page 21

C. Rear edge plate solenoid

Refer to Fig.(7-3).

1)

8-3

2)

8-4

3)

5)

[6] ADJUSTMENTS

Adjustments are required when replacing the following parts:

A. Rear edge plate unit

B. Side guide plate

C. Gate solenoid right

4)

2)

D. Gate solenoid left

E. Upper alignment solenoid

F. Shutter solenoid

G. Rear edge plate solenoid

H. Paper holding solenoid

A. Rear edge plate unit

1. Staple 5 sheets of A4 or LT paper, and check the slide shift of the

paper bundle in the transport direction (Y-axis).

2. When the shift of the paper bundle is within 1mm, there is no need

to adjust.

3. If the shift of the paper bundle is greater than 1mm, execute SIM

3-6-3 to adjust the rear edge plate position.

D. Shutter drive solenoid

Refer to Fig.(7-3).

8-5

2)

3)

E. Transport switch gate solenoid

Refer to Fig.(1-A-1) to (1-A-5).

Refer to Fig.(6-1) to (6-2).

8-7

2)

1)

B. Side guide plate

1. Staple 5 sheets of A4 or LT paper, and check the slide shift of the

paper bundle in the vertical direction (X-axis) to the transport direction.

2. When the shift of the paper bundle is within 1mm, there is no need

to adjust.

4)

1)

1)

3. If the shift of the paper bundle is greater than 1mm, execute SIM

3-6-2 to adjust the side guide plate position. Also check that the

paper bundle is in parallel with the alignment reference wall of the

side guide plate.

SIM 3-6 Finisher alignment member adjustment

(Initial screen)

Sim3-6 JOGGER ADJ.

1:PAPER SIZE

2:JOGGER POS X

3:JOGGER POS Y

1

When a sub code is entered, the above display is shown.

1. In SIM 3-6-1, press [OK] and select [1] - [10] to specify the paper

size.

2. Enter SIM 3-6-2 Jogger pos X (side guide plate) or SIM 3-6-3

Jogger pos Y (rear edge plate) and press [OK]. The alignment

section (rear edge plate unit), side guide plate) will be operated.

During the load operation, the [OK] key is highlighted.

3. Keep the alignment member at the paper alignment position, and

open the alignment section. Insert paper of the sam e size into the

alignment member and check that the tightness is proper. 1~2 mm

smaller (tight) than the paper size is O.K.

4. When the adjustment value of the simulation is decreased by 1,

the clearance between paper and the side guide plate is decreased by 0.41mm, and between paper and the rear edge plate

0.83mm, and vice versa.

Page 22

C. Gate solenoid right

E. Upper alignment solenoid

Mark the solenoid installing position before replacement, and fix a new

one to the marked position.

After fixing, press the plunger with your finger to adjust so that the

lead edge of the gate right is in a position 16.5mm ~ 17mm apart from

the alignment tray transport surface. Release the finger and check

that it returns smoothly by the spring and that the lead edge of the

gate right is in a position 36mm apart from the transport surface.

36mm

Mark the solenoid installing position before replacement, and fix a new

one to the marked position.

After fixing, pull the plunger with your finger and check that the upper

alignment holding plate is in contact with the alignment tray. Then

release the finger and check that the plunger returns sm oothly by the

spring.

16.5 17

mm

D. Gate solenoid left

Mark the solenoid installing position before replacement, and fix a new

one to the marked position.

After fixing the solenoid, check and adjust so that the gate left edge is

in contact with the transport surface on the transport PG with the

plunger released, and so that the gate left edge is 6.5 - 7mm from the

transport surface.

F. Shutter solenoid

Mark the solenoid installing position before replacement, and fix a new

one to the marked position.

After fixing, pull the plunger with your finger and check that the shutt er

rotates 90 degrees and makes contact with the tray. Then release the

finger and check that the shutter returns smoothly by the spring and

that it is vertical to the alignment tray after returning.

O

90

6.5 7mm

Page 23

G. Rear edge plate solenoid

H. Paper holding solenoid

Mark the solenoid installing position before replacement, and fix a new

one to the marked position. (The solenoid and the installing plate

positions are determined by the round hole.)

After fixing, pull the plunger with your finger and check that the rear

edge plate rotates 90 degrees and makes contact with the rear edge

plate slide. Then release the finger and check that the rear edge plate

returns smoothly by the spring and that it is vertical to the alignment

tray after returning.

Fix the paper holding solenoid below the long fixing hole so that the

whole paper hold installing plate unit is in the lower limit of the adjustment range.

(The solenoid and the installing plate positions are determined by the

round hole.)

[7] MAINTENANCE

Note: Before maintenance, disconnect the power cable from the body.

Be sure to avoid communication during maintenance. It is very dangerous.

For maintenance, refer to the DISASSEMBLY AND ASSEMBLY and the Parts Guide.

The table below shows the maintenance parts and the work contents.

Part name Work content Condition of execution Cycle

Transport rollers Cleaning Maintenance/Servicing 40K or 2 years

Paper guides Cleaning Maintenance/Servicing 40K or 2 years

Gears Lubrication, greasing Maintenance/Servicing 40K or 2 years

Belts Check Maintenance/Servicing 80K or 2 years

Staple unit Replacement Maintenance/Servicing 200K (Number of operations)

Sensors Check Maintenance/Servicing 40K or 2 years

OF roller cleaner Cleaning Maintenance service When the lead edge or rear edge of paper is dirtied or at 20 - 25K

For maintenance of the OF roller cleaner, refer to the figure below.

Reference: 65 ~ 66 times of staple replacement

Page 24

[8] TROUBLESHOOTING

1. List

Trouble code

Main code Sub code

F1 00 Finisher communication trouble FIN

01 Finisher jogger shift trouble

06 Finisher shift motor abnormality

08 Finisher staple shift motor trouble

11 Pusher motor trouble

15 Finisher elevator motor trouble

Details of trouble Trouble detection

2. Selfdiagnostics

Trouble code

Main code Sub code

F1 00 Content Finisher communication trouble

Details Communication li ne test error occurs when power is turned on or after the exit of a simulation mode.

Cause Connection trouble or disconnection of the connector and harness between the body and the finisher.

Check and

remedy

01 Content Finisher jogger shift trouble

Details Jogger shift trouble

Cause Motor lock.

Check and

remedy

06 Content Finisher shift motor abnormality

Details Finisher shif t motor breakdown

Cause Motor lock

Check and

remedy

08 Content Finisher staple shift motor trouble

Details Staple motor drive trouble

Cause Motor lock.

Check and

remedy

11 Content Pusher motor trouble

Details Pusher motor trouble

Cause Motor lock

Check and

remedy

15 Content Finisher elevator motor trouble

Details Elevator motor trouble

Cause Motor lock.

Check and

remedy

Error in Finisher communication

Finisher control PWB trouble Control PWB failure Malfunction by noises

Turn off/of the power to cancel the trouble.

Check connector/harness of communication line

Replace the finisher control PWB.

Motor rpm abnormality

Overcurrent to motor

Finisher control PWB failure

Check the jogger motor operation with SIM 3-3.

Motor rpm abnormality

Overcurrent to motor

Finisher control PWB failure

Check the shift motor operation with SIM 3-31.

Motor rpm abnormality

Overcurrent to motor

Finisher control PWB failure

Check the operation of the staple motor with SIM 3-3.

Motor rpm abnormality

Overcurrent to motor

Finisher control PWB failure

Check the pusher motor operation with SIM 3-3.

Motor rpm abnormality

Overcurrent to motor

Finisher control PWB failure

Check the elevator motor operation with SIM 3-31.

Details of trouble

Page 25

3. Troubleshooting

1) Copier communication trouble (F1-00)

Check item Step Cause/Trouble position Result Remedy

Is the illustration of the finisher displayed on the LCD of

the operation panel?

Is the power supplied normally? (5V, 3.3V) 2 Machine OP interface PWB No Replace the OP interface PWB.

Does replacement of the finisher PWB cancel the trouble? 3 Finisher PWB Yes End

2) Paper exit unit trouble

2-1) Lift-up motor trouble (F1-15)

Check item Step Cause/Trouble position Result Remedy

Do the offset tray upper limit and lower limit sensors

respond correctly?

Does the paper hold sensor respond correctly? 2 Paper hold sensor No Replace the sensor(s). Check

Does the lift-up encoder respond correctly? 3 Lift-up encoder No Replace the sensor(s). Check

Is wiring between the finisher PWB and the lift-up motor

normal?

Does replacement of the offset motor cancel the trouble? 5 Lift-up motor No Replace the lift-up motor.

Does replacement of the finisher PWB cancel the trouble? 6 Finisher PWB Yes End

2-2) Offset motor trouble (F1-06)

Check item Step Cause/Trouble position Result Remedy

Does the offset tray home position sensor respond

normally?

Is the wiring between the finisher PWB and the offset

motor proper?

Does replacement of the offset motor cancel the trouble? 3 Offset motor No Replace the offset motor.

Does replacement of the finisher PWB cancel the trouble? 4 Finisher PWB Yes End

1 Machine connection cable No Replace the machine connection

cable.

1 Upper/lower limit sensors No Replace the sensor(s). Check

wiring.

the wiring.

wiring.

4 Wiring No Replace or repair the wiring.

1 Offset home position sensor No Replace the sensor. Check the

wiring.

2 Wiring No Replace or repair the wiring.

3) Alignment unit trouble

3-1) Side guide plate hom e po si tio n err o r (F1-0 1)

Check item Step Cause/Trouble position Result Remedy

Does the side guide plate position sensor respond

normally?

Is the wiring between the finisher PWB and the side guide

plate motor proper?

Does replacement of the side guide plate cancel the

trouble?

Does replacement of the finisher PWB cancel the trouble? 4 Finisher PWB Yes End

1 Side guide plate home position

sensor

2 Wiring No Replace or repair the wiring.

3 Side guide plate motor No Replace the side guide plate

No Replace the sensor. Check the

wiring.

motor.

3-2) Rear edge plate home position error (F1-11)

Check item Step Cause/Trouble position Result Remedy

Does the rear edge plate position sensor respond

normally?

Is the wiring between the finisher PWB and the rear edge

plate motor proper?

Does replacement of the rear edge plate motor cancel

the trouble?

Does replacement of the finisher PWB cancel the trouble? 4 Finisher PWB Yes End

1 Rear edge home position sensor No Replace the sensor. Check the

wiring.

2 Wiring No Replace or repair the wiring.

3 Rear edge plate motor No Replace the rear end plate

motor.

4) Staple motor error (F1-08)

Check item Step Cause/Trouble position Result Remedy

Does the home position sensor respond normally? 1 Staple unit No Replace the staple unit.

Is the wiring of the finisher staple unit proper? 2 Wiring No Replace or repair the wiring.

Does replacement of the staple unit cancel the trouble? 3 Staple unit No Replace the staple unit.

Dose replacement of the finisher PWB cancel the trouble? 4 Finisher PWB Yes End

Page 26

[9] CIRCUIT DESCRIPTIONS

1. General

The finisher main circuit sends/receives commands to/from the copier’s MCU PWB, and control s loads according to the commands and controls

input/output of sensor/switch information.

The finisher is composed of this circuit, the circuit which makes inputs from sensors and switches, the circuit which drives motors/solenoids/clutches,

ROM, RAM, and the peripheral circuits.

2. Block diagram

The finisher block diagram is shown below.

FINISHER BLOCK DIAGRAM

2TRAY FINISHER

COPIER

/FINCRDY

/FINSRDY

STAPLE SWITCH

CARTRIDGE SWITCH

P-IN SENSOR

PAPER WIDE SENSOR

TRAY1 P-OUT SENSOR

TRAY2 P-OUT SENSOR

STAPLE HP SENSOR

SELF PRIMING SENSOR

LIFT UP ENCODE

SIDE HP SENSOR

BACK HP SENSOR

TRAY2 UP SENSOR

TRAY2 DOWN SENSOR

ADJUST TRAY PAPER

SENSOR

PAPER POSITION SENSOR

(T2PD)

TRAY1 P-FULL SENSOR

OFFSET HP SENSOR

FINSTS

FINCMD

/RES

Reserved

/FINDET

GP1S44S1

GP1S44S1

GP1S44S1

GP1S44S1

GP1A71A

GP1A71A

GP1A71A

GP1A71A

GP1A71A

GP1A71A

GP1A71A

GP1A71A

GP1A71A

GP1A71A

GP1A71A

9.8304MHz

+24V

PS

+5V

+3.3V

S-GND

P-GND

BUFFER

LS244

BUFFER

LS244

H8S/2350

/CRDY

/SRDY

RxD

TxD

/RES

CPU

RAM

2K

A0~A16

D0~D15

RY/BY

/WE

/CE

/OE

(256K bit)

FLASH ROM

M29F200BA

DRIVER

MTD1361

DRIVER

MTD1361

DRIVER

MTD1361

DRIVER

DRIVER

TA7291P

DRIVER

TA7291P

DRIVER

TD62318

DRIVER

TD62318

Level

switch

circuit

SRAM

+24V

PULSE

MAIN MOTOR

MOTOR

BACK BOARD

PULSE

MOTOR

PULSE

MOTOR

DC

MOTOR

DC

MOTOR

DC

MOTOR

SL

SL

SL

SL

SL

CL

SL

MOTOR

SIDE CONTROL

STAPLER MOTOR

LIFT UP MOTOR

OFFSET MOTOR

GATE-L SOLENOID

ADJUST SOLENOID

SHUTTER SOLENOID

GATE-R SOLENOID

BACK BOARD

SOLENOID

P-OUT CLUTCH

PAPER HOLD

SOLENOID

STAPLER COVER

SWITCH

PG COVER SWITCH

MOTOR

SW24

+5V

TRAY COVER SWITCH

Page 27

3. CPU (H8S/2350)

3.1. General

The CPU controls the finisher loads and controls the system by sending/receiving commands to/from the machine MCU PWB through the

serial communication line.

3.2. Features

The H8S/2350 is a microcomputer based on the H8S/2000 CPU, in

which the peripheral functions required for the system are integrated.

The H8S/2000 CPU is of internal 32bit composition, and is equipped

with the general-purpose registers of 16bit x 16 and the simple, optimized command set with high-speed operations. It can handle 16MB

linear address space.

Its major functions include the DMA controller (DMAC), the bus master of the data transfer controller (DTC), RAM, memory, the 16bit timer

pulse unit (TPU), the programmable pulse generator (PPG), the watch

dog timer (WDT), the serial communication interface (SCI), the A/D

converter, the D/A converter, the I/O port, and other peripheral functions.

3.3. Pin configuration

AVCC

VREF

P40/AN0

P41/AN1

P42/AN2

P43/AN3

P44/AN4

P45/AN5

P46/AN6/DA0

P47/AN7/DA1

AVSS

VSS

P17/PO15/TIOCB2/TCLKD

P16/PO14/TIOCA2

P15/PO13/TIOCB1/TCLKC

P14/PO12/TIOCA1

P13/PO11/TIOCD0/TCLKB

P12/PO10/TIOCC0/TCLKA

P11/PO9/TIOCB0/DACK1

P10/PO8/TIOCA0/DACK0

MD0

MD1

MD2

PG0/CAS

PG1/CS3

PG2/CS2

φ

P52

P51

P53/ADTRG

102

101

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

12345678910111213141516171819202122232425262728293031323334353637

P50

PF2/LCAS/WAIT/BREQ0

PF1/BACK

VSS

VSS

9998976995949392919089888786858483828180797877767574737271706968676665

100

PF3/LWR

PF0/BREQ

PF4/HWR

PF5/RD

PF6/AS

PF7/

EXTAL

VSS

XTAL

VCC

VCC

STBY

NMI

WDTOVF

RES

P21/PO1/TIOCB3

P20/PO0/TIOCA3

P27/PO7/TIOCB5

P26/PO6/TIOCA5

P25/PO5/TIOCB4

P24/PO4/TIOCA4

P23/PO3/TIOCD3

P22/PO2/TIOCC3

P63/TEND1

P62/DREQ1

VSS

VSS

P60/DREQ0/CS4

P61/TEND0/CS5

VSS

38

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

P35/SCK1

P34/SCK0

P33/RXD1

P32/RXD0

P31/TXD1

P30/TXD0

VCC

PD7/D15

PD6/D14

PD5/D13

PD4/D12

VSS

PD3/D11

PD2/D10

PD1/D9

PD0/D8

PE7/D7

PE6/D6

PE5/D5

PE4/D4

VSS

PE3/D3

PE2/D2

PE1/D1

PE0/D0

VCC

VSS

PG3/CS1

PG4/CS0

VSS

VCC

PC0/A0

VSS

PC1/A1

PC2/A2

PC3/A3

PC4/A4

PB0/A8

PC5/A5

PC6/A6

PC7/A7

PB1/A9

PB2/A10

PB3/A11

VSS

PB4/A12

PB5/A13

PB6/A14

PB7/A15

PA0/A16

PA1/A17

PA2/A18

PA3/A19

VSS

PA5/A21/IRQ5

PA6/A22/IRQ6

PA7/A23/IRQ7

PA4/A20/IRQ4

VSS

VSS

P65/IRQ1

P67/CS7/IRQ3

P66/CS6/IRQ2

P64/IRQ0

Page 28

3.4. CPU H8S2350 port table

Pin No. Signal name CPU operation mode Input/Output Function Logic

1 CS1 /CS1 Output Chip Select L; Select

2 CS0 /CS0 Output Chip Select L; Select

3 Vss Vss Power Power GND

4NC NC NCNC GND

5 Vcc Vcc Power Power 5V

6 A0 A0 Output System Bus (Address)

7 A1 A1 Output System Bus (Address)

8 A2 A2 Output System Bus (Address)

9 A3 A3 Output System Bus (Address)

10 Vss Vss Power Power GND

11 A4 A4 Output System Bus (Address)

12 A5 A5 Output System Bus (Address)

13 A6 A6 Output System Bus (Address)

14 A7 A7 Output System Bus (Address)

15 A8 A8 Output System Bus (Address)

16 A9 A9 Output System Bus (Address)

17 A10 A10 Output System Bus (Address)

18 A11 A11 Output System Bus (Address)

19 Vss Vss Power Power GND

20 A12 A12 Output System Bus (Address)

21 A13 A13 Output System Bus (Address)

22 A14 A14 Output System Bus (Address)

23 A15 A15 Output System Bus (Address)

24 A16 A16 Output System Bus (Address)

25 A17 A17 Output System Bus (Address) Not Used

26 A18 A18 Output System Bus (Address) Not Used

27 A19 A19 Output System Bus (Address) Not Used

28 Vss Vss Power Power GND

29 A20 A20 Output System Bus (Address) Not Used

30 /T2OD# PA5, /IRQ5 Input Tray2 Paper Out Sensor L; Paper Detect

31 CASW# PA6, /IRQ6 Input Cartridge Switch H; No Cartridge

32 /SEPL# PA7, /IRQ7 Input Self Priming Sensor L; Ready

33 STHP# P67, /IRQ3 Input HP Sensor L; Home Position

34 SNSW P66, /IRQ2 Input Stapler Needle Switch H; No Needle

35 Vss Vss Power Power GND

36 Vss Vss Power Power GND

37 WDPD# P65, /IRQ1 Input Paper Wide Detect L; Paper Detect

38 INPD# P64, /IRQ0 Input Paper in Sensor L; Paper Detect

39 Vcc Vcc Power Power 5V

40 STM+ PE0 Output Stapler Motor Control H; ON(+)

41 STM- PE1 Output Stapler Motor Control H; ON(-)

42 LUM+ PE2 Output Lift Up Motor Control H; ON(+)

43 LUM- PE3 Output Lift Up Motor Control H; ON(-)

44 Vss Vss Power Power GND

45 OFM+ PE4 Output Offset Motor Control H; ON(+)

46 OFM- PE5 Output Offset Motor Control H; ON(-)

47 GLSL1 PE6 Output Gate-L Solenoil Drive H; ON(1)

48 GLSL2 PE7 Output Gate-L Solenoil Drive H; ON(2)

49 D0 D8 Bi-Directional System Bus (DATA)

50 D1 D9 Bi-Directional System Bus (DATA)

51 D2 D10 Bi-Directional System Bus (DATA)

52 D3 D11 Bi-Directional System Bus (DATA)

53 Vss Vss Power Power GND

54 D4 D12 Bi-Directional System Bus (DATA)

55 D5 D13 Bi-Directional System Bus (DATA)

56 D6 D14 Bi-Directional System Bus (DATA)

57 D7 D15 Bi-Directional System Bus (DATA)

58 Vcc Vcc Power Power 5V

59 FINCMD TxD0 Output

60 FMMD P31 Out put Main Motor Current Control H; Low

61 FINSTS RxD0 Input

62 BKMD P33 Output Back Motor Current Control H; Low

63 SDMD P34 Output Side Motor Current Control H; Low

Page 29

Pin No. Signal name CPU operation mode Input/Output Function Logic

64 DCCON P35 Output DC Motor ON/OFF Control H; ON

65 Vss Vss Power Power GND

66 reserve P60

67 Vss Vss Power Power GND

68 Vss Vss Power Power GND

69 /T1OD# P61 Input Tray1 Paper Out Sensor L; Paper Detect

70 STSL P62 Output Shutter Solenoid Drive H; ON

71 AJSL P63 Output Adjust Solenoid Drive H; ON

72 FMM/B P27 Output Main Motor Drive

73 FMM/A P26 Output Main Motor Drive

74 FMMB P25 Output Main Motor Drive

75 FMMA P24 Output Main Motor Drive

76 SDM/B P23 Output Side Control Motor Drive

77 SDM/A P22 Output Side Control Motor Drive

78 SDMB P21 Output Side Control Motor Drive

79 SDMA P20 Output Side Control Motor Drive

80 N.C. /WDTOVF Output Watch Dog Timer Overflow

81 /RES /RES Input Master Reset L; RESET

82 N.C. NMI Input Not Used

83 N.C. /STBY Input Not Used

84 Vcc Vcc Power Power 5V

85 XTAL XTAL Input Oscilator Input

86 EXTAL EXTAL Input Oscilator Input

87 Vss Vss Power Power GND

88 /RCSREA DY PF7 Input

89 Vcc Vcc Power Power 5V

90 N.C. /AS Output Address Strobe

91 /RD /RD Output Read Strobe L; Active

92 /HWR /HWR Output High Write Strobe L; Active

93 N.C. /LWR Output Low Write Strobe

94 RD/ BY PF2 Input Lady/Busy Signal

95 /FINCRDY# PF1 Input L; Active

96 /FINSRDY# PF0 Output L; Active

97 /OFSL P50 Output Offset Solenoid Drive L; ON

98 / ORCL P51 Output P-Out Roller Clutch L; ON

99 Vss Vss Power Power GND

100 Vss Vss Power Power GND

101 GRSL P52 Output Gate-R Solenoil Drive L; ON

102 BKSL P53 Output Back Solenoid Drive L; ON

103 Vcc AVcc Power Power (Analog) 5V

104 Vcc Vref Reference Reference Voltage 5V

105 SDHP# P40 Input Side Motor HP Sensor H; Home Posit ion

106 BKHP# P41 Input Back Motor HP Sensor H; Home Position

107 T2UP# P42 Input Tray2 Up sensor L, L; Up

108 T2DN# P43 Input Tray2 Down sensor L, H; Down

109 T1PD# P44 Input Tray1 Paper Position Sensor L; Paper Detect

110 T2PD# P45 Input Tray2 Paper Position Sensor L; Paper Detect

111 reserve P46

112 ATPD# P47 Input Adjust Tray Paper Sensor H; Paper Detect

113 Vss AVss Power Power (Analog) GND

114 Vss Vss Power Power GND

115 BKM/B P17 Output Back Control Motor Drive

116 BKM/A P16 Output Back Control Motor Drive

117 BKMB P15 Output Back Control Motor Drive

118 BKMA P14 Output Back Control Motor Drive

119 OFHP# P13 Input Offset Motor Home Position H; Home Position

120 LUEN# P12 Input Lift Up Encorder Sensor

121 reserve P11

122 reserve P10

123 MD0 MD0 Input Mode Select 0 H

124 MD1 MD1 Input Mode Select 1 L

125 MD2 MD2 Input Mode Select 2 H

126 TCSW PG0 Input Tray Cover Monitor L; Open

127 SCSW PG1 Input Stapler Cover Monitor L; Open

128 PGSW PG2 Input PG Cover Monitor L; Open

Page 30

4. I/F circuit and reset circuit

This unit performs serial communication with the copier in the advancement synchronization mode where synchronization is made in

the unit of a character.

The signal (FINSTS) sent from the machine and the communication

allow signal (/FINCRDY) are received by the CPU on the finisher side

through the buffer circuit. Similarly, the send signal (FINCMD) from

the finisher and the communication allow signal (/FINSRDY) are received by the CPU on the machine through the buffer IC 74VHC244

(IC104).

Similarly, the reset signal is passed to the CPU reset pin on the

finisher side through the IC105.

Signal name Content Logic (Connector level)

FINSTS Line of signals sent from the copier to the finisher H: Start bit detected

L: Normal (Mark state)

FINCMD Line of signals sent from the finisher to the copier L: Start bit detected

/FINCRDY Line of signal which indicates the status of the communication request answer when

sending signals from the finisher to the copier

/FINSRDY Line of signal which indicates the status of the communication request when sending

signals from the finisher to the copier

/RES Line of hard reset signal from the copier L: Reset state

H: Normal (Mark state)

H: Communication disable

L: Communication enable

H: No request for communication

L: Communication request state

H: Reset cancel state

PF1

RxD0

/RES

P60

PF0

TxD0

/FINCRDY#

FINSTS#

/RES

reserve

/FINSRDY#

FINCMD#

5V

R141

4.7k

C145

1000pF/50V

5V

R142

4.7k

C146

1000pF/50V

45

22000pF/25V

5

5V

182736

BR1

10kX4

IC105

18

1Y1

16

1Y2

14

1Y3

12

1Y4

9

2Y1

7

C139

5V

1827364

BR2

10kX4

C180

0.1uF/25V

2Y2

5

2Y3

3

2Y4

74VHCT244M

20

11

13

15

17

19

10

3.3V

2

4

6

8

1

5V

20

VCC

1A1

1A2

1A3

1A4

2A1

2A2

2A3

2A4

1G

2G

GND

10

IC104

VCC

1A1

1A2

1A3

1A4

2A1

2A2

2A3

2A4

1G

2G

GND

74VHC244M

2

4

6

8

11

13

15

17

1

19

18

1Y1

16

1Y2

14

1Y3

12

1Y4

9

2Y1

7

2Y2

5

2Y3

3

2Y4

C181

0.1uF/25V

/FINCRDY

FINSTS

/RES

/FINSRDY

FINCMD

Page 31

5. Sensor input circuit

Any input signal from each sensor is connected to the pull-up resistor

(10Kohm) and the noise-eliminating capacitor (1000pF), and passed

through the buffer IC (74LS244) to the CPU input port.

5V

5V

0.1uF/25V

20K

PHOTO

UDZS5.6B

1000pF/50V

6. Switch input circuit

This circuit detects open/close of the PG staple cover. When the cover

is closed, the contact is closed and the micro switch is closed.

The switches are connected in series to the +24V, forming the power

switch of the drive sections (the staple motor and the main motor).

Only when two micro switches are closed, +24V is supplied.

The tray cover switch is not treated as an interlock. When the cover is

open, it is not driven.

When the PG cover switch is open, staple cover open is not detected.

VCC

20

2

1A1

4

1A2

6

1A3

8

1A4

11

2A1

13

2A2

15

2A3

17

2A4

1

1G

19

2G

10

GND

74LS244

5V

1Y1

1Y2

1Y3

1Y4

2Y1

2Y2

2Y3

2Y4

18

16

14

12

9

7

5

3

CPU

24V

D12

PG cover SW

Staple cover SW

0.047uF/50V

Signal

Status

C193

1SS133

D9

1SS133

C194

0.047uF/50V

PGSW SCSW Remark

Machine power interruption d.c. d.c.

PG cover SW open L d.c.

Stapler cover SW open H L

R179

20K

R177

20K

0.22/2W

D8

1SS133

D15

1SS133

128PGSW

PG2

127

SCSW

+24V

C182

0.047uF/

50V

5V

D10

1SS133

D11

1SS133

C183

0.047uF/50V

R180

4.7K

R178

4.7K

R8

C197

0.047uF/

50V

C195

0.047uF/

50V

C198

0.047uF/

50V

C196

0.047uF/50V

R9

1K/2W

D13

1SS133

PG1

CPU(IC1)

(To each motor)

L: DOOR OPEN (or POWER OFF)

H: DOOR CLOSE (POWER ON)

d.c. unsettled (Since power is turned off on the upper side,

the status cannot be seen.)

Page 32

7. Solenoid/clutch drive circuit

The solenoid/clutch drive circuit uses non-reverse type transistor array

TD62318AF (IC6, 9). When the input signal is at LOW, the solenoid

and the clutch are turned on.

24V

24V

GLSL1D

GLSL2D

STSLD

AJSLD

ORCLD

BKSLD

GRSLD

OFSLD

5V

IC9

1

VCC1

2

O1

15

O4

8 9

VCC2

7

O2

10

O3

4

GND

5

GND

5V

IC6

1

VCC1

2

O1

15

O4

8 9

VCC2

7

O2

10

O3

4

GND

5

GND

COM

COM

GND

GND

TD62318AF

COM

COM

GND

GND

TD62318AF

24V

16

3

I1

14

I4

6

I2

11

I3

12

13

24V

16

3

I1

14

I4

6

I2

11

I3

12

13

/GLSL1

/GLSL2

/STSL

/AJSL

ORCL

BKSL

GRSL

OFSL

70

71

102

101

47

PE6

48

PE7

P62

P63

98

P51

P53

P52

97

P50

CPU(IC8)

8. Pulse motor drive circuit

There are three kinds of pulse motors: the transport motor which

drives rollers for paper transport, the side guide plate motor which

aligns paper in the vertical direction to the paper transport direction,

and the rear edge plate motor which aligns in the paper transport

direction.

· Drive pattern of the side guide plate/rear edge plate motor and the main transport motor (1200dpi)

Stop excitement

between jobs

A

B

/A

/B

SDM

BKM

FMM

Front side

Paper exit side

Paper exit side

The control signal sent from the CPU is passed to the driver IC

MTD1361 (IC1, 2, 7) exclusive for each pulse motor, driving each

motor.

The drive system is the uni-polar 1-2 phase (switchover between

2-phase and 1-2 phase for the transport motor) excitem ent constantcurrent drive system.

The drive pattern of each motor is shown below.

Yes

Yes

Rear side

Paper entry side

No reverse

Page 33

· Drive pattern of the transport motor (600dpi)

A

B

/A

/B

FMM

SDM

FMM

24VM

FMMDA

FMMDB

FMMD/A

FMMD/B

24VS

SDMDA

SDMDB

SDMD/A

SDMD/B

Paper exit side

F4

ICP-N38

+

C5

47uF/35V

F5

ICP-N38

+

C6

47uF/35V

C120

0.047uF/

50V

C125

0.047uF/

50V

SW24V

10

18

20

17

16

15

14

12

11

13

21

27

24V

10

18

20

17

16

15

14

12

11

13

21

27

C121

0.047uF/50V

IC1

1

8

7

MTD1361

C126

0.047uF/50V

IC2

1

8

7

MTD1361

Vmm

OUT A

OUT B

OUT /A

OUT /B

NC

NC

NC

NC

NC

NC

PG

PG

PG

LG

Vmm

OUT A

OUT B

OUT /A

OUT /B

NC

NC

NC

NC

NC

NC

PG

PG

PG

LG

VrefA

VrefB

VrefA

VrefB

R1

390/2W

C3

47uF/35V

24V

1.0/2W

1.0/2W

1.0/2W

1.0/2W

7.5K

C109

0.1uF/25V

C106

0.1uF/25V

R125

7.5K

C113

0.1uF/25V

C110

0.1uF/25V

C122

2200pF/50V

C127

2200pF/50V

R119

2.4K

R117

2.4K

R124

R122

2.4K

2.4K

0.1uF/25V

0.1uF/25V

C117

0.1uF/

R127

510

R126

330

Q1

DTC114EK

R118

C119

68

10k

10k

R129

510

R128

330

Q2

DTC114EK

R123

C124

68

10k

10k

25V

R116 R120

7.5K

C118

2200pF/

50V

C108

3300pF/50V

2

CrA

26

CrB

4

VsA

9

RsA

3

25

19

RsB

24

VsB

5

In /A

6

In A

23

In /B

22

In B

2

CrA

26

CrB

4

VsA

9

RsA

3

25

19

RsB

24

VsB

5

In /A

6

In A

23

In /B

22

In B

R112

1K

R3

R2

R111

1K

C107

3300pF/50V

182736

45

BR3

10X4

R121

7.5K

C123

2200pF/

50V

C112

3300pF/50V

R114

1K

R5

R4

R113

1K

C111

3300pF/50V

182736

45

BR4

10kX4

3

C4

100uF/16V

VOUT

IC3

KIA7805

FMM/A 77

FMMA 79

FMM/B 76

FMMB 78

FMMD 60

SDM/A 73

SDMA 75

SDM/B 76

SDMB 78

SDMD 63

1

VIN

GND

2

CPU(IC8)

SDM

24VB

BKMDA

BKMDB

BKMD/A

BKMD/B

F10

ICP-N38

47uF/35V

24V

+

C7

C152

0.047uF/

50V

1

10

18

8

20

17

16

15

14

12

11

7

13

21

27

C153

0.047uF/50V

IC7

Vmm

OUT A

OUT B

OUT /A

OUT /B

NC

NC

NC

NC

NC

NC

PG

PG

PG

LG

MTD1361

VrefA

VrefB

2

CrA

26

CrB

4

VsA

9

RsA

3

25

19

RsB

24

VsB

5

In /A

6

In A

23

In /B

22

In B

R135

1K

R134

1K

45

R147

7.5K

182736

3300pF/50V

BR7

10kX4

C150

2200pF/

50V

C142

3300pF/50V

C143

R7 1.0/2W

R6 1.0/2W

C141

R151

7.5K

0.1uF/25V

C140

0.1uF/25V

C154

2200pF/50V

R150

R148

2.4K

2.4K

0.1uF/25V

R153

510

R152

330

BKM/A 116

BKMA 118

BKM/B 115

BKMB 117

Q5

DTC114EK

R149

C151

68

10k

10k

BKMD 62

Page 34

9. DC motor drive circuit

There are two kinds of DC motors: the lift-up motor which moves up

and down the offset tray, and the offset motor which distribute paper.

The control signal sent from the CPU is passed to the H driver IC

TA7291S (IC5, 11) exclusive for each DC motor, driving the motor.

The driver IC can be controlled in CW/CCW. The offset motor can be

controlled only in CW.

24V

LUM

OFM

LUMD+

LUMD-

OFMD+

OFMD-

10uF/35V

10uF/35V

R167

10K

DTC114EK

R136

100K

D6

1SS133

2SA1680

Q9

D1

1SS133

2SA1680

Q8

0.047uF/50V

R168

10K

Q3

0.047uF/50V

R137

100K

C169

10k

10k

C133

C163

0.047uF/50V

C114

0.047uF/50V

R169

R138

10K

10K

R155

10K

R115

10K

8

2

10

4

1

D2

1SS133

8

2

10

4

1

IC11

VS

OUT1

OUT2

Vref

GND

TA7291P

IC5

VS

OUT1

OUT2

Vref

GND

TA7291P

VCC

VCC

5V

7

5

IN1

6

IN2

3

NC

9

NC

IN1

IN2

NC

NC

10uF/16V

7

5

6

3

9

10uF/16V

+

C9

5V

+

C2

R170

47K

R140

47K

R139

47K

R164

47K

DCCON 64

R132

47K

LUM+

LUM-

OFM+ 45

OFM-

42

PE2

43

PE3

P35

PE4

46

PE5

F12

ICP-N38

+

C8

R162

100K

R163

100K

24V

F3

ICP-N38

+

C1

R130

100K

R131

100K

CPU(IC8)

Q4

DTC114EK

10k

10k

· Lift-up motor

LUM+ LUM- Rotating direction Operating direction

0 0 Stop Stop

10 CW Up

0 1 CCW Down

11 Brake Brake

· Offset motor

LUM+ LUM- Rotating direction Operating direction

0 0 Stop Stop

1 0 CW Offset operation

0 1 CCW Not used

11 Brake Brake

Page 35

10. Staple motor drive circuit

The control signal sent from the CPU is passed through the transistor

array TD62504 (IC106) to the H driver circuit which is composed of

large-current drive transistors (Q6, 7, 10, 11), driving the staple mot o r.

STM

STMD+

STMD-

1SR124

SW24V

D3

T1.25A/250V

D7

1SR124

F13

2SB1258

2SD1785

D5

1SS133

R159

R158

200

1K

R157

200

R156

1K

STM+ 40

STM- 41

PE0

PE1

CPU(IC8)

D4

1SS133

C178

10000pF/50V

C167

10000pF/50V

Q6

Q7

0.22/2W

Q10

2SB1258

5V

R1741KR173

C185

R145

3.9K

R144

1.2K

1K

Q11

2SD1785

0.1uF/25V

R10

R160

4.7K

R161

4.7K

C184

0.1uF/25V

5V

R143

100

C161

0.1uF/

25V

R165

4.7K

R166

4.7K

C160

0.1uF/25V

5

6

16

15

14

13

12

11

10

9

IC106

O1

O2

O3

O4

O5

O6

O7

NC

TD62504F

5V

84

+

-

COM-E

IC102B

NJM2903M

1

I1

2

I2

3

I3

4

I4

5

I5

6

I6

7

I7

8

5V

R146

2.2K

7

C149

0.1uF/25V

11. Staple unit

The staple unit can staple max. 30 pages of paper of 80g/m2. This unit

is composed of the drive DC motor (STM), the home position sensor

(STHP), the staple empty sensor (SNSW), the cartridge sensor

(/CASW), and the self-priming sensor (/SEPL) which detects that staples are at a staplable position.

Page 36

[10] OUTLINE MAP

Paper exit unit

Escape tray

+5V

Offset tray unit

+24V

+5V

Paper exit detection

T1OD

Paper detection

T1PD

PG open/close detection

TCSW

Lift-up motor

LUMD(+,-)

Offset motor