Page 1

DIGITAL COPIER : AR-280

Date

:

Mar. 31, 1999

1.CHANGE IN PARTS TO INCORPORATE PARTS MANUFACTURED BY SHARP INTO ASSEMBLED UNITS CARRIED OUT AS

A MEASURE TO IMPROVE PRODUCTIVITY.

2.MEASURE TO ESTABLISH UNIFORMITY OF THE HIGH VOLTAGE PWB CARRIED OUT AS A MEASURE TO IMPROVE

PRODUCTIVITY.

3.CHANGE IN PART CODE CARRIED OUT IN ACCORDANCE WITH A CHANGE TO IN-HOUSE PRODUCTION OF THE LSU UNIT.

4.MEASURE TO ESTABLISH UNIFORMITY OF THE PCU PWB CARRIED OUT AS A MEASURE TO IMPROVE PRODUCTIVITY.

5.MEASURE TO ALLEVIATE PROBLEMS OF SCATTERING OF THE WASTE TONER.

No. : ARE-154

1. Change in parts to incorporate parts manufactured by Sharp into assembled units

carried out as a measure to improve productivity.

1.Model Name: AR-280/285/335

2.General: A change in some of the parts has been carried out in accordance with the

incorporation of an LSU unit and copy lamp unit which have been manufactured

in-house.

3.Description:

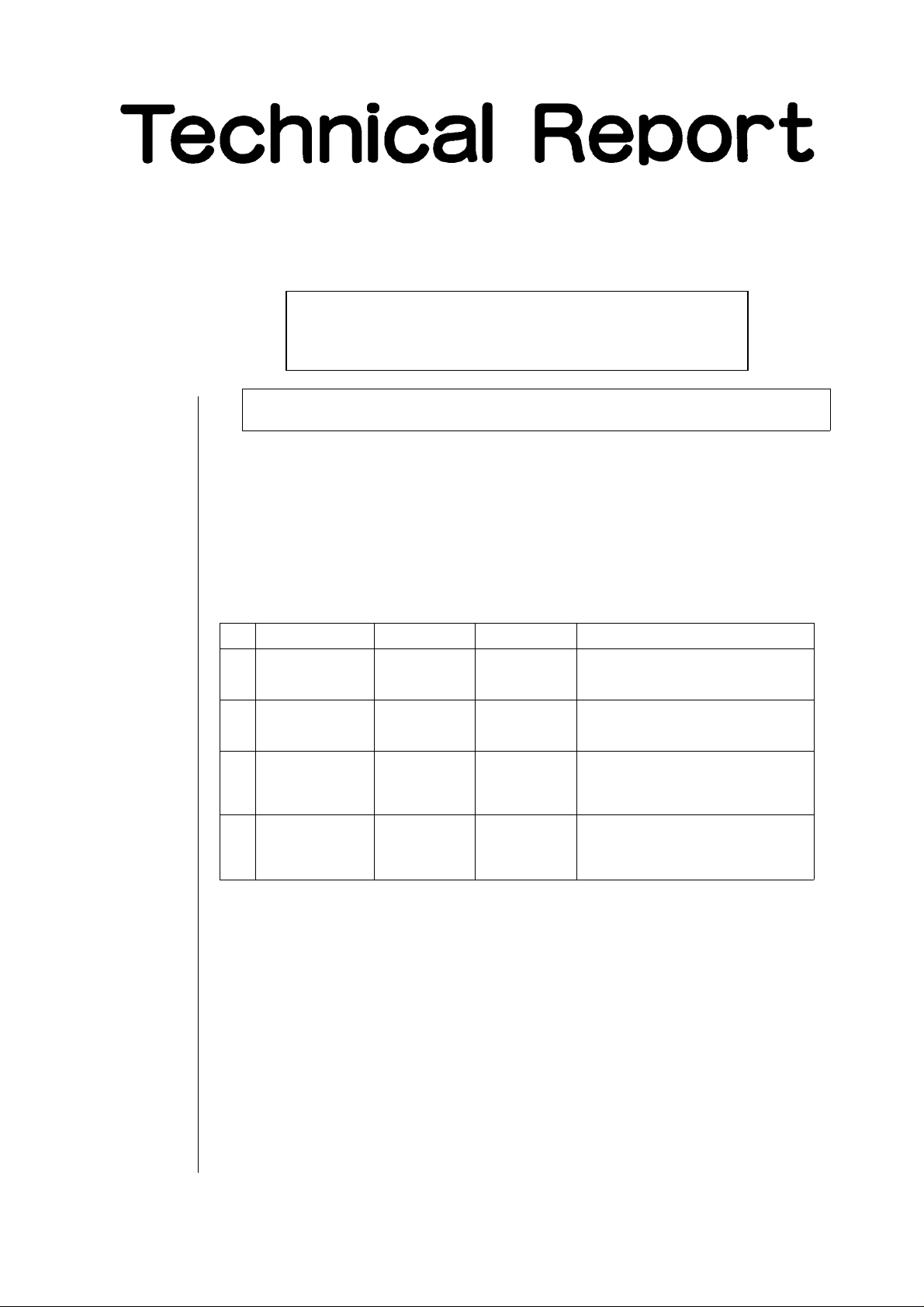

Part name Old New

<1> Wire fixing plate LPLTM5434FCZZ LPLTM5434FCZ1

<2> LSU Harness cover PCOVP1455FCZZ PCOVP1513FCZZ

LSU Interface harness

<3>

(Japan market)

LSU Interface harness

<4>

(overseas market)

DHAI-2945FCZZ DHAI-2945FC11

DHAI-2865FCZZ DHAI-2865FC11

Carried out as a measure to establish

uniformity between model AR-S400 and model

AR-S405.

Carried out as a measure to establish

uniformity between model AR-S400 and model

AR-S405.

Change carried out in the length of the harness

and change carried out in the color of the

distinguishing tape (red has been changed to

yellow).

Change carried out in the length of the harness

and change carried out in the color of the

distinguishing tape (black has been changed to

blue).

It is possible to use the new part described in <1> above with either the old copy lamp

units or with the new ones, but the old parts can only be used with the old copy lamp

units. The same is true for the new part described in <2> above.

The new parts described in both <3> and <4> above are not interchangeable with the

corresponding old parts.

4.Action: From the 1st lot of 1999 February production.

SHARP CORPORATION Reprography Division

1/4

Green

C

Page 2

2. Measure to establish uniformity of the high voltage PWB carried out as a measure to

improve productivity.

1.Model Name: AR-280/285/335

2.General: A change has been carried out in the high voltage PWB used in the models listed

above. The new high voltage PWB is the same one which is used in model AR-405.

This action has been carried out as a measure to establish uniformity of the models

listed above with model AR-405. It is important to note that both the old parts and the

new parts can be used in the models listed above.

3.Action: From the 1st lot of 1999 February production.

3. Change in part code carried out in accordance with a change to in-house production

of the LSU unit.

1.Model Name: AR-280/285/335

2.General: A change in the part code of the LSU unit has been carried out in accordance with the

in-house manufacturing of the unit.

3.Action: Model AR-285 (only for machines bound for the US market destinations):

From the 1st lot of 1999 February production.

For all units other than the one listed above:

From the 1st lot of 1999 March production.

4. Measure to establish uniformity of the PCU PWB carried out as a measure to

improve productivity.

1.Model Name: AR-405

2.General: The PCU PWB which is in accordance with noise standards (for the 200 V series) had

been established, but in accordance with the loosening of the noise standards, the PCU

PWB which is in accordance with the old standards has been discontinued, and the

PCU PWB used with other machines is now being used in the model listed above.

3.Action: From the 1st lot of 1999 February production.

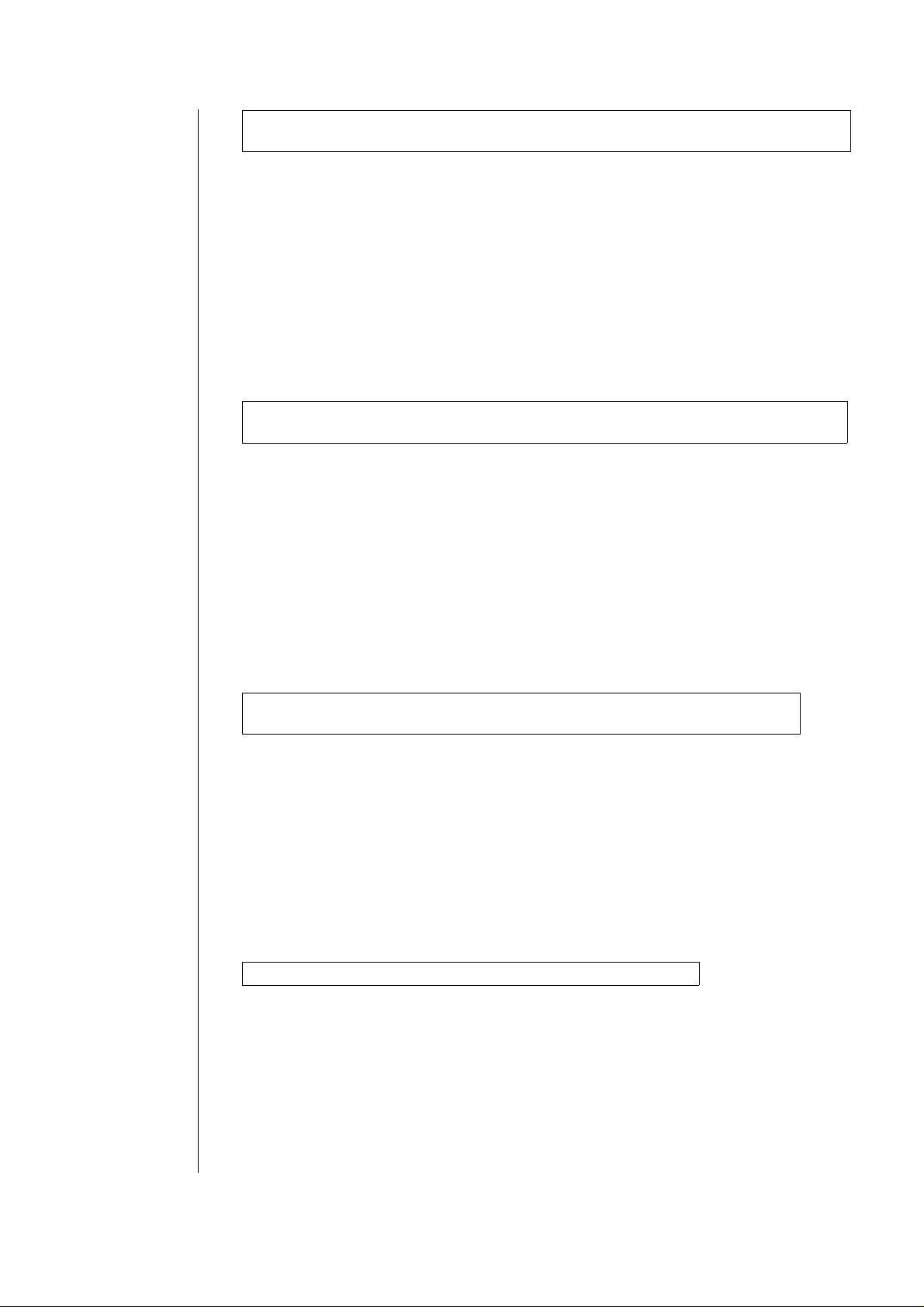

5. Measure to alleviate problems of scattering of the waste toner.

1.Model Name: AR-405

2.General: The addition of a mylar sheet and a molt has been carried out. This action has been

carried out as a measure to alleviate problems of scattering of the waste toner. Please

rever to the attached supplementary document for details concerning the attachment

locations of these new parts. Insert the following figure here.

2/4

Page 3

After the assembly process has been completed,

the shutter should open and close smoothly.

Attachment standard for

the side mylar sheet.

Waste toner transport pipe

Side mylar

Moveable shutter

Side mylar

Attachment standard for

the side mylar sheet.

Alignment with the

attachment standard.

Care should be exercised to insure that no sagging

or tears occur during attachment operations.

Side molt

Moveable shutter

Attachment standard

for the side molt

Attachment

standard line

Side molt

Attachment standard

for the side molt

Attachment

standard line

3/4

Page 4

Waste toner transport pipe

Waste toner transport pipe

Attachment standard for the

drop opening mylar sheet

Attachment

standard line

Attachment

standard line

3.Action: From 1998 mid-December production.

Ref.

No.

1

2

Model

name

AR-280

AR-285

AR-335

Version P/G No.

6 -5

5 -30

All

5 -31

10 -36

Current parts New parts

Parts code Parts code

LPLTM5434FCZZ LPLTM5434FCZ1 AC Wire fixing plate

PCOVP1455FCZZ PCOVP1513FCZZ AG LSU harness cover

DHAI-2865FCZZ DHAI-2865FC11 AS LSU interface harness 4

RTRNZ0533FCZZ RTRNZ0533FCZ1 BT High voltage PWB

Drop opening mylar sheet

Attachment standard for the

drop opening mylar sheet

Drop opening mylar sheet

Price

rank

Parts name

Effec-

tive

time

1st lot

’99/2

Inter-

change-

ability

3

Note

4/4

AR-285 U.S.A.

3

AR-280

AR-285

AR-335

4 AR-405

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with ‘‘ ’’ is important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

9 -501

*

10 -12

41 -901

DUNT-6984FC11 DUNT-6984FC22 CL LSU unit

CPWBN1403FC51 CPWBN1267FC53 CB PCU PWB

5. Interchangeable if replaced with same types of

related parts in use.

6. Others.

1st lot

1st lot

* Other than the above.

’99/3

’99/2

1

Loading...

Loading...