Page 1

4M-1 OM

SHARP

SERVICE MANUAL

LCD COLOUR TELEVISION

MODEL

4M-IOM

In the interests of user-safety (Required by safety regulations in some countries ) the set should be

restored to its original condition and only parts identical to those specified should be used.

/

f

CONTENTS

Page

l

IMPORTANT SERVICE SAFETY PRECAUTION

. . . . . . . . . . . . . . . . . . . . . . . . . .

2

l

ELECTRICAL SPECIFICATIONS

. . . m . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

l

LOCATION AND IDENTIFICATION OF CONTROLS

. . . . . . . . . . . . . . . . . . . . . .

4

l DISASSEMBLY AND REASSEMBLY

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

l

TROUBLE SHOOTING TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . a.. . . . .

6

l

ADJUSTMENT PROCEDURES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8

l

CHASSIS LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11

l

SCHEMATIC DIAGRAM AND WAVEFORMS

. . . . . . . . . . . . . . . . . . . . . . . . . .

13

l

PRINTED WIRING BOARD ASSEMBLIES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19

. BLOCK DIAGRAM

25

0 REPLACEMENTPARfSCI;S”::::::::::::::::::::::::::::::::::::::::

27

. PACKING OF THE SET

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

37

SHARP CORPORATION

Page 2

4M-1 OM

IMPORTANT SERVICE SAFETY PRECAUTION

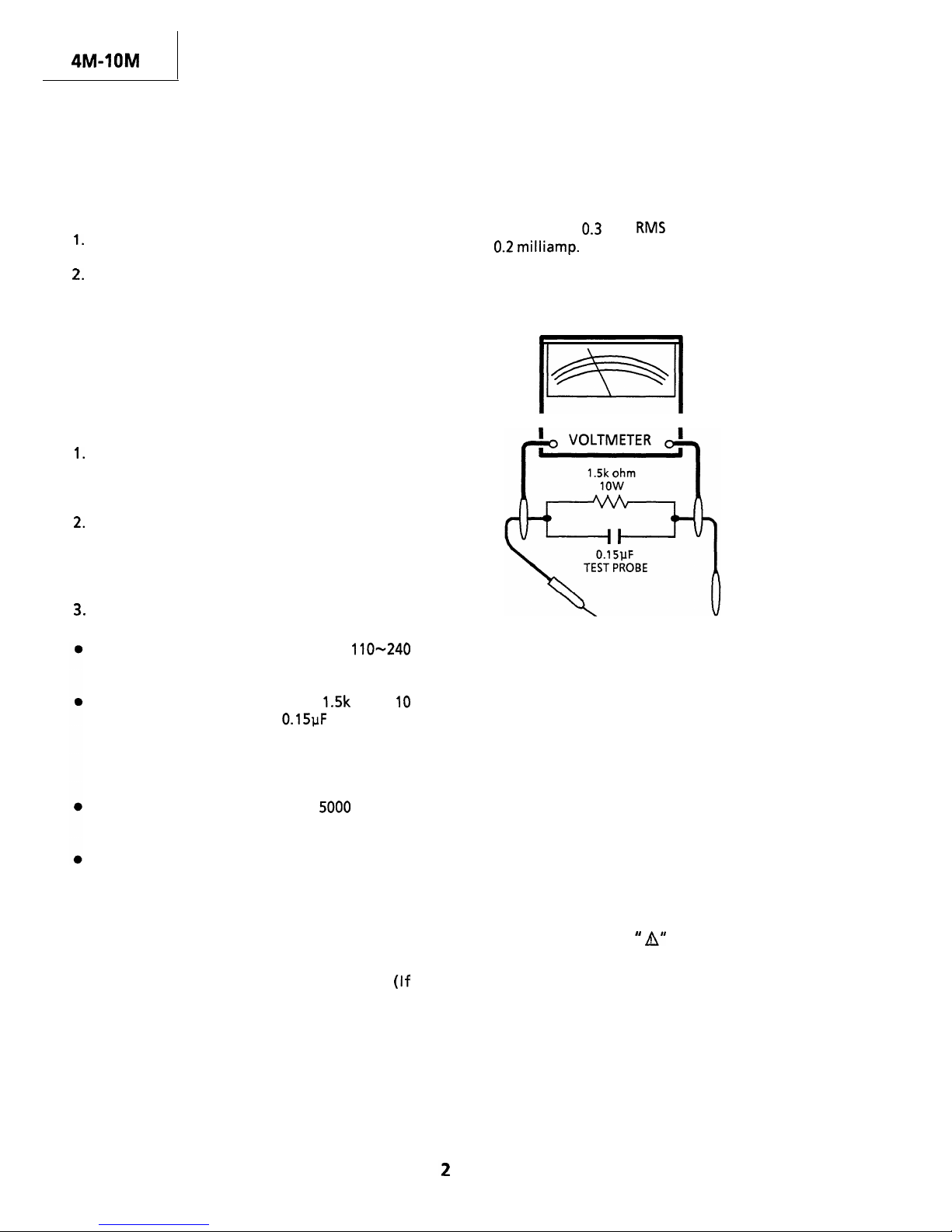

n Service work should be performed only by qualified service technicians who are

thoroughly familiar with all safety checks and servicing guidelines which follow:

WARNING

1.

For continued safety, no modification of any

circuit should be attempted.

2.

Disconnect AC power before servicing.

Any reading of

0.3

volt

RMS

(this corresponds

to

0.2

milliamp. AC.) or more is excessive and

indicates a potential shock hazard which must

be corrected before returning the receiver to

the owner.

BEFORE RETURNING THE RECEIVER

(Fire &Shock Hazard)

Before returning the receiver to the user,

perform the following safety checks:

1.

Inspect all lead dress to make certain that leads

are not pinched, and check that hardware is

not lodged between the chassis and other

metal parts in the receiver.

2.

Inspect all protective devices such as non-

metallic control knobs, insulating materials,

cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacity

networks, mechanical insulators, etc.

3.

To be sure that no shock hazard exists, check

for current leakage in the following manner.

Plug the AC Adaptor directly into a

110-240

volt AC outlet, (Do not use an isolation

transformer for this test).

Using two clip leads, connect a

1.5k

ohm,

10

watt resistor paralleled by a

0.15~.1F

capacitor in

series with all exposed metal cabinet parts and

a known earth ground, such as electrical

conduit or electrical ground connected to an

earth ground.

Use an AC voltmeter having with

5000

ohm per

volt, or higher, sensitivity to measure the AC

voltage drop across the resistor.

Connect the resistor connection to all exposed

metal parts having a return path to the chassis

(antenna, metal cabinet, screw heads, knobs

and control shafts, escutcheon, etc.) and

measure the AC voltage drop across the

resistor.

All checks must be repeated with the AC

Adaptor plug connection reversed.

(If

necessary, a nonpolarized adapter plug must

be used only for the purpose of completing

these checks.)

I

AC

I

TO EXPOSED’

CONNECT TO

METAL PARTS

KNOWN EARTH

GROUND

SAFETY NOTICE

Many electrical and mechanical parts in television

receivers have special

safety-related

characteristics.

‘These characteristics are often not evident from

visual inspection, nor can protection afforded by

them be necessarily increased by using

replacement components rated for higher

voltage, wattage, etc.

Replacement parts which have these special

safety characteristics are identified in this

manual; electrical components having such

features are identified by H A“ and shaded areas

in the Replacement Parts Lists and Schematic

Diagrams.

For continued protection,

replacement parts must be identical to those used

in the original circuit.

The use of a substitute

replacement parts which do not have the same

safety characteristics as the factory recommended

replacement parts shown in this service manual,

may create shock, fire, or other hazards.

Page 3

4M-1 OM

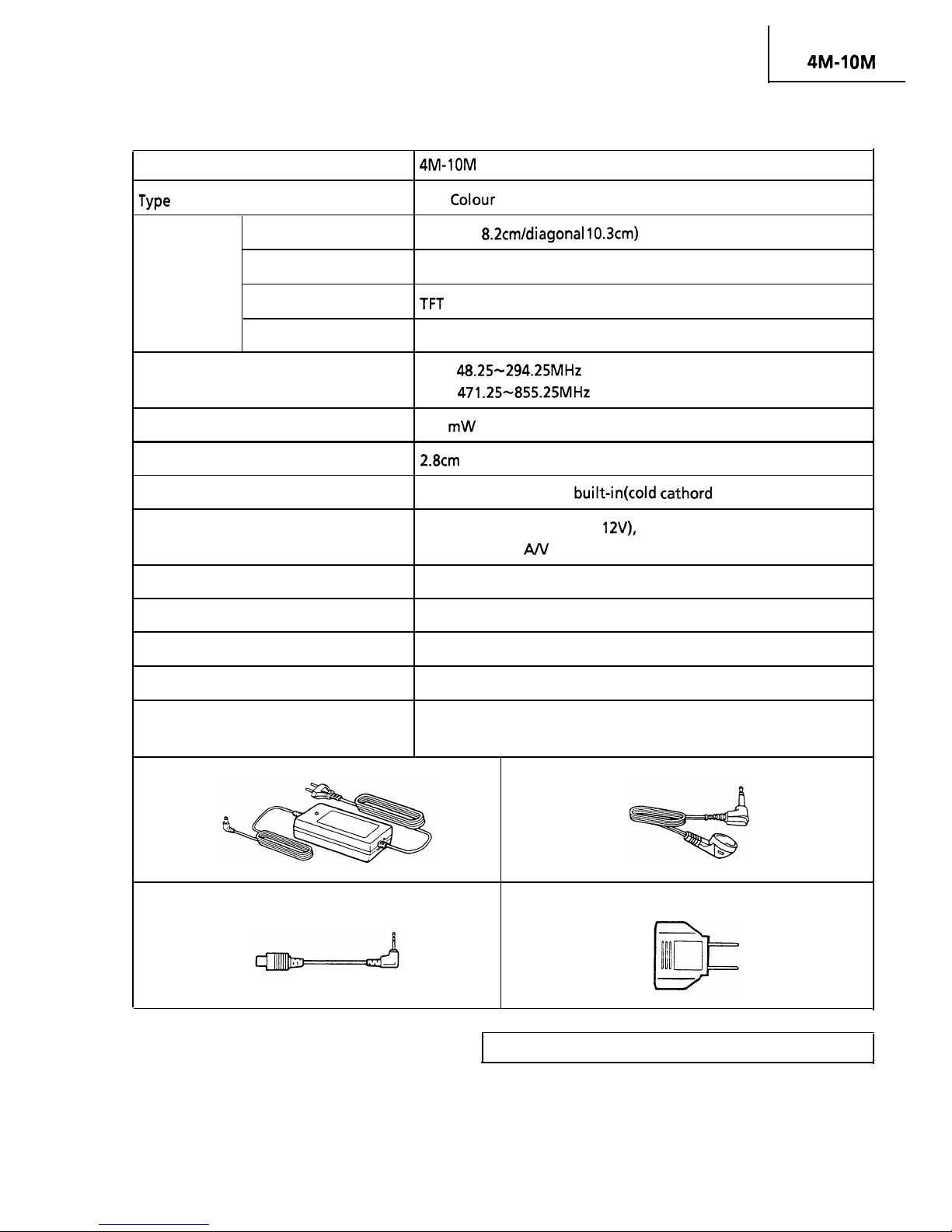

ELECTRICAL SPECIFICATIONS

Model

Type

TV screen

Screen Size

LCD Panels

Drive method

Number of pixels

Receiving frequency

Audio output

Speaker

Light source

Terminals

Power supply

Power consumption

Dimensions (W x H x D)

Weigh

Supplied Accessories

AC Adaptor (1)

4M-10M

LCD

Colour

TV

4” (6.2 x

8.2cm/diagonal 10.3cm)

Transmission TN LCD panel

TFT

(Thin Film Transistor) active matrix system

37,440

(117

x 320)

VHF:

48.25-294.25MHz

UHF:

471.25~855.25MHz

200 mW

2.8cm

round type x 1

Fluorescent light tube, built-in(cold cathord type)

External power supply (DC

12V),

External antenna jack,

Earphone jack,

A/V

Input jack, Driver output jack

AC 110~240V 50/60Hz (AC adaptor supplied)

When using AC adaptor: Approx. 11 W (AC)

15.9x11.1 x 5.5cm

Approx. 570g (not including Set Stand)

AC Adaptor (1), Earphone (1), Antenna Adaptor (1), Adaptor

Socket plug(1)

Earphone (1)

Antenna Adaptor (1)

Adaptor Socket Plug (1)

Specifications are subject to change without notice

3

Page 4

4M-10M

LOCATION AND

INDENTIFICATION

OF CONTROLS

External antenna socket

Speaker

AN input

Diversity socket

Earphone jack

Video input indicator

Tint control

Colour control

Colour/Sound AUTO indicator

Mounting socket

Channel

VIA

buttons

Channel Number Recall button

Power switch

Mode switch

Set Memory button

System switch

12V

DC power socket

Volume V / A buttons

Brightness V / A buttons

System change button

Rod antenna

Set stand

I LCD screen panel

4

Page 5

4M-I OM

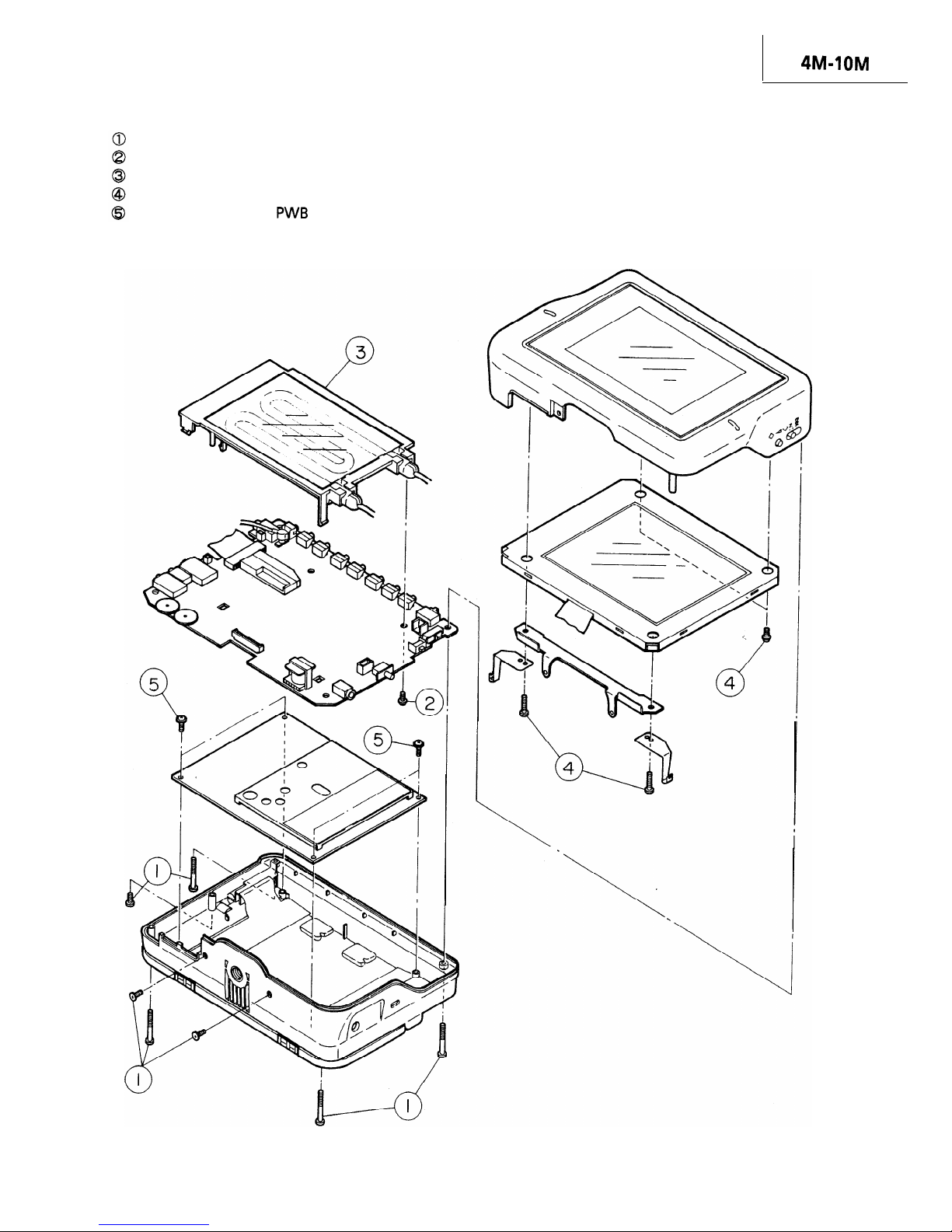

DISASSEMBLY AND REASSEMBLY

Remove the 7 rear cover fastening screws.

Remove the light guide fastening screws.

Undo the 3 light guide hooks.

Remove the 4 LCD holder fastening screws.

Remove the 4 Tuner

PWB

fastening screws.

5

Page 6

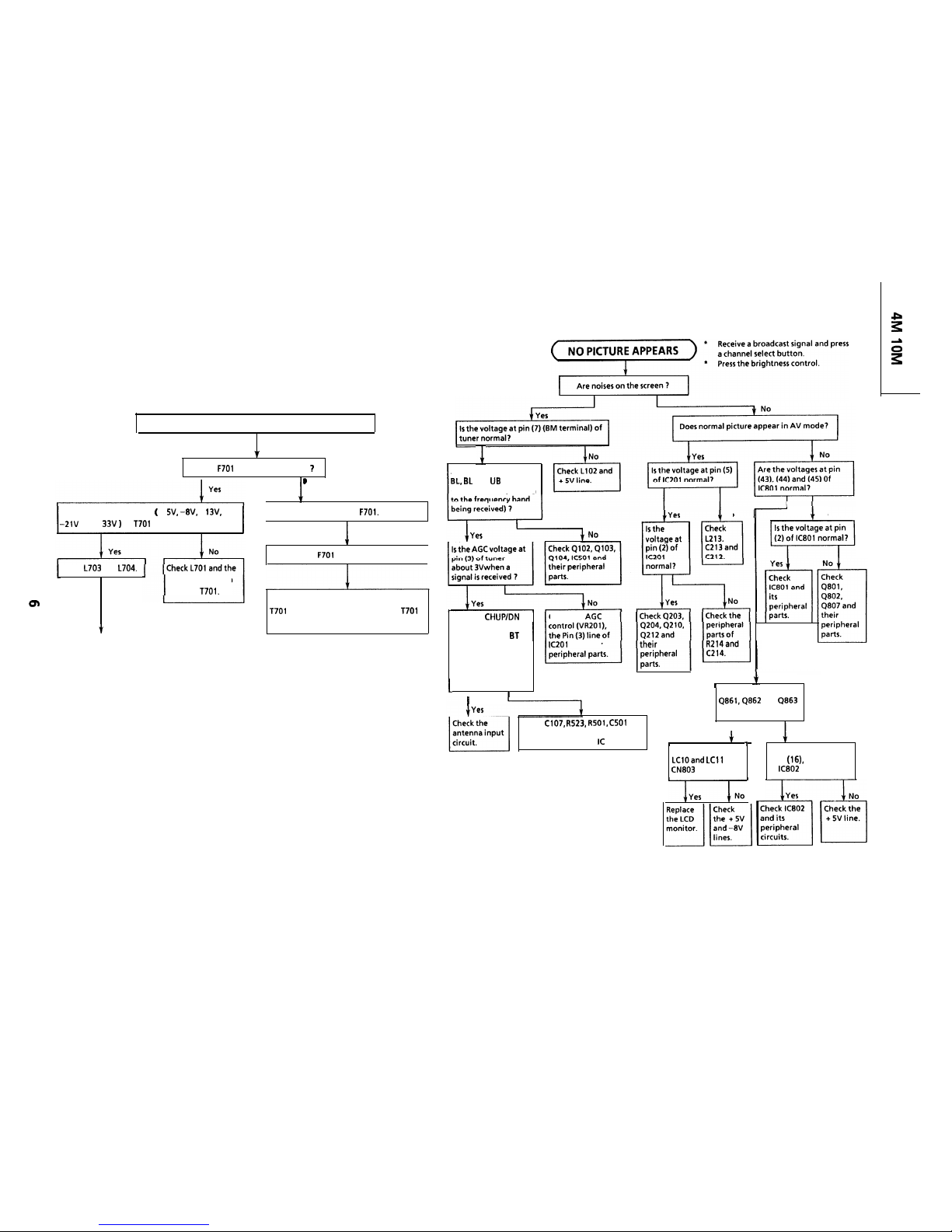

TROUBLE SHOOTING TABLE

(Continued)

Prior checks:

TROUBLE SHOOTING TABLE

f

I

s

3

NEITHER IMAGE NOR SOUND COMES OUT

Yes

Are voltages applied at

BL, BL

and UB terminals

of tuner (corresponding

Is fuse

F701

normally functioning

7

D

No

Replace fuse

F701.

Fuse

F701

easily blows out.

1

Check the peripheral parts of 5701 and

T701

as well as the secondary load of

T701

for a short-circuit.

Are the secondary outputs ( +

5V. -8V,

+

13V,

-21V

and + 33V ) of

T701

all normal?

I

No

h

No

Check

L703

and

L704.

primary oscillation

circuit of T701.

QI

Push the CH

UPlDN

buttons in search

mode. Does the

BT

voltage at pin (4) of

tuner change?

Does the voltage go

up as the channel

1

,

numbers go up ?

I

Check the

AGC

IC201

and their

Continued to the following pages

I

#

Yes

Are the voltages of

Q861,Q862

and

4863

normal?

I

I

No

Yes

1

Are the voltages at

Are the voltages at

LClOand

LCll of

pins

(16)

(19) and (30)

CN803

normal?

of

IC802

normal ?

I

No

Check

C107, R523, R501, C501

and their peripheral parts, as well

as the Pin (20) line of IC 401.

Page 7

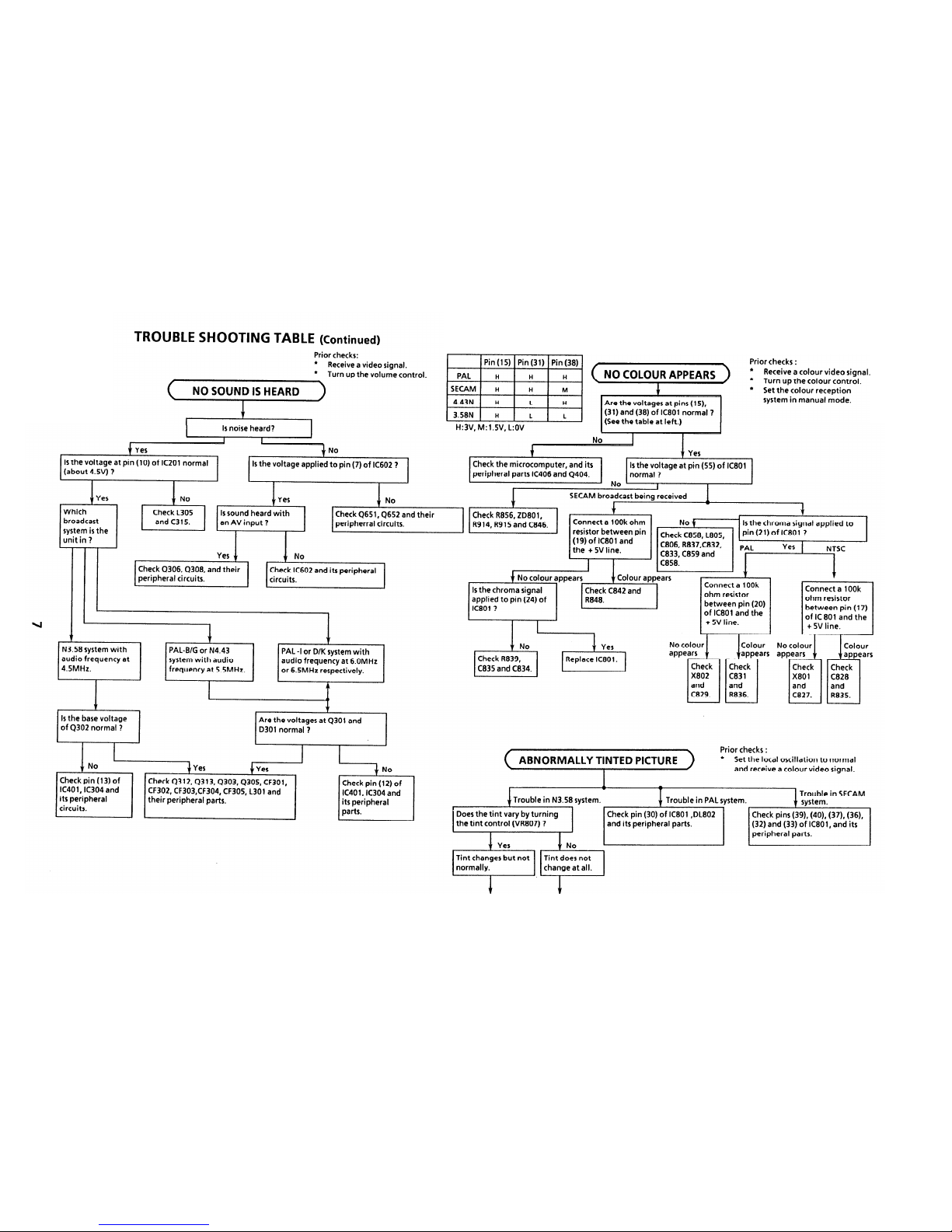

TROUBLE SHOOTING TABLE

(Continued)

TROUBLE SHOOTING TABLE

(Continued)

Prior checks:

NO SOUND IS HEARD

Page 8

ADJUSTMENT PROCEDURES ADJUSTMENT PROCEDURES

(Continued )

I

Adjusting Conditions

l

SIF

ADJUSTMENT : 1301

Adjusting Procedures

1. Feed colour bar signal.

(Set the input field strength to 58dBp)

2. Connect a the DC voltage meter to

TP205.

1. Adjust

L301

so that the voltage at TP205 be

1.42O.lV.

I

Adjusting Conditions Adjusting Procedures

. + B ADJUSTMENT :

VR701

1. Connect the DC voltage meter to

TP701.

1. Adjust

VR701

so that the + 5V line becomes

5 f 0.05v.

l

LLD

ADJUSTMENT : L209

1. Feed sweep signal to

TP20 I.

2. Add fixed bias to

TP202

(Pin (1) of IC201)

I

1. Adjust 1209 to make the

38.9MHz

marker as low

as possible.

I

l

SIGN POSlTlON ADJUSTMENT :

VR401

(0.5V-1 .OV

and

2.OV)

3. Connect an oscilloscope to

TP203.

1. Using the

CH-CALL

button, make

“20-20”

on

screen.

2. Adjust

VR401

to

position the “20-20” sign as

1. Feed colour bar signal.

(Set the input field strength to 58dBp)

2. Set the MODE switch 5401 to MEMORY (0)

position.

l

AFT ADJUSTMENT : L210

---A

,+-

i

9flmm

20-20’

1. Feed IF sweep signal to TPl 01.

2. Add fixed bias to

TP202.

3. Connect the oscilloscope to

TP204.

1. Adjust

L210

so that the

38.9MHr

marker be

positioned as shown below.

00

l

SIGN ADJUSTMENT : VR501

.

RF-AGC

ADJUSTMENT :

VR201

1. Set the MODE switch 5401 to SEARCH

(HI)

position.

2. Connect a diode and lk ohm resistor between

pins (16) and (33) of

IC401.

Set the unit to

MANUAL SEARCH mode.

1. Using the UP/DOWN key (A ,

v),

set the channel

bar at the leftmost end of the VHF sign (just

before changing to the UHF sign).

See the figure below.

1. Feed colour bar signal.

(Set the input field strength to 58

dBp)

2. Check the below

Colour mode : PAL

Sound mode : AUTO

1. Adjust

VR201

so that the voltage at

TPlO2

be

3

?O.lV.

r-Channel

bar

. AFT FINE ADJUSTMENT :

L210

1. Apply the output from the SG (Signal Generator)

to the TPlOl.

(Output from SG : 38.9MHz

(CW) 100dBp)

1. With the tuning in UP search mode, adjust

L210

so

that the voltage at

TP204

be 2.25V.

-

lk

ohm

3. Connect pin (24) of

lC501

to the + 5V line and cut

off the AFT.

2. Adjust

VR501

so that the tuner’s BT voltage at pin

(4) be 0.2V f O.lV.

Page 9

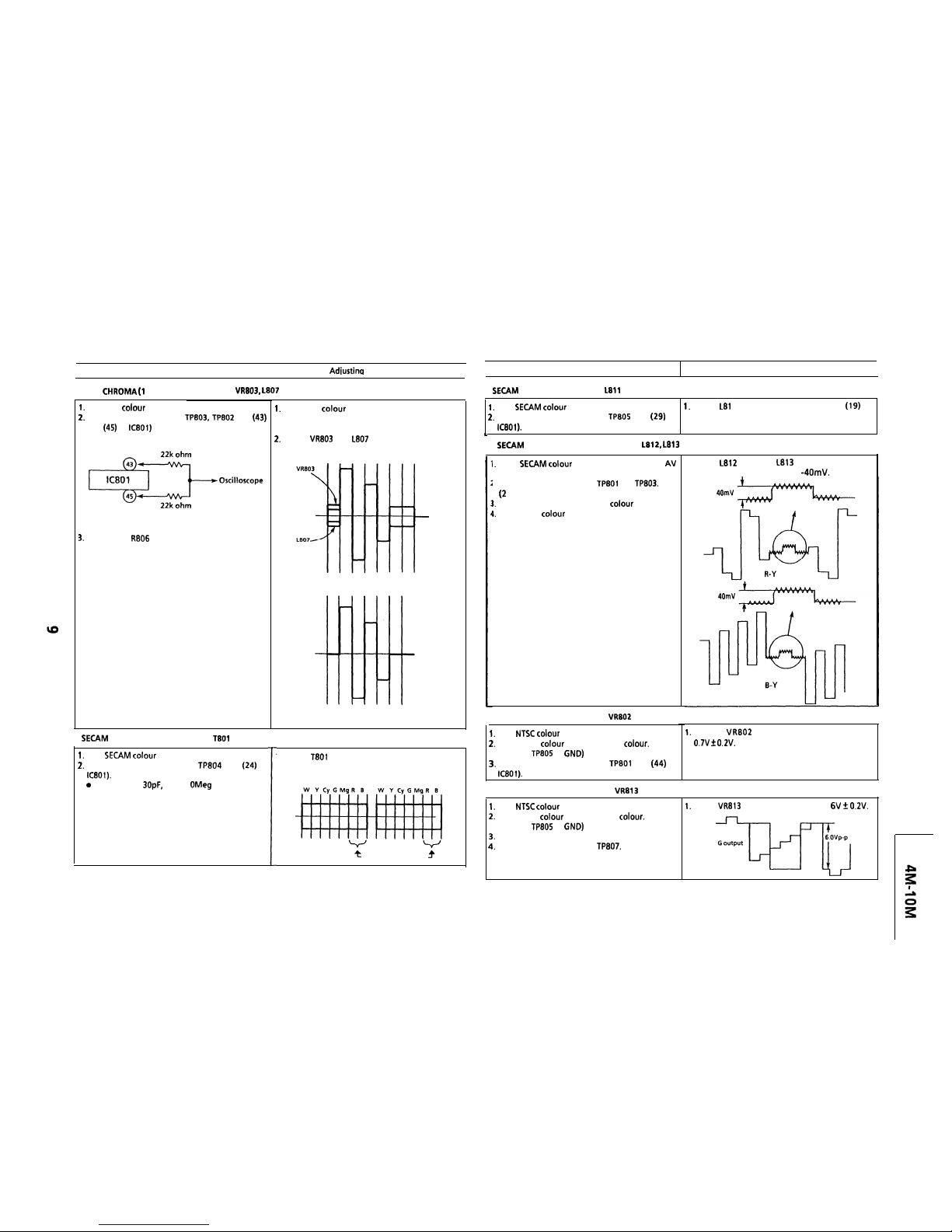

ADJUSTMENT PROCEDURES

(Continued)

I

Adjusting Conditions

I

Adiustino Procedures

I

l

PAL CHROMA (1 H DELAY) ADJUSTMENT : VR803,

L807

1.

Feed PAL colour bar signal.

2.

Connect an oscilloscope to

TPB03,

TP802 (pin (43)

and (45) of IC801) with a resistor, one for each, in

between.

3.

Short-circuit

R806

to cut off the Y signal.

.

SECAM

ADJUSTMENT : BELL FILTER

T801

1.

Feed

SECAM

colour bar signal.

2.

Connect the oscilloscope to

TP804

(pin

(24)

of

IC801).

0 Probe: Below

3OpF,

Over 1

OMeg

ohms.

1

1.

Turn the

colour

control to make the biggest

difference between the green and magenta

levels.

2.

Adjust

VR803

and

L807

to obtain the waveform

shown at bottom.

Waveform before adjustment

Waveform after adjustment

I. Adjust

T801

so that the R and B levels be the

same.

t

To be at the same level

9

ADJUSTMENT PROCEDURES

(Continued )

I

Adjusting Conditions

Adjusting Procedures

I

.

SECAM

KILLER ADJUSTMENT :

L811

1.

Feed

SECAM

colour bar signal.

1.

Adjust

LB1

1 so that the DC level at pin

(19)

be

2.

Connect the oscilloscope to

TP805

(pin

(29)

of

maximum.

ICBOl).

c

l

SECAM

DEMODULATION ADJUSTMENT :

L812, L813

I.

Feed

SECAM colour

bar signal through the AV

jack.

I. Connect the oscilloscope to

TP801

and

TP803.

(2

Channels)

L

Cut off the Y component of the colour bar signal.

1.

Turn up the colour control all the way.

l

VIDEO OUTPUT ADJUSTMENT : VR802

1.

Feed

NTSC colour

bar signal.

2.

Turn on the colour killer to turn off colour.

(Connect

TP805

to

GND)

3.

Connect the oscilloscope to

TP801

(pin

(44)

of

lC801).

. SUB BRIGHTNESS ADJUSTMENT : VR813

1.

Feed

NTSC

colour bar signal.

2.

Turn on the colour killer to cut off

colour.

(Connect

TP805

to

GND)

3.

Set the brightness control in middle position.

4.

Connect the oscilloscope to

TPB07.

I. Adjust

LB12

(B-Y) and

L813

(R-Y) so that the DC

level of R-Y and

B-Y signals be -40 mV.

40mV

40mV

1.

Adjust VR802 so that the white level be

0.7v f

0.2v.

1.

Adjust VR813 so that the amplitude be 6V + 0.2V.

q-p-q)

Page 10

ADJUSTMENT PROCEDURES

(Continued

)

Adjusting Conditions

I

Adjusting Procedures

0

CONTRAST ADJUSTMENT :

VR811

1.

Take the standard settings.

Set the brightness

1.

Adjust

VR811

so that the white level be 4V + 0.2V.

control to middle position.

2.

Feed

NTSC

colour bar signal through the AV jack.

3.

Turn on the colour killer to turn off

colour.

[Standard settings]

2.

Press the ” + ” side of BRIGHT and VOLUME keys.

3.

Connect the oscilloscope to

TP807.

:QfJJ,j+

1.

Press the MEMORY,

CH-CALL

and MEMORY keys

in this order.

. R-WHITE BALANCE ADJUSTMENT : VR810, VR812

1.

Feed monoscope pattern signal through the AV

1.

Turn

VR810

and

VRB12

until the peak-to-peak

jack.

amplitude of the waveform on the oscilloscope

2.

Set the brightness control to middle position.

screen becomes minimum.

3.

Connect the oscilloscope to

TP807 (G

-out).

(CH-1)

4.

Connect the

CH-2

cable of the oscilloscope to

TP808. (Oscilloscope in ADD mode)

5.

Invert the waveform of

channel-2

and add the

signal of channel-l to the channel-2.

. B-WHITE BALANCE ADJUSTMENT : VR807, VR806

1.

Feed monoscope pattern signal through the AV

jack.

2.

Set the brightness control to middle position.

3.

Connect the oscilloscope to

TP807

(G-out) (Cl-t-l).

4.

Connect the

CH-2

cable of the oscilloscope to

TP806. (Oscilloscope in ADD mode)

5.

Invert the waveform of

channel-2

and add the

signal of channel-l to the

channel-2.

1.

Turn

VR807

and

VR806

until the peak-to-peak

amplitude of the waveform on the oscilloscope

screen becomes minimum.

. COUNTER ELECTRODE BIAS ADJUSTMENT : VR814

1.

Feed 1 O-tone black-and-white pattern signal.

2.

Set the brightness control to middle position.

1.

Turn

VRB14

until the contrast gets sharpest.

l

SUB-BRIGHTNESS ADJUSTMENT : VR813

1 1.

Feed lo-tone black-and-white pattern signal.

12.

Set the brightness control to middle position.

1 1.

Turn

VR813

until the second tone on the scale

gets whitish on the screen.

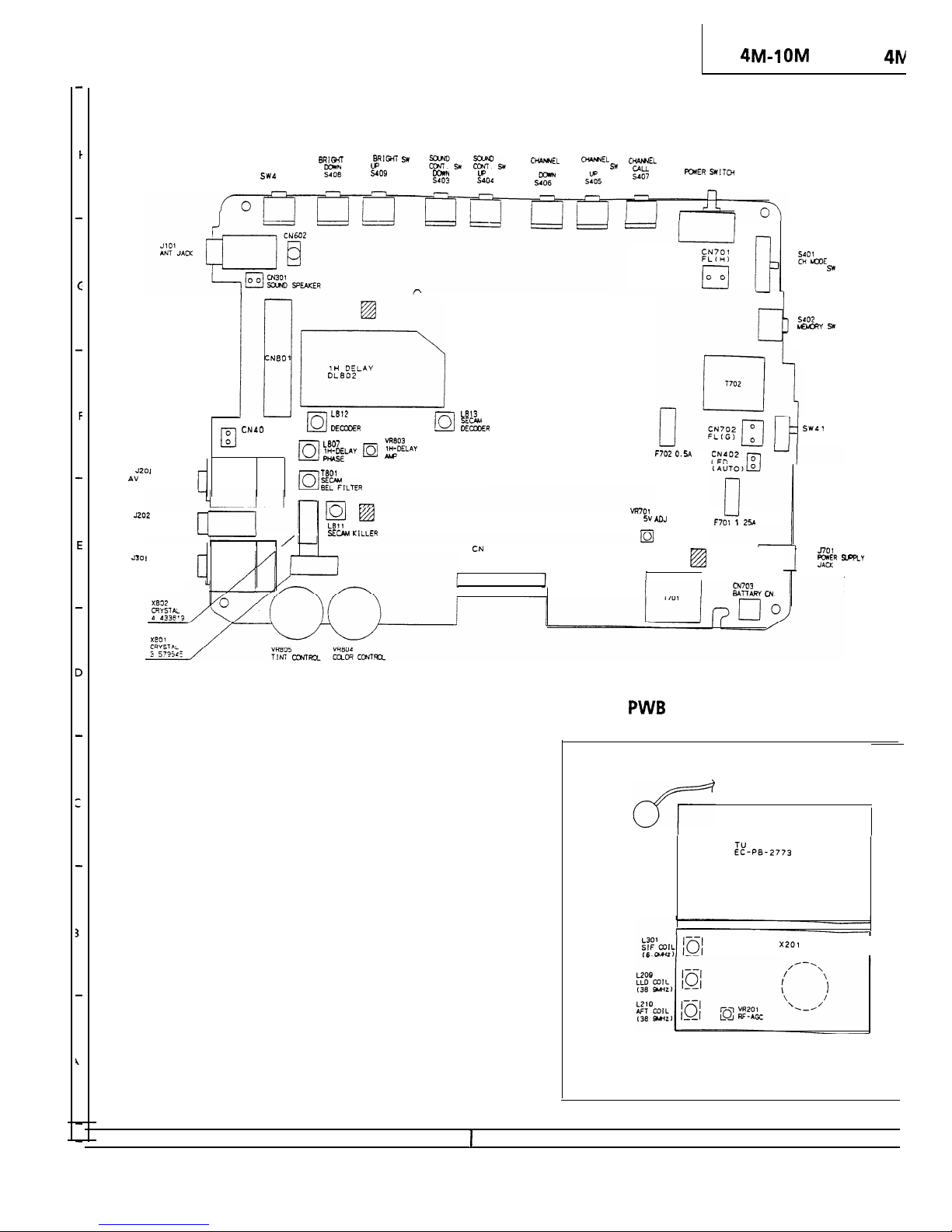

Page 11

4M-1 OM

4N

CHASSIS LAYOUT

SYSTEM

BRIGHT

SW BRlGKi

m

CHnNNEL

CHAMEL

CWEL

CHANGE SW

s

up

Efhw

Es?,

SELECT

SW

SW4 10

s.409 OWN

LP

SELECT SW

303

SAOC

GE

SZ5

E%

5701

FCMR

5WITcH

U

EB

Jr

(Component Side)

NE0

1

1H DELAY

DLB02

Le.12

L813

SEW

CN40

1

(oi

DECCOER

ioi

zEi%R

LED

(A/V)

•l

LB07

lti-EL”’ n EELA’

JZO I

TBOl

AV INPUT JACK

B”E%LTER

-u

CN701

FL(H)

SPOl

CtikCOE

0

SELECT

SW

0

0 0

F702 O.SA

5402

LEhCRYW

VR701

DC 5V

ADJ

F701 t

2%

SW41

1

SYSTEM

J202

DIVERSITY JACK

SECAM KILLEQ

CN 803

J30

I

LCD MODULE

EARPHONE JACK

ia

L-

1

CN703

BATTAQY

134

. TUNER

PWB

SELECT SW

1

J701

PCmER %@PLY

JACK

0

TU

101 TUNER

EC-Pa-2773

x201

SAW FILTER

I

J

1 I

2

I

3

1

4

I

5

I

6

I

11

Page 12

10M

AIN PWB

0

VR601

S&J POSITION

•l

(Wiring Side)

0

7

0

BB

-

0

/

. LED

PWB

0408

LED A/V

O

(GREEN)

0407

LED AUTO

‘I-

0

0

7

I

8

I

9

I

10

I

11

I

12

I

12

Page 13

4M-1 OM

SCHEMATIC DIAGRAM AND WAVEFORMS

n

Voltages were measured with a 20k ohm tester under the following conditions; supply voltage at AC

1

lo-240V (SO/60

Hz), colour bar signal input from servicing colour bar signal generator, and

adjustment controls at their best positions.

n

Waveforms were observed with colour bar signal input from servicing colour bar signal generator and

adiustment

controls at their

best positions.

0

2

7.5Vp-p

O.Sms/div

0

3

300mVp-p

2OysIdiv

20mVp-p

20ps/div

Audio

Chroma

0

4

Blue

0

5

ZOmVp-p 20ps/div

Green

9 9Vp-p

20ps/div

R-Out

SVp-p 20vs/div

COM (LC12)

10

SVp-p 20vs/div

11

SVp-p

2O@div

H. Sync

(LCl)

FRP (LC2)

12

SVp-p

2O@div

CSY (LC3)

0

14

36Vp-p 1

Ops/div

36Vp-p

2Ovs/div

2OOOVp-p SOvs/div

DC-AC Drive

0

15

0

16

COM (LC12)

DC-AC Out

13

Page 14

4M-1 OM

SCHEMATIC DIAGRAM : AC ADAPTOR

A

AND SHADED

(

) COMPONENTS

=

SAFETY RELATED PARTS.

1

I

2

I

3

I

4

5

I

6

I

14

Page 15

4M-1 OM

4M-IO

SCHEMATIC DIAGRAM : MAIN

III I

I

I I

1

-

-

-

-

-

-

-

1

I

2

I

3

I

4

I

5

I

6

I

7

15

Page 16

4M-IOM

’

1

JI-1OM

ClZl

:,z

I

+

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

1

-

-

-

-

-

I

’

I

I

I

I

I

I

I

I

I

I

I

I

t

I

I

I

6

I

7

I

8

I

9

I

10

I

11

I

12

16

Page 17

4M-1 OM

SCHEMATIC DIAGRAM : TUNER

---

-3

--

Cl06

All3

RI14

RI

I5

Cl05 47” I20

120

I20

.Olt

I6Vl

ll,lOWl

ll/lOWl

ll,lOWl

Cl12

66P EF

loo

ICI6

P+

f-

LlO3

.22uI

m

7”lOl

EC-F’&2773

m

OIOZ

..%A 15661

0502

DTC144EU

RIO9

6.6N

I1

i

I

0103

2SA1566Y

I

lC502

TC74HCOOAF

CF304

YSL6 5h4C6

I

Page 18

4M-1 OM

C

(s-

-

-

t

r

CL

,056

7,

R33I

IOU

-

R530

IOY

IC503

TC7SOBF

AFT/BAND/TUNING

R323

620

It324

62C

------1

b

I

22u

I

22K

I

L-------l

i

c333

D% 194ElJ

T

"OOP

r------

I

47K

m

47K

L------

CKZO I

52043-2020

0307

DTA

I24EU

aT

c319

56oop

R223

Z.ZK

L207

15Iu

3

I

f

5

6OWX

PI226

R229

IOK

l6K

m

I

0212

25041 l6Y

‘. I

7

I

8

I

9

I

10

I

11

I

12

I

18

Page 19

4M-1 OM

4M-i

PRINTED WIRING BOARD ASSEMBLIES

l

MAIN

PWB

(Component Side)

Page 20

l

LED

PWB

(Component Side)

I

8

I

9

I

10

I

11

I

12

20

Page 21

4M-1 OM

l

MAIN

PWB

(Wiring

Side)

1

I

2

I

3

I

4

I

5

I

6

21

Page 22

4M-1 OM

l

LED

PWB

(Wiring Side)

7

I

8

I

9

I

10

I

11

I

12

I

22

Page 23

1

4M-IOM

.

4h

PRINTED WIRING BOARD ASSEMBLIES (Continued)

l

TUNER

PWB

(Component Side)

1

I

2

I

3

I

4

I

5

I

6

I

23

Page 24

I

0

TUNER

PWB

(Wiring Side)

7

I

8

I

9

I

10

I

11

I

12

I

24

Page 25

L

41

BLOCK DIAGRAM

i!l

d

b

1

a

b

i

1,

umo

ICSO

I

va ComRoL

I

“mm

11

ICSOZ

AUDIO

up.

l%E

“%

aa01

DELI

1

I

J

I

1

I

2

I

3

I

4

1

5

I

25

Page 26

I

KEY MATRIX

.,3V

i

.IN

3

.,"

I I

--I

i

Y

A

12

ii-

iii

0

0

7

s

5

4

i

3

2

o(lOl

UAIW PWB

-VI

I

L

TO

ki%LE

I

7

I

8

I

9

I

10

I

11

I

12

1

26

Page 27

4M-1 OM

PARTS LIST

l[

PARTS REPLACEMENT

Replacement parts which have these special

saFety

characteristics

identiFied

in this manual: electrical components having such

Features are

identiFied

by A in the Replacement Parts Lists.

The use OF a substitute replacement part which does not have

the same

saFety

characteristics as the Factory recommended

replacement parts shown in this service manual may create

shock, Fire or other hazards.

“HOW TO ORDER REPLACEMENT PARTS”

To have your order Filled promptly and correctly, please Furnish

the Following informations.

1. MODEL NUMBER 2. Ref. No.

3. PART NO. 4. DESCRIPTION

MARK *:SPARE PARTS-DELIVERY SECTION

I

Ref. No.

I

Part No.

I I

*

Description

I

CO&

PRINTED WIRING BOARD ASSEMBLIES

( NOT REPLACEMENT ITEM )

9AP6C02852-1

J

MainPWBUnit

9AP6A00433-1

J

TunerPWBUnit

-

J

LED PWB Unit

UNIT PARTS

RUNTK0366CEZZ

J LCD Module Unit

**

9AP6C02852-1

MAIN

PWB

UNIT

IC40

1

lC405

IC406

IC407

IC408

IC409

IC601

IC602

IC701

IC801

IC802

INTEGRATED CIRCUITS

9AP8J27725Al

J

M34300

9AP8J27774Tl

J

BU4066BF

9AP8F27644Tl

J

TC4053BF

9APON26206A2

J

M5234FP

9AP8J27971Tl

J TC7SOBF

9AP8J26805Tl

J

M51951BML

9AP8J26706T2

J

M5282FP

9AP8J26740Tl

J

NJM2070M

9APOR2671

IT1

J

FA7610N

VHiTA8795F/-1

J

TA8795

RH-iXl924CEZZ

J

iR3P89

BB

AE

AG

AG

AH

AK

AM

AK

AQ

AZ

AP

4

FLUORESCENT LAMP

KLMP-001 5CEZZ

J

FluorescentLamp

AZ

Ref. No.

Part No.

I I

*

Description

1

I

Code

4403

4404

4405

4406

4407

4601

4602

4603

4604

Q651

Q652

4701

4751

4753

4754

4756

4757

4758

4759

4760

Q761

Q763

4764

4765

QSOl

Q802

Q803

Q804

4805

Q806

4807

Q861

4862

Q863

TRANSISTORS

9AP8H29802T3

J

DTA144EU

9AP8H29723Tl

J

FMA2-T149

9AP8H29802T3

J

DTA144EU

9AP8H29722Tl

J

DTC144EU

9AP8H29802T3

J

DTA144EU

9APCK441 16ZY

J

2SC4116Y

9APAK41586ZY

J

2SA1586Y

9APCK44116ZY

J

2SC4116Y

9APCK42712ZY

J

2SC2712Y

9APCK441 16ZY

J

2SC4116Y

9APDK40874AZ

J

2SD874A

9APCK43518ZK

J

2SC3518-K-Z

9APAK41586ZY

J

2SA1586Y

9APCK44116ZY

J

2SC4116Y

9APAK41586ZY

J

2SA1586Y

9AP8H29717Tl

J

DTC114EU

9AP8H29722Tl

J

DTC144EU

9AP8H29722Tl

J

DTC144EU

9APAK41586ZY

J

2SA1586Y

9APCK43

5

18ZK

J

2SC3518-K-Z

9APCK43518ZK

J

2SC3518-K-Z

9AP8H29722Tl

J

DTC144EU

9APDK41766ZR

J

2SD1766R

9APCK441 16ZY

J

2SC4116Y

9APCK441 16ZY

J

2SC4116Y

9APCK441 16ZY

J

2SC4116Y

9AP8H29717Tl

J

DTCll4EU

9AP8H29717Tl

J

DTC114EU

9APCK44166ZY

J

2SC4116Y

9AP8H29722Tl

J

DTC144EU

9AP8H29722Tl

J

DTC144EU

9APAK41586ZY

J

2SA1586Y

9APAK41586ZY

J

2SA1586Y

9APAK41586ZY

J

2SA1586Y

D401

D402

D403

D404

D405

D409

D410

D701

D702

D703

D704

D705

D751

D752

D755

D756

D758

DBOI

DIODES

9AP8H25708Cl

J

MC2848-Tll

9AP8H25707Cl

J

MC2846-Tll

9AP8H25707Cl

J

MC2846-Tll

9AP8H25707Cl

J

MC2846-Tll

9AP8H25707Cl

J

MC2846-Tll

9AP8H25708Cl

J

MC2848-Tll

9AP8H25708Cl

J

MC2848-ill

9AP8H25684Al

J

SFPB54V

9AP8H25684Al

J

SFPB54V

9AP8H25683Al

J

MA153A-I

9AP8H25700Al

J

lSS250

9APOH25765Cl

J

lSS221

9AP8H25685Al

J

SFPB64V

9APOH25619Cl

J

MA152WK-TX

9APOH25619Cl

J

MA152WK-TX

9APOH25619Cl

J

MA152WK-TX

9APOH25619Cl

J

MA152WK-TX

9AP8H2570BCl

J

MC2848-Tll

AC

AD

AC

AB

AC

AB

AC

AB

AB

AB

AE

AG

AC

AB

AC

AB

AB

AB

AC

AG

AG

AB

AB

AB

AB

AB

AB

AB

AB

AB

AC

AC

AC

AC

AB

AB

AB

AB

AC

AC

AF

AF

AB

AD

AD

AF

AB

AB

AB

AB

AC

27

Page 28

I

4M-1 OM

Ref. No.

Part No.

+

Description

Code

Ref. No.

Part No.

+

Description

Code

9AP6C02852-1

MAIN

PWB

UNIT

(Continued)

DIODES

(Continued )

D861 9APOH25619Cl

J

MA152WK-TX

D862 9APOH25619Cl

J

MA152WK-TX

20751 9AP8H25906CZ

J

ZenerDiode

ZD801 9APOH25763C4

J

ZenerDiode

ZD802 9AP8H25763C4

J

ZenerDiode

TH401 9AP8F38983Al

J Thermistor

AB

AB

AD

AD

AC

PACKAGED CIRCUITS

DL801 9AP6F36508Tl

J Delayline

DL802 9AP8J39886Al

J Delayline

X401 9APOR38498A2

J Crystal

X801 9AP8J38746Al

J Crystal

X802 9AP8138867Al

J Crystal

X803 9AP8J38744Al

J Crystal

AQ

AW

AD

AK

AE

COIL AND TRANSFORMERS

L701

9AP6F16516Al

J

lOO,~HPackingCoil(Chip)AW

L702

9APOL41

33016 J

33,~HPackingCoil(Chip) AE

L703

L704

L751

L801

L802

L804

L805

L806

L807

L808

L809

L810

L811

L812

L813

L814

L815

LC804

1701

T702

T801

9AP6F16320A2

9AP6F16321Al

RCiLC0044CEZZ

9APOL41330J5

9APOL4133OJ6

9APOL4168OJ6

9APOL41 18OJ6

9APOL41 15OJ6

9AP6F16482Al

9APOL41330J6

9APOL4133OJ6

9APOL4133016

9AP6F16480Al

9AP6F16481

Al

9AP6F16481Al

9APOL4133OJ6

9APOL4133OJ6

9AP8J36691Tl

9AP6F10517Al

9AP6F10518Al

9AP6F36492Al

J

100pH

Coil (Chip)

J

100,~H Coil (Chip)

J

390pH

Coil (Chip)

J

33,~H Coil (Chip)

J

33pH

Coil (Chip)

J

68,~H Coil (Chip)

J

18pH

Coil (Chip)

J

15,~H Coil (Chip)

J Coil (Chip)

J

33pH

Coil (Chip)

J

33,~H Coil (Chip)

J

33pH

Coil (Chip)

J Coil (Chip)

J Coil (Chip)

J Coil (Chip)

J

33,~H Coil (Chip)

J

33pH

Coil (Chip)

J Coil

J Trans. DC-DC

J Trans. DC-AC

J Trans.

AC

AE

AD

AD

AE

AE

AE

AE

AF

AE

AE

AE

AF

AF

AF

AE

AE

AG

AW

AW

AF

CONTROLS

VR401 9APOL40202AB

J

2K(B)Sign

AG

VR701 9APOL40102CB

J

lK(B) +B

AD

VR802 9APOL40103AB

J

lOK(B)VideoOutput

AE

VR803 9APOL401 OZCB

J

lK(B)

1H Delay

AD

VR804 9APOG24103LB

J

lOK(B)Colour

AH

VR805 9APOG24103LB

J

lOK(B)Tint

AH

VR806 9APOL401 04AB

J

lOOK(B)SContrast(B)

AE

VR807 9APOL401 04AB

J lOOK(B)SBright(B) AE

VR810 9APOL40473AB

J

47K(B)Sub-Bright(R)

AE

VR811 9APOL40473AB

J

47K(B)Contrast

AE

I

CONTROLS

(Continued)

VR812 9APOL40473AB

J

47K(B)Sub-Contrast(R)

AE

VR813 9APOL40502AB

J

5K(B)Sub-Bright

AE

VR814 9APOL40103AB

J

lOK(B)COMBias

AE

CAPACITORS

C401

9APKP03101

JC J

1OOpF 50V

Ceramic AB

C402 9APKP03101

JC J

1OOpF 50V

Ceramic AB

C403 9APKP03101JC

J

1OOpF 50V

Ceramic AB

C404 9APKP03101JC

J

1OOpF 50V

Ceramic AB

C405 9APKP03101

JC J

1OOpF 50V

Ceramic AB

C406 9APKP03101

JC J

1OOpF 50V

Ceramic AB

C408 9APKP0318OJC

J

18pF

50V

Ceramic AB

C409 9APKP03270JC

J

27pF

50V

Ceramic AB

C410 9APKQ841ROMT

J 1pF

50V

Electrolytic AE

c411

9APEP04104ZF

J 0.1,~F

25V

Ceramic AB

C412 9APGP04103KB

J 0.01,~F

25V

Ceramic AB

C413 9APKQ84RlOMT

J 0.1,~F

50V

Electrolytic AE

C414 9APKP03221JC

J 22OpF

50V

Ceramic AB

C415 9APKP03221

JC J 22OpF

50V

Ceramic AB

C416 9APKQ843R3MT

J 3.3,~F

35V

Electrolytic

AE

C417 9APKP03101

JC J

1OOpF 50V

Ceramic AB

C418 9APKP03101

JC J

1OOpF 50V

Ceramic AB

C419 9APKP03101

JC J

1OOpF 50V

Ceramic AB

C420 9APKP03221JC

J 22OpF

50V

Ceramic AB

C421

9APKP04102KB

J

O.OOlpF5OV

Ceramic AB

C422 9APKP031

21 JC J 12OpF

50V

Ceramic

AB

C423 9APKP031

21 JC J 12OpF

50V

Ceramic

AB

C427 9APKP04103KB

J 0.01/~F

25V

Ceramic AB

C428 9APEQ84100MT

J

10,~F

1OV Electrolytic

AE

C429 9APGP04103KB

J 0.01,~F

25V

Ceramic AB

C430 9APGP04103KB

J

O.OlpF 25V

Ceramic AB

c43

1

9APKP03

121 JC J 12OpF

50V

Ceramic AB

C432 9APKP031

21 JC J 12OpF

50V

Ceramic

AB

C433 9APGP04103KB

J

O.OlpF 25V

Ceramic AB

C434 9APKP03101

JC J

1OOpF 50V

Ceramic AB

C436 9APKP03221JC

J 22OpF

50V

Ceramic AB

C437 9APKP03221

JC J 22OpF

50V

Ceramic AB

C441

9APKP031 OODC

J

1OpF

50V

Ceramic

C601

9APAQ41331

Ml J 33OpF

6.3V

Electrolytic AF

C602 9APEQ50100MS

J

10/~F

16V

Electrolytic AD

C603 9APAQ50470MS

J

47pF

16V

Electrolytic AE

C651

9APCQ50100MS

J

1OpF

1OV Electrolytic AD

C652 9APGP04103KB

J 0.01,~F

50V

Ceramic

AB

C653 9APEK80101

MT J 100,~F

16V

Electrolytic AC

C654 9APEQ41331 M3

J 330,~F

16V

Electrolytic AF

C655 9APGP04103KB

J 0.01,~F

50V

Ceramic

AB

C656 9APGK90104KB

J 0.1,~F

50V

Ceramic AB

C659 9APEK80101

MT J

1OOpF 16V

Electrolytic AC

C660 9APKQ501ROMS

J

l,~uF

5OV Electrolytic AD

C661

9APEQ84100MT

J

10luF

16V

Electrolytic AE

C7Ol 9APEQ41331 M3

J 330,~F

16V

Electrolytic

AF

002 9APKP04103KB

J 0.01,~F

50V

Ceramic

AB

C703 9APEQ84470MT

J

47pF

16V

Electrolytic AE

C704 9APEQ84100MT

J

1OpF 16V

Electrolytic

AE

C705 9APKQ28222GT

J 22OOpF

50V PolyproFilm AF

C706 9APKP04223ZF

J

0.022,~F5OV

Ceramic AB

C707 9APKP04181 JM

J 18OpF

50V

Ceramic AB

C708 9APKP04181 JM

J 18OpF

50V

Ceramic AB

C709 9APEP04104ZF

J

O.lpF 16V

Ceramic AB

28

Page 29

I

Ref. No.

I

Part

No.

I I

+

Description

I

I

Code

9AP6C02852-1

MAIN

PWB

UNIT

(Continued)

c710

c711

C712

c713

c714

c715

C716

c717

C718

c719

C720

C72

1

C722

C723

C724

C725

C728

c729

c730

c731

C732

c751

C752

c753

c754

c755

9APEQ84100MT

J

10,~F

16V

Electrolytic AE

C756

9APKP04103KB

J

O.OlpF 50V

Ceramic AB

c757

9APKP04103KB

J

0.01,~F 50V

Ceramic AB

C758

9APRP87 104J

F J

O.lpF 250VPolyproFilmAD

c759

9APKP03331JC

J

33OpF 50V

Ceramic AB

C760

9APKP03331

JC J

33OpF 50V

Ceramic

AB

C761

9AP4Q47330JM

J

33pF

3kV

Ceramic

C762

9APEP88101

MT J

1OOpF 16V

Electrolytic AD

C763

9APCP07105Ml

J

~/LF

1OV Tantalum AD

C801

9APAQ84101

MT J

1OOpF 6.3VElectrolytic AE

C802

9APEP04104ZF

J 0.1,~F

16V

Ceramic AB

C803

9APAQ50470MS

J 47,uF

6.3V

Electrolytic AE

C804

9APEP04104ZF

J

O.lpF 16V PolyproFilm

AB

C805

9APCQ50100MS

J

10/~F

1OV Electrolytic AE

C806

9APKP04681

KB J

68OpF 50V

Ceramic

AB

C807

9APCP07105Ml

J 1pF 1OV Tantalum AD

C808

9APKP04103KB

J

0.01,~F 50V

Ceramic AB

C809

9APCP07105Ml

J 1pF 1OV Tantalum AD

C810

9APKP04103KB

J

0.01,~F 50V

Ceramic AB

C811

9APEQ841 OOMT

J 1OpF 1OV Electrolytic AE

C812

9APKP04103KB

J

O.OlpF 50V

Ceramic AB

C813

9APEQ84100MT

J

lO/rF

1OV Electrolytic AE

C814

9APKP04103KB

J

0.01,~F 50V

Ceramic AB

C815

9APKP04103KB

J

O.OlpF 50V

Ceramic AB

C816

9APKP03510JC

J

51pF

50V

Ceramic AB

C817

9APKP03240JC

J

24pF

50V

Ceramic AB

C818

9APEQ84100MT

J

10,~F

1OV Electrolytic AE

C819

9APCP07105Ml

J

lpF

1OV Tantalum AD

C820

9APEQ84100MT

J 10/1F

1OV Electrolytic AE

C82

1

9APCP07105Ml

J

~/LF

1OV Tantalum AD

C822

9APKK90223KB

J

0.022,~F5OV

Ceramic AB

CAPACITORS

(Continued )

9APKP03331JC

J

33OpF 50V

Ceramic AB

9APKP03 151

JC J 15OpF

50V

Ceramic

AB

9APKP04333ZF

J

0.033pF16VCeramic

AB

9APCQ41820Ml

J

82pF

1OV Electrolytic AE

9APAQ4133

1 M 1 J

33OpF 6.3VElectrolytic

AF

9APEK90684ZF

J 0.68,~F

16V

Ceramic AC

9APEP04104ZF

J

O.lpF 16V

Ceramic AB

9APEQ84100MT

J

1OpF

16V

Electrolytic AE

9APKQ84100MT

J

10,~F

16V

Electrolytic AE

9APGP041 53MT

J

0.015,~FlOV

Electrolytic AD

9APKP04103KB

J

O.OlpF 50V

Ceramic AB

9APCQ41820Ml

J

82/.1F

1OV Electrolytic AE

9APKP04103KB

J

O.OlpF 50V

Ceramic AB

9APAQ4133

1 M 1 J 330,~F

6.3VElectrolytic

AF

9APEP04104ZF

J

O.lpF 16V

Ceramic AB

9APKP04103KB

J 0.01,~F

16V

Ceramic AB

9APEK80101MT

J 100,~F

16V

Electrolytic AC

9APiQ841

OOMT

J

1OpF

35V

Electrolytic

AG

9APKP03331

JC J 330,~F

50V

Ceramic

AB

9APKK90104ZF

J

1OOpF 1OOVCeramic

AB

9APNP03101JM

J

1OOpF 1OOVCeramic

AB

9APKP04103KB

J 0.01,~F

16V

Ceramic AB

9APKP04103KB

J

0.01,~F 16V

Ceramic AB

9APEQ41331 M3

J 330,~F

16V

Electrolytic AF

9APEQ851 OOMT

J

10,~F

16V

Electrolytic

AG

(N-P.)

C823

C824

C825

C826

C827

C828

C829

C830

C831

C832

C833

C834

C835

C836

C837

C839

C840

C841

C842

C844

C845

C846

C847

C848

C849

C850

C851

C852

C853

C854

C855

C856

C857

C858

C859

C860

C861

C862

C863

C864

C865

C866

C867

C868

C869

C870

C871

C872

C873

C874

C875

C876

C879

C880

C881

C882

C883

C884

C885

C886

C887

CAPACITORS

(Continued

)

9APCP07225Ml

J

2.2pF

1OV Tantalum

9APKQ321ROMT

J I,uF

50V

Electrolytic

9APCQSOlOOMS

J

1OpF

1 OV Electrolytic

9APKP04103KB

J

0.01,~F 50V

Ceramic

9APKP03 11 OJC

J

1lpF

50V

Ceramic

9APEP04273KR

J

0.027pF16V

Ceramic

9APKP0312OJC

J

12pF

50V

Ceramic

9APKP04103KB

J

0.01,~F 50V

Ceramic

9APEP04273KR

J

0.027,~F16V

Ceramic

9APKP03820JC

J

82pF

50V

Ceramic

9APKP03560JC

J

56pF

50V

Ceramic

9APKP04103KB

J

O.OlyF 50V

Ceramic

9APKP03270JC

J

27pF

50V

Ceramic

9APEP04104ZF

J 0.1,~F

16V

Ceramic

9APKP04103KB

J

O.OlyF 50V

Ceramic

9APCP07105Ml

J

1,uF

1OV Tantalum

9APKP04103KB

J

O.OlpF 50V

Ceramic

9APKP04103KB

J 0.01,~F

50V

Ceramic

9APGK90563KB

J

0.056,~F16V

Ceramic

9APKP04103KB

J

0.01,~F 50V

Ceramic

9APKP03080DC

J

8pF

50V

Ceramic

9APKP04103KB

J 0.01,~F

50V

Ceramic

9APKP04103KB

J

0.01,~F 50V

Ceramic

9APEQ84100MT

J

10/~F

1 OV Electrolytic

9APKP03080DC

J

8pF

50V

Ceramic

9APKP03910JC

J

91pF

50V

Ceramic

9APKP03910JC

J

91pF

50V

Ceramic

9APKP03221

JC J 22OpF

50V

Ceramic

9APKP03 12

1 JC J 12OpF

50V

Ceramic

9APKP03200JC

J 2OpF

50V

Ceramic

9APKP03680JC

J

68pF

50V

Ceramic

9APKP03200JC

J 2OpF

50V

Ceramic

9APKP03680JC

J

68pF

50V

Ceramic

9APKP03390JC

J

39pF

50V

Ceramic

9APKP03470JC

J

47pF

50V

Ceramic

9APKP03560JC

J

56pF

50V

Ceramic

9APGK90104KB

J 0.1,~F

25V

Ceramic

9APGK90104KB

J

O.lpF 25V

Ceramic

9APGK90 104KB

J

O.lpF 25V

Ceramic

9APGK90683ZF

J

0.068pF25V

Ceramic

9APEQ41470Ml

J 47,uF

16V

Electrolytic

9APEP04104ZF

J

O.lpF 16V

Ceramic

9APEP04104ZF

J 0.1,~F

16V

Ceramic

9APEP04104ZF

J

O.lpF 16V

Ceramic

9APKP04821

KB J 82OpF

50V

Ceramic

9APKP03 15

1 JC J 15OpF

50V

Ceramic

9APEP04104ZF

J

O.lpF 16V

Ceramic

9APEP04104ZF

J

O.lpF 16V

Ceramic

9APEP04104ZF

J

O.lpF 16V

Ceramic

9APEQ41470Ml

J 47/~F

16V

Electrolytic

9APKP04103KB

J

0.01,~F 50V

Ceramic

9APKP04103KB

J

O.OlpF 50V

Ceramic

9APKP3560JC

J

56pF

50V

Ceramic

9APKP3560JC

J

56pF

50V

Ceramic

9APKP3560JC

J

56pF

50V

Ceramic

9APKP04103KB

J

0.01,~F 50V

Ceramic

9APEP04104ZF

J 0.1,~F

16V

Ceramic

9APEP04104ZF

J 0.1,~F

16V

Ceramic

9APEP04104ZF

J 0.1,~F

16V

Ceramic

9APAQ84 10

1 MT J

100,~F

6.3V

Electrolytic

9APEP04104ZF

J 0.1,~F

16V

Ceramic

AD

AF

AE

AB

AB

AB

AB

AB

AB

AC

AB

AB

AB

AB

AB

AD

AB

AB

AC

AB

AB

AB

AB

AE

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AE

AB

AB

AB

AB

AB

AB

AB

AB

AC

AB

AB

AB

AB

AB

AB

AB

AB

AB

AE

AB

29

Page 30

4M-1

OM

--

Ref. No.

Part No.

*

Description

Code

Ref. No. Part No.

*

Description

Code

9AP6C02852-1

MAIN

PWB

UNIT (Continued)

C888

C890

C891

C896

C897

CAPACITORS

(Continued )

9APCP07105Ml

J

lpF

1 OV Tantalum

9APCP07225Ml

J 2.2,uF 1OV Tantalum

9APGK90104KB

J

O.lpF 16V

Ceramic

9APKP04103KB

J

O.OlpF 50V

Ceramic

9APKP04103KB

J

O.OlpF 50V

Ceramic

AD

AD

AB

AB

AB

RESISTORS

R401

9APUL49101JA

J 100

1116W

Chip

R402

9APUL49101JA

J 100

1/16W

Chip

R403

9APUL49101JA

J 100

1/16W

Chip

R404

9APUL49101JA

J 100

1/16W

Chip

R405

9APUL49101JA

J 100

1!16W

Chip

R406

9APUL49223JA

J

22k 1/16W

Chip

R407

9APUL49223JA

J

22k 1/16W

Chip

R408

9APUL49223JA

J

22k 1/16W

Chip

R409

9APUL49103JA

J

10k 1/16W

Chip

R410

9APUL49103JA

J

10k 1/16W

Chip

R411

9APUL49101

JA J 100

1/16W

Chip

R412

9APUL491 52JA

J

1.5k ;/16W

Chip

R413

9APUL49391

JA J 390

1/16W

Chip

R414

9APUL49393JA

J

39k 1/16W

Chip

R415

9APUL49393JA

J

39k 1/16W

Chip

R416

9APUL49393JA

J

39k 1/16W

Chip

R417

9APUL49103JA

J

10k 1/16W

Chip

R418

9APUL49562JA

J

5.6k 1/16W

Chip

R419

9APUL49562JA

J

5.6k 1/16W

Chip

R420

9APUL49562JA

J

5.6k 1/16W

Chip

R42

1

9APUL49.334JA

J

330k 1/16W

Chip

R422

9APUL49333JA

J

33k 1/16W

Chip

R423

9APUL49 103JA

J

10k 1/16W

Chip

R424

9APUL49103JA

J

10k 1/16W

Chip

R425

9APUL49153JA

J

15k 1/16W

Chip

R426

9APUL49223JA

J

22k 1/16W

Chip

R427

9APUL49223JA

J

22k 1/16W

Chip

R428

9APUL49223JA

J

22k 1/16W

Chip

R429

9APUL49101JA

J 100

1/16W

Chip

R430

9APUL49101

JA J 100

1/16W

Chip

R43

1

9APUL49101JA

J 100

1/16W

Chip

R432

9APUL49391JA

J 390

1/16W

Chip

R45

1

9APUL49223JA

J

22k 1/16W

Chip

R452

9APUL49394JA

J

390k 1/16W

Chip

R453

9APUL49823JA

J

82k 1/16W

Chip

R454

9APUL49563JA

J

56k 1/16W

Chip

R455

9APUL49223JA

J

22k 1/16W

Chip

R456

9APUL49223JA

J

22k 1/16W

Chip

R459

9APUL49223JA

J

22k 1/16W

Chip

R460

9APUL49183JA

J

18k 1/16W

Chip

R461

9APUL49473JA

J

47k 1/16W

Chip

R462

9APUL49103JA

J

10k 1/16W

Chip

R463

9APUL49102JA

J

lk

1/16W

Chip

R464

9APUL49152JA

J

1.5k 1/16W

Chip

R465

9APUL49473JA

J

47k 1/16W

Chip

R466

9APUL49473JA

J

47k 1/16W

Chip

R467

9APUL49223JA

J

22k 1/16W

Chip

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

Jl

I

I

I

I

I

RESISTORS

(Continued

)

R468 9APUL49473JA

J

47k 1/16W

Chip

AB

R469 9APUL49183JA

J

18k 1/16W

Chip

AB

R470 9APUL49223JA

J

22k 1/16W

Chip

AB

R473 9APUL49101JA

J

100

1/16W

Chip

AB

R474 9APUL49103JA

J

10k 1/16W

Chip

AB

R475 9APUL49272JA

J

2.7k 1/16W

Chip

AB

R476 9APUL49204JA

J

200k 1/16W

Chip

AB

R477 9APUL49274JA

J

270k 1/16W

Chip

AB

R479 9APUL49103JA

J

10k 1/16W

Chip

AB

R480 9APUL49105JA

J

1Meg 1/16W

Chip

AB

R482 9APUL49104JA

J

100k 1/16W

Chip

AB

R483 9APUL49103JA

J

10k 1/16W

Chip

AB

R484 9APUL49330JA

J 33

1/16W

Chip

AB

R485 9PAUL49103JA

J

10k 1116WChip

AB

R487 9PAUL49330JA

J 33

1/16W

Chip

AB

R488 9PAUL49330JA

J 33

1/16W

Chip

AB

R489 9PAUL49330JA

J 33

1/16W

Chip

AB

R601

9APUL490ROZA

J 0

1/16W

Chip

AB

R602 9APUL49122JA

J

12k 1/16W

Chip

AB

R603 9APUL49102JA

J

lk

1/16W

Chip

AB

R604 9APUL49102JA

J

lk

1/16W

Chip

AB

R605

9APUL49102JA

J

lk

1/16W

Chip AB

R606 9APUL49101JA

J 100

1/16WChip

AB

R607 9APUL49104JA

J

100k 1/16W

Chip

AB

R608 9APUL49680JA

J 68

1/16W

Chip AB

R609 9APUL49680JA

J 68

1/16W

Chip

AB

R610 9APUL49122JA

J

1.2k 1/16W

Chip

AB

R611

9APUL49100JA

J 10

1/8W

Chip

AB

R651

9APUL49330JA

J 33

lJ16W

Chip

AB

R652 9APUL49123JA

J

12k 1/16W

Chip

AB

R653 9APUL49104JA

J

100k 1/16W

Chip

AB

R654 9APUL49103JA

J

10k 1/16W

Chip

AB

R655 9APUL491ROJA

J 1

1/16W

Chip

AB

R656 9APUL49100JA

J 10

ll8W

Chip AB

R657 9APUL49681JA

J 680

1/16W

Chip

AB

R658 9APUL49681

JA J 680

1/16W

Chip

AB

R659 9APUL49124JA

J

120k 1/16W

Chip

AB

R660 9APUL49101JA

J 100

1/16WChip

AB

R661

9APUL49102JA

J

lk

1/16W

Chip AB

R662 9APUL498R2JA

J 8.2

1/16W

Chip AB

R663 9APUL493R3JA

J 3.3

1/16W

Chip AB

R664 9APUL49104JA

J

100k 1/16W

Chip

AB

R701

9APUL49100JA

J 10

1/16W

Chip

AB

R702 9APUL49184JA

J

180k 1/16W

Chip

AB

R703 9APUL49684JA

J

680k 1/16W

Chip

AB

R704 9APUL49473FA

J

47k

1/16W

Chip AB

R705 9APUL49105JA

J

1Meg 1/16W

Chip AB

R707 9APUL49682JA

J

6.8k

1/16W

Chip AB

R708 9APUL49222JA

J

2.2k

1/16W

Chip AB

R710 9APUL49223JA

J

22k

1/16W

Chip AB

R711

9APUL49122JA

J

1.2k

1/16W

Chip AB

R753 9APUL49223JA

J

22k

1/16W

Chip AB

R754 9APUL49273JA

J

27k 1/16W

Chip AB

R755

9APUL49683JA

J

68k

1/16W

Chip AB

R756 9APUL49221JA

J 220

l/l 6W Chip

AB

R757 9APUL49153JA

J

15k

1/16W

Chip AB

R759 9APEL093R9JL

J 3.9

2W

Metal

OxideAC

R760 9APUL49332JA

J

3.3k

1/16W

Chip AB

R761

9APUL49273JA

J

27k

1/16W

Chip AB

R762 9APZL495

1 1 JA J 510

l/low

Chip AB

R763 9APUL49102JA

J

lk

1/16W

Chip AB

30

Page 31

4M-1 OM

Ref. No.

Part No.

*

Description

Code

Ref. No. Part No.

*

Description

Code

--I-

9AP6C02852-1

MAIN

PWB

UNIT

(Continued)

R764

9APUL49102JA

R766

9APZL4951

1

JA

R767

9APUL49102JA

R768

9APZL49331

JA

R769

9APZL49331

JA

R770

9APZL49331

JA

R771

9APUL49332JA

R772

9APUL49223JA

R773

9APUL49473JA

R801

9APUL49331JA

R802

9APUL49153JA

R803

9APUL49822JA

R804

9APUL49102JA

R805

9APUL49102JA

R806

9APUL49102JA

R807

9APUL49102JA

R808

9APUL49103JA

R811

9APUL49103JA

R812

9APUL49103JA

R813

9APUL49103JA

R815

9APUL49103JA

R816

9APUL49822JA

R817

9APUL49222JA

R819

9APUL49393JA

R820

9APUL49123JA

R82

1

9APUL49152JA

R823

9APUL49473JA

R824

9APUL49103JA

R826

9APUL49134JA

R827

9APUL49472JA

R828

9APUL49472JA

R829

9APUL49103JA

R830

9APUL49103JA

R832

9APUL49515JA

R833

9APUL49391

JA

R834

9APUL49222JA

R835

9APUL49515JA

R836

9APUL49515JA

R837

9APUL49821

JA

R838

9APUL49103JA

R839

9APUL49121JA

R840

9APUL49203JA

R841

9APUL49203JA

R842

9APUL49202JA

R843

9APUL49271

JA

R844

9APUL49221

JA

R846

9APUL49222JA

R847

9APUL49302JA

R848

9APUL49474JA

R849

9APUL49101JA

R856

9APUL49332JA

R857

9APUL49103JA

R861

9APUL49561

JA

R862

9APUL49102JA

R863

9APUL49333JA

R864

9APUL49103JA

R866

9APUL49273JA

RESISTORS

(Continued )

J

lk

J

510

J

lk

J

330

J

330

J

330

J

3.3k

J

22k

J

47k

J

330

J

15k

J

8.2k

J

lk

J

lk

J

lk

J

lk

J

10k

J

10k

J

10k

J

10k

J

10k

J

8.2k

J

2.2k

J

39k

J

12k

J

1.5k

J

47k

J

10k

J

130k

J

4.7k

J

4.7k

J

10k

J

10k

1/16W

Chip

1/16W

Chip

l/lOW

Chip

l/lOW

Chip

l/lOW

Chip

l/lOW

Chip

1/16W

Chip

1/16W

Chip

1/16W

Chip

1/16W

Chip

1/16W

Chip

ll16W

Chip

1/16W

Chip

1/16W

Chip

1/16W

Chip

1/16W

Chip

1/16W

Chip

1/16W

Chip

1/16W

Chip

1/16W

Chip

1/16W

Chip

1/16W

Chip

1/16W

Chip

1/16W

Chip

1/16W

Chip

1/16W

Chip

l/lOW

Chip

1/16W

Chip

1/16W

Chip

1/16W

Chip

1/16W

Chip

1/16W

Chip

1/16W

Chip

5.1 Meg l/l 6W Chip

390 1/16W

Chip

2.2k

1/16W

Chip

5.1 Meg l/l 6W Chip

5.1 Meg l/l 6W Chip

820

1!16W

Chip

10k

ll4W

Chip

120 1/16W

Chip

2Ok

1/16W

Chip

2Ok

1/16W

Chip

2k

1/16W

Chip

270 1/16W

Chip

220

1/16W

Chip

2.2k

1/16W

Chip

3k

1/16W

Chip

470k 1/16W

Chip

100

1/16W

Chip

3.3k

1/16W

Chip

10k

1/16W

Chip

560

1/16W

Chip

lk

1/16W

Chip

33k

1/16W

Chip

10k

1/16W

Chip

27k

1/16W

Chip

R874 9APUL49471

JA

470-1/16W

Chip

A8

AB

AB

AB

AB

AB

A8

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

A8

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

A8

AB

AB

AB

A8

AB

AB

AB

AB

AB

AB

AB

R875

R876

R877

R878

R879

R881

R882

R883

R884

R885

R886

R887

R891

R892

R893

R894

R895

R896

R897

R898

R899

R911

R913

R914

R915

R916

R917

R918

&F701

AF702

J401

J601

J602

J603

J604

J701

s401

S402

s403

5404

s405

S406

s407

S408

s409

s410

s411

s701

CN40

1

CN402

CN601

CN602

CN701

CN702

CN703

CN801

CN803

I

RESISTORS

(Continued )

9APUL49102JA

J

lk

1/16W

Chip

9APUL49471

JA

470 1/16W

Chip

9APUL49102JA

J

lk

1/16W

Chip

9APUL49471

JA

470 1/16W

Chip

9APUL49102JA

J

lk

1/16W

Chip

9APUL49103JA

J

10k

1/16W

Chip

9APUL49103JA

J

10k

1/16W

Chip

9APUL49392JA

J

3.9k

1/16W

Chip

9APUL49152JA

J

1.5k

1/16W

Chip

9APUL49152JA

J

1.5k

1/16W

Chip

9APUL49152JA

J

1.5k

1/16W

Chip

9APUL49103JA

J

10k

1/16W

Chip

9APUL49822JA

J

8.2k

1/16W

Chip

9APUL49682JA

J

6.8k 1/16W

Chip

9APUL49103JA

J

10k 1/16W

Chip

9APUL49103JA

J

10k

1/16W

Chip

9APUL49682JA

J

6.8k 1/16W

Chip

9APUL49560JA

J

56

1/16W

Chip

9APUL49102JA

J

lk

1/16W

Chip

9APUL49120JA

J 12

1/16W

Chip

9APUL49103JA

J

10k

1/16W

Chip

9APUL49822JA

J

8.2k

1/16W

Chip

9APUL49392JA

J

3.9k

1/16W

Chip

9APUL49182JA

J

1.8k

1/16W

Chip

9APUL490ROZA

J 0

1/16W

Chip

9APUL49222JA

J

2.2k

1/16W

Chip

9APUL49222JA

J

2.2k

1/16W

Chip

9APUL49560JA

J

56

1/16W

Chip

MISCELLANEOUS PARTS

9AP8F32695F4

J

Fuse,1.25A

9AP8F32694F9

J

Fuse,500mA

9AP8J42759Al

J

Jack,RemoteControl

9AP8J42847Al

J

Jack,Antenna

9AP8J42679Al

J

Jack,External lmput

9AP8J4281

2Al

J

Jack,Diversity

9AP8J42680Al

J

Jack,Earphone

9AP8J42677Al

J

Jack,DC12Vlnput

9AP8J45784Al

J

Switch,Mode

9AP8J45783Al

J

Switch,SetMemory

9AP8J45710Al

J

Switch,VolumeDown

9AP8J4571

OAl

J

Switch,VolumeUp

9AP81457

1

OAl

J

Switch,Channel

Up

9AP8J4571 OAl

J

Switch,Channel

Down

9AP8J4571

OAl

J

Switch,ChannelCall

9AP814571

OAl

J

Switch,Bright.Down

9AP8145710Al

J

Switch,Bright.Up

9AP8145674Al

J

Switch,VideoSystem

9APOR45986Al

J

Switch,AudioSystem

9AP8J45799Al

J

Switch,Power

9AP8J40692Al

J

Connector,2pin

9AP8J40692Al

J

Connector,Zpin

9AP8140692Al

J

Connector,Zpin

9AP8142252Al

J

Connector,lOpin

9APOJ40190Al

J

Connector,Zpin

9APOJ40642Al

J

Connector,Zpin

9APOR40724A3

J

Connector,3pin

9APOR40996A9

J

Connector,ZOpin

9APOR40726A7

J Connector,

16pin

J

I

AB

A8

AB

A8

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

A8

AB

AB

AB

AB

AB

AB

AB

AL

AL

AG

AH

AL

AG

AL

AF

AH

AG

AE

AD

AD

AD

AD

AD

AD

AD

AH

AH

AC

AC

AC

AF

AB

AC

AQ

AK

31

Page 32

Ref. No. Part No.

+

Description

Code

Ref. No. Part No.

*

Description

Code

9AP6A00433-1

TUNER

PWB

UNIT

(Continued)

TUNER

NOTE:

THE PARTS HERE SHOWN ARE SUPPLIED AS AN

ASSEMBLY BUT NOT INDEPENDENTLY.

TUlOl 9AP8J34863Al

J Tuner

BQ

INTEGRATED CIRCUITS

lC201

9AP8J26761Tl

J

TA8805F

IC304 9AP8127703Tl

J

TC7WU04F

IC501

RH-iXl605CZZZ

J

iX1605CF

IC502 9AP8J27704Al

J TC74HCOOAF

IC503 9AP8J27971Tl

J

TC7S08F

AU

AF

AQ

AE

AH

TRANSISTOR

QlOl 9APCK43356ZR

J

2SC3356

4102

9APAK41586ZY

J

2SA1586Y

4103

9APAK41 586ZY

J

2SA1586Y

4104

9APAK41586ZY

J

2SA1586Y

Q201 9APCK42735ZZ

J

2SC2735J

4202

9AP8H29715Tl

J

DTC114YU

4203 9APCK441

16ZY

J

2SC4116Y

4204 9APAK41586ZY

J

2SA1586Y

Q205 9APCK441

16ZY

J

2SC4116Y

4207 9APAK41 586ZY

J

2SA1586Y

Q210 9APAK41586ZY

J

2SA1586Y

Q211 9AP8H29717Tl

J

DTC114EU

4212

9APCK441 16ZY

J

2SC4116Y

4213 9APAK41586ZY

J

2SA1586Y

4301

9AP8H29717Tl

J

DTC114EU

4302 9AP8H29717Tl

J

DTC114EU

4303

9APCK441 16ZY

J

2SC4116Y

4304

9AP8H29717Tl

J

DTC114EU

4305

9APCK441 16ZY

J

2SC4116Y

4306 9APCK441

16ZY

J

2SC4116Y

4307

9AP8H29714Tl

J*

DTA124EU

4308 9APCK441

16ZY

J

2SC4116Y

4311

9AP8H29722Tl

J

DTC114EU

4312 9APAK41586ZY

J

2SA1586Y

4313

9APCK441 16ZY

J

2SC4116Y

Q501 9AP8H29722Tl

J

DTC114EU

4502 9AP8H29722Tl

J

DTC114EU

AH

AC

AC

AC

AC

AB

AB

AC

AB

AC

AC

AB

AB

AC

A8

A8

AB

AB

AB

AB

AB

AB

AB

AC

AB

AB

AB

DIODES

DlOl 9AP8H25708Cl

J

MC2848

D201 9AP8H25701Al

J

lSS312

D202 9AP8H25702Al

J

lSS313

0203

9AP8H25708Cl

J

MC2848

D204 9AP8H25708Cl

J

MC2848

D301 9AP8H25708Cl

J

MC2848

D501 9AP8H25708Cl

J

MC2848

D503 9AP8H25708Cl

J

MC2848

AC

AD

AD

AC

AC

AC

AC

AC

PACKAGED CIRCUITS

x201

9AP8F36723Al

J

Crystal,SAWFilter

X301 9APOJ38595AF

J Crystal

X302 9APON38489Al

J Crystal

AT

AD

AC

COILS AND TRANSFORMERS

CF201

9AP8F3671

1Al

J

CeramicFilter

CF202 9APOJ36596Al

J

CeramicFilter

CF203 9AP8F36899Al

J

CeramicFilter

CF301

9AP8J36757Al

J

CeramicFilter

CF302 9AP8J36757A2

J

CeramicFilter

CF303 9AP8J36757A3

J

CeramicFilter

CF304 9AP8J36757A4

J

CeramicFilter

CF305 9AP8J36757A3

J

CeramicFilter

LlOl

9APOL41 R39M6

J

0.39pH PackingCoil

(Chip)

LlO2 9APOL41

15OJ6

J

15pH PackingCoil

(Chip)

L103 9APOL41 R22M6

J

0.22pH PackingCoil

(Chip)

L201

9APOL41 R82M6

J

0.82pH PackingCoil

(Chip)

L203

9APOL41 R68M6

J

0.68pH PackingCoil

(Chip)

L204 9APOL41 R82M6

J

0.82pH PackingCoil

(Chip)

L205

9APOL418R2K6

J

8.2pH PackingCoil

(Chip)

L206

9APOL41

15OJ6

J

15pH PackingCoil

(Chip)

L207 9APOL41

15OJ6

J

15/H PackingCoil

(Chip)

L208 9APOL41270J6

J 27,~H

PackingCoil

(Chip)

L209 9AP6F16491Al

J

Coil(Chip)

L210 9AP6Fl 6491Al

J

Coil(Chip)

L211

9APOL41 R22M6

J

0.22pH PackingCoil

(Chip)

L212

9APOL41 R22M6

J

0.22pH PackingCoil

(Chip)

L213

9APOL41 33OJ6

J

33pH PackingCoil

(Chip)

L214 9APOL412RZK6

J 2.2,~H

PackingCoil

(Chip)

L301

9AP6Fl 6479Al

J

Coil(Chip)

L302

9APOL41

221 J6 J

220/1H PackingCoil

(Chip)

L303 9APOL418R2K6

J

8.2pH PackingCoil

(Chip)

L304 9APOL41

15OJ6

J

15pH PackingCoil

(Chip)

L305

9APOL41

33OJ6

J

33pH PackingCoil

(Chip)

AF

AE

AD

AD

AE

AE

AF

AE

AE

AE

AE

AE

AE

AE

AE

AE

AE

AF

AF

AE

AE

AF

AE

AE

AE

AE

32

Page 33

4M-1 OM

Ref. No.

Part No.

*

Description

Code

Ref. No.

Part No.

*

Description

Code

r

CAPACITORS

(Continued)

9AP6A00433-1

TUNER

PWB

UNIT

(Continued)

CONTROLS

C315 gAPAQ5047OMS

J

47pF 6.3VElectrolytic

AE

C316 9APKP0307ODC

J

7pF

50V

Ceramic AC

C317 gApKp03820JC

J

82pF 50V

Ceramic AC

C318 gApGpO4103KB

J

0.0l/~F 25V

Ceramic AB

C319 9APKp04562KB

J

56OOpF WV

Ceramic AC

C321

9APKQ501ROMS

J

1pF

50V

Electrolytic AD

C333 9APKP04222KB

J

22OOpF

50V Ceramic

AB

C334 9APAQ50470MS

J 47,~F

6.3VElectrolytic

AE

C336 9APGK90104KB

J

O.lpF 25V

Ceramic AB

C337 9APGP04103KB

J

O.Ol$ 25V

Ceramic AB

C338 9APKP03330JC

J

33pF

5OV Ceramic AC

C339 9APKP03820JC

J

82pF

50V

Ceramic AC

C341

9APGP04130KB

J

O.OlpF 25V

Ceramic AB

c501

9APKQ3 1563J

1 J

0.056pF5OV Plastic

AD

C502 9APKP04103KB

J

O.OlpF 50V

Ceramic AB

C503 9APKQSOlROMS

J

l/sxF

50V

Electrolytic AD

C504 9APKQ50R33MS

J

0.33pF 50V

Electrolytic AD

C505 9APKP04102KB

J

1OOOpF 50V

Ceramic AB

C506 9APKQ50RlOMS

J

O.lpF 50V

Electrolytic AD

C507 9APGP04103KB

J

O.OlpF 25V

Ceramic AB

C508 9APKQ501ROMS

J 1pF

50V

Electrolytic AD

C509 9APGP04103KB

J

O.OlpF 25V

Ceramic

A8

C510 9APGP04103KB

J

O.OlpF 25V

Ceramic AB

VR201 9APOL40103CB

J

lOk(8) AGCAdj.

AE

VR501 9APOL40473CB

J

47k(B) SlGHAdj.

AE

CAPACITORS

Cl01

9APKP031 51 JC

J 15OpF

50V

Ceramic

AB

Cl02 9APKP03471

JC J

47OpF 50V

Ceramic AB

Cl03 9APKP03120JC

J

12pF

50V

Ceramic AC

Cl04 9APKP03680JC

J

68pF

50V

Ceramic AB

Cl05 9APGP04103KB

J

O.OlpF 25V

Ceramic AB

Cl06 9APEQ41470M

1

J 47,uF

16V

Electrolytic AE

Cl07 9APiP07334Ml

J

0.33pF 35V

Tantalum AD

Cl08 9APGP04103KB

J

O.OlpF 25V

Ceramic AB

Cl09 9APAK80221

MT J 22OpF

6.3VElectrolytic

AD

Cl12 9APKP03680JC

J

68pF

50V

Ceramic AB

Cl13 9APGP04103KB

J

O.OlpF 25V

Ceramic AB

Cl14 9APGP04103KB

J

O.OlpF 25V

Ceramic AB

Cl15 9APKP04103KB

J

O.OlpF 50V

Ceramic AB

Cl16 9APGP04103KB

J

O.OlpF 25V

Ceramic AB

Cl17 9APGP04103KB

J

O.OlpF 25V

Ceramic AB

c201

9APAP08106Ml

J

1OpF 6.3VTantaIum

AF

C202 9APGP04103KB

J

O.OlpF 25V

Ceramic AB

C203 9APKP04020CC

J

2pF

50V

Ceramic AB

C204 9APGP04103KB

J

0.0l/~F 25V

Ceramic AB

C205 9APKP04222KB

J 22OOpF

50V

Ceramic AB

C207 9APKP04222KB

J 22OOpF

50V

Ceramic AB

C208 9APKP04222KB

J 22OOpF

50V

Ceramic AB

C209 9APKP04222KB

J 22OOpF

50V

Ceramic AB

C210 9APKP04222KB

J 22OOpF

50V

Ceramic

A8

C211 9APGP04103KB

J

O.OlpF 25V

Ceramic AB

C212 9APGP04103KB

J

O.OlpF 25V

Ceramic AB

C213 9APAQ50470MS

J 47/1F

6.3V

Electrolytic

AE

C214 9APGP07474Ml

J

0.47pF 25V

Tantalum AD

C215 9APGP07474Ml

J

0.47pF 25V

Tantalum AD

C216 9APGP04103KB

J

O.OlpF 25V

Ceramic AB

C217 9APKP03680JP

J

68pF

50V

Ceramic AB

C218 9APKP03180JP

J

18pF

50V

Ceramic AK

C219 9APKP03680JP

J

68pF

50V

Ceramic AB

C220 9APKP03180JC

J

18pF

50V

Ceramic AK

c221

9APKP03080DC

J

8pF

50V

Ceramic AB

C222 9APAM69100MT

J 1OpF

6.3VElectrolytic

AC

C225 9APGP04103KB

J

O,OlpF 25V

Ceramic AB

C226 9APKP03470JC

J

47pF

50V

Ceramic AB

c301

9APKP04222KB

J 22OOpF

50V

Ceramic AB

C302 9APKP04222KB

J 22OOpF

50V

Ceramic AB

C3O3

9APKP03391JC

J

39OpF 50V

Ceramic AB

C304 9APGP04103KB

J

O.OlpF 25V

Ceramic AB

C305 9APKP03561JM

J 560/~F

50V

Ceramic AB

C306 9APEP04104ZF

J

O.lpF 16V

Ceramic AB

C307 9APKP03101

JC J

100pF 50V

Ceramic AB

C308 9APKP03271JC

J 27OpF

50V

Ceramic AB

C309 9APKP04222KB

J 22OOpF

50V

Ceramic AB

C310 9APEP04104ZF

J

O.lpF 16V

Ceramic

AB

C311

9APEP04104ZF

J

O.lpF 16VCeramic

A8

C3l2 9APKP03101JC

J

1OOpF 50V

Ceramic

AB

C314 9APGP04103KB

J

O.OlpF 25V

Ceramic AB

RESISTORS

RlOl

9APUL49270JA

J

27

l/l 6W

(Chip)

AB

R102 9APUL49681JA

J

680 1/16W

(Chip)

AB

R103 9APUL49272JA

J

2.7k ll16W

(Chip)

AB

R104 9APUL49271JA

J

270 ll16W

(Chip)

AB

R105 9APUL49560JA

J

56

1 I1 6W (Chip)

AB

R106 9APUL49103JA

J

10k ll16W

(Chip)

AB

R107 9APUL49272JA

J

2.7k ll16W

(Chip)

AB