Page 1

AR-SP5

AR-D16

SERVICE MANUAL

CODE : 00ZARSP5//A1E

DIGITAL COPIER OPTIONS

AR-PG2 AL-12PKM

[ 1 ] GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

[ 2 ] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

[ 3 ] AR-SP5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

[ 4 ] AR-D16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

MODEL

CONTENTS

AR-SP5

AR-D16

AR-PG2

(SPF)

(1 TRAY UNIT)

(GDI/Scanner Kit)

AL-12PKM

(GDI/Scanner Kit)

[ 5 ] AR-PG2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

● PARTS GUIDE

Parts marked with “ ” are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

[1] GENERAL

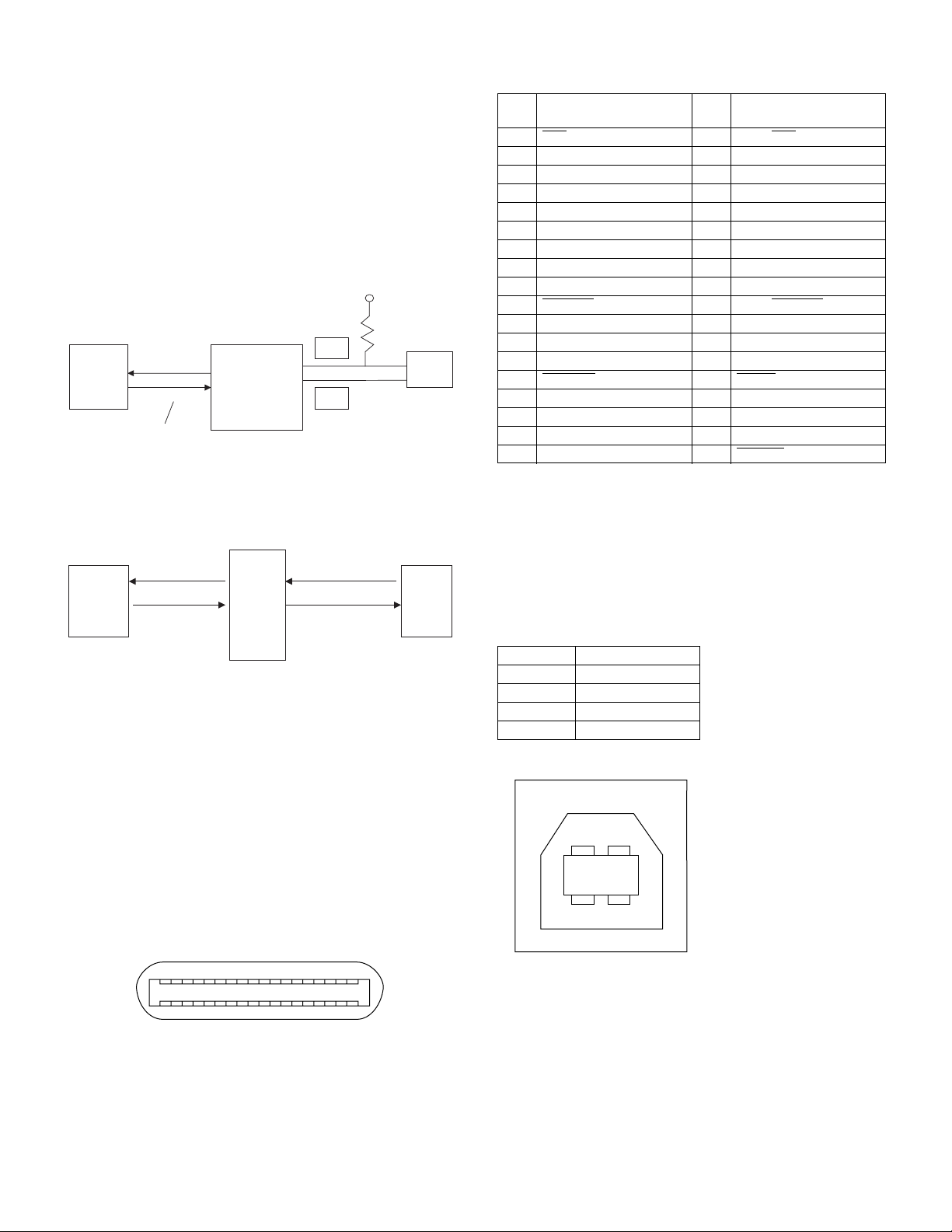

1. List of available options

Model

AR-122E AR-152E AR-153E AR-157E

Option

AR-SP5

(SPF)

AR-D16

(1 TRAY UNIT)

AR-PG2

(GDI/Scanner Kit)

AL-12PKM

(GDI/Scanner Kit)

: Option available

: Option not available

B. AR-D16 (250 - Sheet Paper Feed Unit)

The paper feed unit provides the convenience of increased paper

capacity for the copier and a greater choice of paper sizes readily

available for copying.

Part names

Side cover

Tray

2. Outline and specifications of each option

A. AR-SP5 (Single Pass Feeder)

The single pass feeder (SPF) holds up to 30 originals for automatic

feeding.

Part names

Original guides

Document feeder tray

Specifications

Acceptable

originals

Power supply Drawn from the copier

Weight Approx. 6.6 lbs. (3kg)

Dimensions 19.6" (W)

Weight: 14 to 23.9 lbs.

Size: 5-1/2"

Capacity: Up to 30 sheets

(498 mm (W)

× 8-1/2" to 8-1/2" × 14"

× 15" (D) × 4.3" (H)

× 380 mm (D) × 110 mm (H))

Feeding roller cover

SPF exit area

Specifications

Copy paper size 5-1/2" × 8-1/2" to 8-1/2" × 14"

Paper weight 15 lbs. to 21 lbs.

Paper capacity One paper tray with capacity for 250 sheets of

Weight Approx. 6.6 lbs. (3 kg)

Dimensions 19.6" (W)

Power supply Drawn from the copier

21 lb. bond paper

× 15.6" (D) × 3.5" (H)

(498 mm (W)

× 395 mm (D) × 88 mm (H))

C. AR-PG2, AL-12PKM (GDI/Scanner Expansion Kit)

Printing system Dry, electrostatic transfer

Printing size A6 to A4 (3-1/2"

Print speed Max. 12 pages/min. (Letter or A4)

Continuous printing Max. 99 pages subtractive counter

First-print time

(Approximately)

Resolution Printer 600 dpi

Scanner 600

Emulation SHARP GDI

Page orientation Portrait or landscape

Interface port USB interface (USB1.1 Standard)/

*1: Feed paper lengthwise only.

*2: Data transmission time is not included.

9.6 seconds (Paper: A4) *2

× 1200 dpi

IEEE1284-compliant bi-directional parallel

interface (Only for printer)

× 5-1/2" to 8-1/2" × 14") *1

AR-SP5 GENERAL 1 - 1

Page 3

[2] UNPACKING AND INSTALLATION

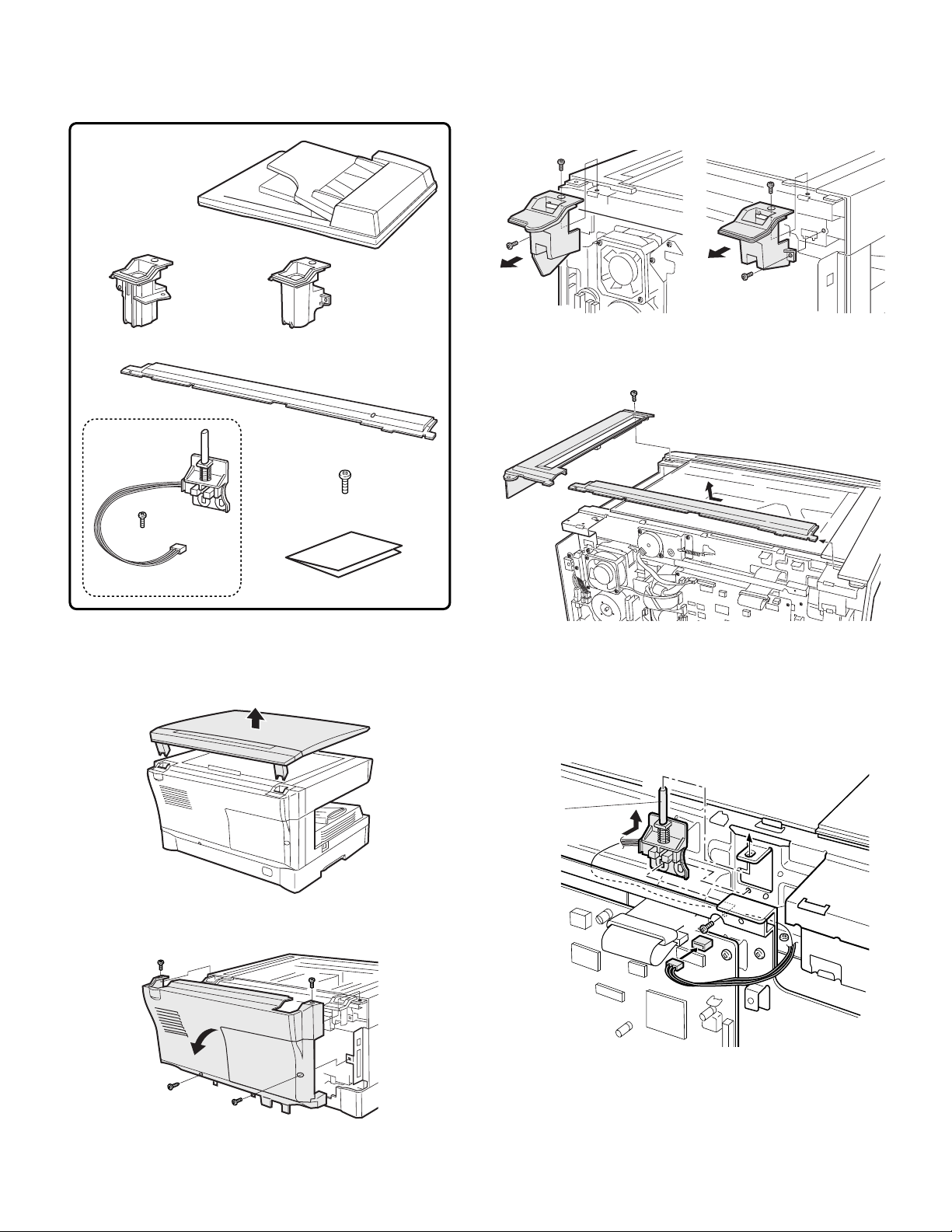

1. AR-SP5 Installation Manual

•

Parts included

• SPF unit

• Hinge guide L • Hinge guide R

• SPF rear cover, 1 pc.

• Screws (M3 × 8), 1 pcs.

3) Remove the hinge guides L and R.

Remove the screws (two for each) and then remove the hinge

guides L and R.

4) Remove the rear cover for the document glass.

<1> Remove the screw and then remove the right glass holder.

<2> Slide the rear cover for the document glass to remove it.

1

2

• Book sensor unit, 1 pc.

Turn the main switch to the “OFF” position and remove the power plug

from the outlet.

1) Remove the document cover.

Remove the document cover from the copier.

2) Remove the rear cabinet.

Remove the four screws and then remove the rear cabinet.

• Installation manual, 1 sheets

5) Attach the book sensor unit.

Insert the actuator of the book sensor unit into the mounting por-

tion in the copier and fix it using the supplied screw (M3

Note: When attaching the sensor unit, fix it using the screw while

pushing the unit upward.

Connect the connector to the connector of the copier and arrange

the wiring as shown in the illustration.

1

Actuator

2

3

× 8).

AR-SP5 UNPACKING AND INSTALLATION 2 - 1

Page 4

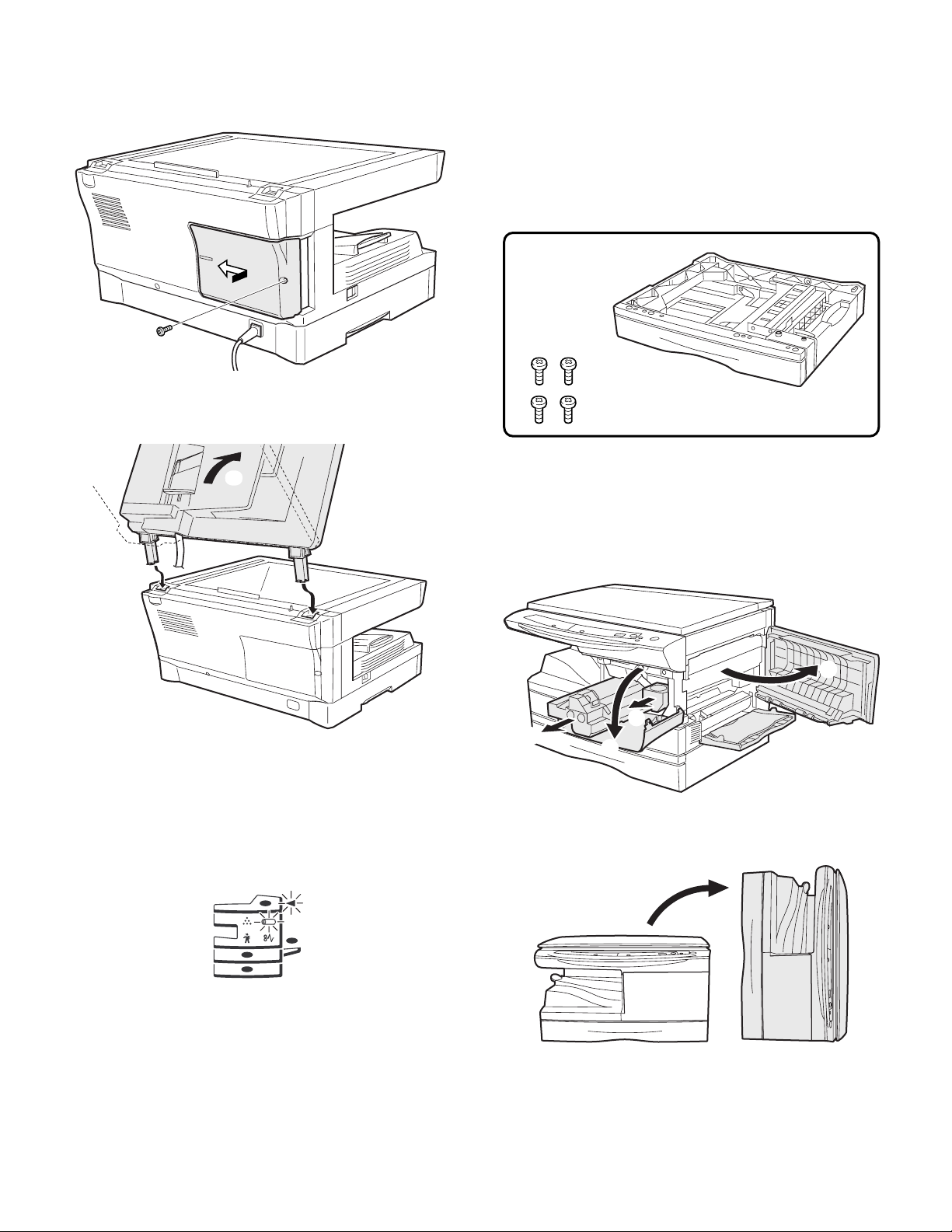

6) Attach the SPF rear cover.

<1> Pass the actuator of the book sensor into the hole of the SPF

rear cover and slide the SPF rear cover to attach it. At this

time, check that the pawl on the back side of the SPF rear

cover is inserted into the copier frame.

<2> Reattach the right glass holder to its original position and fix it

using the screw.

Note: Check that the actuator moves smoothly.

Take care to prevent entry of dirt into the scanner unit.

2

1

7) Attach the hinge guides L and R.

Attach the hinge guides L and R by fitting the pawls (two for each)

into the frame of the copier and secure them with the two screws

for each that have been removed in step 3.

9) Connect the SPF with the copier using the relay harness.

<1> Fit the snap band to the position shown in the illustration.

<2> Connect the connector.

<3> Fit the grounding terminal using the supplied screw (M3

1

3

10) Attach the rear cabinet.

Remove the rib from the rear cabinet.

Note: While pushing down the actuator of the sensor unit, attach

the rear cabinet so that the actuator is inserted into the hole

of the rear cabinet.

<1> Hang the four pawls shown in the illustration below on the

plate.

<2> Push down the actuator of the sensor unit.

<3> Position the cabinet to the upper screw positions.

<4> Ensure that the actuator is inserted into the square hole of

the cabinet.

2

× 8).

Pawls

8) Place the SPF on the copier.

Pawls

Side view

Pawl

M3×8

Pawl

M3×8

M4×12

AR-SP5 UNPACKING AND INSTALLATION 2 - 2

Page 5

11) Attach the cover to the rear cabinet.

<1> Align the arrow marks as shown in the illustration.

<2> Then slide the cover to the left.

<3> Secure the cover with a screw.

17) Check the copy ratio, and then check the center displacement and

leading edge image void.

Place an original on the document glass and make a copy.

Then, place an original in the document feeder tray and make a

copy.

If the center of the copy from the document glass is displaced from

the copy from the document feeder, adjust the center referring to

the service manual.

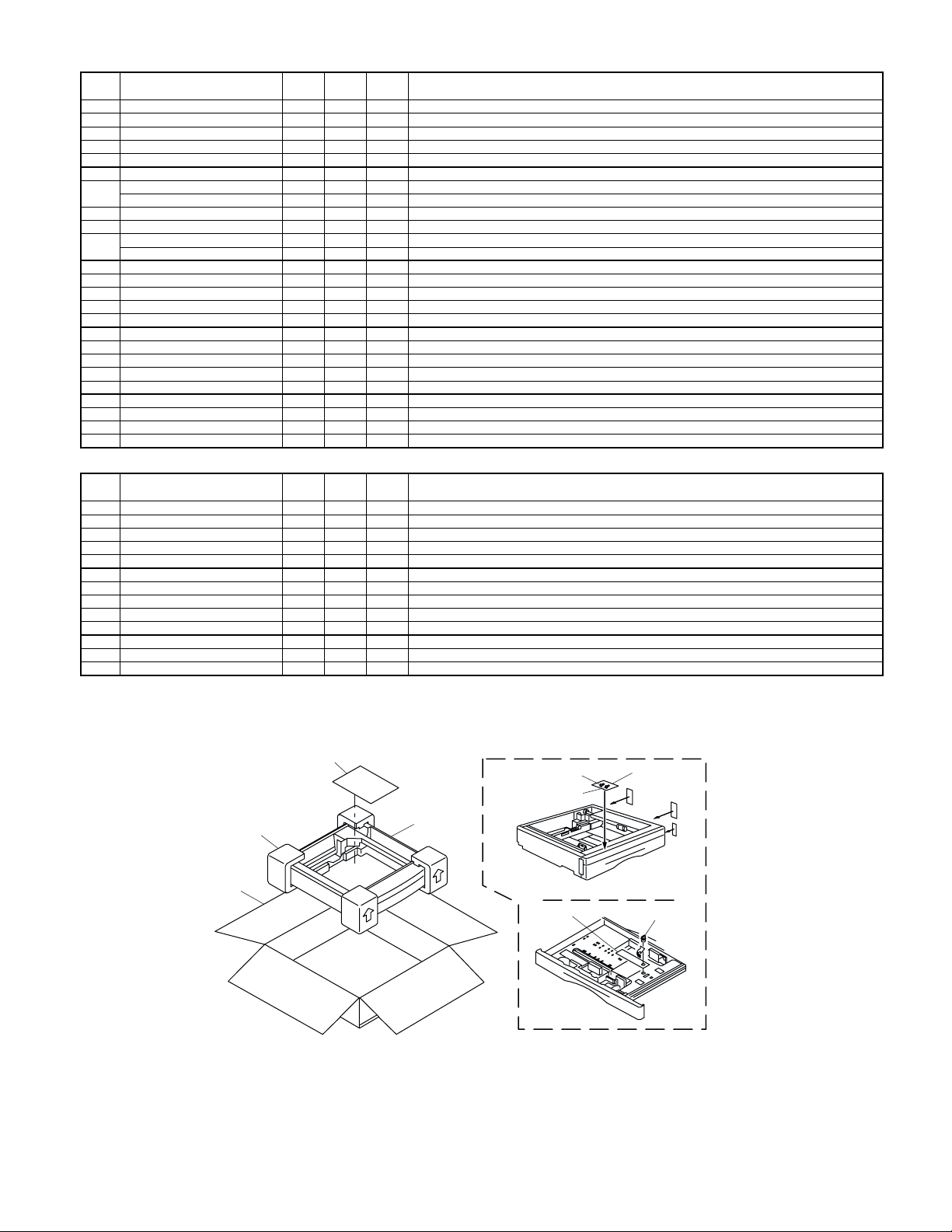

2. AR-D16 Installation Manual

•

Parts included

12) Attach the SPF to the copier.

Attach the SPF by inserting the hinge guide sections of the SP5

into the hinge guides L and R.

1

2

2

13) Insert the power plug into the outlet and turn the main switch of the

copier to the “ON” position.

14) Perform SIM setting.

Execute simulation [2] of [26] and enter [1].

15) Check the ON/OFF operation of the open detection sensor.

Execute simulation [2] of [2] and check that the indicator on the

operation panel lights up and goes out by opening and closing the

SPF.

• Screws (M4 × 16), 4 pcs.

Turn the main switch to the “OFF” position and remove the power plug

from the outlet.

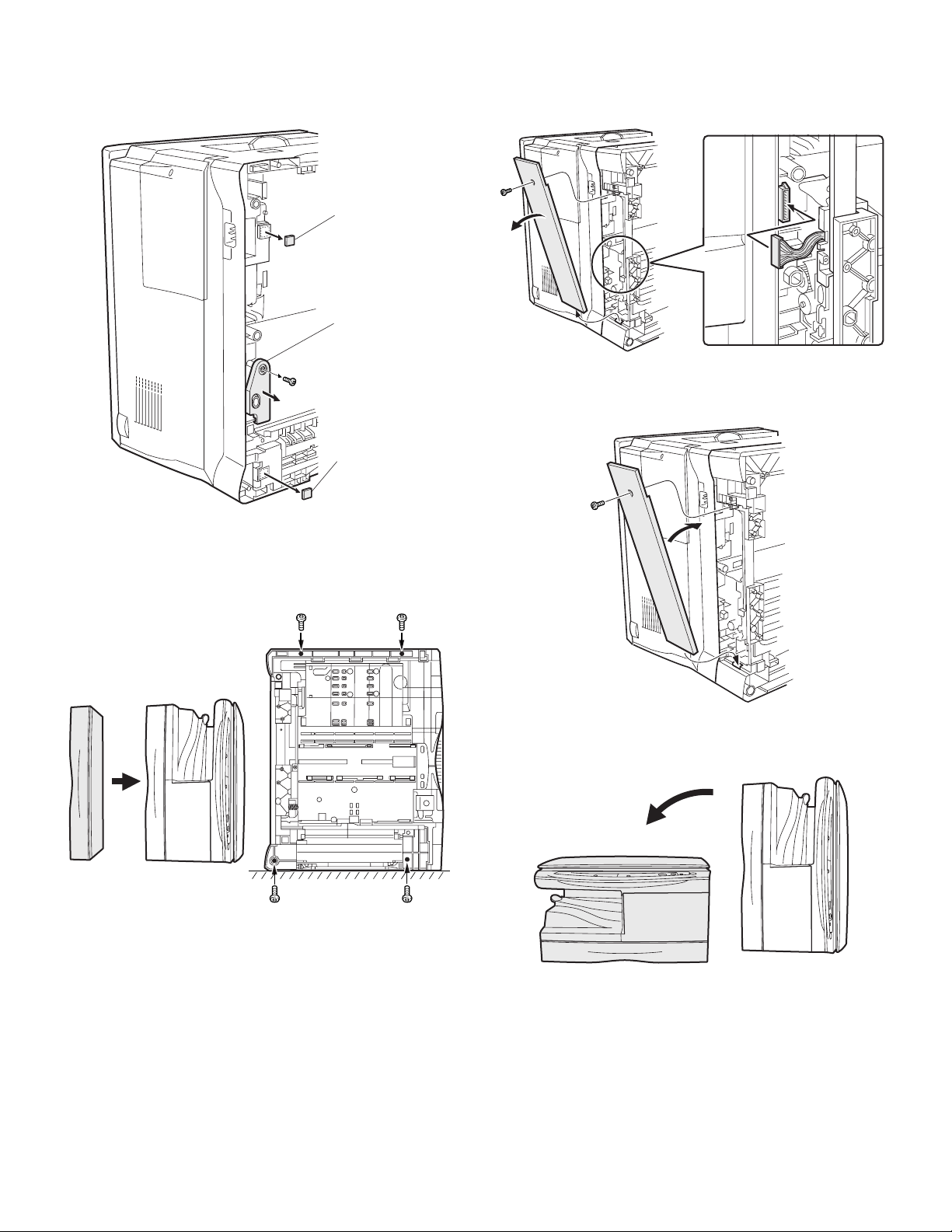

1) Remove the DV cartridge and the drum cartridge from the copier.

Open the tray, the side door, and the front cabinet, and then

remove the DV cartridge and the drum cartridge.

Note: Be sure to carry out the operation in the order of (1), (2), (3),

and (4).

1

4

3

2

2) Make the copier upright.

Close the front cover, side cover, and bypass tray, and then make

the copier upright in the orientation shown in the illustration.

16) Carry out automatic adjustment of SPF scanning position.

Execute simulation 53-08 to carry out automatic adjustment of

SPF scanning position.

For details, see the service manual.

AR-SP5 UNPACKING AND INSTALLATION 2 - 3

Page 6

3) Remove the OP gear cover and rubber feet from the bottom of the

copier.

Remove the screw and remove the OP gear cover.

Then, take off and remove the rubber feet.

Rubber foot

OP gear cover

Rubber foot

5) Remove the rear cover and connect the connector.

Remove the screw and remove the rear cover.

Then, connect the connector of the second cassette unit to that of

the copier.

6) Attach the rear cover.

Attach the rear cover to its original position and secure it with the

screw (M4

× 12).

4) Install the second cassette unit to the copier.

If the second cassette unit is aligned to the copier, it can be posi-

tioned automatically.

Hold the copier lightly to prevent it from toppling down and secure

the second cassette unit with four screws (M4

× 16).

7) Return the copier to the normal orientation.

When returning the copier to the normal orientation, gently return it

without giving a shock.

AR-SP5 UNPACKING AND INSTALLATION 2 - 4

Page 7

8) Insert the drum cartridge and the DV cartridge into the copier.

Open the tray, the side door, and the front cabinet, insert the drum

cartridge and the DV cartridge, and then close the front cabinet,

the side door, and the tray.

Note: Be sure to carry out the operation in the order of (1), (2), (3),

and (4).

11) Load paper into the paper tray.

When loading paper, do not exceed the maximum height line.

3

1

2

9) Remove the paper tray lock for packing.

Remove the paper tray lock for packing that secures the turning

plate in the paper tray by rotating it in the direction of the arrow and

store it in the specified position.

10) Set the paper tray side guide.

Squeeze the lever of the paper tray side guide to slide the guide to

the position for the paper size to be used.

4

12) Insert the power plug into the outlet and turn the main switch to the

“ON” position. Then, perform the following procedure.

13) Perform SIM setting.

Execute simulation [3] of [26] and enter [1].

14) Check the center displacement.

Place an original on the document glass and make a copy using

the tray in the copier.

Then, make a copy using the tray in the installed optional paper

feed unit.

If the center of the copy from the optional paper feed unit is dis-

placed from the copy from the tray in the copier, adjust the center

referring to the service manual.

3. AR-PG2/AL-12PKM

A. Installation Manual

• Parts included

• Printer board ... 1

(AR-PG2)

• Screws ... 5

• Software CD-ROM ... 1

AR-SP5 UNPACKING AND INSTALLATION 2 - 5

• Printer board ... 1

(AL-12PKM)

• Core ... 1

• Cable ... 1

(AL-12PKM only)

• Screwdriver ... 1

(AL-12PKM only)

• Installation manual ... 1

Page 8

Turn the main switch to the “OFF” position and remove the power plug

from the outlet.

1) Removing the cabinet cover.

<1> Ensure that the power switch on the unit is in the off position.

Remove the power cord from the power cord socket at the

rear of the unit.

<2> Remove the screw from the cabinet cover at the rear side of

the unit using the supplied screwdriver.

<3> Slide the cabinet cover in the direction indicated by the arrow

and pull the cover while raising it a little to remove it.

<4> Secure the printer board using the supplied five screws.

<5> Insert the cable into the printer board connector, with the side

with the blue parts facing right.

(AL-12PKM)

Printer board

connector

Blue parts

<6> Insert the core through to the middle position of the cable.

(AL-12PKM)

2) Installing the printer board.

<1> Remove the printer board from the protective bag.

<2> Insert the core as shown in the illustration.

<3> Install the printer board so that the parallel interface connec-

tor of the board is fitted into the hole for the connector.

(AR-PG2)

Hole for the

connector

Core

(AL-12PKM)

Hole for the

connector

<7> Connect the board cable to the connector of the unit.

3) Replace the cabinet cover.

<1> Bend the end of the cabinet cover at the slit and break it off.

Caution: Take care in handling the cabinet cover because the

exposed edge could be sharp and may injure your

hands.

<2> Secure the cabinet cover using the screw which has been

removed.

AR-SP5 UNPACKING AND INSTALLATION 2 - 6

Page 9

B. Installing the software

The following term is used in this section.

MFP

Means the unit as a printer and scanner.

• For this description, it is assumed that the mouse is configured for

right hand operation.

• To print or scan, the MFP must be in the online state.

• The scanner feature only works when using a USB interface cable.

• If any error message appears, solve the problem following the

instructions on the screen. After your problem is solved, the installing

procedure will be continued. Depending on your problem, you may

have to exit the installer. In this case, click the "Cancel" button to exit

the installer. After solving your problem, reinstall the software from

the beginning.

(1) Windows XP (USB/parallel interface)

Before starting the installation, make sure the USB or parallel interface

cable is not connected to the MFP.

1) Insert the supplied CD-ROM into your CD-ROM drive.

2) Click the "start" button, click "My Computer", and then double-click

the CD-ROM icon.

• When any of "Found New Hardware Wizard" messages appear

during the software installation, be sure to click the "Cancel" button.

3) Double-click the "Setup" icon.

If the language selection screen appears after you double click the

"Setup" icon, select the language you wish to use and click the

"Next" button. (Normally, the correct language is selected automatically.)

4) Select the software packages to be installed, and then click the

"Next" button.

The software packages with checkmark on the list on the screen

will be installed.

Click the "Display README" button to show the information on the

selected package.

5) Review the software packages to be installed on the screen, and

then click the "Start" button.

The software packages to be installed will be displayed on the

screen. If inappropriate packages are displayed, click the "Back"

button to select appropriate packages again.

6) Copying files for MFP driver installation and parallel interface setup

(This step will start if it was selected in step 4).

1. After confirming the message in the "Welcome" window, click

the "Next" button.

2. A dialog box appears asking you to verify that the USB or par-

allel interface cable is not connected to the MFP. Make sure

that the interface cable is not connected and click the "Next"

button.

3. Click the "Next" button in the dialog box to install the MFP

driver or Cancel to quit the installation.

The setup program will start to copy the files.

If the following screen appears while the files are being copied

(the message may appear more than once), click "Continue

Anyway".

• If you are using the parallel interface connection, do not select

the Button Manager checkbox because this feature is not supported with the parallel interface.

• If the following screen appears, click the "OK" button. Review

the contents in "BEFORE INSTALLATION", and then select only

appropriate the software packages to be installed.

4. When the "The MFP driver installation is complete." dialog box

appears, click the "OK" button.

The Button Manager installer will start.

7) Begin installation of the Button Manager (This step will start if it

was selected in step 4).

1. After confirming the message in the "Welcome" window, click

the "Next" button.

2. Read the message in the "Please read the following informa-

tion." window, and then click the "Next" button.

3. When a message appears that lets you specify the location for

the software to be installed, click the "Next" button.

4. If the program displays, "Do you want the Button Manager

added to Windows Startup?", check "Yes" and click the "OK"

button.

The setup program will start to copy the files.

5. Click the "Finish" button when the message informs you that

setup is successful.

The Sharpdesk installer will start.

8) Begin installation of the Sharpdesk (This step will start if it was

selected in step 4).

1. After confirming the message in the "Welcome to Sharpdesk

installation" window, click the "Next" button.

2. Read the message in the "Information" window, and then click

the "Next" button.

3. When the "Choose Destination Location" window appears,

click the "Next" button.

AR-SP5 UNPACKING AND INSTALLATION 2 - 7

Page 10

4. When the "Select Program Folder" window appears, click the

"Next" button.

The setup program will start to copy the files.

If the dialog box asking "If you have TIFF files saved using

Photo-Shop or Imaging for Windows you should hit Skip"

appears. Answer the question to continue the Sharpdesk

installation.

5. Click the "Finish" button when the message informs you that

Setup is complete.

9) Click the "Close" button when the message informs you that

"Setup has finished". When the "Now connect the MFP interface

cable to the PC" dialog box appears, click the "OK" button.

• After the installation, a message to restart your computer may be

displayed. In this case, click the "Yes" button to restart your computer.

• For parallel interface connection ensure that your computer and

MFP are turned off before connecting the cable.

(2) Windows 98/Me/2000 (USB interface)

Before starting the installation, make sure the USB interface cable is

not connected to the MFP.

1) Insert the supplied CD-ROM into your CD-ROM drive.

2) Double-click "My Computer", and then double-click the CD-ROM

icon.

• When any of "Hardware Found", or "Found New Hardware Wiz-

ard" messages appear during the software installation, be sure

to click the "Cancel" button.

3) Double-click the "Setup" icon.

• If the language selection screen appears after you double click

the "Setup" icon, select the language you wish to use and click

the "Next" button. (Normally, the correct language is selected

automatically.)

4) Select the software packages to be installed, and then click the

"Next" button.

The software packages with checkmark on the list on the screen

will be installed. Click the "Display README" button to show the

information on the selected package.

10) Connect the USB interface cable or parallel interface cable (see

page 5-8).

Windows will detect the MFP and the Plug and Play screen will

appear. If you are using Windows XP with the parallel interface, go

to step 12.

11) Begin installation of the scanner driver.

1. "SHARP AL-xxxx" (where xxxx is the model name of your

MFP) will appear in the "Found New Hardware Wizard" dialog

box. Select "Install the software automatically (Recommended)" and click the "Next" button.

2. The "Install hardware" dialog box will appear. Click the "Con-

tinue Anyway" button.

3. When installation of the driver is completed, click the "Finish"

button to finish the scanner driver installation.

12) Begin installation of the printer driver.

1. "SHARP AL-xxxx" (where xxxx is the model name of your

MFP) will appear in the "Found New Hardware Wizard" dialog

box. Select "Install the software automatically (Recommended)" and click the "Next" button.

2. The "Hardware Installation" dialog box will appear. Click the

"Continue Anyway" button.

3. When installation of the driver is completed, click the "Finish"

button to finish the printer driver installation.

You have completed the installation of all the software.

• If the following screen appears, click the "OK" button. Review

the contents in "BEFORE INSTALLATION", and then select the

appropriate driver software packages to be installed.

5) Review the software packages to be installed on the screen, and

then click the "Start" button.

The software packages to be installed will be displayed on the

screen. If inappropriate packages are displayed, click the "Back"

button to select appropriate packages again.

6) Copying files for MFP driver installation.

1. After confirming the message in the "Welcome" window, click

the "Next" button.

2. A dialog box appears asking you to verify that the interface

cable is not connected to the MFP. Make sure that the interface cable is not connected and click the "Next" button.

3. Click the "Next" button in the dialog box showing the files to be

copied for installation of the MFP driver.

The setup program will start to copy the files.

In Windows 2000, if the following screen appears while the

files are being copied (the message may appear more than

once), click "Yes" in Windows 2000.

AR-SP5 UNPACKING AND INSTALLATION 2 - 8

Page 11

4. The following screen appears when all of the files for the USB

interface connection have been copied. If you are not using a

parallel interface cable for connection to the MFP, please click

the "No" button.

5. When the "The MFP driver installation is complete." dialog box

appears, click the "OK" button.

The Button Manager installer will start.

7) Begin installation of the Button Manager (This step will start if it

was selected in step 4).

1. After confirming the message in the "Welcome" window, click

the "Next" button.

2. Read the message in the "Please read the following informa-

tion." window, and then click the "Next" button.

3. When a message appears that lets you specify the location for

the software to be installed, click the "Next" button.

4. If the program displays, "Do you want to add Button Manager

to Startup program?", check "Yes" and click the "OK" button.

The setup program will start to copy the files.

5. Click the "Finish" button when the message to inform you of

the completion of the installation appears.

The Sharpdesk installer will start.

8) Begin installation of the Sharpdesk (This step will start if it was

selected in step 4).

1. After confirming the message in the "Welcome to Sharpdesk

installation" window, click the "Next" button.

2. Read the message in the "Information" window, and then

click the "Next" button.

3. When the "Choose Destination Location" window appears,

click the "Next" button.

4. When the "Select Program Folder" window appears, click the

"Next" button.

The setup program will start to copy the files.

If the dialog box asking "If you have TIFF files saved using

Photo-Shop or Imaging for Windows you should hit Skip"

appears. Answer the question to continue the Sharpdesk

installation.

9) Click the "Close" button when the message to inform you of the

completion of the installation appears. When the "Now connect the

MFP interface cable to the PC. This will finalize the drivers installation and settings." dialog box appears, click the "OK" button.

• After the installation, a message to restart your computer may be

displayed. In this case, click the "Yes" button to restart your computer.

10) Connect the USB interface cable (see page 5-8).

Windows will detect the MFP and the Plug and Play screen will

appear.

11) Follow the instructions in the Plug and Play screen that appears in

your version of Windows to begin the installation.

You have completed the installation of the software.

(3) Windows 95/98/Me/NT4.0/2000 (Parallel interface)

Before starting the installation, make sure the USB or parallel interface

cable is not connected to the MFP.

1) Insert the supplied CD-ROM into your CD-ROM drive.

2) Double-click "My Computer", and then double-click the CD-ROM

icon.

• When any of "Hardware Found", or "Found New Hardware Wiz-

ard" messages appear during the software installation, be sure

to click the "Cancel" button.

3) Double-click the "Setup" icon.

• If the language selection screen appears after you double click

the "Setup" icon, select the language you wish to use and click

the "Next" button. (Normally, the correct language is selected

automatically.)

4) Select the software packages to be installed, and then click the

"Next" button.

The software packages with checkmark on the list on the screen

will be installed.

Click the "Display README" button to show the information on the

selected package.

5. Click the "Finish" button when the message to inform you of

the completion of the installation appears.

AR-SP5 UNPACKING AND INSTALLATION 2 - 9

• In Windows 95/NT 4.0, "Button Manager" does not appear. In

Windows 98/Me/2000, do not select the "Button Manager"

checkbox. because this is not supported when using the parallel

interface.

5) The next screen appears. Make sure that the parallel interface

cable is not connected, and click "OK".

Windows 95/NT 4.0 Windows 98/Me/2000

Page 12

6) Check the contents of the package on the screen, and then click

the "Start" button.

The software packages to be installed will be displayed on the

screen. If inappropriate packages are displayed, click the "Back"

button to select only appropriate software packages.

7) Copying files for MFP driver installation and parallel interface setup

(This step will start if it was selected in step 4).

1. After confirming the message in the "Welcome" window, click

the "Next" button.

2. A dialog box appears asking you to verify that the USB or par-

allel interface cable is not connected to the MFP. Make sure

that the interface cable is not connected and click the "Next"

button.

3. Click the "Next" button in the dialog box to install the MFP

driver or Cancel to quit the installation.

The setup program will start to copy the files.

In Windows 2000, if the following screen appears while the

files are being copied (the message may appear more than

once), click "Yes" in Windows 2000.

4. The following screen appears. Click the "Yes" button, and then

the Model screen will appear. Select the model number that is

the same as the model name of your MFP and click the "Next"

button.

Be sure to select the displayed model number that is the same

as the MFP's model name. If they are not the same, the driver

will not be installed correctly.

8) Begin installation of the Sharpdesk (This step will start if it was

selected in step 4).

1. After confirming the message in the "Welcome to Sharpdesk

installation" window, click the "Next" button.

2. Read the message in the "Information" window, and then click

the "Next" button.

3. When the "Choose Destination Location" window appears,

click the "Next" button.

4. When the "Select Program Folder" window appears, click the

"Next" button.

The setup program will start to copy the files.

If the dialog box asking "If you have TIFF files saved using

Photo-Shop or Imaging for Windows you should hit Skip"

appears. Answer the question to continue the Sharpdesk

installation.

5. Click the "Finish" button when the message to inform you of

the completion of the installation appears.

9) Click the "Close" button when the message to inform you of the

completion of the installation appears.

5. Establish the printer settings and click the "Next" button.

Select "LPT1" for the port to be used. If "LPT1" does not

appear, it is likely that another printer or peripheral device is

using "LPT1". Check your other printers and peripheral

devices, and change the port setting as needed so no device is

using "LPT1". If you wish the MFP to be your default printer,

select "Yes". If not, select "No".

6. When the "Setup has completed gathering all necessary installation information" dialog box appears, click the "Yes" button.

The parallel interface driver is installed.

7. When the "The MFP driver installation is complete." dialog box

appears, click the "OK" button.

The Sharpdesk installer will start.

• After the installation, a message to restart your computer may be

displayed. In this case, click the "Yes" button to restart your computer.

10) Connect the parallel interface cable.

You have completed the installation of all the software.

• For parallel interface connection ensure that your computer and

MFP are turned off before connecting the cable (see page 5-8).

AR-SP5 UNPACKING AND INSTALLATION 2 - 10

Page 13

[3] AR-SP5

1. Operational descriptions

A. Outline

The SPF (Single Path Feeder) is installed to the AR-153E as a standard provision, and it automatically copies up to 30 sheets of documents of a same

size. (Only one set of copies)

B. Document transport path and basic composition

(1) Pickup roller (2) Sheet of document for paper feed (3) Set detection ACT

(4) Paper stopper (5) Document feed roller (6) Separation sheet

(7) Paper entry sensor (8) PS roller D (9) Transport follower roller

(10) Paper exit roller (11) Paper exit follower roller (12) Document tray

C. Operational descriptions

Time chart (Tray feed)

Document set

(Copier side)

MM rotation

CPFS ON

PPD ON

RRC ON

(Transfer)

(Fusing)

POD ON

SPID ON

Document feed unit lamp ON

PSW ON

MIRM rotation

Main motor rotation

Paper feed

Synchronization

Paper transport

Document set sensor

Copy start

The scanner is shifted

to the exposure position.

(SPF side)

SPFM rotation

SPUS ON

SPPD ON

(Exposure)

(Document exit)

SPF motor rotation

Document feed

Document transport sensor

Document transport

(Paper exit)

In the zooming mode, the magnification ratio in the sub

scanning direction (paper transport direction) is adjusted

by changing the document transport speed.

AR-SP5 AR-SP5 3 - 1

Page 14

D. Cases where a document jam is caused

a. When SPPD is ON (document remaining) when the power is turned on.

b. When SPPD is not turned ON within about 1.5 sec (at 100% copy) after starting the document feed operation.

c. When SPPD is not turned on within about 4.7 sec (at 100% copy) after turning on SPPD.

d. When the SPF document jam release door or the OC cover is opened during document transport (SPF motor rotating).

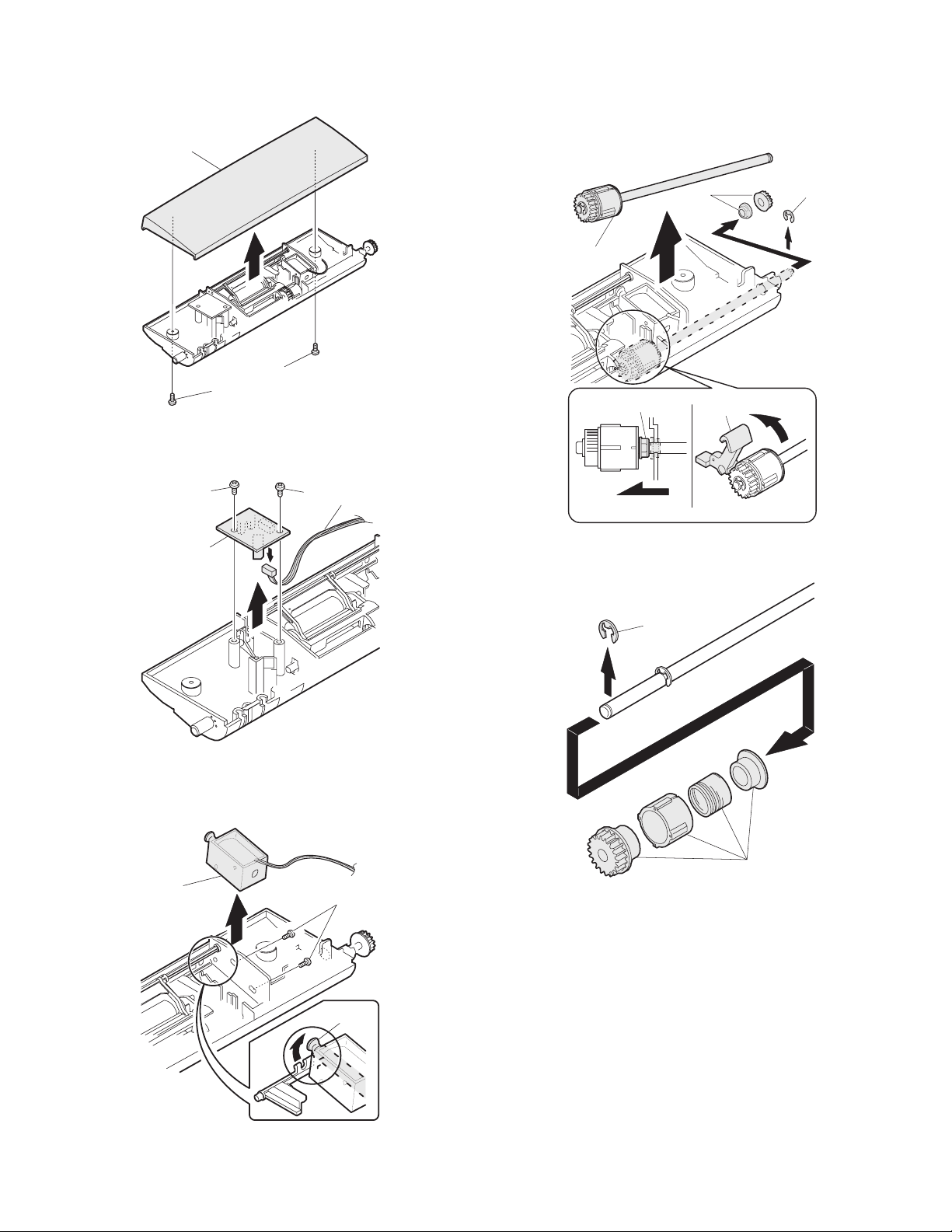

2. Disassembly and assembly

No. Part name Ref.

A Sensor PWB

B Pickup solenoid

C Clutch

D Manual paper feed roller, pickup roller

EBelt

F SPF motor

G Paper entry sensor

H PS roller

I Paper exit roller

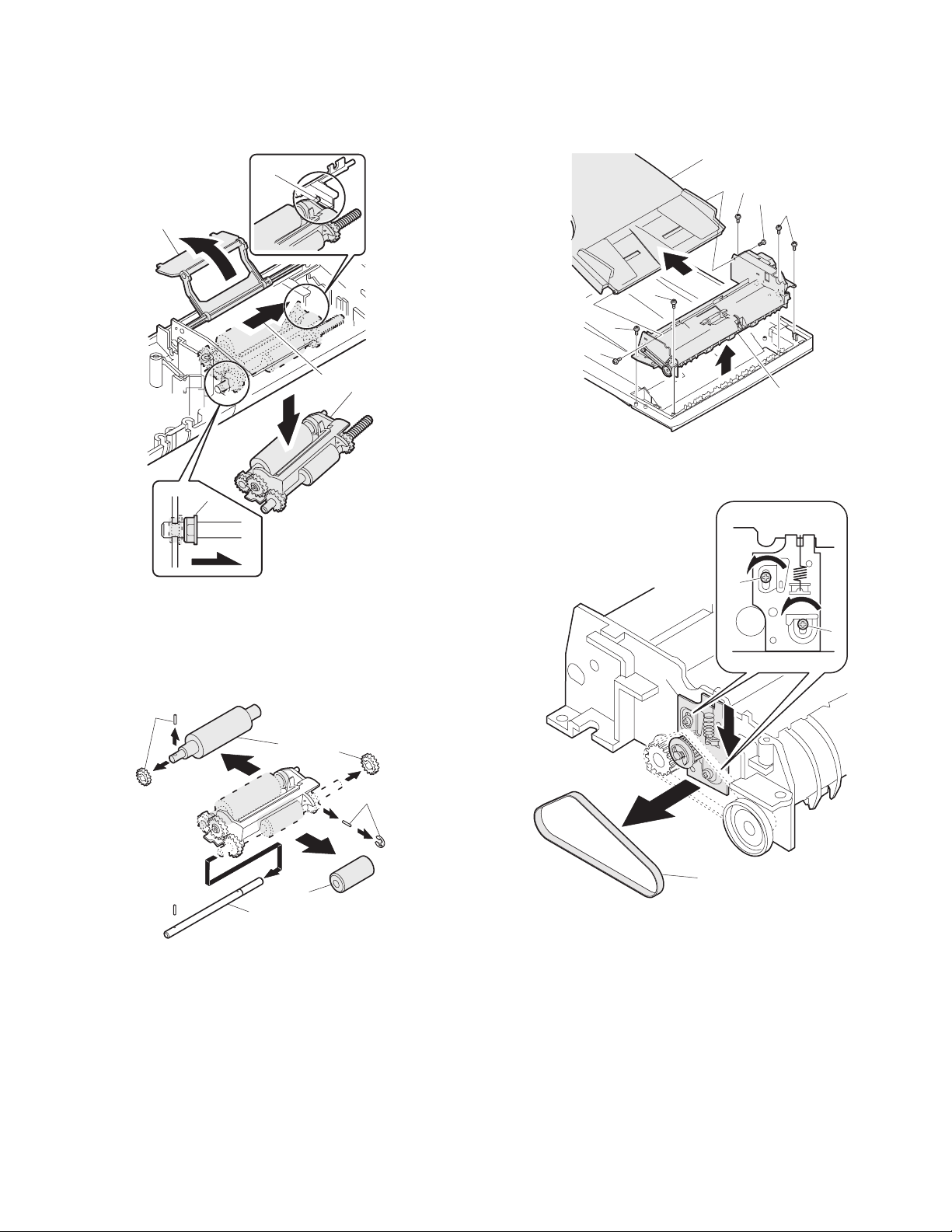

Pickup unit removal

1) Remove three fixing pawls from the bottom of the machine.

2) Remove the front cover and the rear cover.

2

2

1) Remove the belt, the paper feed frame Spring, and two harnesses.

2) Remove the pickup unit.

1

1

2

3

4

3

1

1

1

* When installing the parts, be careful of the hole position of the paper

frame Spring.

AR-SP5 AR-SP5 3 - 2

Page 15

A. Sensor PWB

1) Remove two screws from the bottom of the pickup unit.

2) Remove the upper cover.

2

C. Clutch

1) Remove the E-ring.

2) Remove the pulley and bush.

3) Slide the bush in the arrow direction.

4) Lift the clutch, and 5) remove the clutch.

1

1) Remove two screws.

2) Remove the sensor PWB.

3) Remove the harness.

1

2

2

1

5

1

3

1

3

1) Remove the E-ring.

2) Remove the parts.

1

4

B. Pickup solenoid

1) Remove two screws.

2) Remove the pickup solenoid

2

* When installing, hang iron core A on the solenoid arm.

1

A

2

AR-SP5 AR-SP5 3 - 3

Page 16

D. Manual paper feed roller, pickup roller

1) Lift the paper stopper.

2) Slide the take-up roller unit.

3) Slide the bushing in the direction of the arrow.

4) Remove the take-up roller unit.

A

1

2

4

3

Transport unit removal

1) Remove two screws.

2) Remove the document tray unit.

3) Remove five screws.

4) Remove the transport unit.

3

3

1

E. Belt

1) Remove the belt.

2

3

1

3

4

* When installing the take-up roller, hang the projection of the take-up

roller unit on the solenoid arm.

1) Remove the parts.

2) Remove the manual paper feed roller.

3) Remove the pickup roller.

4) Remove the parts.

4

3

1

1

1

2

1

1

2

3

AR-SP5 AR-SP5 3 - 4

Page 17

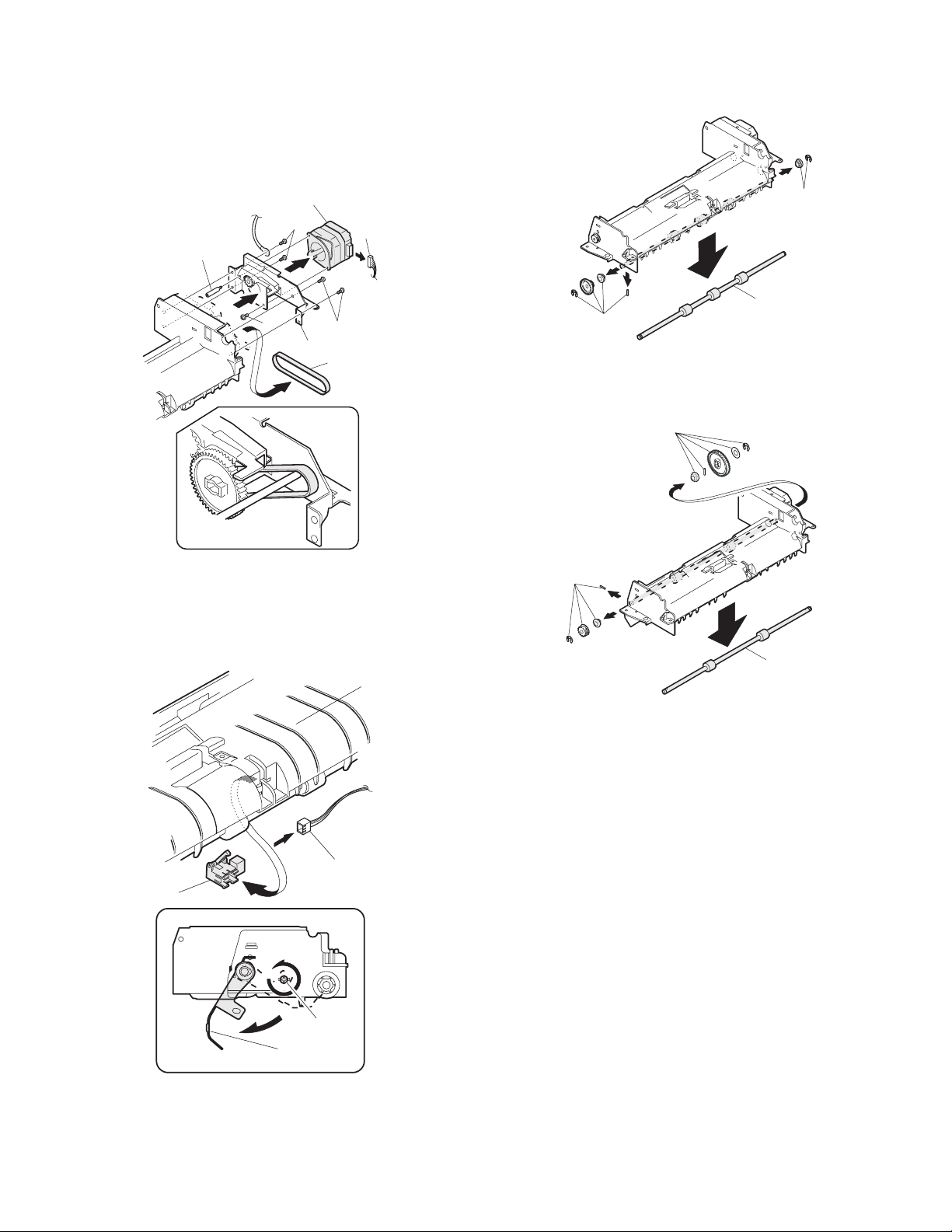

F. SPF motor

1) Remove the harness.

2) Remove four screws.

3) Remove the drive unit.

4) Remove the belt.

5) Remove two screws.

6) Remove the SPF motor.

H. PS roller

1) Remove the parts.

2) Remove the paper supply roller.

5

G. Paper entry sensor

1) Loosen the screw.

2) Open the paper exit paper guide.

3) Remove the paper entry sensor.

4) Remove the harness.

6

2

1

1

2

5

2

3

4

I. Paper exit roller

1) Remove the parts.

2) Remove the paper exit roller.

1

1

1

2

4

3

1

2

AR-SP5 AR-SP5 3 - 5

Page 18

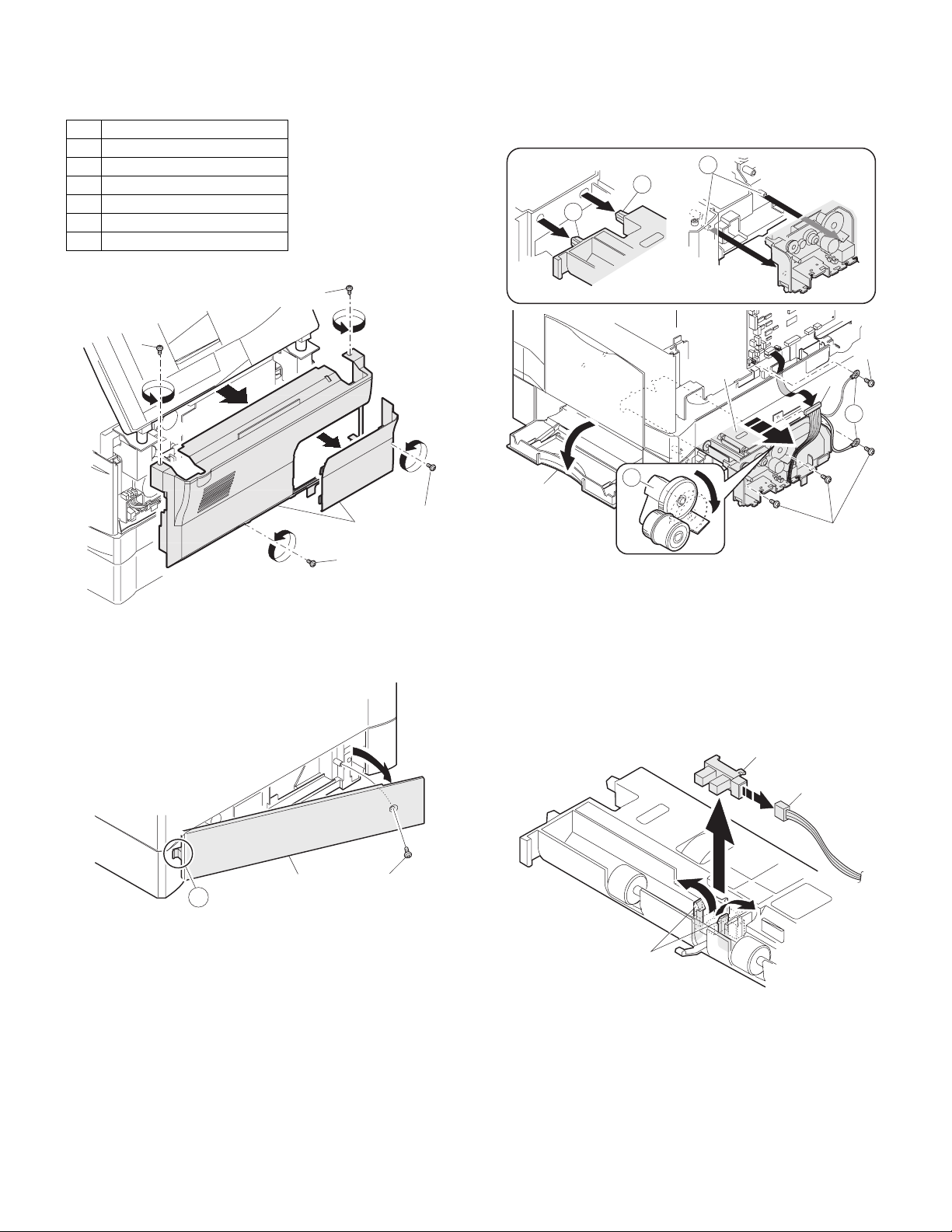

[4] AR-D16

1. Disassembly and assembly

No. Part name Ref.

A Paper sensor

B Cassette detection SW

C Paper feed solenoid

D Transport roller

E Paper feed clutch

F 2nd paper feed roller

Paper feed unit removal

1)

1) Open the right cabinet.

2) Remove three screws.

3) Remove one connector from MCU.

4) While tilting down the 2nd connection arm A, pull and remove the

paper feed unit toward you.

C

D

D

1)

2)

1)

1) Remove the screw.

2) Remove the rear cover.

* When installing, engage the pawl and install the unit.

2

4

3

B

1

1)

A

2

* When installing, securely insert two bosses C on the machine side

and two bosses D on the paper feed unit side. Be sure to secure the

ground wire B.

* Insert the 2nd page feed.

A. Paper sensor

1) Remove the pawl.

2) Remove the paper sensor.

3) Remove the harness.

2

3

2

1

A

1

AR-SP5 AR-D16 4 - 1

Page 19

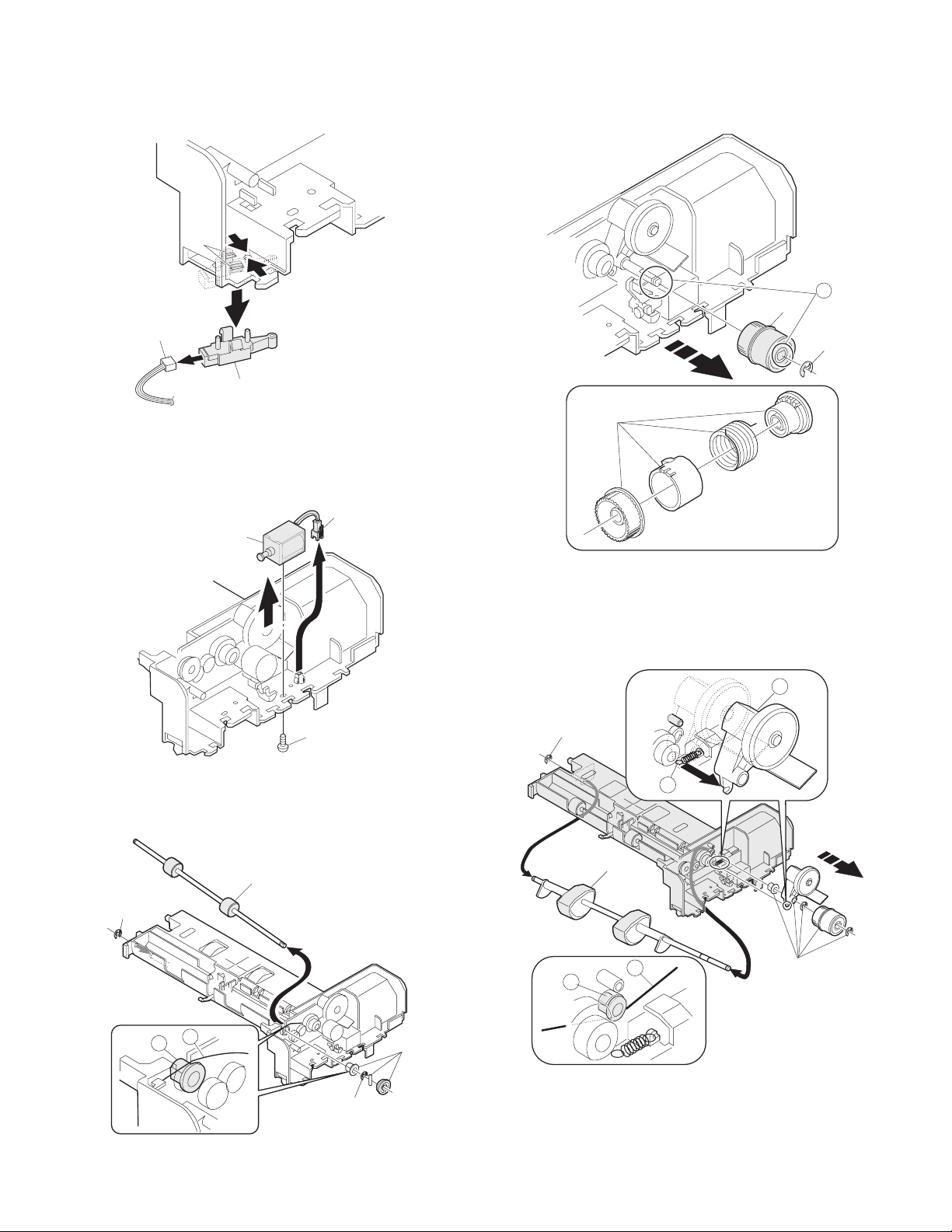

B. Cassette detection switch

1) Remove the pawl.

2) Remove the cassette detection switch.

3) Remove the harness.

1

3

2

E. Paper feed clutch

1) Remove the E-ring.

2) Remove the paper feed clutch.

3) Remove the parts.

A

2

1

C. Paper feed solenoid

1) Remove the screw.

2) Remove the connector.

3) Remove the paper feed solenoid.

3

D. Transport roller

1) Remove two E-rings.

2) Remove the transport roller.

4

3

2

* When installing, fit the cut surface A.

F. 2nd paper feed roller

1) Remove the E-ring and the parts.

2) Remove the 2nd paper feed roller.

A

1

1

B

2

1

A

B

3

2

* Install so that the earth spring A is brought into contact over bearing

B.

AR-SP5 AR-D16 4 - 2

D

C

* When installing, hang the 2nd connection arm on the 2nd

connection arm Spring B. Be sure to install so that the earth spring

C is in contact under the bearing D.

1

Page 20

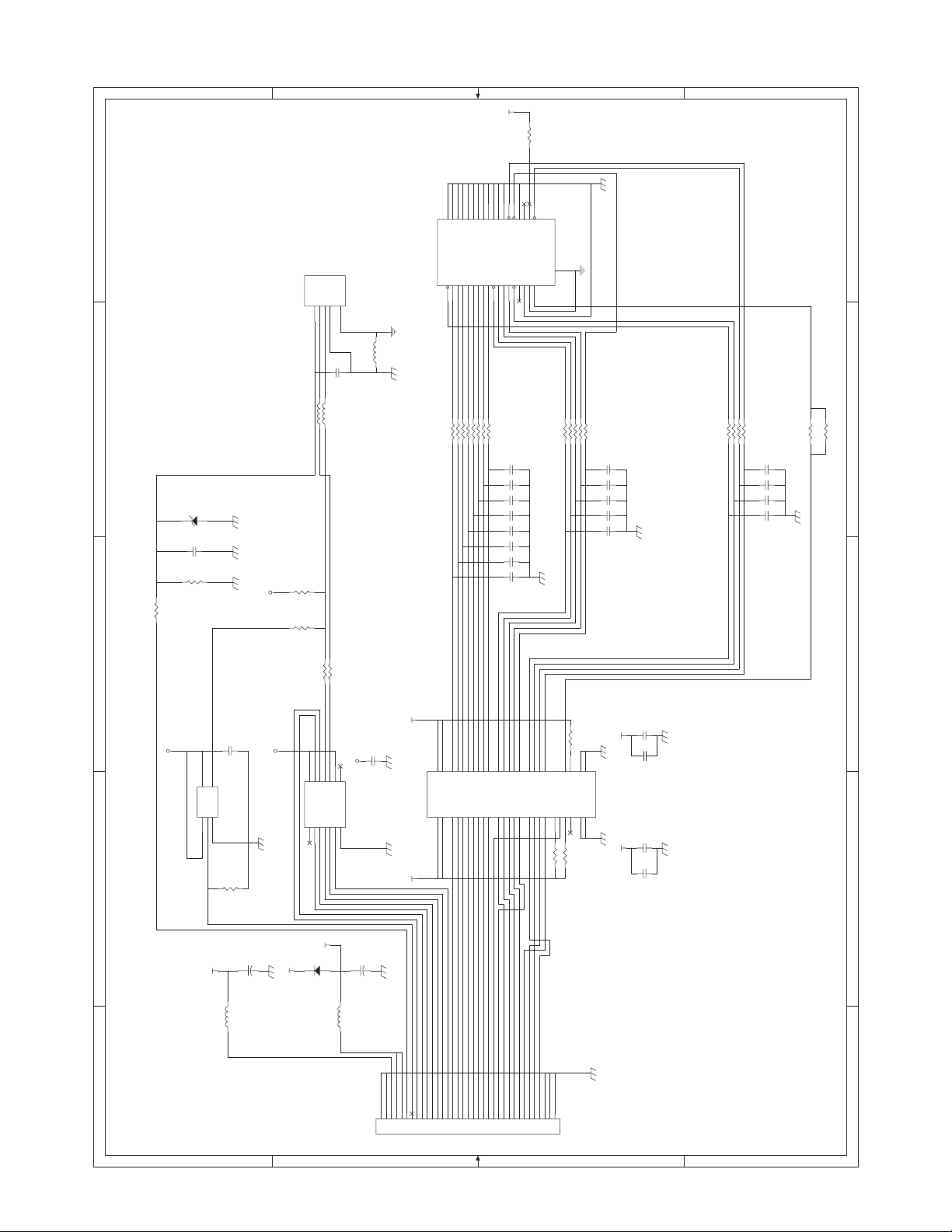

[5] AR-PG2

1. Electrical section

A. I/F circuit

(1) General

The I/F circuit is composed of the USB driver and the IEEE1284 driver,

and performs hard interface with the ASIC (MCU PWB).

(2) USB circuit

With the USB driver, the differential signals (analog) of USB are

converted into digital signal, which are sent to the ASIC. In the reverse

procedure, interface between the ASIC (engine) and the host is

performed.

D+

USB driver

ASIC

OE, RCV, VP, VM

Suspend, VMO

VPO

IC401

D-

(3) IEEE1284 circuit

The IEEE1284 driver is used to perform interface between the ASIC

(engine) and the host.

IEEE1284

driver

ASIC

IC403

USB

connector

Centronics

connector

2. Interface

A. PARALLEL INTERFACE

This printer uses a bi-directional parallel interface. Use the supplied

interface cable.

Connector

36-pin DDK 57LE-40360-730B (D29) female connector or equivalent

connector

Cable

Shielded type bi-directional parallel interface

For best results,, use a printer interface cable which is IEEE1284

compliant.

Pin configuration

The pin numbers and signal names are listed in the following table.

Pin

No.

1STB

Signal name

Pin

No.

Signal name

19 GND (STB RET)

2 DATA1 20 GND (DATA1 RET)

3 DATA2 21 GND (DATA2 RET)

4 DATA3 22 GND (DATA3 RET)

5 DATA4 23 GND (DATA4 RET)

6 DATA5 24 GND (DATA5 RET)

7 DATA6 25 GND (DATA6 RET)

8 DATA7 26 GND (DATA7 RET)

9 DATA8 27 GND (DATA8 RET)

10 ACKNLG

28 GND (ACKNLG RET)

11 BUSY 29 GND (BUSY RET)

12 PE (Paper End) 30 GND (PE RET)

13 SLTC 31 INPRM

14 AUTO LF

32 FAULT

15 (NC) 33 (NC)

16 GND (0 V) 34 (NC)

17 FG 35 +5 V

18 +5 V 36 SLTC IN

B. USB INTERFACE

Connector

4-pin DDK DUSB-BRA42-T11

Type-B connector

Cable

Shielded twisted pair cable

(2 m (6 feet) Max.: high-speed transmission equivalent)

Pin configuration

The pin numbers and signal names are listed in the following table.

Pin No. Signal name

1+5V

2–DATA

3+DATA

4GND

2

1

18

1

36 19

34

AR-SP5 AR-PG2 5 - 1

Page 21

3. Circuit diagram

5V2

3.3KJ

R420

E

31

34

36

32

30

26

27

28

20

21

D-GND

D-GND

Data 02Data 1

3

22

23

D-GND

D-GND

Data 2

4

5

Data 3

25

D-GND

D-GND

D-GND24D-GND

Data 5

Data 6

Data 46Data 7

7

8

9

29

D-GND

/ACK10BUSY11PE

D-GND

D-GND

12

/INIT

13

33

NC

D-GND

/FAULT

SG

NC15SLCT

/AUTO FD

16

14

35

HLHIN

FG

17

/SLCT IN

Shield

PLHOUT

18

IEEE1284_CN

F.G

+5V1D-2D+3GND4Shield

CN402

USB_CN

CN401

19

D-GND

/D STB

1

E

F.G

L405

C403

D

L404 N.M.

L403 N.M.

ZENER_6.2V

D402

100p

C426

R429

10kJ

R430 24J

3.3V1

R404

R423

N.M.(1.5kJ)

1.5kJ

C

beads

0.1u

D

22J

R406

22J

R407

22J

22J

22J

22J

R408

R409

R410

R411

22J

R412

22J

R413

C411

C410

C409

C408

C407

C406

C405

C404

22J

22J

22J

R414 22J

R415 22J

R416

R417

R421

C418

100p

100p

100p

100p

100p

100p

100p

100p

C415

C414

C413

C412

100p

100p

100p

100p

100p

22J

R405

22J

R418

22J

R419

22J

R422

C419

C417

C416

C422

100p

100p

330p

100p

10kJ

R427

N.M.

R401

C

B

A

3.3V1

I/F PWB

4 4

IC402

5

4

Y

VCC

A1GND

B

3

2

3.3V1

0.1u

C420

NC7S08M5

R428

10kJ

L402

N.M.

+

C402

47u/16V

3.3V1

5V2

R402 24J

R403 24J

11

10

9

13

12

14

D-

D+

VCC

VPO

VMO

SPEED

NC1OE#2RCV3VP4VM5SUSPEND6GND

5V1

D401

11EQS06

L401

3.3V1

8

NC

7

IC401 USB_Transceiver

+

C401

N.M.

C421

47u/16V

CN403

C423

0.1u

5V1

0.1u

74LVX161284

3.3V1

C424

C427

C425

0.1u

0.1u

B

0.1u

3.3V1 5V1

IC403

31

42

Vcc-cable

Vcc-cable

Vcc

7

18

33

B832B7

B635B536B437B3

A716A817Vcc

14

46

38

41

47

B240B1

Y9

Y1343Y1244Y1145Y10

A92A103A114A125A13

A18A2

A311A412A513A6

6

9

30

29

C1726C1627C1528C14

HD

A1420A1521A1622A1723HLH

DIR

1

19

48

R426 10kJ

R425 10kJ

PLH

PLHin

R424 10kJ

25

24

HLHin

34

39

GND

GND

GND

GND

10

15

A

D_CONT

VMO

5VEN

VPO

USB_IN

5VEN

3.3V

OEN

VMIN

VPIN

RCV

SUSPEND

PARAAD0

PARAAD1

PARAAD3

PARAAD2

PARAAD5

PARAAD6

PARAAD4

35

3 3

PARAAD7

REV

/FAULT

/ACK

BUSY

10111213141516171819202122232425262728293031323334

/STB

/SLCTIN

IF_DET

/AUTOFD

/INTI

SLCT

PE

123456789

35FE-BT-VK-N

2 2

1 1

AR-SP5 AR-PG2 5 - 2

Page 22

Page 23

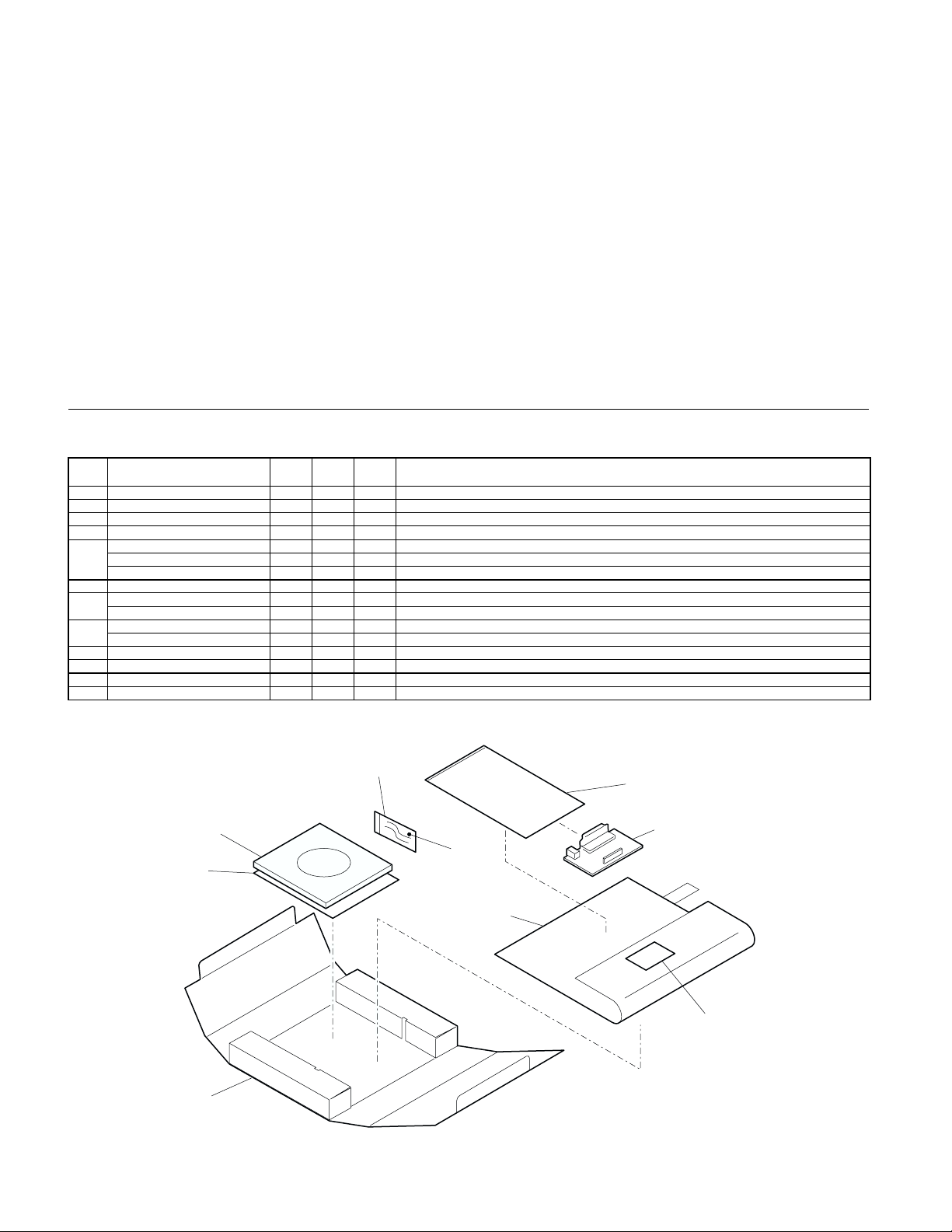

q

PARTS GUIDE

CODE:00ZARSP5///P1

AR-SP5

AR-D16

MODEL

CONTENTS

1

AL-12PK (Except USA) (Packing material & accessories)

AR-PG2 (USA) (Packing material & accessories)

2

AL-12PK (IF PWB)

AR-PG2 (IF PWB)

3

AR-D16 (Packing material & Accessories)

4

AR-D16 (2nd frame unit)

5

AR-D16 (2nd paper feeding unit)

6

AR-SP5 (Packing material & Accessories)

7

AR-SP5 (Exteriors)

8

AR-SP5 (Pick up unit)

AR-PG2 ( )

AL-12PK( )

USA

Except

USA

9

AR-SP5 (Transport unit)

■

Index

Because parts marked with " !" is indispensable for the machine safety maintenance and operation, it must

Be replaced with the parts specific to the product specification.

This document has been published to be used for

SHARP CORPORATION

after sales service only.

The contents are subject to change without notice.

Page 24

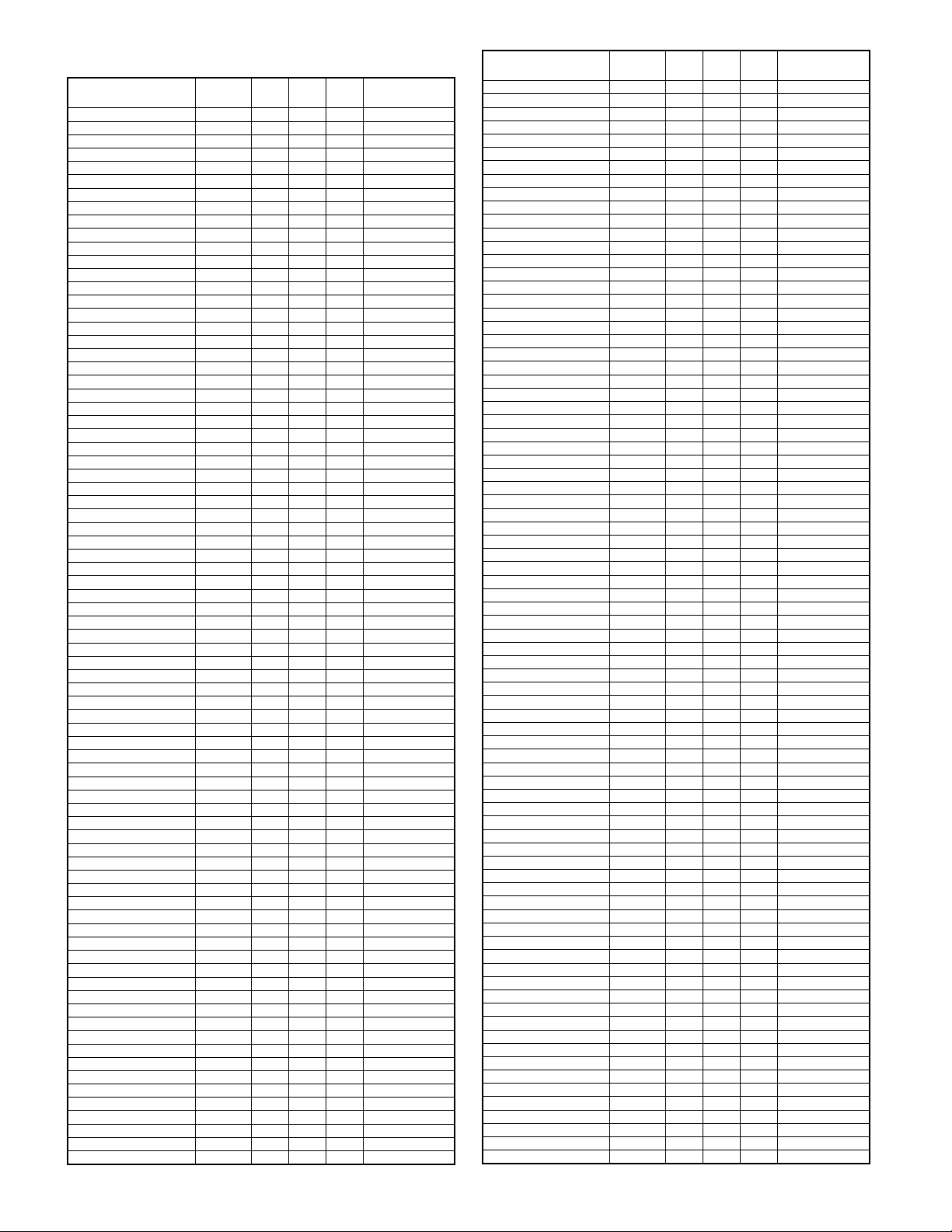

DEFINITION

The definition of each Rank is as follows and also noted in the list

A: Parts necessary to be stocked as High usage parts.

B: Parts necessary to be stocked as Standard usage parts.

C: Low usage parts.

D: Parts necessary for refurbish.

E: Unit parts recommended to be stocked for efficient after sales service.

Please note that the lead time for the said parts may be longer than normal parts.

S: Consumable parts.

Please note that the following parts used in Copier under the same description are classified into A or B Rank depending upon

the place used.

Example: Gear made of Metal, Sprocket, Bearing, Belt made of Rubber, Spring clutch mechanism.

ARank : The parts which may be with the revolution or loading.

BRank : Parts similar to A Rank parts, but are not included in Rank A.

Because parts marked with "!" is indispensable for the machine safety maintenance and operation, it must be replaced with

the parts specific to the product specification.

F Other than this Parts Guide, please refer to documents Service Manual(including Circuit Diagram)of this model.

F Please use the 13 digit code described in the right hand corner of front cover of the document, when you place an order.

F For U.S. only-Use order codes provided in advertising literature. Do not order from parts department.

AL-12PK(Except USA)/AR-PG2(USA) (Packing material & accessories)

1

PRICE

NEW

NO. PARTS CODE

1 SPAK-548ECCZZ AB D Vinyl bag

2 SPAKA5824FCZZ AF D ARMM protect sheet

3 DHAI-0283QSZZ AD C MCU-I/Fharness

4 SSAKH0130QCZZ AA D Vinyl bag(80×140mm)

XBBSE30P08000 AA C Screw(3×8)

5

UKOGD0001QSZZ AG C Screwdriver

RCORF1028LCZZ AP C Core

6 CDSKA0019QS32 AL N D CD-ROM

TCADZ0199QSZZ AF N D Card (AL-12PK Except USA)

7

TCADZ0203QSZZ AG N D Card (AR-PG2 USA)

SPAKC0412RS12 AG N D Packing case (AL-12PK Except USA)

8

SPAKC0424RSZZ AG N D Packing case (AR-PG2 USA)

RANK

MARK

PART

RANK

DESCRIPTION

AL-12PK(Except USA)/AR-PG2(USA) (Packing material & accessories)

1

4

6

5

7

2

8

1

IF PWB

3

PRP00939

– 1 –

Page 25

AL-12PK/AR-PG2 (IF PWB)

2

PRICE

NEW

NO. PARTS CODE

1 DHAI-0310QSZZ AB C IF GND harness

2 QCNCW0078QSZZ AF C Connector(35Pin)(35FE-BT-VK-N) [CN403]

3 QSOCN0002ESZZ AH C Connector(36Pin)(RBE42-36K1153) [CN401]

4 QSOCN0005ESZZ AE C Connector(UBR23-4K2200) [CN402]

5 RFILN0010QSZZ AB C Coil(BLM18BB121SN1D) [L405]

6 RH-DX0001ESZZ AC B Diode(11EQS06-TA1B2) [D401]

VCCCCY1HH101J AA C Capacitor(50WV 100pF/1608Type/CH) [C404∼415,417∼419]

7

VCCCCY1HH101J AA C Capacitor(50WV 100pF/1608Type/CH) [C421,426]

8 VCCCCY1HH331J AB C Capacitor(50WV 330pF) [C416]

9 VCEAGA1CW476M AB C Capacitor(16WV 47µF) [C401,402]

VCKYCY1CF104Z AA C Capacitor(16WV 0.1µF) [C403,420,421,423]

10

VCKYCY1CF104Z AA C Capacitor(16WV 0.1µF) [C424,425,427]

11 VHEUDZS6.2B-1 AC B Zener diode(UDZS6.2B) [D402]

12 VHI74LVX16128 AP B IC(74LVX16128) [IC403]

13 RH-IX0005ESZZ AE B IC(IX0005ES) [IC402]

14 VHIUSB11AMX-1 AH B IC(USB1T11AMX) [IC401]

15 VRS-CY1JD000J AA C Resistor(1/16W 0Ω ±5%) [L403,404]

16 VRS-CY1JD103J AA C Resistor(1/16W 10KΩ ±5%) [R424∼429]

17 VRS-CY1JD152J AA C Resistor(1/16W 1.5KΩ ±5%) [R423]

18 VRS-CY1JD220J AA C Resistor(1/16W 22Ω ±5%) [R405∼419,421,422]

19 VRS-CY1JD240J AA C Resistor(1/16W 24Ω ±5%) [R402,403,430]

20 VRS-CY1JD332J AA C Resistor(1/16W 3.3KΩ ±5%) [R420]

AR-D16 (Packing material & Accessories)

3

NO. PARTS CODE

1 TTAG-0002QSZZ AB C Tray rotation tag

2 LHLDW1226FCZZ AB C Holder

3 TCADZ0204QSZZ AE N D Card

4 SPAKA5108FCZZ AF D Packing add

5 SSAKH0021SCZZ AC D Vinyl bag

6 SPAKC0422RSZZ AT N D Packing case

7 XEBSE40P12000 AA C Screw(4×12)

8 XEBSE40P16000 AA C Screw(4×16)

9 SSAKA2011KCZZ AA D Vinyl bag(60×100mm)

RANK

PRICE

RANK

MARK

NEW

MARK

PART

RANK

PART

RANK

DESCRIPTION

DESCRIPTION

AR-D16 (Packing material & Accessories)

3

3

4

6

7

9

8

5

1

2

PRP00940

– 2 –

Page 26

AR-D16 (2nd frame unit)

4

PRICE

NEW

NO. PARTS CODE

1 GCOVA0005QSJZ AL D Front cover

2 XEBSE40P12000 AA C Screw(4×12)

3 GCOVA0006QSJZ AN D Rear cover

4 PGIDM0016QSJZ AY C Guide L

5 XEBSD40P12000 AA C Screw(4×12)

6 LPLTM0036QSZZ AF C 2ND joint plate R

7 GLEGG0064FCZZ AC D Rubber foot

8 PGIDM0015QSJZ AY C Guide R

9 MSPRC2544FCZZ AC C 2ND transport cover spring

10 GCOVA0007QSZZ AK D Transport cover

11 NROLP1060FCZZ AF C U-turn roller

12 MSPRT0112QSZ1 AC C Transport collar spring

13 MARMP0012QSZZ AD C 2ND door arm

14 GCOVA0008QSJZ AK D Right cover

15 XHBSD40P08000 AA C Screw(4×8)

16 XEBSE40P16000 AA C Screw(4×16)

17 CFRM-0009RS55 BF N E 2nd paper feeding unit

AR-D16 (2nd frame unit)

4

RANK

MARK

PART

RANK

2

DESCRIPTION

2

16

1

2

2

15

3

5

5

4

5

6

17

9

8

7

9

13

7

11

12

16

10

16

11

12

13

14

– 3 –

16

PRP00941

Page 27

AR-D16 (2nd paper feeding unit)

5

PRICE

NEW

NO. PARTS CODE

1 NROLP0019QSZ1 AP C Transport roller

2 NBRGC0016QSZZ AD C Bearing(B-F5-13)

3 XRESP40-06000 AA C E-ring

5 NGERH0992FCZZ AB C Gear(20T)

6 XPSSP20-07000 AA C Spring pin(φ2-7)

7 LBOSZ1031FCZZ AC C Clutch boss

8 MSPRC0161QSZZ AF C Clutch spring

9 PPIPP0007QSZZ AD C Clutch pipe

10 NGERH1132FCZZ AH C Clutch gear(29T)

11 NGERH1207FCZZ AF C Joint gear(40T)

12 MARMP0229FCZZ AE C Joint arm

13 MSPRC2545FCZZ AB C 2nd joint arm spring

14 DHAI-0266QSZZ AK N C 2nd harness

15 VHPGP1A71A1-1 AG B Photo sensor(GP1A71A1)

16 MLEVP0033QSZZ AF C PPDI actuator

17 MSPRD0058QSZZ AG C Earth spring

18 RPLU-0010QSZZ AN B PF solenoid

19 XHBSD30P06000 AA C Screw(3×6)

20 PTME-0008QSZZ AD C PF clutch pawl

21 MSPRC2546FCZZ AB C 2nd clutch pawl spring

22 NGERH0041QSZZ AF C 2nd gear ID(18T/26T)

23 NGERH0990FCZZ AB C Gear(16T)

24 QSW-B0003QSZZ AF B Tray detect switch

25 CROLP0015QS01 AU C Paper feeding roller

26 LFRM-0009QSZ2 AQ D Paper feeding frame

31 LBNDJ0013FCZ1 AA C Wire band

(Unit)

901 CFRM-0009RS55 BF N E 2nd paper feeding unit

RANK

MARK

PART

RANK

DESCRIPTION

AR-D16 (2nd paper feeding unit)

5

24

14

14

15

26

1

16

2

18

6

5

3

17

13

11

12

8

9

2

10

3

3

7

20

22

21

3

23

23

31

19

24

14

3

25

PRP00942

– 4 –

Page 28

AR-SP5 (Packing material & Accessories)

6

PRICE

NEW

NO. PARTS CODE

1 SSAKA0019SCZZ AA D Vinyl bag(120×180mm)

2 TCADZ0205QSZZ AE N D Inst.manual

4 SSAKH3012KCZZ AD D Vinyl bag(790×740mm)

5 SPAKA0219QSZZ AP D Packing add L

6 SPAKA0220QSZZ AQ D Packing add R

7 SPAKC0423RSZZ AT N D Packing case

8 SPAKA0242QSZZ AL D OC protect sheet

11 XHBSE30P08000 AA C Screw(3×8)

12 SSAKA2011KCZZ AA D Vinyl bag(60×100mm)

13 DUNT-0280RSZZ AU N E Book sensor unit

14 PGIDM0019QSJZ AH C Hinge guide L

15 PGIDM0020QSJZ AH C Hinge guide R

16 GCOV-0045QSZZ AG D Rear cover SPF

100 PCUSS0025QSZZ AQ D OC mat

AR-SP5 (Packing material & Accessories)

6

RANK

MARK

PART

RANK

1

DESCRIPTION

14

15

5

11

2

12

12

13

12

4

8

6

16

– 5 –

7

PRP00943

Page 29

AR-SP5 (Exteriors)

7

PRICE

NEW

NO. PARTS CODE

1 LSOU-0035QSZZ AR D Original tray

2 LPLTP0011QSJZ AH C Control plate F

3 LPLTP0012QSJZ AH C Control plate R

4 NGERR0377FCZZ AD C Manual feeding rack gear

5 XEPSD30P08X00 AA C Screw(3×8X)

6 NGERH0193FCZZ AB C Manual feeding gear

7 MSPRP0059QSZZ AD C Control plate spring

11 CFRM-0011RS58 BF E SPF pick up unit

13 XEBSD40P10000 AA C Screw(4×10)

14 CFRM-0013RS57 BP E SPF transport unit

15 LBNDJ0013FCZ1 AA C Wire band

16 PSHEZ0384QSZZ AD C Base tray sheet

17 PSHEP0063QSZZ AC C Transport sheet

18 MSPRP0113QSZ1 AD C Earth spring

19 PSHEZ0379QSZZ AD C OC sheet

20 XEBSD30P08000 AA C Screw(3×8)

21 MHNG-0017QSZZ AQ C SPF hinge

22 XEBSE40P14000 AA C Screw(4×14)

23 NROLP0011QSZZ AD C Delivery roller

24 PSPO-0001QSZZ AB C Sponge

25 NSFTZ0010QSZZ AE C Delivery shaft

26 MSPRT0061QSZZ AC C Delivery spring

27 MSPRP0060QSZZ AD C Transport spring

28 NROLP0010QSZZ AD C Transport roller

29 NSFTZ0009QSZZ AE C Transport shaft

30 LPLTM0096QSZZ AF C Base tray reinforce plate

31 LX-BZ0016QSZZ AC C Screw(3×8)

33 LSOU-0005QSJ4 BA D Base tray

34 PCUSS0025QSZZ AQ D OC mat

35 PSHEZ0102QSZZ AD C Motor pressure sheet

36 PSHEZ0112QSZZ AE C Delivery earth sheet SPF

37 MSPRC0149QSZZ AC C PS earth spring SPF

38 PSHEZ0386QSZZ AB D Rear side mylar A

39 PSHEZ0387QSZZ AB D Rear side mylar B

40 PSHEZ0388QSZZ AD C OC sheet mylar 2

45 PSHEZ0383QSZZ AC C Book detect sheet

501 CSOU-0035RS51 AZ E SPF original tray unit

RANK

MARK

PART

RANK

DESCRIPTION

AR-SP5 (Exteriors)

7

2

501

11

1

3

15

13

22

14

13

4

4

5

5

6

45

22

7

5

13

17

17

16

39

13

35

38

23

31

39

25

24

20

28

26

20

31

28

27

24

30

31

37

20

23

27

31

36

29

22

18

21

40

31

34

33

21

22

19

PRP00944

– 6 –

Page 30

AR-SP5 (Pick up unit)

8

PRICE

NEW

NO. PARTS CODE

1 GCAB-0008QSJZ AM D Open and shut exterior

2 PSPO-0002QSZZ AC C Stopper sponge

4 MARMP0003QSZ1 AD C Stopper arm

5 LSTPP0001QSZZ AD C Paper stopper R

6 XEBSD30P08000 AA C Screw(3×8)

7 CPWBF0009RS51 AG E SPF sensor PWB

8 DHAI-0293QSZZ AE C Sensor harness

9 MLEVP0009QSZZ AD C Set detect lever ACT

10 MLEVP0010QSZZ AE C Open and shut detect lever ACT

11 RPLU-0004QSZ1 AQ B PU solenoid

12 XBPSD30P06KS0 AA C Screw(3×6KS)

13 MARMP0002QSZZ AD C Solenoid arm

14 MSPRT0067QSZ1 AB C Solenoid arm spring

15 XRESP40-06000 AA C E-ring

16 NGERH0073QSZZ AE C Clutch gear(20T)

17 PPIPP0008QSZZ AD C Clutch sleeve

18 MSPRC1316FCZ1 AE C MF clutch spring B

19 LBOSZ1851FCZZ AC C STK clutch boss

20 LBSHZ0303FCZZ AC C M bushing C

21 NSFTZ0012QSZZ AG C Clutch shaft

22 LBSHZ0006QSZZ AC C M Bushing 2

23 NPLYZ0010QSZZ AE C 20MXL pulley

24 XRESP30-06000 AA C E-ring

25 MSPRT0066QSZ1 AC C Clutch pawl spring

26 PTME-0019QSZZ AD C Clutch pawl

27 NROLP0024QSZ1 AH C Pick up roller

28 NGERH0990FCZZ AB C Gear(16T)

29 XPSSP20-07000 AA C Spring pin(φ2-7)

30 NGERH0992FCZZ AB C Gear(20T)

31 NROLR0922FCZZ AR C Manual feeding roller

32 NSFTZ0011QSZ2 AF C PF shaft

33 MSPRC0115QSZZ AB C Paper feeding spring

34 MARMP0004QSZZ AF C Pick up arm

35 LFRM-0011QSJ2 AL D Paper feedind frame

36 MSPRD0114QSZ1 AD C PF frame spring

(Unit)

901 CFRM-0011RS58 BF E SPF pick up unit

RANK

MARK

PART

RANK

DESCRIPTION

AR-SP5 (Pick up unit)

8

6

7

8

36

1

2

15

11

17

4

16

18

19

21

15

14

5

13

20

12

23

24

20

9

6

6

10

35

12

6

– 7 –

29

22

25

28

26

30

29

27

30

34

30

29

31

33

15

32

PRP00945

20

Page 31

AR-SP5 (Transport unit)

9

PRICE

NEW

NO. PARTS CODE

1 PGIDM0042QSJZ AL C U-turn paper guide

2 XEBSD30P12000 AA C Screw(3×12)

3 LX-BZ0012QSZZ AC C Screw

4 NGERH0972FCZZ AB C Gear(27T)

5 MARMP0001QSZZ AF C Drive arm

6 XBPSD30P05K00 AA C Screw(3×5K)

7 RMOTP0013QSZZ BB B SPF motor

9 DHAI-0290QSZZ AN C SPF interface harness

10 LBNDJ0013FCZ1 AA C Wire band

11 MSPRT0064QSZ1 AC C Drive arm spring

12 LFRM-0013QSZZ AG C Drive frame

13 XRESP50-06000 AA C E-ring

14 PSHEP3029FCZZ AA C Flange sheet DUP2

15 NBLTT0006QSZZ AG B Belt(83MXL4.8)

16 NGERH0047QSZZ AF C Gear(48T/15T)

17 LPINS0019QSZZ AB C Spring pin(φ2.5-9)

18 NBRGC0017QSZZ AC C Bearing

19 NBRGM0501FCZZ AB C Metal D

20 LFRM-0012QSZZ AD C Frame R

21 PSHEZ0039QSZZ AG C Sheet

22 LPLTP0013QSZZ AD C Plate

23 MSPRC0062QSZZ AC C Pressure spring

24 MSPRP0065QSZZ AD C Open and shut lock spring

25 PSHEZ2174FCZZ AB C Paper feeding sheet

26 NPLYZ0146FCZZ AB C 22MXL pulley

27 NBLTT0003QSZZ AG B Belt(B75MXL4.8)

28 JKNBZ0004QSZZ AD C JAM release knob

29 MSPRC0063QSZZ AB C Delivery paper guide spring

30 PGIDM0024QSZ3 AN C Transport paper guide

31 RDTCT0004QSZZ AL B Inlet detect sensor

32 NROLM0023QSZ1 AP C Delivery roller

33 PBRSR0003QSZ2 AG B Discharge brush

34 PGIDH0029QSZZ AL C Delivery paper guide

35 PSHEP0044QSZZ AF C White sheet

36 NROLM0022QSZ1 AL C PS roller

37 PCOVP0037QSJZ AH D Front cover

38 PCOVP0038QSJ1 AL D Rear cover

39 XEBSE30P10000 AA C Screw(3×10)

40 CPLTM0298QS01 AF C SPF tension plate

41 MSPRT0294QSZZ AC C SPF tension spring

(Unit)

901 CFRM-0013RS57 BP E SPF transport unit

RANK

MARK

PART

RANK

DESCRIPTION

AR-SP5 (Transport unit)

9

13

41

26

13

39

17

26

13

27

13

19

40

28

17

24

37

19

29

2

25

32

22

23

30

31

21

38

2

1

13

18

17

16

14

2

3

15

4

9

7

10

39

11

5

12

6

39

13

24

19

20

29

36

35

34

33

PRP00946

– 8 –

Page 32

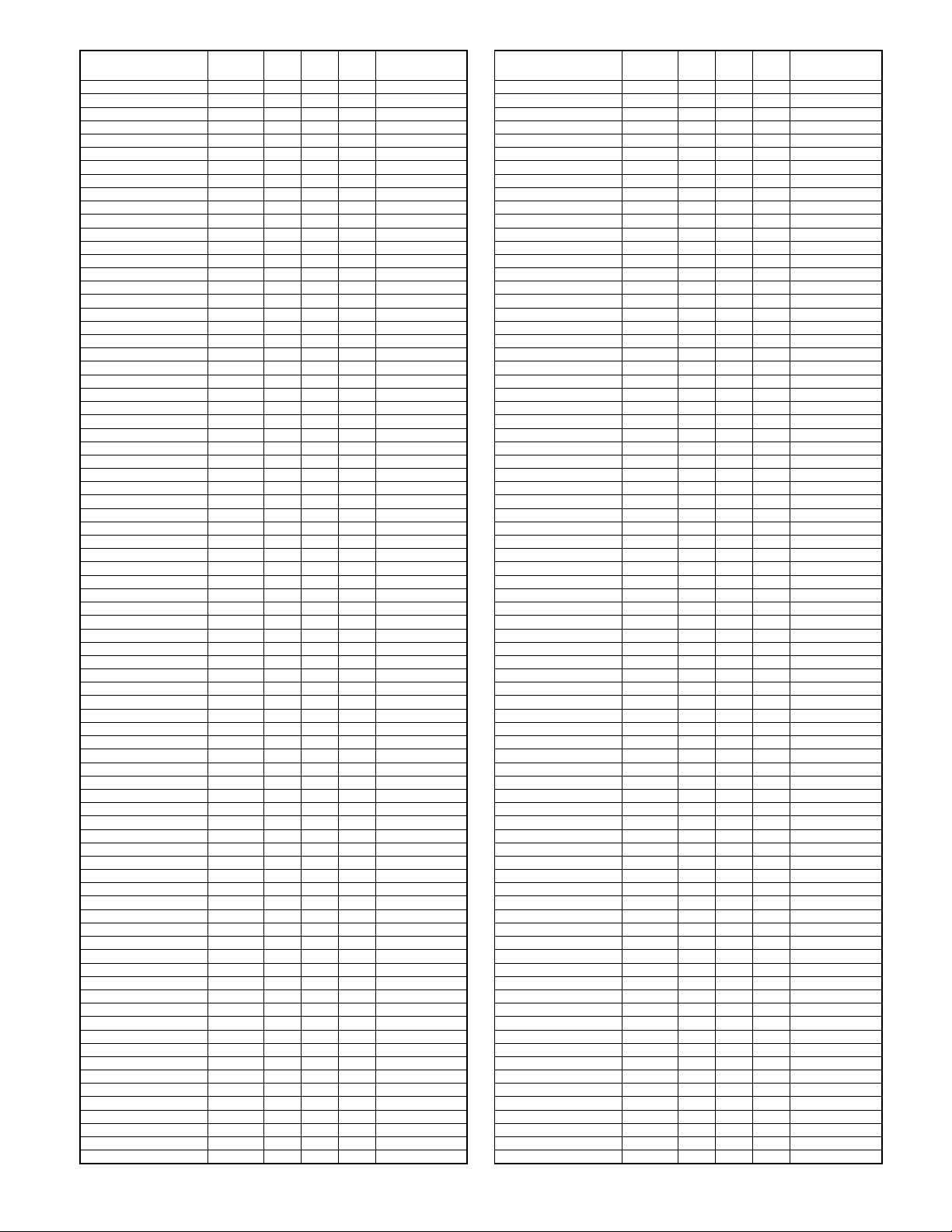

■

Index

PARTS CODE NO.

[C]

CDSKA0019QS32

CFRM-0009RS55

CFRM-0011RS58

CFRM-0013RS57

CPLTM0298QS01

CPWBF0009RS51

CROLP0015QS01

CSOU-0035RS51

DHAI-0266QSZZ

DHAI-0283QSZZ

DHAI-0290QSZZ

DHAI-0293QSZZ

DHAI-0310QSZZ

DUNT-0280RSZZ

GCAB-0008QSJZ

GCOV-0045QSZZ

GCOVA0005QSJZ

GCOVA0006QSJZ

GCOVA0007QSZZ

GCOVA0008QSJZ

GLEGG0064FCZZ

JKNBZ0004QSZZ

LBNDJ0013FCZ1

LBOSZ1031FCZZ

LBOSZ1851FCZZ

LBSHZ0006QSZZ

LBSHZ0303FCZZ

LFRM-0009QSZ2

LFRM-0011QSJ2

LFRM-0012QSZZ

LFRM-0013QSZZ

LHLDW1226FCZZ

LPINS0019QSZZ

LPLTM0036QSZZ

LPLTM0096QSZZ

LPLTP0011QSJZ

LPLTP0012QSJZ

LPLTP0013QSZZ

LSOU-0005QSJ4

LSOU-0035QSZZ

LSTPP0001QSZZ

LX-BZ0012QSZZ

LX-BZ0016QSZZ

MARMP0001QSZZ

MARMP0002QSZZ

MARMP0003QSZ1

MARMP0004QSZZ

MARMP0012QSZZ

MARMP0229FCZZ

MHNG-0017QSZZ

MLEVP0009QSZZ

MLEVP0010QSZZ

MLEVP0033QSZZ

MSPRC0062QSZZ

MSPRC0063QSZZ

MSPRC0115QSZZ

MSPRC0149QSZZ

MSPRC0161QSZZ

MSPRC1316FCZ1

MSPRC2544FCZZ

MSPRC2545FCZZ

MSPRC2546FCZZ

MSPRD0058QSZZ

MSPRD0114QSZ1

MSPRP0059QSZZ

MSPRP0060QSZZ

MSPRP0065QSZZ

MSPRP0113QSZ1

"

"

"

[D]

[G]

[J]

[L]

"

"

[M]

PRICE

NEW

MARK

PART

RANK

RANK

1- 6 AL N D

4- 17 BF N E

5- 901 BF N E

7- 11 BF E

8- 901 BF E

7- 14 BP E

9- 901 BP E

9- 40 AF C

8- 7 AG E

5- 25 AU C

7- 501 AZ E

5- 14 AK N C

1- 3 AD C

9- 9 AN C

8- 8 AE C

2- 1 AB C

6- 13 AU N E

8- 1 AM D

6- 16 AG D

4- 1 AL D

4- 3 AN D

4- 10 AK D

4- 14 AK D

4- 7 AC D

9- 28 AD C

5- 31 AA C

7- 15 AA C

9- 10 AA C

5- 7 AC C

8- 19 AC C

8- 22 AC C

8- 20 AC C

5- 26 AQ D

8- 35 AL D

9- 20 AD C

9- 12 AG C

3- 2 AB C

9- 17 AB C

4- 6 AF C

7- 30 AF C

7- 2 AH C

7- 3 AH C

9- 22 AD C

7- 33 BA D

7- 1 AR D

8- 5 AD C

9- 3 AC C

7- 31 AC C

9- 5 AF C

8- 13 AD C

8- 4 AD C

8- 34 AF C

4- 13 AD C

5- 12 AE C

7- 21 AQ C

8- 9 AD C

8- 10 AE C

5- 16 AF C

9- 23 AC C

9- 29 AB C

8- 33 AB C

7- 37 AC C

5- 8 AF C

8- 18 AE C

4- 9 AC C

5- 13 AB C

5- 21 AB C

5- 17 AG C

8- 36 AD C

7- 7 AD C

7- 27 AD C

9- 24 AD C

7- 18 AD C

PARTS CODE NO.

MSPRT0061QSZZ

MSPRT0064QSZ1

MSPRT0066QSZ1

MSPRT0067QSZ1

MSPRT0112QSZ1

MSPRT0294QSZZ

[N]

NBLTT0003QSZZ

NBLTT0006QSZZ

NBRGC0016QSZZ

NBRGC0017QSZZ

NBRGM0501FCZZ

NGERH0041QSZZ

NGERH0047QSZZ

NGERH0073QSZZ

NGERH0193FCZZ

NGERH0972FCZZ

NGERH0990FCZZ

"

NGERH0992FCZZ

"

NGERH1132FCZZ

NGERH1207FCZZ

NGERR0377FCZZ

NPLYZ0010QSZZ

NPLYZ0146FCZZ

NROLM0022QSZ1

NROLM0023QSZ1

NROLP0010QSZZ

NROLP0011QSZZ

NROLP0019QSZ1

NROLP0024QSZ1

NROLP1060FCZZ

NROLR0922FCZZ

NSFTZ0009QSZZ

NSFTZ0010QSZZ

NSFTZ0011QSZ2

NSFTZ0012QSZZ

[P]

PBRSR0003QSZ2

PCOVP0037QSJZ

PCOVP0038QSJ1

PCUSS0025QSZZ

"

PGIDH0029QSZZ

PGIDM0015QSJZ

PGIDM0016QSJZ

PGIDM0019QSJZ

PGIDM0020QSJZ

PGIDM0024QSZ3

PGIDM0042QSJZ

PPIPP0007QSZZ

PPIPP0008QSZZ

PSHEP0044QSZZ

PSHEP0063QSZZ

PSHEP3029FCZZ

PSHEZ0039QSZZ

PSHEZ0102QSZZ

PSHEZ0112QSZZ

PSHEZ0379QSZZ

PSHEZ0383QSZZ

PSHEZ0384QSZZ

PSHEZ0386QSZZ

PSHEZ0387QSZZ

PSHEZ0388QSZZ

PSHEZ2174FCZZ

PSPO-0001QSZZ

PSPO-0002QSZZ

PTME-0008QSZZ

PTME-0019QSZZ

[Q]

QCNCW0078QSZZ

QSOCN0002ESZZ

QSOCN0005ESZZ

QSW-B0003QSZZ

[R]

RCORF1028LCZZ

RDTCT0004QSZZ

RFILN0010QSZZ

RH-DX0001ESZZ

RH-IX0005ESZZ

PRICE

NEW

MARK

PART

RANK

RANK

7- 26 AC C

9- 11 AC C

8- 25 AC C

8- 14 AB C

4- 12 AC C

9- 41 AC C

9- 27 AG B

9- 15 AG B

5- 2 AD C

9- 18 AC C

9- 19 AB C

5- 22 AF C

9- 16 AF C

8- 16 AE C

7- 6 AB C

9- 4 AB C

5- 23 AB C

8- 28 AB C

5- 5 AB C

8- 30 AB C

5- 10 AH C

5- 11 AF C

7- 4 AD C

8- 23 AE C

9- 26 AB C

9- 36 AL C

9- 32 AP C

7- 28 AD C

7- 23 AD C

5- 1 AP C

8- 27 AH C

4- 11 AF C

8- 31 AR C

7- 29 AE C

7- 25 AE C

8- 32 AF C

8- 21 AG C

9- 33 AG B

9- 37 AH D

9- 38 AL D

6- 100 AQ D

7- 34 AQ D

9- 34 AL C

4- 8 AY C

4- 4 AY C

6- 14 AH C

6- 15 AH C

9- 30 AN C

9- 1 AL C

5- 9 AD C

8- 17 AD C

9- 35 AF C

7- 17 AC C

9- 14 AA C

9- 21 AG C

7- 35 AD C

7- 36 AE C

7- 19 AD C

7- 45 AC C

7- 16 AD C

7- 38 AB D

7- 39 AB D

7- 40 AD C

9- 25 AB C

7- 24 AB C

8- 2 AC C

5- 20 AD C

8- 26 AD C

2- 2 AF C

2- 3 AH C

2- 4 AE C

5- 24 AF B

1- 5 AP C

9- 31 AL B

2- 5 AB C

2- 6 AC B

2- 13 AE B

– 9 –

Page 33

PARTS CODE NO.

RMOTP0013QSZZ

RPLU-0004QSZ1

RPLU-0010QSZZ

[S]

SPAK-548ECCZZ

SPAKA0219QSZZ

SPAKA0220QSZZ

SPAKA0242QSZZ

SPAKA5108FCZZ

SPAKA5824FCZZ

SPAKC0412RS12

SPAKC0422RSZZ

SPAKC0423RSZZ

SPAKC0424RSZZ

SSAKA0019SCZZ

SSAKA2011KCZZ

"

SSAKH0021SCZZ

SSAKH0130QCZZ

SSAKH3012KCZZ

[T]

TCADZ0199QSZZ

TCADZ0203QSZZ

TCADZ0204QSZZ

TCADZ0205QSZZ

TTAG-0002QSZZ

[U]

UKOGD0001QSZZ

[V]

VCCCCY1HH101J

VCCCCY1HH331J

VCEAGA1CW476M

VCKYCY1CF104Z

VHEUDZS6.2B-1

VHI74LVX16128

VHIUSB11AMX-1

VHPGP1A71A1-1

VRS-CY1JD000J

VRS-CY1JD103J

VRS-CY1JD152J

VRS-CY1JD220J

VRS-CY1JD240J

VRS-CY1JD332J

[X]

XBBSE30P08000

XBPSD30P05K00

XBPSD30P06KS0

XEBSD30P08000

"

XEBSD30P12000

XEBSD40P10000

XEBSD40P12000

XEBSE30P10000

XEBSE40P12000

"

XEBSE40P14000

XEBSE40P16000

"

XEPSD30P08X00

XHBSD30P06000

XHBSD40P08000

XHBSE30P08000

XPSSP20-07000

"

XRESP30-06000

XRESP40-06000

"

XRESP50-06000

PRICE

NEW

MARK

PART

RANK

RANK

9- 7 BB B

8- 11 AQ B

5- 18 AN B

1- 1 AB D

6- 5 AP D

6- 6 AQ D

6- 8 AL D

3- 4 AF D

1- 2 AF D

1- 8 AG N D

3- 6 AT N D

6- 7 AT N D

1- 8 AG N D

6- 1 AA D

3- 9 AA D

6- 12 AA D

3- 5 AC D

1- 4 AA D

6- 4 AD D

1- 7 AF N D

1- 7 AG N D

3- 3 AE N D

6- 2 AE N D

3- 1 AB C

1- 5 AG C

2- 7 AA C

2- 8 AB C

2- 9 AB C

2- 10 AA C

2- 11 AC B

2- 12 AP B

2- 14 AH B

5- 15 AG B

2- 15 AA C

2- 16 AA C

2- 17 AA C

2- 18 AA C

2- 19 AA C

2- 20 AA C

1- 5 AA C

9- 6 AA C

8- 12 AA C

7- 20 AA C

8- 6 AA C

9- 2 AA C

7- 13 AA C

4- 5 AA C

9- 39 AA C

3- 7 AA C

4- 2 AA C

7- 22 AA C

3- 8 AA C

4- 16 AA C

7- 5 AA C

5- 19 AA C

4- 15 AA C

6- 11 AA C

5- 6 AA C

8- 29 AA C

8- 24 AA C

5- 3 AA C

8- 15 AA C

9- 13 AA C

PARTS CODE NO.

PRICE

RANK

NEW

MARK

PART

RANK

– 10 –

Page 34

Page 35

(For USA,CANADA)

CAUTION FOR BATTERY DISPOSAL

Contains lithium-ion battery. Must be disposed of properly.

Remove the battery from the product and contact

agencies for information on recycling and disposal options.

federal or state environmental

Page 36

cc

COPYRIGHT 2002 BY SHARP CORPORATION

No part of this publication may be reproduced,

electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission of the publisher.

Trademark acknowledgments

Windows and Windows NT are trademarks of Microsoft Corporation in the U.S.A.

and other countries.

IBM and PC/AT are trademarks of International Business Machines Corporation.

PCL is a trademark of Hewlett-Packard Company.

Pentium is a registered trademark of Intel Corporation.

All other trademarks and copyrights are the property of their respective owners.

c

All rights reserved.

Printed in Japan.

stored in a retrieval system, or transmitted,

in any form or by any means,

SHARP CORPORATION

Digital Document System Group

Products Quality Assurance Department

Yamatokoriyama, Nara 639-1186, Japan

2002 July Printed in Japan

Loading...

Loading...