Page 1

DIGITAL COPIER : AR-5132

Date

:

Nov. 20, 1997

1. MEASURE TO ALLEVIATE PROBLEMS OF Z-FOLDING DURING COPY

OPERATIONS CARRIED OUT ON SMALL SIZED ORIGINAL DOCUMENTS.

2. MEASURE TO ALLEVIATE PROBLEMS OF SOILED COPY PAPER

EDGES.

1. Measure to alleviate problems of Z-folding during copy operations carried out on

small sized original ducuments.

1.Model Name: AR-5132

2.General: There have been problems of Z-folds sometimes occurring during production when

small sized original documents (sizes such as A5, invoice, etc.) were transported through

the machine during feeding operations. The problems of Z-folds were caused due to the

fact that the paper feed drive load was light, causing the paper feeding speed to

increase. As a measure to alleviate this problem, the action described below has been

carried out.

No. : ARE-054

3.Description: When the paper feeding speed is detected as having overshot the paper feeding speed

control during paper feeding movement (with the exception of preparatory feeding), the

electrical power being supplied to the paper feeding motor is momentarily cut, causing

the paper feeding speed to decrease slightly. To achieve these ends, a change has been

carried out in the EP ROM of the PBA control PWB. In accordance with the change

described above, a change has been carried out in the part codes for the EP ROM and

the PBA control PWB.

From 1997 mid-August production, action concerning this problem has been carried out

in the production operations. Checks are being carried out on all machines produced,

and therefore there is no particular problem with the old PWBs or the old ROMs.

Furthermore, even if a machine is equipped with an old PWB, the replacement of the

ROM will be sufficient to change the old PWB into the equivalent of a new PWB.

4.Action: From 1997 mid-August production.

SHARP CORPORATION Reprography Division

1/3

Green

C

Page 2

2. Measure to alleviate problems of soiled copy paper edges.

1.Model Name: AR-5132 (only machines bound for 200V destinations).

2.General: There has been some trouble with soiling of copy paper edges during double-side copy

operations. This problem was caused by the toner which had become adhered to the TC

guide in the TC unit. As a measure to alleviate this problem, the action described below

has been carried out.

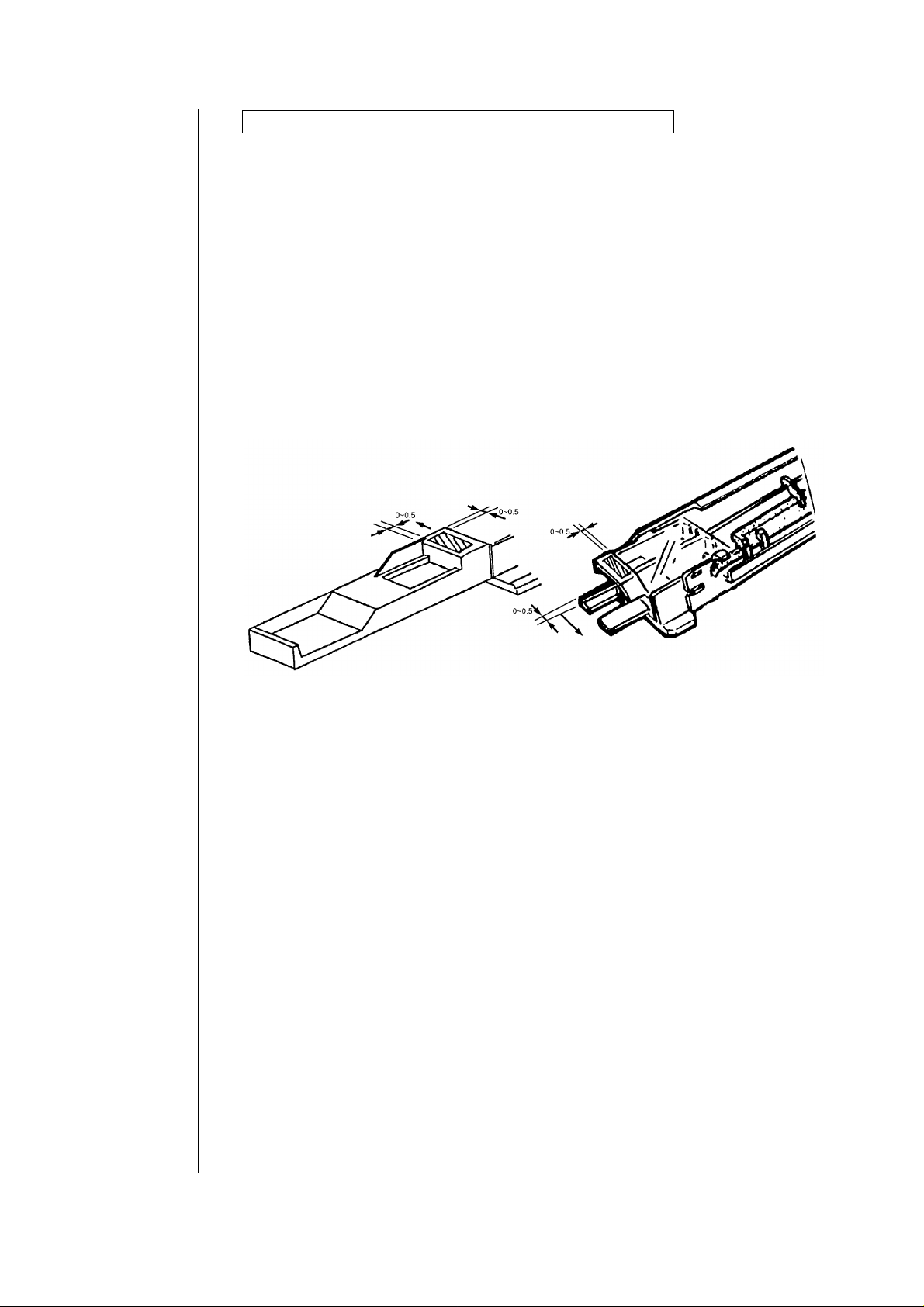

3.Description: (1) A change has been carried out in the Teflon tape attached to the TC guide.

In addition to this change, the addition of a TC drum spacer has been carried out to

maintain a gap between the TC guide and the drum.

Cannot protrude

Attachment position for

the TC drum spacer

Standard

Standard

Standard

Cannot protrude

F Side R Side

(2) The total transfer current has been raised by approximately 20µA. This change has

been carried out to standardize the current with the drum current.

Note: In accordance with the action described in (1) above, a change has been carried

out in the part code of the TC unit.

4.Action: From 1997 mid-April production. (Temporary action has been carried out from the 1st lot

of mass production until mid-April production.)

2/3

Page 3

Ref.

Model

No.

name

1

AR-5132

2 200V series

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with ‘‘ ’’ is important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

Version P/G No.

61 -93 0CW2214K234// 0CW2214K234C/ AY EP ROM

All

34 -27

61 -94

29 -8 CGIDM1358FC04 CGIDM1358FC06 BA TC guide

29

29 -901 CCASZ0235FC61 CCASZ0235FC62 BB TC case unit 3

Current parts New parts

Parts code Parts code

0CW2214K226// 0CW2214K226D/ CA PBA-control PWB

---- PSPAZ1406FCZZ AB TC drum spacer 1 Q’ty 2

Price

rank

5. Interchangeable if replaced with same types of

related parts in use.

6. Others.

Parts name

Effec-

tive

time

Mid-

’97/8

Mid-

’97/4

Inter-

change-

ability

1

3

Note

3/3

Loading...

Loading...