Sharp AY-X36RU, AE-X36RU Service Manual

AY-X36RU

AE-X36RU

1

PRODUCT SPECIFICATION

----------------------------- 2

[1] SPECIFICATION

---------------------------------------- 2

[2] EXTERNAL DIMENSION

----------------------------- 3

ELECTRIC CIRCUIT

----------------------------------------- 4

[1] WIRING DIAGRAM

------------------------------------- 4

[2] CONTROL UNIT PWB WRING

---------------------- 5

FUNCTION AND CONTROL

----------------------------- 6

[1] Remote Control Introduction

------------------------- 6

TROUBLESHOOTING

------------------------------------ 10

[1] Error Code List

----------------------------------------- 10

SERVICE MANUAL

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its

original condition and only parts identical to those specied should be used

This document has been published to be used for after sales service only.

The contents are subject to change without notice.

CONTENTS

[2] Troubleshooting for Main Malfunction ----------- 14

[3] Troubleshooting for Normal Malfunction

--------- 29

REFRIGERATION CYCLE

------------------------------ 31

[1] Refrigerant System Diagram

---------------------- 31

[2] PERFORMANCE CURVES

------------------------ 31

DISASSEMBLY PROCEDURE

------------------------ 33

[1] INDOOR UNIT

----------------------------------------- 33

[2] OUTDOOR UNIT

-------------------------------------- 36

S0402AYX6RCU/c

SPLIT TYPE AIR CONDITIONERS

INDOOR UNIT OUTDOOR UNIT

MODELS

AY-X36RU AE-X36RU

2

AY-X36RU

AE-X36RU

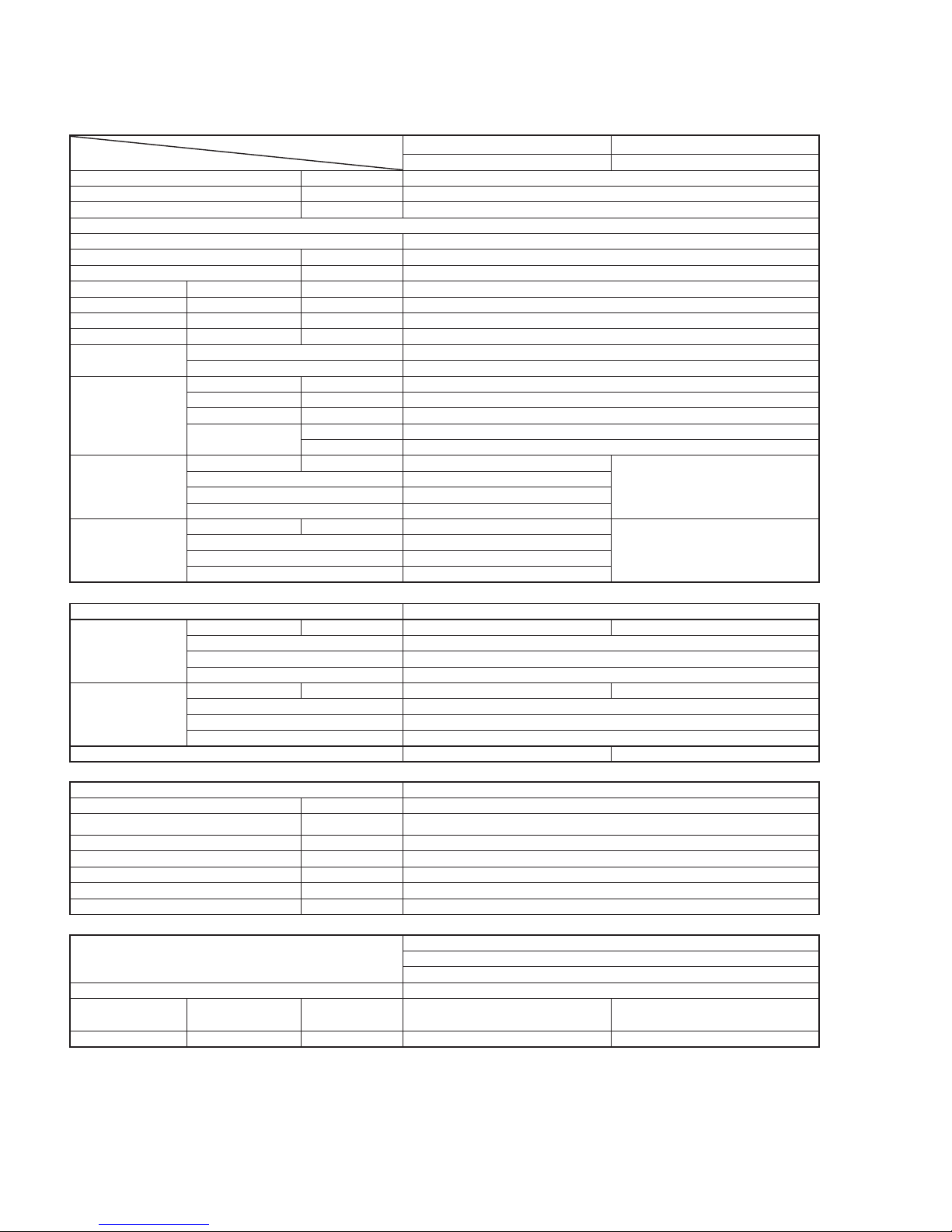

PRODUCT SPECIFICATION

[1] SPECIFICATION

MODEL

ITEMS

INDOOR UNIT OUTDOOR UNIT

AY-X36RU AE-X36RU

Rated cooling capacity (Min. - Max.) Btu/h 33600 ( 7400 - 36000 )

Rated heating capacity (Min. - Max.) Btu/h 34600 ( 15000 - 36000 )

Moisture removal (at cooling) pints/h 7.4

Electrical data

Phase Single

Rated frequency Hz 60

Rated voltage V 208/230

Rated current Cool A 17

(Min.-Max.) Heat A 16.5

Rated input Cool W 4100 ( 450 - 4300 )

(Min.-Max.) Heat W 3800 ( 560 - 4300 )

Compressor

Type Rotary

Model TNB306FPGMC

Refrigerant system

Evaporator Aluminum Fin-copper tube type

Condenser Aluminum Fin-copper tube type

Control Expansion valve

Refrigerant

type R410A

oz. ( g ) 91.7 ( 2600 )

Noise level

(at cooling)

Turbo dB(A) 54

65

High 50

Low 44

Soft 38

Noise level

(at heating)

Turbo dB(A) 54

65

High 50

Low 44

Soft 38

Fan system

Drive Direct drive

Air ow quantity

(at cooling)

Turbo CFM(m3/min) 736 ( 20.8 ) 2589(73.3)

High 647 ( 18.3 )

Low 530 ( 15 )

Soft 412 ( 11.7 )

Air ow quantity

(at heating)

Turbo CFM(m3/min) 736 ( 20.8 ) 2589(73.3)

High 647 ( 18.3 )

Low 530 ( 15 )

Soft 412 ( 11.7 )

Fan Cross ow fan Propeller fan

Connections

Refrigerant coupling Flare type

Refrigerant tube size (Gas line ) inch (mm) 5/8 (16)

Refrigerant tube size (Liquid line ) inch (mm) 1/4 ( 6.35 )

Maximum length ft ( m ) 98.4 ( 30 )

Maximum charge-less length ft ( m ) 24.6 ( 7.5 )

Maximum height difference

ft ( m ) 32.8 ( 10 )

Additional charge oz./ft ( g/m ) 0.5 ( 50 )

Drain pipe O.D. inch (mm) 5/8 (16 )

Others

Safety device

Compressor: Thermal protector

Pressure switch

Fuse, Micro computer control

Air llters Polypropylene net (Washable)

Net dimensions

Width / Height /

Depth

inch

(mm)

53-1/7 / 12-5/6 / 10

( 1350 / 326 / 253 )

38-4/7 / 31-1/9 / 16-4/5

( 980 / 790 / 427 )

Net weight lb. (kg) 41.9 ( 19 ) 161 ( 73 )

NOTE: Test conditions are based on AHRI 210/240. ( Refrigerant piping length : 25ft [7.6m] )

* : Voltage is 230V

AY-X36RU

AE-X36RU

3

[2] EXTERNAL DIMENSION

Indoor Unit

12.8 (326)

10.0 (253)

3.64 (92.5)

2.2 (56)

3.64 (92.5)

6.7 (170)

53.1 (1350)

Unit: inch (mm)

Thickness: 0.9 (22.5) Thickness: 0.93 (23.5)

Outdoor Unit

14.6 (371)

36 (914.1)

24 (609.6)

15.7 (398.8)

31.1 (790)

38.6 (980)

16.7 (424.2)

Unit: inch (mm)

4

AY-X36RU

AE-X36RU

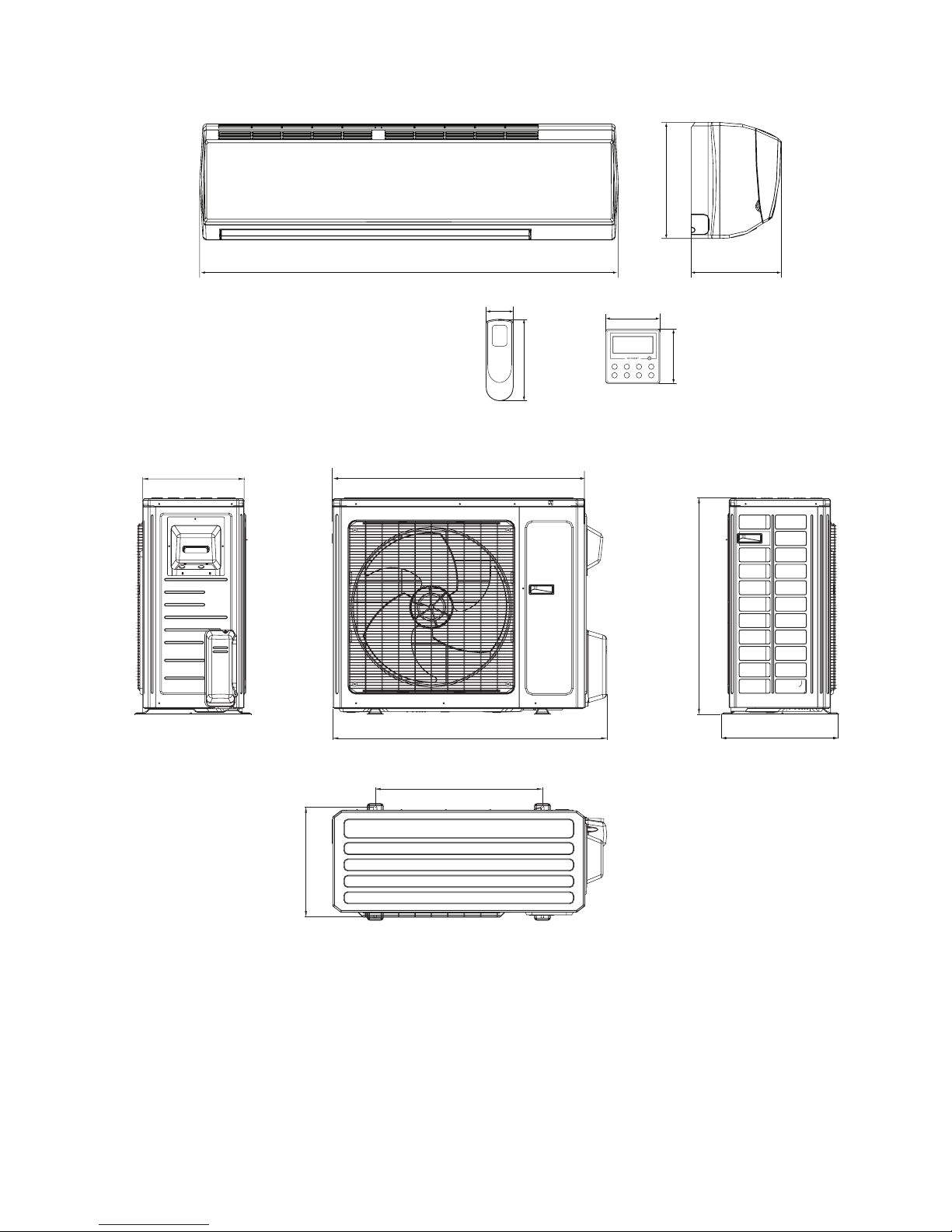

ELECTRIC CIRCUIT

[1] WIRING DIAGRAM

Instruction

Symbol Symbol Color or Name Symbol Symbol Color or Name

WH White BN Brown

YE Yellow BU Blue

RD Red BK Black

YEGN Yellow/Green OG Orange

VT Violet CAP Jumper cap

GN Green COMP Compressor

NOTE: Jumper cap is used to determine fan speed and the swing angle of horizontal lover for this model.

Indoor Unit

Please don't touch any

electronic component or

terminal when the machine

is running,stopping or

has been powered off for

less than 3 minutes to

prevent electric shock !

Outdoor Unit

Please don't touch any

electronic component or

terminal when the machine is

running , stopping or has

been powered off for less

than 30 minutes to prevent

the risk of electric shock !

NOTE:

Motor ground only

applies to the

iron shell motor.

AY-X36RU

AE-X36RU

5

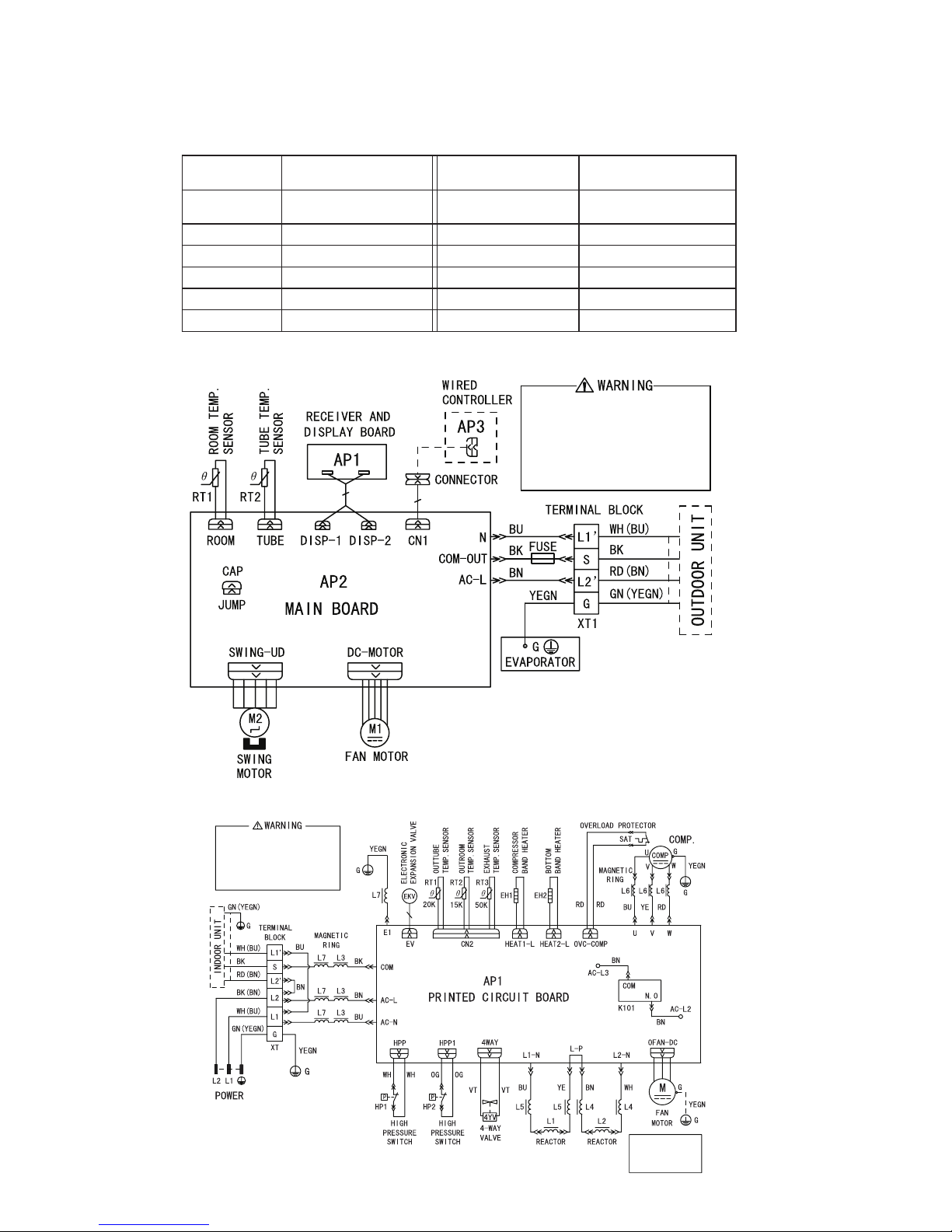

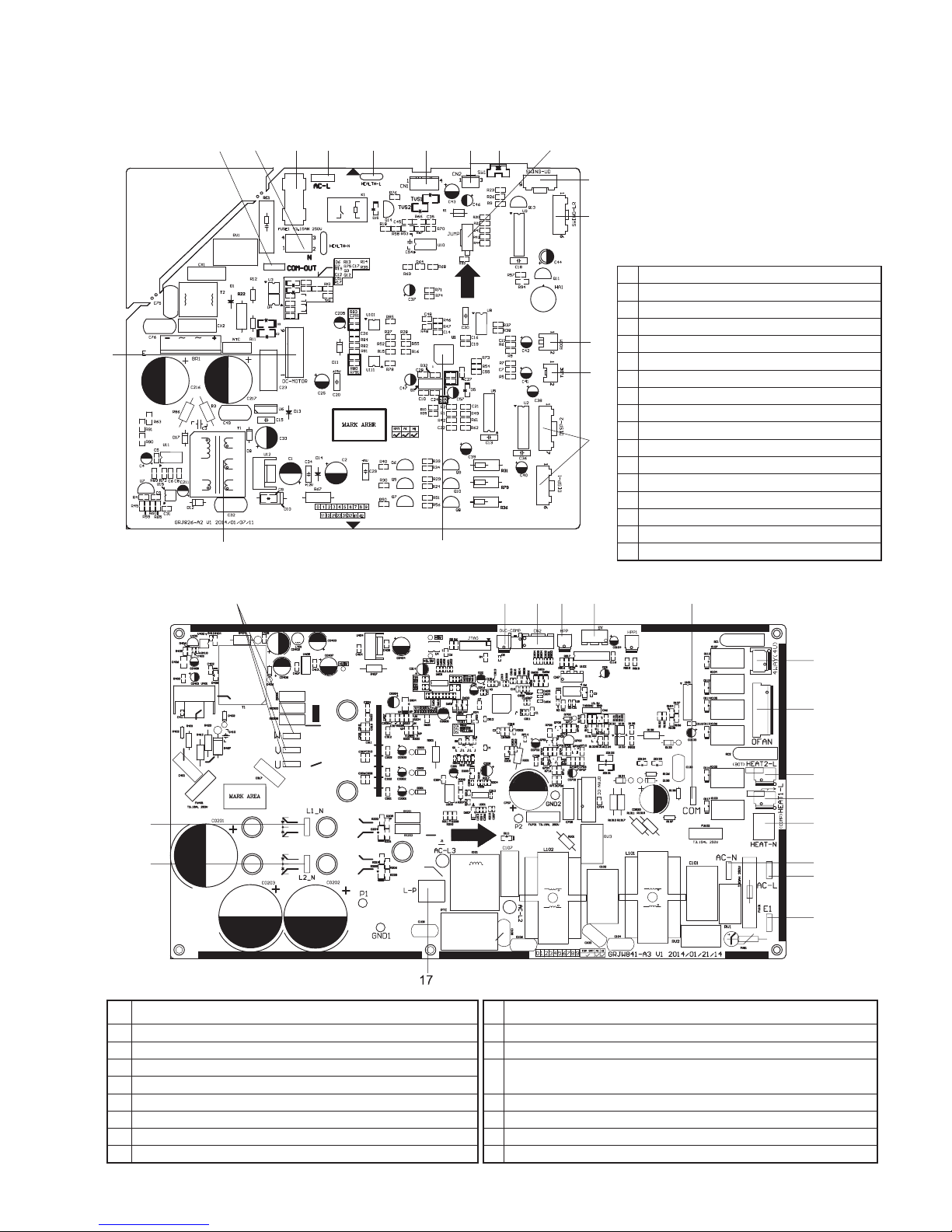

[2] CONTROL UNIT PWB WRING

INDOOR

1

17

16

15

14

13

12

11

10

98

76543

2

1 Interface of fan motor

2 Interface of communication

3 Power supply neutral wire

4 Fuse

5 Power supply live wire

6 Interface of live wire for health function

7 Interface of wired controller

8 Interface of BMS

9 Auto button

10 Jumper cap

11 Interface of up and down swing terminal

12 Interface of left and right swing terminal

13 Ambient temperature sensor interface

14 Indoor tube temperature sensor interface

15 Interface of display

16 Fuse

17 High-frequency terminal

OUTDOOR

3

2

1

4 5 6 7 8

9

10

11

12

13

14

15

16

1 Interface of reactor 1 10 Interface of outdoor fan

2 Interface of reactor 2 11 Electric heater band of chassis HEAT2-L

3 U, V, W three-phase interface of compressor 12 Electric heater band of compressor HEAT1-L

4 Overload protection terminal of compressor OVC-COMP

13

Interface of neutral wire for compressor electric heating and

chassis electric heating

5 Terminal of temperature sensor CN2

6 High pressure protection terminal HPP 14 Interface of live wire

7 Electric expansion valve terminal EV 15 Interface of neutral wire

8 Interface of indoor unit and outdoor unit communication 16 Interface of ground wire

9 Interfacel of 4-way valve 17 Interface of reactor1 and reactor2

6

AY-X36RU

AE-X36RU

FUNCTION AND CONTROL

[1] Remote Control Introduction

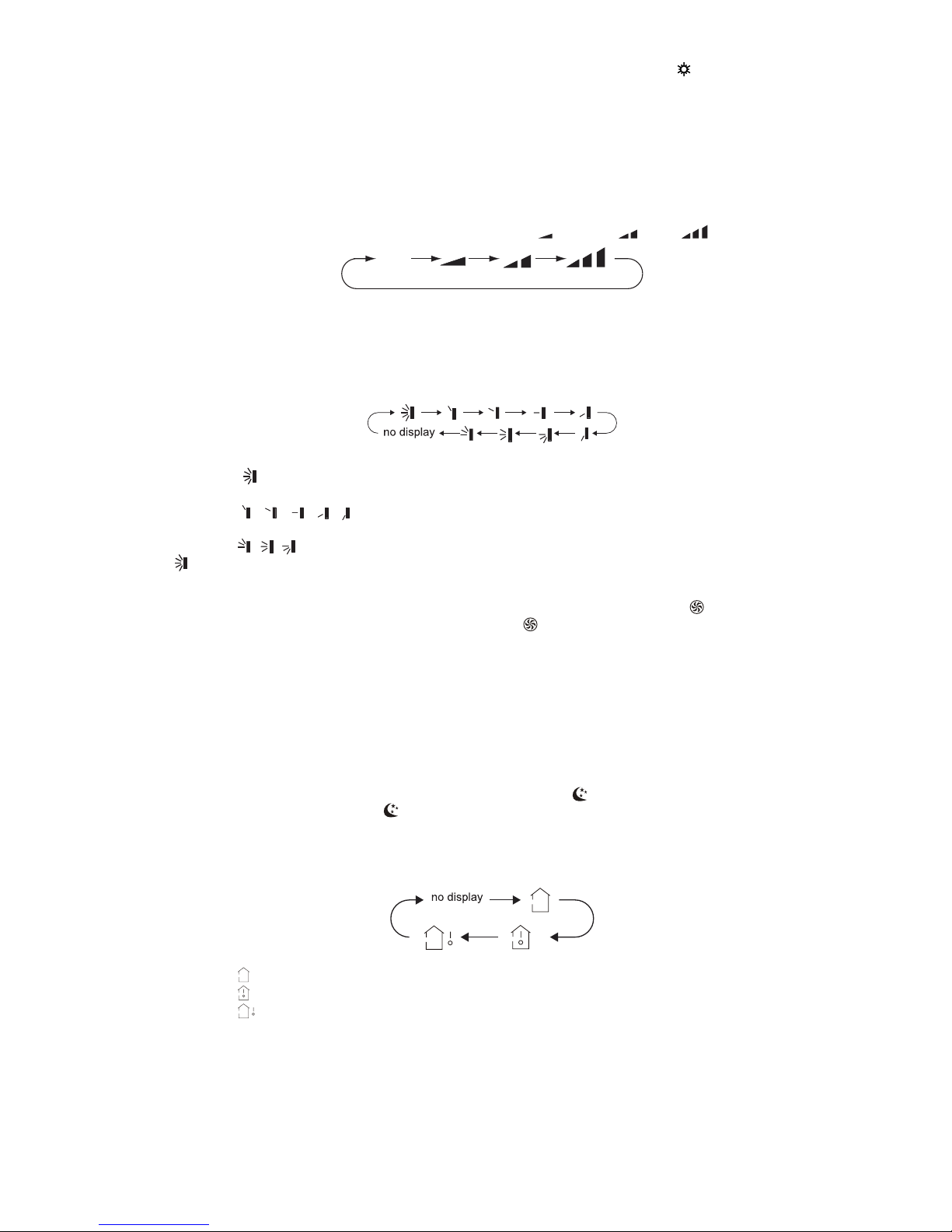

Buttons on the Remote Control

2

4

7

9

11

12

1 ON/OFF Button

2 MODE Button

3 FAN Button

4 SWING Button

5 TURBO FAN Button

6

/ Button

7 SLEEP Button

8 TEMP Button

9 COMFORT Button

10 DISPLAY Button

11 CLOCK Button

12 TIMER ON/TIMER OFF Button

1

3

5

6

8

10

MODE FAN

TURBO

TEMP

DISPLAY

COMFORT

TIMERONTIMER

OFF

ON/OFF

SWING

SLEEP

CLOCK

Note:

● Once popower is connected, the air conditioner will give out a sound. Operation indictor “ “ is ON (red indicator). After that, the

air conditioner can be operated by using the remote controller.

● Under ON status, pressing the button on the remote controller, the signal icon “ “on the display of remote controller will blink

once and the air conditioner will give out a “de” sound, which means the signal has been sent to the air conditioner.

● Under OFF status, set temperature and clock icon will be displayed on the display of remote controller (If timer on, timer off and

light functions are set, the corresponding icons will be displayed on the display of remote controller at the same time); Under ON

status, the display will show the corresponding set function icons.

1. ON/OFF button

Press this button can turn on or turn off the air conditioner. After turning on the air conditioner, operation indicator " "on indoor

unit’s display is ON (green indicator), and indoor unit will give out a sound.

2. MODE button

Press this button to select your required operation mode.

● When selecting auto mode, air conditioner will operate automatically according to ex-factory setting. Set temperature can’t be

adjusted and will not be displayed as well. Press "FAN" button can adjust fan speed. Press "SWING" button can adjust fan

blowing angle.

● After selecting cool mode, air conditioner will operate under cool mode. Cool indicator " "on indoor unit is ON. Press "▲" or "

▲" button to adjust set temperature. Press "FAN" button to adjust fan speed. Press "SWING" button to adjust fan blowing angle.

● When selecting dry mode, the air conditioner operates at low speed under dry mode. Dry indicator " " on indoor unit is ON.

Under dry mode, fan speed can’t be adjusted. Press "SWING" button to adjust fan blowing angle.

● When selecting fan mode, the air conditioner will only blow fan, no cooling and no heating. All indicators are OFF. Press "FAN"

button to adjust fan speed. Press "SWING" button to adjust fan blowing angle.

AY-X36RU

AE-X36RU

7

● When selecting heating mode, the air conditioner operates under heat mode. Heat indicator " " on indoor unit is ON. Press "▲"

or "▼" button to adjust set temperature. Press "FAN" button to adjust fan speed. Press "SWING" button to adjust fan blowing

angle. (Cooling only unit won’t receive heating mode signal. If setting heat mode with remote controller, pressing ON/OFF button

can’t start up the unit).

Note:

● To preven cold air after starting up in heating mode, indoor unit will delay 1~5 minutes to blow air (actual delay time is depend

on indoor ambient temperature).

● Set temperature range from remote controller: 16~30°C(61°F~86°F); Fan speed: auto, low speed, medium speed, high speed.

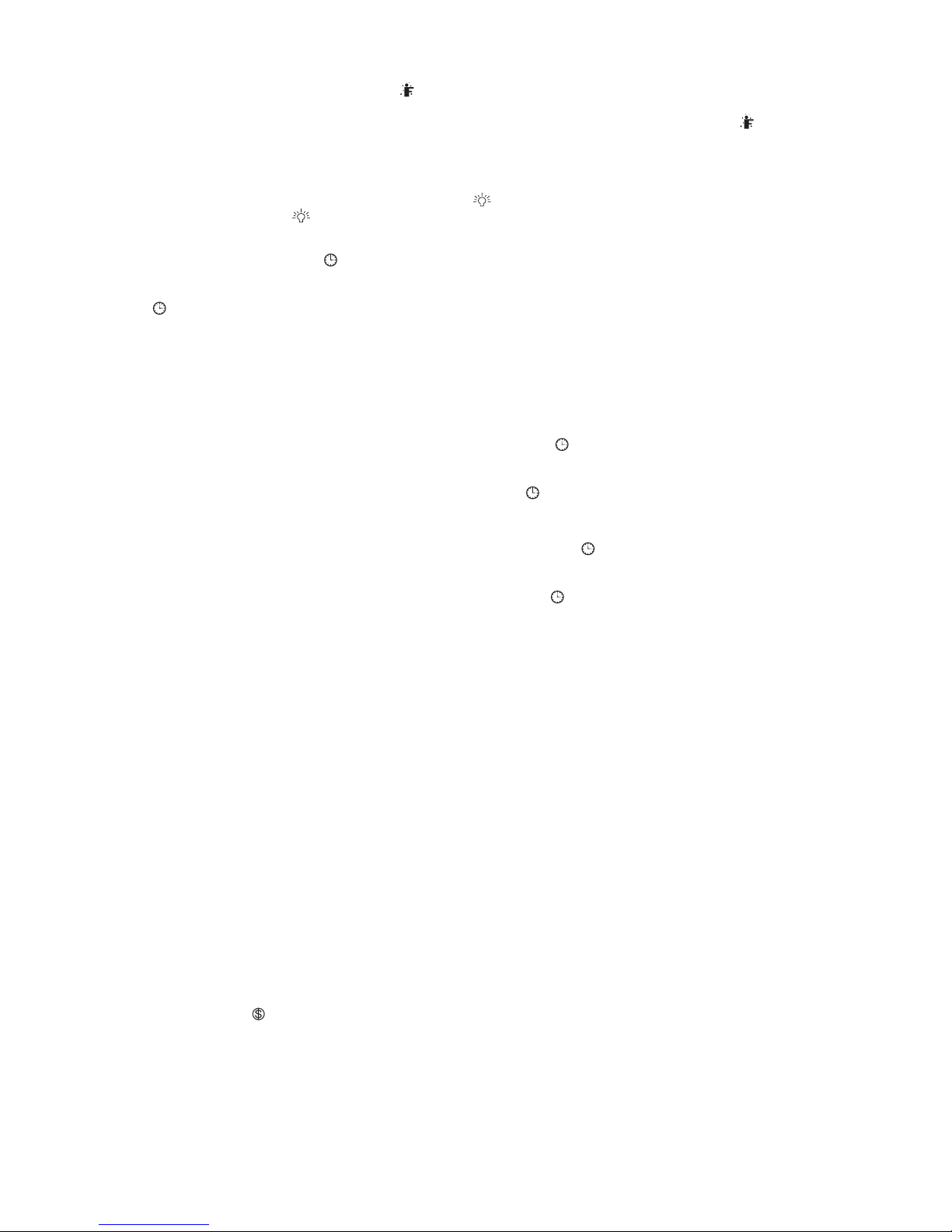

3. FAN button

Pressing this button can set fan speed circularly as: auto (AUTO), low ( ), medium ( ), high ( ).

Auto

Note:

● Under AUTO speed, air conditioner will select proper fan speed automatically.

● Fan speed under dry mode is low speed.

4. SWING button

Press this button can select up&down swing angle. Fan blow angle can be selected circularly as below:

(horizontal louvers stops at current position)

● When selecting " ", air conditioner is blowing fan automatically. Horizontal louver will automatically swing up & down at

maximum angle.

● When selecting "

, , , ,

", air conditioner is blowing fan at xed position. Horizontal louver will stop at the xed

position.

● When selecting "

, ,

" , air conditioner is blowing fan automatically.

● Hold " "button above 2seconds to set your required swing angle. When reaching your required angle, release the button.

5. TURBO FAN button

Under COOL or HEAT mode, press this button to turn to quick COOL or quick HEAT mode. " " icon is displayed on remote

controller. Press this button again to exit TURBO FAN function and " " icon will disappear.

6. ▲/▼ button

● Press "▲" or "▼" button once increase or decrease set temperature 1°C(1~2°F). Holding "▲" or "▼" button, 2seconds later,

set temperature on remote controller will change quickly. On releasing button after setting is nished, temperature indicator on

indoor unit will change accordingly. (Temperature can’t be adjusted under auto mode)

● When setting TIMER ON, TIMER OFF or CLOCK, press "▲" or "▼" button to adjust time. (Refer to CLOCK, TIMER ON, TIMER

OFF buttons) When setting TIMER ON, TIMER OFF or CLOCK, press "▲" or "▼" button to adjust time. (Refer to CLOCK,

TIMER ON, TIMER OFF buttons)

7. SLEEP button

Under COOL or HEAT mode, press this button to start up SLEEP function. " " icon is displayed on remote controller. Press this

button again to cancel SLEEP function and " " icon will disappear.

8. TEMP button

By pressing this button, the indoor set temperature, indoor ambient temperature or outdoor ambient temperature is shown on the

indoor unit’s display. The setting on remote controller is selected circularly as below:

● When selecting " " or no display with remote controller, temperature indicator on indoor unit displays set temperature.

● When selecting " " with remote controller, temperature indicator on indoor unit displays indoor ambient temperature.

● When selecting " " with remote controller, temperature indicator on indoor unit displays outdoor ambient temperature.

Outdoor temperature display is not applicable for this unit. The temperature indicator displays indoor set temperature.

Note:

● It’s defaulted to display set temperature when turning on the unit.There is no display in the remote controller.

● Only for the models whose indoor unit has dual-8 display.

● When the selecting display of indoor or outdoor ambient temperature, indoor temperature indicator displays corresponding

temperature and automatically turn to display set temperature after three or ve seconds.

8

AY-X36RU

AE-X36RU

9. COMFORT button

Press this button to start COMFORT function and " " will be displayed on the remote controller. After this function is set, the

remote controller will send the detected ambient temperature to the controller and the unit will automatically adjust the indoor

temperature according to the detected temperature. Press this button again to cancel COMFORT function and "

" will disappear.

● Please put the remote controller near user when this function is set. Do not put the remote controller near the object of high

temperature or low temperature in order to avoid detecting inaccurate ambient temperature.

10. DISPLAY Button

Press this button to turn off the display light on the indoor unit. " " icon on the remote controller disappears. Press this button

again to turn on the display light. " " icon is displayed.

11. CLOCK Button

Press this button to set the clock time. " " icon on the remote controller will blink. Press "▲" or "▼" button within 5seconds to set

the clock time. Each pressing of "▲" or "▼" button, clock time will increase or decrease 1 minute. If hold "▲" or "▼" button,

2seconds later, time will change quickly. Release this button when reaching your required time. Press "CLOCK" button to conrm

the time. " " icon stops blinking.

Note:

● Clock time adopts 24-hour mode.

● The interval between two operation can’t exceeds 5seconds. Otherwise, remote controller will quit setting status. Operation for

TIMER ON/TIMER OFF is the same.

12. TIMER ON / TIMER OFF button

● TIMER ON button

"TIMER ON" button can set the time for timer on. After pressing this button, " " icon disappears and the word "ON" on remote

controller blinks. Press "▲" or "▼"button to adjust TIMER ON setting. After each pressing "▲" or "▼" button, TIMER ON setting

will increase or decrease 1min. Hold "▲" or "▼" button, 2seconds later, the time will change quickly until reaching your required

time. Press "TIMER ON" to conrm it. The word "ON" will stop blinking. " " icon resumes displaying. Cancel TIMER ON: Under

the condition that TIMER ON is started up, press "TIMER ON" button to cancel it.

● TIMER OFF button

"TIMER OFF" button can set the time for timer off. After pressing this button," " icon disappears and the word "OFF" on

remote controller blinks. Press "▲" or "▼" button to adjust TIMER OFF setting. After each pressing "▲" or "▼" button, TIMER

OFF setting will increase or decrease 1min. Hold "▲" or "▼" button, 2seconds later, the time will change quickly until reaching

your required time. Press "TIMER OFF" word "OFF" will stop blinking. "

" icon resumes displaying. Cancel TIMER OFF.

Under the condition that TIMER OFF is started up, press "TIMER OFF" button to cancel it.

Note:

● Under on and off status, you can set TIMER OFF or TIMER ON simultaneously.

● Before setting TIMER ON or TIMER OFF, please adjust the clock time.

● After starting up TIMER ON or TIMER OFF, set the constant circulating valid. After that, air conditioner will be turned on or

turned off according to setting time. ON/OFF button has no effect on setting. If you don’t need this function, please use remote

controller to cancel it.

Function Buttons on the Remote Control

1. Energy-saving function (This function is not explained on the operation manual nor the catalogue)

Under cooling mode, press "TEMP" and "CLOCK" buttons simultaneously to start up or turn off the energy-saving function.

When the energy-saving function is started up, "SE" will be shown on remote controller, and air conditioner will adjust the

set temperature automatically according to ex-factory setting to reach to the best energy-saving effect. Press "TEMP" and

"CLOCK"buttons simultaneously again to exit energy-saving function.

Note:

● Under the energy-saving function, fan speed is defaulted at auto speed and it can’t be adjusted.

● Under the energy-saving function, set temperature can’t be adjusted. Press "TURBO" button and the remote controller won’t

send signal.

● Sleep function and energy-saving function can’t operate at the same time. If energy-saving function has been set under cooling

mode, press sleep button will cancel energy-saving function. If sleep function has been set under cooling mode, start up the

energy-saving function will cancel sleep function.

2. 8°C (46°F) heating function (This function is not explained on the operation manual nor the catalogue)

Under heating mode, press "TEMP" and "CLOCK" buttons simultaneously to start up or turn off the 8°C heating function. When

this function is started up, " " and "8°C" will be shown on the remote controller, and the air conditioner keep the heating status at

8°C. Press "TEMP" and "CLOCK" buttons simultaneously again to exit 8°C heating function.

Note:

● Under the 8°C heating function, fan speed is defaulted at auto speed and it can’t be adjusted.

● Under the 8°C heating function, set temperature can’t be adjusted. Press "TURBO" button and the remote controller won’t send

signal.

● The sleep function and the 8°C heating function can’t operate at the same time. If 8°C heating function has been set under

cooling mode, press sleep button will cancel 8°C heating function. If sleep function has been set under cooling mode, start up

the 8°C heating function will cancel sleep function.

AY-X36RU

AE-X36RU

9

● Under °F temperature display, the remote controller will display 46°F heating.

3. Lock function

Press "▲" and "▼" simultaneously to turn on or turn off lock function. When lock function is on, " " icon is displayed on remote

controller. If you operate the remote controller, the " " icon will blink three times without sending signal to the unit.

4. Temperature display switch over function

Under OFF status, press "▲" and "MODE" buttons simultaneously to switch temperature display between °C and °F.

Operation guide

1. Once power is connected, press "ON/OFF" button on remote controller to turn on the air conditioner.

2. Press "MODE" button to select your required mode: AUTO, COOL, DRY, FAN, HEAT.

3. Press "▲" or "▼" button to set your required temperature. (Temperature can’t be adjusted under auto mode).

4. Press "FAN" button to set your required fan speed: auto, low, medium and high speed.5. Press "SWING" button to select fan

blowing angle.

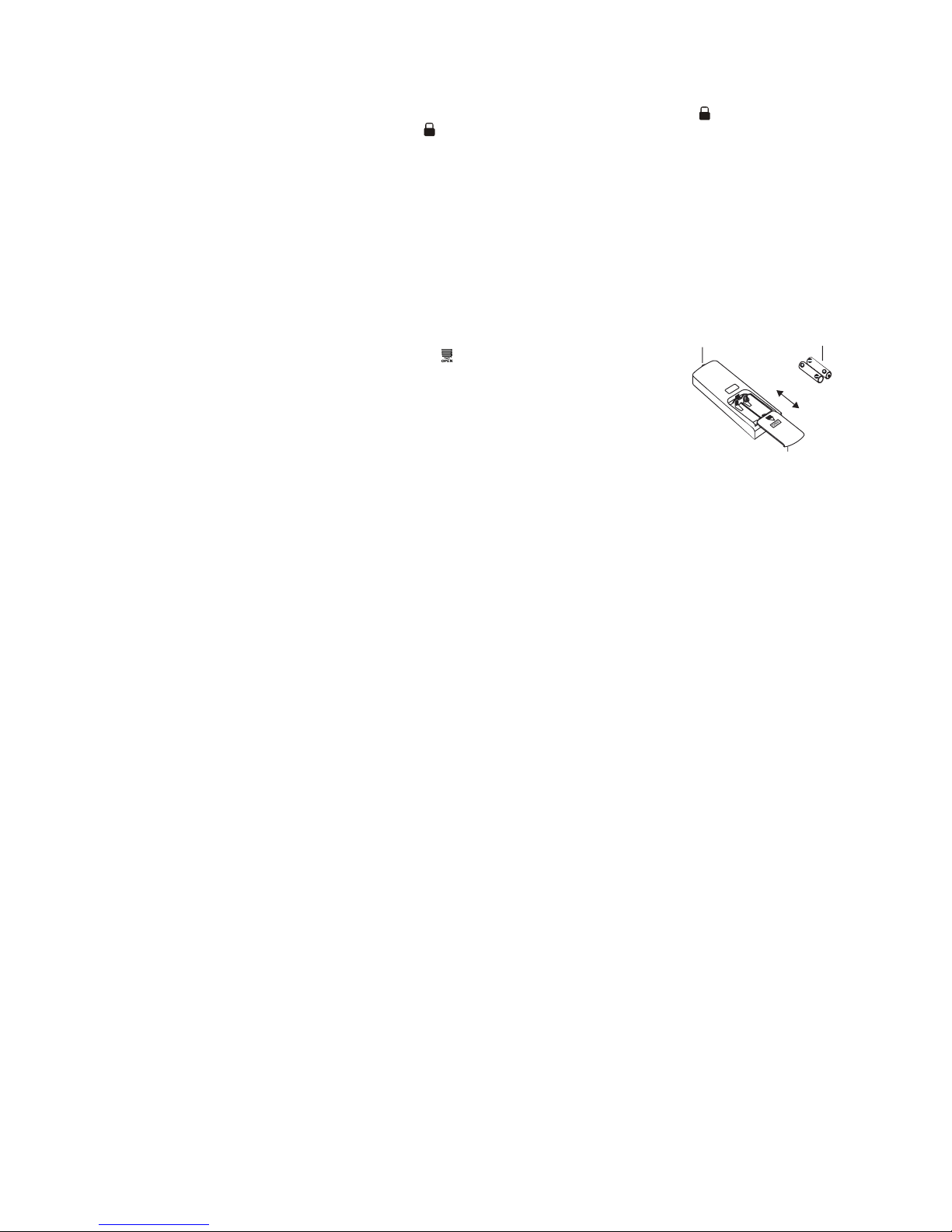

Replacement of batteries in remote controller

1. Press the back side of remote controller marked with " ", as shown in the g, and then

push out the cover of battery box along the arrow direction.

2. Replace two 7# (AAA 1.5V) dry batteries, and make sure the position of "+" polar and

"-" polar are correct.

3. Reinstall the cover of the battery box.

Battery

Cover of battery box

Reinstall

Remove

Signal sender

Note:

● During operation, point the remote control signal sender at the receiving window of the indoor unit.

● The distance between signal sender and receiving window should be no more than 8m, and there should be no obstacles between

them.

● Signal may be interfered easily in the room where there is uorescent lamp or wireless telephone; remote controller should be close

to indoor unit during operation.

● Replace new batteries of the same model when replacement is required.

● When you don’t use remote controller for a long time, please take out the batteries.

● If the display on remote controller is fuzzy or there’s no display, please replace batteries.

10

AY-X36RU

AE-X36RU

TROUBLESHOOTING

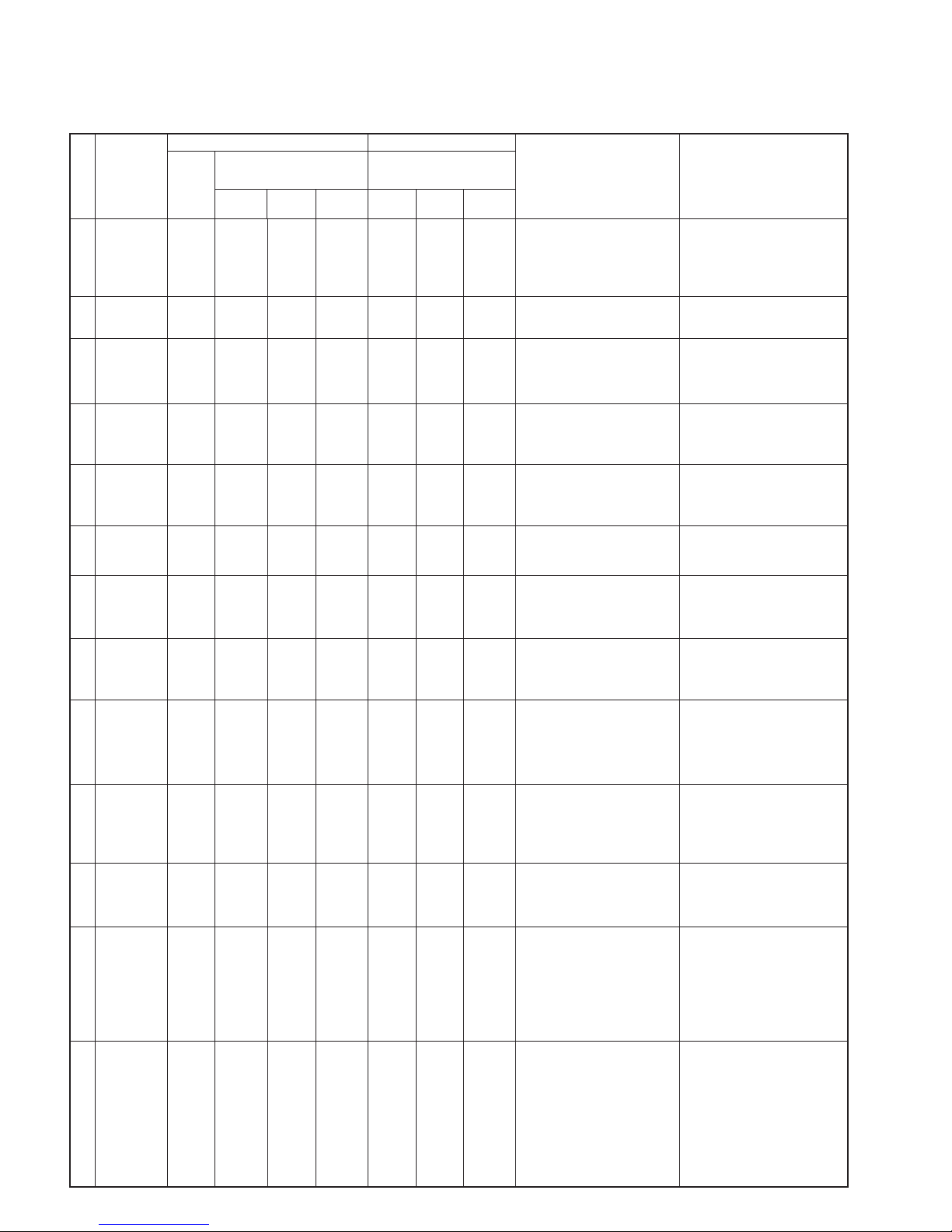

[1] Error Code List

NO.

Malfunction

Name

Display Method of Indoor Unit Display Method of Outdoor Unit

A/C status Possible Causes

Dual 8

Code

Display

Indicator Display (during blink-

ing, ON 0.5s and OFF 0.5s)

Indicator has 3 kinds of display

status and during blinking, ON

0.5s and OFF 0.5s

Operation

Indicator

Cool

Indicator

Heating

Indicator

Yellow

Indicator

Red

Indicator

Green

Indicator

1

High pressure

protection of

system

E1

OFF 3s

and blink

once

During cooling and drying operation, except indoor fan operates, all

loads stop operation. During heating operation, the complete unit

stops.

Possible reasons:

1. Refrigerant was superabundant;

2. Poor heat exchange (including

fifth blockage of heat exchanger

and bad radiating environment );

Ambient temperature is too high.

2

Antifreezing

protection

E2

OFF 3S

and blink

twice

OFF 1S

and blink

3 times

During cooling and drying operation, compressor and outdoor fan

stop while indoor fan operates.

1. Poor air-return in indoor unit;

2. Fan speed is abnormal;

3. Evaporator is dirty.

3

In defect of

refrigerant

F0

OFF 1S

and blink

9 times

The Dual 8 Code Display will show

F0 and the complete unit stops.

1. In defect of refrigerant;

2. Indoor evaporator temperature

sensor works abnormally;

3. The unit has been plugged up

somewhere.

4

High discharge

temperature

protection of

compressor

E4

OFF 3S

and blink

4 times

OFF 1S

and blink

7 times

During cooling and drying operation, compressor and outdoor fan

stop while indoor fan operates.

During heating operation, all loads

stop.

Please refer to the malfunction

analysis (discharge protection, overload).

5

Over current

protection

E5

OFF 3S

and blink

5 times

OFF 1S

and blink

5 times

During cooling and drying operation, compressor and outdoor fan

stop while indoor fan operates.

During heating operation, all loads

stop.

1. Supply voltage is unstable;

2. Supply voltage is too low and

load is too high;

3. Evaporator is dirty.

6

Communication Malfunction

E6

OFF 3S

and blink

6 times

Always

ON

During cooling operation, compressor stops while indoor fan motor

operates. During heating operation,

the complete unit stops.

Refer to the corresponding malfunction analysis.

7

High temperature resistant

protection

E8

OFF 3S

and blink

8 times

OFF 1S

and blink

6 times

During cooling operation: compressor will stop while indoor fan will

operate.

During heating operation, the complete unit stops.

Refer to the malfunction analysis

(overload, high temperature resistant).

8

EEPROM malfunction

EE

OFF 3S

and blink

15 times

OFF 1S

and blink

11 times

During cooling and drying operation, compressor will stop while

indoor fan will operate; During

heating operation, the complete

unit will stop

Replace outdoor control panel AP1

9

Limit/decrease

frequency

due to high

temperature of

module

EU

OFF 3S

and blink

6 times

OFF 3S

and blink

6 times

All loads operate normally, while

operation frequency for compressor is decreased

Discharging after the complete unit

is de-energized for 20mins, check

whether the thermal grease on IPM

Module of outdoor control panel AP1

is sufficient and ahether the radiator

is inserted tightly. If its no use, please

replace control panel AP1

.

10

Malfunction

protection of

jumper cap

C5

OFF 3S

and blink

15 times

Wireless remote receiver and button are effective, but can not dispose the related command

1. No jumper cap insert on main

board.

2. Incorrect insert of jumper cap.

3. Jumper cap damaged.

4. Abnormal detecting circuit of

main board.

11

Gathering

refrigerant

Fo

OFF 3S

and blink

1 times

OFF 3S

and blink

1 times

OFF 1S

and blink

17 times

When the outdoor unit receive signal of Gathering refrigerant

,the system will be forced to run

under cooling mode for gathering

refrigerant

Nominal cooling mode

12

Indoor ambient

temperature

sensor is open/

short circuited

F1

OFF 3S

and blink

once

During cooling and drying operation, indoor unit operates while

other loads will stop; during heating

operation,

the complete unit will stop operation.

1. Loosening or bad contact of

indoor ambient temp. sensor and

main board terminal.

2. Components in main board fell

down leads short circuit.

3. Indoor ambient temp. sensor

damaged.(check with sensor

resistance value chart)

4. Main board damaged.

13

Indoor evaporator temperature sensor

is open/short

circuited

F2

OFF 3S

and blink

twice

AC stops operation once reaches

the setting temperature. Cooling,

drying: internal fan motor stops

operation while other loads stop

operation; heating: AC stop operation

1. Loosening or bad contact of

Indoor evaporator temp. sensor

and main board terminal.

2. Components on the main board

fall down leads short circuit.

3. Indoor evaporator temp. sensor

damaged.(Check temp. sensor

value chart for testing)

4. Main board damaged.

AY-X36RU

AE-X36RU

11

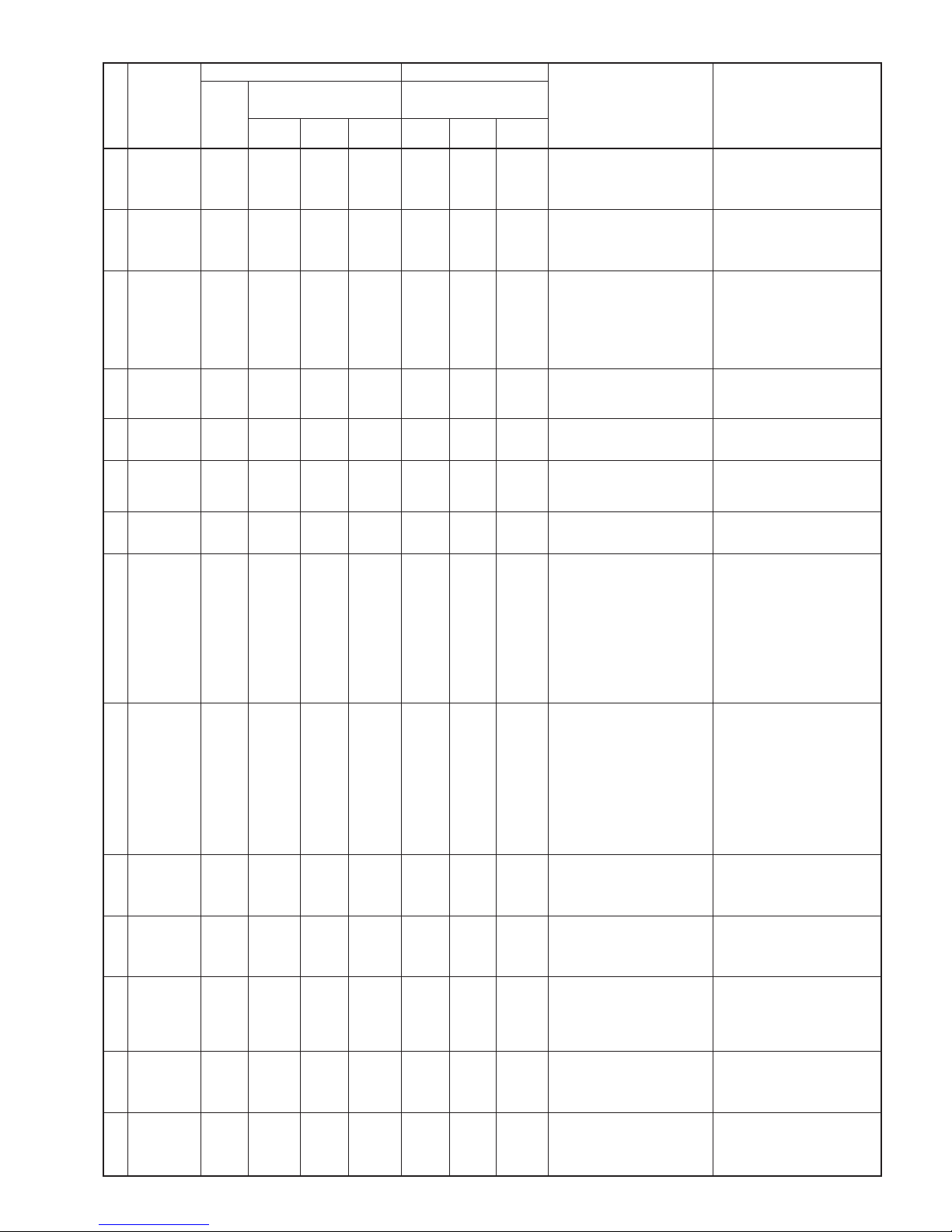

NO.

Malfunction

Name

Display Method of Indoor Unit Display Method of Outdoor Unit

A/C status Possible Causes

Dual 8

Code

Display

Indicator Display (during blink-

ing, ON 0.5s and OFF 0.5s)

Indicator has 3 kinds of display

status and during blinking, ON

0.5s and OFF 0.5s

Operation

Indicator

Cool

Indicator

Heating

Indicator

Yellow

Indicator

Red

Indicator

Green

Indicator

14

Outdoor ambient temperature sensor

is open/short

circuited

F3

OFF 3S

and blink

3 times

OFF 1S

and blink

6 times

During cooling and drying operating, compressor stops while indoor

fan operates; During heating operation, the complete unit will stop

operation

Outdoor temperature sensor hasn’t

been connected well or is damaged.

Please check it by referring to the

resistance table for temperature

sensor)

15

Outdoor

condenser

temperature

sensor is open/

short circuited

F4

OFF 3S

and blink

4 times

OFF 1S

and blink

5 times

During cooling and drying operation, compressor stops while indoor

fan will operate; During heating

operation, the complete unit will

stop operation.

Outdoor temperature sensor has

not been connected well or is damaged. Please check it by referring to

the resistance table for temperature

sensor)

16

Outdoor

discharge

temperature

sensor is open/

short circuited

F5

OFF 3S

and blink

5 times

OFF 1S

and blink

7 times

During cooling and drying operation, compressor will sop after

operating for about 3 mins, while

indoor fan will operate; During

heating operation, the complete

unit will stop after operating for

about 3 mins.

1. Outdoor temperature sensor

has not been connected well or

is damaged. Please check it by

referring to the resistance table

for temperature sensor)

2. The head of temperature sensor

has not been inserted into the

copper tube

17

Limit/ decrease

frequency due

to overload

F6

OFF 3S

and blink

for 6

times

OFF 1S

and blink

3 times

All loads operate normally, while

operation frequency for compressor is decreased

Refer to the malfunction analysis

(overload, high temperature resistant)

18

Decrease frequency due to

overcurrent

F8

OFF 3S

and blink

8 times

OFF 1S

and blink

once

All loads operate normally, while

operation frequency for compressor is decreased

The input supply voltage is too low;

System pressure is too high and

overload

19

Decrease

frequency due

to high air discharge

F9

OFF 3S

and blink

9 times

OFF 1S

and blink

twice

All loads operate normally, while

operation frequency for compressor is decreased

Overload or temperature is too high;

Malfunction of electric expansion

valve (EKV)

20

Limit/ decrease

frequency due

to antifreezing

FH

OFF 3S

and blink

2 times

OFF 3S

and blink

2 times

OFF 1S

and blink

4 times

All loads operate normally, while

operation frequency for compressor is decreased

Poor air-return in indoor unit or fan

speed is too low

21

Voltage for DC

bus-bar is too

high

PH

OFF 3S

and blink

11 times

OFF 1S

and blink

13 times

During cooling and drying operation, compressor will stop while

indoor fan will operate; During

heating operation, the complete

unit will stop operation.

1. Measure the voltage of position L

and N on wiring board (XT), if the

voltage is higher than 265VAC,

turn on the unit after the supply

voltage is increased to the normal range.

2. If the AC input is normal, measure the voltage of electrolytic

capacitor C on control panel

(AP1), if its normal, there is malfunction for the circuit, please

replace the control panel (AP1)

22

Voltage of DC

bus-bar is too

low

PL

OFF 3S

and blink

21 times

OFF 1S

and blink

12 times

During cooling and drying operation, compressor will stop while

indoor fan will operate; During

heating operation, the complete

unit will stop

1. Measure the voltage of position L

and N on wiring board (XT), if the

voltage is higher than 150VAC,

turn on the unit after the supply

voltage is increased to the normal range.

2. If the AC input is normal, measure the voltage of electrolytic

capacitor C on control panel

(AP1), if its normal, there’s malfunction for the circuit, please

replace the control panel (AP1)

23

Compressor

Min frequence

in test state

P0

(during

blinking,

ON 0.25s

and OFF

0.25s)

(during

blinking,

ON 0.25s

and OFF

0.25s)

Showing during min. cooling or min.

heating test

24

Compressor

rated frequence in test

state

P1

(during

blinking,

ON 0.25s

and OFF

0.25s)

(during

blinking,

ON 0.25s

and OFF

0.25s)

Showing during nominal cooling or

nominal heating test

25

Compressor

maximum frequence in test

state

P2

(during

blinking,

ON 0.25s

and OFF

0.25s)

(during

blinking,

ON 0.25s

and OFF

0.25s)

Showing during max. cooling or

max. heating test

26

Compressor

intermediate

frequence in

test state

P3

(during

blinking,

ON 0.25s

and OFF

0.25s)

(during

blinking,

ON 0.25s

and OFF

0.25s)

Showing during middle cooling or

middle heating test

27

Overcurrent

protection of

phase current

for compressor

P5

OFF 3S

and blink

15 times

During cooling and drying operation, compressor will stop while

indoor fan will operate; During

heating operation, the complete

unit will stop operation.

Refer to the malfunction analysis

(IPM protection, loss of synchronism

protection and over current protection of phase current for compressor.

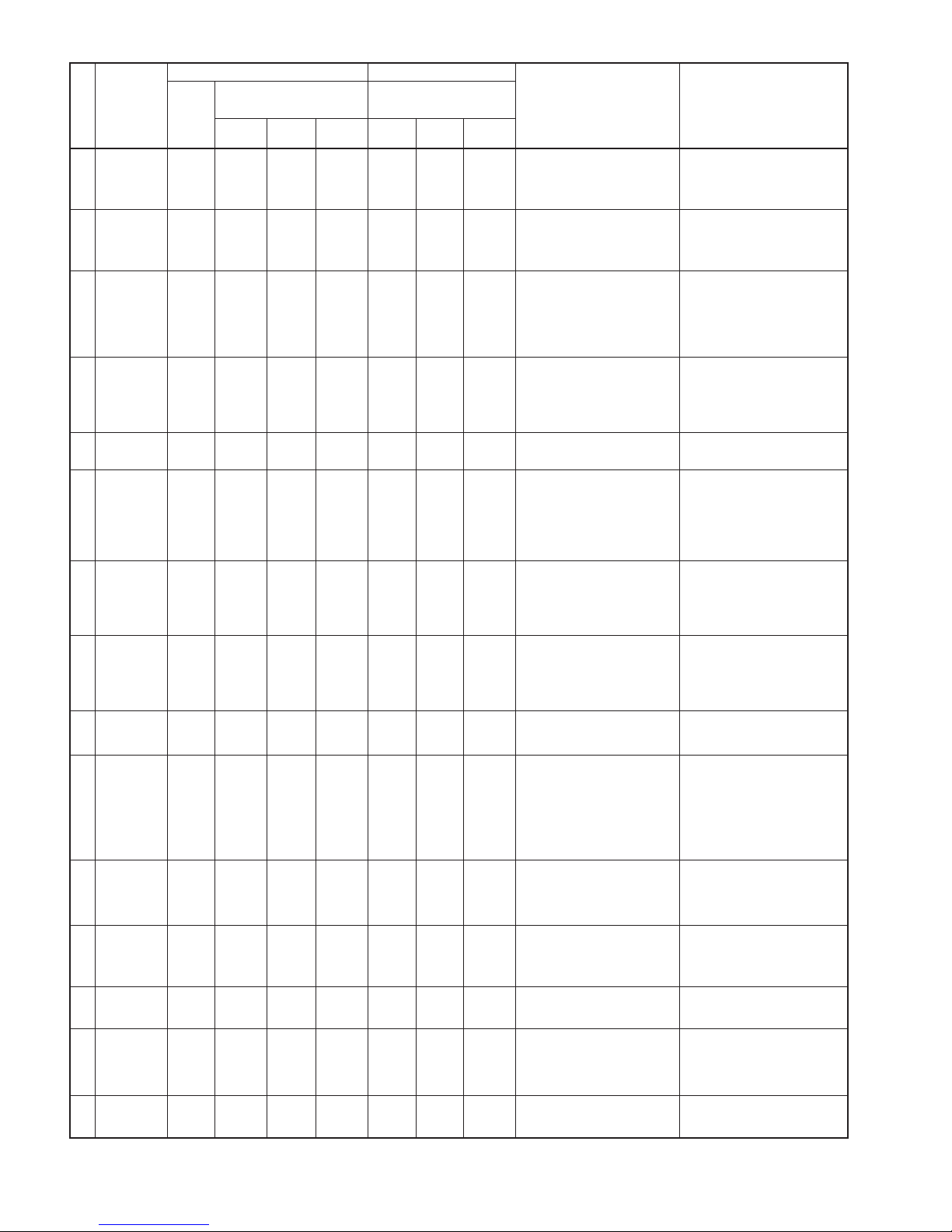

12

AY-X36RU

AE-X36RU

NO.

Malfunction

Name

Display Method of Indoor Unit Display Method of Outdoor Unit

A/C status Possible Causes

Dual 8

Code

Display

Indicator Display (during blink-

ing, ON 0.5s and OFF 0.5s)

Indicator has 3 kinds of display

status and during blinking, ON

0.5s and OFF 0.5s

Operation

Indicator

Cool

Indicator

Heating

Indicator

Yellow

Indicator

Red

Indicator

Green

Indicator

28

Charging

malfunction of

capacitor

PU

OFF 3S

and blink

17 times

During cooling and drying operation, compressor will stop while

indoor fan will operate; During

heating operation, the complete

unit will stop

Refer to the part three—charging

malfunction analysis of capacitor

29

Malfunction

of module

temperature

sensor circuit

P7

OFF 3S

and blink

18 times

During cooling and drying operation, compressor will stop while

indoor fan will operate; During

heating operation, the complete

unit will stop

Replace outdoor control panel AP1

30

Module high

temperature

protection

P8

OFF 3S

and blink

19 times

During cooling operation, compressor will stop while indoor fan will

operate;

During heating operation, the complete unit will stop

After the complete unit is de- energized for 20mins, check whether

the thermal grease on IPM Module

of outdoor control panel radiator is

inserted tightly. If its no use, please

replace control panel AP1.

31

Decrease frequency due to

high temperature resistant

during heating

operation

H0

OFF 3S

and blink

10 times

All loads operate normally, while

operation frequency for compressor is decreased

Refer to the malfunction analysis

(overload, high temperature resistant)

32

Static dedusting protection

H2

OFF 3S

and blink

twice

33

Overload

protection for

compressor

H3

OFF 3S

and blink

3 times

OFF 1S

and blink

8 times

During cooling and drying operation, compressor will stop while

indoor fan will operate; During

heating operation, the complete

unit will stop operation.

1. Wiring terminal OVC-COMP is

loosened. In normal state, the

resistance for this terminal should

be less than 1ohm.

2. Refer to the malfunction analysis

(discharge protection, overload)

34

System is

abnormal

H4

OFF 3S

and blink

4 times

OFF 1S

and blink

6 times

During cooling and drying operation, compressor will stop while

indoor fan will operate; During

heating operation, the complete

unit will stop operation.

Refer to the malfunction analysis

(overload, high temperature resistant)

35 IPM protection H5

OFF 3S

and blink

5 times

OFF 1S

and blink

4 times

During cooling and drying operation, compressor will stop while

indoor fan will operate; During

heating operation, the complete

unit will stop operation.

Refer to the malfunction analysis

(IPM protection, loss of synchronism

protection and over current protection of phase current for compressor.

36

Module temperature is too

high

H5

OFF 3S

and blink

5 times

OFF 1S

and blink

10 times

37

Internal motor

(fan motor) do

not operate

H6

OFF 3S

and blink

11 times

Internal fan motor, external fan

motor, compressor and electric

heater stop operation,guide louver

stops at present location.

1. Bad contact of DC motor feedback terminal.

2. Bad contact of DC motor control

end.

3. Fan motor is stalling.

4. Motor malfunction.

5. Malfunction of main board rev

detecting circuit.

38

Desynchronizing of compressor

H7

OFF 3S

and blink

7 times

During cooling and drying operation, compressor will stop while

indoor fan will operate; During

heating operation, the complete

unit will stop operation.

Refer to the malfunction analysis

(IPM protection, loss of synchronism

protection and over current protection of phase current for compressor.

39

PFC

protection

HC

OFF 3S

and blink

6 times

OFF 1S

and blink

14 times

During cooling and drying operation, compressor will stop while

indoor fan will operate; During

heating operation, the complete

unit will stop operation.

Refer to the malfunction analysis

40

Outdoor DC

fan motor malfunction

L3

OFF 3S

and blink

23 times

OFF 1S

and blink

14 times

Outdoor DC fan motor malfunction

lead to compressor stop operation,

DC fan motor malfunction or system

blocked or the connector loosed

41

power protec

-

tion

L9

OFF 3S

and blink

20 times

OFF 1S

and blink

9 times

Compressor stop operation and

Outdoor fan motor will stop 30s latter , 3 minutes latter fan motor and

compressor will restart

To protect the electrical components

when detect high power

42

Indoor unit and

outdoor unit

doesn't match

LP

OFF 3S

and blink

19 times

OFF 1S

and blink

16 times

Compressor and Outdoor fan

motor can’t work

Indoor unit and outdoor unit doesn't

match

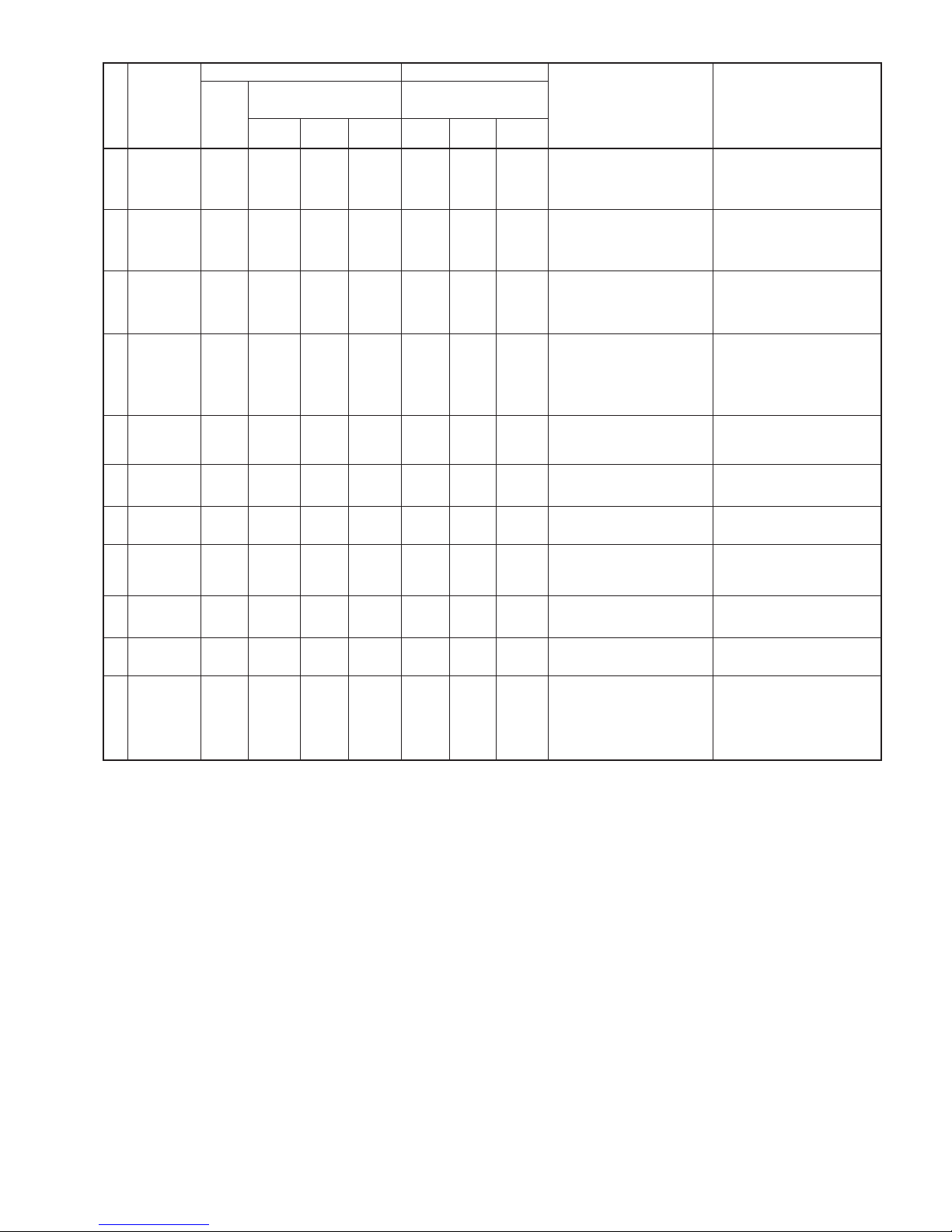

AY-X36RU

AE-X36RU

13

NO.

Malfunction

Name

Display Method of Indoor Unit Display Method of Outdoor Unit

A/C status Possible Causes

Dual 8

Code

Display

Indicator Display (during blink-

ing, ON 0.5s and OFF 0.5s)

Indicator has 3 kinds of display

status and during blinking, ON

0.5s and OFF 0.5s

Operation

Indicator

Cool

Indicator

Heating

Indicator

Yellow

Indicator

Red

Indicator

Green

Indicator

43

Failure startup

LC

OFF 3S

and blink

11 times

During cooling and drying operation, compressor will stop while

indoor fan will operate; During

heating operation, the complete

unit will stop operation.

Refer to the malfunction analysis

45

Malfunction of

voltage dropping for DC

bus-bar

U3

OFF 3S

and blink

20 times

During cooling and drying operation, compressor will stop while

indoor fan will operate; During

heating operation, the complete

unit will stop

Supply voltage is unstable

46

Malfunction of

complete units

current detection

U5

OFF 3S

and blink

13 times

During cooling and drying operation, the compressor will stop while

indoor fan will operate;

During heating operating, the complete unit will stop operation.

There’s circuit malfunction on outdoor units control panel AP1, please

replace the outdoor units control

panel AP1.

47

The four-way

valve is abnormal

U7

OFF 3S

and blink

20 times

If this malfunction occurs during

heating operation, the complete

unit will stop operation.

1. Supply voltage is lower than

AC175V;

2. Wiring terminal 4V is loosened or

broken; 3.4V is damaged, please

replace 4V.

48

Zero- crossing

malfunction of

outdoor unit

U9

OFF 3S

and blink

18 times

During cooling operation, compressor will stop while indoor fan will

operate; during heating,the complete unit will stop operation.

Replace outdoor control panel AP1

49

Frequency limiting (power)

OFF 1S

and blink

13 times

50

Compressor

running

OFF 1S

and blink

once

51

The temperature for turning

on the unit is

reached

OFF 1S

and blink

8 times

52

Frequency limiting (module

temperature)

OFF 1S

and blink

11 times

53

Normal communication

OFF 0.5S

and blink

once

54 Defrosting

OFF 3S

and blink

once (during blinking, ON

10s and

OFF 0.5s)

OFF 1S

and blink

twice

Defrosting will occur in heating

ode. Compressor will operate while

indoor fan will stop operation.

Its the normal state

14

AY-X36RU

AE-X36RU

[2] Troubleshooting for Main Malfunction

1.

Malfunction of Temperature Sensor F1, F2

Main detection points:

● Is the wiring terminal between the temperature sensor and the controller loosened or poorly contacted?

● Is there short circuit due to trip-over of the parts?

● Is the temperature sensor broken?

● Is main board broken?

Is the problem fixed?

Is the problem fixed?

Is the problem fixed?

Replace it with the

temperature sensor.

Loading...

Loading...