Page 1

AE-X4M30PU

SERVICE MANUAL

S3302AEX4M3PUT

MULTI SPLIT TYPE

ROOM AIR CONDITIONERS

OUTDOOR UNIT

MODEL

In the interests of user-safety (Required by safety regulations in some countries)

the set should be restored to its original condition and only parts identical to those

specied should be used

AE-X4M30PU

CONTENTS

SPECIFICATION

SPECIFICATION ---------------------------------------------------------------------------------------------------------- 2

EXTERNAL DIMENSION ------------------------------------------------------------------------------------------------4

CAPACITY TABLE --------------------------------------------------------------------------------------------------------5

ELECTRICAL PARTS ----------------------------------------------------------------------------------------------------8

CYCLE PARTS -------------------------------------------------------------------------------------------------------------8

WIRING DIAGRAMS ----------------------------------------------------------------------------------------------------- 8

EXPLANATION OF CIRCUIT AND OPERATION

BLOCK DIAGRAM ------------------------------------------------------------------------------------------------------12

FUNCTIONS --------------------------------------------------------------------------------------------------------------13

TROUBLE SHOOTING GUIDE

SELF-DIAGNOSIS FUNCTION --------------------------------------------------------------------------------------16

PROTECTIVE FUNCTIONS AND OPERATIONS --------------------------------------------------------------25

REFRIGERATION CYCLE

DISASSEMBLING PROCEDURE

PROCEDURE ------------------------------------------------------------------------------------------------------------29

Position of the thermistors. --------------------------------------------------------------------------------------------32

How to disassemble the control box assembly -------------------------------------------------------------------33

---------------------------------------------------------------------------------------------------------------2

--------------------------------------------------------------12

----------------------------------------------------------------------------------------16

-----------------------------------------------------------------------------------------------26

------------------------------------------------------------------------------------------29

This document has been published to be used for after sales service only.

The contents are subject to change without notice.

1

Page 2

AE-X4M30PU

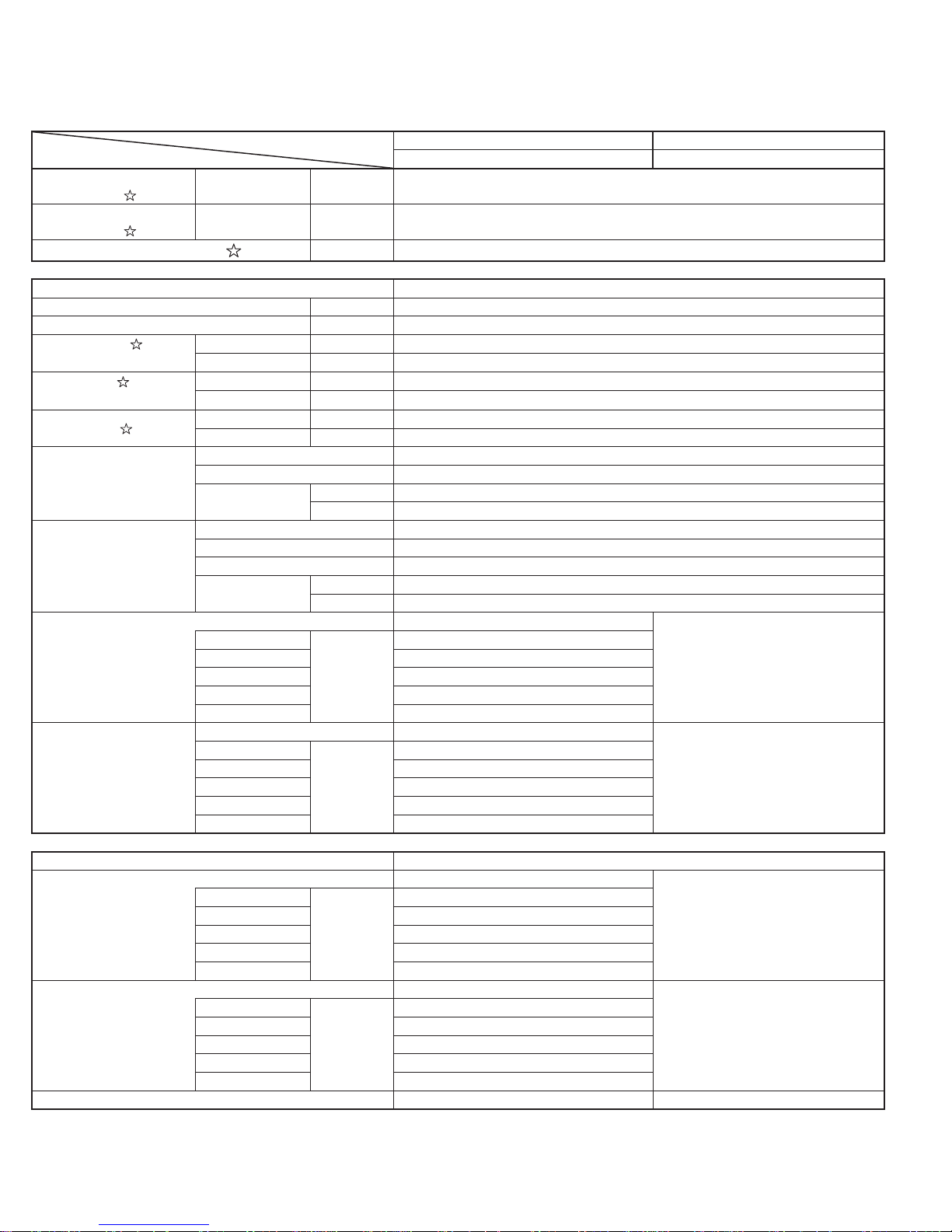

SPECIFICATION

SPECIFICATION

MODEL

ITEMS

Rated cooling capacity

(Min. - Max.)

Rated heating capacity

(Min. - Max.)

Moisture removal (at cooling)

Electrical data

Phase Single

Rated frequency Hz 60

Rated voltage V 208/230

Rated current

(Min.-Max.)

Rated input

(Min.-Max.)

Power factor

Compressor

Refrigerant system

Noise level

(at cooling)

Noise level

(at heating)

Fan system

Drive Direct drive

Air ow quantity

(at cooling)

Air ow quantity

(at heating)

Fan Cross ow fan Propeller fan

9K&7K&7K&7K Btu/h 29000 ( 12000 ~ 31000)

9K&7K&7K&7K Btu/h 33000 ( 12000 ~ 37000)

pints/h 1.7×3 & 2.1

Cool A 13.6 ( 3.3 ~ 15.6) *

Heat A 12.6 ( 3.7 ~ 14.3) *

Cool W 3080 ( 640 ~ 3530)

Heat W 2860 ( 800 ~ 3250)

Cool % 98 *

Heat % 99 *

Type Twin rotary

Model SNB172FEKMT

Oil charge

Evaporator Louver Fin and Grooved tube type

Condenser Corrugate Fin and Grooved tube type

Control Expansion valve

Refrigerant

07PU

09PU 39 / 26

12PU 44 / 27

15PU 44 / 32

18PU 45 / 33

07PU

09PU 40 / 28

12PU 43 / 29

15PU 44 / 34

18PU 46 / 35

07PU

09PU 343 / 198 ( 9.7 / 5.6)

12PU 382 / 216 ( 10.8 / 6.1)

15PU 466 / 307 ( 13.2 / 8.7)

18PU 477 / 311 ( 13.5 / 8.8)

07PU

09PU

12PU 410 / 244 ( 11.6 / 6.9)

15PU 505 / 332 ( 14.3 / 9.4)

18PU 512 / 336 ( 14.5 / 9.5)

type FV50S

oz. ( cc) 27.4 ( 700)

type R410A

oz. ( g) 88.2 ( 2500)

dB(A)

dB(A)

CFM

3

/min)

(m

CFM

3

/min)

(m

AY-XPC07PU/09PU/12PU/15PU/18PU AE-X4M30PU

High / Soft

38 / 26

High / Soft

39 / 28

High / Soft

332 / 198 ( 9.4 / 5.6)

High / Soft

332 / 230 ( 9.4 / 6.5)

343 / 230 ( 9.7 / 6.5)

INDOOR UNIT OUTDOOR UNIT

53

55

1802 ( 51)

1802 ( 51)

2

Page 3

AE-X4M30PU

MODEL

ITEMS

Connections

Refrigerant coupling Flare type

Refrigerant tube size

( Gas line)

Refrigerant tube size (Liquid line) inch (mm) 1/4 ( 6.35)

Minimum - Maximum length ( per unit) ft ( m) 10 - 82 ( 3 -25)

Maximum length

Maximum charge-less length ft ( m) 164 ( 50)

Maximum height difference ft ( m) 49 ( 15)

Additional charge oz./ft ( g/m) 0.16 ( 15)

Drain pipe O.D. inch (mm) 5/8 (16)

Others

Safety device

Air llters Polypropylene net (Washable)

Net dimensions

(Width x Height x Depth)

Net weight

7K, 9K, 12K

15K, 18K 1/2 (12.7)

2 units

3 or 4 units 230 ( 70)

07PU , 09PU ,

12PU

15PU , 18PU

07PU , 09PU ,

12PU

15PU 28.7 ( 13)

18PU 29.8 ( 13.5)

inch (mm)

ft ( m)

inch

(mm)

inch

(mm)

lb. (kg)

AY-XPC07PU/09PU/12PU/15PU/18PU AE-X4M30PU

3/8 ( 9.52)

164 ( 50)

Compressor: Thermal protector

Fan motors: Thermal fuse

Fuse, Micro computer control, Pressure switch

36-7/32 x 11-13/32 x 9-7/16

( 920 x 290 x 240)

38 x 12-5/16 x 9-27/32

( 965 x 313 x 250)

22 ( 10)

INDOOR UNIT OUTDOOR UNIT

35 x 31-1/2 x 12-19/32

( 890 x 800 x 320)

137 ( 62)

NOTE: Test conditions are based on AHRI 210/240. ( Refrigerant piping length [per unit] : 25ft[7.6m])

* : Voltage is 230V

: Representative connection

3

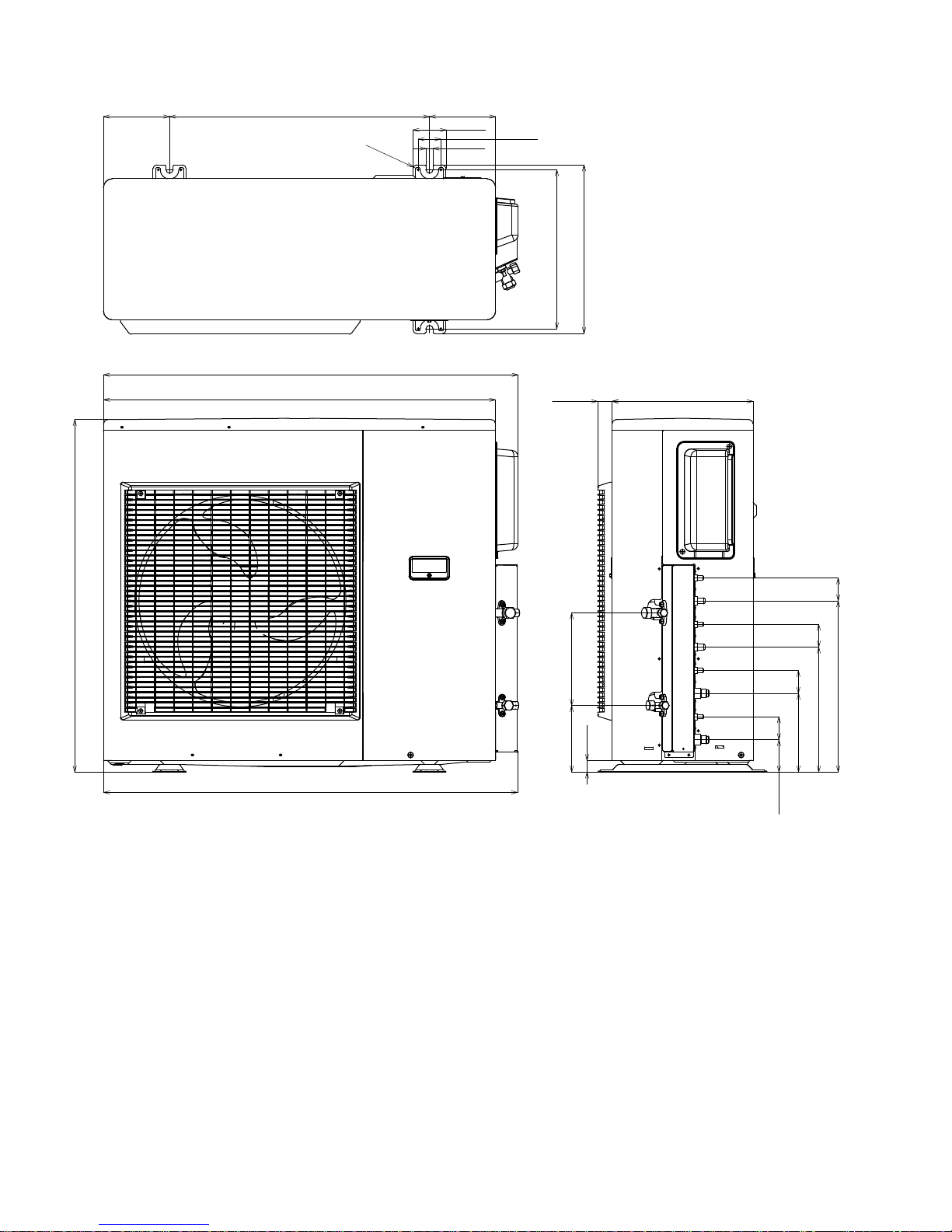

Page 4

AE-X4M30PU

EXTERNAL DIMENSION

5.9 (150)

23.2 (590)

37 (941)

35 (890)

R0.3 (8.5)

5.9 (150)

3 (75)

0.6 (16)

2 (51.3)

14.2 (361)

15.1 (383)

1.3 (32.7)

Length unit : inch (mm)

12.6 (320)

31.5 (800)

37 (940)

8.3 (210)5.9 (151.1)

1 (26.2)

2 (52)

2 (52)

7 (178.6)

2.9 (73.6)

2 (52)

2 (52)

15.3(388.6)

11.2 (283.6)

4

Page 5

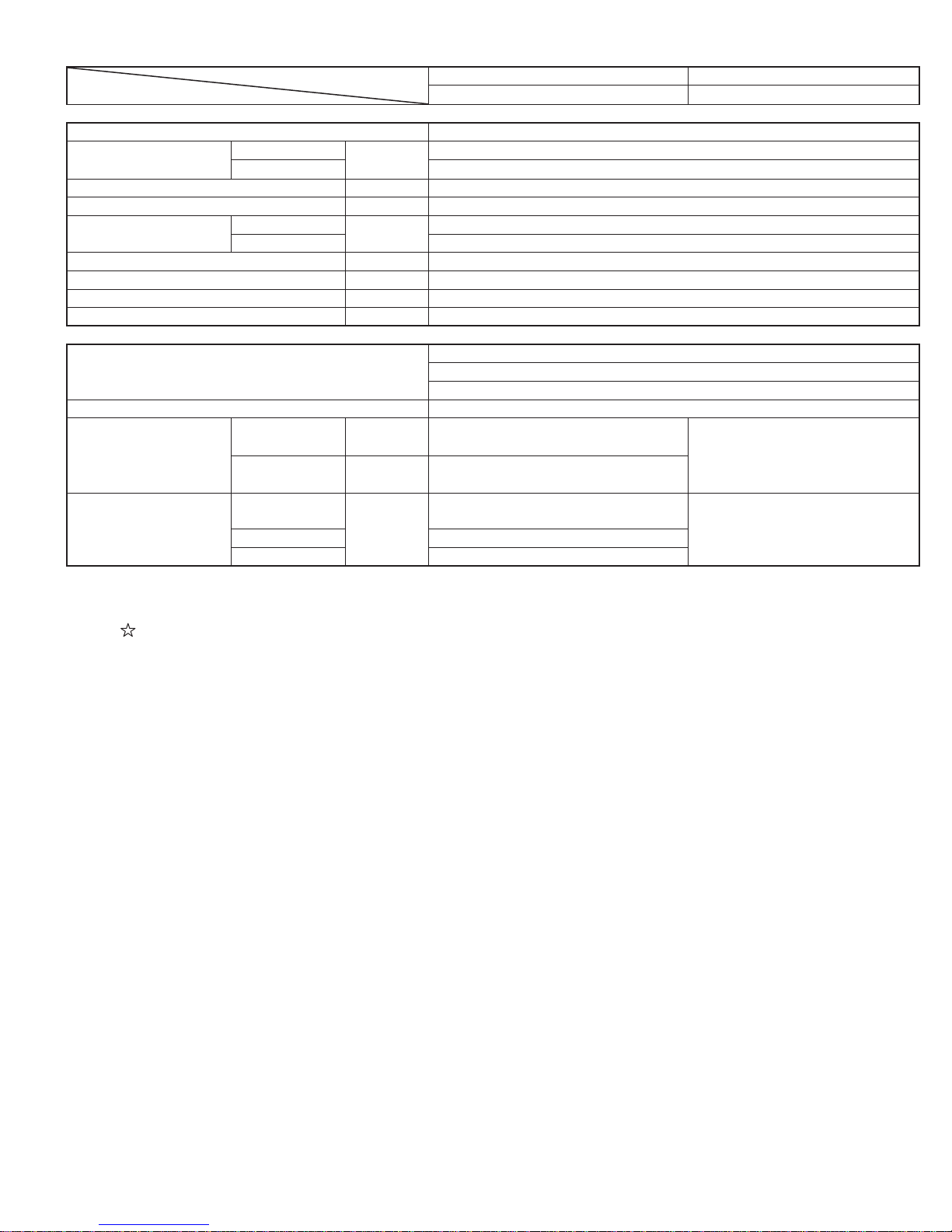

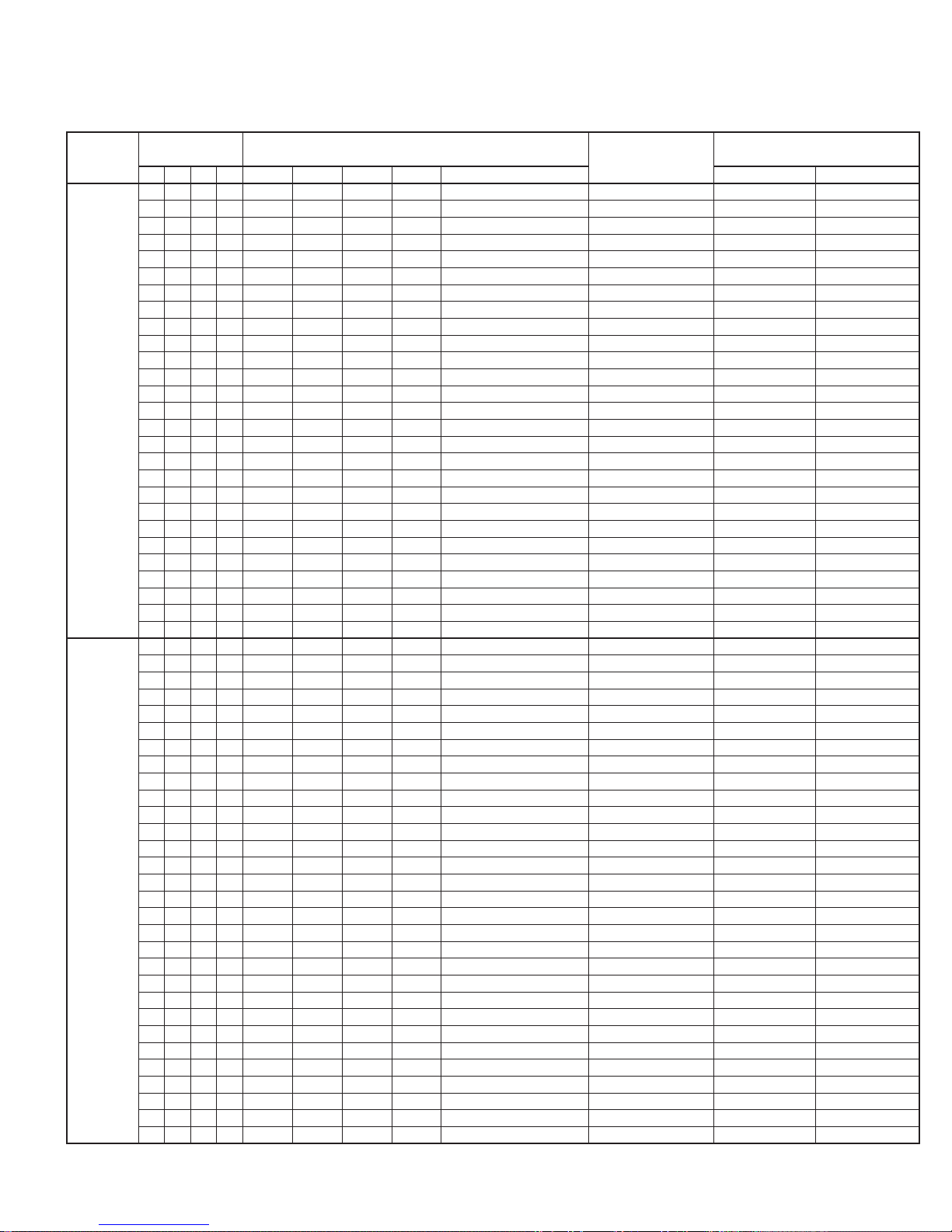

CAPACITY TABLE

COOLING CAPACITY TABLE

Operating

Status

4-indoor unit

operation

3-indoor unit

operation

Indoor unit

combination

A B C D A B C D Rating ( Min - Max) 208V 230V

18 12 7 7 11,864 7,909 4,614 4,614 29,000 (12,000 - 31,000) 3,080 (640 - 3,530) 15.1 (3.7 - 17.2) 13.6 (3.3 - 15.6)

18 9 9 9 11,600 5,800 5,800 5,800 29,000 (12,000 - 31,000) 3,080 (640 - 3,530) 15.1 (3.7 - 17.2) 13.6 (3.3 - 15.6)

18 9 9 7 12,140 6,070 6,070 4,721 29,000 (12,000 - 31,000) 3,080 (640 - 3,530) 15.1 (3.7 - 17.2) 13.6 (3.3 - 15.6)

18 9 7 7 12,732 6,366 4,951 4,951 29,000 (12,000 - 31,000) 3,080 (640 - 3,530) 15.1 (3.7 - 17.2) 13.6 (3.3 - 15.6)

18 7 7 7 13,385 5,205 5,205 5,205 29,000 (12,000 - 31,000) 3,080 (640 - 3,530) 15.1 (3.7 - 17.2) 13.6 (3.3 - 15.6)

15 15 7 7 9,886 9,886 4,614 4,614 29,000 (12,000 - 31,000) 3,080 (640 - 3,530) 15.1 (3.7 - 17.2) 13.6 (3.3 - 15.6)

15 12 9 9 9,667 7,733 5,800 5,800 29,000 (12,000 - 31,000) 3,080 (640 - 3,530) 15.1 (3.7 - 17.2) 13.6 (3.3 - 15.6)

15 12 9 7 10,116 8,093 6,070 4,721 29,000 (12,000 - 31,000) 3,080 (640 - 3,530) 15.1 (3.7 - 17.2) 13.6 (3.3 - 15.6)

15 12 7 7 10,610 8,488 4,951 4,951 29,000 (12,000 - 31,000) 3,080 (640 - 3,530) 15.1 (3.7 - 17.2) 13.6 (3.3 - 15.6)

15 9 9 9 10,357 6,214 6,214 6,214 29,000 (12,000 - 31,000) 3,080 (640 - 3,530) 15.1 (3.7 - 17.2) 13.6 (3.3 - 15.6)

15 9 9 7 10,875 6,525 6,525 5,075 29,000 (12,000 - 31,000) 3,080 (640 - 3,530) 15.1 (3.7 - 17.2) 13.6 (3.3 - 15.6)

15 9 7 7 11,447 6,868 5,342 5,342 29,000 (12,000 - 31,000) 3,080 (640 - 3,530) 15.1 (3.7 - 17.2) 13.6 (3.3 - 15.6)

15 7 7 7 12,083 5,639 5,639 5,639 29,000 (12,000 - 31,000) 3,080 (640 - 3,530) 15.1 (3.7 - 17.2) 13.6 (3.3 - 15.6)

12 12 12 9 7,733 7,733 7,733 5,800 29,000 (12,000 - 31,000) 3,080 (640 - 3,530) 15.1 (3.7 - 17.2) 13.6 (3.3 - 15.6)

12 12 12 7 8,093 8,093 8,093 4,721 29,000 (12,000 - 31,000) 3,080 (640 - 3,530) 15.1 (3.7 - 17.2) 13.6 (3.3 - 15.6)

12 12 9 9 8,286 8,286

12 12 9 7 8,700 8,700 6,525 5,075 29,000 (12,000 - 31,000) 3,080 (640 - 3,530) 15.1 (3.7 - 17.2) 13.6 (3.3 - 15.6)

12 12 7 7 9,158 9,158 5,342 5,342 29,000 (12,000 - 31,000) 3,080 (640 - 3,530) 15.1 (3.7 - 17.2) 13.6 (3.3 - 15.6)

12 9 9 9 8,923 6,692 6,692 6,692 29,000 (12,000 - 31,000) 3,080 (640 - 3,530) 15.1 (3.7 - 17.2) 13.6 (3.3 - 15.6)

12 9 9 7 9,405 7,054 7,054 5,486 29,000 (12,000 - 31,000) 3,080 (640 - 3,530) 15.1 (3.7 - 17.2) 13.6 (3.3 - 15.6)

12 9 7 7 9,943 7,457 5,800 5,800 29,000 (12,000 - 31,000) 3,080 (640 - 3,530) 15.1 (3.7 - 17.2) 13.6 (3.3 - 15.6)

12 7 7 7 10,545 6,152 6,152 6,152 29,000 (12,000 - 31,000) 3,080 (640 - 3,530) 15.1 (3.7 - 17.2) 13.6 (3.3 - 15.6)

9 9 9 9 7,250 7,250 7,250 7,250 29,000 (12,000 - 31,000) 3,080 (640 - 3,530) 15.1 (3.7 - 17.2) 13.6 (3.3 - 15.6)

9 9 9 7 7,676 7,676 7,676 5,971 29,000 (12,000 - 31,000) 3,080 (640 - 3,530)

9 9 7 7 8,156 8,156 6,344 6,344 29,000 (12,000 - 31,000) 3,080 (640 - 3,530) 15.1 (3.7 - 17.2) 13.6 (3.3 - 15.6)

9 7 7 7 8,700 6,767 6,767 6,767 29,000 (12,000 - 31,000) 3,080 (640 - 3,530) 15.1 (3.7 - 17.2) 13.6 (3.3 - 15.6)

7 7 7 7 7,050 7,050 7,050 7,050 28,200 (12,000 - 30,400) 2,950 (640 - 3,330) 14.4 (3.7 - 16.2) 13.0 (3.3 - 14.7)

18 18 9 - 11,600 11,600 5,800 - 29,000 (12,000 - 31,000) 3,080 (620 - 3,530) 15.1 (3.6 17.2) 13.6 (3.2 - 15.6)

18 18 7 - 12,140 12,140 4,721 - 29,000 (12,000 - 31,000) 3,080 (620 - 3,530) 15.1 (3.6 17.2) 13.6 (3.2 - 15.6)

18 15 12 - 11,600 9,667 7,733 - 29,000 (12,000 - 31,000) 3,080 (620 - 3,530) 15.1 (3.4 - 16.9) 13.6 (3.1 - 15.3)

18 15 9 - 12,429 10,357 6,214 - 29,000 (12,000 - 31,000) 3,080 (620 - 3,530) 15.1 (3.4 - 16.9) 13.6 (3.1 - 15.3)

18 15 7 - 13,050 10,875 5,075 - 29,000 (12,000 - 31,000) 3,080 (620 - 3,530) 15.1 (3.4 - 16.9) 13.6 (3.1 - 15.3)

18 12 12 - 11,743 7,829 7,829 - 27,400 (12,000 - 31,000) 2,980 (600 - 3,500) 14.6 (3.4 - 17.0) 13.2 (3.1 - 15.4)

18 12 9 - 12,646 8,431 6,323 - 27,400 (12,000 - 31,000) 2,980 (600 - 3,500) 14.6 (3.4 - 17.0) 13.2 (3.1 - 15.4)

18 12 7 * 13,330 8,886 5,184 * 27,400 (12,000 - 31,000) 2,980 (600 - 3,500) 14.6 (3.4 - 17.0) 13.2 (3.1 - 15.4)

18 9 9 * 13,700 6,850 6,850 * 27,400 (12,000 - 31,000) 2,980 (600 - 3,500) 14.6 (3.4 - 17.0) 13.2 (3.1 - 15.4)

18 9 7 * 14,506 7,253 5,641 * 27,400 (12,000 - 31,000) 2,980 (600 - 3,500) 14.6 (3.4 - 17.0) 13.2 (3.1 - 15.4)

18 7 7 * 15,413 5,994 5,994 * 27,400 (12,000 - 31,000) 2,980 (600 - 3,500) 14.6 (3.4 - 17.0) 13.2 (3.1 - 15.4)

15 15 12 - 10,357 10,357 8,286 - 29,000 (12,000 - 31,000) 3,080 (600 - 3,480) 15.1 (3.4 - 16.9) 13.6 (3.1 - 15.3)

15 15 9 - 11,154 11,154 6,692 - 29,000 (12,000 - 31,000) 3,080 (600 - 3,480) 15.1 (3.4 - 16.9) 13.6 (3.1 - 15.3)

15 15 7 * 11,757 11,757

15 12 12 - 10,538 8,431 8,431 - 27,400 (12,000 - 31,000) 2,980 (600 - 3,500) 14.6 (3.4 - 17.0) 13.2 (3.1 - 15.4)

15 12 9 * 11,417 9,133 6,850 * 27,400 (12,000 - 31,000) 2,980 (600 - 3,500) 14.6 (3.4 - 17.0) 13.2 (3.1 - 15.4)

15 12 7 * 12,088 9,671 5,641 * 27,400 (12,000 - 31,000) 2,980 (600 - 3,500) 14.6 (3.4 - 17.0) 13.2 (3.1 - 15.4)

15 9 9 * 12,455 7,473 7,473 * 27,400 (12,000 - 31,000) 2,980 (600 - 3,500) 14.6 (3.4 - 17.0) 13.2 (3.1 - 15.4)

15 9 7 * 13,258 7,955 6,187 * 27,400 (12,000 - 31,000) 2,980 (600 - 3,500) 14.6 (3.4 - 17.0) 13.2 (3.1 - 15.4)

15 7 7 * 14,172 6,614 6,614 * 27,400 (12,000 - 31,000) 2,980 (600 - 3,500) 14.6 (3.4 - 17.0) 13.2 (3.1 - 15.4)

12 12 12 * 9,133 9,133 9,133 * 27,400 (10,600 - 29,200) 3,010 (600 - 3,440) 14.7 (3.4 - 16.8) 13.3 (3.1 - 15.2)

12 12 9 * 9,964 9,964 7,473 * 27,400 (10,600 - 29,200) 2,990 (600 - 3,420)

12 12 7 * 10,606 10,606 6,187 * 27,400 (10,600 - 29,200) 2,990 (600 - 3,420) 14.6 (3.4 - 16.7) 13.2 (3.1 - 15.1)

12 9 9 * 10,960 8,220 8,220 * 27,400 (10,600 - 29,200) 2,990 (600 - 3,420) 14.6 (3.4 - 16.7) 13.2 (3.1 - 15.1)

12 9 7 * 11,314 8,486 6,600 * 26,400 (10,600 - 28,800) 2,690 (600 - 3,310) 13.1 (3.4 - 16.1) 11.9 (3.1 - 14.6)

12 7 7 * 11,631 6,785 6,785 * 25,200 (10,600 - 27,600) 2,410 (600 - 2,960) 11.8 (3.4 - 14.4) 10.6 (3.1 - 13.0)

9 9 9 * 8,600 8,600 8,600 * 25,800 (10,600 - 28,200) 2,540 (600 - 3,120) 12.4 (3.4 - 15.2) 11.2 (3.1 - 13.8)

9 9 7 * 8,856 8,856 6,888 * 24,600 (10,600 - 27,000) 2,270 (600 - 2,780) 11.1 (3.4 - 13.6) 10.0 (3.1 - 12.3)

9 7 7 * 9,078 7,061 7,061 * 23,200 (10,600 - 25,600) 2,010 (600 - 2,460) 9.8 (3.4 - 12.0) 8.9 (3.1 - 10.9)

7 7 7 * 7,267 7,267 7,267 * 21,800 (10,600 - 24,000) 1,770 (600 - 2,160) 8.6 (3.4 - 10.5) 7.8 (3.1 - 9.5)

AE-X4M30PU

Cooling capacity (Btu/h)

6,214 6,214 29,000 (12,000 - 31,000) 3,080 (640 - 3,530) 15.1 (3.7 - 17.2) 13.6 (3.3 - 15.6)

5,486 * 29,000 (12,000 - 31,000) 3,080 (600 - 3,480) 15.1 (3.4 - 16.9) 13.6 (3.1 - 15.3)

Power input (W)

Rating (Min. - Max.)

Running curent (A)

Rating (Min. - Max.)

15.1 (3.7 - 17.2) 13.6 (3.3 - 15.6)

14.6 (3.4 - 16.7) 13.2 (3.1 - 15.1)

5

Page 6

AE-X4M30PU

Operating

Status

2-indoor unit

operation

1-indoor unit

operation

Indoor unit

combination

A B C D A B C D Rating ( Min - Max) 208V 230V

18 18 * - 14,500 14,500 * - 29,000 (11,500 - 30,200) 3,080 (630 - 3,480) 15.1 (3.6 - 16.9) 13.6 (3.3 - 15.3)

18 15 * - 15,818 13,182 * - 29,000 (11,500 - 30,200) 3,080 (630 - 3,480) 15.1 (3.6 - 16.9) 13.6 (3.3 - 15.3)

18 12 * * 16,440 10,960 * * 27,400 (10,000 - 28,800) 2,930 (630 - 3,320) 14.3 (3.6 - 16.2) 12.9 (3.3 - 14.6)

18 9 * * 17,600 8,800 * * 26,400 (10,000 - 28,800) 2,640 (630 - 3,320) 12.9 (3.6 - 16.2) 11.7 (3.3 - 14.6)

18 7 * * 17,856 6,944 * * 24,800 (10,000 - 28,800) 2,360 (630 - 3,320) 11.5 (3.6 - 16.2) 10.4 (3.3 - 14.6)

15 15 * * 13,700 13,700 * * 27,400 (11,000 - 30,200) 3,070 (660 - 3,590) 15.0 (3.8 - 17.5) 13.6 (3.4 - 15.8)

15 12 * * 14,111 11,289 * * 25,400 (9,900 - 27,400) 2,620 (580 - 3,300) 12.8 (3.3 - 16.1) 11.6 (3.0 - 14.5)

15 9 * * 14,625 8,775 * * 23,400 (9,900 - 27,400) 2,230 (580 - 3,300) 10.9 (3.3 - 16.1) 9.8 (3.0 - 14.5)

15 7 * * 14,864 6,936 * * 21,800 (9,900 - 26,400) 1,980 (580 - 3,020) 9.7 (3.3 - 14.7) 8.7 (3.0 - 13.3)

12 12 * * 11,100 11,100 * * 22,200 (8,300 - 25,600) 2,240 (500 - 3,210) 10.9 (2.9 - 15.6) 9.9 (2.6 - 14.1)

12 9 * * 11,543 8,657 * * 20,200 (8,300 - 24,400) 1,860 (500 - 2,810) 9.1 (2.9 - 13.7) 8.2 (2.6 - 12.4)

12 7 * * 11,747 6,853 * * 18,600 (8,300 - 23,000) 1,630 (500 - 2,450) 7.9 (2.9 - 11.9) 7.2 (2.6 - 10.8)

9 9 * * 9,000 9,000 * * 18,000 (8,300 - 22,200) 1,520 (500 - 2,270) 7.4 (2.9 - 11.1) 6.7 (2.6 - 10.0)

9 7 * * 9,225 7,175 * * 16,400 (8,300 - 20,400) 1,300 (500 - 1,940) 6.3 (2.9 - 9.5) 5.7 (2.6 - 8.6)

7 7 * * 7,400 7,400 * * 14,800 (8,300 - 18,400) 1,100 (500 - 1,620) 5.3 (2.9 - 7.9) 4.8 (2.6 - 7.2)

18 * * *

15 * * * 16,200 * * * 16,200 (7,200 - 18,000) 1,440 (500 - 1,730) 7.0 (2.9 - 8.5) 6.3 (2.6 - 7.6)

12 * * * 12,200 * * * 12,200 (5,800 - 13,200) 1,090 (420 - 1,280) 5.3 (2.4 - 6.3) 4.8 (2.2 - 5.7)

9 * * * 9,700 * * * 9,700 (5,800 - 10,800) 790 (420 - 920) 3.8 (2.4 - 4.5) 3.5 (2.2 - 4.1)

7 * * * 7,800 * * * 7,800 (5,800 - 9,000) 600 (420 - 700) 2.9 (2.4 - 3.4) 2.6 (2.2 - 3.1)

19,200 * * * 19,200 (7,200 - 21,000) 1,810 (500 - 2,190) 8.8 (2.9 - 10.7) 8.0 (2.6 - 9.7)

Cooling capacity (Btu/h)

* When connected indoor unit is not in operation.

- When no unit is connected.

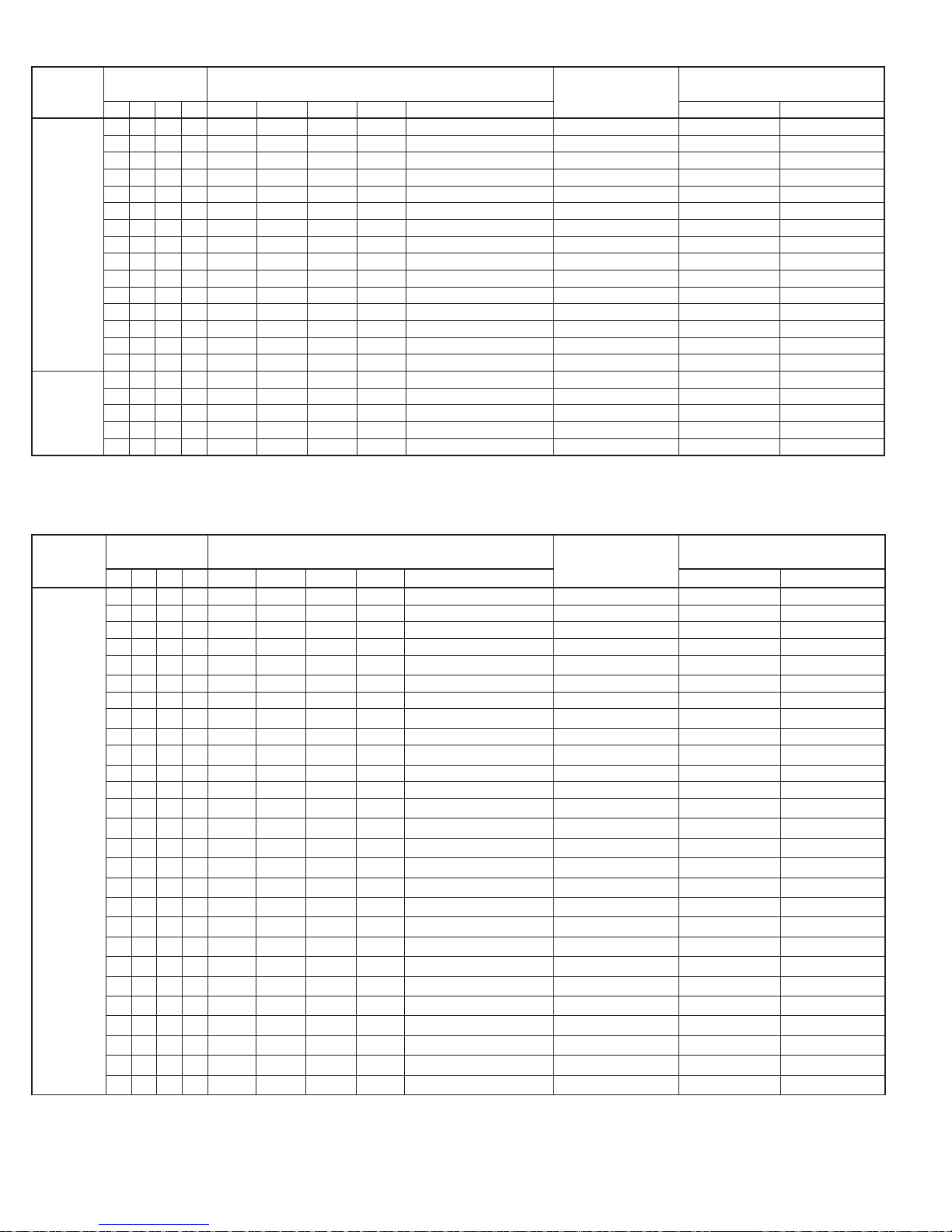

HEATING CAPACITY TABLE

Operating

Status

4-indoor unit

operation

Indoor unit

combination

A B C D A B C D Rating ( Min - Max) 208V 230V

18 12 7 7 13,500 9,000 5,250 5,250 33,000 (12,000 - 37,000) 2,860 (800 - 3,250) 13.9 (4.1 - 15.8) 12.6 (3.7 - 14.3)

18 9 9 9 13,200 6,600 6,600 6,600 33,000 (12,000 - 37,000) 2,860 (800 - 3,250) 13.9 (4.1 - 15.8) 12.6 (3.7 - 14.3)

18 9 9 7 13,814 6,907 6,907 5,372 33,000 (12,000 - 37,000) 2,860 (800 - 3,250) 13.9 (4.1 - 15.8) 12.6 (3.7 - 14.3)

18 9 7 7 14,488 7,244 5,634 5,634 33,000 (12,000 - 37,000) 2,860 (800 - 3,250) 13.9 (4.1 - 15.8) 12.6 (3.7 - 14.3)

18 7 7 7 15,231 5,923 5,923 5,923 33,000 (12,000 - 37,000) 2,860 (800 - 3,250) 13.9 (4.1 - 15.8) 12.6 (3.7 - 14.3)

15 15 7 7 11,250 11,250 5,250 5,250 33,000 (12,000 - 37,000) 2,860 (800 - 3,250) 13.9 (4.1 - 15.8) 12.6 (3.7 - 14.3)

15 12 9 9 11,000 8,800 6,600 6,600 33,000 (12,000 - 37,000) 2,860 (800 - 3,250) 13.9 (4.1 - 15.8) 12.6 (3.7 - 14.3)

15 12 9 7 11,512 9,209 6,907 5,372 33,000 (12,000 - 37,000) 2,860 (800 - 3,250) 13.9 (4.1 - 15.8) 12.6 (3.7 - 14.3)

15 12 7 7 12,073 9,659 5,634 5,634 33,000 (12,000 - 37,000) 2,860 (800 - 3,250) 13.9 (4.1 - 15.8) 12.6 (3.7 - 14.3)

15 9 9 9 11,786 7,071 7,071 7,071 33,000 (12,000 - 37,000) 2,860 (800 - 3,250) 13.9 (4.1 - 15.8) 12.6 (3.7 - 14.3)

15 9 9 7 12,375 7,425 7,425 5,775 33,000 (12,000 - 37,000) 2,860 (800 - 3,250) 13.9 (4.1 - 15.8) 12.6 (3.7 - 14.3)

15 9 7 7 13,026 7,816 6,079 6,079 33,000 (12,000 - 37,000) 2,860 (800 - 3,250) 13.9 (4.1 - 15.8) 12.6 (3.7 - 14.3)

15 7 7 7 13,750 6,417 6,417 6,417 33,000 (12,000 - 37,000) 2,860 (800 - 3,250) 13.9 (4.1 - 15.8) 12.6 (3.7 - 14.3)

12 12 12 9 8,800 8,800 8,800 6,600 33,000 (12,000 - 37,000) 2,860 (800 - 3,250) 13.9 (4.1 - 15.8) 12.6 (3.7 - 14.3)

12 12 12 7 9,209 9,209 9,209 5,372 33,000 (12,000 - 37,000) 2,860 (800 - 3,250) 13.9 (4.1 - 15.8) 12.6 (3.7 - 14.3)

12 12 9 9 9,429 9,429

12 12 9 7 9,900 9,900 7,425 5,775 33,000 (12,000 - 37,000) 2,860 (800 - 3,250) 13.9 (4.1 - 15.8) 12.6 (3.7 - 14.3)

12 12 7 7 10,421 10,421 6,079 6,079 33,000 (12,000 - 37,000) 2,860 (800 - 3,250) 13.9 (4.1 - 15.8) 12.6 (3.7 - 14.3)

12 9 9 9 10,154 7,615 7,615 7,615 33,000 (12,000 - 37,000) 2,860 (800 - 3,250) 13.9 (4.1 - 15.8) 12.6 (3.7 - 14.3)

12 9 9 7 10,703 8,027 8,027 6,243 33,000 (12,000 - 37,000) 2,860 (800 - 3,250) 13.9 (4.1 - 15.8) 12.6 (3.7 - 14.3)

12 9 7 7 11,314 8,486 6,600 6,600 33,000 (12,000 - 37,000) 2,860 (800 - 3,250) 13.9 (4.1 - 15.8) 12.6 (3.7 - 14.3)

12 7 7 7 12,000 7,000 7,000 7,000 33,000 (12,000 - 37,000) 2,860 (800 - 3,250) 13.9 (4.1 - 15.8) 12.6 (3.7 - 14.3)

9 9 9 9 8,250 8,250 8,250 8,250 33,000 (12,000 - 37,000) 2,860 (800 - 3,250) 13.9 (4.1 - 15.8) 12.6 (3.7 - 14.3)

9 9 9 7 8,735 8,735 8,735 6,794 33,000 (12,000 - 37,000) 2,860 (800 - 3,250)

9 9 7 7 9,281 9,281 7,219 7,219 33,000 (12,000 - 37,000) 2,860 (800 - 3,250) 13.9 (4.1 - 15.8) 12.6 (3.7 - 14.3)

9 7 7 7 9,900 7,700 7,700 7,700 33,000 (12,000 - 37,000) 2,860 (800 - 3,250) 13.9 (4.1 - 15.8) 12.6 (3.7 - 14.3)

7 7 7 7 7,600 7,600 7,600 7,600 30,400 (12,000 - 34,000) 2,520 (800 - 2,950) 12.3 (4.1 - 14.4) 11.1 (3.7 - 13.0)

Heating capacity (Btu/h)

7,071 7,071 33,000 (12,000 - 37,000) 2,860 (800 - 3,250) 13.9 (4.1 - 15.8) 12.6 (3.7 - 14.3)

Power input (W)

Rating (Min. - Max.)

Power input (W)

Rating (Min. - Max.)

Running curent (A)

Rating (Min. - Max.)

Running curent (A)

Rating (Min. - Max.)

13.9 (4.1 - 15.8) 12.6 (3.7 - 14.3)

6

Page 7

AE-X4M30PU

Operating

Status

3-indoor unit

operation

2-indoor unit

operation

1-indoor unit

operation

Indoor unit

combination

A B C D A B C D Rating ( Min - Max) 208V 230V

18 18 9 - 13,200 13,200 6,600 - 33,000 (12,000 - 37,000) 2,780 (800 - 3,250) 13.6 (4.1 - 15.8) 12.3 (3.7 - 14.3)

18 18 7 - 13,814 13,814 5,372 - 33,000 (12,000 - 37,000) 2,780 (800 - 3,250) 13.6 (4.1 - 15.8) 12.3 (3.7 - 14.3)

18 15 12 - 13,200 11,000 8,800 - 33,000 (12,000 - 37,000) 2,780 (800 - 3,250) 13.6 (4.1 - 15.8) 12.3 (3.7 - 14.3)

18 15 9 - 14,143 11,786 7,071 - 33,000 (12,000 - 37,000) 2,780 (800 - 3,250) 13.6 (4.1 - 15.8) 12.3 (3.7 - 14.3)

18 15 7 - 14,850 12,375 5,775 - 33,000 (12,000 - 37,000) 2,780 (800 - 3,250) 13.6 (4.1 - 15.8) 12.3 (3.7 - 14.3)

18 12 12 - 13,114 8,743 8,743 - 30,600 (12,000 - 33,400) 2,720 (780 - 3,150) 13.3 (4.0 - 15.3) 12.0 (3.6 - 13.9)

18 12 9 - 14,123 9,415 7,062 - 30,600 (12,000 - 33,400) 2,720 (780 - 3,150) 13.3 (4.0 - 15.3) 12.0 (3.6 - 13.9)

18 12 7 * 14,886 9,924 5,789 * 30,600 (12,000 - 33,400) 2,720 (780 - 3,150) 13.3 (4.0 - 15.3) 12.0 (3.6 - 13.9)

18 9 9 * 15,300 7,650 7,650 * 30,600 (12,000 - 33,400) 2,720 (780 - 3,150) 13.3 (4.0 - 15.3) 12.0 (3.6 - 13.9)

18 9 7 * 16,200 8,100 6,300 * 30,600 (12,000 - 33,400) 2,720 (780 - 3,150) 13.3 (4.0 - 15.3) 12.0 (3.6 - 13.9)

18 7 7 * 17,213 6,694 6,694 * 30,600 (12,000 - 33,400) 2,720 (780 - 3,150) 13.3 (4.0 - 15.3) 12.0 (3.6 - 13.9)

15 15 12 - 11,357 11,357 9,086 - 31,800 (12,000 - 34,200) 2,710 (800 - 3,170) 13.2 (4.1 - 15.4) 12.0 (3.7 - 14.0)

15 15 9 - 12,231 12,231 7,338 - 31,800 (12,000 - 34,200) 2,710 (800 - 3,170) 13.2 (4.1 - 15.4) 12.0 (3.7 - 14.0)

15 15 7 * 12,892 12,892 6,016 * 31,800 (12,000 - 34,200) 2,710 (800 - 3,170) 13.2 (4.1 - 15.4) 12.0 (3.7 - 14.0)

15 12 12 - 11,769 9,415 9,415 - 30,600 (12,000 - 32,400) 2,750 (780 - 3,190) 13.4 (4.0 - 15.5) 12.1 (3.6 - 14.1)

15 12 9 * 12,750 10,200

15 12 7 * 13,500 10,800 6,300 * 30,600 (12,000 - 32,400) 2,750 (780 - 3,190) 13.4 (4.0 - 15.5) 12.1 (3.6 - 14.1)

15 9 9 * 13,909 8,345 8,345 * 30,600 (12,000 - 32,400) 2,750 (780 - 3,190) 13.4 (4.0 - 15.5) 12.1 (3.6 - 14.1)

15 9 7 * 14,806 8,884 6,910 * 30,600 (12,000 - 32,400) 2,750 (780 - 3,190) 13.4 (4.0 - 15.5) 12.1 (3.6 - 14.1)

15 7 7 * 15,828 7,386 7,386 * 30,600 (12,000 - 32,400) 2,750 (780 - 3,190) 13.4 (4.0 - 15.5) 12.1 (3.6 - 14.1)

12 12 12 * 10,200 10,200 10,200 * 30,600 (12,000 - 32,400) 2,940 (780 - 3,220) 14.3 (4.0 - 15.7) 13.0 (3.6 - 14.2)

12 12 9 * 11,127 11,127 8,345 * 30,600 (12,000 - 32,400) 2,940 (780 - 3,240) 14.3 (4.0 - 15.8) 13.0 (3.6 - 14.3)

12 12 7 * 11,845 11,845 6,910 * 30,600 (12,000 - 32,400) 2,940 (780 - 3,250) 14.3 (4.0 - 15.8) 13.0 (3.6 - 14.3)

12 9 9 * 12,240 9,180 9,180 * 30,600 (12,000 - 32,400) 2,940 (780 - 3,270)

12 9 7 * 13,114 9,836 7,650 * 30,600 (12,000 - 32,400) 2,940 (780 - 3,280) 14.3 (4.0 - 16.0) 13.0 (3.6 - 14.5)

12 7 7 * 14,123 8,238 8,238 * 30,600 (12,000 - 32,400) 2,940 (780 - 3,290) 14.3 (4.0 - 16.0) 13.0 (3.6 - 14.5)

9 9 9 * 10,200 10,200 10,200 * 30,600 (12,000 - 32,400) 2,940 (780 - 3,300) 14.3 (4.0 - 16.1) 13.0 (3.6 - 14.5)

9 9 7 * 11,016 11,016 8,568 * 30,600 (12,000 - 32,400) 2,960 (780 - 3,310) 14.4 (4.0 - 16.1) 13.0 (3.6 - 14.6)

9 7 7 * 11,191 8,704 8,704 * 28,600 (12,000 - 31,600) 2,530 (780 - 3,070) 12.3 (4.0 - 15.0) 11.2 (3.6 - 13.5)

7 7 7 * 8,600 8,600 8,600 * 25,800 (12,000 - 29,200) 2,180 (780 - 2,620) 10.6 (4.0 - 12.8) 9.6 (3.6 - 11.6)

18 18 * - 16,500 16,500 * - 33,000 (12,000 - 35,600) 3,040 (850 - 3,570) 14.8 (4.4 - 17.4) 13.4 (3.9 - 15.7)

18 15 * - 18,000 15,000 * - 33,000 (12,000 - 35,600) 3,040 (850 - 3,570) 14.8 (4.4 - 17.4) 13.4 (3.9 - 15.7)

18 12 * * 18,360 12,240 * * 30,600 (12,000 - 31,200) 3,030 (780 - 3,320) 14.8 (4.0 - 16.2) 13.4 (3.6 - 14.6)

18 9 * * 20,400 10,200 * * 30,600 (12,000 - 31,200) 3,030 (780 - 3,320) 14.8 (4.0 - 16.2) 13.4 (3.6 - 14.6)

18 7 * * 21,456 8,344 * * 29,800 (12,000 - 31,200) 2,880 (780 - 3,320) 14.0 (4.0 - 16.2) 12.7 (3.6 - 14.6)

15 15 * * 15,700 15,700 * * 31,400 (12,000 - 34,000) 2,970 (810 - 3,460) 14.5 (4.1 - 16.9) 13.1 (3.8 - 15.2)

15 12 * * 16,667 13,333 * * 30,000 (11,600 - 31,200) 3,110 (780 - 3,490) 15.2 (4.0 - 17.0) 13.7 (3.6 - 15.4)

15 9 * * 17,750 10,650 * * 28,400 (11,600 - 31,200) 2,840 (780 - 3,490) 13.8 (4.0 - 17.0) 12.5 (3.6 - 15.4)

15 7 * * 17,591 8,209 * * 25,800 (11,600 - 31,200) 2,430 (780 - 3,490) 11.9 (4.0 - 17.0) 10.7 (3.6 - 15.4)

12 12 * * 14,000 14,000 * * 28,000 (11,000 - 28,400) 3,040 (760 - 3,240) 14.8 (3.9 - 15.8) 13.4 (3.5 - 14.3)

12 9 * * 14,286 10,714

12 7 * * 14,400 8,400 * * 22,800 (11,000 - 28,400) 2,140 (760 - 3,240) 10.4 (3.9 - 15.8) 9.4 (3.5 - 14.3)

9 9 * * 10,700 10,700 * * 21,400 (11,000 - 28,400) 1,980 (770 - 3,240) 9.7 (3.9 - 15.8) 8.7 (3.6 - 14.3)

9 7 * * 10,688 8,313 * * 19,000 (11,000 - 26,000) 1,650 (770 - 2,830) 8.1 (3.9 - 13.8) 7.3 (3.6 - 12.5)

7 7 * * 8,200 8,200 * * 16,400 (11,000 - 22,800) 1,350 (770 - 2,300) 6.6 (3.9 - 11.2) 6.0 (3.6 - 10.2)

18 * * * 23,000 * * * 23,000 (11,000 - 25,000) 2,890 (880 - 2,990) 14.1 (4.5 - 14.6) 12.7 (4.1 - 13.2)

15 * * * 19,000 * * * 19,000 (10,000 - 21,600) 2,250 (870 - 2,810) 11.0 (4.5 - 13.7) 9.9 (4.0 - 12.4)

12 * * * 15,600 * * * 15,600 (8,600 - 17,000) 1,930 (850 - 2,340) 9.4 (4.4 - 11.4) 8.5 (3.9 - 10.3)

9 * * * 11,400 * * * 11,400 (8,600 - 15,600)

7 * * * 8,400 * * * 8,400 (8,600 - 12,000) 850 (850 - 1,370) 4.2 (4.4 - 6.7) 3.8 (3.9 - 6.1)

Heating capacity (Btu/h)

7,650 * 30,600 (12,000 - 32,400) 2,750 (780 - 3,190) 13.4 (4.0 - 15.5) 12.1 (3.6 - 14.1)

* When connected indoor unit is not in operation.

- When no unit is connected.

Power input (W)

Rating (Min. - Max.)

* * 25,000 (11,000 - 28,400) 2,490 (760 - 3,240) 12.1 (3.9 - 15.8) 11.0 (3.5 - 14.3)

1,230 (850 - 2,080) 6.0 (4.4 - 10.2) 5.5 (3.9 - 9.2)

Running curent (A)

Rating (Min. - Max.)

14.3 (4.0 - 15.9) 13.0 (3.6 - 14.4)

7

Page 8

AE-X4M30PU

ELECTRICAL PARTS

Fuse 1, 5 — QFS-GA065JBZZ(20A,250V)

Fuse 2 — QFS-GA062JBZZ(3.15A,250V)

Fuse 3, 6 — QFS-GA063JBZZ(2A,250V)

CYCLE PARTS

PARTS MODEL TYPE PARTS CODE

Compressor SNB172EFKMT 17.2cc DC TWIN ROTARY 1200W PCMPRA718JBEZ

Fan motor ARW8404SH DC MOTOR 8Poles, 60W CMOTLB541JBEZ

Refrigerant control

Expansion valve (Body) Φ1.8 PVLVRA047JBEZ

Expansion valve (Coil) DC12V RMOTSA050JBZZ

PRESSURE SWITCH ACB-4UB65 OFF:4.5MPa / ON:3.5MPa RBIM-A003JBEZ

Reverse Valve

(Body) SHF-7H-34U-P PVLVXA081JBEZ

(Coil) 50/60Hz 220-240V CCIL-A185JBKZ

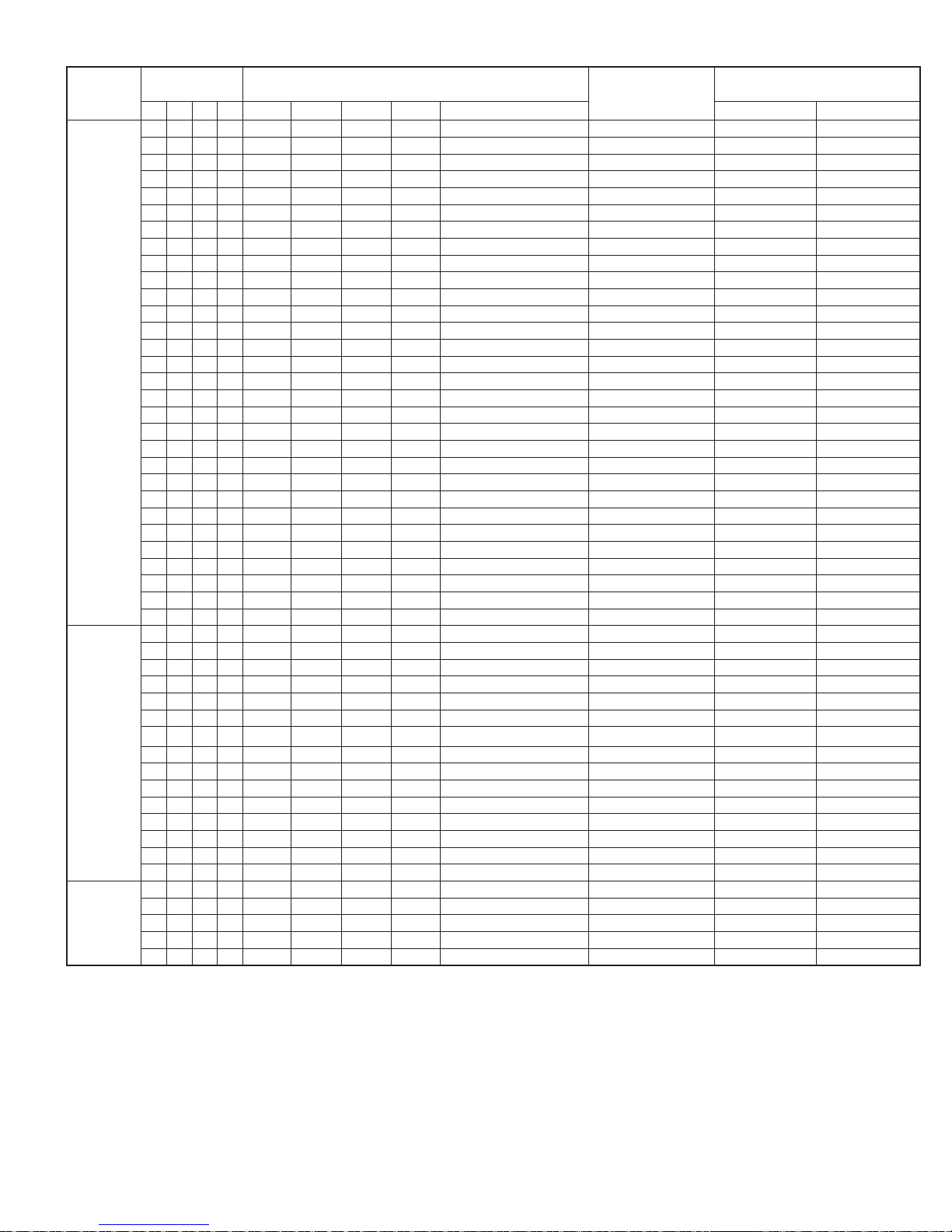

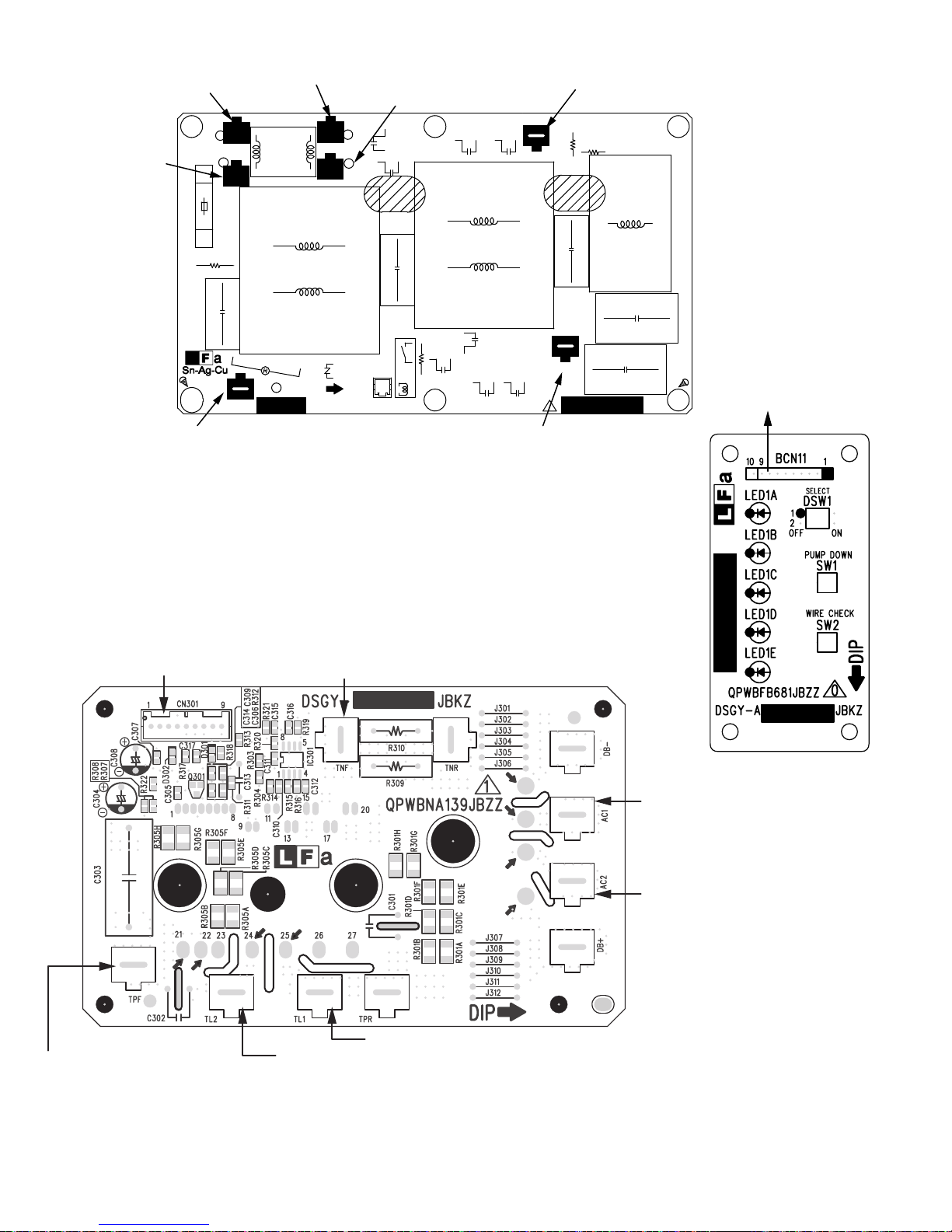

WIRING DIAGRAMS

WIRING DIAGRAM

CAUTION

(UNIT C)

(UNIT A)

The voltage is high at C8, C9, C11(electrolytic capacitors) on outdoor unit. For maintenance discharge at C8, C9, C11 to prevent electric shock,

in case that FUSE5(protector) has been fused, the voltage is kept high at C8, C9, C11.

BL

OR

RD

CN6

(UNIT D)

L1 L1

L2 L2

(UNIT B)

L1 L1

L2 L2

BK

VT

BL

BN

BK

CN2

BK

VT

The 4 LEDs of the display board will all flash synchronously. For patterns No.1, No.2

and No.4, only the LED corresponding with the abnormal unit will flash in the patterns

above, and the LED for the normal unit will flash in the slow flashing cycle.

BL

BN

OR

RD

G/Y

BL

L1

L2

BN

BL

BN

G/Y

BL

BN

T23

T22

T21

T20

CE011

EXV.

UNIT A

CN12A

20A

250V

EXV.

UNIT B

CN12B

C1

RY3

C2

L3

EXV.

UNIT C

CN12C

1

2

PRESSURE

SWITCH

4WAY

VALVE

FILTER BOARD

C3

L4

EXV.

UNIT D

CN12D

The microcomputer’s GND line which

control the thermistor,etc. share the

same line of 330V line. This circuit is

non-insulation type. Do not touch

CN15B

the control circuit components as it

may result in electrical shock hazard.

Do not earth osilloscope etc. during

measurement, as it may result in

damage.

CN4

RY1

NR2

T11

C4

C5

L5

T10

T13

BL

T14

BN

UNIT D

TH9

YL

CN8M

FUSE2

250V

3.15A

CT1

UNIT C

TH8

BN

PTC1

MRY1

TH7

WT

UNIT B

UNIT A

TH6

BL

9

BCN13

CN301

AC1

DB301

GY

+

-

BK

T15

AC2

PFC MODULE BOARD

BK

CN8A

LED1A

LED1B

LED1C

LED1D

GN

DSW1

1

2

OFF

PUMP DOWN

WIRE CHECK

TL1

PFCM

301

BK: BLACK

BL: BLUE

BN: BROWN

LED pattern

No.

RD

OR

CN11

BCN11

ON

SW1

SW2

Example: No.3 Overheat error (Compressor, Power module)

FUSE3

2A

C9 C11

+

250V

FUSE6

+

L1

TL2

TPF

TNF

YL

BL

BT11

C8

+

BT12

OR: ORANGE

GY: GRAY

RD: RED

GN: GREEN

WT: WHITE

YL: YELLOW

Abnormal comments

Normal

Abnormal signal line

Short circuit of the thermistor

Overheat error (Compressor, Power module)

Pressure switch error

Open circuit of the thermistor

Power module(IPM) abnormality

Abnormal AC current

Abnormal wire check

Cycle temperature error

EEPROM error

Rotation error of the fan motor

Thermal fuse error of terminal board

Compressor rotation error

Power factor (PFC)module error

or clock signal error

3

4

5

8

2A

250V

FUSE5

20A

250V

C14

N

G(/Y): GREEN/YELLOW

VT: VIOLET

DC FAN MOTOR

CN3

2

1

RD

U

T7

WT

V

T8

V

W

T9

OR

IPM

U

W

8

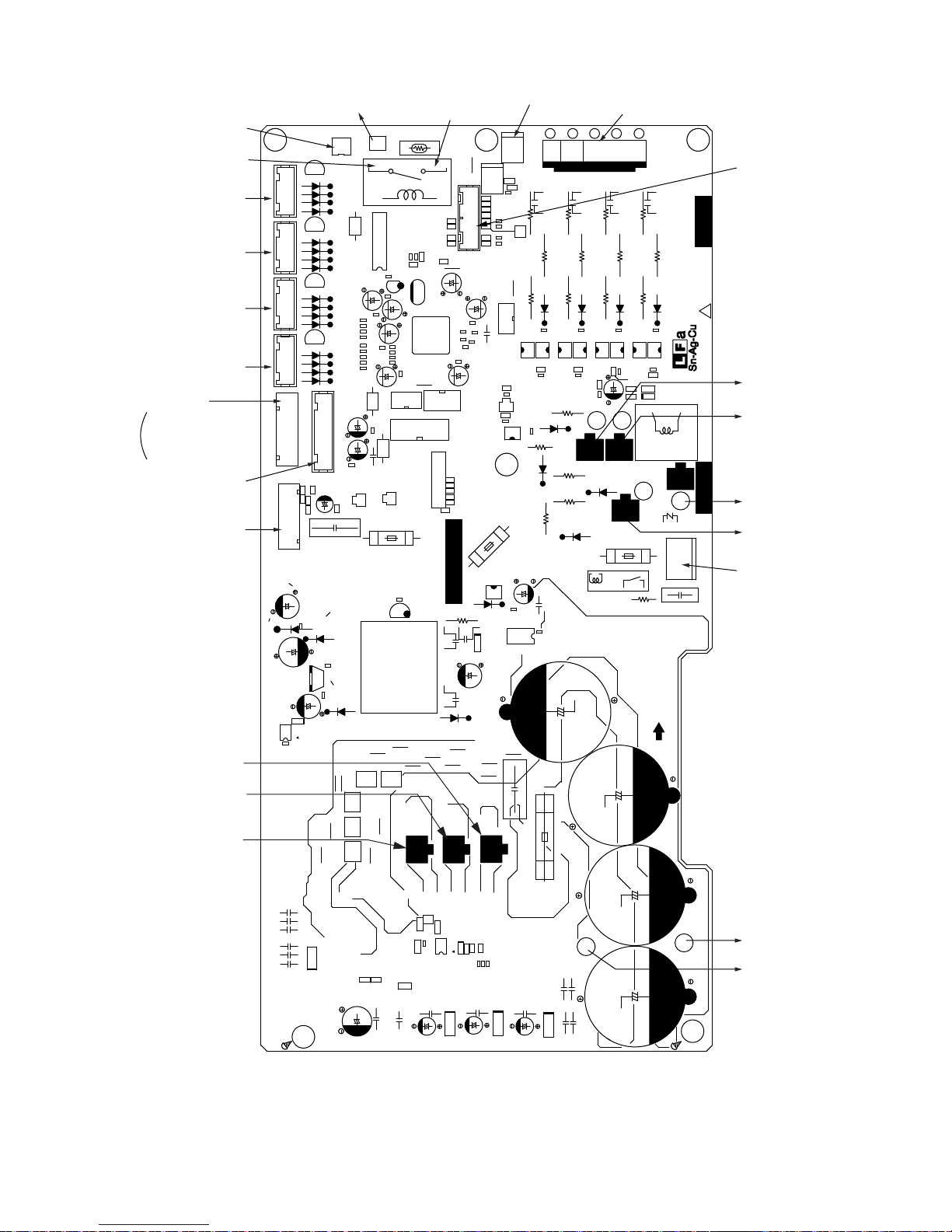

Page 9

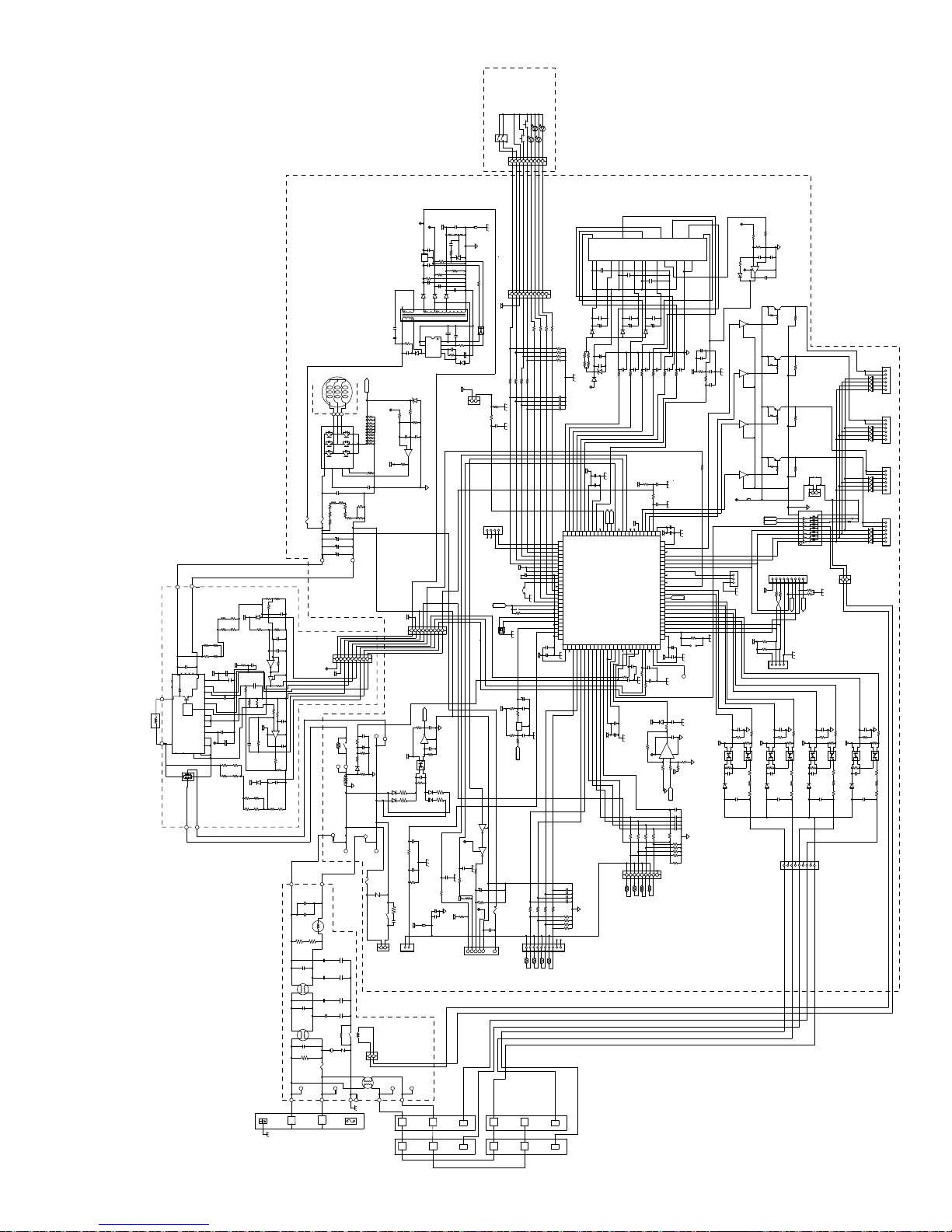

AE-X4M30PU

from Terminal Board

Power Supply (Black)

from MAin PWB BT6 (Blue)

from Exporsion Valve A

from Exporsion Valve B

from Exporsion Valve C

from Exporsion Valve D

from Thermistor

Comp. Temp.

Heat Exchange T emp.

Outdoor Temp/

Suction

from Suction Thermistor

from Fan Motor

from Compressor (U)(Red)

from Compressor (V)(White)

from Compressor (W)(Orange)

to Filter PWB CN14

(THERMAL FUSE)

CN2

2

6

(VALVE A)

1

6

(VALVE B)

1

6

(VALVE C)

1

6

(VALVE D)

1

9

(THERMISTOR A)

1

1

(DC FAN MOTOR)

CN3

8

12V

IC9

Q6AQ6BQ6C

CN12A

C

E8B

D22A

D23A

D24A

D25A

CN12BCN12C

C

B

E

D22B

D23B

D24B

D25B

C

B

E

D22C

D23C

D24C

D25C

Q6D

E

C

B

CN12D

D22D

D23D

D24D

D25D

10

CN8M

CN8A

1

○

R104

R245

C100

R109

R103

R100

5V

C24

0V

C23

D7

D12

C20

C26

IC4

15V

C25

D6

C19

D26

C89

JP26

JP24

JP23

(THERMISTOR M)

C48

R101

JP25

R241

R240

R49

FB2

C54D

C54C

C54B

C54A

C47

1

C69

C68

C67

C66

C64

Q3

C99

(To CN14)

2

MRY_IN(BLUE)

MRY1

9

16

C123

FB3

C61

E

9

TR1

16

R242

BCN14

C124

C128

C45

C31

C125

C126

C103

C106

C107

C60

FU6

JP76

JP22

1

8

IC7

1

IC5

C32

C33

51

C90

75

4

CNM

(MONITOR)

9

(FLASH WRITER EEPROM)

FB1

E

Q4

250V/2A

C21

JP69

R243

JP21

C127

from PFCM PWB

AC1 (Black)

PTC1

CN15A(12V)

1

JP93

10

CN11

MRY_OUT(BLACK)

R53

R52

R55

R51

R43

C300

C301

R44

OSC1

50

76

JP94

1

1

1

BCN13

(To CN301)

9

IC3

JP77

T9

(ORANGE)

R263

JP58

CN-2

R255

C98

8

1

JP92

26

C93

IC1

1 25

C95

100

5

CND

1

R76

R102

R107

R108

R73

R75

R17

C105

C27

C85

D14

JP66

JP78

T8

(WHITE)

R54

1

(DISPLAY)

C104

C102

C101

C77

C74

C94

R105

PC6

1

2

D5

0V-P

C84

JP73

JP65

(RED)

from Pressure

Switch

(PRESSURE SWITCH)

1

2

CN15B

2

R258

R259

C137

R96D

R96C

R96B

R96A

R31D

C59

C58

R57

R56

C57

C56

JP7

C30

C46

CN-1

PC2D

1

R106

C83

Q6

C82

2

3

4

1

PC3

R238

FU3

250V/2A

C15

43

D4

C16

4

IC2

5

JP70

T7

CN6

9

R32D

R33D

2

3

4

2

3

C81

D17

1

C18

C14

250V/20A

FU5

from Terminal Board

Unit D "2", Unit C "2", Unit B "2", Unit A "2", "L1"

B

D18C

14

PC1C

PC2B

1

D13

RY1

R31B

R33B

2

3

4

2

3

R147

C97

(BROWN)

BT13

FU2

N

A

(TERMINAL BOARD)

R31A

C39B

R32B

R33A

D18B

C38B

4

1

PC1B

PC2A

4

1

C37B

R35B

R91

R90

C79

CT1

T13

(BROWN)

(To F-T10)

250V/3.15A

R180

C11

3

2

T14

1

2

3

BT14

(BLUE)

(To F-T11)

R89

D2

(BLUE)

C39A

C37A

R35A

C38A

NR2

DIP

R32A

D18A

1

PC1A

4

(To MRYIN)

T6

(BLUE)

C129

C8

BT6

(BLUE)

1

CN4

3

from Display PWB

JBKZ

DSGY-

2

to PFCM PWB AC2 (Gray)

QPWBNA221JBZZ

to Filter PWB T10 (Brown)

JBKZ

to Main PWB MRY1 (Blue)

to Filter PWB T11 (Blue)

FH-IXA

from 4 way Valve

(4 WAY VALVE)

C

D

R31C

C39C

C39D

R32C

R33C

D18D

2

3

C38C

C38D

4

1

PC2C

PC1D

4

1

2

R35C

R35D

3

C37D

C37C

R236

BT15

(GRAY)

D16

(GRAY)

(To P-AC2)

T15

R237

R235

R234

D15

C17

C43 C44C42

C41

C40

D11

C134

34

R50

ZD3

R262

R249

R250

C138

R261

R260 R248

29

C135

R233

C53

C122

C136

○

C133

R247

D27

IC11

C131

C132

C130

C51

○

○

○

○

○

D10

○

○

○

○

○

D9

C52

40

(YELLOW)

(To PFC-TPF)

BT11

C55

C72

1

C49

○

○

○

○

C70

D8

C50

C71

C9

(BLUE)

(To PFC-TNF)

to PFCM PWB TNF (Blue)

BT12

to PFCM PWB TPF (Yellow)

C10

9

Page 10

AE-X4M30PU

from Terminal Board AB (L1)

(Brown)

from Terminal Board

(L2) (Brown)

(FROM TERMINAL BOARD

(FROM TERMINAL BOARD

POWER SUPPLY L)

FU1

250V/20A

C1

from Control Box (Green/ Yellow)

from Terminal Board AB (L2)

(Blue)

T22

BT22

(BROWN)

INDOOR UNIT 1)

R4

BT20

(BROWN)

T20

L6

L3

(FROM TERMINAL BOARD

SA1

(GREEN/YELLOW)

T4

BT4

DSGY-

T23

(FROM TERMINAL BOARD

INDOOR UNIT N)

T21

POWER SUPPLY N)

NR1

DIP

JBKZ

from Terminal Board (L1)(Blue)

BT23

C13B

(BLUE)

C14B

BT21

(BLUE)

C2

RY3

R3

(FROM BCN14)

2

CN14

C11B

1

QPWBNA223JBZZ

C12B

C13C

from Main PWB (T14)(Blue)

C14C

(FROM T14)

L4

T10

(BROWN)

(FROM T13)

C12C

C11C

(BLUE)

2

R2

C3

C4

C5

R1

T11

from Main PWB (T13)(Brown)

L5

to Main PWB (CN11)

from Main PWB

BCN13

from Main PWB BT11 (Yellow)

from Main PWB BT12 (Blue)

from Main PWB

MRY1 OUT (Black)

from Main PWB T15 (Gray)

from PFC coil

from PFC coil

10

Page 11

AE-X4M30PU

UNIT D

WIRE CHECK SW

UNIT B

UNIT A

UNIT C

PUMP DOWN SW

SW2

LED1D

LED1B

2: PRE HEAT SELECT

1: -15°C AUTO OFF SELECT

1

2

SW1

DSW1

LED1A

LED1C

1

23456

(DISPLAY PWB)

789

BCN11

[BOARD IN]

5V

C23

FB1

25V

0.1μF

F

10KΩ

15V

3

1

BAJ5CC0T

R22

22KΩ

C19

D6

2

16

1

TR1

8

5

C85

250V

4700pF

R17

300KΩ

C105

250V

4700pF

7

5

D5

C27

Fp022 Vk1

Z

COMPRESSOR

T7

T9

T8

373839

VWU

NWNU NV

NOTE: All Resistance that is not indicated watt are 1/10W.

(MAIN PWB)

250V

2A

FU3

F

F

TNF

TPF

1/4W

F

1/4W

R305F

180KΩ

R305H

F

F

1/4W

1/4W

R305E

1/4W

180KΩ

180KΩ

R305D

180KΩ

F

R305B

630V

0.33μF

C303

1/4W

1/4W

25V

C308

R305C

100μF

R305A

- +

F

180KΩ

F

180KΩ

13

16

14

22

21

P

P

5V

N

N

N15N

VTH

11

10

RTH

12

9

25V

C307

CSC

0.1μF

8

CFOD

L

7

24

VFO

6

25V

C306

5

0.033μF

IGBT

DRIVER

COM

4

3

COM

2

VCC

C305

0.1μF

L1

TL1 TL2

1

NR

20

- +

PFCM301

PR

NR

25

19

15V

S

NR

R

NR

25V

C304

26

27

DB301

AC1

100μF

18

17

F

1/4W

R301D

R301B

180KΩ

1/4W

180KΩ

R301A

F

AC2

(PFCM PWB)

F

5V

180KΩ

D302

1/4W

R320

R305G

F

180KΩ

5V

0.1μF

C314

6.8kΩ

R318

50V

C313

1000pF

1KΩ

R311

10mΩ

R309

R314

C310 100pF

F

180KΩ

1/4W

5V

F

1/4W

R301C

180KΩ

F

R301H

R301F

180KΩ

1/4W

R301E

R301G

180KΩ

F W4/1

TERMINAL BOARD

2KΩ

R307

1.1KΩ

R308

F

15KΩ

R322

1μF

10V

C317

F

R321

15KΩ

F

0.1μF

C316

15KΩ

C315

0.1μF

6

5

-

+

1MΩ

IC301/B

R319

7

Q301

R317

1KΩ

R31010mΩ

1KΩ

R315

R316

1KΩ

5V

3

2

100pF

C312

-

+

8 4

15KΩ

1

C311

0.1μF

IC301/A

R313

13KΩ

R312

2KΩ

D301

F

C309

0.1μF

180KΩ

1/4W

F

F

R303

1KΩ

R304

2KΩ

1/4W

180KΩ

F

T11

275V

C5

C4

275V

510KΩR11/4W

1/4W

510KΩ

C3

1μF

275V

L4

C2

1μF

275V

L3

C1

275V

R4

1MΩ

1/2W

(FILTER PWB)

BT21

T21

L1

34

35

36

CIN

VSC

CFO

P

IPM/A QM1 (PS21A79)

250V

20A

FU5

BT11

T10

2.2μF

2.2μF

R2

C12C

C14B

1μF

FU1

T20

R233

24

25

40

19

630V

0.1μF

C14

R128

~R217

R127

R210

1/4W 82KΩF×8

×3

C11

C9

750uF

420V

C8

BT12

1

2

7

8

345

6

9

CN301

[PNI]

5V

15V

C97

50V

10KΩ

0.01μF

R147

C79

+

220μ

PTC1

MRY1/B

F

R91

1KΩ

R90

6.49KΩ

D2

BT6

T6

F

KΩ

R89

1

1/4W

CT1

0V

T14

T13

BT14

FU2

L5

250V

4700pF

250V

C14C

0.01μF

C13C

250V

250V

0.01μF

C11C

4700pF

250V

250V

C13B

0.01μF

4700pF

250V

250V

C11B

C12B

4700pF

0.01μF

1MΩ

1/2W

R3

RY3/B

RY3/A

1

CN14

NR1

SA1

510V

250V

20A

L6

BT20

T4

BT4

L2

FUSE

TEMP

102?

ZD3

F

F

1/4W

R50

1.8KΩ

KΩ

15V

62

R262

R261

,R254

C138

50V

C122

0.01μF

,R240~244

2W 140mΩF ×7

R49

-

+

6

5

7

5V

IC11/B

5.1KΩ

1/4W

R260

10KΩ

C72

50V

0.022μF

F

15.4KΩ

F

15.4KΩ

5V

1

2

345

BCN13

[BOARD IN]

R106

Q6

3.3KΩ

BT15

T15

10V

F

5V

3

4

PC3

1

2

0V

D13

1/2W

R235

150KΩ

R238

1/4W

39KΩ

R234

1/2W

D15

150KΩ

C301

50V

0.01μF

R44

10KΩ

BT13

0.1μF

25V

C300

250V

3.15A

NR2

510V

R43

10KΩ

100Ω

R180

1W

RY1/B

C129

5V

275VAC

0.033μF

2

1

1

3

CN2

CN4

[VH]

[PASK]

TEMP FUSE)

(TERMINAL BOARD

(4 WAY VALVE)

[PNI]

2

BT22

BT23

T23

T22

L1L1

A

B

F

R24

12V

0Ω

R25

R26

10KΩ

25V

C21

25V

C26

0.1μF

2

IC4

C25

25V

0.1μF

+

35V

150μF

D7

13

S8VDD

S

IC2

F

2.2KΩ

50V

1000pF

0V

0.1μF

R23

470Ω

R21

2.2KΩ

IC3

R82

R88

22KΩ

10KΩ

1/4W

+

+

C20

35V

C24

D12

680μF

25V

11

50V

C18

1μF

C17

1

FB

2

CL

3

VCC4D

C16

C15

50V

R16

F

261KΩ

2200pF

5V

(PRESSURE SWITCH B)

[PNISK]

R15

12345

6

470Ω

150μF

9

23

PC6

4 1

50V

2200pF

- +

R14

15KΩ

50V

2.2μF

D4

1

2

CN15B

[VH]

R259

10KΩ

789

10

CN11

5V

R96A

ΩK2.2 C69R

ΩK2.2 B69R

ΩK2.2 D69R

2.2KΩ

10KΩ

10KΩ

10KΩ

R54

R55 10KΩ

R56

R57

R258

10KΩ

50V

C137

0.01μF

0V

CN-1

2

134

5V

+

C98

25V

4.7μF

JP7

JP92

Q

R255

789

6

OSC1

DD

50V

0V

C83

1000pF

0.01μF

50V

C82

R105

22KΩ

50V

C81

0.01μF

D17

1/2W

R237

150KΩ

R236

D16

1/2W

150KΩ

0.1μF

25V

C101

10KΩ

R104

10V

C61

0V

100μF

+

5V

FB3

25V

C60

0.1μF

(FAN MOTOR)

L2L2

5V

BC

E

Q4

RN1405(T5L,F,T)

BC

15V

E

Q3

50V

0.01μF

C102

RN2402(T5L,F,T)

R101

10KΩ

R109

10KΩ

10V

C100

47μF

R103

3.3kΩ

R100

5V

6.8kΩ

R245

FU6

3.3kΩ

15V

630V

C99

0.1μF

5

8

123

4

CN3

[XNISK]

2

C

2

L1 L1

D

0.1μF

25V

C124

10MHz

5V

+

10V

C123

100μF

C33

50V

4.7μF

100KΩ

R80

C32

25V

0.1μF

R79

12

100Ω

3

IC5

R78

270Ω

25V

C31

R77

270Ω

0.1μF

R

10KΩ

10KΩ

10KΩ

250V

2A

R97D

R97A

R97C

R97B

1

678910

234

5

CN8M

TH7

TH6

TH8

TH9

(THERMISTOR M)

(Suction UnitD)

(Suction UnitA)

(Suction UnitB)

(Suction UnitC)

L2 L2

IPM/B

QM1(PS21A79)

7

1

VP

UP

VP19VVFB

VUFS

VP1

VUFB

VVFS12VP1

3

4

6

10

50V

C55

0.1uF

C70

50V

0.1uF

29VN28

13

27

26

FO

UN

WP

WN

VNC22VPC

VWFB

VWFS

VN1

VOT

21

14

15

16

18

23

C71

50V

0.1uF

(DISPLAY)

0.1uF

C49

50V

0.1uF

D8

C50

33Ω

1/4W

1/4W

33Ω

10KΩ

R263

25V

C135

R51

+

R162

R48

R52

R53

R47

R161

33Ω

1/4W

33Ω

1/4W

D4

D11

Z

15V

1000pF

~C59

50V

C56

5V

C30

+

100μF

25V

C93

PS0 26

PP4 16

PP5 17

PQ1 21

PQ2 22

PQ3 23

PQ4 24

PQ0 20

PQ5 25

VSS 18

VCC 19

PS1 27

PS2 28

PS3

29

PS4 30

PS5 31

VCC 32

VCC 33

VSS 34

C 35

PR0 36

PR1 37

PR2 38

PR3 39

PR4 40

PR5 41

MD2 42

MD1 43

MD0 44

X0 45

X1 46

VSS 47

INITX 48

PA2 49

VSS 50

06 0DP

95 7CP

85 6CP

75 5CP

65 4CP

55 3CP

45 2CP

35 1CP

25 0CP

15 CCV

C54A,C54B,C54C,C54D

50V 0.01uF

C54D

C54C

C54B

C54A

0V

10KΩ

R98A

R98B

R98C

6.8KΩ F

R98A,R98B,R98C,R98D

R98D

[XNISK]

0.1uF

C51

50V

C53

50V

25V

25V

100μF

100μF

50V

C136

R134

24V

10V

0.1μF

I

HH

PP1 13

PP2 14

PP3 15

36 2HRVA

26 01CCVA

16 1DP

C126

5V

C125

25V

C52

100μF

C133

100μF

D10

D9

50V

50V

0.1uF

C44

C40

C43 50V

1000pF

C41 50V

1000pF

1000pF

100Ω

100Ω

R137

R135

100Ω

100Ω

R136

5V

C77

10KΩ

R75

R73

1KΩ

5V

P86 2

P90 4

P91 5

P87 3

PF0 11

PP0 12

PM0 7

PM2 9

PM1 8

PM3 10

NMIX 6

IC1

17 6BP

47 1AP

37 0AP

27 7BP

07 5BP

46 01SSVA

96 4BP

86 3BP

76 2BP

56 0BP

66 1BP

50V

C103

50V

C106

0.01μF

0.01μF

1KΩ

R107

10KΩ

R102

C107

50V

0.01μF

25V

C104

0.1μF

1KΩ

R108

5V

0.1μF

25V

+

10V

R123

100μF

15V

10KΩ F

10KΩ

10KΩ

10KΩ

R66

10KΩ

R65

R64

R63

123

45678

CN8A

TH4

TH3

TH2

TH1

)

(THERMISTOR A)

(Suction)

ut door Temp)

(Compressor)

(O

(Heat Exchange

1000pF

R132

VCC 1

57 SSV

IC9/B

R120

9

100Ω

25V

001 SSV

99 58P

89 48P

79 38P

69 28P

59 18P

49 08P

39 7JP

29 6JP

19 5JP

09 4JP

98 3JP

88 2JP

78 1JP

68 0JP

58 2HP

48 1HP

38 0HP

28 5GP

18 4GP

08 3GP

97 2GP

87 1GP

77 0GP

67 CCV

5V

D26

F

2KΩ

50V

0.1μF

C74

5V

C128

1

-2+

R143

0V

R62

[XNISK]

C42

1000pF

R133

100Ω

50V

0.01μF

C94

10V

+

C95

25V

10V

+

100μF

50V

C90

R124

100Ω

25V

C89

4 8

3

F

2KΩ

5V

Z

C68

C69

10KΩ

R71

R70

R68

R61

0V

0.1μF

25V

C48

5V

50V

C134

1000pF

100μF

0.1μF

DD

25V

JP94

C127

0.1μF

F

F output

1000pF

0V

0.1μF

F

20KΩ

R151

0V

F

R150

20KΩ

C64

C66

C67

50V 0.01uF

C64,C66,C67,C68,C69

0V

R69

6.8KΩ F

R61,R68,R69,R70,R71

10V

C47

+

R45

10KΩ

1KΩ

R46

R76

R256

F

F

15V

F

R248

10KΩ

3.9KΩ

R249

R247

1.2KΩ

0V

F

50V

0.01μF

C131

3

2

10KΩ

R250

50V

-

+

C132

IC11/A

8 4

0.01μF

1

15V

D27

50V

C130

0.01μF

PNP

Q6D

EC

B

Q5D

1k

R92D

10KΩ

R93D

2.2k

CEB

1/4W

100μF

0.01μF

50V

C45

50V

C46

1000pF

1KΩ

1KΩ

5V

PC1D

3.3KΩ

R30D

D18D

1/4W

PNP

Q6C

EC

B

Q5C

R92C

R94C R94D

1k

10KΩ

1/4W

CEB

R93C

2.2k

1/4W

PNP

Q6B

EC

B

Q5B

R92B

R94B

10KΩ

R93B

1/4W

2.2k

CEB

W4/1 k1

PNP

Q6A

EC

B

Q5AE

R92A

R94A

1k

10KΩ

1/4W

BC

12V

3

2

1

C37D

4.7KΩ

R35D

4

3

2

1

25V

C38D

250V

C39D

2.2k

JP93

R93A

1/4W

1

2

SWITCH A 12V)

(PRESSURE

CN15A

[VH]

FB2

CN-2

5V

5V

R155

4.7KΩ

F

50V

0V

1000pF

R36D

1.8KΩ

5V

R34D

56KΩ

1

2

PC2D

PC1C

4

3

3.3KΩ

R30C

R33D

0.1μF

R32D

D18C

2W 1.0KJ ×3

R31D

4700pF

0V

8

1KΩ

R153

1

2

1000pF

50V

1

PC2C

4

R33C

0.1μF

R32C

R31C

250V

4700pF

913

CN6

[VH]

710

6

5

4

3

2

116

69578

R

Q

[PH]

F

0V

1.8KΩ

R36C

5V

R34C

56KΩ

2

PC1B

3

R30B

2W 1.0KJ ×3

5

7

9

11

12

13

14

15

IC7

ULN2004L-D16-T

BCN14

1KΩ

R99 R257

1KΩ

F

1000pF

0V

50V

C37B

4.7KΩ

R36B

R35B

R34B

56KΩ

1

2

4

3

PC2B

1

2

4

3

3.3KΩ

R33B

25V

0.1μF

C38B

R32B

D18B

2W 1.0KJ ×3

R31B

C39B

250V

4700pF

HH

I

[PH]

CND

134

2

1KΩ

R152

4.7KΩ

R154

4

3

CNM

C37C

4.7KΩ

R35C

4

3

1

2

25V

C38C

C39C

(SERIAL)

SK][X

CN12D

[XNI

6

5

4

D22D

3

D23D

2

D24D

1

D25D

CN12C

[XNISK]

6

5

4

D22C

3

D23C

2

D24C

1

D25C

CN12B

[XNISK]

6

5

4

D22B

3

D23B

D24B

2

1

D25B

NISK]

RY1/A

MRY1/A

CN12A

6

5

4

D22A

3

D23A

2

D24A

1

D25A

1

2

[BOARD IN]

(EXPANSION VALVE)

F

0V

50V

1000pF

C37A

4.7KΩ

1.8KΩ

1.8KΩ

R36A

5V

R35A

R34A

56KΩ

3

4

1

2

PC1A

PC2A

1

2

4

3

R30A

3.3KΩ

R33AR31A

25V

C38A

0.1μF

R32A

D18A

2W 1.0KJ ×3

250V

C39A

4700pF

2

2

11

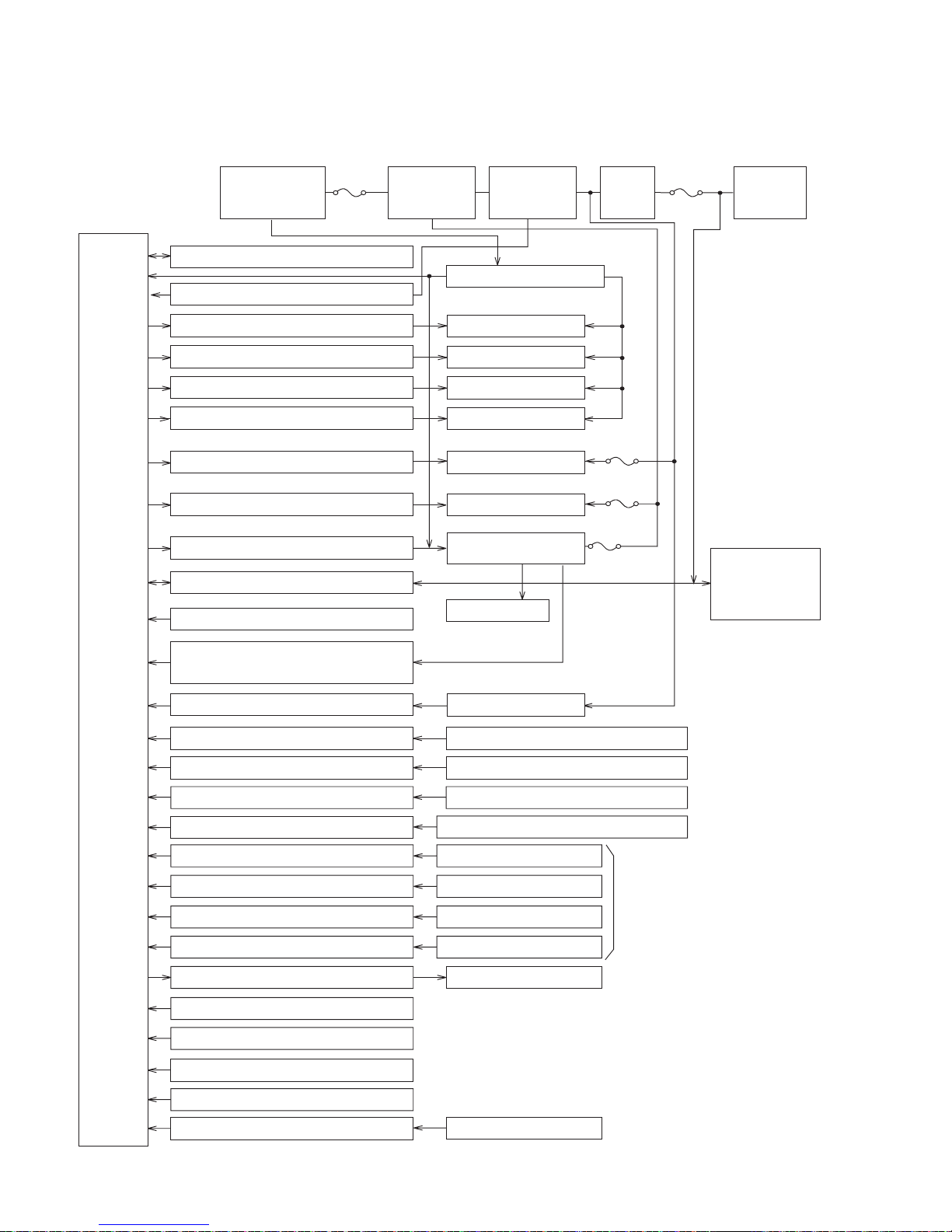

Page 12

AE-X4M30PU

EXPLANATION OF CIRCUIT AND OPERATION

BLOCK DIAGRAM

CPU

2A

Power supply

circuit

CPU oscillator circuit

DC over voltage detection circuit

Expansion valve A drive circuit

Expansion valve B drive circuit

Expansion valve C drive circuit

Expersion valve D drive circuit

4-way valve relay drive circuit

Outdoor fan motor drive circuit

Power transistor module drive circuit

Serial I/O circuit

CPU reset circuit

DC overcurrent detection circuit /

Power transistor module overheat

Fuse

Smoothing

circuit

PFCM

module

DC power supply circuit

Expansion valve A

Expansion valve B

Expansion valve C

Expansion valve D

4-way valve

Outdoor fan motor

Power transistor

module

Compressor

Filter

circuit

3.15 A

Fuse

2 A

Fuse

20 A

Fuse

20 A

Fuse

AC power

Unit - unit wiring

(AC power and

serial signals)

AC overcurrent detection circuit

Compressor thermo circuit

Heat exchanger pipe thermo circuit

Outdoor temp. thermo. circuit Outdoor temperature thermistor (GN)

Suction pipe thermo circuit

Unit A thermo. circuit

Unit B thermo. circuit

Unit C thermo. circuit Thermistor unit C (BN)

Unit D thermo. circuit Thermistor unit D (YL)

LED drive circuit

DIP SW1

DIP SW2

Pump down switch circuit

Wire check switch circuit

Position detection circuit

Current transformer

Compressor thermistor (RED)

Heat exchanger pipe thermistor (OR)

Suction pipe thermistor (BK) CN8A

Thermistor unit A (BL)

Thermistor unit B (WT)

LED

Compressor

Suction thermistor

CN8M

CN8A

CN8A

CN8A

12

Page 13

AE-X4M30PU

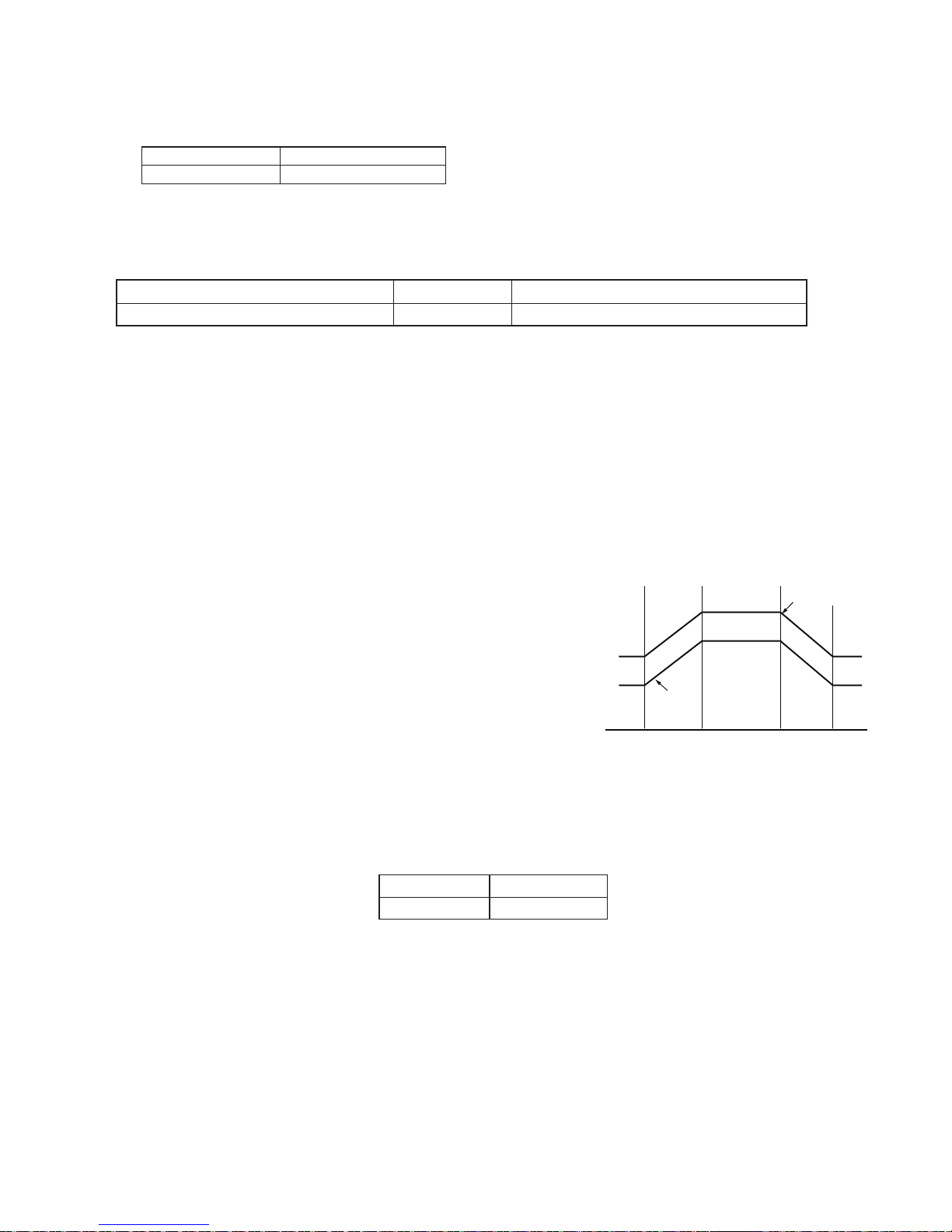

FUNCTIONS

1. FREQUENCY CONTROL

1) AC current peak control

Cooling mode Heating mode

17.6A 18.4A

2) Prevention control of outdoor heat exchanger overheating

If the temperature of the outdoor heat exchanger exceeds the overheating prevention line 1or 2 during cooling, the operating

frequency is lowered by approximately 5 to 15Hz. After that, the frequency is lowered approximately 5Hz once every 60

seconds or approximately 15Hz once every 120 seconds. If the frequency is lowered to minimum frequency without the

temperature of the outdoor heat exchanger decreasing and this condition lasts for 1 minute, the compressor will be stopped.

Overheating Prevention line 1 129.2°F (54°C) Lower 5Hz once every 60 seconds

Overheating Prevention line 2 134.6°F (57°C) Lower 15Hz once every 120 seconds

3) Prevention control of compressor overheating

If the temperature of the compressor exceeds approximately 226.4°F (108°C), the operating frequency is lowered

approximately 5Hz. After that, the frequency is lowered approximately 5Hz once every 60 seconds. When the compressor

temperature drops below approximately 226.4°F (108°C), the frequency is raised approximately 5Hz once every 60 seconds,

and normal operation is restored. If the frequency is lowered to minimum frequency without the temperature of the compressor

decreasing, and this condition lasts for 1 minute, the compressor will be stopped.

4) Prevention control of indoor heat exchanger overheating

Two minutes after room several decrease If the temperature of any of indoor heat exchangers exceeds the overheating prevention

line 1 or 2 during heating, the operating frequency is lowered to minimum frequency. When the temperature of all of indoor heat

exchangers go below [the overheating prevention line 1 -45.5

60 seconds, and normal operation is restored. If the condition that the frequency is minimum lasts for 2 minutes, the compressor

will be stopped.

<When normal >

If the temperature of any of indoor heat exchangers exceeds the overheating prevention line 1 or 2 during heating, the operating frequency

is lowered by approximately 5 to 15Hz. After that, the frequency is

lowered approximately 5Hz once every 60 seconds or approximately 15Hz once every 90 seconds. When the temperature of all of

indoor heat exchangers go below [the overheating prevention line 1

-45.5

°

F(-7.5

°C)], the frequency is raised by approximately 5Hz once

every 60 seconds, and normal operation is restored. If the condition

that the frequency is minimum lasts for 2 minutes, the compressor will

be stopped.

2. OVER CURRENT PROTECTION

DC over current detection, AC over current detection To protect against over current due to sudden change in load, the

compressor is stopped if 25A DC is exceeded in the DC section. If the set value of AC current is exceeded in the AC section, the

compressor is stopped. 90 seconds after the compressor has been stopped, another starting try will be made. Three retries are

allowed. On the fourth retry, a complete stop request signal is sent to the indoor unit, and the outdoor unit will remain stopped until

the indoor operation is stopped. DC over current is detected by the power module. AC over current is detected by CT1, on the

outdoor PWB.

Cooling mode Heating mode

18A 18A

°

F(-7.5

°C)]

, the frequency is raised by approximately 5Hz once every

Overheating

131ºF (55°C)

143.6ºFº (62°C)

125.6ºF (52°C)

116.6ºF (47°C)

140.0ºF (60°C)

111.2ºF (44°C)

134.6ºF (57°C)

Overheating

prevention

line 1

900

138.2ºF (59°C)

When ON

(When OFF)

2200 5800 7200

prevention line 2

123.8ºF (51°C)

134.6ºF (57°C)

118.4ºF (48°C)

129.2ºF (54°C)

3. COMPRESSOR PROTECTION CONTROL

If the temperature of the compressor exceeds 235.4°F (113°C), the compressor is stopped. In this case, the outdoor fan is

not stopped until the temperature of compressor drops below 210.2°F (99°C). In 90 seconds after the compressor is stopped,

if the temperature is below 194°F (90°C), another starting try will be made. Three retries are allowed. On the fourth retry, a

complete stop request signal is sent to the indoor unit, and the outdoor unit will remain stopped until the indoor operation is

stopped.

4. POWER TRANSISTOR MODULE PROTECTION

If the temperature of the chips in the power transistor module exceeds 212°F (100°C), the compressor is stopped. In this

case, the outdoor fan is not stopped until the temperature of power module drops below 185°F (85°C). In 90 seconds after the

compressor is stopped, if the temperature is below 185°F (85°C), another starting try will be made. Three retries are allowed.

On the fourth retry, a complete stop request signal is sent to the indoor unit, and the outdoor unit will remain stopped until the

indoor operation is

stopped.

13

Page 14

AE-X4M30PU

5. SERIAL SIGNALS

Serial signals consist of all 96-bit signals. If the condition as outdoor unit unable to receive a serial signal from the indoor unit

continues for 30 seconds, it closes the expansion valve which corresponds to the room which can not be communicated. If all

indoor units can not communicate with the outdoor unit, the compressor is stopped.

6. THERMISTOR OPEN OR SHORT

When compressor, heat exchanger, outdoor thermistor, suction thermistor (CN8A) are in OPEN or SHORT condition, even if they are

in the condition which an operation signal is transmitted from indoors, the compressor will not start. If any suction thermistors (CN8M)

become OPEN or SHORT resistance, the protective procedure will work only for the cycle corresponding to the malfunctioning suction

thermistor.

7. MISWIRING CHECK

“Mis-wiring check” is conducted by detecting the indoor heat exchanger temp. For example, when the expansion valve for only room

A is open, and the wiring is correct, the indoor heat exchanger temp for room A will reduce. If the wiring is incorrect, the indoor heat

exchanger temp for a different room will reduce.

8. SAFETY TIME

When the unit is operated by the remote control after the breaker is turned on, the safety device of the compressor will work and the

compressor will not operate for 90 seconds.

9. PUMP DOWN SWITCH

When the PUMP DOWN SWITCH (SW1) is pressed for 5 seconds or more, the total A/C system will start its PUMP DOWN

automatically and the compressor frequency will be 40 Hz.

10. CONTROL OF COMPRESSOR AND EXPANSION VALVE

For 90 seconds after turning on the AC power, the compressor will not be activated even if indoor units request the compressor to

do so. If the compressor receives a request from one or more indoor units after 90 seconds have passed, it will be turned on and the

expansion valve corresponding to the requesting indoor unit will be opened. When the indoor unit of a room requests for the cooling

operation to the outdoor unit and it runs responding to the request, requests for the heating can’t be accepted if the indoor units in

other rooms send individual requests. If the indoor unit in another room sends a request for the heating operation, the operation lamp

and timer lamp of the indoor unit in that room start ashing in turn to inform that the unit is in the standby mode. If the operation in

one room is stopped while the indoor unit in another room is in the stand-by mode, the operation mode requested by the indoor unit

which is now in the stand-by mode will be accepted. At this time, the compressor will be temporarily stopped to switch the four- way

valve and restart after 90 seconds. During the cooling or dry operation, the expansion valve corresponding to the indoor unit that is not

running is closed. Therefore, the refrigerant will not ow into those units. However,if the heating operation is in progress, it is possible

that it ows into indoor units which are out of operation depending on the cycle conditions. As a result, the indoor exchanger may be

heated up even if it is not activated. This is not abnormal. When the operations in all rooms are stopped, the compressor is off and the

expansion valves in all rooms are fully opened.

11. DEFROST OPERATION

1) Overview

Defrosting begins during heating if the conditions for compressor

operation time and outdoor heat exchanger temperature are

met. When defrosting begins, the indoor and outdoor fans stop.

Defrosting stops when the temperature of the outdoor heat

exchanger goes above approximately 59°F

time exceeds 10 minutes.

2) Defrosting

If the compressor operation time is more than 20 minutes in

the heating mode and the outdoor air temperature and outdoor

heat exchange temperature satisfy the defrosting conditions, the

defrosting operation is started. When the defrosting operation

is started, the indoor fan s tarts to run intermittently. When the

outdoor heat exchanger temperature reaches approx. 59°F

or above or when the defrosting time exceeds 10 minutes, the

defrosting operation is quit.

(15°C)

or defrosting

(15°C)

Defrost

mask time

Heating

begins

Defrosting

Max. 10 min.

More than

20 min.

Defrost

mask time

Defrosting

Max. 10 min.

More than

20 min.

Defrost

mask time

More than

20 min.

Heating

operation

start

Defrosting

Max. 10 min.

Defrosting

Max. 10 min.

14

Page 15

AE-X4M30PU

3) During defrosting

When defrosting begins, the compressor stops. Approximately 1 minutes later, the compressor reactivates in the refrigeration

cycle, and the outdoor heat exchanger is defrosted. Each mode is as follows:

The outdoor fan is s topped.

The operating frequency is as shown in the table below.

The indoor fan is s topped.

All expansion valve are open. for 5 minutes 4800 rpm

ater that 4000 rpm

4) Defrost stop

When defrosting time exceeds 10 minutes When the temperature of the outdoor heat exchanger rises above approximately

(15°C)

Defrost stop is determined by either of the above conditions, and the compressor is s topped. At the same time, the outdoor

59°F°C

fan go ON. The compressor is reactivated in the heating cycle 1 minutes after it was stopped, and normal control resumes.

12. 5°F(-15°C) AUTO STOP FUNCTION

• During the heating operation, the unit will automatically stop when the

SELECT switch (DSW1)

outdoor temperature drops below 5°F(-15°C) to prevent the outdoor unit

from the damage caused by the freezing of the drained water. The unit

will stop its operation for 4 hour and then resume the operation when the

LED1A

outdoor temperature rises above 7°F(-13.9°C).

• To inactivate this function, slide the SELECT switch(DSW1) #1 to OFF side.

DSW1

LED1B

LED1C

1

2

OFF

ON

LED1D

13. Preheat

When heating is stopped, applying a small amount of voltage to the compressor to make heating start more quickly.

The preheat function will active according to outdoor temperature and compressor temperature.

To inactivate this function, slide the SELECT switch (DSW1) #2 to OFF side.

DSW1

1

2

OFF

ON

SELECT

DSW1

1

2

OFF

ON

PUMP DOWN

SW1

WIRE CHECK

SW2

15

Page 16

AE-X4M30PU

TROUBLE SHOOTING GUIDE

SELF-DIAGNOSIS FUNCTION

NOTE: WHEN TURN ON THE POWER SUPPLY AGAIN, WAIT MORE THAN 10 MINUTES AFTER TURN OFF TO PRE-

VENT ELECTRIC SHOCK.

Indoor unit

• To display the self-diagnosis, hold down the AUX button for over 5 seconds on the indoor unit when the indoor unit is not operating.

• The operation lamp (green), timer lamp (orange) and Plasmacluster lamp (blue) ash to indicate the information of malfunction.

• If the power cord is unplugged or the circuit breaker is turned off, the self-diagnosis memory is lost.

AUX

Plasmacluster lamp (Blue)

Operation lamp (Green)

Timer lamp (orange)

<Display of self-diagnosis result>

The operation lamp (green) and the Plasmacluster lamp (blue) ash in synchronization with the timer lamp (orange).

Timer lamp (1 cycle)

1st 2nd 3rd 4th 5th

1-second

ON

1-second

ON

1-second

ON

1-second

ON

1-second

ON

ON

OFF

ON

OFF

1-second

OFF

0.5-second

ON

0.5-second

ON

5-second OFF

0.5-second ON0.5-second

ON

1-second

OFF

1-second

OFF

1-second

OFF

Outdoor unit

• The self-diagnosis is indicated the error information by ashing LED1 on the outdoor unit.

• The self-diagnosis of outdoor unit is displayed for about 3-10 minutes. Then, the LED1 returns to normal display.

Normal

LED1

SELECT

LED1A

LED1B

LED1C

LED1D

DSW1

1

2

OFF

PUMP DOWN

WIRE CHECK

SW1

SW2

ON

2-time

3-time

16

ON

OFF

ON

OFF

0.5-second

0.5-second

ON

0.5-second

0.5-second

ON

0.5-second

OFF

0.5-second

OFF

0.5-second

OFF

OFF

0.5-second

OFF

0.5-second

2-time

0.5-second ON0.5-second

ON

OFF

0.5-second

OFF

0.5-second

3-time

0.5-second ON0.5-second ON0.5-second

ON

OFF

0.5-second

OFF

0.5-second

ON

ON

Page 17

<INDOOR UNIT> ○:1-second ON / 1-second OFF

Problem

symptom

Normal

condition

Indoor and

outdoor units

do not operate.

Indoor and

outdoor units

do not

operate.

Indoor unit

operates.

Outdoor

unit does

not operate

temporarily

Indoor and

outdoor

units do not

operate.

Indoor and

outdoor

units do not

operate.

Indoor and

outdoor

units do not

operate.

Outdoor unit

indication

(LED1)

Normal

blinking

1 time O O O O O Timer (Orange) 1 0 Outdoor unit

2 time

3 time O O O O O Timer (Orange) 3 0 Temporary

5-time O O O O O Timer (Orange) 5 0 Outdoor unit

O O O O O Timer (Orange) 0 0 Normal

O O O O O Timer (Orange) 1 Outdoor temperature

O O O O O Timer (Orange) 2 Suction thermistor

O O O O O Timer (Orange) 3 Suction thermistor

O O O O O Timer (Orange)

O O O O O Timer (Orange) 1 Compressor

O O O O O Timer (Orange) 2 Outdoor unit heat

O O O O O Timer (Orange) 3 Indoor unit heat

O O O O O Timer (Orange) 4 IPM high

O O O O O Timer (Orange) 5 IPM high

O O O O O Timer (Orange) 7 High pressure error

O O O O O Timer (Orange) 1 Outdoor temperature

O O O O O Timer (Orange) 2 Suction thermistor

O O O O O Timer (Orange) 3 Suction thermistor

O O O O O Timer (Orange) 4 Discharge thermistor

O O O O O Timer (Orange) 5 Heat sink thermistor

Indoor unit

→

O Operation (green)

O Operation (green)

O Plasmacluster (blue)

O Operation (green)

O Plasmacluster (blue)

O Operation (green)

O O Plasmacluster (blue)

O Operation (green)

O Operation (green)

O Plasmacluster (blue)

O Operation (green)

O Plasmacluster (blue)

O Operation (green)

O O Plasmacluster (blue)

O Operation (green)

O Plasmacluster (blue)

O Operation (green)

O O Plasmacluster (blue)

O Operation (green)

O O O Plasmacluster (blue)

O O Operation (green)

O O Operation (green)

O O Operation (green)

O Plasmacluster (blue)

O O Operation (green)

O Plasmacluster (blue)

O O Operation (green)

O O Plasmacluster (blue)

O O

O Plasmacluster (blue)

O O Operation (green)

O O Plasmacluster (blue)

Lamp Main Sub Main Sub

Operation (green)

Plasmacluster (blue)

Plasmacluster (blue)

Plasmacluster (blue)

Plasmacluster (blue)

Plasmacluster (blue)

Operation (green)

Malfunction

No.*

2 0 Cycle

Content of diagnosis

thermistor

short-circuit

temperature

stop

thermistor

open-circuit

Heat exchanger

thermistor short

circuit error

thermistor short

circuit error

short circuit error

(for unit A, B, C, D)

short circuit error

Compressor high

temperature error

discharge overheat.

exchanger overheat.

exchanger overheat.

temperature error

temperature error

Temporary stop due

to low temperature

of out door

Heat exchanger

thermistor open

circuit error

thermistor open

circuit error

open circuit error

(for unit A, B, C, D)

open circuit error

open circuit error

open circuit error

Check point Action

1) Measure the resistance

of the outdoor unit

thermistors.

(TH2-4, 6-8: Approx. 4.4kΩ at

77°F(25°C))

2) Check the lead wire of the

outdoor unit thermistor

for torn sheath and

shortcircuit.

3) 1) 2):Normal

1) Check the outdoor unit air

outlet for blockage.

2) Check if the power supply

voltage is AC 230V at full

power.

3) Check the pipe connections

for refrigerant leaks.

4) Measure resistance of the

outdoor unit compressor

thermistor.

(TH1:Approx.50kΩ at 77°F(25°C)

5) Check the expansion valve

for proper operation.

(Temporary stop for cycle

protection)

(Temporary stop for cycle

protection)

(Temporary stop for cycle

protection)

Measure resistance of the

heat-sink thermistor.

Replace the outdoor unit

control PCB assembly.

Check pressure sensor -

(Temporary stop for cycle

protection)

1) Check connector CN8A

and CN8C of the outdoor

unit thermistor for secure

installation.

2) Measure resistance of

outdoor thermistors TH14, 6-8.

3) Check the lead wires of

thermistors TH1- 4, 6-8

on the outdoor unit control

PCB for open-circuit.

4) 1) 2) 3):Normal

1) Replace the outdoor unit

thermistor assembly.

2) Replace the outdoor unit

thermistor assembly.

3) Replace the outdoor unit

control PCB assembly.

1) Ensure unobstructed air

ow from the outdoor

unit air outlet.

2) Connect power supply

of proper voltage.

3) Charge the specied

amount of refrigerant.

4) Replace the outdoor unit

compressor thermistor

assembly.

5) Replace the expansion

valve coil, expansion

valve or outdoor unit

control PCB assembly.

If the temperature of

outdoor is not lower than

5°F(-15°C), check the

outdoor temp. thermistor.

1) Correct the installation

2) Replace the outdoor unit

thermistor assembly.

3) Replace the outdoor unit

thermistor assembly.

4) Replace the outdoor unit

control PWB assembly.

AE-X4M30PU

-

-

-

-

-

17