Page 1

Date: May. 21, 1999

DIGITAL COPIER(OPTION): AR-280

1. MEASURE CARRIED OUT TO PREVENT PROBLEMS OF BAD CONNECTIONS BETWEEN THE FFC HARNESS AND THE

CCD PWB.

2. MEASURE CARRIED OUT TO ALLEVIATE PROBLEMS OF CONTACT BETWEEN THE ICU PWB AND THE SUB PWB GUIDE.

3. PERMANENT MEASURE CARRIED OUT TO ALLEVIATE PROBLEMS OF IMPROPERLY TIGHTENED FIXING SCREWS OF

THE MAIN MOTOR.

4. MEASURE CARRIED OUT TO DECREASE THE AMOUNT OF ABNORMAL NOISE IN THE ADU UNIT.

5. CHANGE IN THE SHAPE OF THE ICU COVER CARRIED OUT IN ACCORDANCE WITH A CHANGE THAT WAS CARRIED

OUT IN THE ATTACHMENT LOCATIONS OF SOME OF THE PARTS IN THE ICU PWB.

No. : ARE-163

1. Measure carried out to prevent problems of bad connections between the FFC

harness and the CCD PWB.

1.Model Name: AR-280/285/335/405

2.General: There was a possibility of bad connections of the FFC harness which is connected from

the CCD unit to the ICU PWB. As a measure to alleviate this problem, the action

described below has been carried out.

3.Cause: There was a possibility of bad connections occurring due to the vibrations which occur

when the FFC harness came in contact with the HDD. The vibrations were caused by

operation deviance due to the extreme length of the FFC harness.

4.Measure: A change has been carried out in the length of the FFC harness. The FFC harness has

been shortened by 30 mm as a measure to prevent contact between the FFC harness

and the HDD.

5.Action: From the 1st lot of 1999 March production.

2. Measure carried out to alleviate problems of contact between the ICU PWB and the

sub PWB guide.

1.Model Name: AR-405

2.General: There was a section of the gap between the ICU PWB and the ICU sub PWB guide R in

which there was very little margin of error. As a measure to alleviate this problem, the

attachment of a mylar sheet has been carried out to insure that contact is not made.

SHARP CORPORATION Document Division I

1/4

Green

C

Page 2

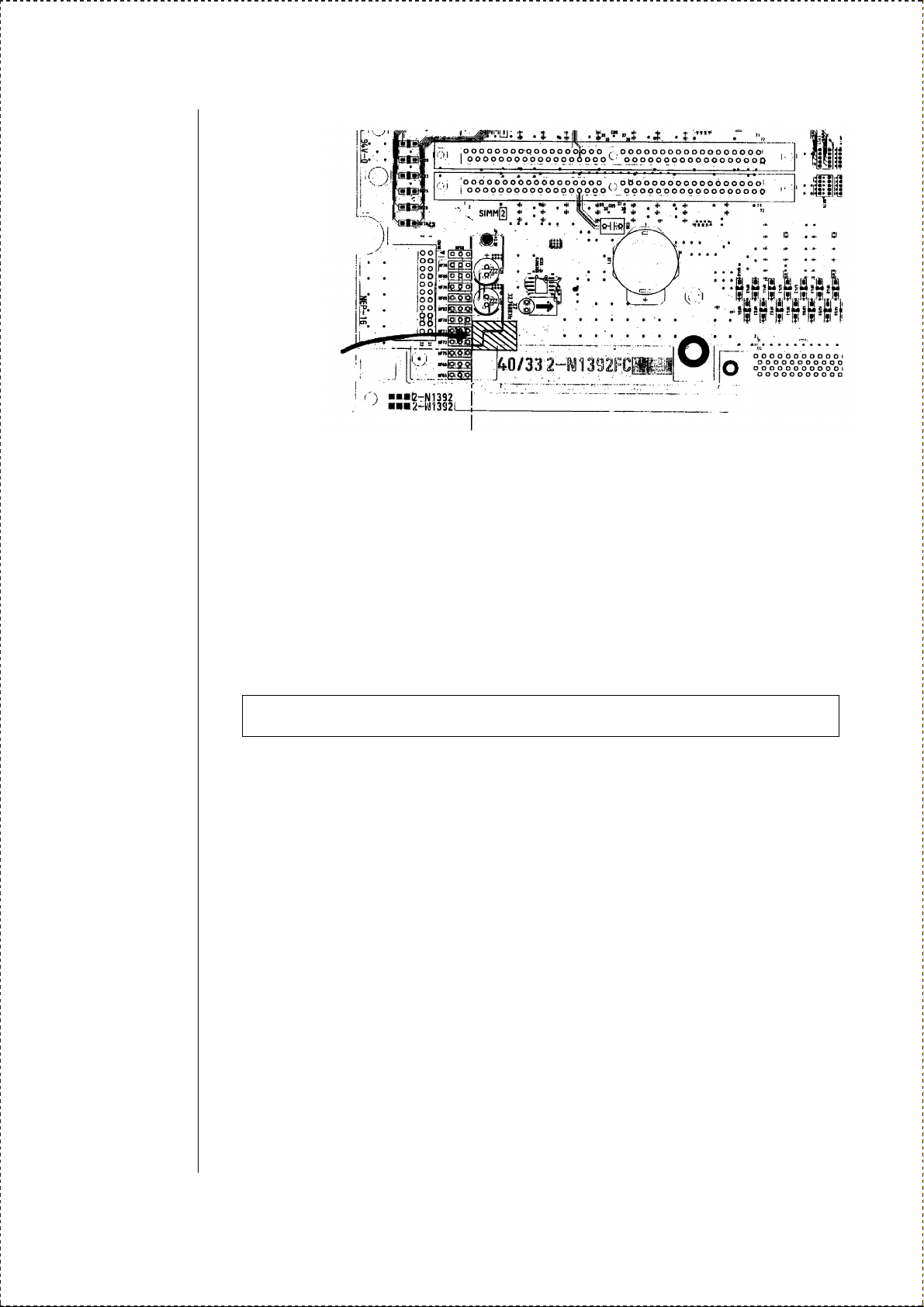

Added mylar sheet

PSHEP0293GCZZ

Attachment

standard

(NF 75 silk)

Attachment standard

(NF 75 silk)

The silkscreened markings of the PWBs which have undergone the action described

above are as shown below.

40/332-N1392FC

40/331-N1393FC

28N1404FC

3.Action: From the 1st lot of 1999 March production.

3. Permanent measure carried out to alleviate problems of improperly tightened fixing

screws of the main motor.

1.Model Name: AR-280/285/335/405

2.General: There was a possibility of 1 of the 4 fixing screws of the main motor being improperly

tightened. As a measure to alleviate this problem, a change that was carried out in the

length of the fixing screws and the addition of a washer that was carried out were

reported in T/R No. ARE-142. As a permanent measure to alleviate this problem,

however, a change has been carried out in the thickness of the metal plate in the

location where there was a possibility of improper tightening of the fixing screw. The

thickness of the metal plate has been decreased. The fixing screw has been changed

once again, and is now the original size of 4 × 8. In addition to this change, the washer

has now been discontinued.

3.Action: *1 AR-S400/405: From the 1st lot of 1999 March production.

Japanese domestic production except for the models listed above:

Running change carried out from 1999 mid-February production.

Chinese (SOCC) production except for the models listed above:

From the 1st lot of 1999 April production.

2/4

Page 3

4. Measure carried out to decrease the amount of abnormal noise in the ADU unit.

1.Model Name: AR-285/335/405 (only for machines bound for the 200 V series market destinations.)

2.General: There was a problem of abnormal noise which was occurring during ADU operations.

As a measure to alleviate this problem, the action described below has been carried out.

3.Cause: There was a problem of looseness in the reversion roller shown in the figure below,

which caused the abnormal noise to occur during operations.

4.Measure: The addition of a plastic slider on the F and R sides of the reversion roller has been

carried out as a measure to eliminate the looseness of the reversion roller.

Added plastic sliders

5.Action: AR-405: From 1999 mid-February production.

For all models except the model listed above:

From the 1st lot of 1999 March production.

5. Change in the shape of the ICU cover carried out in accordance with a change that

was carried out in the attachment locations of some of the parts in the ICU PWB.

1.Model Name: AR-405

2.General: A change was carried out in the attachment locations of some of the parts in the ICU

PWB. Some of the parts which had been attached to the rear side of the ICU PWB

have now been attached to the front side of the ICU PWB, and as a result of this

change, there was a problem of obstruction of the ICU cover. As a measure to alleviate

this problem, a change has been carried out in the shape of the ICU cover.

The cut-away portion

has been enlarged.

3.Action: From the 1st lot of 1999 March production.

3/4

Page 4

Ref.

Model

No.

AR-280

AR-285

1

AR-335

AR-405

2 AR-S405

AR-280

AR-285

AR-335

AR-405 11 -20

3

AR-280

AR-285

AR-335

AR-405

4

AR-285

AR-335

5 AR-405 All

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with ‘‘ ’’ is important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

name

Version P/G No.

5 -15

5 -16

5

11 -1

All

11

11 -19

200V

series

2

5 -68

Current parts New parts

Parts code Parts code

QCNW-0151FCZZ QCNW-0160FCZZ AE

QCNW-0152FCZZ QCNW-0161FCZZ AF

---- PSHEP0293GCZZ AB PS front sheet

XHBSD40P10000 XHBSE40P08000 AA Screw (4 × 8)

XWHSD40-08100 Discontinued ---- Washer

---- LX-WZ0126FCZZ AA Plastic slider

PCOVP1470FCZ1 PCOVP1470FCZ2 AS ICU cover 4

Price

rank

5. Interchangeable if replaced with same types of

related parts in use.

6. Others.

Parts name

FFC1 harness and

the CCD PWB

FFC2 harness and

the CCD PWB

Effec-

tive

time

1st lot

’99/3

*1

1st lot

’99/3

*1

1st lot

’99/3

Mid-

’99/2

1st lot

’99/3

Inter-

change-

ability

1

6

Note

*2

4/4

*2: 1 location

Loading...

Loading...