Page 1

CODE: 00ZAL841//F1E

DIGITAL LASER

MULTIFUNCTION

MODEL AL-841

AL-841

CONTENTS

[ 1 ] SYSTEM CONFIGURATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

[ 2 ] SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

[ 5 ] EXTERNAL VIEW AND INTERNAL STRUCTURE . . . . . . . . . . . . 2

[ 6 ] MACHINE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

[ 7 ] ADJUSTMENTS, SETTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

[ 8 ] SIMULATION (Test Command) ⋅ USER PROGRAM . . . . . . . . . . 5

[ 9 ] ACTUAL WIRING CHART. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

[10] CIRCUIT DIAGRAM AND PARTS LOCATION CHART . . . . . . . 10

PARTS GUIDE

This Service Manu al de scr i be s only th e di f fe r en t po i nt s f rom th e AL - 84 0.

For servicing of the AL-841, therefore, use this Service Manual together

with that of the AL-840.

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

AL-841

At the produc tion line, the ou tput power of

the scanner unit is adjusted to 0.33

MILLI-WATT PLUS 20 PCTS and is

maintained cons tant by th e operatio n of the

Automatic Power Control (APC).

Even if the APC circuit fails in operation for

some reason, the maximum output power

will only be 15 MILLI-WATT 0.1 MICROSEC. giving an acceptable emission level

of 42 MICRO-WATT w hich is still -less than

the limit of CLASS-1 laser product.

Caution

The fusing unit is hot. Exercise care when inspecting it.

Do not switch the printer rapidly on and off. After turning the printer off,

wait 10 to 15 seconds before turning it back on.

Printer power must be turned off before installing any supplies.

CAUTION

VORSICHT

ADVARSEL

ADVERSEL

Laserstrahl

VAROITUS! LAITTEEN KÄYTTÄMINEN MUULLA

KUIN TÄSSÄ KÄYTTÖOHJEESSA MAINITULLA

TAVALLA SAATTAA ALTISTAA KÄYTTÄJÄN

TURVALLISUUSLUOKAN 1 YLITTÄVÄLLE

NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE.

VARNING - OM APPARATEN ANVÄNDS PÅ ANNAT

SÄTT ÄN I DENNA BRUKSANVISNING

SPECIFICERATS, KAN ANVÄNDAREN UTSÄTTAS

FÖR OSYNLIG LASERSTRÅLNING, SOM

ÖVERSKRIDER GRÄNSEN FÖR LASERKLASS 1.

VARNING

VARO!

INVISIBLE LASER RADIATION WHEN OPEN AND INTERLOCKS

DEFEATED AVOID EXPOSURE TO BEAM.

UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET UND SICHERHEITSVERRIEGELUNG ÜBERBRÜCKT. NICHT DEM STRAHL AUSSETZEN.

USYNLIG LASERSTRÅLNING VED ÅBNING. NÅR SIKKERHEDSBRYDERE ER UDE AF FUNKTION. UNDGÅ UDSAETTELSE FOR STRÅLNING.

USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES OG SIKKERHEDSLÅS BRYTES.

UNNGÅ EKSPONERING FOR STRÅLEN.

OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD OCH SPÄR RAR ÄR

URKOPPLADE. STRÅLEN ÄR FARLIG. BETRAKTA EJ STRÅLEN

AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA

NÄKYMÄTÖNTÄ LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN

CLASS 1

LASER PRODUCT

.

.

The foregoing is applicable only to the 220V

model, 230V model and 240V model.

Caution

This product contains a low power laser

device. To ensure continued safety do not

remove any cover or attempt to gain access

to the inside of the product. Refer all

servicing to qualified personnel.

LASER KLASSE 1

LUOKAN 1 LASERLAITE

KLASS 1 LASER APPARAT

Wave length

Pulse times

Output Power

780 ± 15nm

(9.3 ± 2µs)/7mm

0.4mW ± 0.05mW

Page 3

[1] SYSTEM CONFIGURATION

3. SOFTWARE

Items Contents Media

GDI Printer driver Printer driver CD-ROM

Twain driver Scanner driver

4. OPERATING ENVIRONMENT

(1) System requirements

Host computer Operating system Emulation Plug and play Network

IBM PC/AT or

100% compatible

(Supported ECP mode)

MS-DOS 3.3 + (Printer only)

∗

(2) Interface

Type Host computer Operating system Protocol

IEEE1284P × 1 IBM PC/AT or

MS-DOS 3.3 +

MS-Windows 3.1X or later

MS-Windows 95/98

MS-Windows NT 4.0

100% compatible

Sleek type GDI (Printer)

Twain (Scanner)

MS-DOS 3.3 +

MS-Windows 3.1X or later

MS-Windows 95/98

MS-Windows NT 4.0

Supported Not supported

Peppy

Nibble

ECP

AL-841

[2] SPECIFICATIONS

D. Scanner mode

(1) System requirements

a. Operating conditions

Host computer Operating system Software/Driver Plug and play Network

IBM PC/AT or compatible

(Supported ECP mode)

b. Interface

Type Host computer Operating Protocol

IEEE 1284 P IBM PC/AT or compatible Windows 3.1x ECP

Windows 3.1x Twain driver Supported Not supported

Windows 95/98

Windows NT 4.0

Windows 95/98

Windows NT 4.0

– 1 –

Page 4

AL-841

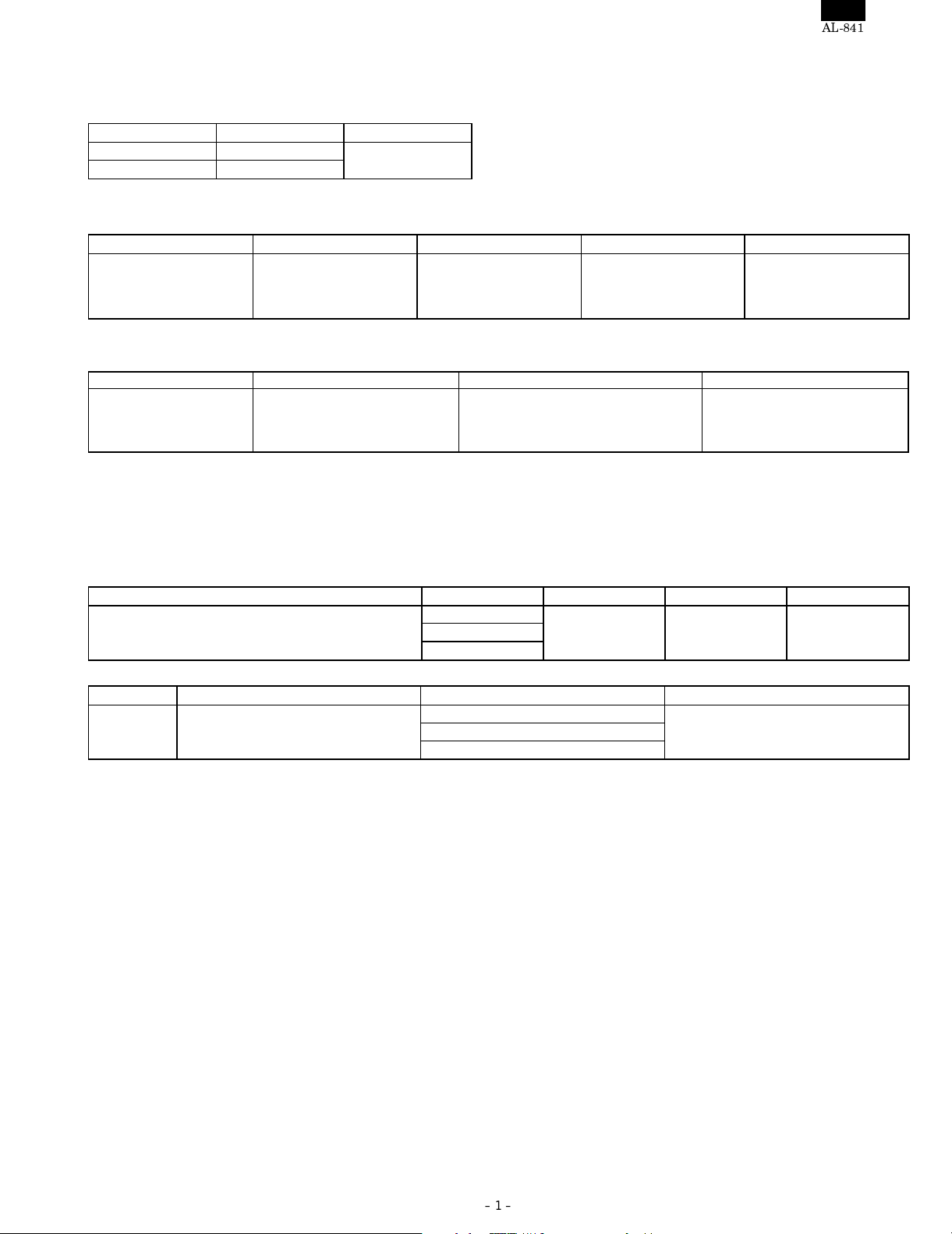

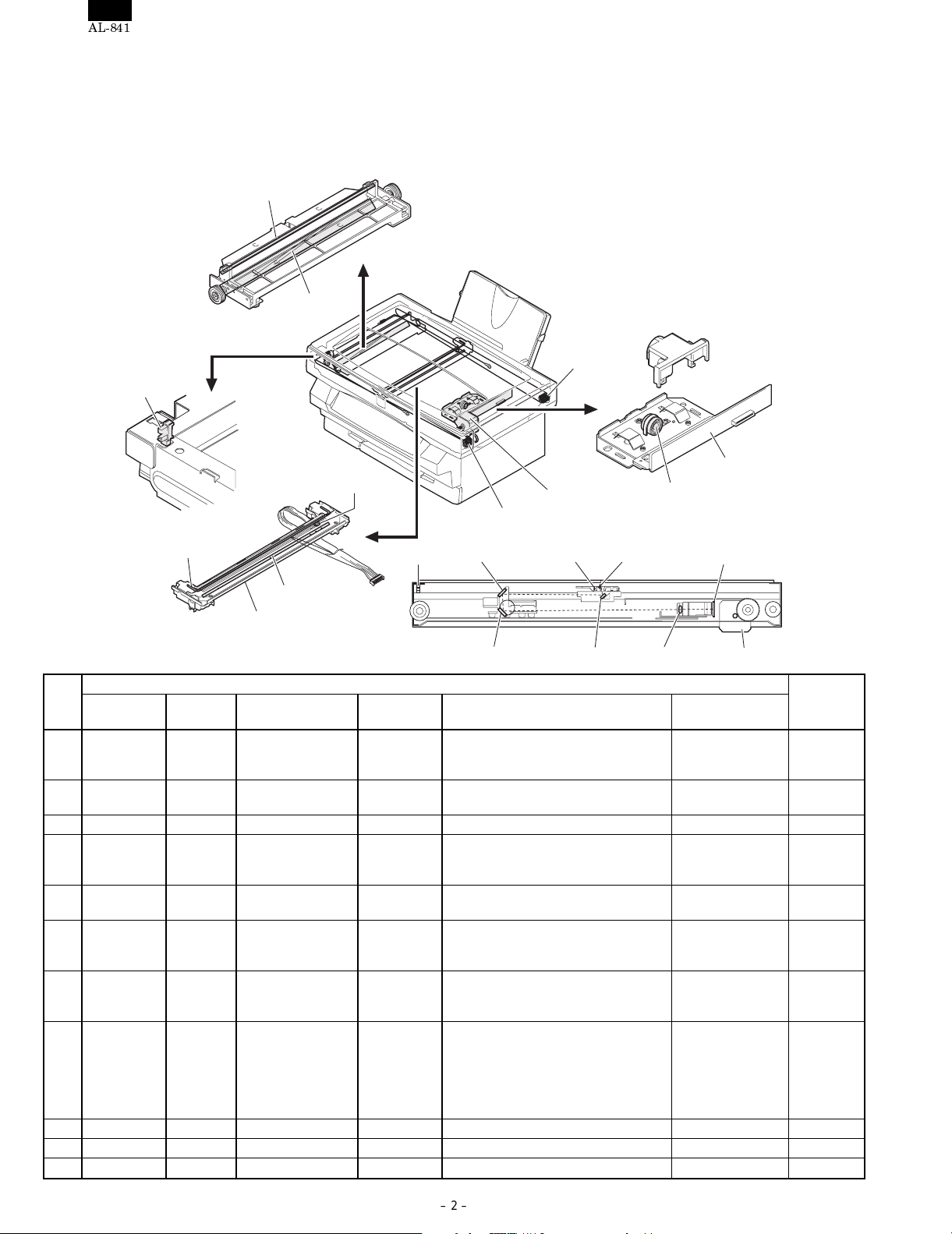

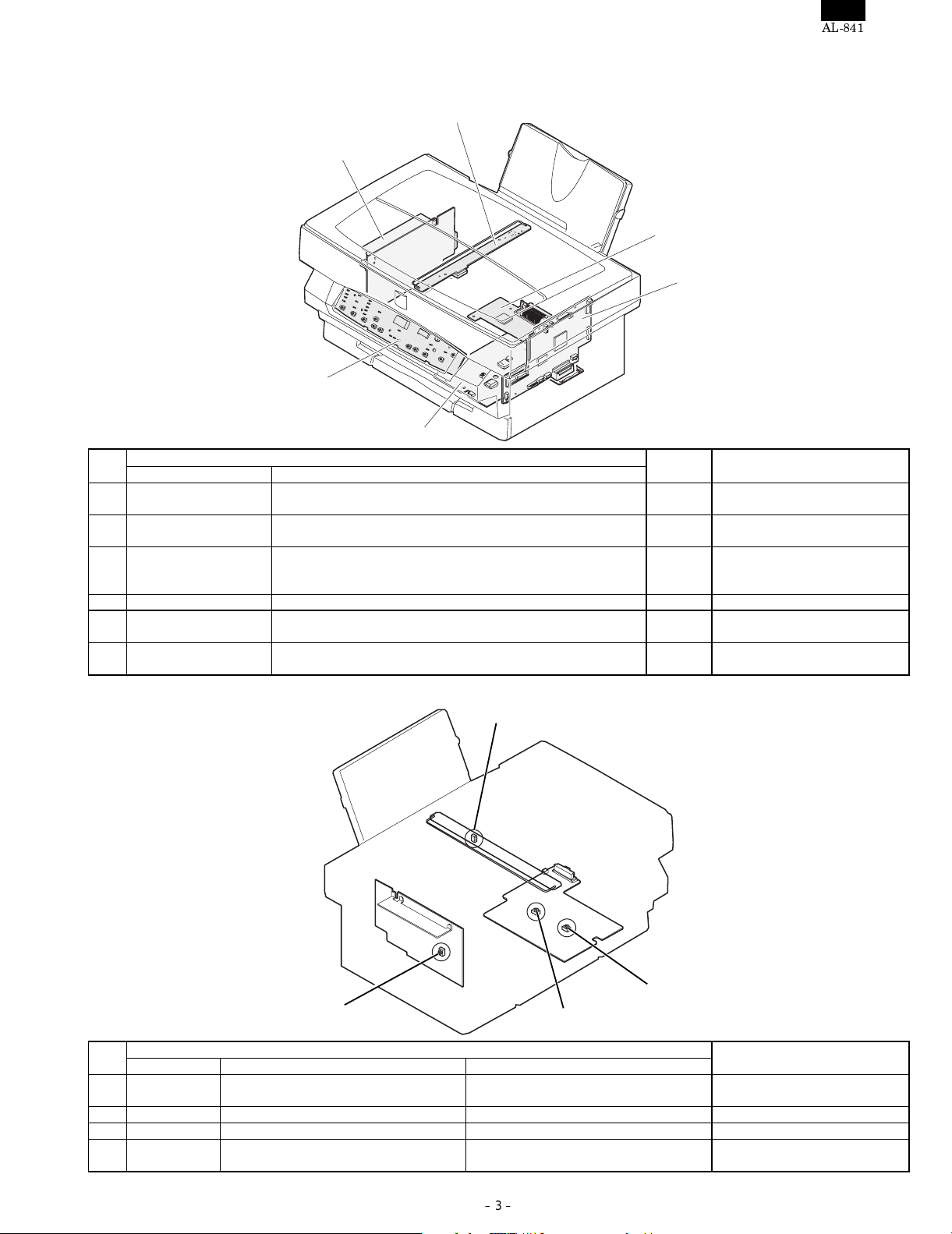

[5] EXTERNAL VIEW AND INTERNAL STRUCTURE

B. Internal parts

(1) Parts in each section

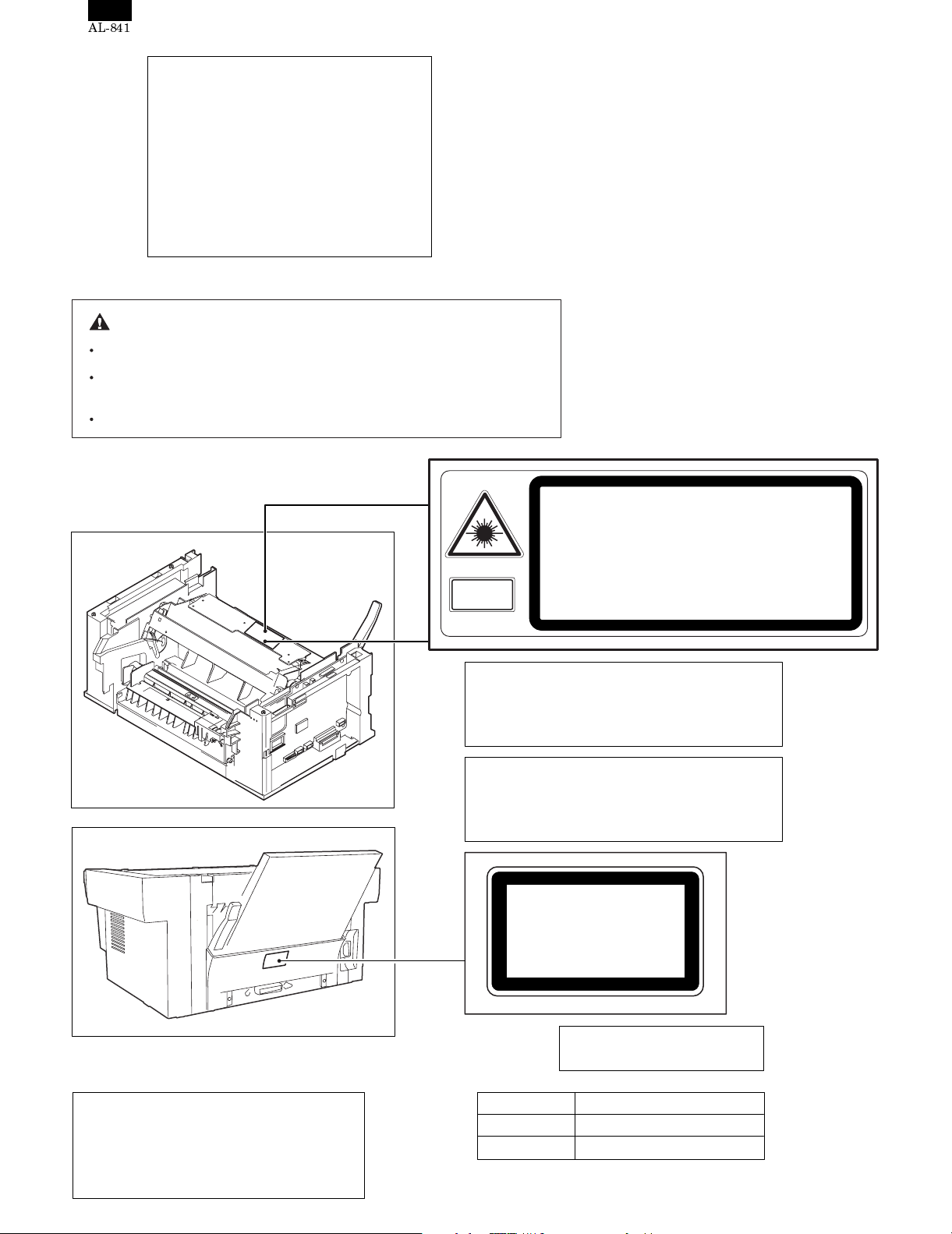

c. Optical section

<1> Scanner (reading) section

10)

11)

4) MHPS

8) SL SENSOR

2)

3)

2)

6) CCD SENSOR

5)

7)

9)

1)

4) MHPS

10) 8) SL SENSOR 7) 6) CCD SENS

11) 9) 5) 3)

Parts

No.

Code

1 Scanner lamp

Signal

name

Name Type Function/operation Active condition

Drives the scanner lamp. Maintains

control PWB

the lamp light quantity at a constant

level.

2 Scanner drive wire Transmits the scanner motor power

to the scanner unit.

3 Scanner motor Drives the scanner unit.

4 MHPS MHPS Scanner home

position sensor

Photo

transmission

sensor

Detects the scanner home position.

By this signal the image scanning

operation is controlled.

5 Lens Transfers the document image to

CCD.

6 CCD

SENSOR

CCD OUT CCD (Image)

sensor

CCD Scans the document images (photo

signals) and converts them into

electrical signals.

7 Scanner lamp Radiates light to the document to

allow the CCD to scan the document

images.

8 SL SENSOR PDA/PDK Scanner lamp light

quantity sensor

Photo diode Detects the scanner lamp light

quantity. This signal is inputted to the

scanner lamp control PWB to control

the scanner lamp drive voltage to

maintain a constant level of light

quantity.

9 No. 1 mirror Leads the document image to CCD.

10 No. 2 mirror Leads the document image to CCD.

11 No. 3 mirror Leads the document image to CCD.

OR

Note

HIGH (5V) when

the home position

is detected.

Digital signal (8Bit)

Analog signal

(0 ∼ 0.5V)

– 2 –

Page 5

AL-841

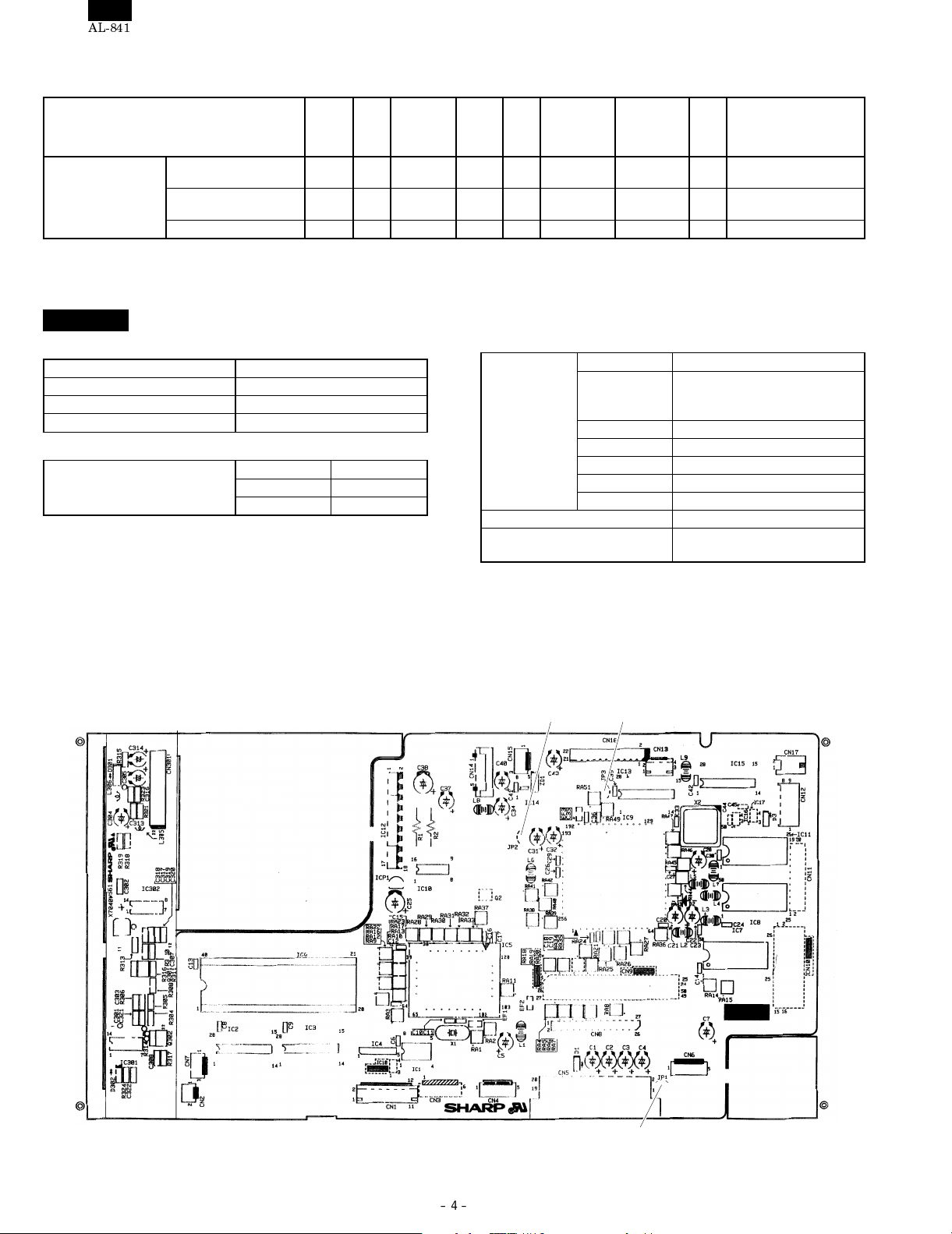

C. Functional parts

(5) PWB

2)

1)

3)

4)

6)

5)

No.

Name Function/operation

1 Power PWB Outputs DC power. Drives the heater lamp. The voltage specification differs

2 Scanner lamp drive

Controls light quantity of the scanner lamp.

PWB

3 ICU PWB Converts print data set from the host and converts it into bit

image data and send to the MCU.

4 MCU (PCU) PWB Controls the image process section and the engine sect ion.

5 High voltage power

PWB

Outputs the high voltage for the image process section.

Controls the main motor.

6 Operation control PWB Displays the value information. Outputs the key operation

signal.

(11) Adjustment volume

Parts

MODEL Note

depending on the destination.

Allows connection with one

host computers. Printer models

only

1)

VR801

VR601

No.

Code Name Function/operation

Parts

1 VR1 Scanner lamp light quantity adjustment

Adjusts the scanner lamp light quantity.

VR802

volume

2 VR601 Output voltage adjustment vol ume Adjust the DC output voltage (+24V).

VR801 Main charger voltage adjustment volume Adjusts the main charger voltage.

VR802 Developing bias voltage adjustment

Adjusts the developing bias voltage.

volume

– 3 –

Note

Page 6

AL-841

[6] MACHINE OPERATION

ON

LINE

LAMP

ON OFF — OFF OFF OFF OFF ON

ON ON — OFF OFF OFF OFF ON

Scanner operation

Machine condition

Scanning cannot be

performed. (OFFLINE)

Scanning can be

performed. (ONLINE)

During scan/preview OFF ON — OFF OFF OFF OFF ON

READY

LAMP

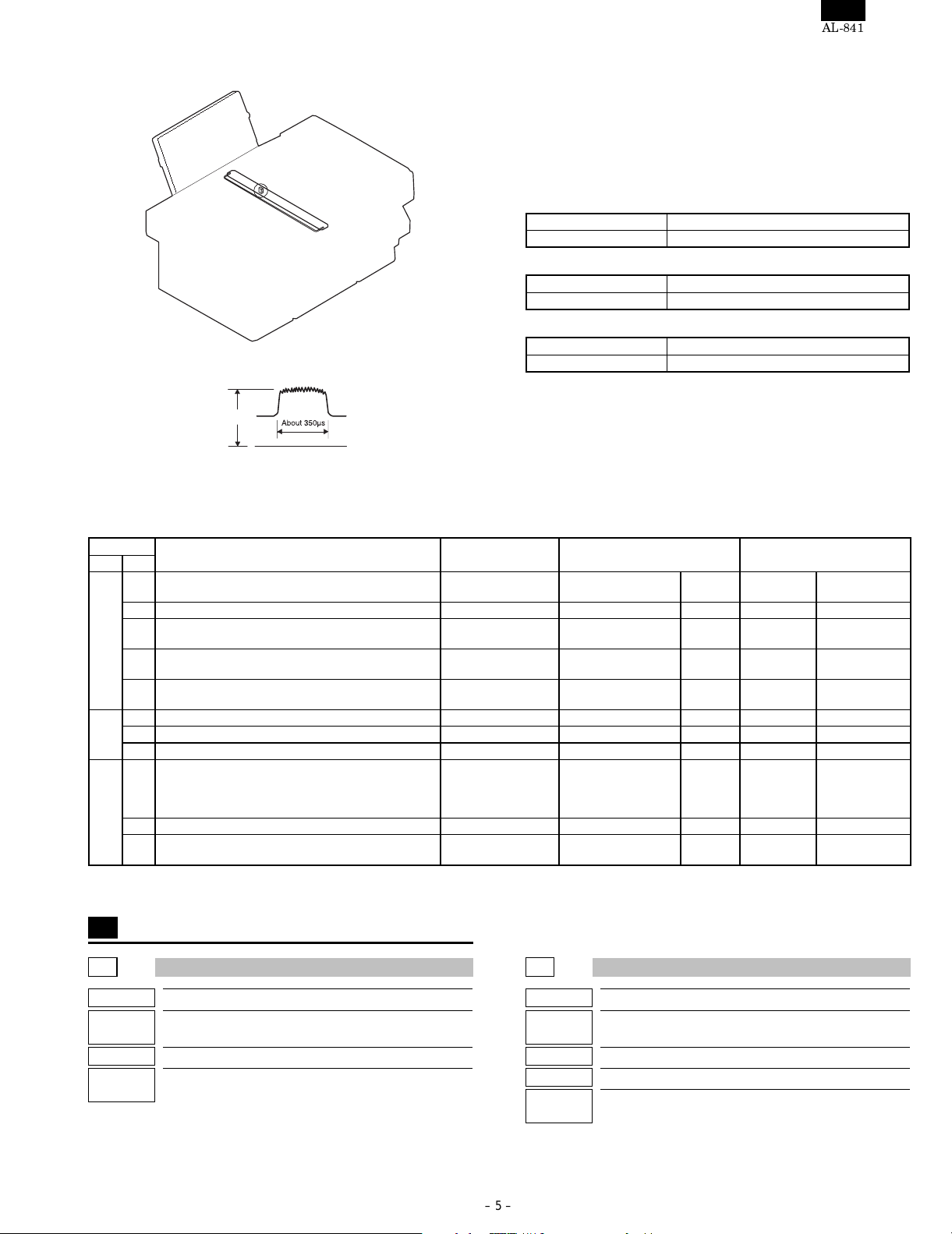

[7] ADJUSTMENTS, SETTING

ADJ M9

Location value

∗

Range (MIN) 3.9 V

Range (MAX) 4.1 V

Standard value 4.0 V

Default 4.0 V

Program used

∗

Test command (Simulation) MODE Normal

Copy lamp light quantity adjustment

MAIN CODE 63

SUB CODE 1

3 GREEN

7

SEGMENT

LED

PRE-

JAM

HEAT

LAMP

LAMP

Enforcement time

∗

Enforcement

time

Cycle —

Condition Normal copy exposure is not

Necessary condition

∗

1) The scanner section must be clean.

TONER

CERTRIDGE

REPLACE-

MENT LAMP

S 004/Ua

001/

P 002

DRUM

CERTRIDGE

REPLACE-

MENT LAMP

JOB No Content

Copy

lamp

When replacing the scanner

(copy) lamp control PWB

When replacing the copy lamp

In case of E7 (05) trouble

In case of E7 (04) trouble

In case of E7 (12) trouble

In case of E7 (15) trouble

obtained.

NOTE

Job content

∗

1) Put an oscilloscope between the check point JP2 (VIN) on the

MCU (PCU) PWB and GND.

At that time, trigger with the SH (JP3) signal to see the waveform

correctly.

JP2 (VIN) JP3 (SH)

2) Execute simulation 63-1. (The copy lamp lights up in the scanner

unit home position.)

JP1 (GND)

– 4 –

Page 7

AL-841

3) Turn and adjust the volume on the copy lamp drive PWB so that

the CCD output waveform max. value is 4.0 ± 0.1 V.

Trouble caused y improper operation

∗

1) E7 (05) trouble

2) E7 (04) trouble

3) E7 (12) trouble

4) E7 (15) trouble

5) Copy exposure cannot be adjusted.

6) Copy exposure abnormality

Preliminary work

∗

JOB No Content

S 004 Scanner (reading) section cleaning

After-work

∗

JOB No Content

ADJ M1 Copy exposure adjustm ent

Necessary tools

∗

Name Oscilloscope

Parts code/Price rank —

4.0±0.1V

[8] SIMULATION (Test Command) ⋅ USER PROGRAM

(2) Simulation list

Code

Main Sub

22 4 Used to check the number of total mis-feed (jam) in the

machine.

14 Used to check the ROM version. Others Software

17 Used to check the copy count number. Operation data output/

18 Used to check the print count number. Operation data output/

21 Used to check the frequency of use (scanning) of the

scanner (reading).

24 1 Used to clear the mis-feed (jam) counter in the machine. Data clear Counter

8 Used to clear the copy counter. Data clear Counter Copier

9 Used to clear the print counter. Data clear Counter Printer

26 2 Used to set Enable/Disable of the SPF and the FAX

functions. (When a trouble occurs in the SPF and the

FAX section, disable those functions to allow only copying

and scanning functions.

6 Used to set the specifications depending on destination. Setting Specifications Destination

7 Used to set the model (hardware) specifications. Setting PCU Specifications Operation mode

Function (Purpose) Purpose Section Item

Operation data output/

Check (Display/Print)

Check (Display/Print)

Check (Display/Print)

Operation data output/

Check (Display/Print)

Setting ADF/RADF/UDH/SPF Specifications

Optical (Image

scanning)

Trouble Misfeed

Counter Copier

Counter Printer

Counter Scanner

(3) Details of simulations

22

22-4

22-14

(Common)

Purpose Operation data output/Check (Display/Print)

Function

(Purpose)

Used to check the number of total mis-feed (jam) in

the machine.

Item Trouble Misfeed

Operation/

Procedure

The JAM counter value is displayed in 3 digits × 2

times.

Display example: 12345

012 → Blank → 345 → Blank → 012

0.7s 0.3s 0.7s 1.0s 0.7s

Purpose Others

Function

(Purpose)

Section PCU

Item Software

Operation/

Procedure

– 5 –

Used to check the ROM version.

The ROM version on the MCU PWB is displayed in 3

digits on the copy quantity display.

If any trouble occurs in the software operation, check

the version with this simulation.

Page 8

AL-841

22-17

Purpose Operation data output/Check (Display/Print)

Function

(Purpose)

Item Counter Copier

Operation/

Procedure

Used to check the copy count number.

The display format and the method are same as SIM

22-5 (Total printer counter display).

22-18

Purpose Operation data output/Check (Display/Print)

Function

(Purpose)

Item Counter Printer

Operation/

Procedure

Used to check the print count number.

The display format and the method are same as SIM

22-5 (Total printer counter display).

22-21

Purpose Operation data output/Check (Display/Print)

Function

(Purpose)

Section Optical (Image scanning)

Item Counter

Operation/

Procedure

Used to check the count of use (count of scanning)

of the scanner (reading) unit.

The display system and the method are the same as

those of SIM 22-5 (Total print counter display).

24

24-1

Purpose Data clear

Function

(Purpose)

Item Counter

24-8

Purpose Data clear

Function

(Purpose)

Item Counter Copier

24-9

Purpose Data clear

Function

(Purpose)

Item Counter Printer

Used to clear the mis-feed (jam) counter in the

machine.

Used to clear the copy counter.

Used to clear the print counter.

26

26-2

Purpose Setting

Function

(Purpose)

Section ADF/RADF/UDH/SPF

Item Specifications

Operation/

Procedure

Enter the desired code number corresponding to Enable/Disable

setup and press the Start button, and the setup will be effective.

26-6

Purpose Setting

Function

(Purpose)

Item Specifications

Operation/

Procedure

2) To change the set content, enter the code of your desired

setting and press the start button.

Destination code Detected paper size

Set

value

0

1 EX Japan

2 Japan

When the set value is changed, the paper size specification and the

fixed, enlarged, and reduced copy magnification ratios are changed.

26-7

Purpose Setting

Function

(Purpose)

Section PCU

Item Specifications Operation mode (Common)

Operation/

Procedure

Used to set Enable/Disable of the SPF and the FAX

functions. (When a trouble occurs in the SPF and the

FAX section, disable those functions to allow only

copying and scanning functions.

When this simulation is executed, the code of current

setup of ENABLE/DISABLE of SPF/FAX function is

displayed.

Set code number SPF/FAX function

0 Disable

1 Enable

Used to set the destination.

1) The currently set code of the destination is

displayed.

Destination

Used to set the model (hardware) specifications.

When this simulation is executed, the monitor lamp

corresponding to the model (hardware) is displayed.

Copy quantity display Copy speed (CPM)

66cpm

88cpm

Paper

type

Inch

series

AB

series

AB

series

Paper width

detector ON

11 5 8.5/

14 5 8.5

A4 (210 5

356 mm)

A4 (210 5

356 mm)

Paper width

detector OFF

8.5 5 5.5/

8.5 5 11

A5

B5

– 6 –

Page 9

AL-841

Page 10

S

AL-841

[9] ACTUAL WIRING CHART

Main

motor

PUS

HEATER

POWER-SW

123

AC

CN602

CN603

1 HL-L (100V) 12V 7 7 12V MMTO 7

HL-N (200V)

2

HL-L (200V)

3

4 HL-N (100V) HL 10 10 HL 12V 10

1 L-IN P-GND 14 14 P-GND PGND 14

2 L-OUT P-GND 15 15 P-GND MCON 15

3 N-IN P-GND 16 16 P-GND HLON 16

4 N-OUT 24V(DSW) 17 17 24V(DSW) TC/BIA

GND

AC

Power

supply

PWB

Developing cartridge

Developing roller

Photoconductor cartridge

Main charger roller

5V

GND

CN601

NC 1 1NC 24V(DSW) 1

D-GND 2 2 D-GND DGND 2

D-GND 3 3 D-GND DGND43

5V 4 4 5V

5V 5 5 5V MEN- 5

3.3V 6 6 3.3V MMT1 6

FW 8 8 FW PIN 8

PR 9 9 PR 3.3V 9

24VH 11 11 24VH FW 11

24VH 12 12 24VH

P-GND 13 13 P-GND PGND 13

24V(DSW)

18 18

24V(DSW)

19 19

Earth sheet

123

4

MA

MA-MBMB-

CN802 CN803

1

2

24V

PUS

CN805CN804

5V

High

voltage

24V(DSW)

24V(DSW)

FU

EARTH

DCBIASS

MC

PWB

PID sensor

24VH

PUS 18

PR 19

PWNSIN 20

12

17

Drum

Discharge brush

(Japan only)

Separation electrode

Copy roller

DRUM

EARTH

CB

TC

CN801

24VNC24VS

123

Temperature fuse

– 7 –

Page 11

D-GND

A-GND

CCDOUT

A-GND

A5V5V12V

123456789

CCD PWB

CN301

D-GNDf1D-GNDf2D-GND

SH-

D-GNDRSD-GNDSPD-GNDCPD-GNDNCD-GND

10111213141516171819202122

Laser

scanning

motor

12345

GND

PMD

24V

PMCLK

Laser

24V(DSW)

D-GND

VDATA

SAMP

SYNC-IN

1234567

CN602

LSU PWB

GND

APCSTT

PMCLK

PMD8

LSU unit

CN603

5VL 1 1 5VL

SYNC 2 2 SYNC

GND 3 3 GND

PE sensor

CN601

PEMP-IN

9

Laser beam

sensor

(Start position

detector PWB)

CN604

AL-841

OC

Open/close

SW

1

2

AN-GND

PSIZE-IN

CN17

CN5

1 24V(DSW)

2 DGND D-GND 1 1 D-GND

34DGND 5V1 2 25V1

5V

5 MEN- KIN2 4 4 KIN2

6 MMT1 KIN1 5 5 KIN1

7 MMTO OP-CLK 6 6 OP-CLK

8 PIN OP-LATCH 7 7

9 3.3V

10 12V STR1 9 9 STR1

11 FW STR2 10 10 STR2

24VH

12

13 PGND STR4 12 12 STR4

14 PGND

15 MCON

16 HLON

17 TC/BIAS

18 PUS

19 PR VFMOUT 1 1 VFMOUT

20 PWNSIN NC 2 2 NC

123456789

GND

A-GND

CCDOUT

A-GND

A5V5V12V

CN16

10111213141516171819202122

GNDf1GNDf2GND

SH-

GNDRSGNDSPGNDCPGNDNCGND

123456789

24V(DSW)

D-GND

VDATA

SAMP

SYNC-IN

APCSTT

PMCLK

CN12 CN14

PMD-

PEMP-IN

Scanner

motor

12345

OUT A

OUT B

OUT/A

OUT/B

24V-mir

CN1

KIN3 3 3 KIN3

OP-DATA OP-DATA

88

STR3 11 11 STR3

CN901

OP-LATCH

CN4

NC 3 3 NC

P-GND 4 4P-GND

NC 5 5 NC

MCU PWB

Operation panel

PWB

Fan motor

CN2

AN-GND

RTHIN5VTS IN

1

2

Thermistor

CN6

12345

12345

5V

TS IN

CN15

D-GND

P-GND

P-GND

GND

123

123

D-GNDNCP-GND5VMHPS IN

Toner detector sensor

CN7

MHPS IN5V5V

POUT IN

GD

123

GND

POD sensor

Scanner H.P sensor

5V5VPARAAD0

PARAAD1

PARAAD2

PARAAD3

PARAAD4

123456789

123456789

5V5VPARAAD0

PARAAD1

PARAAD2

PARAAD3

PARAAD4

CN8

PARAAD5

PARAAD6

PARAAD7

/REV

/INIT

/SLCTIN

/AUTOFD

/STB

/ACK

BUSYPE/FAULT

SLCT

/STB

/ACK

BUSYPE/FAULT

SLCT

GND

GND

1011121314151617181920212223242526

1011121314151617181920212223242526

PARAAD5

PARAAD6

PARAAD7

/REV

/INIT

/SLCTIN

/AUTOFD

CN203

GDI/USB PWB

– 8 –

Lamp

CN13

24V 1 1 24V

P-GND 2 2P-GND

ON/OFF 3 3 ON/OFF

NC 4 4 NC

GND

GND

/USB-EN

USB-ON

/1284-EN

3.3V

27

27

GND

GND

/USB-EN

USB-ON

/1284-EN

3.3V

CN1

Inverter PWB

Page 12

AL-841

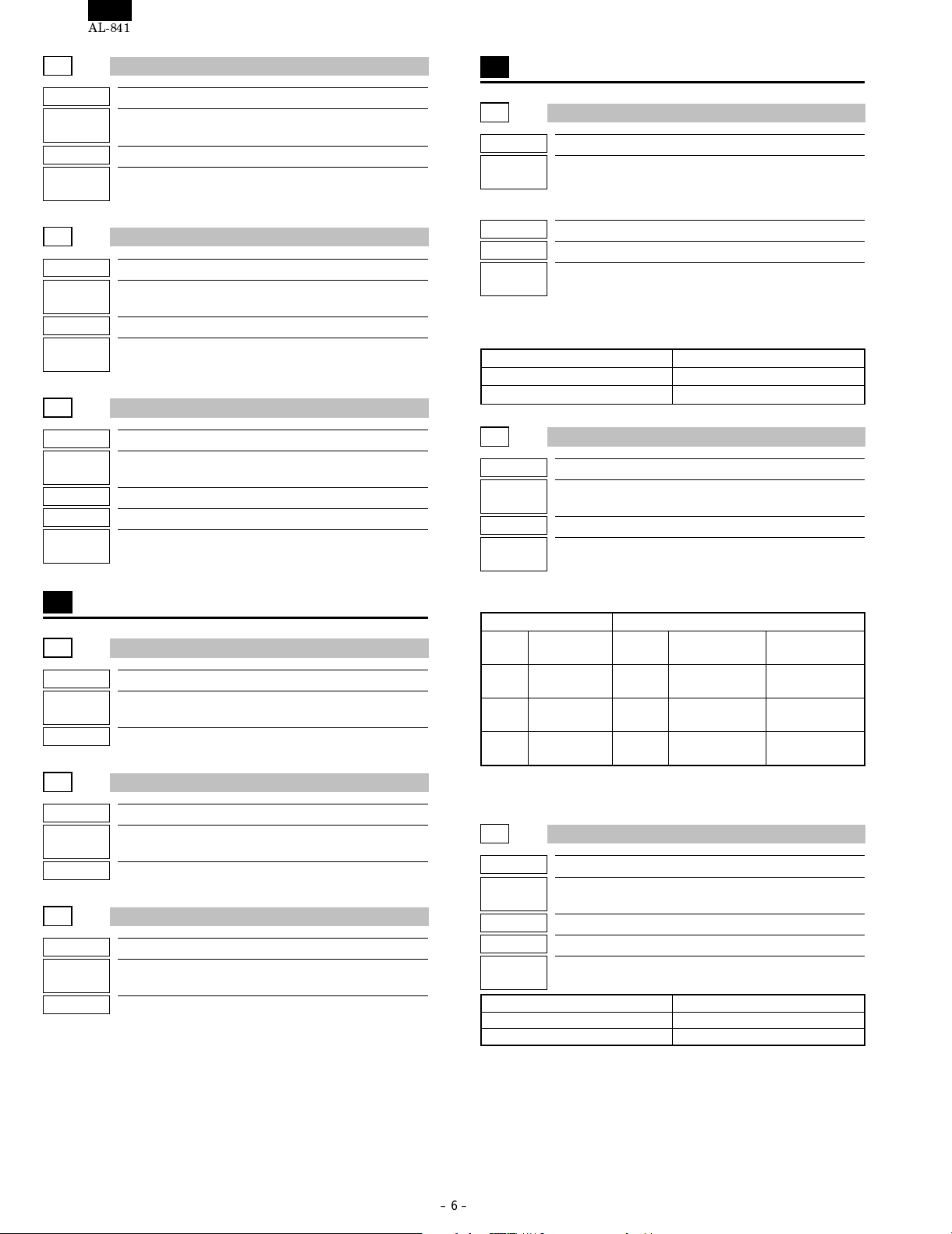

[10] CIRCUIT DIAGRAM AND PARTS LOCATION CHART

4

3

2

1

21

20

23

GND19GND

/DSTB

1

24

GND

GND22GND

GND

DATA 5

DATA 4

DATA 3

DATA 2

DATA 1

4

2

5

3

6

22J

22J

R214

R217

R216

1/1

E

D

5V1

C

IEEE1284 CON

CN202

R229

1.2kJ

R226

1.2kJ

R224

1.2kJ

R222

1.2kJ

R220

1.2kJ

R218

1.2kJ

R215

1.2kJ

R213

1.2kJ

D201

RB501-V40

B

(2-A3)

5V1

5V1

C242

0.1u

5V1

3A34A45A56A67A78A89

2

A1

A2

IC205

B5

B4

B3

B2

B1

C203

47u 10V

L203

SBO-02SAN

(2-A3)

3.3V

14

15

16

17

18

A

31

29

25

GND

DATA 6

7

22J

R219

B6

13

32

28

26

27

GND

GND

GND

GND

/ACK

DATA 8

DATA 7

8

9

10

2

1

2

1

2

1

2

1

22J

22J

R221

R223

C230

C229

C228

C227

C226

C225

C224

C222

C223

19

G

B8

B7

11

12

35

22J

R225

/INPRIM

SLCT

13

100p

100p

100p

100p

100p

100p

100p

100p

0.1u

/FAULT

/AUTOLF

14

D204

D203

D202

D201

22J

R228

74LS245

33

S GND

34

(NC)

(NC)

15

DAP202K

DAP202K

DAP202K

DAP202K

22J

16

3

3

3

3

S GND

17

VCC

F GND

36

/SLCTIN

VCC

18

R238

1.2kJ

R235

1.2kJ

R234

1.2kJ

R231

1.2kJ

R232

5V1

4

2

1A1

1A2

IC206

1Y2

1Y1

18

16

3.3kJ

R239

5V1

SHIELD

5V1

F.G

100J 1/2W

R201

2

3

1

D209

DAP202K

D206

DAP202K

2

3

1

D205

DAP202K

2

3

1

22J

22J

22J

22J

R236

R233

R237

560p

C235

C234

33p

C233

33p

C232

1000p

(2-A2)

(2-A2)

(2-A2)

(2-A2)

/SLCTIN

/STB

/AUTOFD

/INIT

C231

0.1u

19

8

6

13

15

17

11

1G12G

2A1

2A2

2A3

1A3

2A4

1A4

2Y4

2Y272Y3

2Y1

1Y4

1Y3

9

12

14

74LS244

5

3

22J

R240

R241

16

14

18

1Y1

1Y2

1Y3

IC207

1A3

1A2

1A1

4

2

6

5V1

5V1

2

3

1

D208

DAP202K

2

3

1

D207

DAP202K

22J

22J

22J

22J

R243

R242

R244

100p

C241

100p

C240

100p

C239

100p

C238

100p

C237

(2-A4)

(2-A2)

(2-A2)

(2-A3)

(2-A3)

(2-A1)

(2-A1)

(2-A1)

(2-A1)

5

3

7

9

12

2Y1

2Y2

2Y3

2Y4

1Y4

2A4

2A3

2A2

2A1

2G

1A4

8

13

11

74LS244

1G

17

15

19

1

0.1u

C236

(2-A1)

/FAULT

/ACK

BUSY

PE

SLCT

(2-A3)

PARAAD7

(2-A3)

PARAAD6

PARAAD5

PARAAD4

(2-A2)

PARAAD3

(2-A2)

PARAAD2

PARAAD1

PARAAD0

USB-ON

/USB-EN

E

D

C

(2-A4)

B

30

GND

BUSY

11PE12

1

DIR

A

GDI PWB

PARAAD0

PARAAD1

PARAAD2

PARAAD3

PARAAD4

PARAAD6

PARAAD7

/REV

/INIT

/SLCTIN

/AUTOFD

/STB

/ACK

PARAAD5

123456789

CN203

4

BUSYPE/FAULT

1011121314151617181920212223242526

3

SLCT

/1284-EN

/USB-EN

USB-ON

27

27FMN-STK

2

1

– 9 –

Page 13

GDI PWB (PARTS LAYOUT)

[PARTS SURFACE]

AL-841

[SOLDER SURFACE]

123456789

5V5VPARAAD0

PARAAD1

PARAAD2

CN203

PARAAD3

1011121314151617181920212223242526

PARAAD4

PARAAD5

PARAAD6

PARAAD7

/REV

/INIT

/SLCTIN

/AUTOFD

/STB

/ACK

BUSYPE/FAULT

SLCT

GND

GND

GND

/USB-EN

USB-ON

/1284-EN

27

3.3V

– 10 –

Page 14

AL-841

Page 15

PARTS GUIDE

DIGITAL COPI ER

MODEL AL-841

CONTENTS

(Exteriors)

(Operation Panel)

(Packing Material & Accessories)

(Frame Section)

MCU (MCU PWB Unit)

(Upper Frame Section)

1

(Lower Frame Section-1)

2(Lower Frame-2)

(Fusing Unit)

(Scanner Unit)

AL-841 AL-800/840 AL-800/840

(Operation Panel PWB Unit)

GDI (GDI PWB Unit)

1 (Carriage 1 Unit)

&

(Power Supply PWB Unit)

(High Voltage PWB Unit)

(Index)

The AL-841 Parts Guide describes only the different parts from the AL-800/840. Please use this Parts

Guide together that of the AL-800/840.

Page 16

DEFINITION

The definition of each Rank is as follows and also noted in the list

A :Parts necessary to be stocked as High usage parts.

B :Parts necessary to be stocked as Standard usage parts.

C :Low usage parts.

D : Parts necessary for refurbish.

E :Unit parts recommended to be stocked for efficient after sales service.

Please note that the lead time for the said parts may be longer than normal parts.

S : Consumable parts.

Please note that the following parts used in Copier under the same description are classified into A or B Rank depending

upon the place used.

Example: Gear made of Metal, Sprocket, Bearing, Belt made of Rubber, Spring clutch mechanism.

A Rank : The parts which may be with the revolution or loading.

B Rank : Parts similar to A Rank parts, but are not included in Rank A.

Because parts marked with “ ” is indispensable for the machine safety maintenance and operation, it must be replaced with

the parts specific to the product specification.

Other than this Parts Guide, please refer to documents Service Manual (including Circuit Diagram) of this model.

Please use the 13 digit code described in the right hand corner of front cover of the document, when you place an order.

For U.S. only-Use order codes provided in advertising literature. Do not order from parts department.

1 (Exteriors)

NO. PARTS CODE

1

2 AN EQ N C

3 AF DS N C

4 AQ EQ N C

6 AU EZ N C

8 AG DX N C

9 AH DX N C

10 AH DX N C

11

12 AS EQ N C

14 AT EZ N C

15 AG DX N C

16

22 AE DJ N C

23 AU FG N C

24

26

27

29 AC DJ N C

501

502 AU EZ N E

PRICE RANK

Ex. Ja.

AK DX N C

BG GT N E

BG GT N E

AH DX N C

AS EZ C

AG DX N C

AG DX N C

AG DX N C

AG DS N C

AU EZ N E

AT EZ N E

NEW

MARK

PART

RANK

PU EX tray PU

PU tray PU

Paper guide

Rear cabinet

Right cabinet

Delivery tray

Delivery extension lower

Left cabinet lower

Operation panel unit (Japan)

Operation panel unit (USA)

Front cabinet

Left cabinet

OC switch acutuator OCRight cabinet lower

OC hinge OC

OC cover OC

OC mat OC

Operation label (Japan)

Operation label (USA)

Platen label (Japan)

Platen label (USA)

Tray label (Japan Only)

Paper feed unit (Japan)

Paper feed unit (USA)

Oc cover unit OC

DESCRIPTION

-

-

-

– 1 –

Page 17

2 (Operation Panel)

NO. PARTS CODE

1

2 AR EQ C

5

8

9 AK EB N C

10

11

(Unit)

901

PRICE RANK

Ex. Ja.

BV RB N E

AT EZ N C

AV FG C

AV FG N C

AV FG N C

AL EB N C

AF DS C

BG GT N E

BG GT N E

NEW

MARK

PART

RANK

Operation PWB unit

Operation FFC

Operation panel cabinet (Japan)

Operation panel cabinet (USA)

Operation panel (Japan)

Operation panel (USA)

Operation key R

Operation key L

Cable cover sheet

Operation panel unit (Japan)

Operation panel unit (USA)

3 (Frame Section)

NO. PARTS CODE

4

PRICE RANK

Ex. Ja.

AG DS C

NEW

MARK

PART

RANK

Release lever

4 (Upper Frame Section)

NO. PARTS CODE

14

30 BQ LP N E

PRICE RANK

Ex. Ja.

AB DJ C

NEW

MARK

PART

RANK

DV press spring DV

Toner sensor PWB unit

5 1(Lower Frame Section-1)

NO. PARTS CODE

15

39 BB FX C

47 AB DJ C

52

PRICE RANK

Ex. Ja.

AG DX N C

AD DJ C

NEW

MARK

PART

RANK

Tray lock lever

Lower frame

Release lever spring

Electricity plate (Japan Only)

DESCRIPTION

FFC

- R

- L

- -

DESCRIPTION

- -

DESCRIPTION

- -

DESCRIPTION

R

6 2(Lower Frame-2)

NO. PARTS CODE

1

7

9 AP EQ C

13 AG DX N C

14

15

PRICE RANK

Ex. Ja.

CA TV N E

CA TV N E

BK HG E

BL HL N E

BL HL N E

BN HZ E

BP LP N E

NEW

MARK

7 (Fusing Unit)

NO. PARTS CODE

17

26 AV FG C

PRICE RANK

Ex. Ja.

BG GT N E

NEW

MARK

8 (Scanner Unit)

NO. PARTS CODE

1

5 BE GN N E

8 AA DJ C

13 AN EG N B

26 AH DX C

27

28 BB FX B

29

33 AC DJ C

42 BT MW N E

51 AF DS N C

54

PRICE RANK

Ex. Ja.

AK DX C

AX FG C

AK DX C

AX FG B

NEW

MARK

PART

RANK

MCU PWB unit (Japan) MCU

MCU PWB unit (USA) MCU

High voltage PWB unit (Japan)

High voltage PWB unit (USA)

Bottom plate

ICU FFC ICU-FFC

GDI PWB unit GDI

Power supply PWB unit (100V Japan)

Power supply PWB unit (120V USA)

PART

RANK

POD PWB unit P-OUT

FU roller FU

PART

RANK

Dark box

Carriage 1 unit

Table glass rubber

Micro switch unit

Frame R

Mein frame

Mirror motor

Motor fixing plate

Belt tension spring

Lens base unit

Myler CCD

Table glass

DESCRIPTION

DESCRIPTION

DESCRIPTION

1

- R

-

- - -

- -

-

-

– 2 –

Page 18

9 1 (Carriage 1 Unit)

NO. PARTS CODE

1

4

6 AH DX N C

8 AF DS C

11

14

15

16

17 AD DJ N C

18 AA DD C

19 AA DD C

20 AA DD C

(Unit)

901

PRICE RANK

Ex. Ja.

AC DJ N C

AG DX N C

AD DJ N C

AD DJ N C

AC DJ N C

BA FX N E

BE GN N E

NEW

MARK

PART

RANK

Lamp cover L

Inverter harness

Lamp base

Carriage 1

Carriage 1 base F

Carriage 1 base R

Lamp cover R

Lamp PWB unit

Sub reflector

Screw (2×8)

Screw (3×6)

Screw (3×6)

Carriage 1 unit

11 & (Packing Material & Accessories)

NO. PARTS CODE

4

5 AE DJ N D

6 AM EG N D

7

12

104

110 AG DX D

111 AC DJ D

113 AB DJ D

PRICE RANK

Ex. Ja.

AM EG N D

AS EZ N D

AS EZ N D

AM EG N C

AM EG N C

AW FG N D

AW ZZ N D

AE DJ N D

AE DJ N D

AC DJ N D

AF DS N D

NEW

MARK

PART

RANK

Packing add upper

Body vinyl

Packing add lower

Packing case (Japan)

Packing case (USA)

CDROM (Japan) CDROM

CDROM (USA) CDROM

Operation manual (USA)

Operation manual (Japan)

eTypist Operation manual (Japan) eTypist

Up grade guidance (Japan)

Sample card (Japan)

Postcard (Japan)

Drum sheet

Slip sheet (USA)

Label (USA)

DESCRIPTION

- L

- -

1

1 F

1 R

- R

1

DESCRIPTION

-

-

1 (Exteriors)

14

26

11

10

27

4

29

3

15

23

22

22

2

1

501

502

24

12

8

16

9

6

PRPN0030

– 3 –

Page 19

2 (Operation Panel) 3 (Frame Section)

10

2

1

9

8

11

5

4 (Upper Frame Section) 5 1(Lower Frame Section-1)

39

15

30

14

47

47

52

4

6 2(Lower Freme-2) 7 (Fusing Unit)

14

C

1

B

13

A

9

7

B

A

17

15

C

26

PRPN0031

– 4 –

Page 20

8 (Scanner Unit) 9 1 (Carriage 1 Unit)

18

54

9

2

9

18

1

1

6

17

16

15

20

4

5

51

13

8

26

33

29

8

8

8

27

28

42

8

8

11 & (Packing Material & Accessories)

11

19

14

8

12

5

4

6

7

PRPN0032

– 5 –

Page 21

12 MCU (MCU PWB Unit)

NO. PARTS CODE

1

2 AA DD C

3 AB DJ C

4 AB DD C

5 AE DJ C

6 AD DJ C

7 AB DJ C

8 AC DJ C

9 AE DS C

10 AF DS C

11 AG DS C

12 AD DJ C

13 AE DJ C

14 AD DJ C

15 AP EQ B

16 AG DS B

17 AC DJ C

18 AA DD B

19

20 AB DD B

21

22 AA DD C

23 AA DD C

24 AA DD C

25 AA DD C

26 AA DD C

27 AB DD C

28 AB DD C

29 AA DD C

30 AC DD C

31

32

33 AA DD C

34 AB DD C

35 AA DD C

36 AA DD C

37 AA DD C

38 AB DD B

39 AC DD B

40 AC DD B

41 AB DJ B

42 AB DJ B

43 AB DJ B

44 BE GN B

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

PRICE RANK

Ex. Ja.

AD DJ C

AB DD B

AB DD B

AB DD B

AB DD B

AA DD C

AA DD C

AA DD C

AA DD C

AA DD C

AA DD C

AA DD C

AA DD C

AY FQ B

AU EZ B

AC DJ B

AQ EQ B

AY FQ B

AG DS B

AF DS B

AT EZ B

AD DJ B

AF DX B

AQ EQ B

AF DS B

AF DJ B

AH DX B

AE DS B

AN EG B

BA FX B

AF DS B

NEW

MARK

PART

RANK

Connector (2pin) [CN2]

Connector (3pin) [CN15,17]

Connector (5pin) [CN4,6]

Connector (2pin) [CN17]

Connector (5pin) [CN14]

Connector (9pin) [CN12]

Connector (4pin) [CN13]

Connector (12pin) [CN1]

Connector (22pin) [CN16]

Connector (27pin) [CN18]

Connector (20pin) [CN5]

IC socket (40pin) [IC6] IC

Coil (NFM839R02C470R101) [EF1∼EF3]

Coil (SBO-02SAN) [L1∼9]

Crystal (11.85737433MHz) [X2]

Crystal (19.99370079MHz) [X1]

Bead filter (ZE221) [L101]

Block resistor (10Ω×4) [RA5∼8,21,24,45,46]

Block resistor (10KΩ×4 1/32W ±5%)

Block resistor (10KΩ×4 1/32W ±5%)

Block resistor (22Ω×4) [RA49,51]

Block resistor (47Ω×4 1/32W ±5%) [RA10,13,17,23,25∼27]

Block resistor (47Ω×4 1/32W ±5%) [RA30∼36,40∼42]

Capacitor (50WV 10pF) [C137,138]

Capacitor (50WV 100pF)

[C139∼141,146,148,160,161,194∼199,201,211,213,214,239]

Capacitor (50WV 12pF) [C228]

Capacitor (50WV 33pF) [C229]

Capacitor (16WV 22µF) [C3∼5]

Capacitor (25WV 47µF) [C38]

Capacitor (50WV 47µF) [C25]

Capacitor (35WV 10µF) [C21,22,28,31,32,34,37,40,43]

Capacitor (35WV 22µF) [C1,2,7]

Capacitor (25WV 0.10µF)

Capacitor (25WV 0.10µF)

Capacitor (25WV 0.10µF)

Capacitor (25WV 0.10µF)

Capacitor (50WV 1000pF)

Capacitor (50WV 1000pF)

[C113∼115,117∼119,124∼130,133,144,152,154,158,159,162]

Capacitor (50WV 1000pF)

Capacitor (50WV 1000pF)

Capacitor (50WV 2200pF) [C225,240,241,255]

Capacitor (50WV 470pF) [C220,250,276∼280]

Capacitor (50WV 4700pF) [C149]

Capacitor (25WV 0.10µF) [C120,121,134,221,244,247,265,273]

Capacitor (50WV 0.022µF) [C131,132,136,231,232,245]

Diode (DAN202K) [D123]

Diode (DAN217) [D113,114]

Diode (DA204K)

Diode (IN4005E) [D2]

Diode (1SS355) [D1,3]

Zener diode (RLZ2.0A) [ZD1]

IC (HG73C025FD) [IC9] IC

CPU (H8S/2350FP) [IC5] CPU

IC (LH50506N) [IC109] IC

IC (LM358PS) [IC104] IC

IC (LM7121) [IC107] IC

IC (MX27C2048D) [IC6] IC

IC (M24C02WBN6) [IC1] IC

IC (M51953BL) [IC 4]IC

IC (M66236FP) [IC101]IC

IC (NJM2903M) [IC102] IC

IC (NJM3414M) [IC106] IC

IC (SLA7027MU) [IC12] IC

IC (TC7W66FU) [IC14] IC

IC (TC74HC08F1) [IC108] IC

IC (TC74HC14FN) [IC103] IC

IC (TD62003AF) [IC10] IC

IC (W24257A12J) [IC2,3,13,15] IC

64MDRAM (16163CLT-6) [IC7,8,11] 64MDRAM

IC protector (ICPN38) [ICP1] IC

[C30,33,36,39,41,42,104,109,122,123,135,142]

[C151,153,204,209,210,212,215,216,222,224,226]

[C227,230,233∼235,238,242,246,254,262,263,271,272]

[C11,12,16,18,26,35,103,105∼108,110,111]

[C165∼168,180,182,202,206,208,217,218,223,243,249]

[C251,252,256,258∼261,264,266∼270,274,275]

DESCRIPTION

[RA1∼4,9,11,12,14∼16]

[RA18,19,22,28,29,37,39,43,44,47]

[C6,8∼10,13∼15,17,19,20,23,24,27,29]

[D101∼103,111,112,115∼122,124∼127]

– 6 –

Page 22

12 MCU (MCU PWB Unit)

NO. PARTS CODE

63

64 AA DD C

65 AA DD C

66

67

68 AA DD C

69 AA DD C

70 AA DD C

71 AA DD C

72 AA DD C

73 AA DD C

74 AA DD C

75 AA DD C

76 AA DD C

77 AA DD C

78 AA DD C

79 AA DD C

80 AA DD C

81 AA DD C

82 AA DD C

83 AA DD C

84 AA DD C

85 AA DD C

86 AB DD C

87 AA DD C

88 AA DD C

89 AA DD C

90 AA DD C

91 AA DD C

92 AB DD B

(Unit)

901

PRICE RANK

Ex. Ja.

AA DD C

AA DD C

AA DD C

AA DD C

AA DD C

CA TV N E

CA TV N E

NEW

MARK

PART

RANK

Resistor (1/16W 0Ω±5%) [R123,129,141,175,209,250]

Resistor (1/16W 10Ω±5%)

[R103∼105,143,147,154,159,160,163,189,191,207,218,229]

Resistor (1/16W 100Ω±5%) [R134,196,230]

Resistor (1/16W 1.0KΩ±5%)

Resistor (1/16W 1.0KΩ±5%) [R203,231,237∼239,242]

Resistor (1/16W 10KΩ±5%)

Resistor (1/16W 10KΩ±5%) [R225,243,251∼258]

Resistor (1/16W 1.2KΩ±5%) [R200]

Resistor (1/16W 1.6KΩ±5%) [R111,112,119,201]

Resistor (1/16W 20KΩ±5%)

Resistor (1/16W 2.0MΩ±5%) [R195,221]

Resistor (1/16W 22Ω±5%) [R199]

Resistor (1/16W 2.4KΩ±5%) [R219,220]

Resistor (1/16W 270Ω±5%) [R234]

Resistor (1/16W 330Ω±5%) [R139]

Resistor (1/16W 33KΩ±5%) [R115]

Resistor (1/16W 390Ω±5%) [R226]

Resistor (1/16W 47Ω±5%) [R174]

Resistor (1/16W 47KΩ±5%) [R188,205,227]

Resistor (1/16W 680Ω±5%) [R232]

Resistor (1/16W 75Ω±5%) [R213]

Resistor (1/16W 750Ω±5%) [R212]

Resistor (1/16W 7.5KΩ±5%) [R202]

Resistor (1/16W 910Ω±5%) [R133]

Resistor (1/16W 9.1KΩ±5%) [R114]

Resistor (2W 1.0Ω±5%) [R1,2]

Resistor (1/8W 180Ω±5%) [R126]

Resistor (1/8W 4.3KΩ±5%) [R125]

Resistor (1/8W 4.7KΩ±5%) [R192]

Resistor (1/16W 10KΩ±1%) [R208,216]

Resistor (1/16W 16.5KΩ±1%) [R206]

Transistor (2SA1036KQRC) [Q101]

MCU PWB unit (Japan) MCU

MCU PWB unit (USA) MCU

[R109,113,117,118,120,124,131,142,148,151,157,161]

[R106,107,127,128,149,152,158,162,193,204,222,224]

DESCRIPTION

[R108,132,140,144∼146,211,240,241]

13 (Operation Panel PWB Unit)

NO. PARTS CODE

1

2 AC DJ N B

3 AA DD C

4 AB DD C

5 AA DD C

6 AA DD B

7 AN EQ B

8

9

10

11

12 AA DD C

13 AA DD C

14 AA DD C

15 AA DD C

16 AA DD C

17 AD DJ B

(Unit)

901

PRICE RANK

Ex. Ja.

AC DJ C

AP EQ B

AC DJ B

AC DJ B

AC DJ B

AA DD C

BV RB N E

NEW

MARK

PART

RANK

Connector (12pin) [CN901]

Tact swtch (SKQNAB010)

Capacitor (50WV 200PF) [C904∼906]

Capacitor (16WV 47µF) [C902]

Capacitor (50WV 0.022µF) [C901,903]

Diode (DSS133) [D901∼904]

IC (LC7935) [IC901] IC

LED (CST338G-25) [LEDM] LED

LED (MPG3864K)

LED (MPG3864K) [3RE,EXD,EXN,EXL,AE,ME,PE] LED

LED (MVR3864K) [JPL,DPL,TPL] LED

Resistor (1/8W 0Ω±5%) [J900,901]

Resistor (1/10W 1.0KΩ±5%) [R935]

Resistor (1/10W 10KΩ±5%) [R938,962]

Resistor (1/10W 120Ω±5%) [R902∼918]

Resistor (1/10W 150Ω±5%) [R939∼941]

Resistor (1/10W 1.5KΩ±5%) [R936,937]

Digital transistor (DTB113ZK) [Q901∼903]

Operation PWB unit

DESCRIPTION

[OLK,PSW,CLK,1UPK,10UPK,MAGK,ZUPK,

[PML,ONLL,RPL,ZPL,2ENR,1ENR,NOR,1RE,

ZDWK,CRSK,EXUDK,EXMODK]

2RE,3RE,EXD,EXN,EXL,AE,ME,PE] LED

– 7 –

Page 23

14 GDI (GDI PWB Unit)

NO. PARTS CODE

1

2 AF DS C

3 AD DJ C

4 AA DD C

5 AA DD C

6 AA DD C

7 AB DD C

8 AA DD C

9 AA DD C

10 AA DD C

11 AB DD B

12 AH DX B

13

14

15 AA DD C

16 AA DD C

17 AA DD C

18 AA DD C

19 AA DD C

(Unit)

901

PRICE RANK

Ex. Ja.

AH DX C

AF EB B

AA DD C

BL HL N E

NEW

MARK

PART

RANK

Connector (36pin) [CN202]

Connector (27pin) [CN203]

Coil (SBO-02SAN) [L201,203]

Capacitor (50WV 100PF)

Capacitor (50WV 33pF) [C233,234]

Capacitor (50WV 560PF) [C235]

Capacitor (10WV 47µF) [C203]

Capacitor (25WV 4.7uF) [C201]

Capacitor (25WV 0.10µF) [C206,223,231,236,242]

Capacitor (50WV 1000PF) [C232]

Diode (DAP202K) [D201∼209]

IC (74LS244NS1) [IC206,207] IC

IC (74LS245NS1) [IC205] IC

Resistor (1/2W 100Ω±5%) [R201]

Resistor (1/10W 1.0KΩ±5%) [R227,230]

Resistor (1/10W 10KΩ±5%) [R247∼250]

Resistor (1/10W 1.2KΩ±5%)

Resistor (1/10W 22Ω±5%)

Resistor (1/10W 3.3KΩ±5%) [R239]

GDI PWB unit GDI

15 (Power Supply PWB Unit)

NO. PARTS CODE

(Unit)

901

PRICE RANK

Ex. Ja.

BN HZ E

BP LP N E

NEW

MARK

PART

RANK

Power supply PWB unit (100V Japan)

Power supply PWB unit (120V USA)

DESCRIPTION

[C222,224∼230,237∼241]

[R213,215,218,220,222,224,226,229,231,234,235,238]

[R214,216,217,219,221,223,225,228,232,236,237,240∼244]

DESCRIPTION

16 (High Voltage PWB Unit)

NO. PARTS CODE

1

(Unit)

901

PRICE RANK

Ex. Ja.

AR EQ B

BK HG E

BL HL N E

NEW

MARK

PART

RANK

IC (A2918SWH) IC

High voltage PWB unit (Japan)

High voltage PWB unit (USA)

DESCRIPTION

– 8 –

Page 24

■ (Index)

PARTS CODE

JAPAN ONLY

ORDER CODE

PRICE R.

NO.

Ex.

1- 12 AS EQ N C

1-502 AU EZ N E

8- 42 BT MW N E

11- 12 AM EG N C

11- 12 AM EG N C

8- 29 AK DX C

1- 11 BG GT N E

2-901 BG GT N E

1- 11 BG GT N E

2-901 BG GT N E

6- 7 BL HL N E

16-901 BL HL N E

6- 7 BK HG E

16-901 BK HG E

4- 30 BQ LP N E

7- 17 BG GT N E

6- 15 BN HZ E

15-901 BN HZ E

9- 16 BA FX N E

6- 15 BP LP N E

15-901 BP LP N E

6- 14 BL HL N E

14-901 BL HL N E

2- 1 BV RB N E

13-901 BV RB N E

6- 1 CA TV N E

12-901 CA TV N E

6- 1 CA TV N E

12-901 CA TV N E

8- 5 BE GN N E

9-901 BE GN N E

1-501 AT EZ N E

1-501 AU EZ N E

8- 13 AN EG N B

2- 2 AR EQ C

9- 4 AG DX N C

6- 13 AG DX N C

2- 5 AT EZ N C

2- 5 AV FG C

1- 6 AU EZ N C

1- 14 AT EZ N C

1- 4 AQ EQ N C

1- 16 AH DX N C

1- 10 AH DX N C

1- 23 AU FG N C

2- 8 AV FG N C

2- 8 AV FG N C

2- 9 AK EB N C

2- 10 AL EB N C

9- 11 AD DJ N C

9- 14 AD DJ N C

9- 6 AH DX N C

8- 27 AX FG C

5- 39 BB FX C

8- 26 AH DX C

6- 9 AP EQ C

1- 1 AK DX N C

1- 2 AN EQ N C

1- 8 AG DX N C

1- 9 AH DX N C

1- 22 AE DJ N C

5- 15 AG DX N C

3- 4 AG DS C

1- 15 AG DX N C

9- 8 AF DS C

4- 14 AB DJ C

5- 47 AB DJ C

8- 33 AC DJ C

7- 26 AV FG C

8- 1 AK DX C

Ja.

NEW P/R

PARTS CODE

JAPAN ONLY

ORDER CODE

PRICE R.

NO.

9- 1 AC DJ N C

9- 15 AC DJ N C

1- 3 AF DS N C

8- 54 AX FG B

8- 8 AA DJ C

9- 17 AD DJ N C

1- 24 AS EZ C

2- 11 AF DS C

11-110 AG DX D

8- 51 AF DS N C

12- 1 AD DJ C

12- 2 AA DD C

12- 3 AB DJ C

12- 4 AB DD C

12- 5 AE DJ C

12- 6 AD DJ C

14- 1 AH DX C

12- 7 AB DJ C

12- 8 AC DJ C

13- 1 AC DJ C

12- 9 AE DS C

12- 10 AF DS C

14- 2 AF DS C

12- 11 AG DS C

5- 52 AD DJ C

12- 12 AD DJ C

13- 2 AC DJ N B

12- 13 AE DJ C

12- 14 AD DJ C

14- 3 AD DJ C

12- 15 AP EQ B

12- 16 AG DS B

12- 17 AC DJ C

8- 28 BB FX B

12- 18 AA DD B

12- 19 AB DD B

12- 20 AB DD B

12- 21 AB DD B

11- 4 AM EG N D

11- 6 AM EG N D

11- 7 AS EZ N D

11- 7 AS EZ N D

11- 5 AE DJ N D

11-111 AC DJ D

11-104 AE DJ N D

11-104 AE DJ N D

11-104 AC DJ N D

11-104 AF DS N D

11-104 AW FG N D

11-104 AW ZZ N D

11-113 AB DJ D

1- 27 AG DS N C

1- 26 AG DX N C

1- 26 AG DX N C

1- 27 AG DX N C

1- 29 AC DJ N C

12- 22 AA DD C

12- 23 AA DD C

12- 24 AA DD C

12- 25 AA DD C

14- 4 AA DD C

13- 3 AA DD C

14- 5 AA DD C

14- 6 AA DD C

14- 7 AB DD C

14- 8 AA DD C

12- 29 AA DD C

12- 30 AC DD C

12- 26 AA DD C

12- 27 AB DD C

12- 28 AB DD C

13- 4 AB DD C

12- 31 AA DD C

12- 32 AA DD C

12- 33 AA DD C

Ex.

Ja.

NEW P/R

– 9 –

Page 25

PARTS CODE

JAPAN ONLY

ORDER CODE

PRICE R.

NO.

12- 34 AB DD C

12- 35 AA DD C

12- 36 AA DD C

14- 9 AA DD C

14- 10 AA DD C

12- 37 AA DD C

13- 5 AA DD C

12- 42 AB DJ B

12- 40 AC DD B

12- 38 AB DD B

12- 39 AC DD B

14- 11 AB DD B

13- 6 AA DD B

12- 41 AB DJ B

12- 43 AB DJ B

12- 61 BA FX B

14- 12 AH DX B

14- 13 AF EB B

16- 1 AR EQ B

12- 45 AY FQ B

12- 44 BE GN B

13- 7 AN EQ B

12- 46 AU EZ B

12- 47 AC DJ B

12- 48 AQ EQ B

12- 50 AG DS B

12- 51 AF DS B

12- 52 AT EZ B

12- 49 AY FQ B

12- 53 AD DJ B

12- 54 AF DX B

12- 55 AQ EQ B

12- 57 AF DJ B

12- 58 AH DX B

12- 56 AF DS B

12- 59 AE DS B

12- 60 AN EG B

13- 8 AP EQ B

13- 9 AC DJ B

13- 10 AC DJ B

12- 62 AF DS B

14- 14 AA DD C

12- 63 AA DD C

12- 64 AA DD C

12- 65 AA DD C

12- 66 AA DD C

12- 67 AA DD C

12- 68 AA DD C

12- 69 AA DD C

12- 70 AA DD C

12- 71 AA DD C

12- 72 AA DD C

12- 73 AA DD C

12- 74 AA DD C

12- 75 AA DD C

12- 76 AA DD C

12- 77 AA DD C

12- 78 AA DD C

12- 79 AA DD C

12- 80 AA DD C

12- 81 AA DD C

12- 82 AA DD C

12- 83 AA DD C

12- 84 AA DD C

12- 85 AA DD C

12- 86 AB DD C

13- 11 AA DD C

12- 87 AA DD C

12- 88 AA DD C

12- 89 AA DD C

13- 12 AA DD C

14- 15 AA DD C

13- 13 AA DD C

14- 16 AA DD C

13- 14 AA DD C

14- 17 AA DD C

13- 15 AA DD C

13- 16 AA DD C

14- 18 AA DD C

14- 19 AA DD C

12- 90 AA DD C

Ex.

Ja.

NEW P/R

PARTS CODE

JAPAN ONLY

ORDER CODE

PRICE R.

NO.

12- 91 AA DD C

12- 92 AB DD B

13- 17 AD DJ B

9- 18 AA DD C

9- 19 AA DD C

9- 20 AA DD C

Ex.

Ja.

NEW P/R

– 10 –

Page 26

AL-841

Page 27

CAUTION FOR BATTERY REPLACEMENT

(Danish) ADVARSEL !

Lithiumbatteri – Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandoren.

(English) Caution !

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according to manufacturer’s instructions.

(Finnish) VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

(French) ATTENTION

Il y a danger d’explosion s’ il y a remplacement incorrect

de la batterie. Remplacer uniquement avec une batterie du

même type ou d’un type équivalent recommandé par

le constructeur.

Mettre au rebut les batteries usagées conformément aux

instructions du fabricant.

(Swedish) VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent

typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

instruktion.

AL-841

Page 28

AL-841

All rights reserved.

Printed in Japan.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted,

in any form or by any means,

electronic; mechanical; photocopying; recording or otherwise

without prior written permission of the publisher.

SHARP CORPORATION

Digital Document Systems Group

Quality & Reliability Control Center

Yamatokoriyama, Nara 639-1186, Japan

2000 March Printed in Japan

Loading...

Loading...