Page 1

INSTALLATION INSTRUCTIONS FOR

CEIL I NG M O UNTIN G BRACK ET FOR

USE ONLY WITH SHARP

PROJECTOR MODEL

XV-Z2000/DT-400

CEI L I N G MOUNTIN G

BRAC KET AN-CM270

AN-CM270

CEI L I N G MOUNTIN G

BRACKET COMBINED

WITH OPTIONAL

ADJUSTABLE

EXTENSION TUBE

MODEL AN-EP101B

COPYRIGHT ©

2004 SHARP ELECTRONICS CORPORATION

Page 2

INSTALLATION INSTRUCTIONS CEILING BRACKET AN-CM270

C A U T I O N

C A U T I O N

C A U T I O NC A U T I O N

INSTALLATION OF THIS ADJUSTABLE WALL MOUNTING BRACKET

SHOU L D BE P ERF O RMED BY QUALIF IED SERVICE/INSTA LLATION

PERSONNEL FOLLOWING THE INSTALLATION INSTRUCTIONS

IN CL U DED WI T H T H IS BRACKET

THE EXCLAMATION POINT WITHIN AN EQUILATE RAL TRIANGLE

IS INTENDED TO ALERT THE USER TO THE PRESENCE OF IMPORT ANT

OPERATING AND MAINTENANCE (SERVICING) INSTRUCTIONS IN THE

LITERATURE ACCOMPANYING THE APPLIANCE.

IMPORT ANT ! THE INST ALLER SHOULD READ THESE INS TRUCTI ONS TH OROUGHLY

BEFORE BEGINNING THE INSTALLATION AND SHOULD MAKE SURE THAT ALL

T HE WORK IS DONE IN COMPLIANCE WITH NEC AND ALL LOCAL BUILDING

AND SAFETY CODES. SAVE THIS BOOKLET AFTER THE INSTALLATION IS

COMPLETED. THE ACCESSORIES REFERRED TO IN THESE INSTRUCTIONS ARE

INTENDED FOR USE ONLY WITH COMPATIBLE SHARP PROJECTORS. SEE

SHARP PROJECTOR OWNER’S MANUAL OR SHARP DEALER TO DETERMINE

SUITABILITY.

CAUTION: THE BRACKET MOUNTING SCREWS MUST GO DIRECTLY INTO THE

BEAMS. SHEETROCK, LATH AND PLASTER, WILL NOT PROVIDE A

SUFFICIENTLY SECURE SUPPORT.

CAUTION: TO REDUCE THE RISK OF PERSONAL INJURY, USE ONLY THE

COMPONENTS WHICH ARE INCLUDED IN THIS PACKAGE, OR SPECIFIED IN

THESE INSTRUCTIONS.

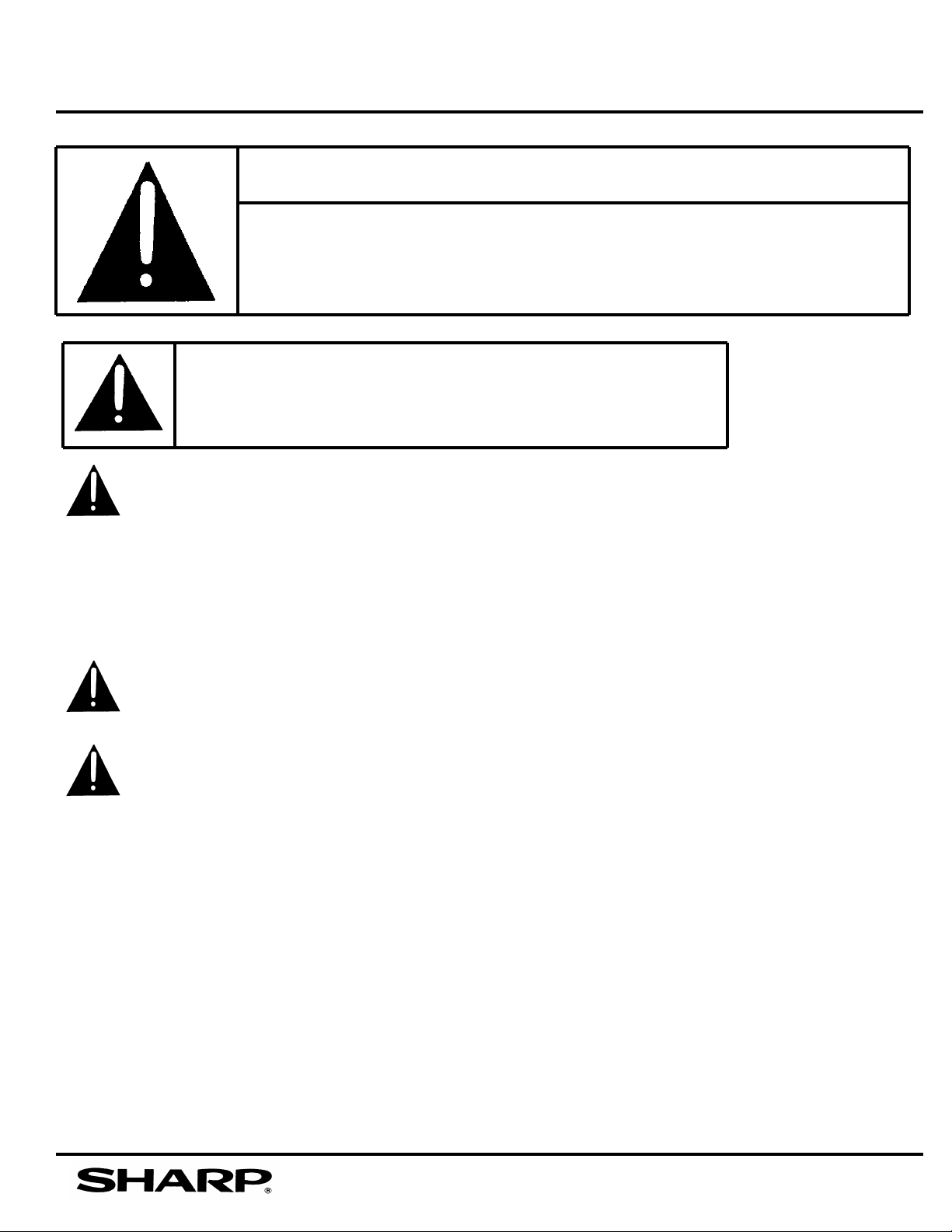

PARTS LIST FOR MODEL AN-CM270 CEILING BRACKET (SEE FIG. 1)

ITEM DESCRIPTION QUANTITY

A. PROJECTOR ATTACHMENT PLATE WHICH INCLUDES THE KNUCKLE

POSITIONING ASSEMBLY. 1

B. LOCKING HEX NUT & WASHER 1

C. STEEL CEILING MOUNTING PLATE 1

D. PLASTIC TRIM FOR CEILING PLATE 1

E. 1/4 X 10 HEX HEAD LAG BOLTS 2-1/2” LONG 6

F. 1/4 X 10 HEX HEAD LAG BOLTS 3” LONG 6

G. 1/4” I.D. WASHERS FOR USE WITH LAG BOLTS 6

H. M4 X 12mm FLAT HEAD MOUNTING SCREWS FOR USE WITH ATTACHMENT PLATE 3

I. M4 X 12mm KNURLED THUMB SCREW 1

J. M4X30mm FLAT HEAD SCREW 1

K. PLASTIC TRIM COLLAR 1

PAGE 2

Page 3

INSTALLATION INSTRUCTIONS CEILING BRACKET AN-CM270

FIGURE 1. I L L U STRA T I ON OF PAR T S FOR CEILIN G BRA C KET

A.

B.

C.

D.

E.

H.

I.

K.

F.

G.

J.

INVERT THE PROJECTOR IMAGE

Please refer to the owners manual for your LCD Projector for detailed instructions of how to electrically

invert the projected image to accommodate its use in the ceiling mounted mode.

LOCATION OF THE CEILING BRACK ET

Please refer to the owner’s manual for your SHARP LCD PROJECTOR for information which will help

you to determine the best location for the placement of the ceiling mounting bracket assembly.

INSTALLATION OF THE CEILING BRACKET

After you have determined the appropriate location for the ceiling bracket, you must locate the exact

location of the ceiling beam s . Mos t s ta n dar d residen tial cons t ruc tion u ses 16 in c hes between cen t e rs

for overhead beams. You can mount the ceiling bracket b y straddling two beams, or you can ins tall the

bracket in line with a single beam.

CAUTION: THE BRACKET MOUNTING SCREWS MUST GO DIRECTLY INTO THE BEAMS.

SHEETROCK, LATH AND PLASTER, WILL NOT PROVIDE A SUFFICIENTLY SECURE

SUPPORT.

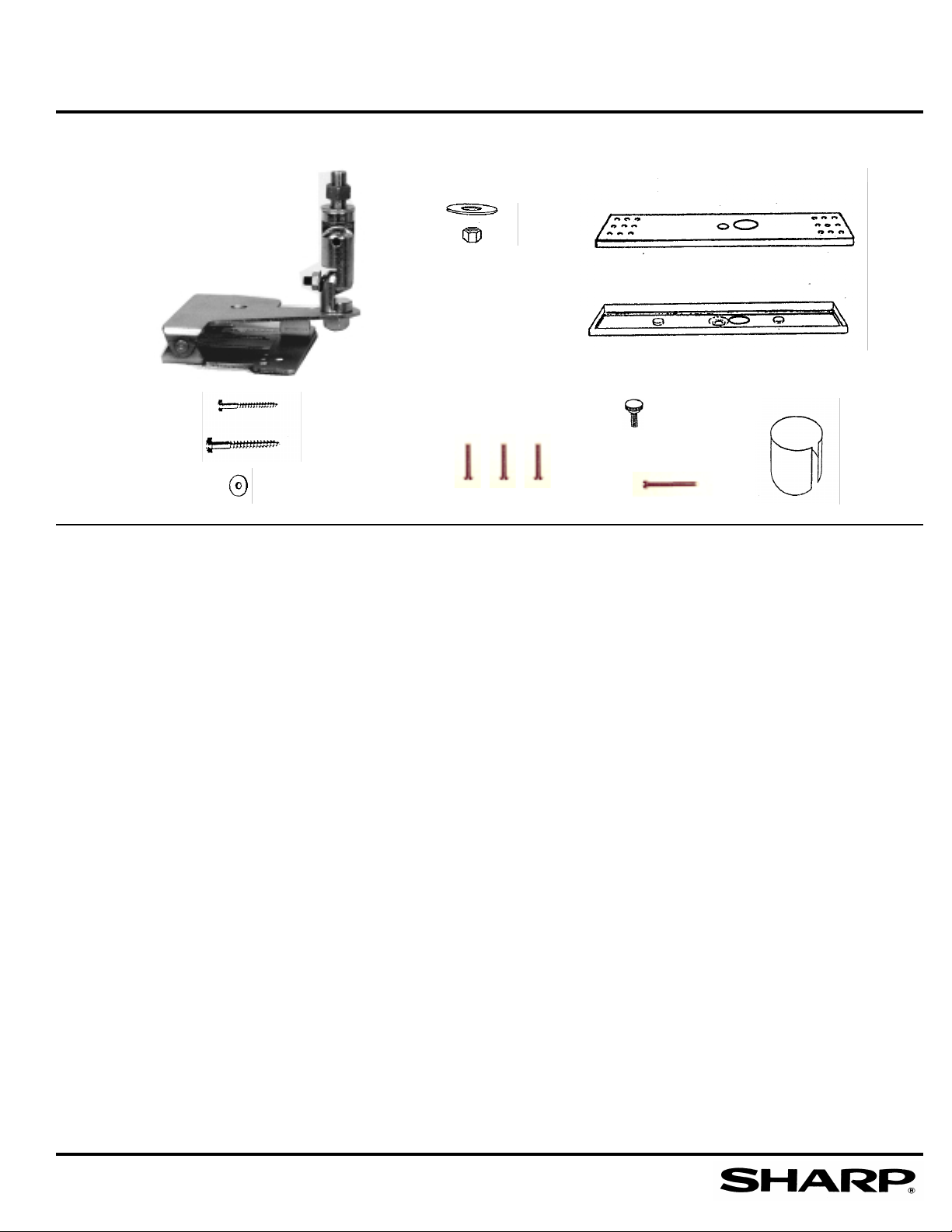

STEP 1. INSTALLATION OF THE METAL CEILING BRACKET

A ft e r t h e l o catio n fo r the ceilin g b ra c ket ha s been determined , (see LCD PROJECTOR

Ow ner ’s Manual), make sure to lo ca te beams in t he ceiling.

PAGE 3

Page 4

INSTALLATION INSTRUCTIONS CEILING BRACKET AN-CM270

1.1 a. Selec t strad dle beam or s ingle beam installation.

b. Use the ceiling bracket as a template to mark the locat ion where the pilot holes

should be drilled.

c. Drill the pilot holes for the support screws using a 1/8” drill bit into the center of

the beam. (See Figs. 2 and 3).

1.2 Screw the ceiling plate to the beams. Use at least 6 screws and metal washers

supplied with the unit. These screws should be tightened firmly to insure a

v ibration-free support. (See Figs. 2 and 3).

Two sizes of hex head lag bolts are provided. Use shorter screws for sheet rock

surfaces and use the longer screws if the ceiling surface is constructed of a wood

lath and plaster.

CAUTION: THE BRACKET MOUNTING SCREWS MUST GO DIRECTLY INTO

THE BEAMS. SHEETROCK OR LATH AND PLASTER WILL NOT PROVIDE A

SUFFICIENTLY SECURE SUPPORT.

FIGURE 2. ILLUSTRATION OF STRADDLE BEAM CEILING BRACKET INSTALLATION

Sheetrock or lath

and plaster ceiling

Ceiling Mounting

Bracket

Velcro

Plastic Ceiling

Bracket Trim Cover

Washers

1/4 X 10 Lag Bolt

NOTE: THE OUTER ROW OF HOLES ARE 16” BETWEEN CENTERS WHICH IS

THE MOST COMMON BEAM SPACING IN RESIDENTIAL WOOD FRAME

CONSTRUCTION.

Ceiling Beam

PAGE 4

Page 5

INSTALLATION INSTRUCTIONS CEILING BRACKET AN-CM270

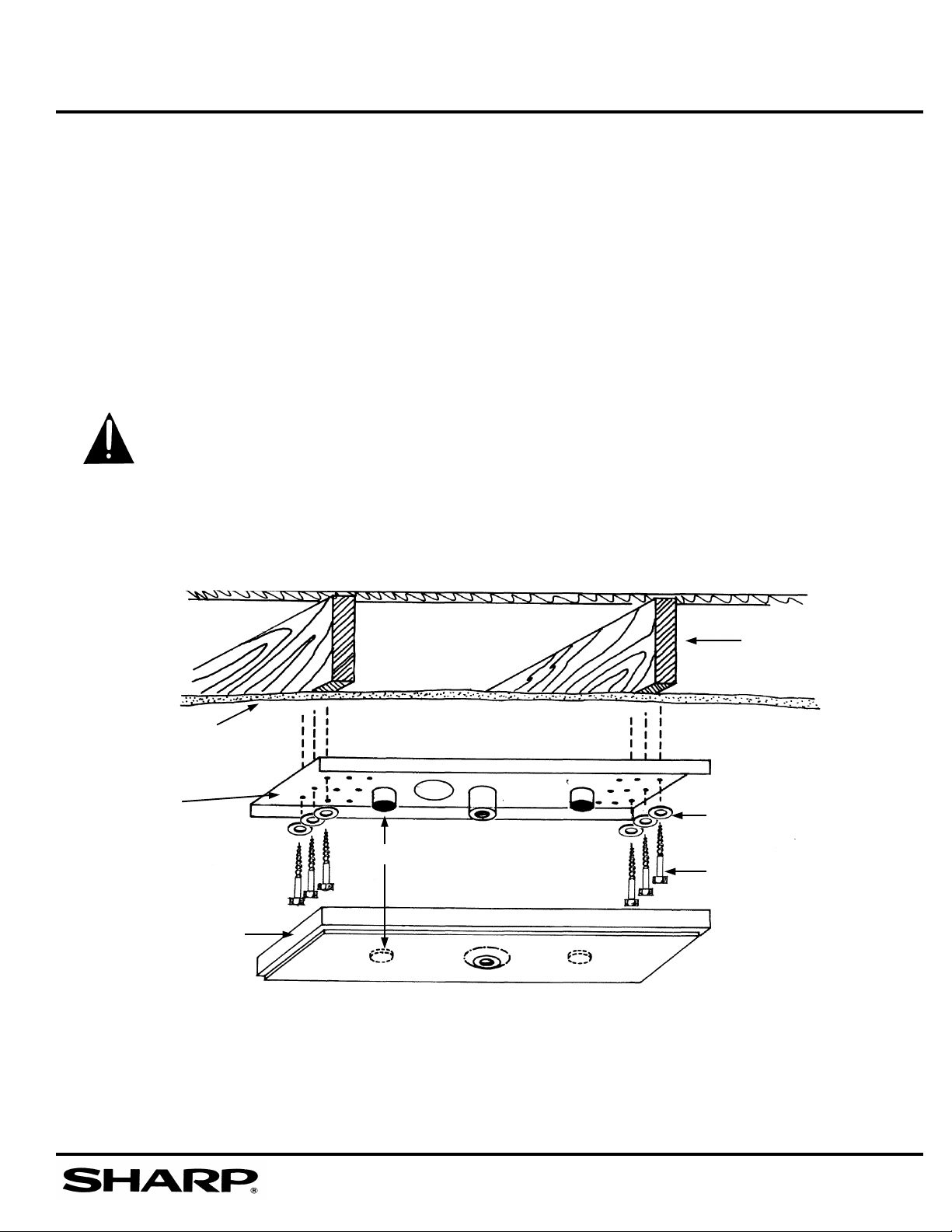

FIGURE 3 ILLUSTRATION OF SINGLE BEAM CEILING BRACKET INSTALL A TION

Ceiling Beam

Ceiling Mounting Bracket

Washers

Sheetrock or lath

and plaster ceiling

1/4 x 10 Lag Bolts

DO NOT RUN THE AC POWER CORD THROUGH THE CEILING PLATE AND TRIM COVER

STEP 2. INSTALL THE CEILING MOUNT PLASTIC TRIM

2.1 The Access Hole (See Fig. 4) in the ceiling attachment plate is large enough to accommodate the

molded connectors commonly used the with projector.

2. 2 Audio, Video and other low v oltage connections may be passed through t he access hole in t he

ceiling plate and may also be passed through the plastic trim cover. There is a l abel (See Fig. 4) on

the inside of the plastic trim cover, adjacent to the center mounting bushing.

2.3 Select the contour appropriate for your application and cut out the opening along the line indicated

on the label. Use a very sharp cutting tool.

2.4 Thread the cable through the plastic trim cover. Place the plastic trim cover in place over the

ceiling plate and press the velcro tabs together.

Velcro

FIGURE 4 I NST ALL A T ION OF PLASTIC TRIM ON T HE CEILING BRACKET

Cable Access Hole

Access Hole Template Label

Press Velcro Tabs together

to secure plastic trim cover

in position

PAGE 5

Page 6

INSTALLATION INSTRUCTIONS CEILING BRACKET AN-CM270

STEP 3 DETACH THE POSITIONING ASSEMBLY FROM THE PROJECTOR ATTACHMENT

PLATE.

FIGURE 5

NOTE: PLEASE LOOK OVER THE EXACT MANNER IN WHICH THE

POSITIONING ASSEMBLY AND T HE ATT ACH MENT PLATE GO

TOGETHER SO THAT YOU WILL BE ABLE TO REASSEMBLE THEM

WHEN YOU HANG THE PROJECT OR.

3.1 Using 9 / 16 ” box wrench, remove the nut from the lower knuckle

(vert ical position) and slide t he center an d upper k n u ckle assembly apar t

from t he bottom knuck le w h ic h is part o f the

attachment plate. (See Fig. 5)

SPECIAL NOTE TO INSTALLERS: In s ome instances the relationship of

the locat ion o f t he projec ti on screen to t he exact po siti on o f t he ceiling

moun t in g b racke t m akes it desirable t o have the center line of t he lens at

the center of the mounting bracket. I f you find it necessary to have the

lens at t he cen ter line o f t h e mo un t , r emo ve the lo w e r element of the

positioning knuck le f rom its original posit ion and re-mount it in the D

shaped h o le i n the mounti n g p late lo c ated i n t he area over t he lens. Th is

will align the centerline of the lens with the center of the mounting

bracket. T he posit ioning knuc k le assembly can easily compensate f or the

slight loss of sta ti c balance of t he m ounted projector.

STEP 4 INSTALLA TION OF THE PROJECTOR ATT ACH MENT PLATE

4. 1 Place the attachment plate over t he bott om o f the projector (See Fig. 6)

and al ign the holes of the plate with the threaded fittings on the projector case.

4. 2 Install the three M 4 x 12 mm long screws provided. Fasten these securely but

DO NOT overtighten. (See Fig. 7)

4. 3 Install the longer, M4 x 3 0 mm flat head scre w in to t he indicated hole. (I t goes

into the recessed fitting in th e plastic housing).

FIGURE 6.

FIGURE 7.

M4x12mm mounting

screw

PAGE 6

M4x30mm screw

M4x12mm screw

Page 7

INSTALLATION INSTRUCTIONS CEILING BRACKET AN-CM270

4. 3 Fold the at tachm ent plate down on i t s hinge. See Fig. 8

4. 4 Install the M4 knurled thumb screw b y hand. See Fig. 8. DO NOT USE TOOLS TO

TIGHTEN THIS SCREW.

FIGURE 8

M4 Knurled Thumb Scre w

RE MINDE R : MAKE SURE TO ALLOW SUFFICIENT SLACK IN THE WIRING TO PERMIT THE

PROJECTOR TO SWING DOWN ON THE HINGE TO ALLOW EASY SERVICING OF THE FILTER

AN D THE L AMP A SSEMBLY.

STEP 5 ATTACH THE POSITIONING ASSEMBLY TO THE CEILING PLATE

FIGURE 9

Ceiling Trim Cover Cable Access Hole

Washer

Locking Hex Nut

Upper Knuckle

Assembly

IF Y OU INTEN D TO RUN AUDI O OR VIDEO CABLES THROUGH THE CEILING PLA TE

PROCEED WITH STEP 5.1 AND 5.2, OTHERWISE PROCEED TO STEP 5.3:

5.1 Cut opening in t he ceiling plate trim co ver as indicated on the label inside cover near

the center b ushing.

5.2 Thread cables through the plastic trim cover.

DO NOT RUN THE AC POWER CORD INSIDE THE PLASTIC TRIM COVER.

ALL WIRING MUST COMPLY WITH THE NEC AND ALL LOCAL BUILDING,

ELECTRIC, AND SAFETY CODES.

PAGE 7

Page 8

INSTALLATION INSTRUCTIONS CEILING BRACKET AN-CM270

5.3 Place the plastic trim cover in position over the ceiling plate and press the Velcro

tabs together.

5.4 After completing step #5.3, screw the longer shaft with the locking nut and washer

into the center threaded bush ing on the ceiling plate as far as it will g o. (See Fig. 9)

5.5 Tighten the locking nut against the ceiling plate using a 3/4” open end wrench or an

adjustable c rescent wrench.

5.6 Tighten the locking nut on the upper knuckle using a 9/16” box wrench.

DO NOT RUN THE AC POWER CORD INSIDE THE PLASTIC TRIM COVER.

ALL WIRING M UST COMPLY WITH THE NEC AND ALL LOCAL BUILDING,

ELECTRIC, AND SAFETY CODES.

STEP 6 HANGING THE PROJECTOR FROM POSITIONING ASSEMBLY

6.1 Raise the projector with the mounting plate attached and slide the fitting (See Fig. 10)

o ver the support stud on the hanging position.

6. 2 Replace the locking nut (removed in step 3 .1). Using the 9/16” box wrench run the nut

up but do not ti ght en all the way.

FIGURE 10

STEP 7 A I M THE PROJECTOR

7.1 A fter t he pro ject or has been property wi red, t u rn i t o n and loosen the posi tio ning

assembly adjustment nuts just enough so that you can move the p r ojector fairly easily.

(See Fig. 11) DO NOT COMPLETELY LOOSEN THE NUTS.

7. 2 Set t he Horizontal Centering by loosening the ceiling locking nut, mo ve t he projector to

center the image and tighten the nut. (Use 3/4” open end wrench).

7.3 Set the vertical centering and tighten the lowe r positioning adjustment nut.

(See Fig. 11)

7. 4 Set the Horizontal til t and tighten t he upper positioning adjustmen t nut . (See Fig. 1 1)

PAGE 8

Page 9

INSTALLATION INSTRUCTIONS CEILING BRACKET AN-CM270

FIGURE 1 1 DETAIL OF POSITIONING ASSEMBLY

CEILING PLATE

PLASTIC CEILING PLATE

TRIM CO VER

LOCKING NUT AND HORIZONTAL POSITION ADJUSTMENT

HORIZONTAL T ILT AD J U STMENT

VERTICAL POSITION ADJUSTMENT

STEP 8 INST ALL THE PLASTIC TRIM COLLAR

8.1 T he plastic t r im co lla r m a y be used as a c osm e tic c o n ceal ment of t h e pos i t i o n in g adj us t m e n t kn uc k l e

assembl y and t he audio and video signal cables.

8. 2 The sli t side of t he collar enables the installer to spread the collar enough t o place it over the adjustmen t

k n uc k le . It will c urve back by i t s o wn spr ing ac tion t o wrap around itself enough to c l ose the gap.

(See Fig. 12)

8. 3 If t he project or is hung a t a sharp angle, you m a y t r im the collar f or a better fit . (See Fig. 13)

FIGURE 12 FIGURE 13

DO NOT RUN THE A C POWER CORD INSIDE THE PLASTIC TRIM COLLAR. ALL

WIRING MUST COMPLY WITH T HE NEC AND ALL LOCAL BUILDING, ELECTRIC AND

SAFETY CODES.

NOTE: IN THE EVENT YOU WISH TO USE THE SHARP ADJUSTABLE EXTENSION

ACCESSORY IN CONJUNCTION WITH THE CEILING MOUNTING BRACKET, PLEASE

REFER TO THE INSTALLATION INSTRUCTION MANUAL INCLUDED IN THE

EX TEN S I ON TUBE PACKAGE .

PAGE 9

Page 10

INSTALLATION INSTRUCTIONS CEILING BRACKET AN-CM270

P ROCEDURE FOR S ERVICI N G LAM P HOU SI N G O R AI R FILTER:

A. Remove t he knurled t humb screw. See Fig. 14. The projector will swing down on the

hinge of t he moun tin g bracket. The bot t o m of t he projector wi l l now be in a position to

permit servicing the lamp assembly.

B. Proceed to service th e air filter or the lamp assembly. Follow the appropriate

instruc tions in your projector ow ner’s manual.

FIGURE 14 . H I N GED

ATTACHME NT PLA TE

MAKES SERVICING EASIER

Knurled thumb scre w

C. After completing the service procedure swing the projector back up and re-install the

knurled thumb screw.

NOTE: HINGED A TT A CH MENT PLATE ALLOWS PROJECTOR TO DROP DOWN FOR EASY

ACCESS TO FILTER AND LAMP HOUSING. SEE PROJECTOR OWNER’S MA NUAL FOR

DETAILS OF FILTER OR LAMP REPLACEMENT PROCEDURES.

PAGE 10

Page 11

INSTALLATION INSTRUCTIONS CEILING BRACKET AN-CM270

DIMENSIONS AND MEASURE MENTS OF COMPONENTS FOR

SHARP M OU NTING BRACKET AN- CM70

CEI L I N G PL ATE 4” WI D E X 18” LO N G

DISTANCE BETWEEN SETS OF MOUNTING HOLES: 1st SET 12 ” , 2nd SET 14”, 3rd SET 16”

ADDI TION AL POSSIBLE COMBINATIONS OF MOUNTING HOLE DISTANCE 13” & 15”

THREAD SIZE OF SWIVEL SHAFT & C EILING PLATE BUS HING 1/2” X 20

15

”

VEL-

CABLE ACCESS HOLE

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

12”

14”

16”

18”

VEL-

CENTER BUSHIN G 7/8 ” DEEP

1/2X20 THREADED HOLE

4”

ATTACHMENT PLATE WITH POSITIONING ASS EMBLY:

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

A. From ceiling to in verted bottom of projector: 5 1/2”

B. Length of position adj ustment knuckle assembly: 3 1/2”

C. Lens offset from center of lens to center of mounting bushing: 3”

D. Ceiling to center of lens: 7”

E. Ceiling to top of inverted projector: 8 7/8”

F. M ounting screws M4 X 12 & 30 mm long metric flat head phillips.

PAGE 11

Page 12

INSTALLATION INSTRUCTIONS CEILING BRACKET AN-CM270

ONE YEAR LIMITED WARRANTY

SHARP Electronics Corporation warrants to the first end use purchaser, that this SHARP brand

product (the “Product”), when shipped in its original container, will be free from defective

workmanship and materials, and agrees that it will, at its option, either repair the defect or replace

the defective product or part thereof at no charge to the purchaser for parts or for labor, excluding

costs of removal and/or installation, for one year from date of purchase.

This warranty does not apply to any appearance items of the Product nor to any Product the

exterior of which has been damaged or defaced, which has been subject to misuse, abnormal

service or handling, or which has been altered or modified in design or construction.

In order to avail the purchaser of his/her rights under this limited warranty, the purchaser should

carry in or ship the Product prepaid and insured, including proof of purchase, to:

SHARP Electronics, c/o AVDEX, 115 Henry Street, Freeport, NY 11520.

The limited warranty described above is in addition to whatever implied warranties may be

granted to purchasers by law. To the extent permitted by applicable law ALL IMPLIED

WARRANTIES INCLUDING THE WARRANTIES OF MERCHANTABIL ITY AND FITNESS FOR

USE ARE LIMITED TO THE PERIOD(S) FROM THE DATE OF PURCHASE SET FORTH

ABOVE. Some states do not allow limitations on how long an implied warranty lasts, so the

above limitation may not apply to you.

Neither the sales personnel of the seller nor any other person is authorized to make any

warranties other than those described above, or to extend the duration of any warranties beyond

the time period described above on behalf of SHARP.

The warranties described above shall be the sole and exclusive warranties granted by SHARP

and shall be the sole and exclusive remedy available to the purchaser. Correction of defects, in

the manner and for the period of time described herein, shall constitute fulfillment of all liabilities

and responsibilities of SHARP to the purchaser with respect to the Product, and shall constitute

full satisfaction of all claims, whether based on contract, negligence , strict liab ility or otherwise.

In no event shall SHARP be liable, or in any way responsible, for any damages or defects in the

Product which were caused by repairs or attempted repairs performed by anyone other than

SHARP. Nor shall SHARP be liable or in any way responsible for incidental or consequential

economic or property damage. Some states do not allow the exclusion of incidental or

consequential damages, so the above exclusion may not apply to you.

THE WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS. YOU MAY ALSO HAVE OTHER

RIGHTS WHI CH VARY FROM STATE TO ST ATE.

Specifications are subject to change without notice.

SHARP ELECTRONICS CORPORATION, SHARP PLAZA, MAHWAH, NJ 07430

COPYRIGHT ©

PAGE 12

2004 SHARP ELECTRONICS CORPORATION

Loading...

Loading...