Page 1

AL-1550

CODE: 00ZAL1550/A1E

DIGITAL COPIER

MODEL AL-1550

* This Service Manual describes only the differences from

the AL-1250. For the common items with the AL-1250,

please refer to the AL-1250 manual.

CONTENTS

[ 1 ] GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

[ 2 ] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . 1 - 1

[ 3 ] EXTERNAL VIEWS AND INTERNAL STRUCTURE . . . . 3 - 1

[ 4 ] UNPACKING AND INSTALLATION . . . . . . . . . . . . . 4 - 1

[ 5 ] OPERATIONAL DESCRIPTIONS . . . . . . . . . . . . . . 5 - 1

[ 6 ] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . 6 - 1

[ 7 ] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

[ 8 ] SIMULATION, TROUBLE CODES . . . . . . . . . . . . . . 8 - 1

[ 9 ] USER PROGRAMS . . . . . . . . . . . . . . . . . . . . . . 9 - 1

[10] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . 10 - 1

[11] CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . 11 - 1

● PARTS GUIDE

Parts marked w ith “ ” is important fo r maintaining the sa fety of the set. Be sure to replace these par ts with specified

ones for maintaining the safety and performance of the set.

SHARP CORPORATION

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

AL-1550

[1] GENERAL

1. Main features

A. Duplex copy

The digital system allows automatic duplex copying in the sequence of

pages by face down.

B. R-SPF

The R-SPF unit realizes efficient and smooth duplex copying as well as

single copying.

C. 1 scan multi copy

By combined use with the automatic document feeder, multi copying

from single to single is allowed.

D. Multi function

Realizes MFP by integration of the printer.

E. Compact design

Realizes a compact design of wingless form.

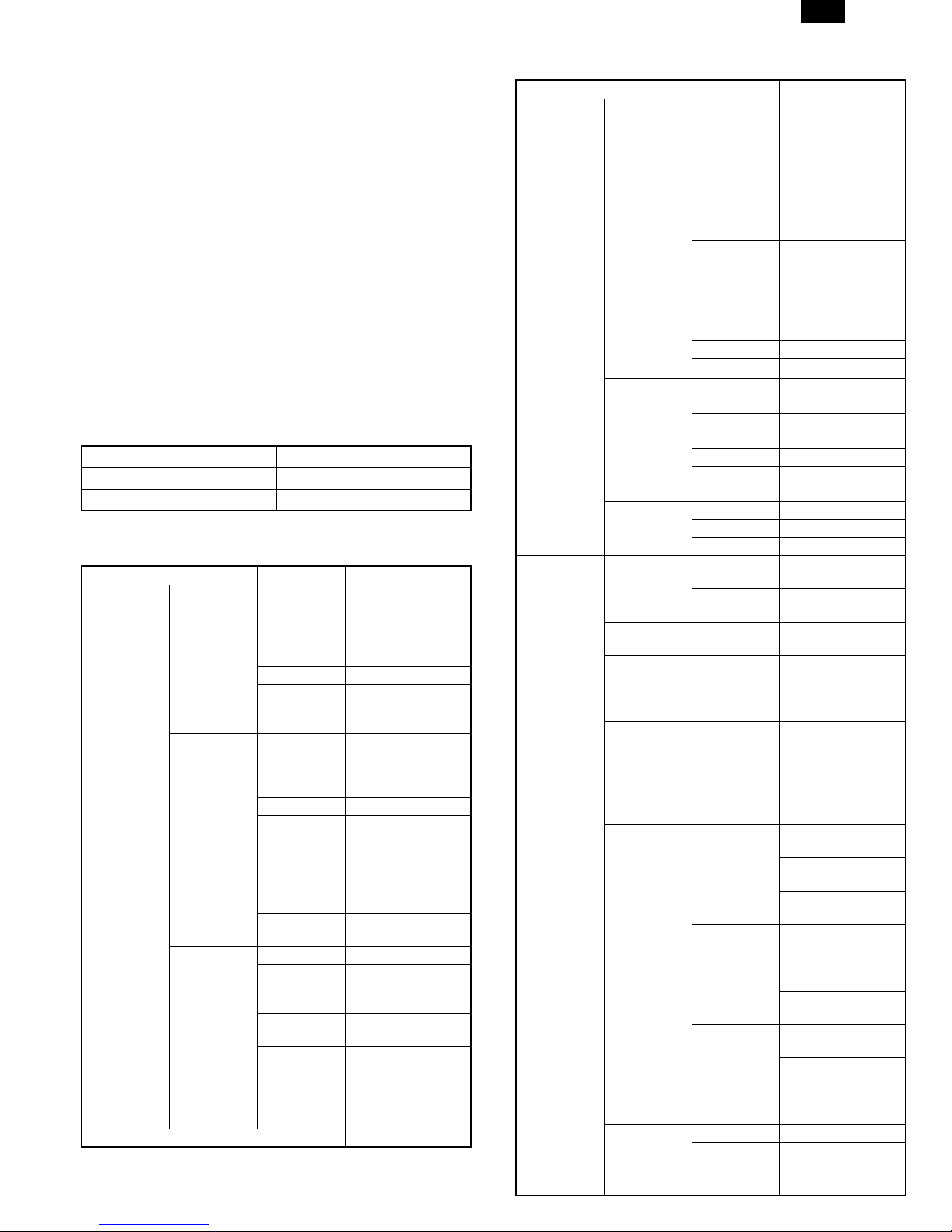

[2] Specifications

1. Basic Specification

Item

External dimensions H464 × W518 × D477 mm

Weight 24.6 kg

2. Operation specification

Section item Details

Paper feed

section

Paper for

Duplex

Electrical

section

Installed memory 6MB

∗1) May fluctuate due to environmental conditions and the input volt-

age.

Paper feed

system

AB system

Inch system

Power

source

Power

consumption

Paper size

Paper weight 56-80g/m

Kinds

Paper size

Paper weight 15-21lbs

Kinds

Voltage

Frequency

Max 1000 W

Average

(during

copying)

Average

(stand-by)

Pre-heat

mode

Auto power

shut-off

mode

2 tray (250sheet ×

2) + Multi bypass

(50sheet)

A4, B5, A5

(Landscape)

Standard paper,

specified paper,

Recycled paper

8-1/2" × 14", 8-

1/2" × 11", 8-1/2"

(Landscape)

Standard paper,

specified paper,

Recycled paper

100V 110V

120/127V 230V

Common use for

50 and 60Hz

285Wh/H ∗1)

70Wh/H ∗1)

40Wh/H ∗1)

18Wh/H ∗1)

2

× 5-1/2"

240V

3. Copy performance

Section item Details

Copy speed

Copy speed

(OC)

Copy Speed

(R-SPF) A4,

8-1/2"-11"

(Landscape)

Void

1 – 1

First copy

time

AB system:

A4

(Landscape)

B5

(Landscape)

Inch

system: 81/2" × 14"

(Landscape)

8-1/2" × 11"

(Landscape)

S to S

S to D Single copy

D to S

D to D Single copy

Void area

OC (Without

Duplex)

Image loss

OC (Without

Duplex)

Void area RSPF

(Without

Duplex)

9.6sec. (Pre-heat

mode: 16sec. or

delow/Auto power-

Tray paper

feed

Manual

paper feed

R-SPF Tray1: 13.5sec.

Same size 15

Enlargement 15

Reduction 15

Same size 15

Enlargement 15

Reduction 15

Same size 12

Enlargement 12

Reduction 12

Same size 15

Enlargement 15

Reduction 15

Single copy

Multi copy

Single copy

Multi copy

Ieading edge 1 ∼ 4mm

Trailing edge 4mm or less

Side edge

void area

Ieading edge

Trailing edge

Side edge

void area

Ieading edge 1 ∼ 4mm

Trailing edge 4mm or less

Side edge

void area

shut-off mode:

23sec. or delow

Feed from

Tray1/Scan Once

Print Many Mode:

13.sec.)

Single:

10.0sec./Multi:

8.0sec. (Pre-heat

mode: 16sec.)

Tray1: 12CPM,

Tray2: 9CPM

Tray1: 15CPM,

Tray2: 15CPM

Tray1: 5.6CPM,

Tray2: 5.4CPM

Tray1: 6.2CPM,

Tray2: 6.2CPM

Tray1: 15CPM,

Tray2: 15CPM

Tray1: 5.2CPM,

Tray2: 5.0CPM

3mm or less (per

side)

Same size: 3.0mm

or less

Enlarge (200):

1.5mm or less

Reduction (50):

6.0mm or less

Same size: 4.0mm

or less

Enlarge (200):

4.0mm or less

Reduction (50):

4.0mm or less

Same size: 2.0mm

or less

Enlarge (200):

2.0mm or less

Reduction (50):

2.0mm or less

3mm or less(per

side)

Page 3

Void

AL-1550

Section item Details

Ieading edge

Image loss

R-SPF

(Without

Duplex)

Trailing edge

Ieading edge 1 ∼ 4mm

Void area

OC (Duplex)

Image loss

OC (Duplex)

Void area RSPF (Duplex)

Image loss

R-SPF

(Duplex)

Trailing edge

Side edge

void area

Ieading edge

Trailing edge

Ieading edge 1 ∼ 4mm

Trailing edge

Side edge

void area

Ieading edge

Trailing edge

Same size: 4.0mm

or less

Enlarge (200):

3.0mm or less

Reduction (50):

7.0mm or less

Same size: 4.0mm

or less

Enlarge (200):

2.0mm or less

Reduction (50):

8.0mm or less

1st Page: 5mm +/–

1.0, 2nd Page:

5mm or less

3mm or less (per

side)

Same size: 3.0mm

or less

Enlarge (200):

2.0mm or less

Reduction (50):

6.0mm or less

Same size: 1st

Page: 5.0mm +/–

1.0, 2nd Page:

5.0mm or less

Enlarge (200): 1st

Page: 2.5mm +/–

1.0, 2nd Page:

2.5mm or less

Reduction (50):

1st Page: 10.0mm

+/– 1.0, 2nd Page:

10.0mm or less

1st Page: 5mm +/–

1.0, 2nd Page:

5mm or less

3mm or less (per

side)

Same size: 4.0mm

or less

Enlarge (200):

3.0mm or less

Reduction (50):

7.0mm or less

Same size: 1st

Page: 5.0mm +/–

1.0, 2nd Page:

5.0mm or less

Enlarge (200): 1st

Page: 2.5mm +/–

1.0, 2nd Page:

2.5mm or less

Reduction (50):

1st Page: 10.0mm

+/– 1.0, 2nd Page:

10.0mm or less

1 – 2

Page 4

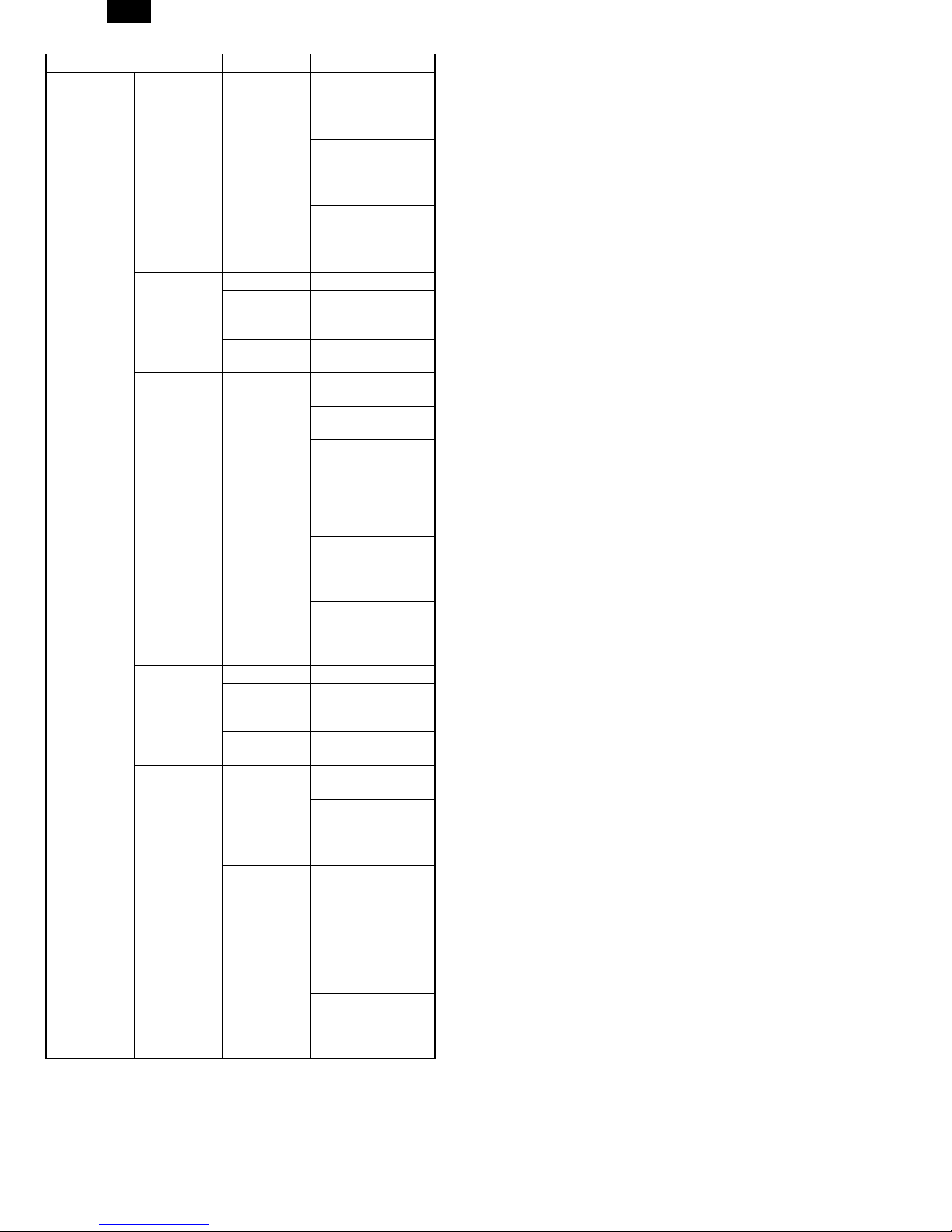

[3] EXTERNAL VIEWS AND INTERNAL STRUCTURES

1. Appearance

4

3

SPF XD103f/ 105f/ 120f

ADF XD155df only

1

15

13

14

1 Control panel 2 Document glass 3 Original exit area

4 Original guides 5 Original feeder tray 6 Document cover

7 Side cover 8 Paper tray bypass paper guides 9 Alternate paper tray

10 Paper guides 11 Release latch 12 Front cover

13 Paper tray 1 14 Paper tray 2 15 Exit tray

16 Lift area 17 Power switch 18 Power connection

19 Parallel port 20 Serial number

∗1 XD104/105f/124f/155df only

∗2 XD120f/124f/155df only

5

6

2

8

10

20

12

7

11

9

18

19

17

AL-1550

15

16

3 – 1

Page 5

AL-1550

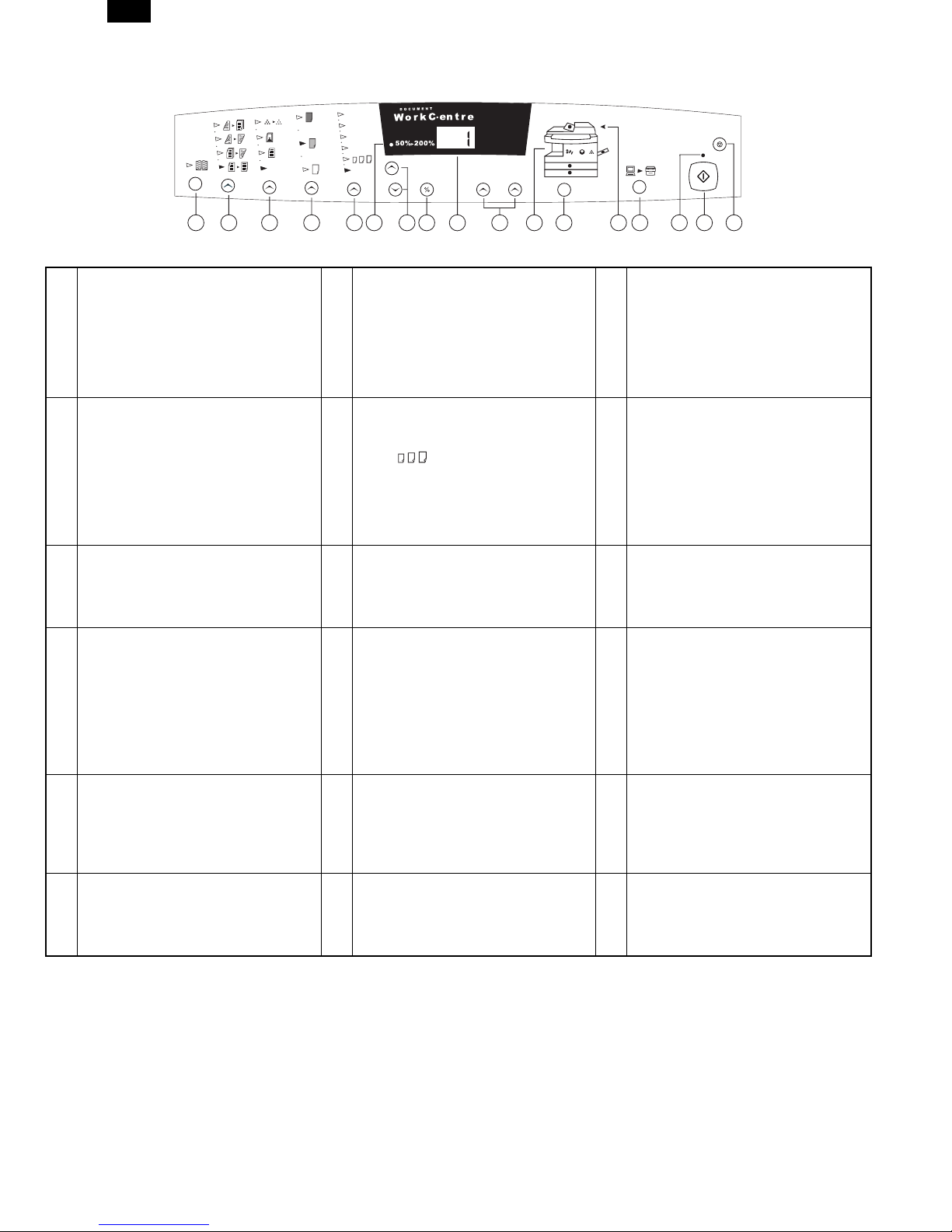

2. Control Panel

20 0% Ma x

129%

86%

78%

Auto

134567810 1416171592 1311 12

The control panel has keys and lights that are used to control and display the conditions of the WorkCentre.

Book Mode (XD104/124f only): Select

book mode when you want to make

copies from a bound document.

1

Copy Contrast: Press the contrast keys

to lighten or darken copies while in the

Text, Photo, or Toner Save settings.

Refer to the Image Quality section for

detailed information.

4

Variable Percentage: Press the down

key to decrease the percentage. Press

7

the up key to increase the percentage.

Any percentage from 50% to 200%

may be selected.

Quantity Keys: Select up to 100

copies. Press the 1 key to increase

the quantity by one. Press the 10 key

to increase the quantity by 10.

10

∗ To display the number of copies

requested during the copy run press

the 10 key.

∗ Press the Clear key to clear the

selected quantity.

SPF/ADF Misfeed Indicator: This

indicator will light when a misfeed

occurs in the SPF or the ADF.

13

Start: Press this key to begin copying.

∗ The display will change to 1 and

16

increases by 1 as each copy is

made.

10 0 %

1

10

1-Sided/2-Sided Mode (XD155df only):

Use the 2-Sided copy feature to make

one or two-sided copies from one or

two-sided originals. Refer to the

2

Making Copies on the Automatic

Document Feeder section for detailed

information.

Preset Reduction/Enlargement: Press

this key to select any of the preset

reductions or enlargements.

∗ The (customer settable)

5

percentage has been set at the

factory for 50%. Refer to

Customizing Your WorkCentre for

information about changing this

percentage.

%: Press this key to display the

reduction/enlargement percentage

8

selected. 9

WorkCentre Diagram: Helps you locate

areas that require your attention. The

indicators will flash in the area

requiring attention. For additional

information refer to the Problem

11

Solving section.

On-line/Off-line Key: Press this button

to alternate between On-line and Offline status. When the light is lit, the

14

printer is On-line.

Clear/Stop: Press this key to stop the

WorkCentre while making copies or to

17

clear copy quantity. If the key is

pressed twice quickly, all programming

will be cleared.

Image Quality Mode: The image quality

mode is used to maximiz e copy quality.

Auto- for originals with a colored

background or mixed text and graphics.

3

Text - for originals that contain mainly text.

Photo - for copying photographs.

Toner Save - decreases the overall

copy density.

Percentage Indicator: The indicator will

light when any reduction or

enlargement setting is selected.

6

Display Window: Copy quantity,

reduction/enlargement settings, and

status codes appear in this area.

Paper Supply Selection

(XD104/105f/120f/124f/155df only):

Press to change the selected paper

supply. The selected paper supply

location will be indicated by a green

12

light on the WorkCentre diagram.

Ready Indicator: When the light is ON

(not flashing), the WorkCentre is ready

to make copies. When the light is

15

flashing after the Start key is pressed,

the WorkCentre is warming up and the

copy cycle will begin automatically.

C

3 – 2

Page 6

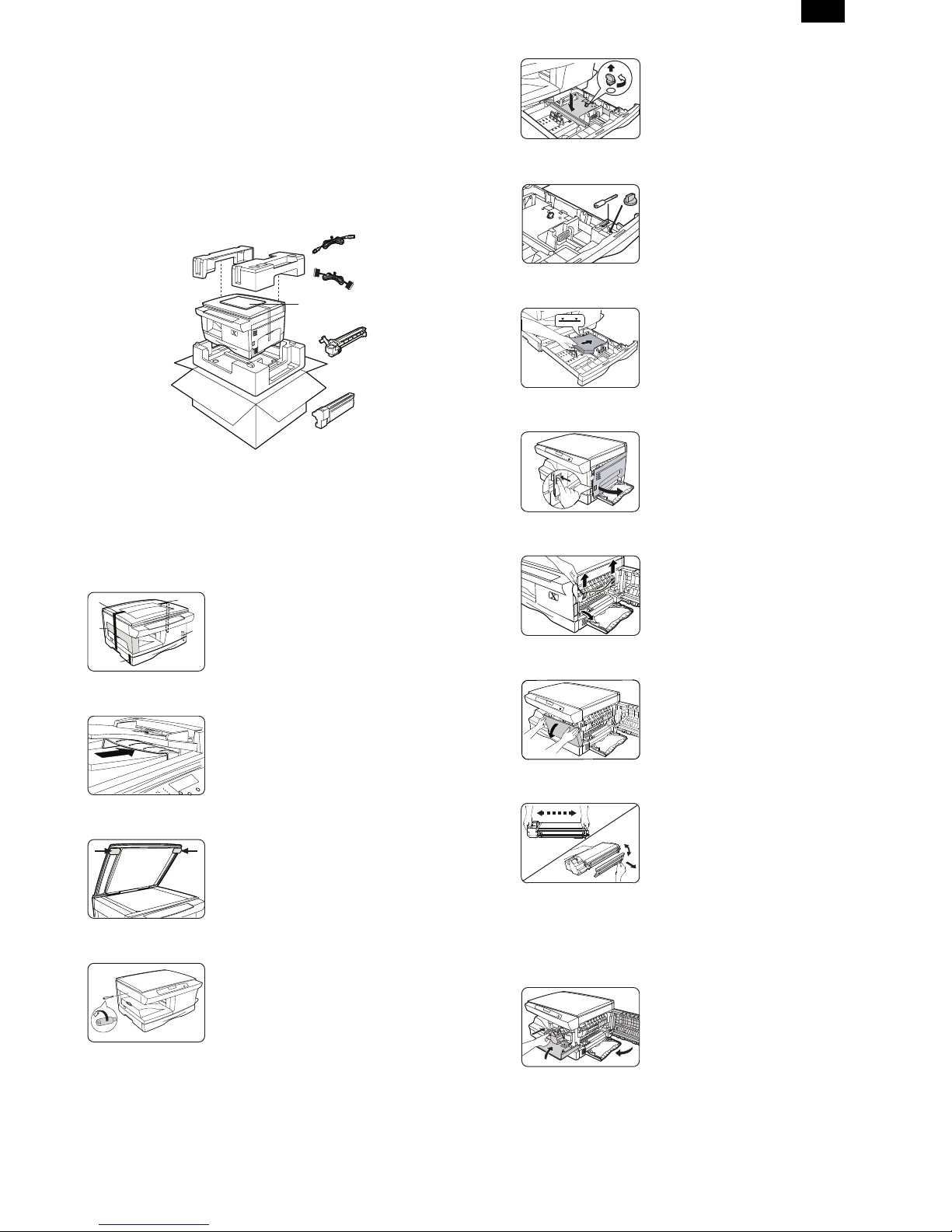

[4] UNPACKING AND INSTALLATION

1. CHECKING PACKED COMPONENTS

AND ACCESSORIES

As you unpack the WorkCentre, familiarize yourself with its contents.

After the WorkCentre is installed, and the Ready Indicator is lit, the

WorkCentre is ready to make copies.

IMPORTANT: Save the carton and packing materials. They should be

used to repack the WorkCentre if it has to be shipped

for servicing or in case you move.

Power cord

IEEE-1284

Parallel Cable *

Packing material

User documentation/

Installation CD

Drum cartridge

(installed in the

machine)

AL-1550

5) Lift and pull open the paper tray.

Turn and remove the paper tray

button.

CAUTION: Paper will misfeed if the paper

For the XD 120f/124f/155df copier only

Note: Be sure to remove the pressure

6) Secure the paper tray button and the

Note: Save the paper tray button and the

7) Load paper into the tray.

8) Push the paper tray firmly back into

tray button is not removed.

plate lock from both paper trays.

shipping screw in the locations shown.

●

Turn the paper tray button to secure

its storage position.

shipping screw. They will be

needed if the WorkCentre has to

be moved.

●

Refer to the Loading Paper section

for additional information.

●

Do not fill above the max line.

the WorkCentre.

Starter toner

cartridge

∗Note: To ensure reliability of the WorkCentre use the IEEE-1284

compliant parallel cable that is supplied with the machine. Only

cables labeled "IEEE-1284" can be used with your WorkCentre.

2. Installation

Follow the steps below to properly set up your Xerox WorkCentre.

A

E

B

1) Remove the bag from the WorkCentre.

D

2) Remove the pieces of tape A, B, C,

C

D, and the packing material E.

XD155df copier only

Remove the tape and the packing material

supporting the clear plastic 2-sided tray.

XD155df copier only

To ensure the 2-sided tray is in the

correct position, gently push it in the

direction shown by the arrow.

3) Open the document cover and

remove the packing materials shown.

4) Unscrew and remove the shipping

screw from the left side of the

WorkCentre.

CAUTION: The WorkCentre will

malfunction if the shipping

screw is not removed.

Note: Ensure that the alternate paper tray

is lowered (XD 104/124f/155df only).

9) Press the release lever to open the

side cover.

10) Remove the Caution tape from the

cover.

11) Remove the two red fuser pins by

pulling the string upward one at a

time.

●

Discard the fuser pins.

Note: Misfeeds will occur if the fuser pins

are not removed.

CAUTION: Ensure that the side cover is

always open before opening

the front cover.

12) Press the front cover release buttons

to open the front cover.

13) Remove the starter toner cartridge

from the silver bag. Vigorously shake

1

2

the cartridge to loosen the toner.

●

Thoroughly shaking the cartridge will

assure maximum copies per

cartridge.

●

Xerox has included a Starter Toner

Cartridge. Purchased replacement

toner cartridges will yield

approximately three times the number

of copies.

14) Remove the toner cartridge cover.

15) Slide the toner cartridge into the

WorkCentre until it locks into place.

16) Close the front cover and the side

1

2

3

cover.

Skip to the Printer Driver Software

Installation section in this User Guide to

set up the WorkCentre XD for printing.

4 – 1

Page 7

AL-1550

17) Plug the power cord into the

18) Turn on the power switch. In

Note: Save the carton and packing

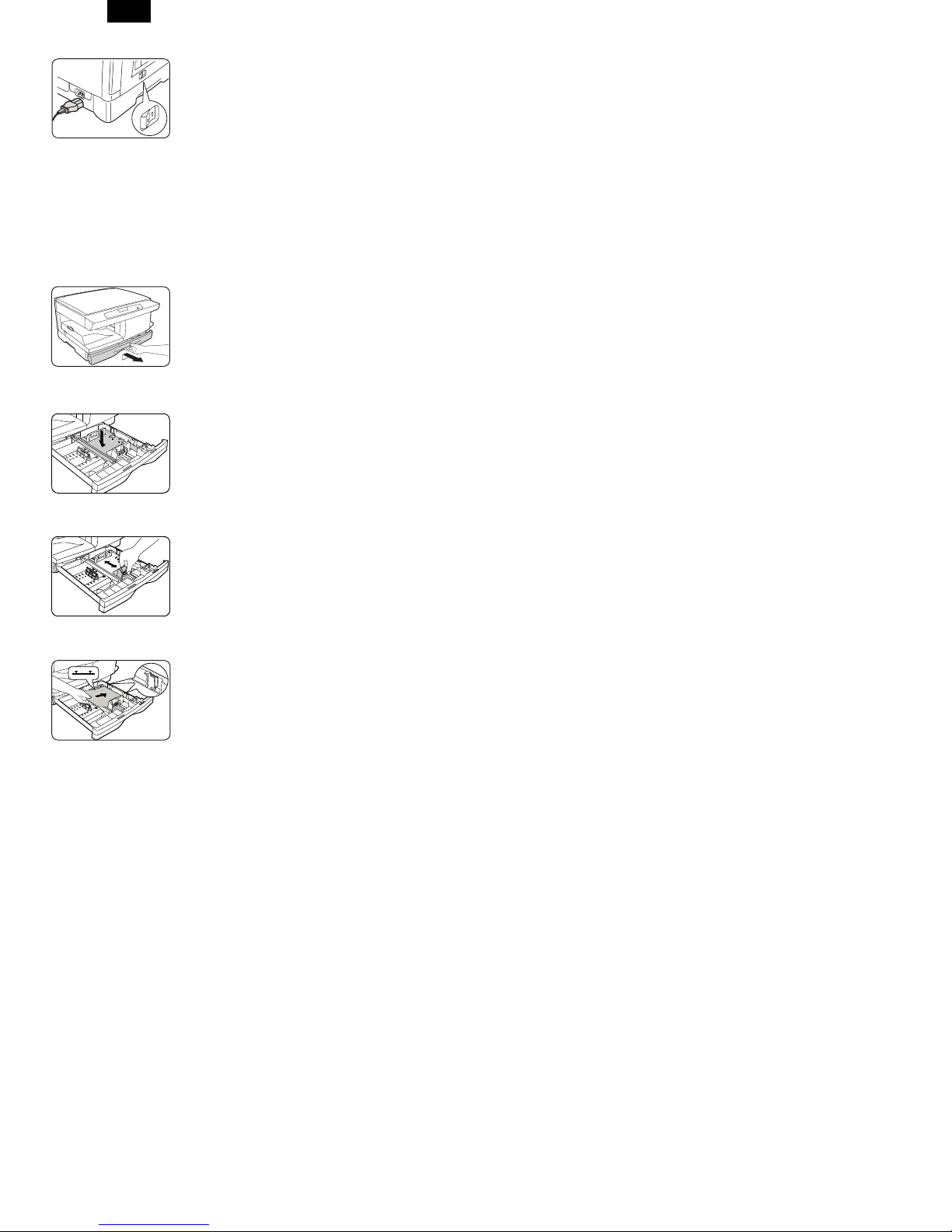

3. P Loading Paper

1) Lift and pull open the paper tray.

2) Push down on the pressure plate

Note: The procedures for loading paper

WorkCentre and then into a grounded

outlet.

approximately two seconds the ready

indicator will light. Copying is now

possible.

materials. They should be used to

repack the WorkCentre if it has to

be shipped for servicing or moved.

until it locks in position.

into tray 1 and tray 2 are identical.

3) Adjust the paper guides to the

desired paper size.

●

Squeeze the side guide.

●

Lift and insert the rear guide.

●

When adding paper larger than

8.5L11/A4, remove the rear guide and

store it in the pocket in front of the

side guide.

4) Fan the paper and insert it into the

tray.

●

Ensure that the paper corners are

under the corner snubbers.

●

Do not fill above the max fill line.

5) Close the paper tray.

6) If copying, press Start to continue. If

printing, the job will automatically

resume.

●

To cancel the flashing P without

restarting copying, press the Clear

button.

4 – 2

Page 8

AL-1550

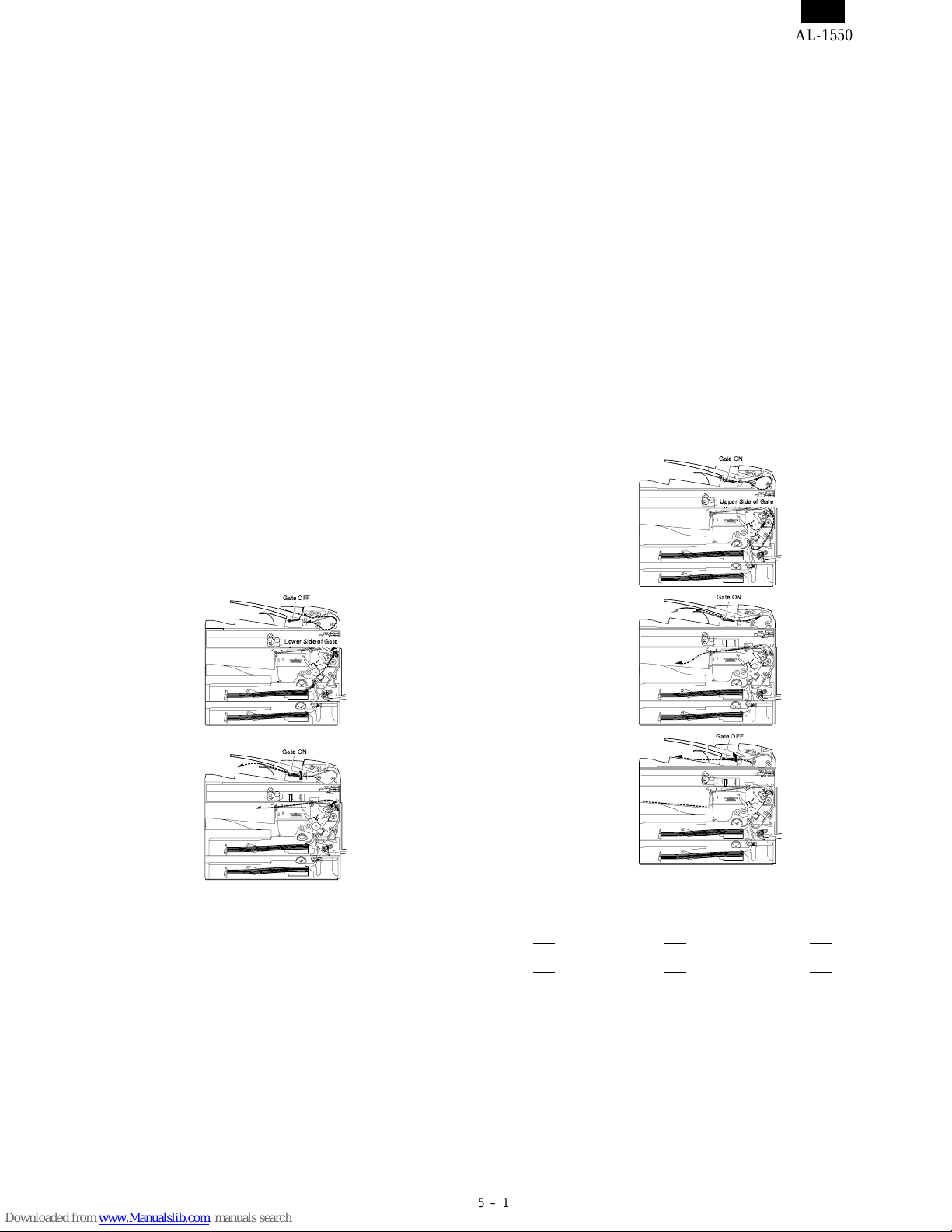

[5] Operational descriptions

1. D-D (Duplex to Duplex) mode

paper/document transport

A. Initial state

Set duplex documents on the document tray.

Set paper on the cassette. (In the duplex mode, the manual feed tray

cannot be selected.)

B. Front copy

Document transport: The document feed roller feeds the document

from the paper feed roller to the PS roller.

→ The document is exposed in the exposure

section, and sent to the document exit section

by the transport/paper exit roller.

→ R-SPF gate solenoid ON

→ The document is sent to the intermediate tray

(but not discharged completely.)

→ The document is stopped once, then

switchback operation is performed. (To the

back copy)

Paper transport: The document is passed through the paper feed

roller and the PS roller by the paper feed roller

and the images on the front surface are transferred.

→ The paper is passed through the fusing sec-

tion and the lower side of the gate section to

the paper exit tray side, (but not discharged

completely.)

→ It is stopped once and switchback operation

is performed. (To the back copy)

Gate OFF

C. Back copy

Document transport: By switchback operation, the document is sent

through the PS roller to the exposure section,

where the back of the document is exposed.

→ It is sent to the document exit section by the

transport roller and the paper exit roller.

→ R-SPF gate solenoid ON. The document is

sent to the intermediate tray, (but not discharged completely.)

→ It is stopped once and switchback operation

is performed.

→ It is sent through the PS roller and the ex-

posure section (without exposure operation)

to the document exit section.

→ R-SPF gate solenoid OFF

→ The document is discharged to the document

exit tray.

Paper transport: Switchback operation is performed.

→ The paper is sent through the upper side of

the gate section and the duplex transport section, and the PS roller, and the images on the

back are transferred.

→ It is sent through the fusing section and dis-

charged to the paper exit tray.

Gate ON

Upper Side of Gate

Gate ON

Lower Side of Gate

Gate ON

Gate OFF

Switchback operation is made after back copying in order to discharge

documents according to the setting.

Set document Documents after discharge,

1

with empty feed

23 4

4

without empty feed

3

32 1

41 2

There are following job modes as well as D-D mode.

S - S (Simplex to Simplex)

S - D (Simplex to Duplex), Rotation copy mode (The back images are

rotated 180˚.)

S - D (Simplex to Duplex), Copy mode without rotation

D - S (Duplex to Simplex)

Rotation copy mode: The front and the back are in upside

down each other.

Copy mode without rotation: The front and the back are not in upside

down.

5 – 1

Page 9

[8] SIMULATION, TROUBLE CODES

1. Contents of simulations

Main code Sub code Content

26 4 Main body duplex setting

(Operation/procedure)

1. When this simulation is executed, the currently set duplex code number is displayed.

2. ???????

Code number Duplex

0 Without Duplex

1 With Duplex

43 1 Fusing temperature setting

(Operation/Procedure)

1. When this simulation is executed, the currently set code number is displayed.

2. Enter the code number and press the START key, and the setting will be changed.

Code number Set temperature (˚C)

0 175

1 180

2 185

3 190

4 195 (∗ Default)

5 200

4 Multi copy fusing temperature setting

(Operation/Procedure)

1. When this simulation is executed, the currently set code number is displayed.

2. Enter the code number and press the START key, and the setting will be changed.

Code number Set temperature (˚C)

0 155

1 160

2 165

3 170 (∗ Default)

4 175

5 180

AL-1550

5 Fusing temperature setting in duplex copying

(Operation/Procedure)

1. When this simulation is executed, the currently set code number is displayed.

2. Enter the code number corresponding to the duplex and press the START key. The setting is changed accordingly.

Code number Shift temperature (˚C)

0 ±0˚C

1 –8˚C

2 –6˚C

3 –4˚C

4 –2˚C

5 ±0˚C

6 +2˚C

7 +4˚C

8 +6˚C

9 +8˚C

The above shift temperature set by this simulation is added to the fusing temperature of single copy.

∗

8 – 1

Page 10

AL-1550

Main code Sub code Content

51 2 Resist amount adjustment (Outline)

Used to adjust the contact pressure of paper onto the copier resist roller and the RSPF resist roller.

(Operation/Procedure)

1. When this simulation is executed, the currently set value is displayed.

2. In a machine with the multi paper feed unit installed, press the copy mode select key, and each setting mode and

display are changed sequentially.

In a machine with the single paper feed unit installed, press the copy mode select key, and each setting mode

and display are changed sequentially.

∗ The selected adjustment mode is indicated by the lamps as follows:

3. Enter the adjustment value with the 10-key and press the SORT key. Then the set value is stored and a copy is

made.

4. Press the clear key to store the set value and exit the simulation.

∗ Machine with the multi manual paper feed

Adjustment mode Display lamp

Main cassette paper feed AE, Main cassette lamp

2nd cassette paper feed AE, 2nd cassette lamp

Manual paper feed AE, Manual paper feed lamp

RSPF document feed (front) AE, TEXT, PHOTO lamp

RSPF document feed (back) AE, TEXT lamp

Duplex back TEXT, PHOTO lamp

∗ Machine with the single manual paper feed

Adjustment mode Display lamp

Main cassette paper feed AE, Main cassette lamp

Manual paper feed AE blinking (Main cassette lamp ON)

RSPF document feed (front) AE, TEXT, PHOTO lamp

RSPF document feed (back) AE, TEXT lamp

Duplex back TEXT, PHOTO lamp

77 1 Memory reverse position adjustment in duplex copy (Operation/Procedure)

1. When this simulation is executed, the currently set correction value is displayed.

2. Enter the correction value with the 10-key, press the START key, and the entered value is stored. (Correction

value: 1 - 99, Correction zero: 0 or 50)

∗ For front printing in S-D mode and even-page printing in D-S mode, reverse memory copying made from the rear

edge of the document.

If, therefore, it is required to adjust the print position of the output image, perform the following procedure.

When the document is scanned in the direction shown in the figure below, images are printed from the scanning

rear edge in reverse memory copying.

If the print head is shifted, set the reference chart so that the reference position is at the rear edge section and

use this simulation so that the lead edge of the print image is fitted.

Printing is started at the print start position in the direction from the bottom to the top of image data stored in the

memory.

When the simulation set value is entered, the scanning end position and resultantly the bottom data position stored

in the memory are changed to adjust the image lead edge position.

Document transport direction

Scanning rear edgeScanning direction

Scanning lead edge

Scanning end position

(Default: Void (1) is cut off.)

Paper transport direction

2 Duplex copy rear edge void adjustment (Operation/Procedure)

1. When this simulation is executed, the currently st value is displayed in top digits. (Center value: 50 However, Set

value 50 = Set value 0)

2. Press the copy mode select key to select the set mode and the display.

3. Enter the adjustment value with the 10-key and press the START key, and the entered value is stored and a copy

is made.

4. Press the CLEAR key, and the entered value is stored and the simulation is terminated. (An increase in the set

value by 1 corresponds to an increase in void amount by 0.1 mm.)

Adjustment mode Lamp ON

Image cut rear edge void amount (RSPF) AE lamp

Paper rear edge void amount TEXT lamp

Print lead edge

Lead edge void (1)

Print start position

Rear edge void

Print rear edge

8 – 2

Page 11

[9] USER PROGRAM

The conditions of factory setting can be changed according to the use conditions.

1. Functions which can be set with the user program

Function Contents Factory setting

●

Auto clear.

Pre-heat.

Auto shut off

passing time.

Stream feeding.

Auto shut off setting

∗Note: The power consumption values in pre-heat and auto shut off may be varied depending on the use conditions.

When a certain time is passed after completion of copying, this function returns to the initial state

automatically. The time to reach the initial state can be set in the range of 10 sec to 120 sec. This

function can be disabled.

●

When the copier is left unused with the power ON, the power consumption is automatically reduced

to about 40Wh/H (∗ Note).

The time to start this function can be set in the range of 30 sec to 90 sec by the unit of 30 sec.

This function cannot be disabled.

●

When this function is operated, the pre-heat lamp on the operation panel lights up.

To return to the initial state, press any key on the operation panel. (When the COPY button is

pressed, a copy is made after returning to the initial state.)

●

When the copier is left unused with the power ON, the power consumption is automatically reduced

to about 18Wh/H (∗ Note). The time to start this function can be set in the range of 2 min to 120

min.

●

When this function is operated, all the lamps except for the pre-heat lamp on the operation panel

turn off.

To return to the initial state, press the COPY button.

After completion of copying with the automatic document feeder (SPF), when documents are set

while the SPF indicator is blinking (for about 5 sec), the documents are automatically fed.

●

Used to set or cancel this function. Set

AL-1550

60 sec

90 sec

5 min

Set

2. Change the setting.

Example: Changing the time to operate the auto shut off function

1) Press the right and the left exposure adjustment keys simul-

● Keep pressing the keys for five sec.

● Displ ay lamps ( , , ) blink simult aneously and “ - -” is

displayed on the copy quantity display.

2) Select the function code with the 10-digit key (copy quantity

● The number of the selected function blinks on the digit of 10 on the

copy quantity display.

● For auto clear, select “1.”

● For setting, refer to the following function codes.

Function

name

Auto clear

∗ : Factory setting

(Change from 60 sec to 90 sec)

taneously to start setting.

set key).

Set code

0 (Cancel)

1 (30 sec) 1 (60 sec) ∗1 (5 min) ∗1 (Setting) ∗1 (Setting)

∗2 (60 sec) ∗2 (90 sec) 2 (15 min)

3 (90 sec) 3 (30 min)

4 (120 sec) 4 (60 min)

5 (10 sec) 5 (120 min)

Function

name

Pre-heat

Set code

0 (30 sec)

Function

name

Auto shut

off

Function name Function code

Auto clear 1

Pre-heat 2

Auto shut off passing time 3

Stream feeding 4∗

Auto shut off setting 5

[Cancel] If a wrong code is entered, press the clear key and enter the

3) Press the COPY button.

● The number blinking on the digit of 10 of the coyp quantity display

● The number of the current set code blinks on the digit of 1.

4) Select the setting code with 1-digit key (copy quantity set key).

● To set to 90 sec, select “3.”

● For setting, refer to the following set codes.

Set code

0 (2 min)

correct function code.

is lighted.

Function

name

Stream

feeding

Set code

0 (Cancel)

Function

name

Auto shut

off setting

Set code

0 (Cancel)

● The number of the selected set code blinks on the digit of 1 of the

copy quantity display.

[Cancel] When a wrong number of the function code is set, press the

clear key and perform the procedure again from 2.

5) Press the COPY button.

● The number blinking on the digit of 1 of the copy quantity display is

lighted up. This means the setting is completed.

[Note] To set another function, press the clear key after completion of

this operation and perform the procedure from 2.

6) Press either one of exposure adjustment keys

( or ) to complete the setting.

● Display lamps ( , , ) go off and the copy quantity dis-

play returns to the normal state.

9 – 1

Page 12

[10] ELECTRICAL SECTION

1. Block diagram

A. Overall block diagram

AL-1550

10 – 1

Page 13

AL-1550

B. Main PWB block diagram

10 – 2

Page 14

2. Circuit descriptions

A. Main PWB (MCU)

(1) CPU signal table

The additional signal is as follows:

Pin No. Signal name In/Out During operation

31 SPPD Input SPF paper transport detection signal

109 SIN3 Input Sensor input 3

115 DMT3 Motor Output Duplex motor control signal

116 DMT2 Motor Output Duplex motor control signal

117 DMT1 Motor Output Duplex motor control signal

118 DMT0 Motor Output Duplex motor control signal

The signals of function change are as follows:

Pin No. Signal name In/Out During operation

119 MRMT3 Motor output Mirror motor/SPF motor control signal

120 MRMT2 Motor output Mirror motor/SPF motor control signal

121 MRMT1 Motor output Mirror motor/SPF motor control signal

122 MRMT0 Motor output Mirror motor/SPF motor control signal

(2) ASIC signal table

The additional signal is as follows:

Pin No. Signal name In/Out Connection Descriptions

SPF gate solenoid control

201 SGS Output TR array IC

202 SRRC Output TR array IC

203 SPUS Output TR array IC

208 SPFS Output TR array IC

209 SMSEL Output TR array IC

227 CPFS2 Output TR array IC

signal. “H”: Gate solenoid

ON (R-SPF only)

SPF resist roller clutch

control signal. “H”: Clutch

ON (R-SPF only)

SPF pickup solenoid control

signal. “H”: Solenoid ON

SPF paper feed solenoid

control signal. “H”: Solenoid

ON (R-SPF only)

SPF/mirror motor relay

switch signal. “L”: Mirror

motor, “H”: SPF motor

2nd cassette paper feed

solenoid control signal. “H”:

Solenoid ON

AL-1550

(3) Input signal table

The additional signals are as follows:

Signal name Descriptions

SPID SPF paper entry detection signal

SPF

2nd

SDOD SPF open/close detection signal

SDSW SPF cover open/close detection signal

CED2 2nd cassette section cassette presence detection

PPD3 2nd cassette section paper transport detection

10 – 3

Page 15

AL-1550

(4) Mirror motor circuit

The mirror motor is a stepping motor. Its driver is IC113 constant-current chopper control IC (SLA7024). For control, the CPU outputs a drive

signal to IC113 to drive the mirror motor by 1-2 phase excitement.

The SPF motor and the mirror motor are switched with relays RY1 and RY2. The switching signal is SMSEL-. When SMSEL- is LOW, a current

flows through the SPF motor. When it is HIGH, a current flows through the mirror motor.

24V-mir

/SMSEL

ULN2003

24V

RY102 G5V-2(OMRON)

RY101 G5V-2(OMRON)

(5) Duplex motor circuit

The duplex motor is a stepping motor. Its driver is IC111 darlington-sink transistor driver IC (TD62064AP). For control, the CPU outputs a drive

signal to IC111 to drive the duplex motor by 1-2 phase excitement.

M

SPF motor

M

(1-C4) DMT0

(1-C4) DMT1

(1-C4) DMT2

(1-C4) DMT3

R286 2.2KJ 3

R285 2.2KJ 6

R278 2.2KJ 11

R279 2.2KJ 14

IC111

I1 O1

4

NC

5

NC

I2 O2

10

NC

I3 O3

12

NC

13

NC

I4 O4

15

NC

GND COM

GND COM

TD62064AF

CP101

24V1

ICP-N38

2

7

9

D123

MTZJ22B

16

M

1

8

Duplex Motor

10 – 4

Page 16

[11] CIRCUIT DIAGRAM

AL-1550

MCU 1

11 – 1

Page 17

AL-1550

MCU 2

11 – 2

Page 18

AL-1550

MCU 3

11 – 3

Page 19

AL-1550

MCU 4

11 – 4

Page 20

AL-1550

MCU 5

11 – 5

Page 21

AL-1550

MCU 6

11 – 6

Page 22

AL-1550

MCU 7

11 – 7

Page 23

AL-1550

OPU

11 – 8

Page 24

AL-1550

ACTUAL WIRING DIAGRAM 1

11 – 9

Page 25

AL-1550

ACTUAL WIRING DIAGRAM 2 (DSPF UNIT)

11 – 10

Page 26

AL-1550

COPYRIGHT © 1999 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted,

in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission of the publisher.

SHARP CORPORATION

Printing & Reprographic Systems Group

Quality & Reliability Control Center

Yamatokoriyama, Nara 639-1186, Japan

1999 March Printed in Japan N

Loading...

Loading...