Page 1

CODE: 00ZARFN1N/A1E

DIGITAL COPIER

OPTION FINISHER

MODEL AR-FN1N

AR-FN1N

CONTENTS

[Note]

• This Service Manual describes only the differences from AR-FN1. The items

which are not described in this Manual are common with the AR-FN1.

• The chapters marked with ∗ are partly modified from those of the AR-FN1.

Refer to the attached list of changes.

*[ 1 ] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

*[ 2 ] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

*[ 3 ] EXTERNAL VIEW AND INTERNAL STRUCTURE . . . . . . . . . . . . . . . 3-1

*[ 4 ] OPERATIONAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

*[ 5 ] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

*[ 6 ] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

*[ 7 ] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

*[ 8 ] TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

*[ 9 ] CIRCUIT DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

*[10] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

PARTS GUIDE

Parts marked with "!" is important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

AR-FN1N

List of changes from AR-FN1 to AR-FN1N

No.

Page Item Content Change

1 1-1 [1]-11 Power consumption

Max. 60W Changed to Max. 70W.

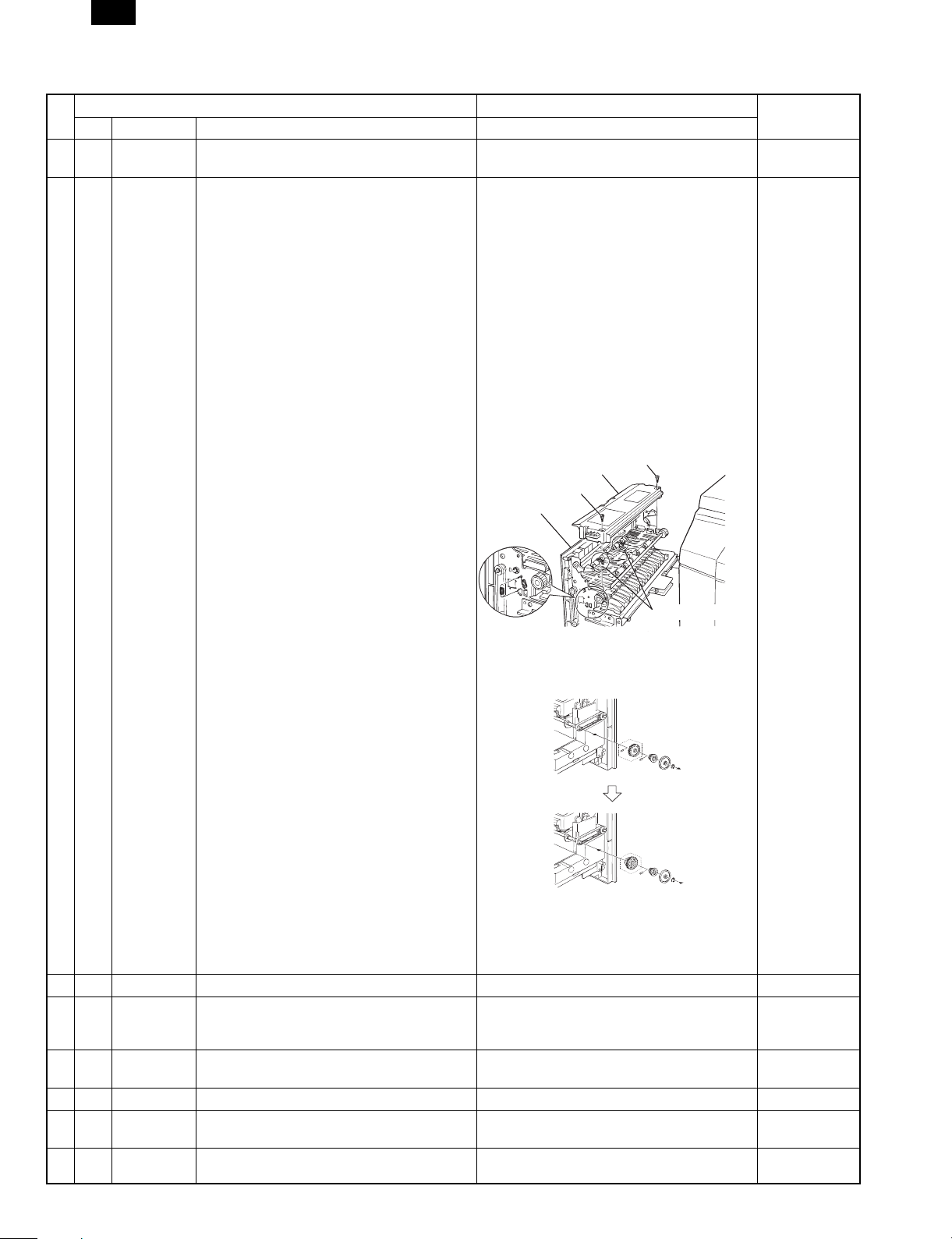

2 2-1 [2]-2 Installation 2. Add the following descriptions to the instal-

AR-FN1 AR-FN1N

lation procedure.

Before installing the AR-FN1:

* In the case of 2 trays

1. Pull out the paper exit unit from the copier

until it stops.

2. Remove the two screws which are fixing

the paper feed cover. Remove the paper

exit cover.

3. Remove the two transport springs attached

to the paper exitcover.

4. Hang the removed transport springs on the

paper exit unitfront frame (Fig. 1) to keep

there.

5. Return the paper exit cover to the original

position and fixit with two fixing screws.

Paper exit cover

Fixing screw

Fixing screw

Paper exit unit

[Fig.1]

Remark

Transport spring

6. Replace the connection gear at the rear of

the paper exit unitwith the gear packed

together with the unit as shown below.

Connection

gear

7. Insert the paper exit unit into the copier.

After completion of the above procedures,

perform installingprocedures according to

the installation manual.

3 2-4 [2]-2-14 Paper exit roller spring removal 14.Delete.

4 3-2 [3]-3 Clutch solenoid

5 3-4 [3]-5 Motor PWB unit

6 4-3 [4]-2-A Table No.(13): Signal name P12CL Signal name iP12CL is changed to T12CL.

7 4-6 [4]-2-E Elevator section

8 5-1 [5] Disassembly and assembly

llustration 12: T30RSL T30RSL is changed to T30RCL.

Table No. 12: T30RSL

Error print is corrected to

Table No.1: Main drive motor

Table No.(2): Name elevator drive unit Corrected to Elevator drive unit.

Table Item 2: Part name staple unit drive motor Corrected to Staple unit drive motor.

Main drive motor.

1/21/1999 – 1 –

Page 3

AR-FN1N

No.

Page Item Content Change

AR-FN1 AR-FN1N

9 6-1 [6] Adjustment

Table Item 1: Part name jogger F/R Delete "1. Jogger F/R" from the table.

[6]-1 Jogger F/R Delete "1 Jogger F/R."

10 6-7 [6]-11 Vertical transport roller unit

Set value Part code and price rank of the jig

are added to the set valuetable.

Set value

11 6-7 [6]-12 Paper entry port decurler unit

Nip amount adjustment

12 8-2 [8]-2-1 The finisher does not operate. (excluding the

case of jam)

Set value

Nip amount 0.5±0.1

External dimension of

shaft

Jigs Color jig R0.5

Part code: OEUKOG0602L//

Price rank: GN

Color jig F0.5

part code OEUKOG0603L//

Price rank: GN

21.6

Part code and price rank are added to the

table of nip amountadjustment.

Nip amount

(Reference)

External shaft

dimension

Inch series F/R

EX AB series F R

Japan F/R

Jig

0.5

0.8

±0.1

1.2

±0.1

±0.1

21.8 21.3 20.9 20.5

Part code: OEUKOG0601L//

Price rank: GN

Delete "upper transport open/close" in the

description. Refer tothe following.

Remark

1.6

±0.1

Check connection of

Is the

main PWB

DSW1.2.3PGOP

signal O.K. ?

YES

the copier, the harness

connection of the

NO

harness which is

connected to the top/

front/upper transport

open/close switch.

Replace if necessary.

13 9-5 [9]-4-D Extension I/O: M66500FP (IC3) expansion sig-

nal

Pin No.

Signal name

16

46 WLCL

48

64

STID2

STSL

T12CL

Specifications

Tray 3 speed reduction

clutch drive signal

(H: ON)

Staple tray paper

holding solenoid (H: ON)

Tray 1/2 speed

reduction clutch drive

signal (L: ON)

main PWB

DSW1.2.3PGOP

signal O.K. ?

Signal name:

Signal name:

Specification:

Signal name:

Specification:

Signal name:

Specification:

Is the

YES

Check connection of

the copier, the harness

NO

connection of the harness

which is connected to the

top/front switch. Replace if

necessary.

STID2 is changed to STID2/.

WLCL is changed to T3SLCL.

"Tray 3 sped change" is changed to

"Tray 3 speed reduction."

STSL is changed to T12CL.

"Staple tray paper holding solenoid

(ON at H)" is changed to "Tray 1/2

speed reduction clutch drive signal

signal (ON at H).

T12CL is changed to T30RCL1.

"Tray 1/2 speed reduction clutch

drive signal (ON at L)" is changed to

"Tray 3 paper exit roller clutch

(ON at L).

– 2 – 1/21/1999

Page 4

AR-FN1N

No.

Page Item Content Change

AR-FN1 AR-FN1N

14 10-1 [10]-1 Actual wiring diagram

Rear

4PIN

RD

RD

CN-C

1+24VIN1

2+24V12

BL

6+5V

CN-A

GY

5GND2

Rear

GY

1+24VINRD3GND1

FG

4PIN

Added.

GY

GY

GY

4GND1

GY

6

GY

FG

CN-C

RD

1+24VIN1

RD

2+24V12

GND2

GND316

CN-A

CN-B

CN-J

BL

CN-A

6+5V

5GND2

1+24VINRD3GND1

15 10-2 [10]-1 Main PWB 2/2

CN-J

GY

15 GND23

LB

14 T3UP4

BL

13 +5V5

6

CN-J

BL

1+5V

PK

2STND/

GY

3GND2

CN-J

GY

15 GND23

LB

14 T3UP4

BL

13 +5V5

6

PPSL/

2

1+24V

1

2

1

2

2

PPSL

CN-J

BL

1+5V

PK

2STND/

GY

3GND2

Added.

16 10-3 [10]-2 Main PWB

2-7C

RMA

2-7C

RMA/

2-7C

RMB

2-7C

RMB/

2-7B

PMA

2-7B

PMA/

2-7B

PMB

2-7B

PMB/

R201 10K

R136 10K

R135 10K

2-7A

STUMA

2-7A

STUMA/

2-7A

STUMB

2-7A

STUMB/

2-5C

OFMA

2-5C

OFMB

1-4A

PPSL

VCCVCC

RMA

RMA/

RMB

RMB/

PMA

PMA/

PMB

PMB/

RESO/

GND

F-RXDF-RXD

N.C

F-TXD

N.C

F-DSRF-DSR

F-DTR

F-DTR

STUMA

STUMA/

STUMB

STUMB/

GND

GND

OFMA

OFMB

STGSL

(YB2SL)

1

VCC

2

TIOCA3/TP8/PB0

3

TIOCB3/TP9/PB1

4

TIOCA4/TP10/PB2

5

TIOCB4/TP11/PB3

6

TOCXA4/TP12/PB4

7

TOCXB4/TP13/PB5

8

%%oDREQ0%%o/TP14/PB6

9

%%oADTRG%%o/%%oDREQ1%%o

10

%%oRESO%%o

11

VSS

12

TXD0/P90

13

TXD1/P91

14

RXD0/P92

15

RXD1/P93

16

%%oIRQ4%%o/SCK0/P94

17

%%oIRQ5%%o/SCK1/P95

18

D0/P40

19

D1/P41

20

D2/P42

21

D3/P43

22

VSS

23

D4/P44

24

D5/P45

25

D6/P46

26

D7/P47

IC02

2-7A

2-7A

2-7A

2-7A

2-5C

2-5C

1-4A

2-7C

2-7C

2-7C

2-7C

2-7B

2-7B

2-7B

2-7B

R201 10K

RMA

RMA/

RMB

RMB/

PMA

PMA/

PMB

PMB/

R136 10K

R135 10K

STUMA

STUMA/

STUMB

STUMB/

OFMA

OFMB

PPSL

VCCVCC

RMA

RMA/

RMB

RMB/

PMA

PMA/

PMB

PMB/

RESO/

GND

F-RXDF-RXD

N.C

F-TXD

N.C

F-DSRF-DSR

F-DTR

F-DTR

STUMA

STUMA/

STUMB

STUMB/

GND

GND

OFMA

OFMB

STSL

(STSL)

1

VCC

2

TIOCA3/TP8/PB0

3

TIOCB3/TP9/PB1

4

TIOCA4/TP10/PB2

5

TIOCB4/TP11/PB3

6

TOCXA4/TP12/PB4

7

TOCXB4/TP13/PB5

8

%%oDREQ0%%o/TP14/PB6

9

%%oADTRG%%o/%%oDREQ1%%o

10

%%oRESO%%o

11

VSS

12

TXD0/P90

13

TXD1/P91

14

RXD0/P92

15

RXD1/P93

16

%%oIRQ4%%o/SCK0/P94

17

%%oIRQ5%%o/SCK1/P95

18

D0/P40

19

D1/P41

20

D2/P42

21

D3/P43

22

VSS

23

D4/P44

24

D5/P45

25

D6/P46

26

D7/P47

IC02

Remark

STGSSS+ (YB2SL) is

changed to STSL.

17 10-5

[10]-2 Main PWB circuit diagram The following figure is added to Main PWB cir-

10-6

cuit diagram D-5 Added.

Added.

+

C03

47U/35V

STUMA

CNH-05

STUMA/

STUMA/

CNH-06

STUMBSTUMB

CNH-07

STUMB/

STUMB/

CNH-08

18 10-8 [10]-2 Main PWB connector signal table D-4 Connector signal table D-4

T3SLCL/ is changed to T3SLCL.

(Refer to the table below.)

CNL (B14B-PHDSS)

SIGNALNO

+24V

01

PPSL/

02

+24V

03

T3SLCL/

04

COM705

PPSL

T3SLCL/

CNL (B14B-PHDSS)

+24V

01

PPSL/

02

03

+24V

04

T3SLCL/

COM705

CNJ-13

+5V

0.1uF

+24V

CNJ-15

SIGNALNO

C75

0.1uF

PPSL

T3SLCL

CNH-29

1-4B

STMB

1-4B

STMA

1/21/1999 – 3 –

Page 5

AR-FN1N

q

COPYRIGHT © 1999 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted,

in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission of the publisher.

SHARP CORPORATION

Printing & Reprographic Systems Group

Quality & Reliability Control Center

Yamatokoriyama, Nara 639-1186, Japan

1999 January Printed in Japan

Loading...

Loading...