Page 1

CODE: 00ZARFN4//A1E

DIGITAL COPIER OPTION

FINISHER

MODEL AR-FN4

CONTENTS

[ 1 ] INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 2 ] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . 2-1

[ 3 ] OPERATIONAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . 3-1

[ 4 ] DISASSEMBLE AND ASSEMBLE . . . . . . . . . . . . . . . . . . . . . . 4-1

[ 5 ] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

[ 6 ] ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[ 7 ] TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[ 8 ] SELF TEST MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[ 9 ] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] ACTUAL WIRING CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

[1] INTRODUCTION

1. Features

1) Compact, light-weight

2) Mono-cock frame

Mono-cock frame reduces the number of covers.

3) Bundle offset sorting/stapling

Paper bundle is made and aligned on the intermediate process

tray to allow bundle offset/stapling.

4) Stack tray

The max. load capacity of the stack tray is 1,000 pages (small

size) or 500 pages (large size).

Fifty stapled bundles (max. 20 pages) can be loaded on the tray.

∗1: Small size: A4, A4R, A5, A5R, B5, B5R, LTR, LTRR

∗2: Middle size: B4 LGL, 8.5" x 13", 8.5" x 14"

∗3: Large size: A3W, A3, 12" x 18", LDR

∗4: The total number of pages must be within the specified range of

numbering.

∗5: Alignable width: Alignable paper width in the backward/forward

direction

∗6: Offset width: Shift of paper bundle when sorting

45

2.5mm

5

2. Specifications

A. Specifications

Item Content

Stack system Stack tray: Tray lift system (Intermediate process

Loading direction Face down loading

Loading

paper size

Paper

weight

Bin number Stack tray 1

Kinds of mode Staple loading

Stack tray

loading

capacity

Alignable

width ∗5

Alignable size A3W, A3, A4, A4R, A5, B4, B5

Staplable size A3W, A3, A4, A4R, A5, B4, B5

Offset width ∗6 20mm

Binding system Punching by the rotational cam

Binding position One at a corner, slant binding (Refer to Fig. 1-101.)

Binding capacity Small size Max. 20 pages 80g/m

Stapler loading system Cartridge (3,000 staples)

Applicable stapler Specified stapler

Stapler empty detection YES

Manual stapling NO

Paper detection YES

Operation panel NO (Operated by the copier.)

Display NO (Displayed on the copier.)

Dimensions (W x D x H) 515mm x 574mm x 381mm (Except for the

Weight About 17kg (without the installing kit)

Power source 24V (Supplied from the copier)

Max. power consumption About 60W

AB series A3W, A3, A4, A4R, A5, A5R, B4, B5, B5R, A6R

Inch series LDR, LGL, LTR, LTRR, 7.25" x 10.5"R, 8.5" x 13",

Face-up 60g/m

Face-down 64 – 128g/m

Non binding Small size 1000 pages 80g/m

Staple sort Small size ∗1 20-page bundle

Non binding 139.7mm – 297mm

Staple 210mm – 297mm (A5: Not staple)

tray fixed)

Face up loading (1 to N)

8.5" x 5.5", 8.5" x 5.5"R, 12" x 18"

2

– 200g/m

Intermediate process tray 1

Non-staple loading

Non-staple bundle offset loading

Middle size 700 pages

Large size 500 pages

Middle size ∗2 20-page bundle

Large size ∗3 15-page bundle

12" x 18", LDR, LGL, LTR, LTRR, 8.5" x 5.5",

8.5" x 13"

LDR, LGL, LTR, LTRR, 8.5" x 5.5", 8.5" x 13"

Middle size Max. 20 pages

Large size Max. 15 pages

installation kit)

About 23kg (with the installing kit)

2

2

equivalent

paper

(Max. 50 bundles)

(Max. 50 bundles)∗4

(Max. 50 bundles)∗4

equivalent

paper

2

2

or

or

5 2.5mm

Fig. 1-101 Binding position

• Cross section view

[1] Stack tray

Alignment plate (Backward/forward)

[2]

[3] Paper feed guide A

[4] Paper feed guide B

[5] Paper exit roller

[6] Paper path

[7] Return roller

[8] Stopper plate

• Top view

[1] Bundle exit belt

[2] Rear alignment plate

[3] Knob

[9] Staple unit

[10] Paper holding lever

[11] Bundle exit belt

[11A] Bundle exit lever

Intermediate process tray load guide plate

[11B]

[12] Intermediate process tray

[13] Frame

Fig. 1-102

[4] Stack extension tray

[5] Stack tray

[6] Front alignment plate

Fig .1-103

1 – 1

Page 3

AR-FN4 Installation Manual

FOR USE WITH COMPATIBLE SHARP COPIERS

SEE SHARP COPIER INSTALLATION MANUAL TO DETERMINE

SUITABILITY

[2] UNPACKING AND

INSTALLATION

1. Un pac king

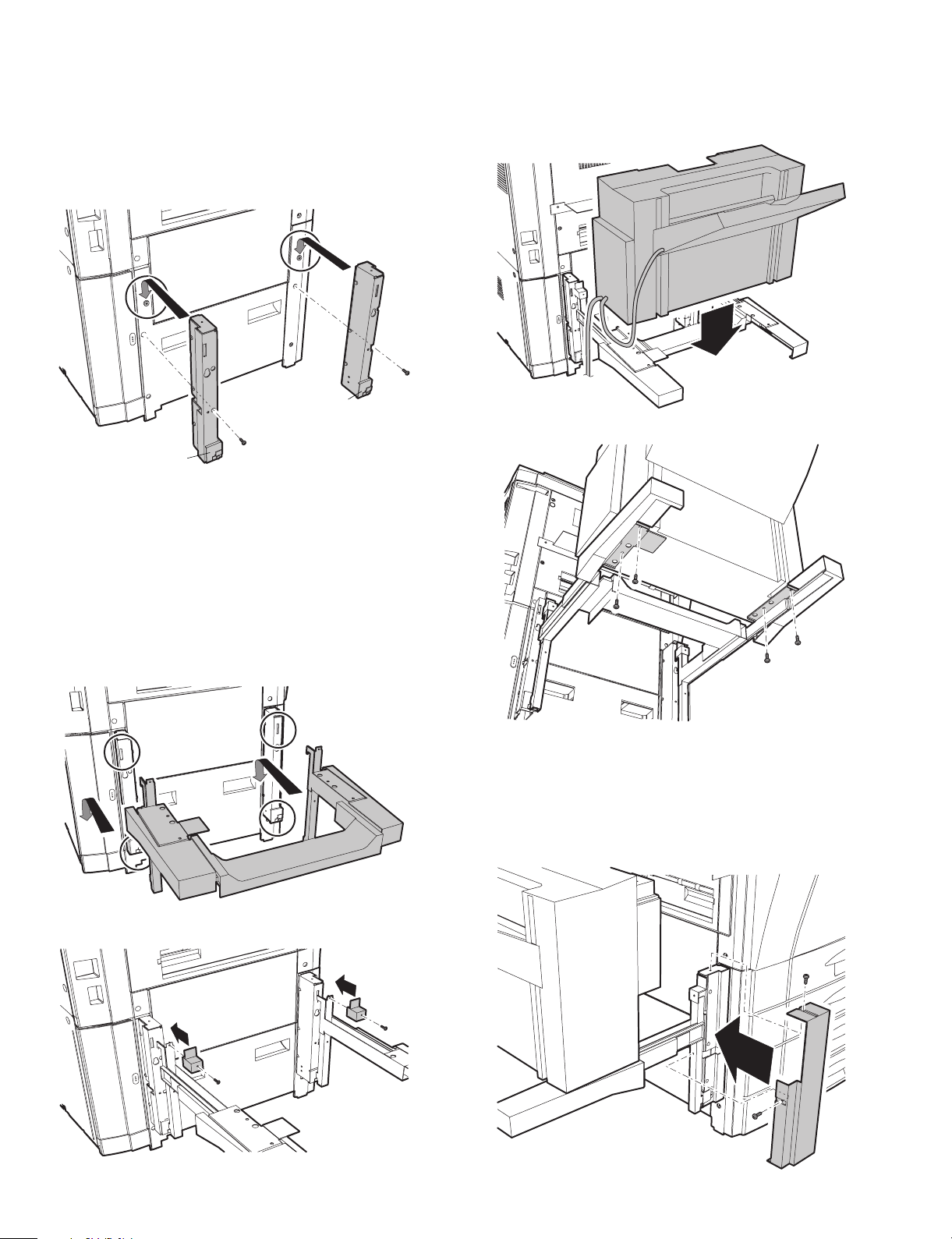

(1) Unpacking and identification of parts

4

Remove the filament tape, and remove each packing.

Alignment plate cushion

2

1

15

14

12

11

: Fold on the side to indicate the filament tape side.

Tightening screws

3

5

6

7

2. Installation

(1) Open the split holes and the installation holes,

13

8

9

10

and attach the step screws.

• Tighten the step screws temporarily.

Cut off the six notch sections. (Cut off the two sections on the upper

left side of the cabinet with nippers, and break the four sections on

the lower side with a screwdriver as shown below.)

Tighten the step screw temporarily as shown in the figure and loosen

one turn.

Cut-out

Step screws

Step screw,

2pcs

1 Machine Pad B

2 Kit spacer U front

3 Kit fixing pawl

4 Latch plate U

5 Screws, latch plate spacers x2

6 Kit spacer U rear

7 Machine pad A

Installation kit (Set this kits after installing the installation kit

8

holding pad.)

Installation kit holding pad (Set between machine pads C and

9

D on the installation kit package.)

10 Machine pad C

11 Machine pad D

Cardboard box seal (Set between machine pads C and D after

12

installing the installation kit.)

13 Machine body

14 Kit cover U (with guide wire)

15 Knob blind cover U

Spacer,

2 pcs

M4 x 18,

4 pcs

Black screw

M4 x 25,

4 pcs

M4 x 6,

4 pcs

Cut-out

(2) Attach the latch holding plate.

Attach the latch holding plate to the split hole on the left cabinet of the

copier with the spacers.

(Screws M4 x 18, 2pcs; spacers, 2 pcs.)

2 – 1

Page 4

(3) Attach the kit spacers (F/R).

Hang the kit spacers (F/R) on the step screws, fix them through the

lower holes with screws, and tighten the step screws to secure. Then

rotate it one turn in the reverse direction.

• When fixing, press down the kit spacers as shown in the figure.

• Be careful of the direction of the kit spacers. There are marks of F

and R on the spacers.

(Screws M4 x 18, 2 pcs.)

F

R

(4) Attach the acuride rail unit.

Hang the frame of acuride rail unit on the lower projections of the

spacer kits, and hang the pawls of the acuride rail unit on the square

holes on the upper side of the kit spacers.

Insert the fixing pawls into the upper pawl section to fix.

• At that time, be careful not to deform the lower projection of the kit

spacer.

Also check that the lower projection and the upper projection are

securely held.

(Screws M4 x 6, 2 pcs.)

(5) Attach the finisher.

Slide the acuride rail unit completely to the left, and while aligning the

finisher to the positioning dowels, fix it in place at its lower side with

the four screws. (Black screws M4 x 25, 4 pcs.)

(6) Attach the kit cover.

Fit the kit cover to the kit spacer (F) and fix with two screws.

(Screws M4 x 6, 2 pcs.)

Fit the front cabinet of the reverse section with the kit cover surface.

(Screws M4 x 6, 2 pcs.)

Fit the upper and the lower lines of the cabinet.

2 – 2

Page 5

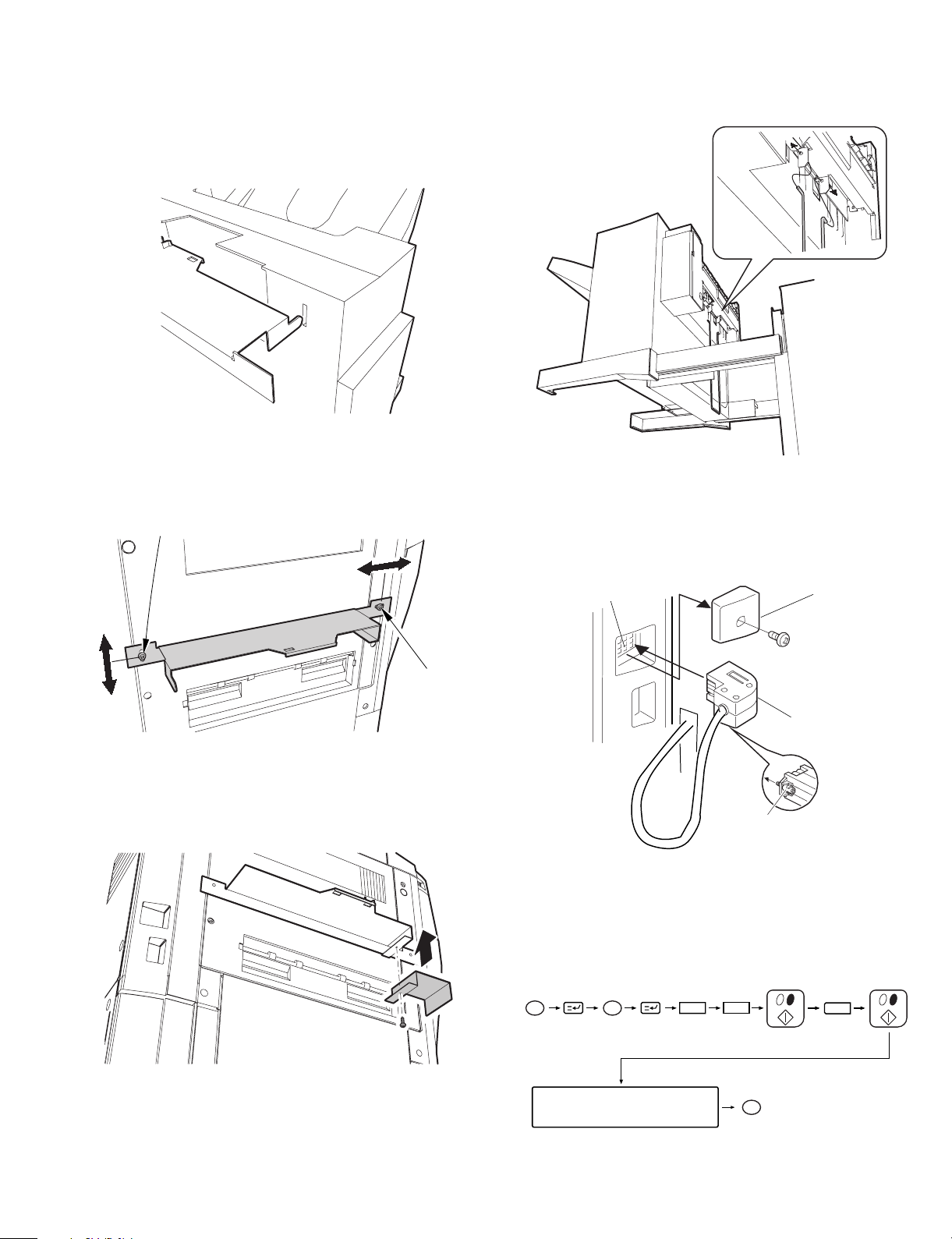

(7) Adjust the installing position of the latch

holding plate.

Slide the finisher to the right (in the locking direction). Adjust the

height with the screw on the rear side of the latch holding plate so

that the sensor contact section of the latch holding plate come at the

center of the sensor hole of the finisher.

Adjust the forward/backward position with the screw on the front side

of the latch holding plate so that the finisher is smoothly caught by the

lock of the latch holding plate.

Screw on

the rear side

(9) Attach the paper guide wire.

Insert the paper guide wire to the holding hole on the lower side of the

reverse section of the finisher.

(10) Connect the finisher connector.

Remove the finisher connector cover from the rear cabinet of the

copier.

Connect the finisher connector to copier’s connector, and tighten the

connector screw to fix.

Screw on

the front side

(8) Attach the blind cover.

While aligning the blind cover to the positioning dowls on the front

side of the latch holding plate, fix it in place at its lower side with the

screws.

Connector of the copier

Finisher connector cover

Finisher connector

Screw

(11) Set the mode

Set the mode with SIM 26.

Insert the power plug of the copier into the power outlet, turn on the

power switch, and follow the procedures below.

• Set the mode with the key operation ot the copier.

PC

Clear

26

1

2 – 3

Select the mode in the LCD

window.

CA

The mode is set with the

above operations.

Page 6

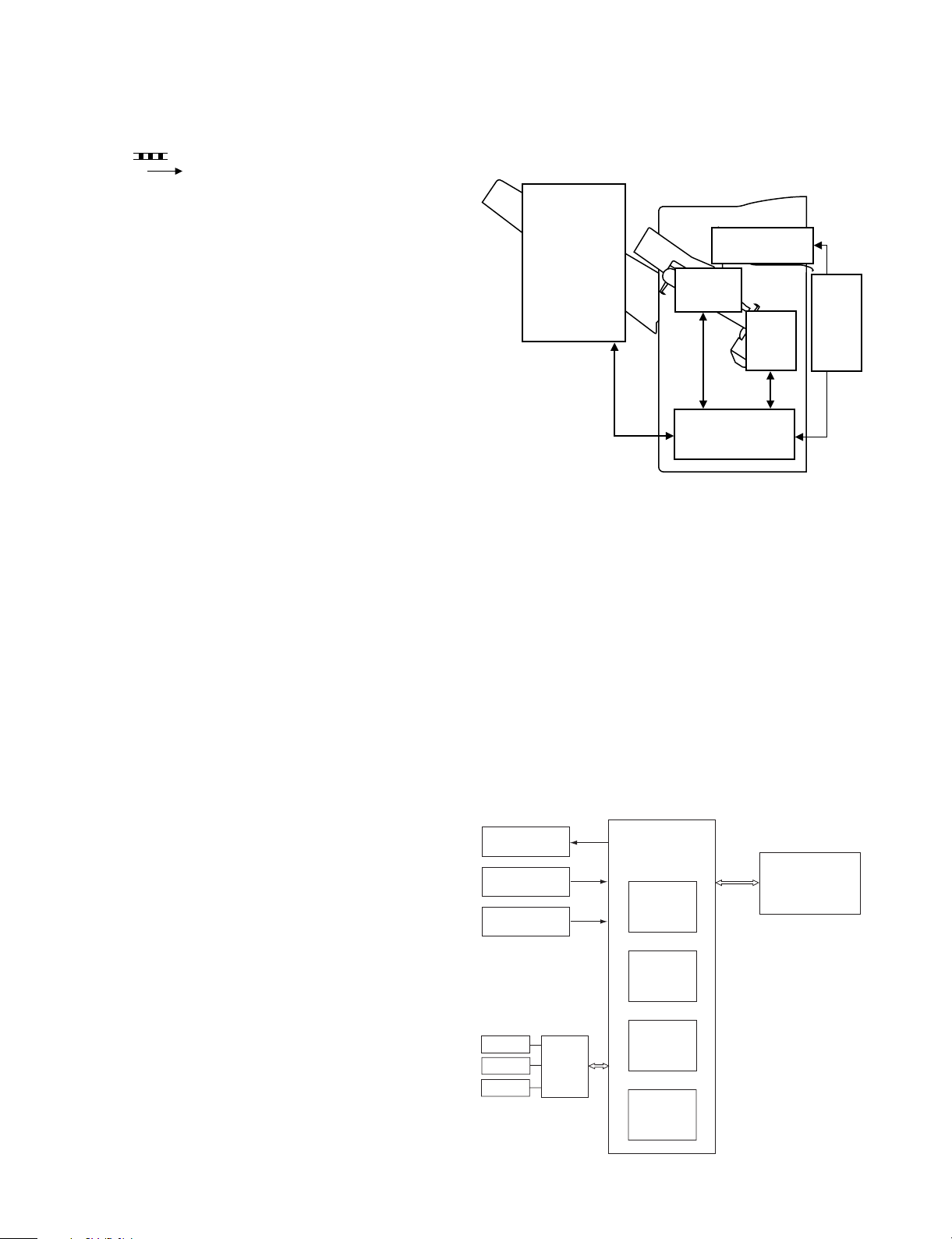

[3] OPERATIONAL DESCRIPTIONS

1) This chapter gives brief descriptions of the purpose and the role of

each function, the relationship between the electrical section and

the mechanical section, and the operating timing of each section.

The mark " " shows a mechanical transmission. If it is

togeth er with " " and a signal na me, it shows a flow of an

electric signal.

2) In the descriptions of the digital circuits in this chapter, "1" shows a

high voltage level of a signal, and "0" a low voltage level of a

signal. The voltage, however, differs in different circuits.

Though this machine employs a microprocessor, operational

descriptions on the microprocessor are omitted because it is virtually impossible to check inside the microprocessor.

Since the print PWB is not repaired by a user on principle, the

descriptions on the print PWB is limited to a brief one with block

diagrams. Therefore, the circuit descriptions of this chapter include

one from the sensor to the input section of the major PWB’s, one

from the output section of the major PWB’s to the load, and block

diagrams of each function.

1. Basic composition

A. Outline

This machine is composed of the following five sections: the reverse

section, the paper exit section, the intermediate process tray section,

the stapler section, and the stack tray section. The figure below

shows the composition.

Paper exit section

Stack tray section

Intermediate

process tray

section

Stapler

section

Finisher controller

PWB

Fig. 3-101

B. Brief description of electric circuit

The operating sequence of the finisher is controlled by the finisher

controller PWB, which employs a 16 bit CPU to make sequence

control (and serial communication with the copier).

The finisher controller PWB drives the motor according to a command

sent from the copier through the serial communication line. It also

sends to the copier various information on the sensors and switches

through the serial communication line.

The major purposes of IC’s integrated in the finisher controller PWB

are as follows:

• IC1 (CPU)

Sequence control

• IC3 (EP-ROM)

Sequence program

• IC4 (Communication IC)

Communication with the copier (IPC II)

• IC12 (Regulator IC)

Generation of 5V for driving sensors and logics

Reverse

section

3 – 1

Motors

Sensors

Switches

Motors

Sensors

Solenoid

Reverse

drive

PWB

Finisher

controller

PWB

IC1

CPU

IC3

EP-ROM

IC4

Communication

IC

IC12

Regulator IC

Fig. 3-102

Copier

Page 7

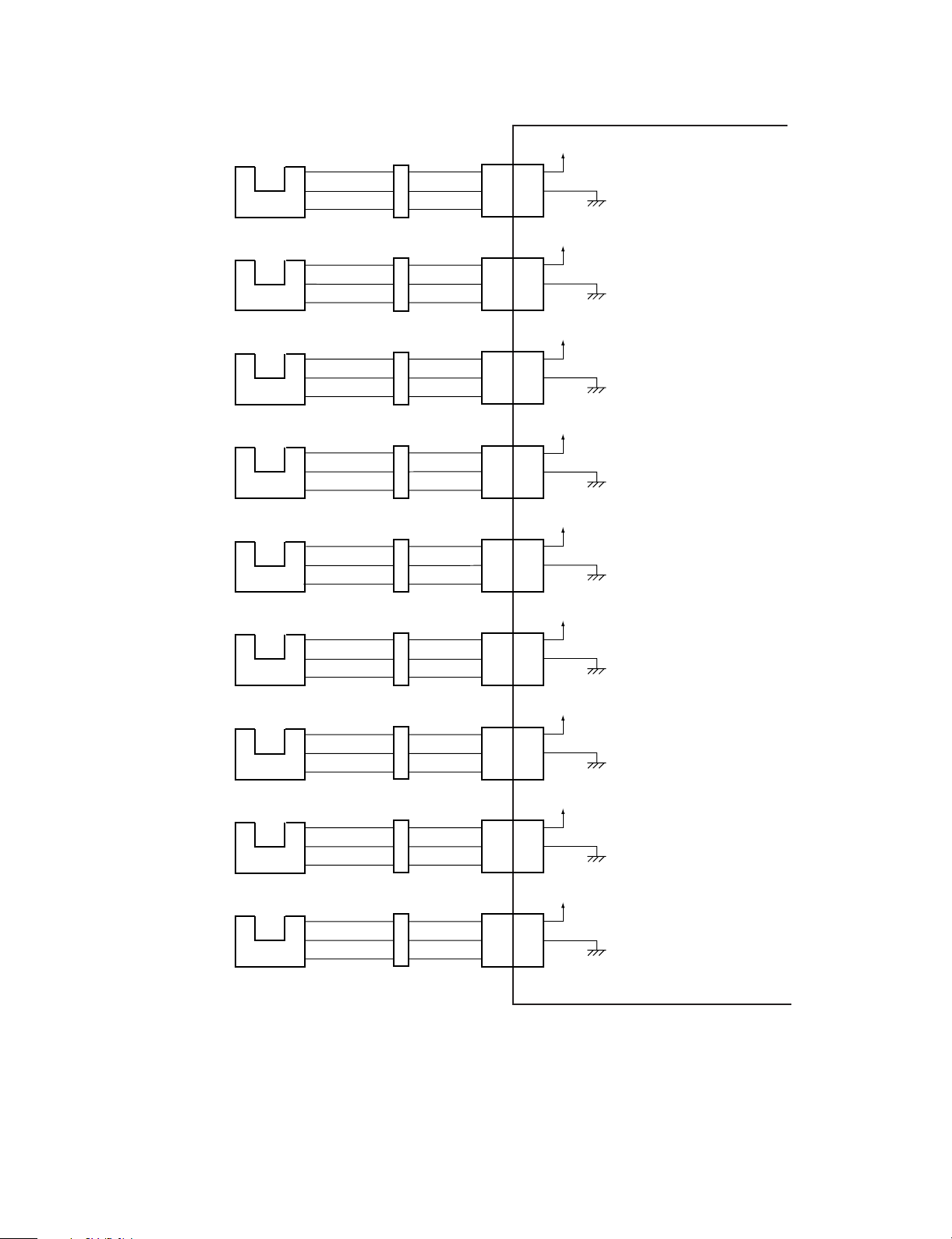

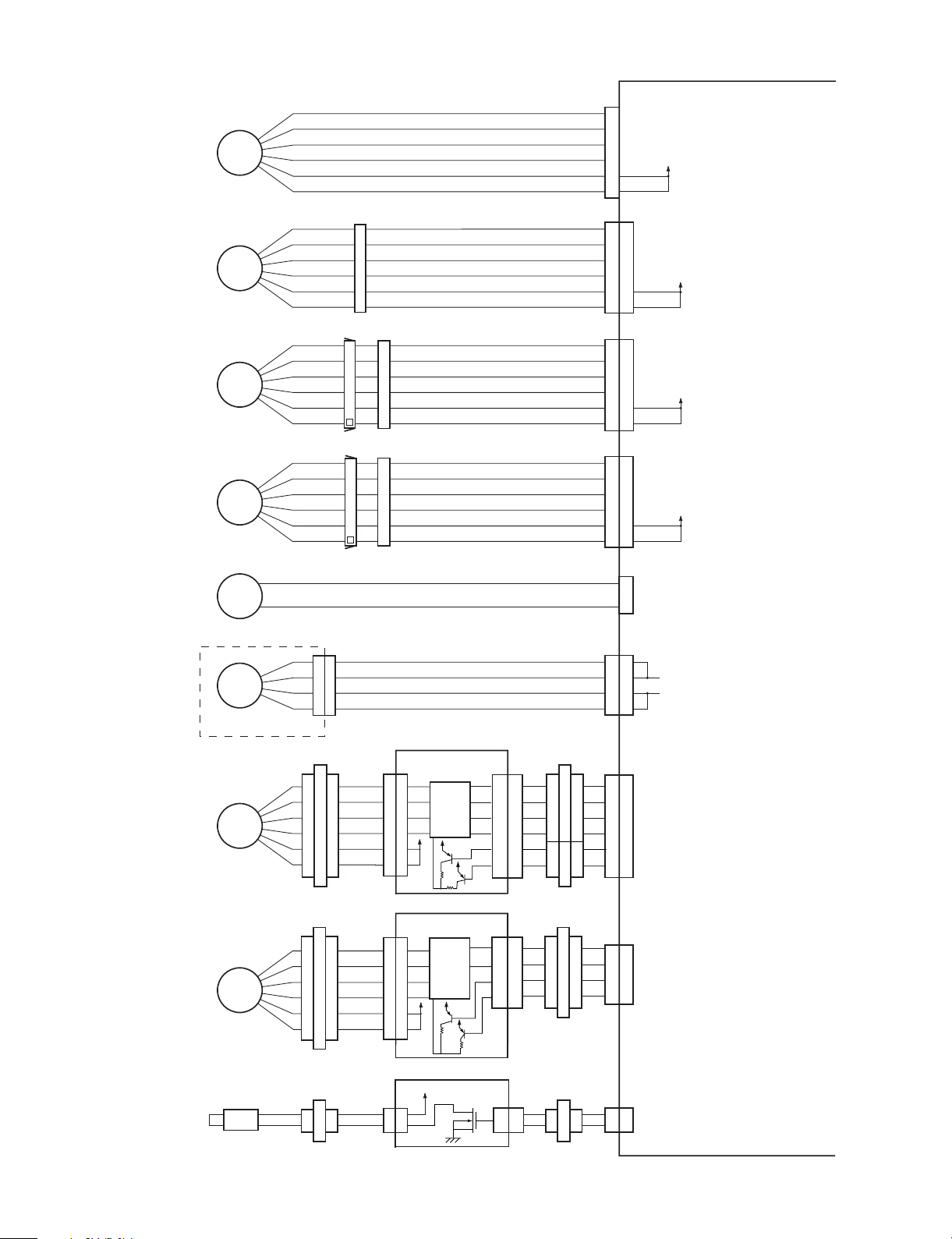

C. Finisher controller PWB input/output

• Finisher controller PWB input (1/2)

Paper exit motor

clock sensor

S1

J602

J601

1

2

3

Finisher controller PWB

J10

+5V

1

2

S1D

3

Pulse corresponding to the rotating

speed of the paper exit motor

Entry port sensor

Return roller

home position sensor

Joint sensor

Intermediate process

tray sensor

Front alignment plate

home position sensor

Rear alignment plate

home position sensor

Bundle exit lever

home position sensor

Stack tray

lift clock sensor

S2

S3

S4

S5

S6

S7

S8

S9

J612

J603

J610

J504

J502

J503

J505

J609

J604B

B10

B11

B12

J601

4

5

6

J604

A4

A5

A6

J501

7

8

9

J501

1

2

3

J501

4

5

6

J501

10

11

12

J604B

B4

B5

B6

J11

B10

B11

B12

J10

4

5

6

J11

A4

A5

A6

J9

7

8

9

J9

1

2

3

J9

4

5

6

J9

10

11

12

J11

B4

B5

B6

S2D

S3D

S4D

S5D

S6D

S7D

S8D

S9D

+5V

"1" when paper is passing over the sensor.

(The light shield plate is at S2.)

+5V

"1" when the return roller is at the home position.

(The light shield plate is at S3.)

+5V

"0" when the finisher is connected with the copier.

(The light shield plate is not at S4.)

+5V

"1" when paper is over the sensor.

(The light shield plate is at S5.)

+5V

"1" when the front alignment

plate is at the home position.

(The light shield plate is at S6.)

+5V

"1" when the rear alignment

plate is at the home position.

(The light shield plate is at S7.)

+5V

"0" when the bundle exit

lever is at the home position.

(The light shield plate is not at S8.)

+5V

Pulse corresponding to the rotating

speed of the stack tray lift motor

Fig. 3-103

3 – 2

Page 8

• Finisher controller PWB input (2/2)

Stack tray

height sensor

S10

J611

J604B

B7

B8

B9

Finisher controller PWB

J11

+5V

B7

B8

B9

S10D

"1" when the top surface of paper

is detected.

(The light shield plate is at S10.)

Stack tray

paper sensor

Stack tray

lower limit sensor

Stack tray

upper limit sensor

Stapler empty

sensor

Stapler cue sensor

Stapler stapling

home position

sensor

S11

S12

S13

S15

S16

S17

J702

J607

J608

8

13

9

11

12

J402

J701

J604A

A7

A8

A9

J604

A1

A2

A3

J401

13

11 11

12 12

J12

1

2

3

J11

A7

A8

A9

J11

A1

A2

A3

J8

8

13

9

S11D

S12D

S13D

S15D

S16D

S17D

+5V

"1" when paper is over the sensor.

(The light shield plate is at S11.)

+5V

"1" when the stack tray is at the

lower limit.

(The light shield plate is at S12.)

+5V

"1" when the stack tray is at the

upper limit.

(The light shield plate is at S13.)

"1" when stapler empty.

(The light shield plate is not at S15.)

"1" when the stapler head is not

at the stapling position.

"0" when the stapler is at

the stapling home position.

(The light shield plate is at S17.)

+5V

1

2

3

8

9

Stapler cartridge

sensor

Reverse roller

Home position

sensor

Reverse paper

exit sensor

Reverse entry port

sensor

(Reflection

transmiss type)

7

S18

Stapler unit

J1201

J1201

S19

S20

+5V

Reverse entry port sensor PWB

J204

1

1

2

2

3

3

Reverse driver PWB

J1501

4

3

2

1

J1401J301

4

3

2

1

+5V

J201 J1006

J1502

Fig. 3-104

J1009

J614

J1402

J1004

J616

J1001

B5 B5B4 B4

J613

7

7

S18D

J14

S190

J17

1

1

2

2

S20D

3

3

1

1

2

3

4

S21D

2

S21AN

3

4

"1" when the stapler cartridge is

not set.

"0" when the reverse roller is at

the D cut.

(When the shield plate is not at S19.)

+5V

"1" when paper is passing over the

sensor.

(When the shield plate is at S20.)

"0" when paper is passing over the

sensor.

+5V

3 – 3

Page 9

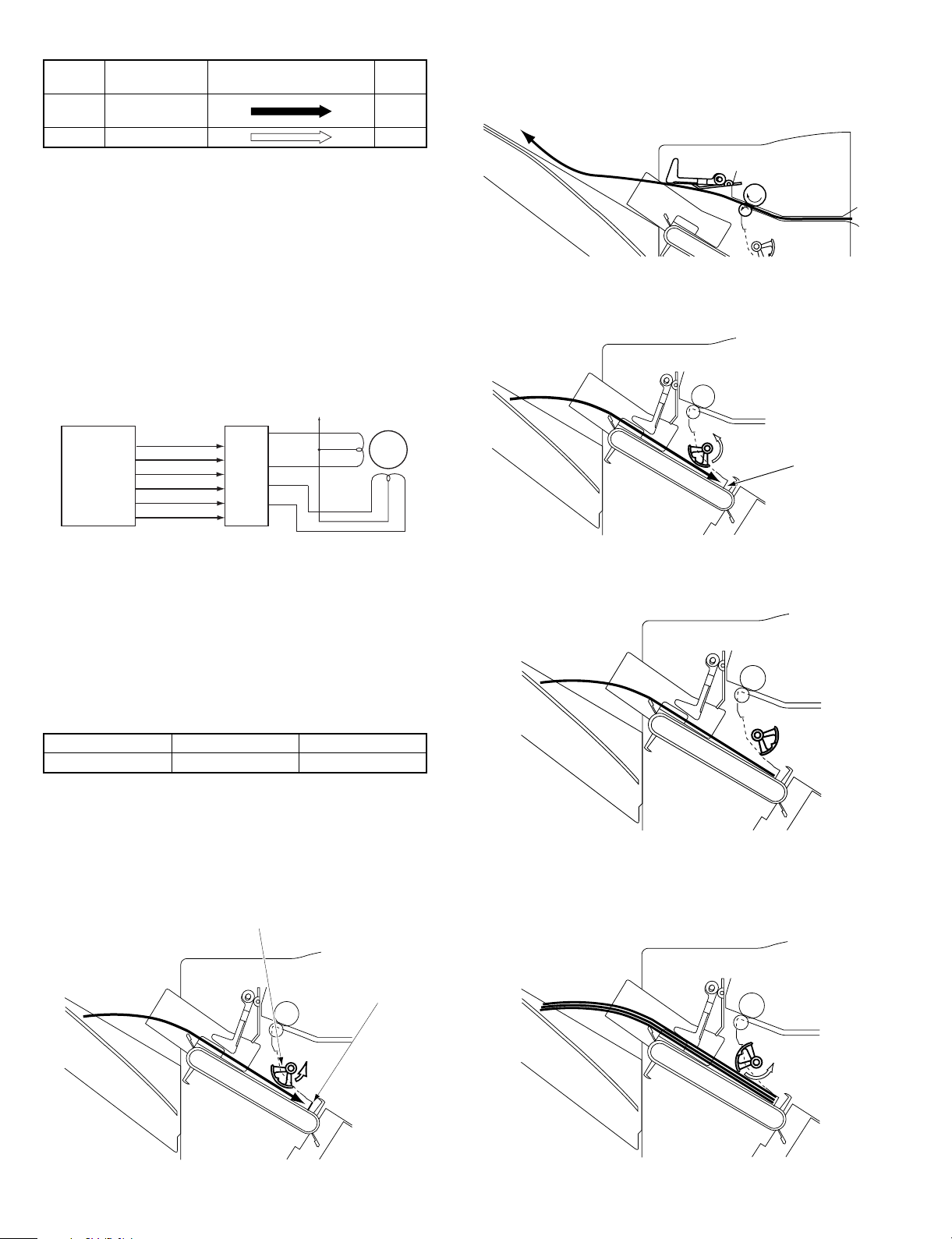

• Finisher controller PWB output

Paper exit

motor

Bundle

process

motor

Front

alignment

motor

Rear

alignment

motor

Stack

tray lift

motor

Staple

motor

M1

M2

M3

M4

M5

M6

Staple unit

J402

Finisher controller PWB

J4

1

M1DA

2

M1DB

3

M1DA*

4

M1DB*

5

6

J5

J201J202

1

1

M2DA

2

2

M2DB

3

3

M2DA*

4

4

M2DB*

5

5

6

6

J6

J301J302J304

1

1

M3DA

2

2

M3DB

3

3

M3DA*

4

4

M3DB*

5

5

6

6

J6

J301J303J305

7

7

M4DA

8

8

M4DB

9

9

M4DA*

10

10

M4DB*

11

11

12

12

J3

M5D1

1

2

M5D2

J8

J401

1

1

2

2

4

4

5

5

The rotating speed and the

rotating timing are controlled

by varying the sequence of

drive pulses (A, A*, B, B*)

and the frequency.

24V

The rotating speed and the

rotating timing are controlled

by varying the sequence of

drive pulses (A, A*, B, B*)

and the frequency.

24V

The rotating speed and the

rotating timing are controlled

by varying the sequence of

drive pulses (A, A*, B, B*)

and the frequency.

24V

The rotating speed and the

rotating timing are controlled

by varying the sequence of

drive pulses (A, A*, B, B*)

and the frequency.

24V

Forward rotation when M5D1

is "0" and M5D2 is "1"

Reverse rotation when M5D1

is "1" and M5D2 is "0"

Stop when M5D1 is "0" and

M5D2 is "1"

Forward rotation when M6DA

is "0" and M6DB is "1"

M6DA

Reverse rotation when M6DA

M6DB

is "1" and M6DB is "0"

Stop when M6DA is "0" and

M6DB is "1"

Reverse

paper exit

motor

Reverse

motor

Reverse

flapper

solenoid

M7

M8

SL1

J1103J1105

J1302J1303

M7DA

M7DB

M7DA∗

M7DB∗

M8DA

M8DB

M8DA∗

M8DB∗

SL1D

J203J1101

1

1

2

2

3

3

4

4

5

5

6

6

Reverse driver PWB

J203J1101

1

1

2

2

3

3

4

4

5

5

6

6

Reverse driver PWB

J1301

J205

1

212

IC201

Moter

driver

24V

IC202

Moter

driver

24V

24V

J201

Reverse driver PWB

Fig. 3-105

A6

A5

A4

A3

B1

B2

A8

A7

A1

A2

B3

J1006

A6

A5

A4

A3

B1

B2

J1006

A8

A7

A1

A2

J1006

B3

J1009

J1003J1008

J1004J1009

J1003J1008

J1004

J1001J1102J1104

J14

A3

A4

A5

A6

B8

B7

A1

A2

A8

A7

TRNSMA

A3

TRNSMB

A4

TRNSMA∗

A5

TRNSMB∗

A6

TRNSMC1

B8

TRNSMC2

B7

J14

BUFMA

A1

BUFMB

A2

BUFC1

A8

BUFC2

A7

By changing the sequence

and the frequency of drive

pulses (A, A∗, B, B∗), the

rotating speed and the

rotating timing are controlled.

By changing the sequence

and the frequency of drive

pulses (A, A∗, B, B∗), the

rotating speed and the

rotating timing are controlled.

J14

B6 B6

BUFSL

"1" when solenoid ON.

3 – 4

Page 10

2. Basic operation

The basic operation is described below.

A. Face-up paper exit

In the face-up paper exit, the flapper solenoid turns on to switch the

paper path. Then paper passes through the following path.

B. Face-down paper exit

1) In the facedown paper exit, the flapper solenoid turns off to switch

the paper path, transporting paper to the reverse section.

3) Reverse rotation the semicircular roller furthermore to transport

paper to the paper exit roller side in the reverse section.

C. Face-up/face-down common operations

1) Paper is transported from the reverse section.

2) When the reverse entry port sensor detects the rear end of paper,

reverse rotation the semicircular roller to hold paper.

Fig. 3-201

2) Paper reaches the intermediate process tray.

Fig. 3-202

3) Paper is fed to make contact with the stopper plate by the return

roller.

3 – 5

Fig. 3-203

Page 11

4) Paper is aligned with the front/rear alignment plates.

Fig. 3-204

5) Operations of 1) through 4) are repeated for the specified pages of

paper, and the pages are loaded on the intermediate process tray.

6) Stapling is performed. (Specified stapling position)

Paper feed guide A

Return roller

Intermediate

process tray

loading guide plate

Bundle exit lever

Paper feed

guide B

S1

M1

J10-3

S1D

J4

Paper exit roller

J11-18

S2D

M2

One-way clutch

J9-9

S5D

J5

Finisher controller PWB

Fig. 3-301

B. Paper exit

Paper fed from the copier is transported to the intermediate process

tray by the paper exit motor (M1). Paper transport is detected by the

entry port sensor (S2).

Paper feed guides A/B are provided at the paper exit port of this

machine. Paper feed guides A/B lower the rear edge of paper by their

weight to support transporting discharged paper to the return roller.

Paper feed guide A

Paper feed guide B

Paper exit roller

Fig. 3-205

7) Paper bundle on the intermediate process tray is discharged to

the stack tray.

Fig. 3-206

3. Transport system

A. Outline

Paper is fed from the copier and discharged to the intermediate

process tray, where alignment and offset and stapling are made.

Then paper is discharged to the stack tray.

A jam in the machine is detected by the entry port sensor (S2).

The figure below shows the composition of the transport system.

Code Name

M1 Paper exit motor

M2 Bundle process motor

S1 Paper exit motor lock sensor

S2 Entry port sensor

S5 Intermediate process tray paper sensor

Tab. 3-301

S2

Fig. 3-302

4. Intermediate process tray section

A. Intermediate process tray operation

(1) Outline

The intermediate process tray makes a bundle of paper to align,

offset, and staple paper discharged from the copier.

The intermediate process tray section is composed of the return roller

and the bundle process belt. The bundle process belt is provided with

the bundle exit lever. The two bundle process levers are driven in

parallel.

When paper is stored in the intermediate process tray, the intermediate process tray paper sensor (S5) turns on.

When the power is supplied to the copier, the bundle process motor

(M2) is driven to return the return roller and the bundle process belts

to their home positions.

Bundle

process

motor

M2

One-way clutch

Return roller home position sensor (S3)

Return roller

Stack tray side

Bundle exit belts

Fig. 3-401

3 – 6

Page 12

Motor

rotation

Drive Arrow in Fig. 3-401

Forward Bundle exit belt

Drive

torque

High

Return roller

Reverse Return roller Low

Tab. 3-401

(2) Bundle process motor (M2) control

The bundle process motor (M2) is a 4-phase stepping motor.

Forward/reverse rotation of the motor and the rotating speed are

controlled by the phase of the pulse signals BUNDPINA,

BUNDPINA*, BUNDPINB and BUNDPINB* sent from the CPU to IC6.

IC6 outputs pulse signals A, A*, B, and B* corresponding to the shift

of BUNDPINA and BUNDPINB to control the motor rotating direction

and the rotating speed.

The motor torque is controlled by the combination of current control

signals BUNDCURA and BUNDCURB sent from the CPU to IC6.

In this machine, the motor is driven at a high torque when driving the

bundle exit belt (forward rotation), and at a low torque when driving

the return roller (reverse rotation).

Bundle

process

J5-1

motor

-5

-3

-2

-6

-4

M2

IC1

CPU

BUNDPINA

BUNDPINB

BUNDPINA*

BUNDPINB*

BUNDCURA

BUNDCURB

IC6

Motor

driver

A

A*

B

B*

Fig. 3-402

(3) Max. load capacity of the intermediate process tray

The max. load capacity of the intermediate process tray is shown in

the table below.

When the set number of pages or the number of documents exceeds

the max . load cap acity , the docu me nts of the max. lo ad capa cit y are

aligned and offset on the intermediate process tray. Then the bundle

of paper is discharged to the stack tray, and the remaining number of

paper is aligned.

When offsetting, all pages of a bundle are offset in the same direction.

Small size Middle size Large size

30 20 15

Tab. 3-402

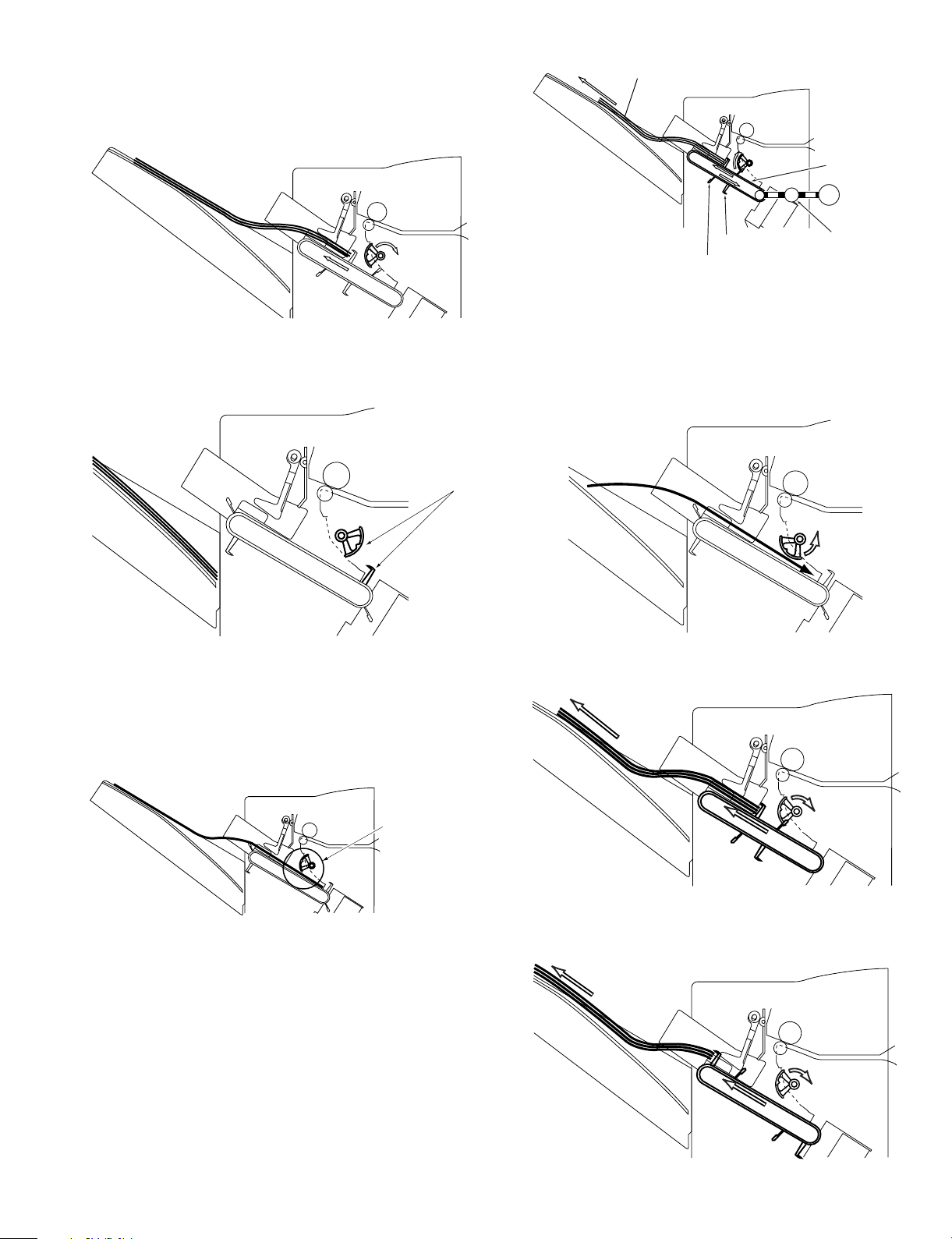

B. Return roller

(1) Outline

The return roller leads the discharged paper from the copier to the

stopper plate to align in the transport direction.

The return roller is driven in the forward direction when the bundle

process motor is reversed.

Return roller

(2) Operational descriptions

The operational descriptions of the return roller are given below.

1) Paper is discharged from the copier.

Fig. 3-405-a

2) The return roller rotates forwardly, and the paper reaches the

intermediate process tray and makes contact with the stopper

plate.

Stopper plate

Fig. 3-405-b

3) The roller rotates one turn and stands by at the home position. In

the case of the large/middle size or manual paper feed, the return

roller holds paper at the stand-by position.

Fig. 3-405-c

4) When the next paper is discharged from the copier, operations of

1) and 2) are repeated to form a bundle of paper.

When the last paper of a bundle is brought into contact with the

stopper plate, the return roller passes the home position and stops

at 1/8 turn.

Fig. 3-404

Stopper plate

Fig. 3-405-d

3 – 7

Page 13

5) After completion of alignment of the first set, the bundle is discharged by the bundle discharge lever. At the same time, the

return roller rotates in the reverse direction. Since, however, the

return roller has been off from the home position, it does not

interfere the bundle.

Bundle of paper

Bundle exit belt

M2

Fig. 3-405-e

6) The bundle process belt reaches the home position to complete

bundle exit. At the same time, the return roller stops at the home

position.

Home position

Fig. 3-405-f

7) When the next bundle is fed, operations of 1) to 6) are repeated.

• Paper holding in manual paper feed of large/middle size paper

In the case of manual paper feed, the max. load capacity of the

intermediate process tray is 5 pages. For manual paper feed of

large/middle size paper, paper tends to be folded. To prevent

against this, the return roller holds paper until the next paper is fed.

Bundle exit lever

Intermediate process tray

load support plate

One-way clutch

Fig. 3-409

(2) Operational descriptions

The operational descriptions of the bundle exit belt are given below.

1) Press the copy start key of the copier, and paper is stored in the

intermediate process tray. The return roller brings paper into contact with the stopper plate to align. The specified number of paper

is loaded in the intermediate process tray.

Fig. 3-410-a

2) The bundle exit belt is driven to transport the bundle of paper to

the stack tray.

The return roller

holds paper after

paper makes

contact with the

stopper plate.

Fig. 3-406

C. Bundle exit belt drive

(1) Outline of operation

The two bundle exit belts are driven in parallel when the bundle

process motor (M2) rotates forwardly.

The bundle exit belt is provided with two bundle exit belts on the

opposing positions. A bundle is discharged with a half turn of the

bundle exit belts.

When the power is supplied to the copier, the bundle process motor

(M2) is driven to set the bundle exit lever to the home position.

Fig. 3-410-b

3) Just before the bundle is discharged to the stack tray, the bundle

exit belt speed is reduced to prevent against misalignment due to

collision.

Fig. 3-410-c

3 – 8

Page 14

4) After discharging the bundle to the stack tray, it stops at the home

position.

Fig. 3-410-d

5) After the stack tray is lowered, the bundle exit belt and the return

roller move to the home position simultaneously, and wait for the

next paper.

Fig. 3-410-e

D. Alignment/offset

(1) Outline

Paper is aligned in the width direction by the front/rear alignment

plates on the intermediate process tray.

The front alignment plate is driven by the front alignment motor (M3),

and the rear alignment plate by the rear alignment motor (M4).

The front alignment plate home position sensor detects the front

alignment plate home position, and the rear alignment plate home

position sensor detects the home position of the rear alignment plate.

The tables below show the alignment positions.

Kind of sorting Alignment position

Non-sort Offset alignment (Front)

Staple sort Rear alignment

Sort Offset alignment

Tab. 3-403

Reference

When the operation is started, this machine is initialized. When, therefore, the power is supplied with the front/rear alignment plates being

off from the home position, they do not move to the home position.

Front side

Front alignment plate

Front alignment

plate home

position

sensor (S6)

Stack tray

Rear alignment plate

(2) Alignment motor control

Fig. 3-413 shows the drive circuit of the front alignment motor (M3)

and the rear alignment motor (M4).

Both motors are 4-phase stepping motors.

IC1 (CPU) delivers the following signals to control the motors. (Tab.

3-405)

Kind Signal name Target motor

Motor rotating direction,

Speed control

Motor drive enable FJOGPER

Drive current select FJOGCUR

IC1 controls the timing of JOGPINA and JOGPINB according to the

drive direction (forward, reverse) and the speed.

IC1 delivers FJOBPER or BJOGPER to IC14 depending on which

motor is driven, the front or the rear motor. When FJOGPER is outputted, IC14 sends JOGPINA and JOGPINB to IC7 (motor driver IC).

IC7 delivers 4-phase motor drive signals (FJOGA, FJOGB, FJOG_A,

and FJOB_B) according to JOGPINA and JOGPINB. In the same

manner, when BJOGPER is outputted, IC14 sends JOGPINA and

JOGPINB to IC8 (motor driver IC). IC8 delivers 4-phase motor drive

signals (BJOGA, BJOGB, BJOG_A and BJOB_B) according to JOGPINA and JOGPINB.

FJOGPER and BJOGPER are motor drive enable signals, and the

motor on the side where the signal is outputted is driven.

During halt of the motor, IC7 and IC8 continue to output the last

phase signal to hold the motor.

FJOGCUR and BJOGCUR outputted from IC1 are the motor current

select signals. (Tab. 3-406)

State Control current

Motor drive High current (High torque)

Motor hold Low current (Low torque)

Finisher controller PWB

IC1

(CPU)

JOGPINA

JOGPINB

FJOGPER

BJOGPER

FJOGCUR

BJOGCUR

JOGPINA

JOGPINB

BJOGPER

BJOGCUR

Tab. 3-405

Tab. 3-406

IC14

5V

5V

IC14

5V

5V

Front alignment motor,

Rear alignment motor

Front alignment motor,

Rear alignment motor

Front alignment motor,

Rear alignment motor

+24VP

FJOGA

FJOG_A

IC7

FJOGB

FJOG_B

+24VP

BJOGA

BJOG_A

IC8

BJOGB

BJOG_B

J6

1

5

3

2

6

4

J6

7

11

9

8

12

10

Front alignment

plate motor

Rear alignment

plate motor

M3

M4

Front alignment motor (M3)

Rear alignment motor (M4)

Rear alignment plate home position sensor (S7)

Fig. 3-412

Fig. 3-413

Rear side

3 – 9

Page 15

(3) Rear alignment (when staple sorting)

The stapler of this machine is fixed on the rear side. When stapling,

therefore, paper is aligned on the rear side.

When the copy start key is pressed and the paper size information is

sent from the copier, the rear alignment plate moves to the home

position, and the front alignment plate moves to the half of paper

width + 10mm forward from the center of the stack tray.

Paper discharged from the copier is transported to the intermediate

process tray.

When the paper is stored in the intermediate process tray, it is

brought into contact with the stopper plate by the return roller and

aligned in the transport direction. Then the paper is shifted to the

staple position. The front alignment plate is driven to align paper to

the rear side.

Rear alignment

plate home

position

To perform alignment backward, the rear alignment plate is driven

to the end of paper to be offset. To perform alignment forward, the

front alignment plate is driven to the end of paper to be offset.

When, however, the paper size is A4, A3, or A3W, the home

position of the front alignment plate serves as the reference of

forward offset, and the home position of the rear alignment plate

as the reference of backward offset. The active alignment plate

(the rear alignment plate for backward alignment, or the front

alignment plate for forward alignment) is in stand-by at the home

position.

When performing alignment, the alignment plate is moved from

the home position to the offset paper end. (Refer to Fig. 3-415-b.)

When the set number of paper or the number of documents exceeds the max. load capacity of the intermediate process tray, the

max. load capacity of paper is then discharged. Then the following

paper is aligned in the same direction.

Rear alignment

plate home

position

Half of

paper width

+ 10mm

Fig. 3-414-a

A3,A4

20mm

Stack tray

center

Front alignment

plate home

position

Rear alignment

plate home

position

Offset

quantity

20mm

Fig. 3-415-a

A3,A4

20mm

20mm

Front alignment

plate home

position

Rear alignment

plate home

position

Front alignment

plate home

position

Fig. 3-414-b

(4) Offset alignment (Non binding)

1) Sort

When sorting, paper bundles are offset and aligned. This is called

offset alignment.

The offset quantity of bundles is 20mm.

The offset direction of the first bundle is in the reverse direction of

the previous job. When the last section of the previous job is offset

backward (toward you), the first bundle is offset forward (to the

rear), and vice versa.

When the paper size information is issued from the copier, the

finisher controller PWB drives the front and the rear alignment

plates simultaneously to shift the paper by the paper width center

+ 10mm. (Refer to Fig. 3-415-a.)

When performing alignment, either of the front or the rear alignment plate is drive.

Front alignment

plate home

position

Fig. 3-415-b

3 – 10

Page 16

2) Non-sort

When non-sorting, paper is aligned at the backward offset position

(toward you) in sorting.

Rear alignment

plate home

position

20mm

3) Paper is stored in the intermediate process tray.

Front alignment

plate home

position

Fig. 3-416-a

Rear alignment

plate home

20mm

A3,A4

position

Front alignment

plate home

position

Fig. 3-416-b

(5) Operational descriptions

a. Staple sort

The staple sort operations are described below.

1) Press the copy start key of the copier.

The copier issues information on staples and the paper size.

2) The front alignment plate is moved to the position of half of paper

width + 10mm backward from the stack tray center.

Rear alignment

plate home

position

Fig. 3-417-b

4) The front alignment plate is driven to align paper.

5) The front alignment plate is returned to the position of 2).

Fig. 3-417-c

6) Operations of 3) to 5) are repeated every time when paper is

discharged from the copier.

7) When alignment of the first set is completed, stapling is performed.

8) The bundle process belt is driven to discharge the bundle to the

stack tray.

Half of

paper width

+ 10mm

Fig. 3-417-a

10mm

Stack tray

center

Front alignment

plate home

position

Fig. 3-417-d

9) The stack tray is moved to the specified height.

10) The operations of 3) to 8) are repeated.

Reference

When the number of documents exceeds the max. load capacity of

the intermediate process tray, stapling is not performed and the

bundle of paper on the intermediate process tray is discharged to the

stack tray. Stapling is not performed for the remaining set number of

paper, either.

3 – 11

Page 17

b. Offset alignment

The offset alignment operations are described below.

When non-sorting, paper is offset only backward (toward you) and

aligned.

1) Press the copy start key of the copier.

The copier issues information on staples and the paper size.

2) The front/rear alignment plates are moved to the position of half of

paper width + 10mm backward/forward from the center of paper

placed on the tray.

Rear alignment

plate home

position

10mm

10mm

6) The operations of 3) to 5) are repeated every time when paper is

discharged from the copier.

7) The bundle is discharged.

(a) When the number of documents is within the max. load

capacity of the intermediate process tray:

Each bundle is discharged to the stack tray.

(b) When the number of documents exceeds the max. load

capacity of the intermediate process tray:

The bundle on the intermediate process tray is discharged to

the stack tray.

The remaining number of documents is aligned at the same

offset position and the bundle is discharged to the stack tray.

Front alignment

plate home

position

Fig. 3-418-a

3) Paper is stored in the intermediate process.

Fig. 3-418-b

4) When aligning backward (toward you), the rear alignment plate is

driven to align paper. When aligning forward, the front alignment

plate is driven.

5) The front or the rear alignment plate comes to the position of 2).

Fig. 3-418-d

8) The stack tray is moved to the specified height.

9) The operations of 3) to 9) are repeated by alternating the alignment plates to be driven.

20mm

Fig. 3-418-e

5. Stapling operation

(1) Outline

The staple unit of this machine is fixed to the rear side, and not

shifted or oscillated.

Stapling is made at one position. Stapler is punched from the lower

side of a bundle before discharge.

This machine is not provided with a manual stapling function.

Stapling home position

Fig. 3-418-c

20mm

Stapling position

Fig. 3-501

3 – 12

Page 18

Reference

When the set number or the number of documents exceeds the staplable number of pages, stapling is not performed and the bundle is

discharged to the stack tray.

(2) Staple unit

The table below shows the motors and the sensors related to the

stapler.

Code Name SW/PI Role Remark

M6 Staple motor

S15 Stapler cue

sensor

Punches staples. Inside the

—

SW Detects if staples

are at the

staple unit

Inside the

staple unit

stapling position.

If not, punching is

made without

stapling to get a

staples ready to

stapling.

S16 Stapler empty

sensor

PI Detects the

remaining

Inside the

staple unit

quantity of

staples in a

cartridge.

S17 Stapler stapling

home position

sensor

S18 Stapler

cartridge sensor

PI Detects the home

position of

stapling.

SW Detects insertion

of a cartridge in

Inside the

staple unit

Inside the

staple unit

the stapler unit.

SW: Micro switch

PI: Photo interrupter

Tab. 3-502

When a finger is inserted into the stapling section, the stapler safety

sensor (S14) cuts off the power supply for safety.

CAUTION

When paper is loaded in the stack tray and the staple mode is

selected on the operation panel, the instruction to remove paper is

displayed and copying is allowed. If, however, copying is started

without removing paper from the stack tray, alignment and stapling

operations cannot be guaranteed.

(3) Staple motor control

Fig. 3-502 shows the drive circuit of the staple motor (M6).

The staple motor is a DC motor.

The motor rotating direction is controlled by the signal sent from the

finisher controller PWB IC4 (Communication IC) to the motor drive

circuit. (Refer to Tab. 3-503.)

24VP

6. Stack tray operations

(1) Stack tray lift operation

a. Outline

This machine is provided with one stack tray. A bundle of paper which

is aligned, offset, and stapled is discharged to the stack tray.

When paper is first discharged to the stack tray, the stack tray paper

sensor (S11) turns on.

The stack tray lift operation is performed by the stack tray lift motor

(M5).

When the power is supplied to the copier, if the stack tray is not at the

home position, the stack tray lift motor drives the stack tray to the

home position. The stack tray home position means the position

12.5mm above from detection of the stack tray top by the stack tray

paper height sensor.

The stack tray position is detected with the clock number of shifting

from the stack tray paper height sensor (S10).

The upper limit of the stack tray is detected by the stack tray upper

limit sensor (S13), the lower limit by the lower limit sensor (S12).

When the stack tray upper/lower limit sensor turns on, the stack tray

lift motor can be driven only in the opposite direction of the sensor

which is on.

The limit of load of the stack tray is detected by the paper height

sensor and the lower limit sensor in the case of non binding. When

stapling, the load count is also used in addition to them. When the

height or the limit of the specified number is detected, the notice of

load over is given to the copier.

Load limit detection

Non binding Paper height detection

Binding Paper height detection or load count

Tab. 3-601

Stack tray upper

limit sensor

Stack tray paper

height sensor flag 2

Stack tray paper

Stack tray

height sensor flag 1

Stack tray paper

height sensor

Paper hold lever

IC4

(COMMUNI-

CATION IC)

Finisher controller PWB

STPLCW

STPLCCW2

STPLCW2

STPLCCW

Q20

5V

Q26

IC9

5V

IC9

Q21

Q25

J8-1

-2

-4

-5

Fig. 3-502

Direction Output signal

Forward STPLCW/STPCW2

Reverse STPLCCW/STPCCW2

Tab. 3-503

Staple motor

M5

M6

Stack tray

lower limit

sensor

Fig. 3-601

b. Stack tray lift operation

When a bundle of paper is discharged to the stack tray, the stack tray

moves down until the stack tray paper height sensor (S10) turns off.

Then the stack tray moves up to 12.5mm above from detection of the

top of paper on the stack tray by the paper height sensor (S10).

3 – 13

Page 19

Stack tray

down

Stack tray

Fig. 3-602

Stack tray

up

Fig. 3-603

(2) Stack tray paper height detection

In any mode, the stack tray load quantity is detected with the height of

paper loaded on the stack tray.

The height of paper on the stack tray is detected by the stack tray

paper height sensor (S11).

When the paper is discharged, the stack tray moves down until the

stack tray paper height sensor (S10) does not detect, and it stops.

Then the paper height sensor (S10) moves up 12.5 mm past the point

where it detects the top of the paper in the stack tray.

When the stack tray lower limit sensor detects the stack tray with the

stack tray paper height sensor being detecting the paper top, the

finisher controller PWB gives the copier notice of over load. When the

loaded paper is removed from the stack tray, the stack tray moves up

to the home position. Then the paper can be discharged.

OFF

Stack tray paper

height sensor

Stack tray paper

height sensor flag

Fig. 3-605-a

ON

The flag is pressed

by the bundle of paper.

Fig. 3-605-b

(3) Stack tray load count

The table below shows the max. load of the stack tray.

When binding, the stack tray load limit is detected with the load count

on the stack tray in addition to the paper height detection. At that

time, a bundle of paper is counted by one. When the count reaches

30 in total, the notice of the stack tray load over is given to the copier.

The copier then gives a display of the instruction on the operation

panel to remove the bundle of paper.

When copying is made continuously, if paper is loaded on the stack

tray and staple sort is selected, the instruction to remove paper is

displayed on the operation panel and copying is allowed. If copying

made without removing paper at that time, alignment and stapling

operations cannot be guaranteed.

When the copy start key is pressed, though paper is not removed, the

count of paper bundles is cleared to zero.

Stack tray max. load capacity

Small size Max. 50 prints (Max. 20 sheets)

Middle size Max. 50 prints (Max. 20 sheets)

Large size Max. 50 prints (Max. 15 sheets)

Tab. 3-602

(4) Stack tray paper holding

The paper hold lever is provided beside the stack tray paper height

sensor.

The paper hold lever prevents against erroneous detection of the

paper height due to curling of a bundle.

The paper hold lever is driven by the stack tray lift motor (M5).

When a bundle of paper is discharged to the stack tray, the bundle is

loaded on the paper hold lever. After a bundle of paper is discharged

to the stack tray, the stack tray moves down until the stack tray paper

height sensor (S10) turns off, and it stops.

At that time, the paper hold lever is stored in the finisher away from

the bundle of paper.

Then the paper height sensor (S10) moves up 12.5 mm past the point

where it detects the top of the paper in the stack tray.

At that time, the paper hold lever appears from the finisher and presses the paper on the stack tray.

The above operations are repeated to hold paper.

3 – 14

Page 20

Semi-circular gear

M5

(Tray lifting up)

M5

(Tray moving down)

The semi-circular gear and

the paper hold lever are fixed

to the same axis.

Paper hold lever

Fig. 3-606

7. Jam detection

A. Outline

To detect paper empty and normal transport of paper, the following

sensors are provided.

• Entry port sensor (S2)

• Return roller home position sensor (S3)

• Bundle exit lever home position sensor (S8)

To detect normal stapling, the following sensor is provided.

• Staple home position sensor (S17)

Jam is checked by the check timing stored in the CPU on the finisher

controller PWB. When a jam is detected, the paper exit operation is

interrupted and a jam display is made on the operation panel.

Entry port

sensor (S2)

Return roller

home position

sensor (S3)

Bundle exit lever

homeposition

sensor (S8)

Fig. 3-607

(5) Tray lift motor control

a. Outline

Fig. 3-608 shows the block diagram of the tray lift motor (M5) drive

circuit.

The tray lift motor is a DC motor.

The rotating direction of the motor is controlled by the signal sent

from the finisher controller PWB IC1 (CPU) to the motor drive circuit.

(Refer to Tab. 3-603.)

When the stack tray reaches the stack tray upper limit sensor (S13)

and the sensor sends a signal (S13D) to IC11, STCTCW2 is interrupted and the motor stops its forward rotation.

Similarly, when the stack tray reaches the stack tray lower limit sensor (S12) and the sensor sends a signal (S12D) to IC11, STCTCCW2

is interrupted and the motor stops its reverse rotation.

Finisher controller PWB

IC1

(CPU)

STKTCW

STKTCCW2

S12D

IC11

S13D

S12

Stack tray

lower limit

sensor

S13

Upper limit

sensor

STKTCW2

STKTCCW

Fig. 3-608

Direction Output signal

Forward STKTCW/STKTCW2

Reverse STKTCCW/STKTCCW2

Tab. 3-603

Q25

Q27IC11

24VP

Q22

Q26

J3-1

Stack tray

lift motor

-2

M5

Fig. 3-701

8. Power system

(1) Outline

When the copier power is turned on, two voltages of 24V DC are

supplied from the copier to the finisher controller PWB. One is for

driving motors. The other is for generating 5V DC in the regulator IC

(IC12) of the finisher controller PWB. 5V DC is used as the power

source for sensors and IC’s on the PWB.

Fig. 3-801 shows the block diagram of the power supply system.

Finisher controller PWB

24V

Staple unit

drive circuit

5V

system

Logic

Copier

24V

Circuit

breaker

CB1

Regulator

IC (IC12)

Fig. 3-801

(2) Protection function

For protection against an overcurrent, the circuit breaker (CB1) is

provided for 24V DC for driving motors.

Motors

M

Staple motor

M6

Sensors

3 – 15

Page 21

[4] DISASSEMBLE AND ASSEMBLE

This Chapter describes the mechanical features, operations, and disassembly and assembly procedures.

When performing disassembly and assembly, observe the following

precautions.

1) Before disassembly and assembly, be sure to disconnect the

power plug.

2) For assembly procedures, reverse the disassembly procedures

unless otherwise specified.

3) Be careful of the kinds (length and diameter) of screws and fixing

positions.

4) For preventing static electricity, a inner-crip is provided at one

position of the metal cover. Be sure to use this shake proof

washer.

5) On principle, do not operate the machine with a part disassembled.

1. Reverse section

A. Reverse unit

Note: When removing the reverse unit, lift the unit and disengage the

hook.

C. Reverse roller/Reverse motor

2. Exterior control

A. Exterior covers

When performing cleaning, inspection, and repair of the machine,

remove the cover as required in the following procedure.

[3]

[1]

[4]

[1]

[2]

[1]

[5]

[4]

[3]

B. Reverse paper exit roller/reverse paper exit

motor

[2]

Fig. 4-101

4 – 1

[1]

Fig. 4-102

[2]

[3]

Page 22

B. Right inside cover and rear cover removal

To remove the right inside cover [1], remove the five fixing screws [2]

and remove the two fixing screws [4] of the rear cover [3].

[2]

[2]

[2]

[4]

[3]

3) Remove the two screws [4] and remove the discharge needle [5].

[5][4]

Fig. 4-106

D. Note for tightening the self tap screw

1) Fit the tip of a screw with a screw hole, and turn the screw

counterclockwise temporarily.

2) Check that the screw meets the screw hole thread.

3) Turn the screw clockwise to fix.

[1]

[2] [4]

Fig. 4-103

C. Discharge needle removal

1) Lift the upper guide plate [1] to the upper limit and fix it with tape.

Fix with tape.

[1]

Fig. 4-104

2) Pull up paper feed guide A [2] and paper feed guide B [3] and fix

with tape.

[3][2][3]

Fig. 4-107

E. Note for handling the load wall

Be careful not to scratch or damage the load wall rails [1]. If

damaged, they would adversely affect the load capacity.

[1]

[1]

Fig. 4-107a

Fig. 4-105

4 – 2

Page 23

F. Use of the stack tray stopper screw

The stack tray stopper screw [1] should be tightened in the plate to

the very end. (It should not be loosened.) If not, tight it may touch and

hook the rail slide.

3. Process tray

A. Process tray removal

1) Remove the right inside cover and the rear cover. (Refer to Fig.

4-103.)

2) Remove the stapler cover.

3) Remove the stapler. (Refer to Fig. 4-619.)

4) Remove the stack tray lift motor clock sensor holding plate. (Refer

to Fig. 4-610.)

5) Remove the fixing screw [1] and remove the entry port sensor [2].

[2] [1]

Fig. 4-301

6) Remove the E-ring [4] of the coupling shaft [3], and slide the gear

[5] and the bushing [6] toward you.

Note: When sliding the gear, be careful not to lose the parallel pin.

[1]

Fig. 4-108

2. Transport section

A. Transport motor removal

1) Remove the right inside cover and the rear cover. (Refer to Fig.

4-103.)

2) Disconnect the connector (J4) [2] on the finisher controller PWB

[1], remove two fixing screws [3], and remove the transport motor

[4].

[4]

[3]

[2]

[3]

[5]

[6]

[4]

Fig. 4-302

Fig. 4-201

[1]

4 – 3

Page 24

7) Remove the belt [8] from the pulley [7] on the rear frame side of

the coupling shaft [3], and pull out the coupling shaft [3].

[8]

[7] [3]

Fig. 4-303

8) Remove two connectors (J6, J9) [10] on the finisher controller

PWB [9], remove two fixing screws [11] inside the machine, and

remove two fixing screws [12] of the machine frame. (The grounding plate [13] will come off at that time.) Remove the process tray

unit [14] toward the machine.

[11] [11]

Note 1: When removing the fixing screw of the machine frame, the

stack tray may be in the way. Rotate the clock plate of the

stack tray shift motor clockwise as shown in Fig. 4-306a to

lower the stack tray, making an easy access to the fixing

screw.

Clock plate

Fig. 4-306a

Note 2: When attaching the process tray, check that the four load

wall rails [15] are securely engaged with the process tray unit

[14] as shown in Fig. 4-306b.

[14]

[14]

[14]

[9]

Fig. 4-304

[12]

[10]

[10]

[15]

Pawl

Fig. 4-306b

B. Alignment motor removal

1) Remove the process tray unit. (Refer to Fig. 4-301 – 306.)

2) Remove two fixing screws [1] and one connector [2], and remove

the alignment motor [3]. (There are two alignment motors. The

removal procedure is the same.)

[2]

[2]

[13]

Fig. 4-305

4 – 4

[1]

[3]

[1]

[1] [3] [1]

Fig. 4-307

Page 25

C. Alignment width adjustment

Note: When "B. Alignment plate angle adjustment" or "C. Sensor flag

overlap quantity adjustment" is performed, be sure to perform

this adjustment.

Refer to the following descriptions of "Adjustments."

D. Alignment plate angle adjustment

Refer to the following descriptions of "Adjustments."

E. Sensor flag overlap quantity adjustment

Refer to the following descriptions of "Adjustments."

4. Return roller

A. Return roller unit removal

1) Remove the process tray unit. (Refer to Fig. 4-301 – 306.)

2) Remove the fixing screw [1], and remove the return roller home

position sensor holding plate [2].

[2] [1]

B. Return roller rubber removal

1) Peel the return roller rubber [1] from the return roller [2].

[1] [2]

Fig. 4-405

C. Return roller rubber installation

1) Attach the return roller rubber [2] to the groove in the surface of

the return roller [1] from the bottom.

At that time, gradually turn the return roller [1] in the paper feed

direction.

[2]

1) 2) 3)

[1]

Fig. 4-401

3) Remove three fixing screws [4] of the lower guide [3], and remove

the return roller unit [5] together with the lower guide.

[3]

Fig. 4-402

[5]

[4]

[6]

[7]

[4]

[3]

[4]

4) Rotate the roller shaft [7] until the return roller [6] is not in contact

with the lower guide [3]. Pull out the return roller unit.

Fig. 4-406

Reference

To turn the return roller [1], turn the transport belt [3] back and forth

by inches. (Fig. 4-407a)

If the transport belt [3] is turned only backward, the transport belt arm

[4] may interfere with the belt home position sensor [5]. (Fig. 4-407b)

When turning the transport belt [3], do not hold the intermediate tray

load guide plate [6]. (Fig. 4-407c)

[3]

Fig. 4-407a

[3]

[4]

[1]

[5]

[3]

[6]

Fig. 4-403 Fig. 4-404

[7]

Fig. 4-407b

4 – 5

Page 26

[3]

[6]

Fig. 4-407c

D. Bundle process motor belt tension adjustment

Refer to the following descriptions of "Adjustments."

7) Remove the fixing screw [1] and remove the joint sensor holding

plate [2]. Remove the two fixing screws [3] and remove the paper

exit motor [4].

[1]

[2]

[3]

[4]

5. Stack tray

A. Stack tray removal

1) Remove the four fixing screws [1] at the back of the stack tray,

and remove the stack tray [2].

Note: When removing the stack tray, be careful not to damage the

wire which connects the stack tray and the finisher controller

PWB.

[1]

[2]

Fig. 4-501

[1]

6. Stack tray lift unit

A. Stack tray lift unit removal

1) Remove the right inside cover, the rear cover, and the stapler

cover. (Refer to Fig. 4-103.)

2) Remove the process tray unit. (Refer to Fig. 4-301 – 306.)

3) Remove the fixing screw [1] and remove the paper height sensor

unit [2] from the copier.

4) Remove the return roller unit. (Refer to Fig. 4-401 – 402.)

5) Remove the finisher controller PWB. (Refer to "8. PWB.")

6) Release the stack tray guide lever fixing plates backward and

forward. (Refer to "D. Stack tray guide lever fixing plate release.")

[3]

Fig. 4-602

8) Remove the fixing screw [8] of the front side plate, and remove the

lower limit sensor holding plate [9].

[9] [8]

Fig. 4-603

9) Remove the two fixing screws [10], and remove the handle unit

[11].

[10] [11] [10]

[1][2]

Fig. 4-601

Fig. 4-604

4 – 6

Page 27

10) Remove the fixing screw [12] and remove the grounding wire

[13].

11) Remove the six fixing screws [14] of the rear side plate.

[14]

14) Remove the five fixing screws [19] under the body frame [18],

and remove the stack tray lift unit together with the right inside

cover.

[19] [19]

[14]

[12]

[13]

[14]

Fig. 4-605

12) Remove the six fixing screws [15] of the front side plate.

[15]

[15]

[19]

[18]

[19]

Fig. 4-608

Note 1: Before installing the stack tray lift unit, check that the stack

tray guide levers (backward and forward) are on the tension

spring.

Tension spring

Stack tray guide lever (Forward)

Forward

Tension spring

[15]

Fig. 4-606

13) Attach the five fixing screws [16] to fix the right inside cover [17].

[16]

[17]

[16]

Fig. 4-607

Stack tray guide lever (backward)

Backward

Fig. 4-609a

Note 2: When installing the stack tray paper height sensor, check

that the coupling sections of sensor flags 1 and 2 are

engaged with each other.

Sensor flag 1

Sensor flag 2

Fig. 4-609b

4 – 7

Page 28

B. Stack tray drive unit removal

1) Remove the right inside cover and the rear cover. (Refer to Fig.

4-103.)

2) Remove the stapler cover.

3) Remove the fixing screw [1] and remove the stack tray lift motor

clock sensor holding plate [2].

2) Attach the stack tray guide lever fixing plate [3] to the stack tray

guide lever by using the holes in the front/rear side plates.

3) Tighten the fixing screw [2] of the belt pulley plate [1], and stretch

the stack tray guide bar belt [4].

[1]

[2]

[2]

Fig. 4-610

4) Remove the three fixing screws [3] and the connector [4], and

remove the stack tray drive unit [5].

[3]

[5] [3]

Fig. 4-611

[1]

[4]

C. Stack tray drive unit belt tension adjustment

Refer to the following descriptions of "Adjustments."

D. Stack tray guide lever fixing plate release

Refer to the following descriptions of "Adjustments."

E. Stack tray guide fixing plate installation

1) Loosen the fixing screw [2] of the belt pulley plate [1] which is in

the upper side of the front/rear side plates, and loosen the tension

of the stack tray guide lever belt [4].

[1]

[2]

[4]

Fig. 4-617

Note: Install the stack tray guide lever fixing plate so that the lower

edge of the stack tray guide lever fits with the mark on the

frame. By this setup, the stack tray guide lever phases (backward and forward) meet each other.

[3]

Fig. 4-616

Guide lever

Mark

Fig. 4-618a

4 – 8

Page 29

8. PWB

A. Finisher controller PWB

1) Remove the rear cover. (Refer to Fig. 4-103.)

2) Remove the connectors [1] and fixing screws [2], and remove the

finisher controller PWB [3].

[1]

[1]

[1]

[1]

[2]

[2]

[1]

Guide lever

Mark

Fig. 4-618b

7. Stapler

A. Stapler removal

1) Remove the right inside cover and the rear cover. (Refer to Fig.

4-103.)

2) Remove the connector (J8) [2] on the finisher controller PWB [1].

Remove the two fixing screws [3] and remove the stapler [4].

[3][4]

[3]

[1]

[2]

[2]

[1]

Fig. 4-801

[1]

[5] MAINTENANCE

1. Periodic replacement parts

2. Consumable parts replacement

standard

No. Part name Q’ty of use Life Remark

1 Stapler 1 200,000 times

2 Discharge needle 1 1 million times

3 Return roller rubber 2 1 million times

3. Periodic maintenance

[3]

Fig. 4-701

[1] [2]

No. Part name Item Time Remark

1 Return roller Clean-up 120,000 times

4 Consumable parts

No. Part name Product name Capacity Remark

1 Staple AR-SC1 3,000 pcs

4 – 9

Page 30

[6] ADJUSTMENT

A. Alignment width adjustment

Note: When "B. Alignment plate angle adjustment" or "C. Sensor flag

overlap quantity adjustment" is performed, be sure to perform

this adjustment.

1) Remove the right inside cover and the rear cover.

(Refer to Fig. 4-103.)

2) Set the front alignment plate to the home position.

2-1) Set SW1 on the finisher controller PWB as shown in Fig.6-101.

6) Loosen the screw [2] of the home position sensor plate [1].

[1][2]

O

F

F

Fig. 6-101

2-2) Press SW2 on the finisher controller PWB.

1

2

3

4

5

6

7

8

• The front alignment plate moves to the home position.

3) Set the rear alignment plate to the home position.

3-1) Set SW1 on the finisher controller PWB as shown in Fig.6-102.

O

F

F

1

2

3

4

5

6

7

8

Fig. 6-104

7) Adjust the position referring to the indication. Move the backward

alignment plate home position sensor (S6).

Example 1) If the width in procedure 2 is 319mm, the difference

from the standard (317mm) is +2mm. Therefore,

move the sensor [3] by 2mm in the direction of arrow

A in Fig. 6-105.

Example 2) If the width in procedure 2 is 316mm, the difference

from the standard (317mm) is -1mm. Therefore, move

the sensor [3] by 1mm in the direction of arrow B in

Fig. 6-105.

[3]

AB

Fig. 6-102

3-2) Press SW2 on the finisher controller PWB.

• The rear alignment plate moves to the home position.

Rear alignment plate home position

Fig. 6-103

4) Measure the alignment width. (Standard: 317mm)

5) Remove the process tray. (Refer to Fig. 4-108 – 113.)

Fig. 6-105

Reference

There is the mark of the standard alignment width (317mm) at the

back of the right inside cover. Fold a large sheet of paper to fit with

the mark and use it for measurement of the alignment width.

Right inside cover

317mm

Large sheet of paper

Fig. 6-106

6 – 1

[4]

Page 31

B. Alignment plate angle adjustment

1) Loosen the two fixing screws [2] of the rear alignment plate [1] with

the process tray unit installed.

[2] [1]

5) With the rear alignment plate adjusted in procedure 2) as the

reference, adjust the front alignment plate so that the clearance

between A4/LTR paper and the lead edge of the front alignment

plate is 0 – 0.5mm), and tighten the fixing screw which was

loosened in procedure 4).

Fig. 6-107

2) Set several sheets of A4/LTR paper on the process tray, and

adjust the rear alignment plate. (At that time, adjust the clearance

between A4/LTR paper and the lead edge of the rear alignment

plate to 0 – 0.5mm.)

Paper

Screw

Alignment

Front alignment plate

Finisher body

Fig. 6-110

Paper

C. Sensor flag overlap quantity adjustment

Normally when a mechanical part is replaced, it is fit with the old scale

shown in Fig. 4-312. If, however, the sensor flag overlap quantity is

varied for some reason, perform the following adjustment.

1) Remove the process tray unit. (Refer to Fig. 4-301 – 406.)

2) Loosen the fixing screw [2] of the alignment plate adjustment plate

[1] on the backward and the forward side. Move the alignment

plate [3] left and right.

[1]

[2]

Push on

Finisher body

0 − 0.5mm

Fig. 6-108

3) Remove the process tray unit. (Refer to Fig. 4-301 – 406.)

4) Loosen the fixing screw [4] of the adjustment plate of the front

alignment plate [3] at the back of the process tray unit.

[3] [4]

Rear alignment plate

[3]

Fig. 6-111

3) Adjust so that the overlap quantity of the flag section of the

front/rear alignment plate over the sensor is 1.5mm – 2.0mm.

Tighten the screw to fix.

Sensor Sensor flag

[2]

[1]

[3]

Fig. 6-109

1.5 − 2.0mm

Fig. 6-112

6 – 2

Page 32

D. Bundle process motor belt tension adjustment

1) Remove the right inside cover and the rear cover. (Refer to Fig.

4-103.)

2) Use 64g/m2 paper to make a sheet of about 10 x 20mm, and fold

the sheet into four.

50mm

10mm

Fig. 6-113

3) Turn the motor shaft [1] to squeeze the sheet of paper [4] between

the belt [2] and the tension roller [3].

[2]

[3]

5) With the sheet of paper squeezed, set the return roller shaft [7] to

the lower limit and tighten the screw [6] of the tension arm plate

[5].

[7][6] [5]

Fig. 6-116

6) Remove the sheet of paper from the belt and the tension arm.

7) Check that the return roller shaft [7] moves smoothly up and down.

[7]

[1]

[4]

Fig. 6-114

4) Loosen the screw [6] of the tension arm plate [5]. (The tension arm

plate is pulled by the tension spring.)

[6] [5]

Fig. 6-117

E. Stack tray drive unit belt tension adjustment

1) Remove the right inside cover.

2) Remove the stack tray lift motor clock sensor holding plate.(Refer

to Fig. 4-610.)

3) Remove the stack tray drive unit. (Refer to Fig. 4-611.)

4) Loosen the adjustment screw [2] of the tension arm [1]. (At that

time, the tension arm returns to the position where a tension is

applied to.)

[1] [2]

Fig. 6-115

6 – 3

[1]

[2]

Fig. 6-118

Page 33

5) Tighten the adjustment screw to fix the tension arm [1] at its return

position.

[1] [2]

[1]

[2]

Fig. 6-119

F. Stack tray guide lever fixing plate release

1) Remove the right inside cover and the rear cover.

(Refer to Fig. 4-103.)

2) Remove the stapler cover.

3) Remove the stack tray. (Refer to Fig. 4-501.)

4) Turn the clock plate of the tray shift motor, and set the stack tray

guide lever fixing plate [1] so that it can be seen from the holes

(backward and forward) in the side plate. (Clockwise: down,

counterclockwise: up). Remove the fixing screw [2] and disengage

the hook of the fixing plate from the stack tray guide lever [3].

(Same procedures for backward and forward)

[1][2] [3]

Fig. 6-120

Note: When removing the fixing screw, press the stack tray guide

lever.

Stack tray lever

Fig. 6-121

6 – 4

Page 34

[7] TROUBLESHOOTING

A. Trouble code

Code Content Details

F1-00 • Copier connection trouble (Disconnection, broken cable) Communication between the copier and the finisher is interrupted,

• Finisher controller PWB or copier trouble

F1-02 • Paper exit clock sensor trouble, connector disconnection, or

broken cable

• Paper exit motor trouble or control PWB abnormality

• Paper exit motor load abnormality

• Reverse motor abnormality or connector disconnection, or

broken cable

• Finisher controller PWB or reverse driver PWB abnormality

• Reverse roller home position sensor abnormality, connector

disconnection, or broken cable

• Reverse roller load abnormality

F1-10 • Staple unit abnormality • In the staple operation, the staple unit once moves away from

• Staple home position sensor abnormality

• Staple binding cable abnormality

• Finisher controller PWB abnormality

F1-11 • Bundle process motor or control PWB abnormality • When the return roller is operated in the initial operation, it

• Return roller home position abnormality, connector

disconnection, or broken cable

• Bundle process motor interface binding cable abnormality

• Bundle push members abnormality

• Return roller abnormality

• Bundle motor or control PWB abnormality • When the bundle push member is operated in the initial

• Bundle push member home position sensor abnormality,

connector disconnection, or broken cable

• Bundle process motor interface binding cable abnormality

• Bundle push member abnormality

• Return roller abnormality

F1-15 • Stack tray motor or control PWB abnormality • When the stack tray is operated, the stack tray upper limit

• Stack tray home position sensor abnormality, connector

disconnection, or broken cable

• Stack tray shift clock sensor abnormality, connector

disconnection, or broken cable

• Stack tray motor load abnormality • When the stack tray is lifted, it does not reach the home

F1-19 • Front alignment motor or control PWB abnormality When the front alignment guide is operated in the initial operation,

• Front alignment home position sensor abnormality, connector

disconnection, or broken cable

• Front alignment motor binding cable abnormality

• Front alignment guide member load abnormality

F1-20 • Rear alignment motor or control PWB abnormality When the rear alignment guide is operated in the initial operation,

• Rear alignment home position sensor abnormality, connector

disconnection, or broken cable

• Rear alignment motor binding cable abnormality

• Rear alignment guide member load abnormality

and is not revived.

• In the initial operation, the edge of the paper exit clock sensor

signal is not detected.

• When the reverse roller is operated in the initial operation, it

does not move from the home position or it does not reach the