Page 1

SERVICE MANUAL

CODE: 00ZARF13//A1E

DIGITAL FULL COLOR COPIER/PRINTER/

MULTIFUNCTIONAL SYSTEM OPTION

SADDLE STITCH FINISHER

AR-F13

MODEL

CONTENTS

[1] INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] EXTERNAL VIEWS AND INTERNAL STRUCTURES . . . . . . . . . . 2-1

[3] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[4] OPERATIONAL DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

[5] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[6] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[7] MACHINE OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[8] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[9] TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

AR-PN1

[10] SIMULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

[11] ELECTRICAL SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

PARTS GUIDE

Parts marked with “ ” are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

[1] INTRODUCTION

1. Product outline

This unit is installed to the following machines to perform the after-process of output paper from a printer, a copier, or a fax machine.

1) Employment of the through-type stapler

Employment of the through-type stapler allows to make saddle

stitch by one stapler.

2) 3 kinds of auto staple functions

There are 3 staple positions available. (One position in the front,

one position at the back, 2 positions at the center)

3) Saddle stitch function

Up to 10 sheets of paper can be stapled at the center and folded

into two and discharged.

4) Punch function (Option)

By installation of a puncher unit, paper can be punched to make

holes for a binder. (Applicable for 64 - 128g/m². OHP films cannot

be used.)

Applicable models AR-C260/C260M

2. Configuration

1. Before installation of this unit, the large-capacity paper feed tray

(AR-LC5) or the 1-stage paper feed desk (AR-D17) or the 3-stage

paper feed desk (AR-D18) or the duplex 2-stage duplex paper feed

desk (AR-D19) must be installed in advance.

2. When installing this unit, the duplex pass and reverse unit (ARPB1) must be installed together.

3. This unit cannot be installed with the sorter (AR-S11) together.

3. Specifications

Model AR-F13

Type 2-bin type saddle stitch finisher

Mount type Floor type

Conditions The paper feed desk and the reverse bypass

Reverse section None (Reverse bypass module takes this

Transport speed Color: 25 sheets/min.; B/W: 32 sheets/min.

Transport alignment Center alignment

Tray type Offset tray Book tray for saddle

Capacity of paper

exit and load

Paper exit direction Face-up/face-down Face-down

module must be installed in advance.

section.)

(LT), 33 sheets/min. (A4)

Upper tray Lower tray

stitch

1,000 sheets:

A4/8.5" x 11"/B5:

2

80 g/m

(Capacity varies

depending on the user

circumstance or paper

condition.)

500 sheets:

Larger size than A4/

8.5" x 11", invoice, A5,

A4R

10 sheets x 10 sets

2

(80 g/m

)

Paper size to be

discharged

Paper weight to be

discharged

Remaining paper

detection

Discharged paper

full detection

Offset function Provided (25mm) N/A

Paper size which

can be stapled

Quantity of paper to

be stapled (max.)

Stapling One at the back,

Stacking Horizontal dislocation: Within 20 mm

Alignment (max.

misalignment)

Staple standard Face-down standard Face-down standard

Staple supply Refill type

Staple detection Staple empty detection: Provided

Power consumption 45W or below

Power supply Supplied from the main unit (paper feed desk)

External dimensions

(W x D x H)

Weight Approx. 39 kg

Communication type Serial communication

Option detection Automatic detection

Face-up

Any paper available.

(Offset is not available

for A3 Wide (12x18),

OHP, postcard,

envelope, A5R and

special.)

Face-down

A3 wide (12” x 18”) A3,

B4, A4, A4R, B5, B5R,

8K, 16K, 16KR

11" x 17", 8.5" x 14",

8.5" x 13", 8.5" x 11",

8.5" x 11"R, 5.5" x 8.5",

7.25 x 10.5R

(Offset is not available

for A3 Wide (12 x 18).)

Face-up

64 to 300 g/m

17 to 80 lbs.

Face-down

64 to 200 g/m

17 to 55 lbs.

Provided Provided

Provided Provided

wo positions:

t

A3, B4, A4, B5,

11

"

x 17", 8.5" x 11",

8K, 16K, Legal,

Letter-R, A4R

one at the back:

A3, B4, A4, A4R,

B5, 11

8

.5" x 14",

"

x 13", 8.5" x 11",

8.5

"

x 11"R, 8K, 16K,

8.5

16KR

30 sheets

(A4/LT: 80 g/m

Target: 50 sheets

(A4: MI paper, M

paper)

two positions (one in

the front)

Vertical dislocation: Within 50 mm

(at offset-staple)

Alignment does not matter for non-offset and

750 sheets or above.

Within 2.5 mm (Nominal)

(at offset-staple)

Cartridge empty detection: Provided

Staple jam detection: Provided

(DC 24V, 2.7A) DC 5V

728 x 603 x 1,000 (mm)

"

x 17

2

/

2

/

",

2

A3, B4, A4R, 11"x17",

8.5"x11"R, 8.5"x14

64 to 105 g/m

17 to 28 lbs.

A3, B4, A4R, 11" x 17",

8.5" x 11"R, 8.5" x 14"

10 sheets

)

(A4/LT: 80 g/m2)

Center stapling, center

folding

2

/

AR-F13 INTRODUCTION 1-1

Page 3

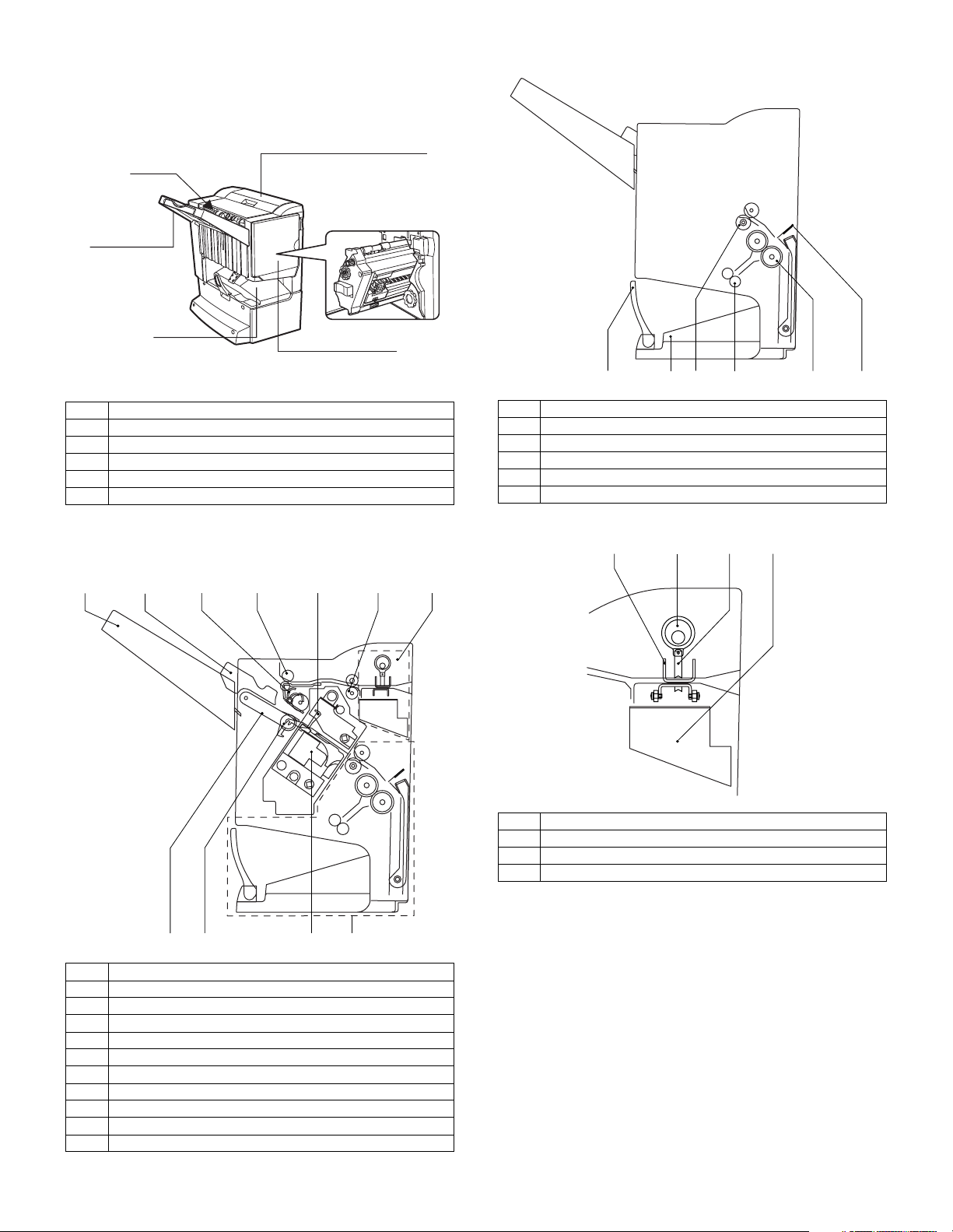

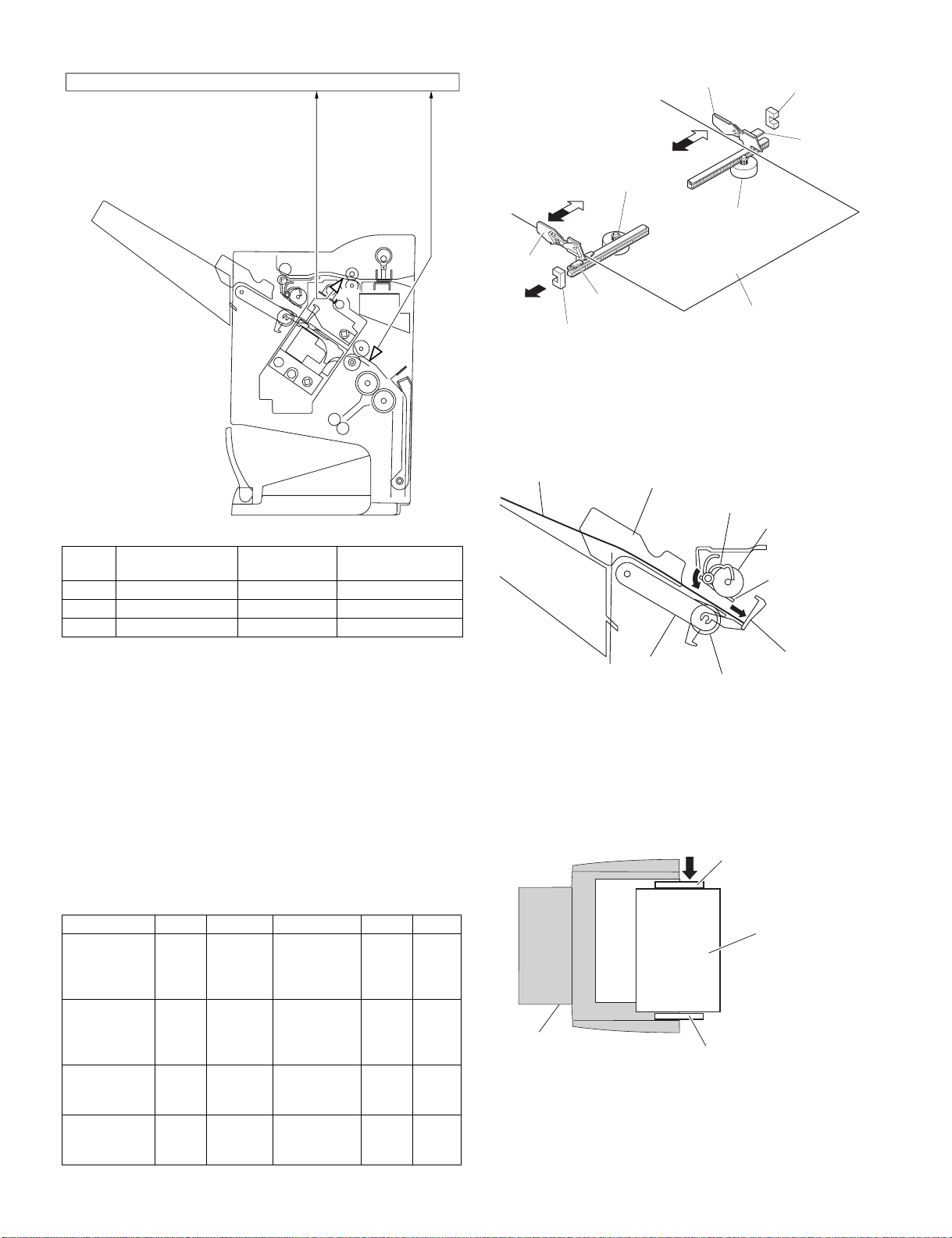

[2] EXTERNAL VIEWS AND

INTERNAL STRUCTURES

1. External view

[1]

[3]

[6]

B. Saddle section

[2]

[5]

[1] Stapler compiler

[2] Top cover

[3] Stapler section

[4] Front cover

[5] Saddle stitch tray

[6] Offset tray

2. Internal structure

A. Finisher section

[1]

[2]

[3] [7][5][4] [6]

[4]

[1]

[1] Book making stopper

[2] Book making tray

[3] Bundle transport roller

[4] Book making exit roller

[5] Paper folding roller

[6] Paper pushing plate

[3]

[4][2]

C. Puncher section (Option: AR-PN11)

[3][1]

[2]

[4]

[5]

[6]

[9]

[8]

[1] Paper exit tray

[2] Alignment plate (Front, back)

[3] Paddle

[4] Paper exit roller

[5] Process tray stopper

[6] Transport roller

[7] Puncher section (Option)

[8] Paper exit belt

[9] Bundle exit roller

[10] Stapler

[11] Saddle section

[1] Dice

[2] Cam

[3] Punch

[4] Punch dust box

[10]

[11]

AR-F13 EXTERNAL VIEWS AND INTERNAL STRUCTURES 2-1

Page 4

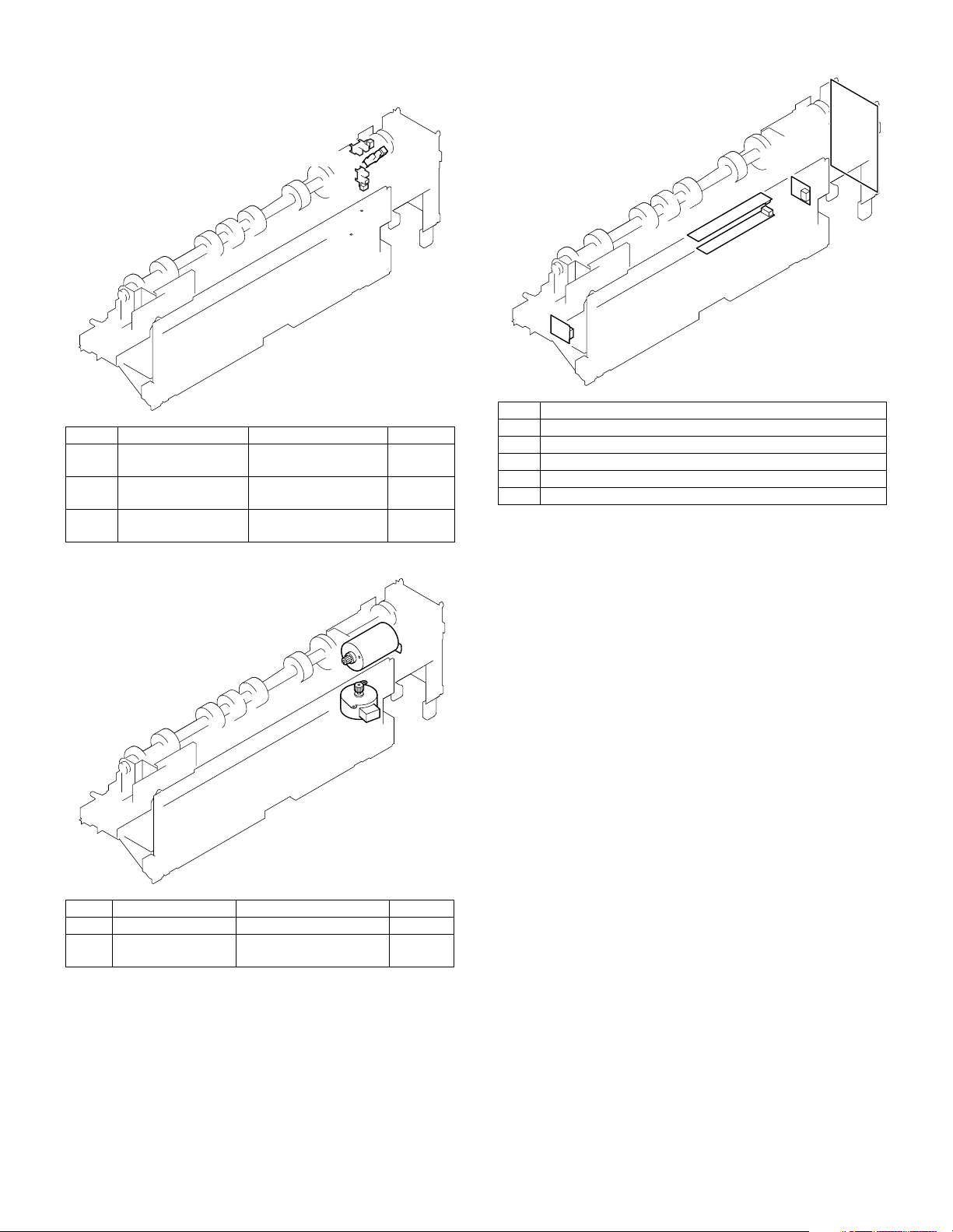

3. Finisher and saddle section

A. Sensor

SSS

LLLS

FJHPS

RJHPS

SLS

LE

PHPS

FRHPS

FPS

FES

ULS

ARHPS

FHPS

PI18

PI19

PI20

PI21

FDSW

BES

FDS

TCS

AS

OBHPS

O

Code Name Active condition Remark

SPS Self prime sensor Cartridge staple

detected : "L"

SS Staple sensor Stapler cartridge

detected : "L"

FDS Front door sensor Front cover open : "H"

FE

TCS Upper cover sensor Upper cover open : "H"

FDSW Front door switch Front door closed : "H"

JS Joint switch Printer connected : "H"

SSS Stapler safety switch Oscillation guide closed :

"H"

B. Motor and PWB

JS

FPM

FFM

FSM

ES

FFC

Code Name Active condition Remark

ES Entry sensor Paper detected : "H"

PHPS Paddle home position

Paddle HP : "H"

sensor

ARHPS Bundle roller home

Oscillation guide HP : "H"

position sensor

FJHPS Alignment home

position sensor (front)

RJHPS Alignment home

position sensor (rear)

Alignment tray (F) HP :

"H"

Alignment tray (R) HP :

"H"

AS Alignment tray sensor Paper detected : "H"

OBHPS Exit belt home

Paper exit belt HP : "H"

position sensor

BES Tray paper sensor Tray paper detected : "H"

SLS Paper level sensor Paper detected : "H"

FPS Bookbinding position

Paper detected : "L"

sensor

FHPS Bookbinding home

position sensor

FRHPS Bookbinding roller HP

sensor

FES Bookbinding paper

Folding operation

HP : "L"

Bundle transport roller

HP : "H"

Paper detected : "H"

sensor

FE Bookbinding clock

sensor

ULS Lift upper sensor Tray upper limit detected :

"H"

LLLS Lift lower sensor Tray lower limit detected :

"H"

LE Lift lock sensor

SHPS Slide home position

Stapler HP : "H"

sensor

STHPS Stapler home position

Stapler stapling HP : "L"

sensor

FAM

FRJM

FFJM

FLM

FFSM

[1]

Code Name Active condition Remark

FFM Transport motor Paper transport

FPM Paddle motor Oscillation guide drive,

paper exit to offset tray

FAM Bundle exit motor Paper exit operation

FFJM Alignment motor (front) Alignment plate (F) drive

FRJM Alignment motor (rear) Alignment plate (R) drive

FLM Shift motor Paper exit tray up/down

FFSM Stapler/Fold motor Stapling/paper folding

FSM Slide motor Staple unit sliding

AR-F13 EXTERNAL VIEWS AND INTERNAL STRUCTURES 2-2

Page 5

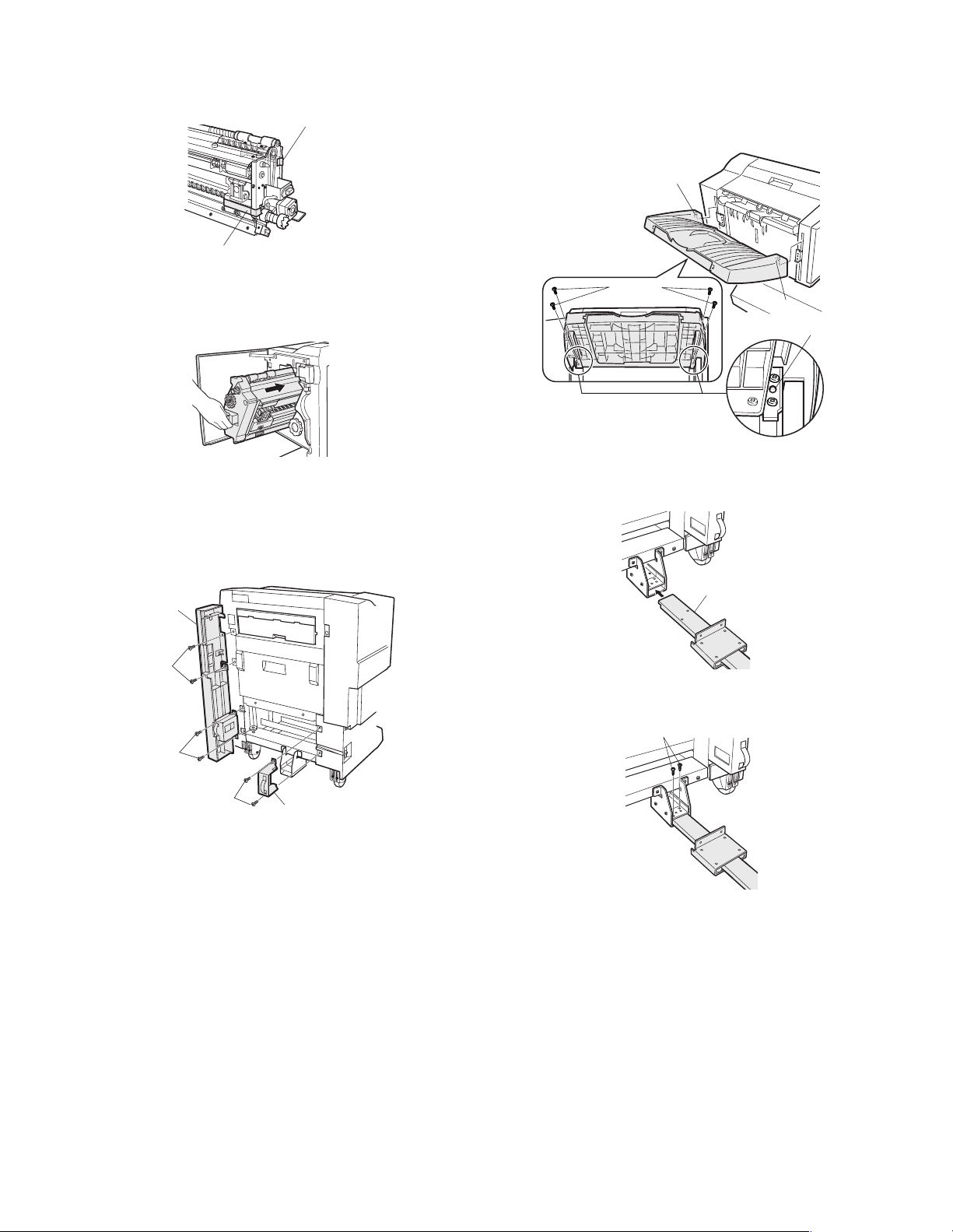

4. Puncher section (AR-PN1)

A. Sensor

C. PWB

PE

Punch home position

PSHPS

Code Name Active condition Remark

Punch home position

sensor

PSHPS Punch side home

position

PE Punch dust sensor In the

Punch HP detected:"L" In the

Punch slide unit HP

detected:"H"

punch unit

In the

punch unit

punch unit

B. Motor

[1]

[4]

[2]

[3]

[5]

Code Name

[1] Punch driver PWB

[2] Side resist photo sensor PWB

[3] Side resist LED PWB

[4] Dust full photo sensor PWB

[5] Dust full LED PWB

FPNM

FPSM

Code Name Active condition Remark

FPNM Punch motor Punch drive

FPSM Punch side motor Punch slide unit

transverse move

AR-F13 EXTERNAL VIEWS AND INTERNAL STRUCTURES 2-3

Page 6

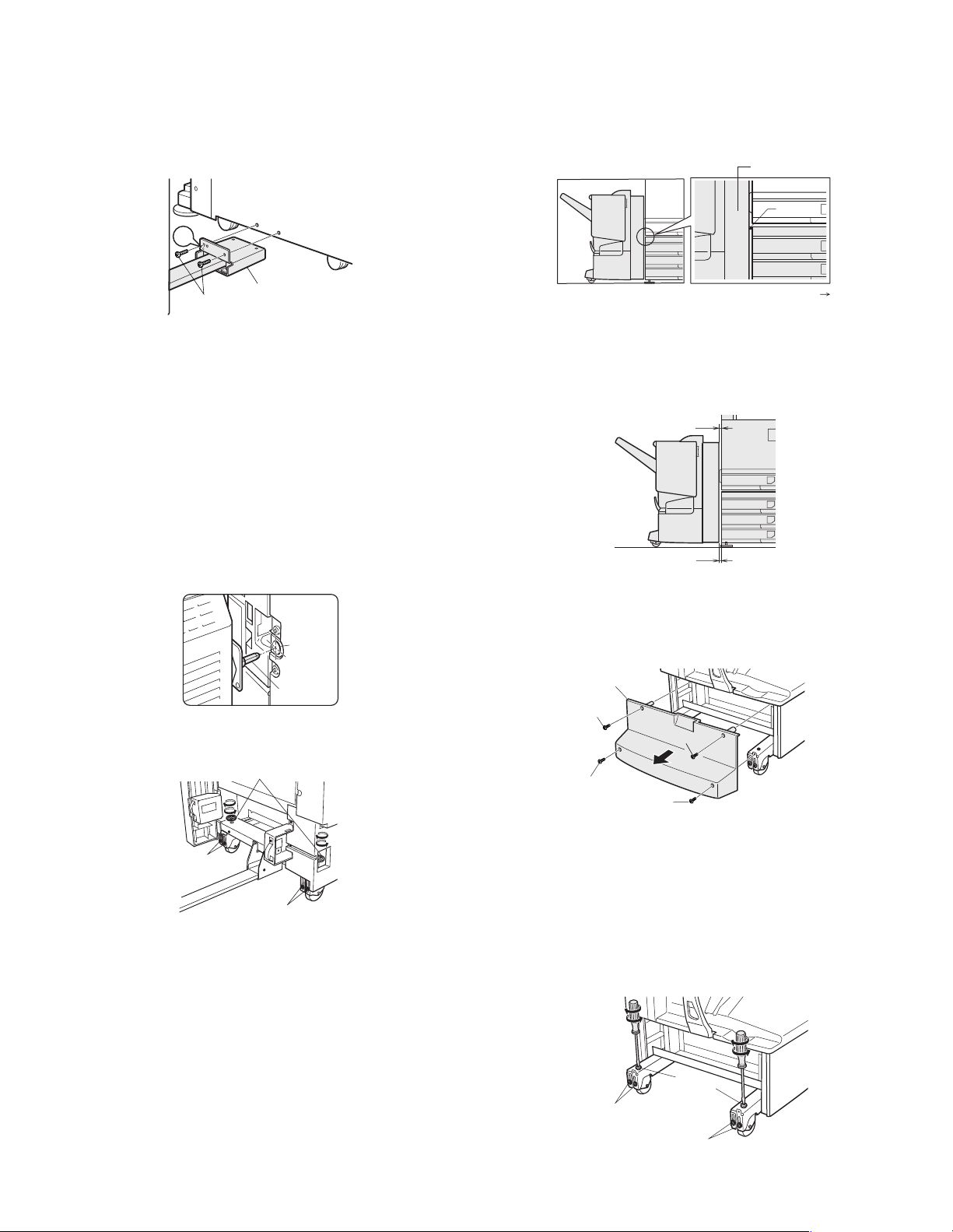

[3] UNPACKING AND

INSTALLATION

1. AR-F13

<Before installation>

• Start installation after checking that the DATA indicator on the operation panel is neither lit nor blinking.

• For installation of AR-F13, an optional stand (AR-D17, AR-D18 or

AR-D19) and a duplex bypass/inverter unit (AR-RB1) must have

been installed.

• Ensure that the connecting plate on the front of the optional stand

and the two supplied connection plates are securely attached.

Parts included

Exit tray:

1 pc.

Staple unit:

1 pc.

Lock plate:

1 pc.

Front cover:

1 pc.

Screw A (M4 x 6):

4 pcs.

Screw B (M4 x 10):

2 pcs.

Screw C (M4 x 18):

5 pcs.

Grounding plate:

1 pcs.

Connecting plate:

1 pc.

Screw E (M4 x 7):

4 pcs.

Staple cartridge: 1 pc.

Staple position label:

1 sheet

2) Remove the actuator.

<1> While holding the base of the exit actuator of the duplex

bypass/inverter unit with one hand, pull the end of the exit

actuator with the other hand to remove the actuator.

<2> If the exit tray is installed to the duplex bypass/inverter unit,

remove it.

Actuator

3) Attach the lock plate and the grounding plate.

<1> Remove the screw from the rear side of the duplex bypass/

inverter unit.

<2> Put the lock plate to the duplex bypass/inverter unit and

attach it with screw C on the front side and with screw D on

the rear side.

<3> Remove the exterior securing screw, put the two grounding

plates to the main unit, and secure them with screws C (two

for each).

∗ At this time, attach the front grounding plate so that marking F is

positioned up.

Screw

Screw D

(M4 x 18 with rosette):

1 pc.

punch position label:

1 sheet

1) Turn off the main switch.

<1> Turn the main switch located at the left side of the main unit

to the "OFF" position.

<2> Remove the power plug from the outlet.

"OFF"

<1>

Screw D

Lock plate

<2>

Screw C

Exterior

securing screw

Screws C

<3>

Grounding plate

AR-F13 UNPACKING AND INSTALLATION 3-1

Page 7

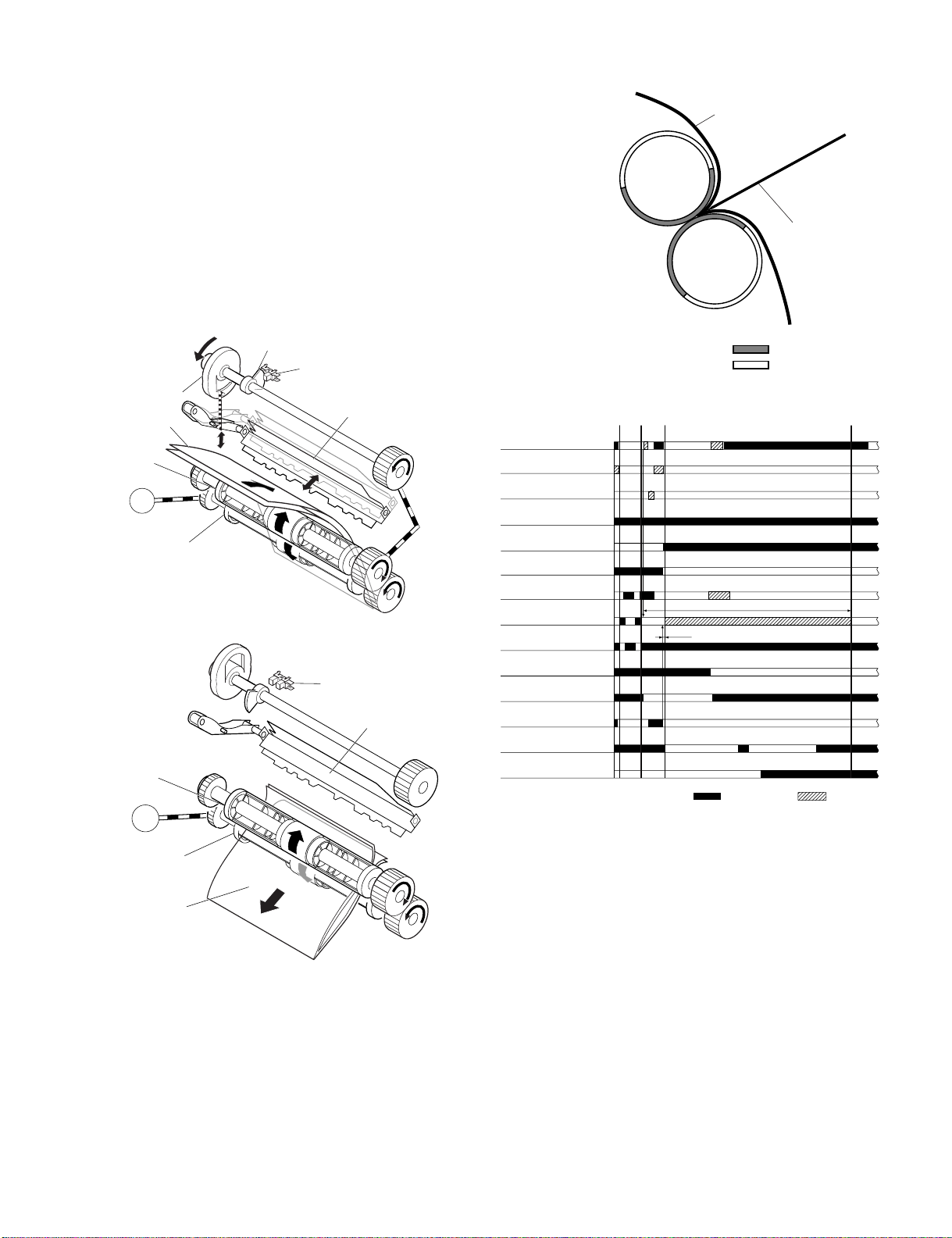

4) Attach the staple unit to the finisher.

Screws A

<1> Open the front cover of the saddle finisher.

<2> Remove the two pieces of packing tape from the staple unit.

Packing tape

Packing tape

6) Attach the exit tray to the saddle finisher.

<1> Put the two pawls of the exit tray onto the saddle finisher.

<2> Secure the exit tray with four screws E.

At this time, ensure that the positioning dowel is securely

inserted.

Pawl

<3> Hold the handle and the bottom side of the staple unit, and

insert the unit into the saddle finisher.

<4> Close the front cover of the saddle finisher.

5) Attach the front cover to the saddle finisher.

<1> Put the plate R to the saddle finisher so that marking R is

positioned up and then secure the plate with two screws A.

<2> Put the front cover to the saddle finisher as shown in the illus-

tration and secure the cover with two screws B at the upper

part and two screws A at the lower part (four screws in total).

Front cover

Screws B

Screws E

Pawl

Positioning dowel

7) Attach the connecting plate to the saddle finisher.

<1> Insert the connecting plate into the sheet metal at the lower

part of the saddle finisher.

Connecting plate

<2> Secure the connecting plate to the saddle finisher with two

screws A.

Screws A

Screws A

Plate R

AR-F13 UNPACKING AND INSTALLATION 3-2

Page 8

8) Connect the saddle finisher to the main unit.

Clearance A

Clearance B

Adjusting part

securing screws

Adjusting part

securing screws

Front side

Rear side

<1> Move the saddle finisher toward the left (exit area) of the main

unit.

<2> Position the connecting plate that has been attached to the

saddle finisher to the two holes at the lower left of the

optional stand, and secure it with two screws C.

At this time, attach the rear screw to the hole with marking C.

Optional stand

<4> Turn the front height adjusting handle so that the height of

the top of the rib on the front cover matches with the height of

the top of the stand.

<5> Tighten the adjusting part securing screws (two for each of

front and rear).

<6> Carry out work B. (next page)

Front cover

Main unit

Rib

C

Screws C

9) Adjust the height of the saddle finisher.

<1> Move the saddle finisher close to the main unit.

<2> Ensure that the guide pin of the lock plate that has been

attached to the duplex bypass/inverter unit is inserted

smoothly into the connecting hole of the saddle finisher.

∗ If the guide pin should not inserted smoothly, adjust it using the pro-

cedure described below.

A. If the connecting hole of the saddle finisher is deviated from the

guide pin of the lock plate:

<1> Loosen the two adjusting part securing screws at the rear of

saddle finisher stand section.

<2> Turn the rear height adjusting handle so that the height of the

guide pin matches with the height of the center of the connecting hole.

<3> Loosen the two adjusting part securing screws at the front of

the saddle finisher stand section.

Connecting plate

Adjusting

hole

Guide pin

Stand

Continued to the next page

B: If the connecting hole of the saddle finisher matches with the guide

pin of the lock plate:

<1> Push the saddle finisher toward the main unit.

<2> Check the clearance between the saddle finisher and the

main unit at the upper and lower parts.

• If clearance A is not equal to clearance B:

<1> Remove the four screws that secure the cover of the saddle

finisher stand and remove the cover.

Cover

Screw

Screw

Front side

Adjusting

part securing

screws

Height adjusting handles

Adjusting part securing screws

Rear side

Screw

Screw

<2> Loosen the adjusting part securing screws (two for each of

front and rear).

<3> Turn the height adjusting screws (one for each of front and

rear) respectively so that clearance A becomes equal to

clearance B.

<4> Check that clearance A and clearance B are uniform both at

the front and at the rear.

<5> Tighten the adjusting part securing screws (two for each of

front and rear).

Height adjusting

screws

AR-F13 UNPACKING AND INSTALLATION 3-3

Page 9

<6> Reattach the removed cover so that the four securing bosses

of the cover are inserted into the four positioning holes and

then tighten the four screws in the order of <1> and <2>

shown in the illustration to secure the cover.

Cover

Screw

<2> Push the staple cartridge securely into the staple section until

it clicks.

<2>

Screw

Screw

<1>

Screw

10) Connect the connector of the saddle finisher.

<1> Remove the screw that secures the power supply cover at

the rear face of the stand and remove the power supply

cover.

<2> Cut out the portion of the power supply cover shown in the

illustration.

<3> Secure the power supply cover to the rear cabinet.

Cut-out portion

Screw

Power supply cover

<4> Connect the connector for connecting the saddle finisher to

the connector on the stand and secure it with the screw on

the connector.

[Note]

Check that the right

and left of the staple

cartridge are not

loose.

13) Attach the staple unit to the finisher.

Insert the staple section and close the front cover of the finisher.

14) Paste the staple position label.

Open the front cover and paste staple position label A to the posi-

tion shown in the illustration.

Screw

Connector

If another peripheral device must be installed, carry out the following

steps at the end of the installation work.

11) Move the staple unit of the saddle finisher to

the cartridge insertion position.

<1> Insert the power plug of the main unit to the outlet and turn

on the main switch.

<2> Wait for some time until the initial operation of the saddle fin-

isher is complete.

12) Set the staple cartridge to the staple unit.

<1> Open the front cover of the saddle finisher and pull out the

staple unit.

For Scanner

X

Y

If the B/W scanner module/DSPF is attached, paste staple position

label B to the position on the B/W scanner module/DSPF shown in

the illustration.

For RADF

Y

X

AR-F13 UNPACKING AND INSTALLATION 3-4

Page 10

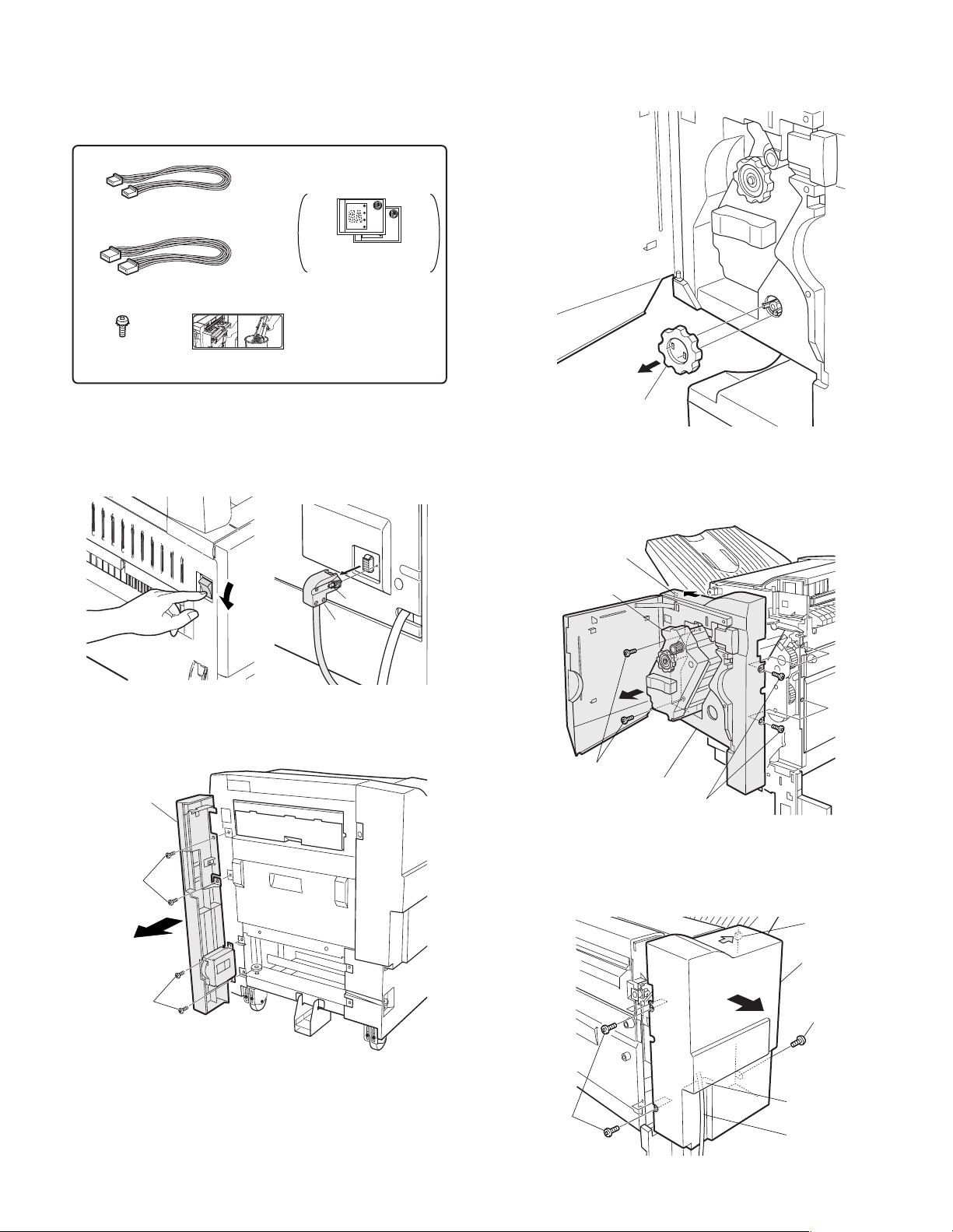

2. AR-PN1

<Before installation>

For installation of AR-PN1A/PN1B/PN1C/PN1D, a saddle stitch

finisher (AR-FN13) must have been installed.

Parts included

Harness A (purple): 1 pc.

Hole punch position label*:

2 sheets

Harness B (orange): 1 pc.

Screw

(M4 x 6 with rosette)

: 1 pc.

Dust box label:

1 sheet

* Will not be used.

Use the hole punch

position labels packed

in AR-F13.

3) Remove the front cabinet and the rear cabinet from the finisher.

<1> Open the front door of the finisher and remove the jam han-

dling dial.

1) Turn off the main switch of the main unit of the printer.

<1> Turn the main switch located on the front side of the main

unit to the "OFF" position.

<2> Then remove the power plug of the main unit from the outlet.

<3> Loosen the screw and remove the connector of the finisher.

Screw

Connector

2) Remove the front cover from the right front of the finisher.

Remove the screws A and B (two for each) that secure the finisher

front cover and remove the front cover.

Front cover

Screws B

Jam handling dial

<2> Remove the four front cabinet securing screws, pull out the

staple unit until it stops, then remove the pawl of the front

cabinet in the direction indicated by the arrow and remove

the front cabinet.

Pawl

Staple unit

Screws

Front cabinet

Screws

<3> Remove the three rear cabinet securing screws, remove the

pawl in the direction indicated by the arrow, and remove the

rear cabinet.

At this time, remove the relay harness through the opening of

the rear cabinet.

Pawl

Screws A

Screw

AR-F13 UNPACKING AND INSTALLATION 3-5

Rear

cabinet

Screw

Opening for

relay harness

Relay harness

Page 11

4) Remove the top cover.

<1> Remove the four top cover securing screws and remove the

top cover.

Screw

Top cover

<2> Remove the four pawls from the top cover and separate the

cover into the upper and lower portions. Reuse the upper

portion.

Pawl

Top cover

Pawl

<2> Remove the two paper-in PG securing screws.

<3> Remove the upper bosses of the paper-in PG.

<4> Remove the lower bosses of the paper-in PG with a minus

screwdriver etc.

5) Remove the paper-in PG of the punch unit.

<1> Remove the dust box.

1

<5> Remove the paper-in PG.

<6> Reattach the dust box.

AR-F13 UNPACKING AND INSTALLATION 3-6

Page 12

6) Attach the punch module.

Screw

Relay harness

Opening for

relay harness

Screws

Rear cabinet

<1> Insert the two bosses of the punch unit into the boss holes of

the finisher and fix the punch module using three screws.

Note: For the screws, use a supplied screw and the two screws

that have been removed in step 4).

Boss hole

Boss hole

Boss

Screw

Punch module

Boss

8) Reattach the covers that have been removed.

<1> Hang the two pawls of the top cover and secure them using

the two screws.

Screw ScrewTop cover

Pawl

Screw

Screw (with rosette)

(supplied with this unit)

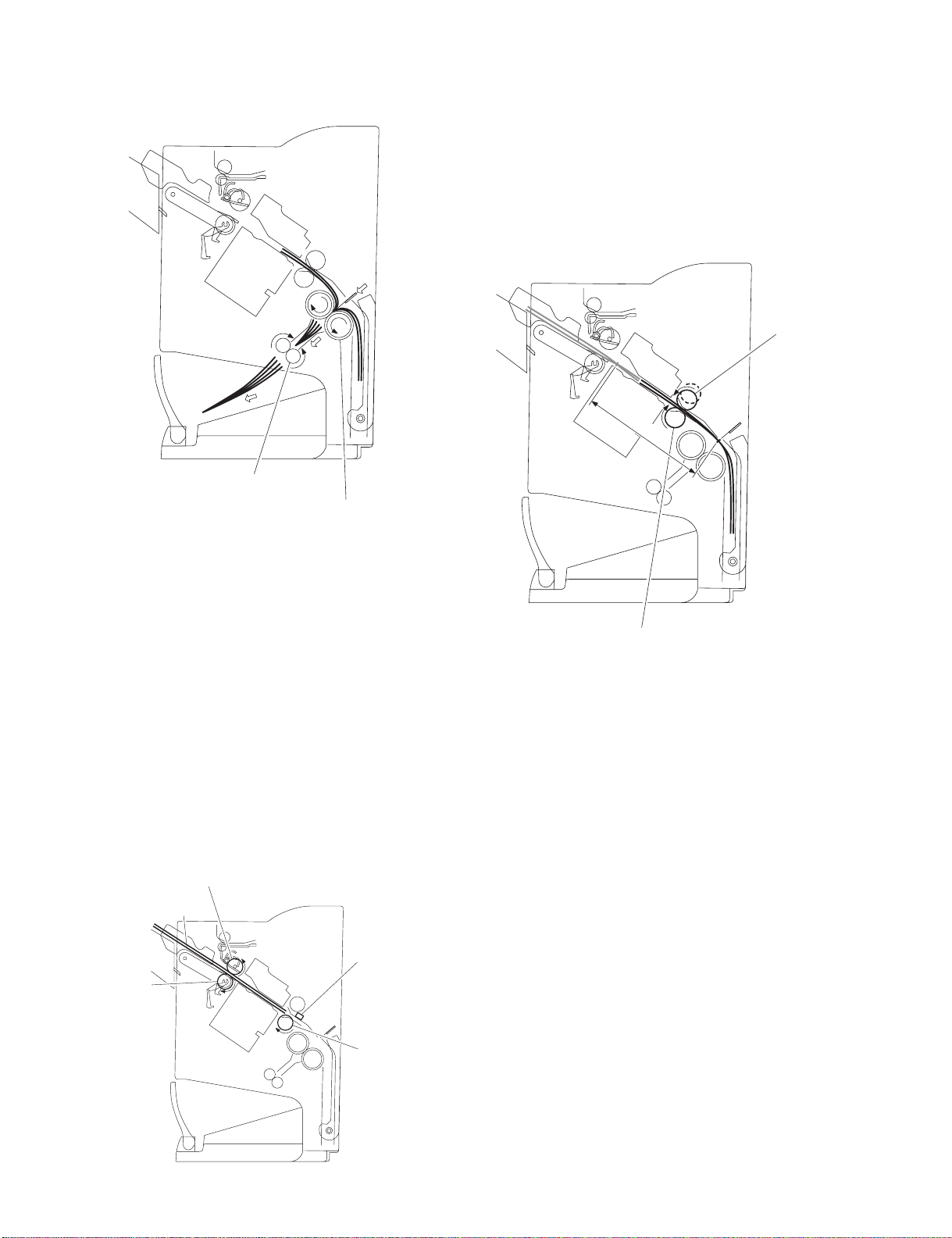

7) Connect the harness of the punch module to the PWB of the finisher.

Remove the clamps that fix the harness, handle the wiring of harness A (purple) and harness B (orange), and fix them with the

clamps.

Harness B (orange)

Harness A (purple)

Clamps

<2> Pass the relay harness to the rear cabinet and secure the

rear cabinet using the three screws.

<3> Remove the lock release lever that has been attached to the

front cabinet.

Reattach the front cabinet to its original position, push in the

staple unit, and attach it using the two screws.

Insert the protrusion (B) of the lock release lever that has

been removed before to the hole (C) of the latch arm.

After attaching it, move the lever to check that it moves

smoothly.

If the lever does not move smoothly, remove the lock release

lever by releasing the pawl at the lower part of the lock

release lever using a flat-blade screwdriver or the like and

then insert it again.

Harness B (orange)

Clamps

Harness A (purple)

Staple unit

Screws

Front cabinet

AR-F13 UNPACKING AND INSTALLATION 3-7

Latch arm

Pawl (D)

Lock release

lever (A)

Projection (B)

Page 13

<4> Reattach the jam handling dial and close the front cover.

9) Reattach the front cover to the right front of the finisher.

<1> Attach the front cover using the screws A and B (two for

each).

Front cover

11) Connect the connector to the stand/paper drawer.

Connect the connector of the relay harness of the finisher to the

stand/paper drawer and tighten the screws of the connector.

Screws

Connector

12) Paste the label.

Paste the label to the position shown in the illustration.

Screws B

Screws A

10) Paste the dust box label to the top cover.

<1> Paste the supplied dust box label to the location indicated in

the illustration.

For RADF

For Scanner

Punch label

STP label

X

Y

Y

On completion of the installation of the AR-F13 finisher, please change

the default output tray of the machine to the top tray of the finisher.

AR-F13 UNPACKING AND INSTALLATION 3-8

Punch label

STP label

X

Page 14

[4] OPERATIONAL DESCRIPTION

1. Basic Operations

A. Specifications

The finisher serves to deliver sheets coming from its host machine. The

mode of delivery may be non-sort stack, job offset*, or staple delivery.

The saddle unit built into the finisher is used to fold a stack of sheets

coming from the finisher unit in half for delivery.

All these operations are controlled by various commands sent by the

host machine in addition to the commands from the finisher controller

PCB.

The puncher unit (option) is designed for installation to the pickup

assembly of the finisher, and is used to punch holes in sheets coming

from the host machine.

The above operations are controlled with various commands from the

finisher controller PCB as well as the commands from the punch

controller PCB.

Puncher unit drive

system (puncher unit;

option)

Alignment drive system

Stapler drive system

Delivery drive system

Control system

Feed drive system

Tray drive system

Saddle unit

drive system

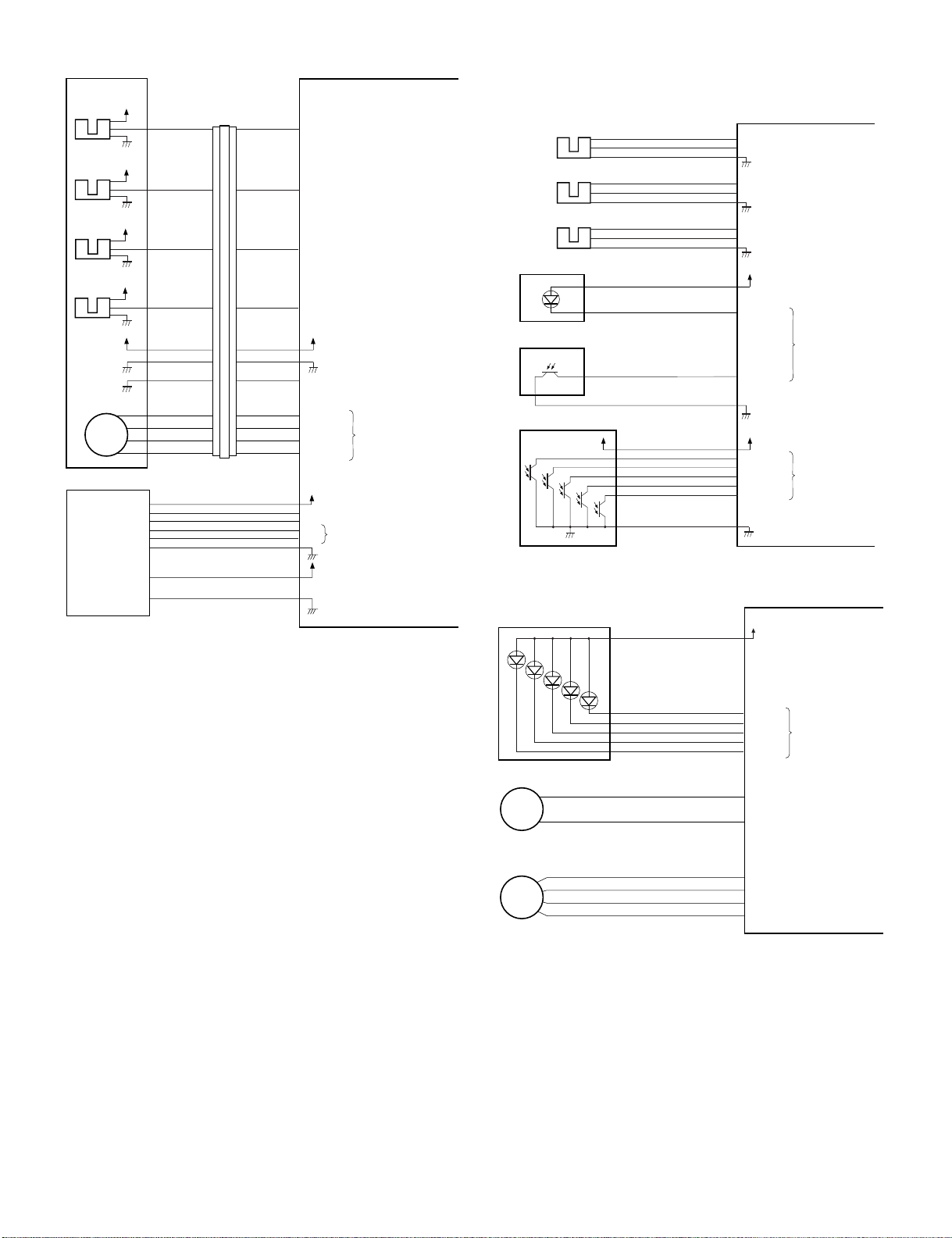

B. Outline of the Electrical Circuitry

The sequence of finisher operations is controlled by the finisher

controller PCB. The finisher controller PCB is a 16-bit microprocessor

(CPU), and is also used for combination with the host machine (serial).

The finisher controller PCB drive motors and other loads in response to

the various commands from the host machine. It also communicates

such data as on the states of various sensors and switches to the host

machine by way of the serial communication line.

The ICs mounted to the finisher controller PCB have the following

functions:

•IC13 (CPU)

Controls sequence of operations.

•IC12 (EEP-ROM)

Backs up adjustment settings.

•IC6 (EP-ROM)

Stores sequence programs.

•IC11 (communication IC)

Communicates with the host machine.

•IC1 (regulator IC)

Generates 5 V.

F02-102-01 shows the flow of signals between finisher and options

controller:

Finisher unit

Host machine DC

Finisher

controller

PCB

IC13

CPU

IC12

EEP-ROM

IC11

Communica-

tion IC

IC6

EP-ROM

IC1

Regulator IC

Motor

Clutch

Switch

Sensor

Puncher unit (option)

Punch controller

PCB

Motor

controller PCB

CPU

Sensor

NOTE:The position of delivery is shifted to the front/rear for each stack to

assist sorting.

AR-F13 OPERATIONAL DESCRIPTION 4-1

Page 15

C. Inputs to and Outputs from the Finisher Controller

PCB

•Inputs to the Finisher Controller PCB (1/2)

CN16-10

CN9-1

CN9-7

CN4

CN5-13

CN5-1

CN5-10

CN16-1

-12

-11

-15

-14

-12

-11

Finisher controller PCB

+5 V

ENT_S

+5 V

-3

PDL_HP

-2

+5 V

-9

BDL_ROL_HP

-8

+5 V

-3

F JOG_HP

-2

+5 V

R JOG_HP

+5 V

-3

ADJ_TRAY_S

-2

-4

+5 V

-6

EJCT_BLT_HP

-5

-7

+5 V

-9

TRY_EMPS

-8

+5 V

LVL_S

+5 V

-2

BIND_P

-3

BIND_L

When the sensor

detects paper, ‘1’ .

When the paddle is at

home position, ‘1’.

When the swing guide

is at home position, ‘1’.

When the aligning

plate (front) is at

home position, ‘1’.

When the aligning

plate (rear) is at

home position, ‘1’.

When the sensor

detects paper, ‘1’.

When the delivery belt

is at home position, ‘1’.

When paper is present

on the tray, ‘1’.

When the paper

surface is detected,

‘1’.

When paper is

detected, ‘0’.

When LED is lit, ‘1’.

Inlet sensor

Paddle home

position sensor

Swing guide

home position

sensor

Aligning plate

home position

sensor (front)

Aligning plate

home position

sensor (rear)

Processing

tray sensor

Delivery belt

home position

sensor

Tray paper sensor

Paper surface

sensor

Folding position

sensor

ES

PHPS

ARHPS

FJHPS

RJHPS

AS

OBHPS

BES

SLS

FPS

CN44-3

CN51-1

CN55-3

CN23-3

CN36-3

CN30-3

CN31-3

CN32-3

CN35-3

CN39-3

CN43-1

-1

-2

-3

-2

CN54-1

-1

-2

-1

-2

-1

-2

CN29-1

-1

-2

-1

-2

-1

-2

CN34-1

-1

-2

CN38-1

-2

-1

CN42-3

CN53-3

CN28-9

CN33-3

CN37-9

-1

-2

-1

-2

-7

-8

-6

-4

-5

-3

-1

-2

-1

-2

-8

-7

-3

-2

-3

-2

-3

-2

-4

-6

-5

-7

-9

-8

-3

-2

-2

-3

•Outputs from the Finisher Controller PCB (1/2)

Binding clutch

FFC

Feed motor

FFM

Paddle motor

FPM

Delivery motor

FAM

Alignment motor

(front)

FFJM

Alignment motor

(rear)

FRJM

CN63-1

CN65-1

-1

-2

-2

-1

CN72

-6

-1

-5

-2

-4

-3

-3

-4

CN56

-2

-5

-1

-6

-6

-1

-5

-2

-4

-3

-3

-4

CN57

-2

-5

-1

-6

-6

-1

-5

-2

-4

-3

-3

-4

CN59

-2

-5

-1

-6

CN62-5

-2

-3

-4

-5

CN64-5

-2

-3

-4

-5

CN18-1

-2

B_CLU

CN10-1

-2

-3

FEEDMTR_A

-4

FEEDMTR_*A

-5

FEEDMTR_B

-6

FEEDMTR_*B

CN10-7

-8

-9

PDLMTR_A

-10

PDLMTR_*A

-11

PDLMTR_B

-12

PDLMTR_*B

CN13-1

-2

-3

EJCTMTR_A

-4

EJCTMTR_*A

-5

EJCTMTR_B

-6

EJCTMTR_*B

CN3-1

-4

-3

-2

-1

-2

FJOGMTR_A

-3

FJOGMTR_*A

-4

FJOGMTR_B

-5

FJOGMTR_*B

CN3-6

-4

-3

-2

-1

-7

RJOGMTR_A

-8

RJOGMTR_*A

-9

RJOGMTR_B

-10

RJOGMTR_*B

Finisher controller PCB

+24 V

When the drive is transmitted,

‘1’.

+24 V

Switches between ‘1’ and

‘0’ according to the

direction of motor rotation.

+24 V

Switches between ‘1’ and

‘0’ according to the

direction of motor rotation.

+24 V

Switches between ‘1’ and

‘0’ according to the

direction of motor rotation.

+24 V

Switches between ‘1’ and

‘0’ according to the

direction of motor rotation.

+24 V

Switches between ‘1’ and

‘0’ according to the

direction of motor rotation.

•Inputs to the Finisher Controller PCB (2/2)

FHPS

Folding home

position sensor

Stack feed roller

(upper) home

position sensor

Bind tray sensor

Staple/fold motor

clock sensor

Shift upper limit

sensor

Shift lower limit

sensor

Shift motor clock

sensor

Front door sensor

Upper cover sensor

Full stack sensor

Joint switch

Front door switch

Stapler safety

switch

FRHPS

FES

FE

ULS

LLLS

LE

FDS

TCS

XXXX

JS

N. O.

FDSW

N. O.

SSS

N. O.

CN40-3

CN41-3

CN47-3

CN52-1

CN50-3

CN49-3

CN48-3

CN25-3

CN24-3

CN73-3

CN69-2

CN68-2

CN66-2

-1

-2

-1

-2

-1

-2

-2

-3

-1

-2

-1

-2

-1

-2

-1

-2

-1

-2

-1

-2

-1

-1

-1

CN38-4

-6

-5

-7

-9

-8

CN37-6

-4

-5

-3

-1

-2

CN15-10

CN16-4

CN15-1

CN9-6

CN15-7

CN15-4

CN4-7

CN4-4

CN19-1

CN8-6

CN8-4

CN8-2

-6

-5

-7

-9

-8

-3

-2

-5

-4

-12

-11

-9

-8

-6

-5

-9

-8

-6

-5

-3

-2

-5

-3

-1

Finisher controller PCB

+5 V

BIND_HP

+5 V

BIND_ROL_HP

+5 V

BIND_EMPS

+5 V

BIND_CLK

+5 V

SIFT_UPLMT

+5 V

SIFT_DNLMT

+5 V

SIFT_CLK

+5 V

FDOOR_S

+5 V

TOPCOV_S

+5 V

PAPER_F

+24 VP

When at folding home position, ‘0’.

When the stack feed roller

(upper) is at home position, ‘1’.

When the sensor

detects paper, ‘1’.

When the staple/fold motor is

rotating, alternates between

‘1’ and ‘0’.

When the tray is at the

upper limit, ‘1’.

When the tray is at the

lower limit, ‘1’.

While the shift motor

is rotating, alternates

between ‘1’ and ‘0’.

When the front door

is open, ‘1’.

When the upper cover

is open, ‘1’.

When the paper is

full, ‘1’.

JOINT SW

FRONT SW

STPLSAFE SW

When connected to

the host machine, ‘1’.

When the front

door is closed, ‘1’.

When the swing

guide is closed, ‘1’.

•Outputs from the Finisher Controller PCB (2/2)

Shift motor

FLM

Staple/fold motor

FFSM

-2

-2

-2

-1

-1

-1

CN70

-2

-2

CN71

-1

-1

CN70

CN6-1

-2

SIFTMTR_1

-2

-1

SIFTMTR_0

CN6-3

BINDMTR_1

-4

BINDMTR_0

Finisher controller PCB

Switches between ‘+’ and

‘–’ according to the

direction of motor rotation.

Switches between ‘+’ and

‘–’ according to the

direction of motor rotation.

AR-F13 OPERATIONAL DESCRIPTION 4-2

Page 16

•Inputs to and Outputs from the Finisher Controller

Stapler unit

Slide home

position sensor

SHPS

Staple home

position sensor

STHPS

Staple empty

sensor

Staple top

position sensor

Slide motor

SPS

SS

FSM

Host

machine

+5 V

+5 V

+5 V

+5 V

+5 V

CN72-5

CN72-4

CN72-3

CN72-2

CN72-6

CN72-1

CN72-7

CN72-10

CN72-11

CN72-12

CN72-13

CN72A-5

CN72A-4

CN72A-3

CN72A-2

CN72A-6

CN72A-1

CN72A-7

CN72B-5

CN72B-4

CN72B-3

CN72B-2

CN72A-5

CN72A-4

CN72A-3

CN72A-2

CN72A-6

CN72A-1

CN72A-7

CN72B-5

CN72B-4

CN72B-3

CN72B-2

CN11-3

CN11-4

CN11-5

CN11-6

CN11-2

CN11-7

CN11-1

CN7-3

CN7-4

CN7-5

CN7-6

CN2-1

CN1-1

SLID_HP

STPL_HP

HOOK_S

SELF_P

STPL_CNCT

SLIDMTR_A

SLIDMTR_*A

SLIDMTR_B

SLIDMTR_*B

-3

GND

-4

GND

-5

TXD

-7

RXD

-6

-2

+5 V

+24 V

+24 V

Finisher controller PCB

When the stapler is at home

position, ‘1’.

When the stapler is at

stapling home position, ‘0’.

When the cartridge has

staples, ‘0’.

When the staple is at top

the stapler, ‘0’.

When the stapler is

connected, ‘0’.

Switches between ‘1’ and

‘0’ according to the direction

of motor rotation.

Communication line

D. Inputs to and Outputs from the Punch Controller

PCB(option)

•Inputs to and Outputs from the Punch Controller PCB

Punch home

position sensor

Horizontal

registration

home position

sensor

Punch motor

clock sensor

Waste full photosensor PCB

PSHPS

Waste full LED PCB

LED121

PT131

Photosensor PCB

PT1

PT2

PT3

J2008-3

-1

-2

J2007-3

-1

-2

PE

J2009-3

-1

-2

+5 V

PT4

PT5

J1006-4

J1006-1

J1006-7

J1005-1

J1005-3

J1007-12

-6

-5

-3

-2

-9

-8

-2

4

-11

-10

-9

-8

-7

-13

XXXX

•Outputs from the Punch Controller PCB

LED5

Punch motor

FPNM

Horizontal

registration

motor

FPSM

LED PCB

LED4

LED3

LED2

LED1

J1007-6

J1002-1

J1001-1

-1

-5

-4

-3

-2

-2

-2

-3

-4

+5 V

PUNCH

+5 V

SLIDE

+5 V

CLOCK

+5V

DUSTLED

DUSTPTR

+5 V

SREG1*

SREG2*

SREG3*

SREG4*

PAEND*

+5V

LEDON5

LEDON4

LEDON3

LEDON2

LEDON1

A

B

A*

B*

Punch controller PCB

When the hole puncher is

at home position, ‘0’.

When the punch slide

unit is at home position,

‘1’.

While the punch motor

is rotating, alternates

between ‘0’ and ‘1’.

When the light is

blocked, ‘0’.

When paper is

detected, ‘0’.

Punch controller PCB

When ‘1’, LED goes ON.

Switches between ‘+’

and ‘–’ according to

the direction of motor

rotation.

Switches the pulse

signals according to

the rotation of the motor.

AR-F13 OPERATIONAL DESCRIPTION 4-3

Page 17

2. Feed/Drive System

A. Outline

The machine performs the following in response to the commands

coming from its host machine on the sheets arriving from the host

machine for delivery: simple stacking, job offset, and stapling or folding

(in two).

If a punch unit (option) is installed, the sheets are pouched and delivered

to the delivery tray.

Sheets may be delivered in either of five ways (including one for the

puncher unit):

Delivery

method

Normal

delivery

Saddle delivery

(1)Normal Delivery

a.Simple Stacking

The machine pulls in the sheet once to the processing tray and then

delivers it to the delivery tray.

Simple stacking

Job offset

Stapling Front 1-point stapling

Rear 1-point stapling

Middle 2-point stapling

Punching

Stitching

Middle 2-point stapling

b.Job Offset

The machine pulls the sheet once to the processing tray. It then moves

the sheet to the front or the rear using the aligning plate. When it has

deposited a specific number of sheets, it delivers them in the form of a

aligning plane. When the number of sheets stacked on the processing

tray reaches a specified value, the sheets are delivered in a form of a

stack. Even if the specified value is not reached, stacked sheets are

temporarily delivered when 10 sheets of large-size paper (300 mm or

longer) or 30 sheets of small-size paper (299 mm or shorter) have been

stacked. (5- and STMT-sizes: 10 sheets)

Tr ay

Paper

Results of offset delivery (4 jobs)

4th set

3rd set

1st set

(direction of delivery)

2nd set

c.Stapling

The machine stacks sheets coming from its host machine on the

processing tray. When the number of sheets stacked on the processing

tray reaches a specified value, the finisher staples them delivers the

stapled stack to the delivery tray.

AR-F13 OPERATIONAL DESCRIPTION 4-4

Page 18

d.Saddle Delivery

The machine deposits a stack of sheets on the processing tray, staples it

(middle 2-point), and then moves it to the saddle unit. The saddle unit

folds the stack in two, and delivers it to the bind tray.

Notation Name Description Connector on finisher

controller PCB

FFM Feed motor Stepping motor CN10

FPM Paddle motor Stepping motor CN10

FAM Delivery motor Stepping motor CN13

FFJM Alignment plate

Stepping motor CN3

motor (front)

FRJM Alignment plate

Stepping motor CN3

motor (rear)

FFSM Staple/fold motor Brush DC motor CN6

Finisher controller PCB (1/2)

Paddle motor

Alignment plate motor

Alignment plate motor

FFJM

(rear) drive signal RJOGMTR

(front) drive signal FJOGMTR

FRJM

drive signal PDLMTR

FPM

Feed motor

drive signal FEEDMTR

Bind clutch drive signal B_CLU

FFM

B.Feed/Delivery

(1)Outline

The machine forwards the sheets coming from its host machine to the

delivery tray, processing tray, or saddle unit according to the type of

delivery used. The sheets forwarded to the processing tray or the saddle

unit are offset, stapled, or folded.

F02-202-01 shows the motors that are associated with moving and

aligning sheets. These motors are controlled (rotated clockwise or

counterclockwise) by the microprocessor (CPU) on the finisher controller

PCB.

The paper path is equipped with the sensors shown in T02-202-02 used

to monitor the arrival or passage of sheets.

If a sheet fails to arrive at or move past a specific sensor within a specific

period of time, the finisher controller will assume a jam, and stops the

ongoing operation and, at the same time, communicates the presence of

a jam to the host machine.

FAM

FLM

Shift motor drive signal SIFTMTR

FSM

Delivery motor drive signal EJCTMTR

Slide motor drive signal SLIDMTR

Finisher controller PCB (2/2)

FFC

PI14

FFSM

Staple/fold motor drive signal BINDMTR

Staple/fold motor clock detect signal

BIND_CLK

AR-F13 OPERATIONAL DESCRIPTION 4-5

Page 19

Finisher controller PCB

Aligning plate (rear)

Sheet to be offset

Tr ay

Aligning plate (front)

Inlet paper detect signal ENT_P

Fold position paper detect signal BIND_P

ES

FPS

Aligning plate (rear)

Alignment plate (front)

motor (FFJM)

Aligning plate

(front)

(Front)

Light-shielding plate

Aligning plate (front) home position sensor (FJHPS)

Alignment plate (rear)

motor (FRJM)

Aligning plate (rear)

home position sensor (RJHPS)

Light-shielding plate

Paper

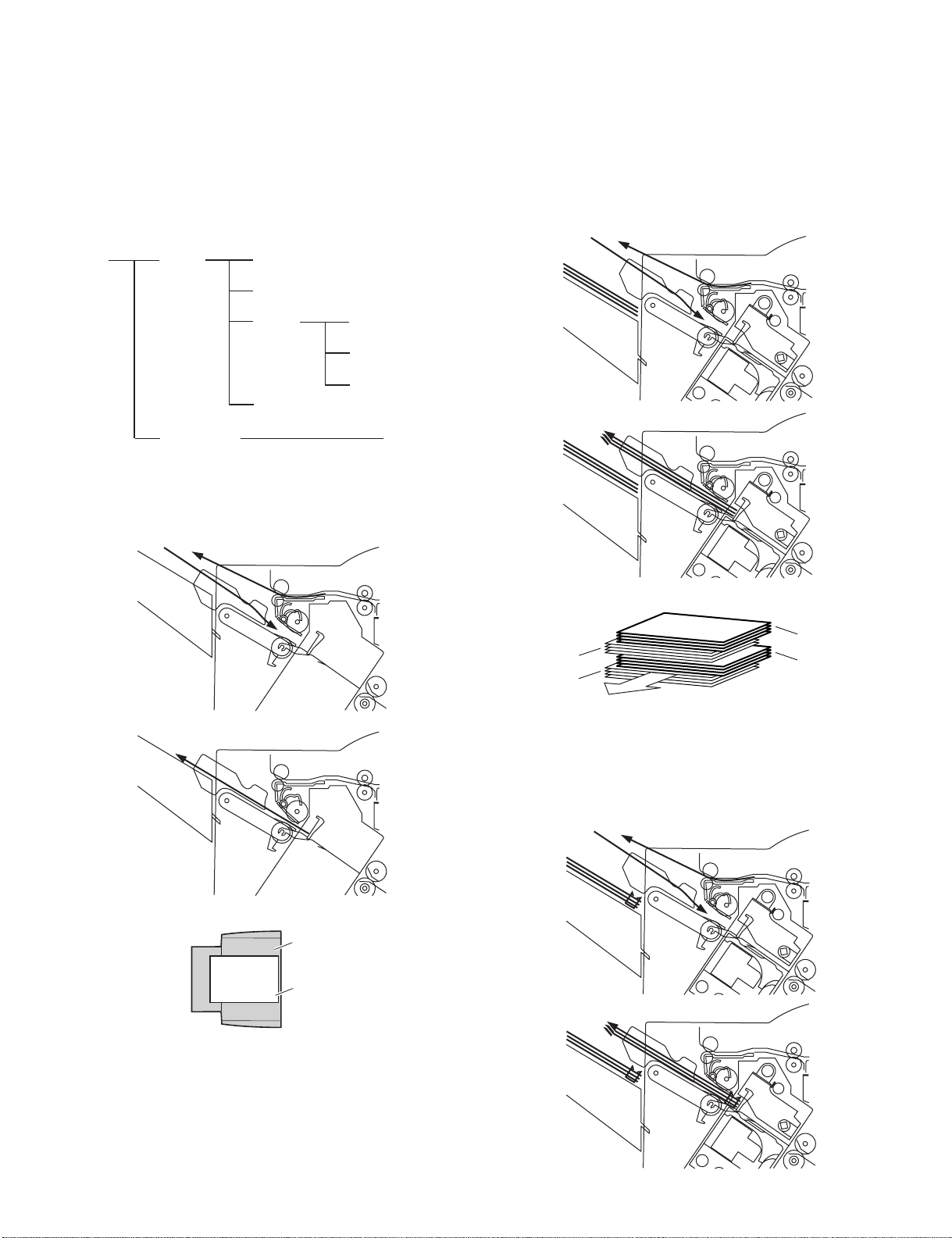

(2)Processing Tray Paper Stacking Operation

A sheet coming between the delivery rollers is fed onto the processing

tray.Then, the paddle taps on the sheet surface twice (once for the

second and subsequent sheets) to locate the sheet against the

processing tray stopper.

Paper

Aligning plate

Paddle

Stack delivery roller (upper)

Notation Name Description Connector on finisher

controller PCB

ES Inlet sensor Photointerrupter CN16

FPS Fold position

Sensor Photointerrupter CN16

C.Job Offset

(1)Outline

"Job offset" refers to the operation by which the machine delivers a set of

sheets with them pulled forward or backward for sorting.

Switching between the forward and backward directions is made using

an aligning plate (front) and an aligning plate (rear).

The sheet coming between the delivery rollers is fed onto the processing

tray and then fed toward the stopper by the paddle.

A swing guide is at the up position while a sheet is being pulled onto the

processing tray or during alignment. It is at the down position during

stack feeding, stack delivery, or stapling.

At power-on, the finisher controller PCB drives the aligning plate (front)

motor (FFJM) and the aligning plate (rear) motor (FRJM) to return the

two aligning plates to their home positions.

Sensor Symbol Connector Function Motor Simbol

Aligning plate

(front) home

position sensor

Aligning plate

(rear) home

position sensor

Swing guide

home position

sensor

Paddle home

position sensor

FJHPS CN4-3 Drives the

aligning plate

(front)

RJHPS CN5-15 Drives the

aligning plate

(rear)

ARHPS CN9-9 Drives the

swing guide

drive.

PHPS CN9-3 Drives the

paddle

(feeds paper).

Aligning

plate

(front)

motor

Aligning

plate

(rear)

motor

Paddle

motor

Paddle

motor

FFJM

FRJM

FPM

FPM

Swing guide

Delivery belt

Stack delivery roller (lower)

Processing tray stopper

(3)Offset Operation

Each sheet is pulled forward or backward using the aligning plate (front)

and the aligning plate (rear).

The offset operation is performed each time a sheet is pulled onto the

processing tray.

Offsetting in the forward direction

AR-F13 OPERATIONAL DESCRIPTION 4-6

Page 20

Offsetting in the backward direction

Aligning plate (rear)

Sheet to be offset

Tr ay

Aligning plate (front)

(4)Stack Delivery Operation

Stack delivery takes place when 10 sheets of large-size paper or 30

sheets of small-size paper (A5- and STMT-sizes: 10 sheets) have been

stacked on the processing tray with them offset in either direction.

The paddle motor rotates and the swing guide descends to hold the

paper stack between the upper and lower stack delivery rollers. The

delivery motor rotates in the forward direction to rotate the delivery

rollers, feeding the paper stack in the delivery direction. The delivery belt

home position sensor is turned OFF. The delivery motor is driven a

specified number of pulses, causing the swing guide to ascend. Next,

the paper delivery motor is driven. Next, the delivery motor is driven to

deliver the paper stack with the nails of the delivery belt that rotates in

sync with the stack delivery rollers.

3. Stapling Operation

A.Outline

Staple operation is performed to staple a specified sheets of paper using

a stapler unit.

The stapling position depends on the staple mode and paper size.

When the machine starts immediately after power-on, the finisher

controller PCB drives the slide motor (FSM) to return the stapler unit to

the home position. The stapler unit starts moving toward the front of the

stapler frame. It stops when the slide home position sensor (SHPS) on

the slide PCB located under the stapler unit. Next, the slide motor is

driven a specified number of pulses. The stapler unit moves to rear

standby position at the back of the machine, entering the standby state.

Sensor Simbol Connector Function Remarks

Slide home

position sensor

Staple home

position sensor

Staple empty

sensor

Staple top

position sensor

Moves the stapler. Slide motor FSM Performs stapling operation. Staple/fold motor FFSM -

SHPS CN11-3 Detects the home

position for the stapler

moving back and forth.

STHPS CN11-4 Detects the home

position for the stapling

In the

stapler

operation

SPS CN11-5 Detects presence or

absence of staples in

In the

stapler

the cartridge.

SS CN11-6 Detects the staple top

position.

In the

stapler

Function Motor Symbol Remarks

Job offset sequence

Inlet sensor (ES)

Processing tray sensor

(AS)

Feed motor (FFM)

Delivery motor (FAM)

Delivery belt home

position sensor (OBHPS)

Paddle motor (FPM)

Paddle home position

sensor (PHPS)

Swing guide home

position sensor (ARHPS)

Stapler safety switch

(SSS)

Alignment motor (front)

(FFJM)

Aligning plate home position

sensor (front) (FJHPS)

Alignment motor (rear)

(FRJM)

Aligning plate home position

sensor (rear) (RJHPS)

Start signal

Host machine delivery signal

360msec

360msec 360msec

60msec

Swing guide

360msec

30msec

220msec

CW rotation CCW rotation

Slide motor

(FSM)

Paper stack

Stapler

(Deliver direction)

Light-shielding plate

Slide home position sensor (SHPS)

AR-F13 OPERATIONAL DESCRIPTION 4-7

Page 21

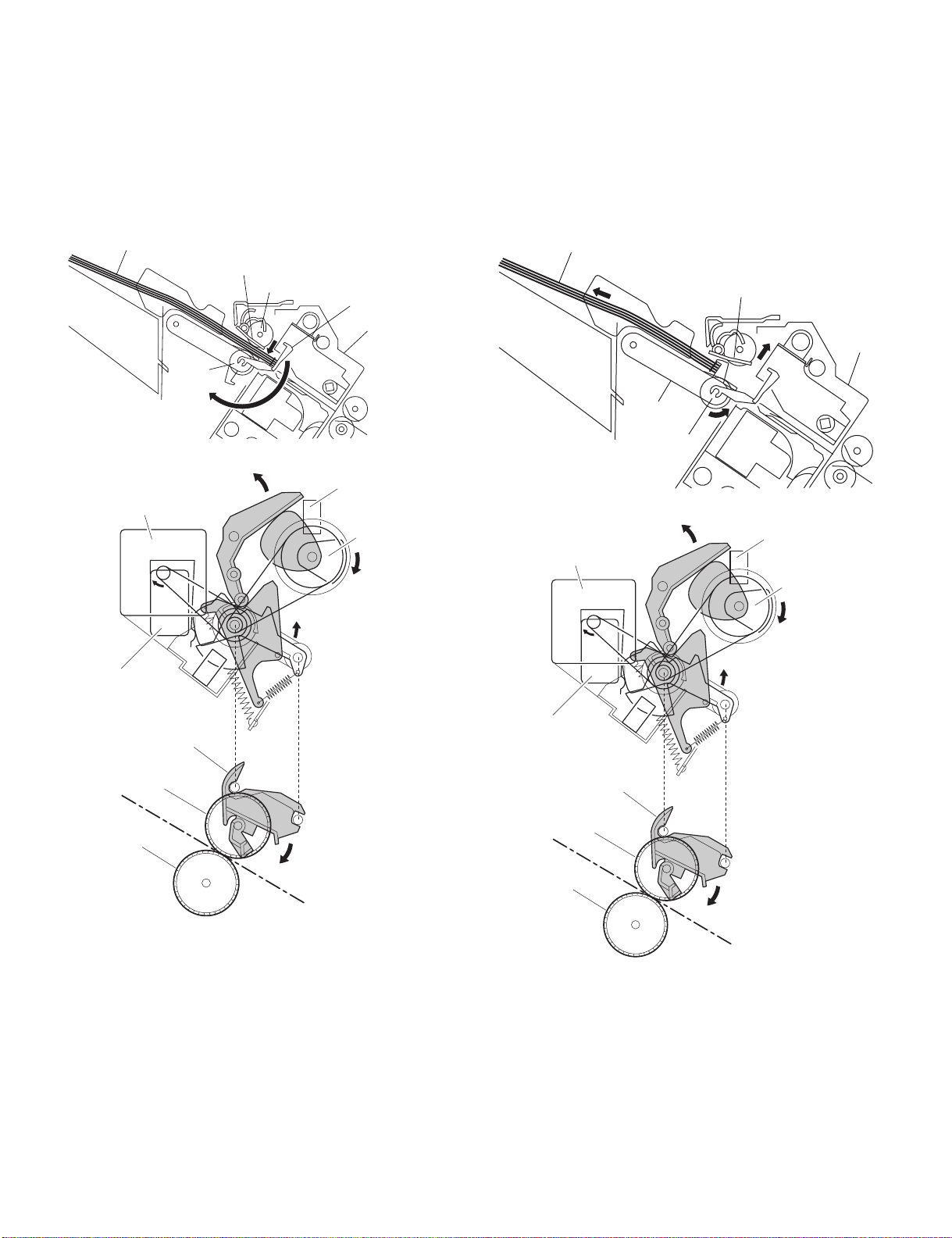

B.Stapling Operation

When stacking and alignment of paper on the processing tray are

complete, the finisher controller PCB drives the paddle motor (FPM) in

the reverse direction and lowers the swing guide. When the swing guide

descends, the paper stack is sandwiched between the upper and lower

stack delivery rollers.

The finisher controller PCB moves the stapler for stapling according to

the specified stapling position (when rear 1-point stapling is specified,

the stapler does not move but it staples at the standby position). As the

stapler moves forward, the processing tray stopper is folded forward.

Paper stack

Swing guide

Stack delivery roller (upper)

Processing tray stopper

Delivery tray

Paddle motor (FPM)

Stack

delivery

roller

(lower)

Stapler

Swing guide home

position sensor (ARHPS)

C.Delivery Operation after Stapling

When stapling is complete, the finisher controller PCB drives the deliver

motor in the forward direction to feed the paper stack (sandwiched

between the stack delivery rollers) in the delivery direction. The delivery

belt home position sensor is turned OFF. The delivery motor is driven a

specified number of pulses, causing the swing guide to ascend. At the

same time, the slide motor is driven to return the stapler back to the

standby position, followed by driving of the delivery motor. Then, the

paper stack is delivered with the nails of the delivery belt that rotates in

sync with the stack delivery rollers.

Paper stack

Swing guide

Delivery tray

Delivery belt

Stack delivery

roller (lower)

Stapler

Staple safety switch

(SSS)

Swing guide

Stack delivery roller

Stack delivery roller

(lower)

(upper)

Light-shielding plate

Paddle motor (FPM)

Staple safety switch

(SSS)

Swing guide

Stack delivery roller

Stack delivery roller

(lower)

(upper)

Swing guide home

position sensor (ARHPS)

Light-shielding plate

AR-F13 OPERATIONAL DESCRIPTION 4-8

Page 22

D.Stapler Unit

The staple/fold motor (FFSM) is used to perform stapling operation. This

motor rotates the cam one turn for stapling. The home position of this

cam is detected by the staple home position sensor (STHPS).

The staple/fold motor is rotated in the forward or reverse direction under

the control of the macro computer (IC13) on the finisher controller PCB.

When the staple home position sensor is OFF, the finisher controller

PCB rotates the staple/fold motor in the forward direction until the sensor

turns ON, allowing the staple cam to the original position.

The staple empty sensor (SPS) is used to detect presence/absence of a

staple cartridge in the machine and presence/absence of staples in the

cartridge.

The stale top position sensor (SS) is used to determine whether staples

are pushed up to the top of the staple cartridge.

The finisher controller circuit does not drive the staple/fold motor (FFSM)

unless the staple safety switch (SSS) is ON (the swing guide is close).

This assures safety in case where you happen to put your finger in the

stapler.

(1)Stapler Movement Controller

The stapler unit is moved by the slide motor (FSM). Its home position is

detected by the slide home position sensor (SHPS). The stapler waits at

the back irrespective of the staple mode and paper size. After paper has

been stacked on the processing tray, the stapler is moved to the

specified stapling position in response to the stapling command from the

host machine.

The standby position of the stapler and the stapling position depending

on the staple mode are shown below.

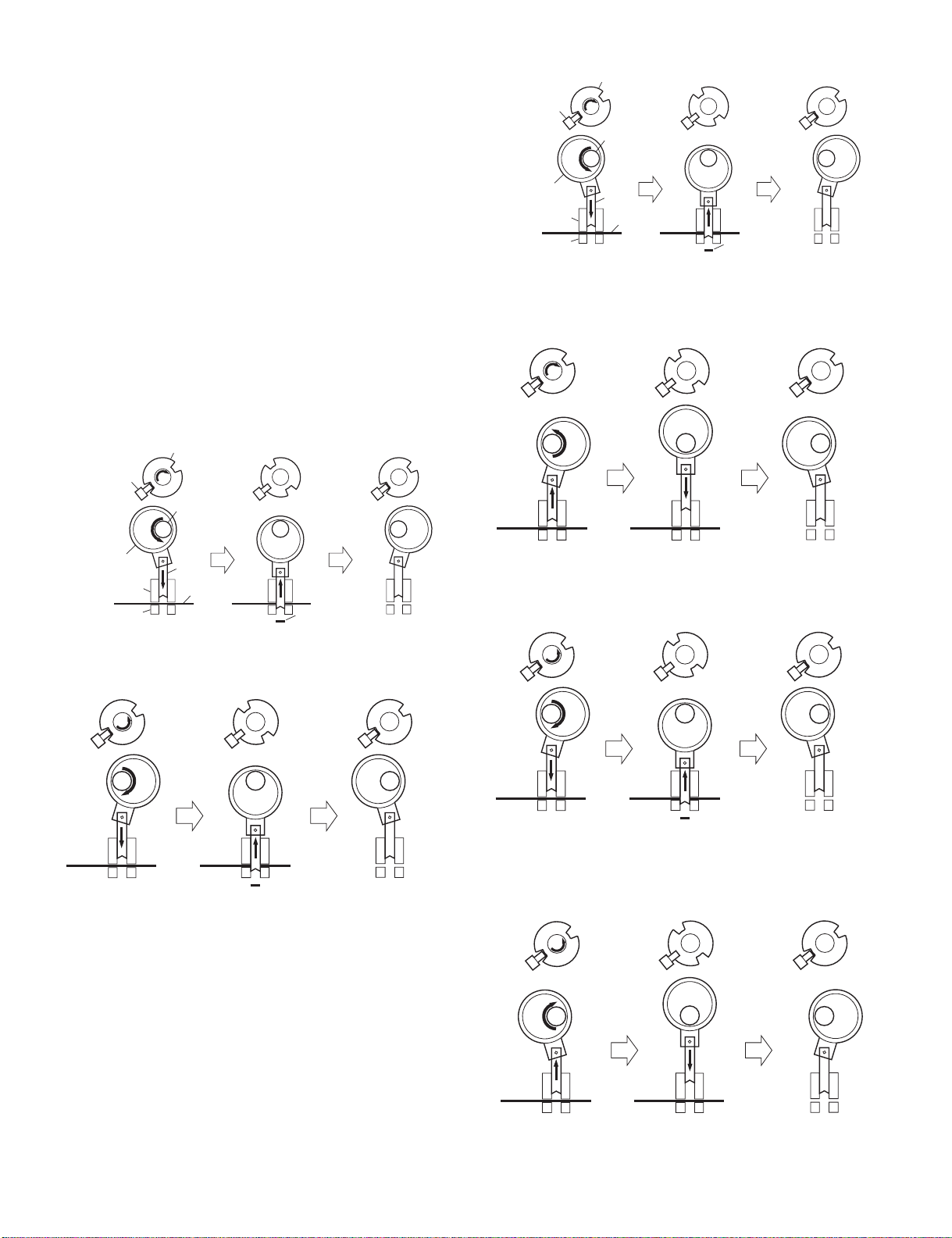

a.Front 1-point stapling

The stapler waits at the back. The stapler moves to and returns from the

stapling position for each stapling operation.

Standby position

Stapler

Feed direction

Stopper

Stapling position

b.Rear 1-point stapling

The stapler waits at the back. The stapling position is the same as the

standby position.

Standby position

Stabling position

Stapler

Feed direction

Stopper

M7

c.Middle 2-point stapling

The stapler waits at the back. The stapler moves to and returns from the

stapling position for each stapling operation. The stapler first staples a

paper stack at the rear stapling position and then staples it at the front

stapling position.

Standby position

Staple top position detect signal

Staple empty detect signal

Staple home position detect signal

Finisher controller PCB

Staple/hold motor drive signal

Feed direction

AR-F13 OPERATIONAL DESCRIPTION 4-9

Stapler

Stapling position

Stopper

Stapling position

Page 23

d.Middle 2-point stapling (bind mode)

The stapler waits at the back. The stapler moves to and returns from the

stapling position for each stapling operation. The stapler first staples a

paper stack at the rear stapling position and then staples it at the front

stapling position.

Standby position

Stapler

Stapling position

Stopper

Feed direction

Stapling position

Stapling Operation Sequence

Rear 1-point Stapling of 2 Sheets

Start signal

Inlet sensor (ES)

Processing tray sensor

(AS)

Feed motor (FFM)

Delivery motor (FAM)

Delivery belt home

position sensor (OBHPS)

Paddle motor (FPM)

Paddle home position

sensor (PHPS)

Swing guide home

position sensor (ARHPS)

Stapler safety switch

(SSS)

Alignment motor (front)

(FFJM)

Aligning plate home position

sensor (front) (FJHPS)

Staple/fold motor

(FFSM)

Staple home position

sensor (STHPS)

Host machine delivery signal

360msec

360msec

20msec

CW rotation CCW rotation

Staple

Stack delivery

10msec

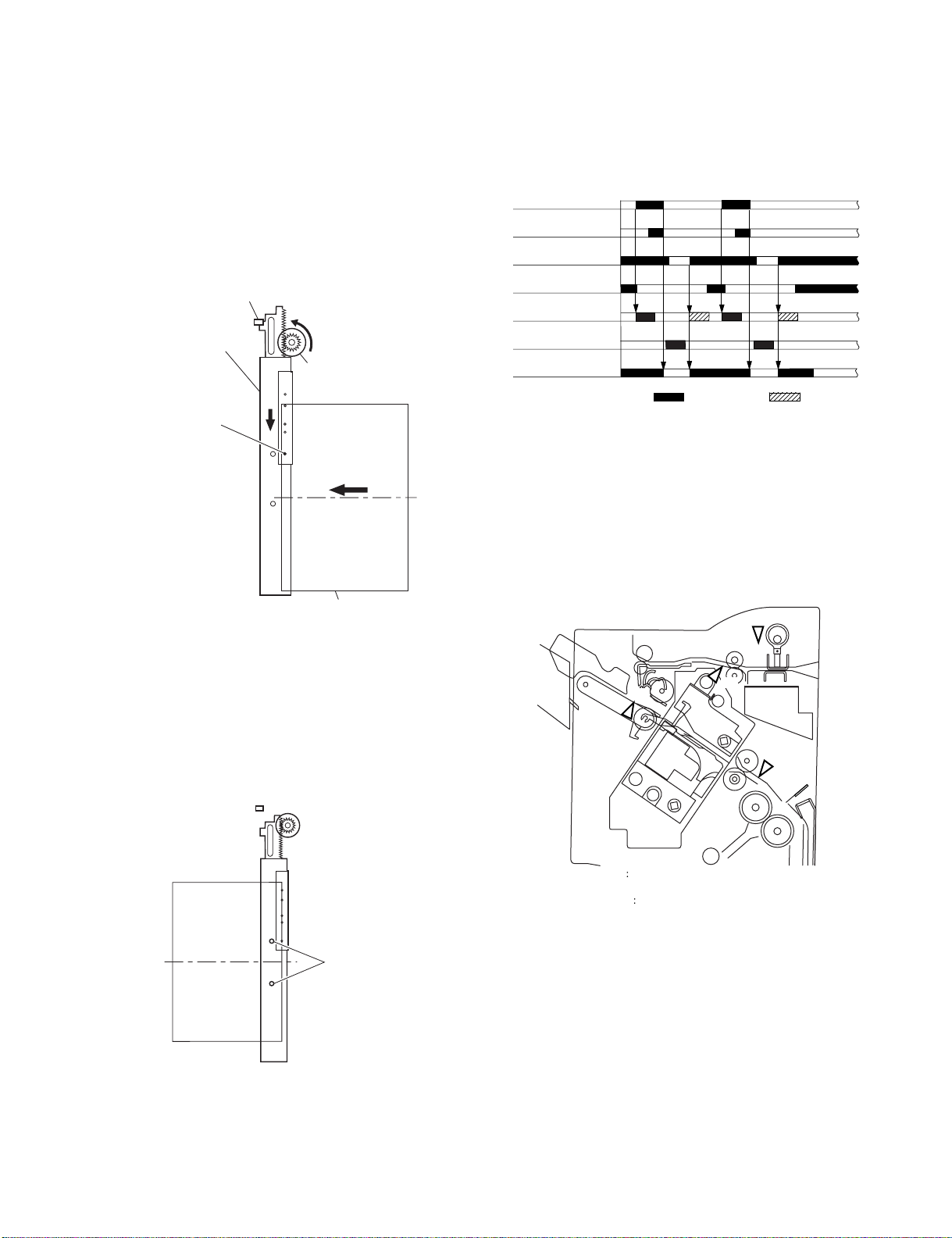

4. Delivery Tray Operation

A.Outline

The machine has a delivery tray in the finisher unit and a bind tray in the

saddle unit.

The bind tray in the saddle unit is of the fixed type and all the folded

paper stacks are delivered to this tray. This tray has a bind tray sensor

(FES) to detect presence/absence of paper.

The delivery tray in the finisher unit is moved up and down using a shift

motor (FLM).

The finisher has a tray paper sensor (BES) to detect presence/absence

of paper on the stack tray.

The home position sensor of the delivery tray is detected by the paper

surface sensor (STHPS). When paper has already been stacked on the

delivery tray, the home position is on the top surface of the stacked

paper. When paper has not yet been stacked on the delivery tray, the

home position is at the position where the edge of the delivery tray is

detected. At power-on, the finisher controller PCB drives the shift motor

(FLM) to return the delivery tray to the home position.

When the paper coming from the processing tray is stacked on the

delivery tray, the shift motor is driven a specified number of pulses,

causing the delivery tray to descend. Clock pulses are detected by the

shift motor clock sensor (LE). Then, the delivery tray returns to the home

position for the next stacking operation.

The upper limit of the delivery tray is detected by the shift upper limit

sensor (ULS). When the shift upper limit sensor (ULS) is turned ON, the

finisher controller PCB stops the shift motor (FLM) that is ascending.

The lower limit of the delivery tray is detected by the shift lower limit

sensor (LLLS). When the shift lower limit sensor (LLLS) is turned ON,

the finisher controller PCB stops the shift motor (FLM) that is

descending.

The finisher unit has a full stack sensor (PI24) to detect overstacking of

large-size or mixed paper according to the stack height.

Shift upper limit sensor

Shift lower limit sensor

Shift motor clock sensor

(ULS)

(LLLS)

(LE)

Tray paper sensor (BES)

Paper surface sensor (SLS)

Edge

Delivery tray

Full stack sensor (XXXX)

AR-F13 OPERATIONAL DESCRIPTION 4-10

Shift motor (FLM)

Page 24

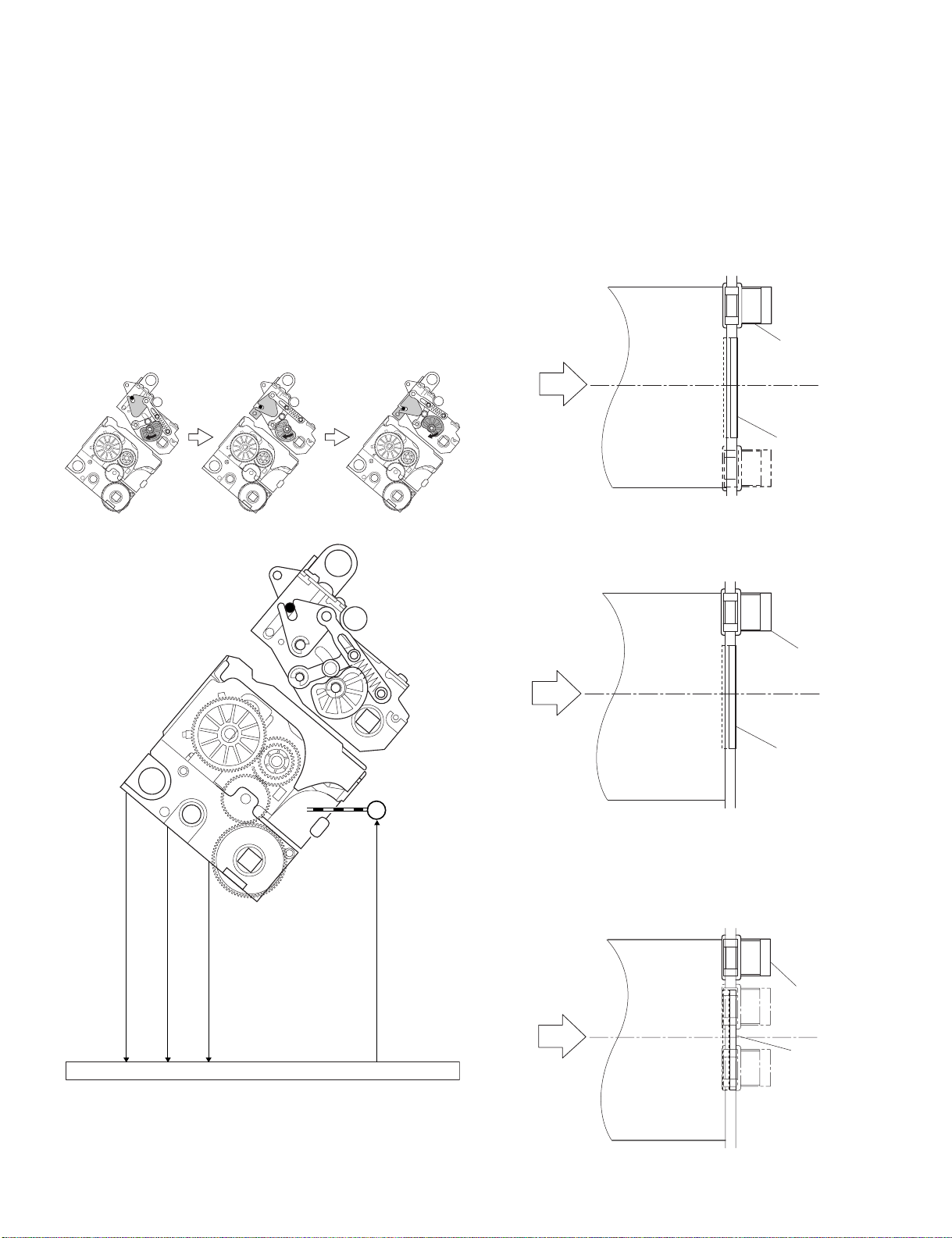

5. Saddle Unit

A.Basic Operations

(1)Outline

The machine stitches a stack of sheets (middle 2-point), then folds the

stack in two in the finisher. These operations are controlled by the

finisher controller PCB.

The finisher controller PCB is controlled by the commands from the host

machine.

B.Feed/Drive System

(1)Outline

This machine stitches the paper stack coming from the finisher, folds it,

and delivers it to the bind tray in the saddle unit in response to the

commands from the host machine.

That is, the machine performs the following operations:

a) Paper feed-in

b) Stitching

c) Stack feed

d) Folding/delivery

b.Stitching

When the center of the paper stack (stitching position) reaches the

stapler's staple position, the stapler stitches the paper stack.

When only one sheet is fed from the host machine, the next step (stack

feed) is performed without performing the stitching operation.

Staple

Stapler (lower)

Stapler (upper)

a) Paper feed-in

d) Folding/delivery

b) Stitching

c) Stack feed

a.Paper feed-in

After being aligned on the processing tray, a stack of sheets is

sandwiched between the stack delivery rollers. As the stack delivery

rollers rotate, the stack is fed toward the saddle unit.

Stack delivery roller (upper)

Paper stack

Stack delivery roller

(lower)

c.Stack feed

The stack feed rollers feed the paper stack to the stack folding/delivery

position where the center of the stack (stitched position) is level with the

paper pushing plate and paper folding roller's nip part.

Stack feed roller (upper)

Paper pushing plate

Stack feed roller (lower)

Paper fold roller

AR-F13 OPERATIONAL DESCRIPTION 4-11

Page 25

d.Folding/delivery

The paper pushing plate pushes in the center of the paper stack to feed it

toward the paper fold rollers. Then, the paper fold rollers and bind

delivery rollers deliver the paper stack to the bind tray.

Bind delivery rollers

Paper fold rollers

D.Stack Feed System

(1)Outline

The stack feed system feeds the stitched paper stack to the folding

position.

When stitching is complete, the feed motor (FFM) rotates, causing the

stack feed roller (upper) to descend. The paper stack is sandwiched

between the stack feed rollers. Then, the bind clutch (FFC) is turned ON

to rotate the feed motor (FFM) in the forward direction, thus feeding the

paper stack to the folding position. The feed amount is equivalent to the

number of pulses used to drive the feed motor (FFM) until the paper

stack reaches the folding position.

Stack feed roller (upper)

Feed amount

C.Paper Feed System

(1)Outline

The paper feed system feeds a stack of sheets (coming from the finisher)

to the position where the center of the paper stack (stitching position) is

aligned to the stapler's staple, allowing the next step (stitching and

folding) to be performed.

When sheets of paper have been stacked and aligned on the processing

tray, the paddle motor (FPM) rotates in the reverse direction, causing the

swing guide to descend. As the swing guide descends, the paper stack

is sandwiched between the upper and lower stack delivery rollers. The

delivery motor (FAM) rotates in the reverse direction, feeding the paper

stack toward the saddle unit. When the leading edge of the paper stack

reaches the folding position sensor (FPS), the finisher controller PCB

drives the delivery motor a specified number of motor pulses to stop the

center of the paper stack (stitching position) at the stapler's staple

position. Before the paper stack passes through the stack feed rollers,

the feed motor (FFM) is driven to rotate the stack feed roller (lower) so

that the leading edge of the paper stack is not bent.

Stack delivery roller (upper)

Paper stack

Fold position sensor

Stack delivery roller

(lower)

Stack feed roller (lower)

E.Fold/Delivery System

(1)Outline

The paper fold mechanism consists of a guide plate, paper fold rollers,

and a paper pushing plate.

The guide plate, paper fold rollers, and paper pushing plate are driven by

the staple/fold motor (FFSM). The drive force is transferred with a

combination of gears and cams. Motor operation is monitored by the

staple/fold motor lock sensor (FE).

Until the paper stack reaches the folding position, the guide plate covers

the paper fold rollers to act as a paper path through which a paper stack

is fed to the saddle unit and to prevent a paper stack from touching the

rollers.

A folding home position sensor (FHPS) is provided to detect the

positions of the paper fold rollers and paper pushing plate.

The paper stack folded in two by the paper fold rollers is delivered by

bind delivery rollers.

The bind delivery rollers are also driven by the staple/fold motor (FFSM).

A bind tray sensor (FES) is provided on the bind tray to detect presence/

absence of a paper stack; however, it is not used to detect a jam.

Stack feed roller (lower)

AR-F13 OPERATIONAL DESCRIPTION 4-12

Page 26

(2)Paper Folding

Paper is folded using paper fold rollers and a paper pushing plate.

Almost concurrently with the start of roller rotation, the paper pushing

plate starts operating to push the paper stack into the gap between the

paper fold rollers. When the paper stack is fed about 10 mm with the

rotation of the paper fold rollers, the paper pushing plate returns to the

home position. Then, the paper stack is delivered to the bind tray using

the paper fold rollers and bind delivery rollers.

Half the entire surface of each paper fold roller is uncovered excluding

the central area and the area at the left and right ends. The uncovered

surface of the upper paper fold roller comes in touch with the uncovered

surface of the lower paper fold roller only at the center and left and right

ends, allowing a paper stack to be fed without causing creases. The

other half of the upper paper fold roller that is covered comes in touch

with the other half of the lower paper fold roller that is also covered,

allowing a paper stack to be folded while being fed.

Sensor flag

Folding home position sensor (FHPS)

Came

Paper stack

Paper fold roller (upper)

Staple/fold

FFSM

motor

Paper fold roller (lower)

Paper fold roller (upper)

Staple/fold

motor

FFSM

Paper pushing plate

Folding

home position sensor (FHPS)

Paper pushing plate

[Paper folding start position]

Outlet

Feed motor (FFM)

Delivery motor (FAM)

Paddle motor (FPM)

Paddle home position

sensor (PHPS)

Swing guide home

position sensor (ARHPS)

Stapler safety switch

(SSS)

Slide motor (FSM)

Staple/fold motor (FFSM)

Staple home position

sensor (STHPS)

Folding position sensor

(FPS)

Stack feed roller (upper)

home position sensor (FRHPS)

Binding cluch (FFC)

Folding home position

sensor (FHPS)

Bind tray sensor (FES)

Staply

Paper stack

Inlet

Paper push plate

Folds/feeds a paper stack.

Feeds a paper stack.

Fold, Delivery

13571msec

50msec

CW rotation CCW rotation

Paper fold roller (lower)

Paper stack

AR-F13 OPERATIONAL DESCRIPTION 4-13

Page 27

6. Puncher Unit (option)

A. Basic Operations

(1)Outline

The puncher unit is an option, and is designed for installation to the

pickup assembly of the finisher. The puncher unit is not equipped with a

paper feeding mechanism, and the sheets from the host machine move

through the puncher unit and then the feed system of the finisher.

When the trailing edge of a sheet from the host machine reaches the

puncher unit, the sheet is stopped once, and the punch shaft is rotated to

punch a hole along the trailing edge. These operations are controlled

with various commands from the finisher controller PCB as well as the

commands from the punch controller PCB.

The punch motor and horizontal registration motor are controlled with

various commands from the finisher controller PCB as well as the

commands from the punch controller PCB.

The waste paper occurring as the result of punching is collected in the

waste paper case. The case is monitored by the LED121 on the waste

full LED PCB and PT131 on the waste full photosensor PCB.

Punch controller PCB (1/2)

Punch drive system

Horizontal registration

drive system

Punch controller PCB

Finisher unit control system

B.Punching Operation

(1)Outline

The puncher unit is located in the pickup assembly of the finisher, and is

used to punch holes in sheets that have been sent from the host

machine and stopped inside it. When the trailing edge of a sheet reaches

the puncher unit, the inlet roller of the finisher assembly stops the sheet

to punch a hole along the trailing edge of the sheet.

The punch unit consists of a die and hole puncher (punch blade).

The hole puncher is driven by the punch motor (FPNM). It is attached to

the eccentric cam of the punch shaft, and the rotation of the punch shaft

is converted into reciprocating motion for punching operation.

The punch motor (FPNM) is a DC motor. The home position of the punch

shaft is detected by the punch home position sensor (PI1P). To make

sure that the punch motor, which is a DC motor, stops exactly at its home

position, the punch motor is stopped in relation to the count of the clock

pulses kept by the punch motor clock sensor (PE).

A single punching operation is executed by rotating the punch shaft 180×

from its home position.

As many as five light-receiving transistors (photosensor PCB) are

mounted over the inlet paper path of the puncher unit; on the other hand,

as many as five LEDs (LED PCB) are mounted under the path, together

serving as five sensors. The frontmost sensor (LED5, PT5) is used to

detect the training edge of sheets, and the remaining four (LED1 through

LED4, PT1 through PT4) are used as horizontal registration sensors to

detect the rear position of sheets when punching holes.

The punch motor, punch unit, and sensors make up the punch slide unit,

which moves to the front/rear to suit the selected paper size. The

movement to the front/rear is driven by the horizontal registration motor

(FPSM). The home position of the punch slide unit is detected by the

horizontal registration home position sensor (PSHPS), and the horizontal

registration motor (FPSM) is a stepping motor.

Trailing edge detection signal

LED121

Punch motor (FPNM) drive

signal

(LED5, PT5) PAEND

Horizonal registration detection

signal (LED1~4, PT1~4) SREG1~4

PT1

2

3

4

5

LED1

2

3

4

5

Punch motor clock (PE)

detection signal PUNCHCLK

Punch controller PCB (2/2)

PT131

Waste full detection signal

(LED121, PT131) DFULL

Punch home position (XXXX)

Horizontal registration home position

(PSHPS) detection signal SREGHP

Horizontal registration motor

(FPSM) drive signal

detection signal PUNCHHP

AR-F13 OPERATIONAL DESCRIPTION 4-14

Page 28

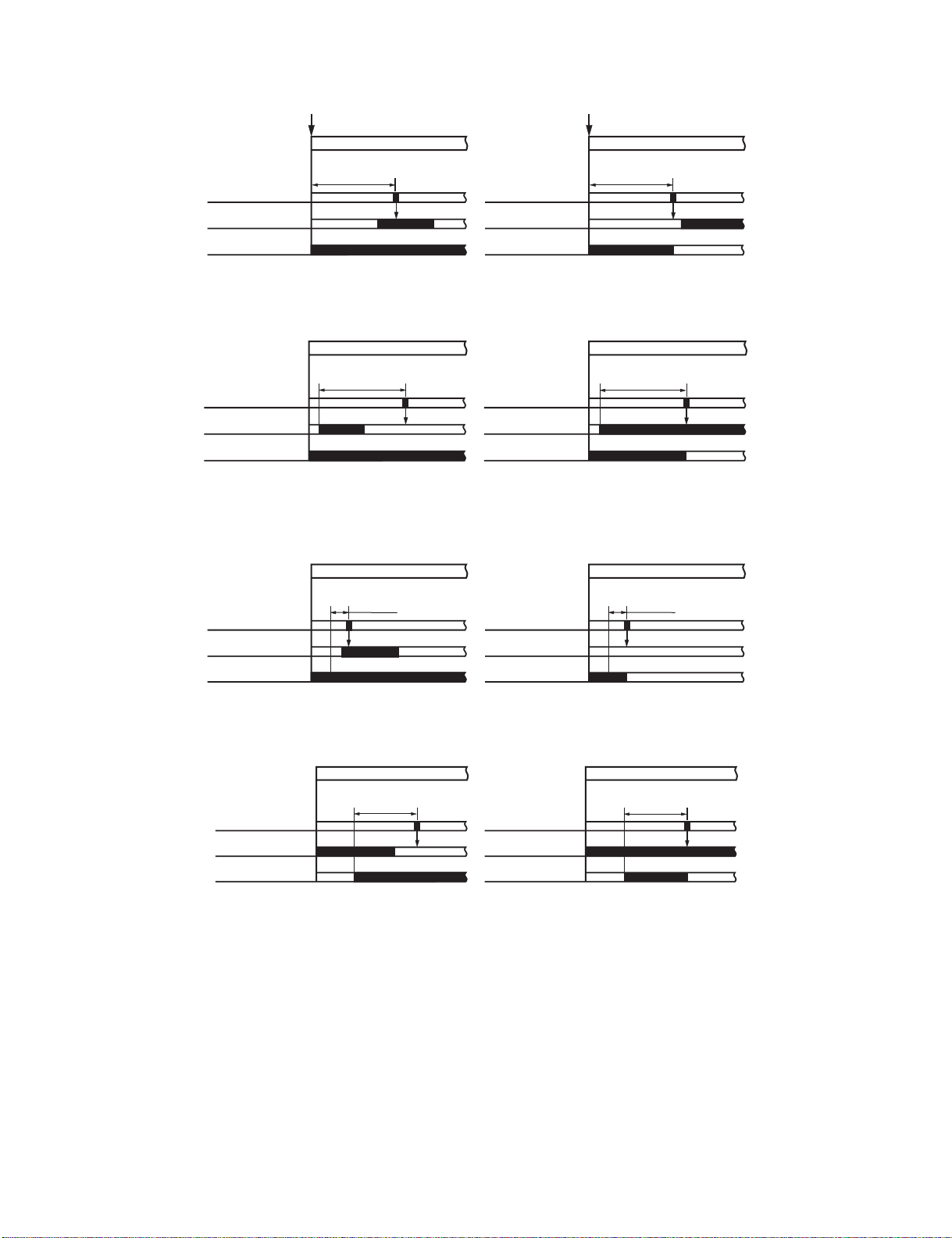

(2)Punching Operation

/

The hole puncher is driven by the punch motor (FPNM). The home

position for the hole puncher is detected by the punch home position

sensor (XXXX).

The punch unit comes in four types, selected to suit the country of

installation: 2-hole (Puncher Unit-J1), 2- and 3-hole (Puncher Unit-K1),

or two types of 4-hole (Puncher Unit-G1, Puncher Unit-H1).

The 2-hole and 4-hole types punch a hole when the punch shaft is

rotated 180× from the home position, causing the punch to make a single

round trip. The 2-/3-hole type punches a hole, but the circumference of

the punch shaft is divided into two (half for 2-hole and the other half for

3-hole).

a.2-Hole, 4-Hole Type

The home position is identified when the punch home position is ON.

The punching operation for the first sheet ends when the punch shaft has

rotated 180× and the punch home position sensor goes ON; the

punching operation for the second sheet ends when the punch shaft has

rotated 180× in reverse and the punch home position sensor goes ON.

The punching operation takes place as follows when making a hole in

two sheets of paper.

1) A hole is punched along the trailing edge of the 1st sheet.

Sensor flag

Punch home position

sensor (PI1P)

Punch shaft

1) A hole is made along the trailing edge of the 1st sheet.

Sensor flag

Punch home position

sensor (PI1P)

Punch shaft

Eccentric cam

Die

Die

(punch shaft at rest/

home position)

Hole

puncher

Paper

(punch shaft CW rotation

by 90˚/hole made)

Waste paper

(punch shaft CW rotation by 180˚/

end of punching operation)

While two holes are being made, the 3-hole puncher makes a single

round trip in escape direction.

Eccentric cam

Die

Die

(punch shaft at rest/

home position)

Hole

puncher

Paper

(punch shaft CW rotation

by 90˚/hole made)

Waste paper

(punch shaft CW rotation by 180˚/

end of punching operation)

2) A hole is made along the trailing edge of the 2nd sheet.

(punch shaft at rest/

home position)

(punch shaft CCW rotation

by 90˚/hole made)

(punch shaft CCW rotation by 180˚/

end of punching operation)

b.2- /3-Hole Type

The home position is identified when the punch home position sensor is

ON. To make two holes, the punching operation for the first sheet ends

when the punch shaft rotates 180° (half circumference) and the punch

home position sensor goes ON. At this time, the 3-hole puncher makes a

single round trip in escape direction (moving up the hole puncher) on a

half circumference of the punch shaft.

The punching operation for the second sheet ends when the Punch shaft

has rotated 180° counterclockwise and the punch home position sensor

goes ON (half circumference). At this time, the 3-hole puncher makes a

single round trip in escape direction (moving up the hole puncher) on the

other half circumference of the punch shaft.

The punching operation takes place as follows when making two holes in

two sheets of paper:

(punch shaft at rest/

home position)

(punch shaft CW rotation by 90˚/

punch at upper limit)

(punch shaft CW rotation by 180˚/

punch back to initial position)

2) Holes are made along the trailing edge of the 2nd sheet.

(punch shaft at rest/

home position)

(punch shaft CCW rotation

by 90

˚/hole made)

(punch shaft CCW rotation by 180˚

end of punching operation)

While two hole are being made, the 3-hole puncher makes a single

round trip in escape direction (moving up the hole puncher).

(punch shaft at rest/

home position)

(punch shaft CCW rotation by

90˚/punch at upper limit)

(punch CCW rotation by 180˚/

punch back at initial position)

AR-F13 OPERATIONAL DESCRIPTION 4-15

Page 29

(3)Horizontal Registration Operation

The horizontal registration drive for the punch slide unit is provided by

the horizontal registration motor (FPSM). The home position of the

punch slide unit is detected by the horizontal registration home position

sensor (PSHPS). The punch slide unit detects the trailing edge of sheets

using the trailing edge sensor (LED5, PT5) and the horizontal

registration sensors (LED1 through 4, SREG1 through 4), and causes a

move to a specific position matching the trailing edge of each sheet

(in relation to the size of the sheet).

The horizontal registration operation takes place as follows:

1) When the leading edge of a sheet from the host machine is detected

by the trailing edge sensor (LED5, PT5), the horizontal registration

motor (FPSM) starts to move the punch slide unit toward the front.

Horizontal registration home

position sensor (P12P)

4) When the punching operation ends, the feed motor (FFM) of the

fisher unit is driven and, at the same time, the horizontal registration

motor (FPSM) is rotated in reverse to return the punch slide unit to

its home position.

5) For each sheet that arrives in succession, the punch slide unit is

returned to its home position, and is caused to repeat steps 1

through 4 .

Trailing edge sensor

(LED5, PT5)

Horizontal registration

sensor (LED1~4, PT1~4)

Punch home position

sensor (XXXX)