Page 1

ADJUSTMENT PRECAUTIONS

SERVICE MODE

This model’s setting are adjusted in two different ways: though the I2C bus control and in the

conventional analog manner. The adjustments via the I2C bus control include preset-only items

and variable data.

1. Setting the service mode by the microprocessor.

1 Make a short-circuit JA373 and JA374, enter into the service mode. (Adjustment through

the I2C bus control). (Use JWS Key to set as well).

2 Press the CH DOWN / UP key on the remote controller to get ready to select the mode

one by one.

3 Press the CH DOWN / UP key on the remote controller to select the modes reversibly

one by one.

4 Using the VOLUME UP/ DOWN key on the remote controller, the data can be modified.

5 When the short circuit between JA373 and JA374 is cut off, it will be released from the

service mode.

2. Factory Presetting.

1 Make a short-circuit JA373 and JA374 and turn on the main power switch. Initial values

are automatically preset, only when a new EEPROM is used (Judge with the first 4

bytes).

2 The initial data are preset as listed in page.

3

3 Make sure the data need modify or not (Initial data).

Note: Once the chassis has been assembly together and ready to be POWER ON for the

FIRST TIME, make sure to make a short-circuit JA373 and JA374 to switch to the

service mode position first and then turn on the main power switch. (See 2-1 above).

Precaution: If haven’t done this initiation, it may possibly generate excessive Beam

current.

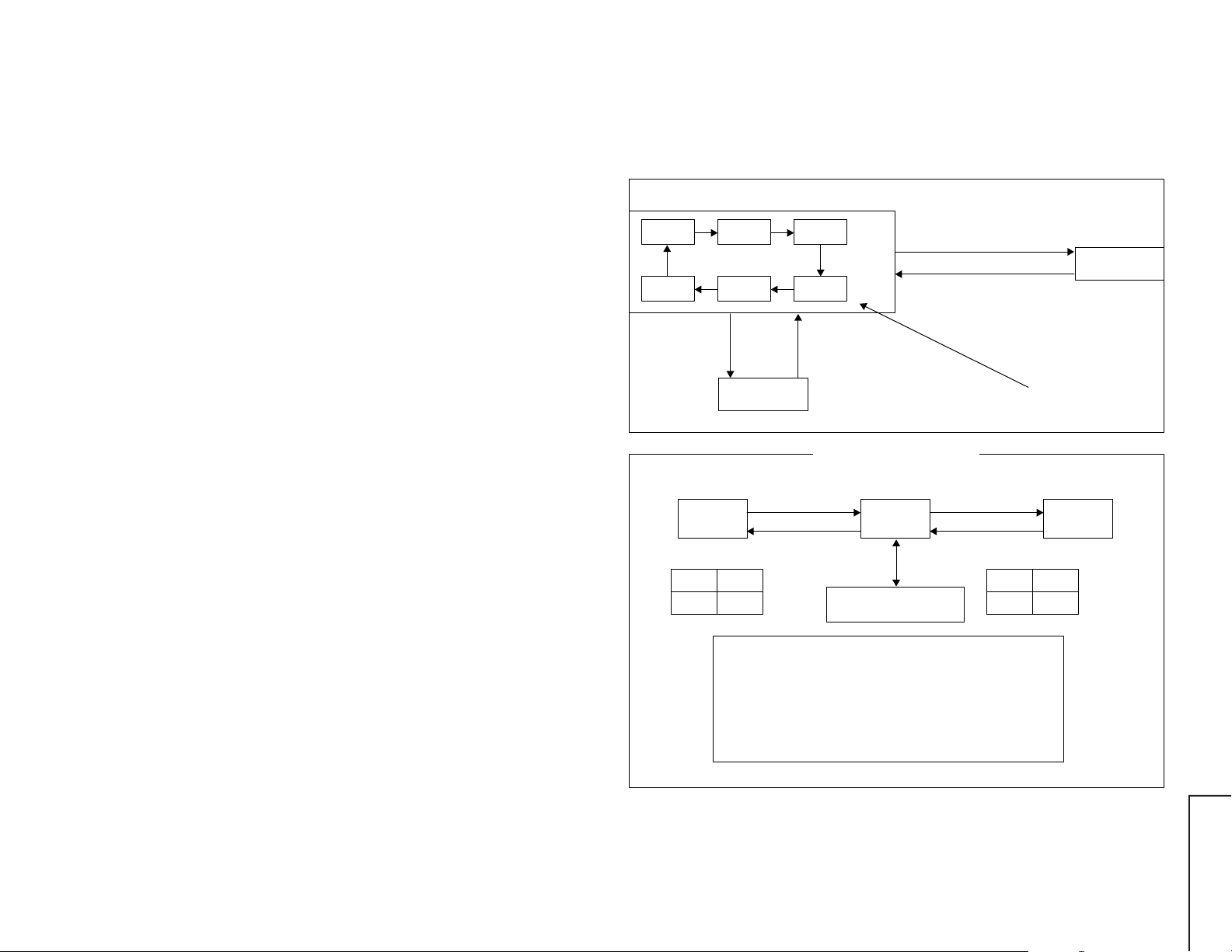

1.) In the Service Mode, Key is used to select the mode in the following order.

SERVICE MODE 1

RASTER

MODE

SUB 2 ADJ.

MODE

Press the MENU button

at the remote controller,

it will enter into

Service Mode Option.

CUT OFF

MODE

60 Hz ADJ.

MODE

SERVICE MODE

OPTION

50Hz ADJ.

MODE

SUB 1 ADJ.

MODE

Press the MENU button

again at the remote controller,

it will jump back to

Service Mode 1.

Press service/ language for 2 sec,

it will enter into service mode 2.

Press service/ language for 2 sec again,

it will jump back to service mode 1.

FORWARD : CH DOWN KEY

REVERSE : CH UP KEY

SERVICE MODE 2

CUT OFF/ BKGD MODE

R-CUT OFF

G-CUT OFF

B-CUT OFF

CUT OFF

DATA

LENGTH

63 - 255 63

INITIAL

DATA

3 sec. TIME OUT

CUT OFF

BKGD

MODE

LATERAL MODE

(R, G, B-CUT OFF)

"—/——"

3 sec. TIME OUT

DATA

LENGTH

0 - 127 63

DRIVE

G-DRIVE

B-DRIVE

INITIAL

DATA

KEY

R-CUT OFF

G-CUT OFF

B-CUT OFF

G-DRIVE

B-DRIVE

UP

1 KEY

2 KEY

3 KEY

7 KEY

8 KEY

3-1 3-2

DOWN

4 KEY

5 KEY

6 KEY

F/B KEY

0 KEY

29WF50

Page 2

50 Hz ADJ. MODE

SERVICE MODE

29WF50

V-SIZE 50 Hz (V-SIZE 50)

V-LINEARITY 50 Hz (V-LINE 50)

VS-CORRECTION 50 Hz (VS-CORR 50)

V-POSITION 50 Hz (V-CENT 50)

V-SIZE 60 Hz (V-SIZE 60)

V-LINEARITY 60 Hz (V-LINE 60)

VS-CORRECTION 60 Hz (VS-CORR 60)

V-POSITION 60 Hz (V-CENT 60)

SUB 1

4

SECAM R-Y (SCM R-Y)

SECAM B-Y (SCM B-Y)

BRIGHT (SUB BRI)

BRIGHT (DVD) (SUB BRI DVD)

SUB CONT (SUB CONT)

SUB CONT (DVD) (SUB CONT DVD)

SUB TINT (SUB TINT)

SUB TINT (DVD) (SUB TINT DVD)

FORWARD : CH DOWN KEY

REVERSE : CH UP KEY

60 Hz ADJ. MODE

TRAPEZIUM 50 Hz (TRAPE 50)

E/W CORNER 50 Hz (E/W COR 50)

E/W PARABOLA 50 Hz (E/W PAR 50)

H-SIZE 50 Hz (H-SIZE 50)

H-POSITION 50 Hz (H-CENT 50)

TRAPEZIUM 60 Hz (TRAPE 60)

E/W CORNER 60 Hz (E/W COR 60)

E/W PARABOLA 60 Hz (E/W PAR 60)

H-SIZE 60 Hz (H-SIZE 60)

H-POSITION 60 Hz (H-CENT 60)

SUB 2

SUB COLOR (SUB COLOR)

SUB COLOR (DVD) (SUB COLOR DVD)

V-ENT (V-ENT)

H-ENT (H-ENT)

RF AGC (RF AGC)

SECAM BELL (SCM BELL)

SPRIT/INTER (S/I)

RF SUB SOUND (RF S-SOUND)

HEAD PHONE (HP SUB VOL)

SUB VOLUME ADJ.

COLOR TEMP. (WT)

PIFVCO (PIFVCO)

LNA (LNA)

SIF 574 (SIF 574)

AFC (AFC)

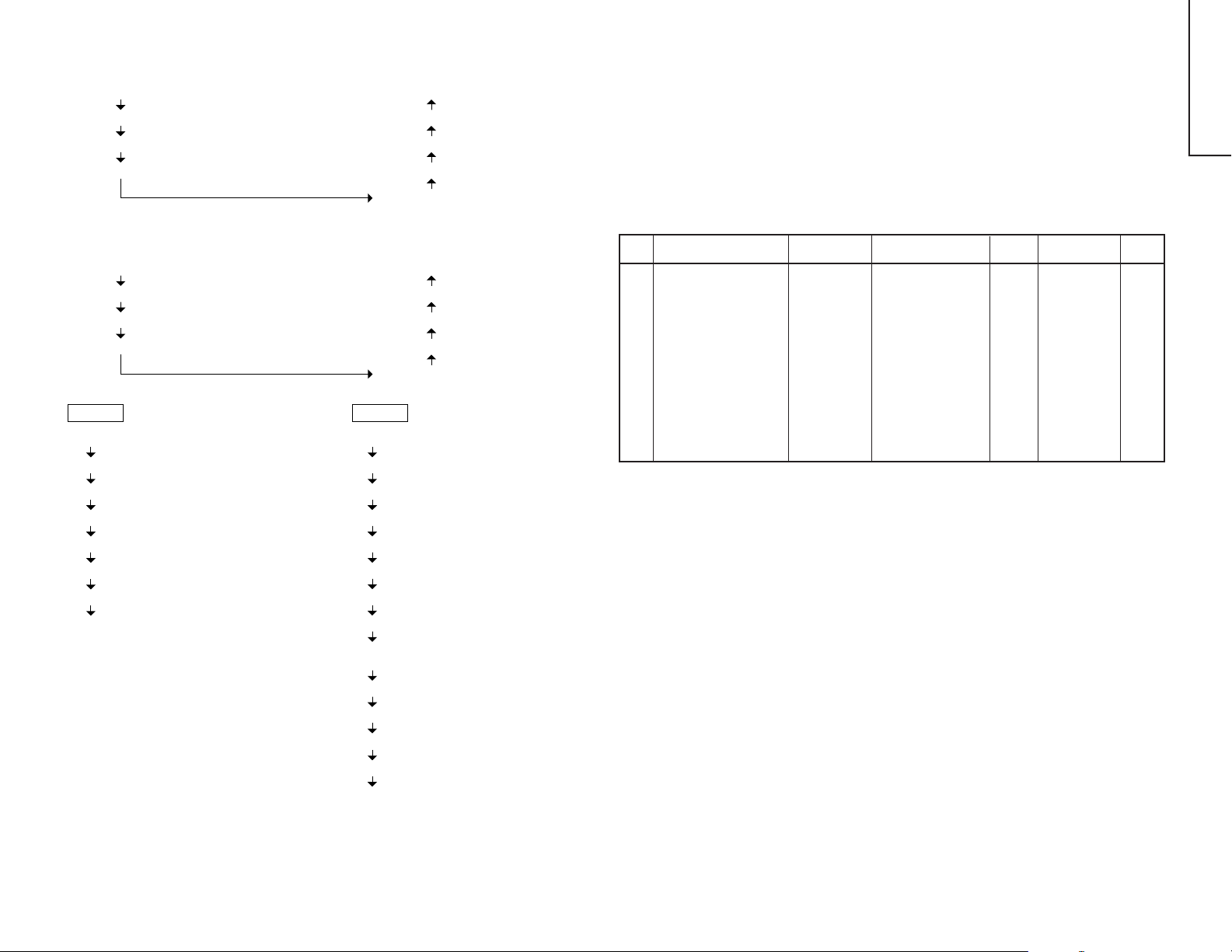

User Data in Service Mode Option

• While SERVICE MODE 1 on, EEPROM DATA will switch to the service data.

Also, once press the menu button at the remote controller, EEPROM will switch

to SERVICE MODE OPTION.

Once press the menu button again at the remote controller, EEPROM will switch

back to SERVICE MODE 1.

• In the service option the user data establish as below,

Service Mode Option

No. EEPROM ITEM DATA LENGTH OSD IC DATA SETTING INITIAL

DATA

1 COMB OPTION ON/OFF COMB OP OPTION OFF

2 DVD OPTION ON/OFF DVD OP OPTION OFF

3 PAL OPTION ON/OFF PAL OP OPTION ON

4 6.5 M SIF FIX 0 ~ 1 6.5 M 1 CHIP 6.5 M SIF FIX (0) 0

5 ROTATION OPTION ON/OFF ROTA OP OPTION OFF

6 SYAKIT OPTION ON/OFF SYAKIT OP OPTION OFF

7 SPATIALIZER OPTION ON/OFF SPA OP OPTION OFF

8 FLAT OPTION ON/OFF FLAT OP OPTION (ON:FLAT) OFF

9 SPEAKER 1 ~ 4 SPEAKER OPTION SP1 (1) 1

10 HOTEL ON/OFF ON/OFF H MODE OPTION OFF

11 HOTEL POSITION 0 ~ 99 H POSITION OPTION 0

12 HOTEL VOLUME 0 ~ 60 H VOLUME OPTION 0

13 LANGUAGE OPTION 1 ~ 2 LANGUAGE OPTION 2

14 MONO BILINGUAL ON/OFF MO/BIL OPTION ON OFF

4-1 4-2

Page 3

After short JA373 & JA374, and turn on the main power switch, read data from EEPROM Address

00H ~ 03H, and compare to the list below, if different, initialize the EEPROM.

Address Data Address Data

00H 23H 02H 18H

01H 23H 03H A3H

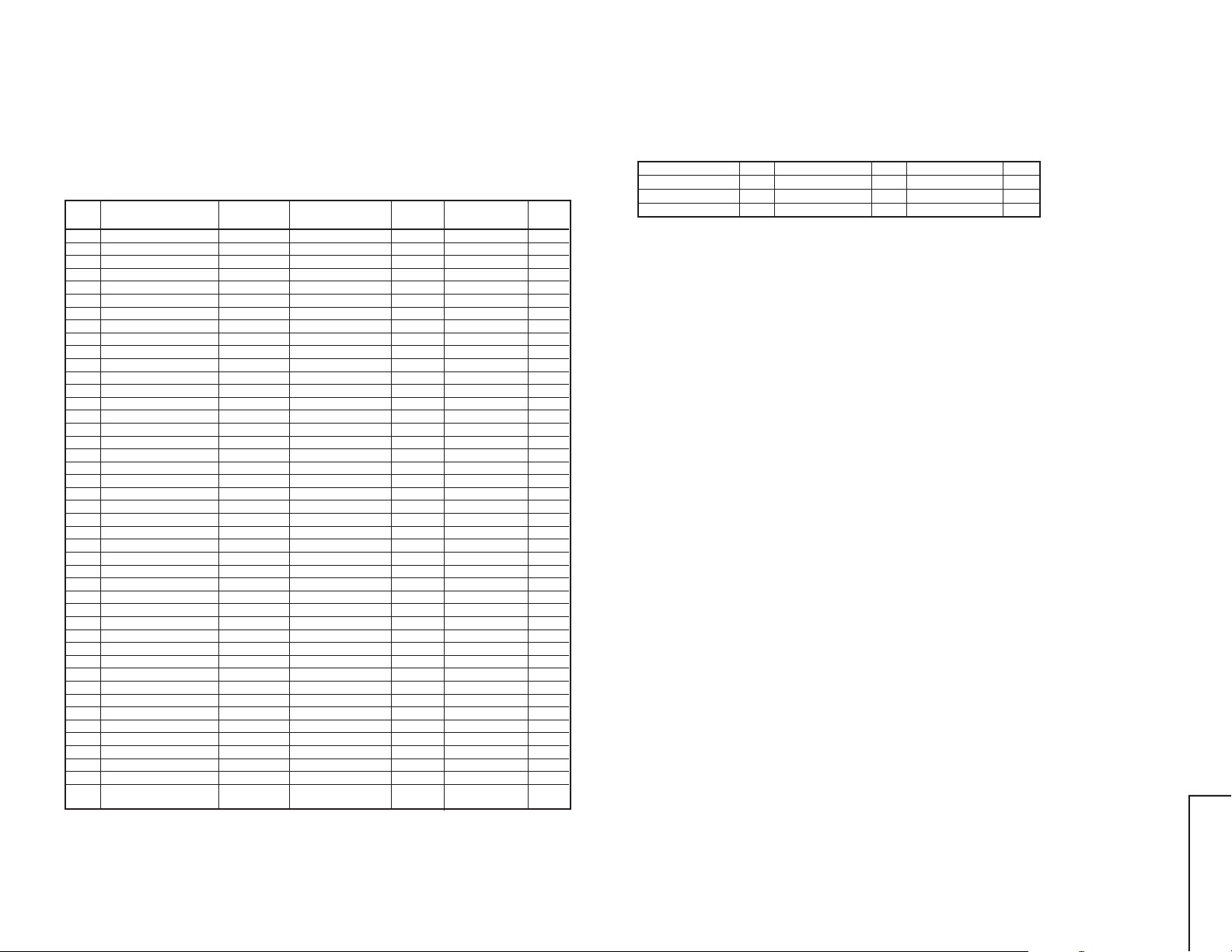

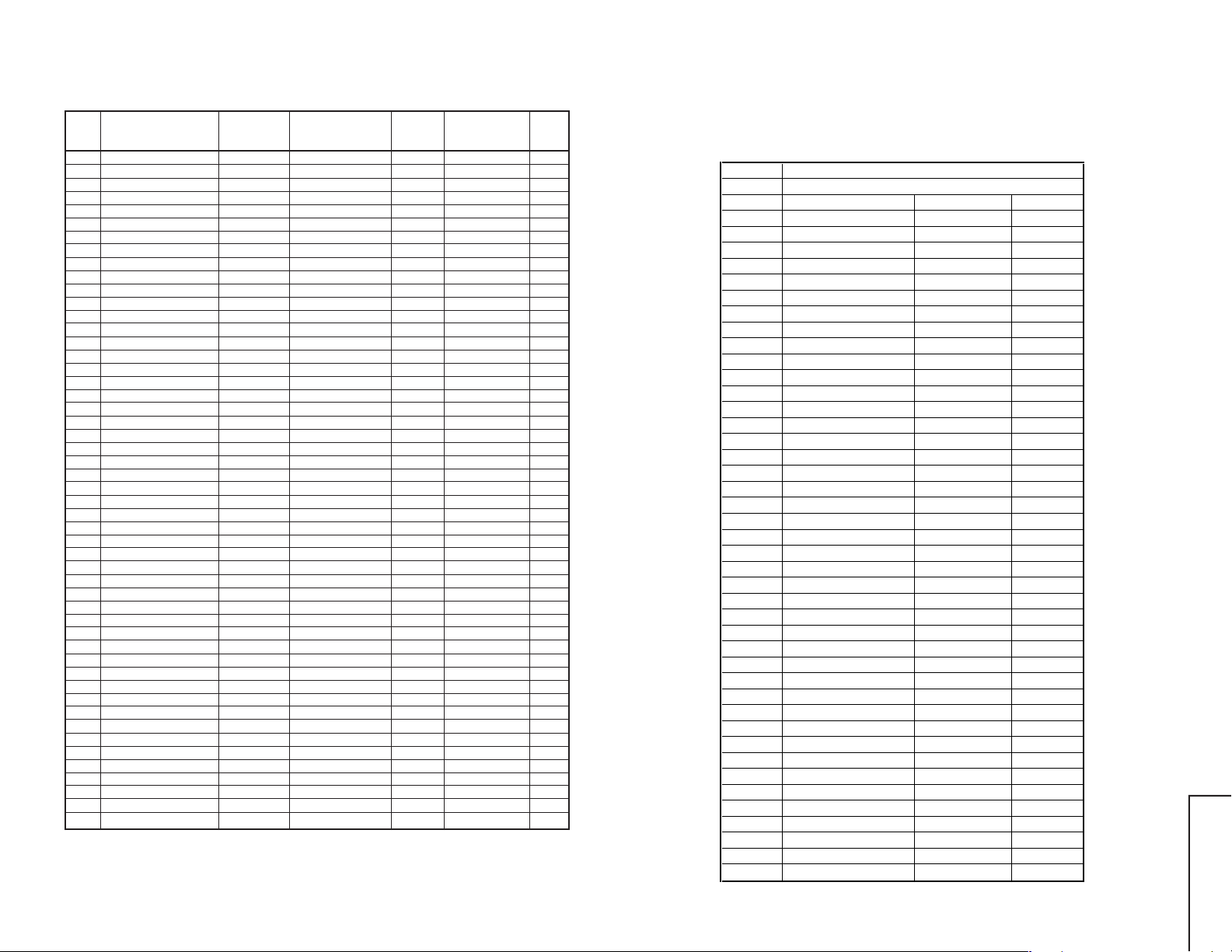

1. SERVICE MODE 1

No. EEPROM SETTING

0 MICOM INFO. DISPLAY SERVICE MODE

1 CUT OFF REFER # CUTOFF BKGD

2 CUT OFF (DVD) REFER # CUTOFFBKGD (DVD)

3 V-SIZE 0 ~ 63 V-SIZE 50 1 CHIP V-SIZE 30

4 V-LINEARITY (50Hz) #2 0 ~ 15 V S-LINE 50 1 CHIP V-LINEARITY 10

5

VS-CORRECTION (50Hz) #2

6 V-POSITION #2 0 ~ 7 V-CENT 50 1 CHIP V-PHASE 5

7 H-POSITION #2 0 ~ 31 H-CENT 50 1 CHIP H-PHASE 11

8 H-SIZE (50Hz) #2 0 ~ 63 H-SIZE 50 1 CHIP H-SIZE 32

9

E/W-PARABOLA (50Hz) #2

10 E/W CORNER (50Hz) #2 0 ~ 15 E/W COR 50 1 CHIP E/W CORNER 6

11 TRAPEZIUM (50Hz) #2 0 ~ 31 TRAPE 50 1 CHIP TRAPEZIUM 17

12 SECAM R-Y #3 0 ~ 15 SCM R-Y 1 CHIP SR-Y 8

13 SECAM B-Y #3 0 ~ 15 SCM B-Y 1 CHIP SB-Y 8

14 BRIGHT 0 ~ 127 SUB BRI 1 CHIP BRIGHTNESS 80

15 BRIGHT (DVD) 0 ~ 127 SUB BRI DVD 1 CHIP BRIGHTNESS 80

16 SUB CONT 0 ~ 15 SUB CONT 1 CHIP SUB CONT 3

17 SUB CONT (DVD) 0 ~ 15 SUB CONT DVD 1 CHIP SUB CONT 3

18 TINT 0 ~ 127 SUB TINT 1 CHIP TINT 64

19 TINT (DVD) 0 ~ 127 SUB TINT DVD 1 CHIP TINT 16

5

20 V-SIZE 0 ~ 63 V-SIZE 60 1 CHIP V-SIZE 39

21 V-LINEARITY 0 ~ 15 V-LINE 60 1 CHIP V-LINEARITY 10

22 VS-CORRECTION (60Hz) 0 ~ 15 V S-CORR 60 1 CHIP

23 V-POSITION (60Hz) 0 ~ 7 V-CENT 60 1 CHIP V-PHASE 2

24 H-POSITION (60Hz) 0 ~ 31 H-CENT 60 1 CHIP H-PHASE 14

25 H-SIZE (60Hz) 0 ~ 63 H-SIZE 60 1 CHIP H-SIZE 34

26 E/W PARABOLA (60Hz) 0 ~ 63 E/W PAR 60 1 CHIP E/W PARABORA 19

27 E/W CORNER (60Hz) 0 ~ 15 E/W COT 60 1 CHIP E/W CORNER 4

28 TRAPEZIUM (60Hz) 0 ~ 31 TRAPE 60 1 CHIP TRAPEZIUM 6

29 COLOUR 0 ~ 127 SUB COL 1 CHIP COLOUR 60

30 COLOUR (DVD) 0 ~ 127 SUB COL DVD 1 CHIP COLOUR 60

31 V-ENT 0 ~ 7 V-ENT 1 CHIP V-ENT 6

32 H-ENT 0 ~ 7 H-ENT 1 CHIP H-ENT 4

33 RF AGC 0 ~ 63 RF AGC 1 CHIP RF AGC 46

34 SECAM BELL 0 ~ 1 SCM BELL 1 CHIP S BELL 0

35 SPRIT/INTER 0 ~ 1 S/I 1 CHIP SPRIT/INTER 0

36 RF SUB SOUND 0 ~ 127 RF S-SOUND 1 CHIP RF SUB SOUND 96

37 SUB VOLUME 0 ~ 63 SUB VOL SOR/SPA VOLUME 45

38

H. PHONE SUB VOL. ADJ.

39 COLOUR TEMP. 0 ~ 1 WT OPTION 1

40 PIF VCO #4 PIFVCO 41 LNA ON/OFF LNA OPTION OFF

42 SIF574 ON/OFF SIF574 1 CHIP SIF574 ON

43 AFC ON/OFF AFC 1 CHIP AFC OFF:OFF OFF

DATA LENGTH

0 ~ 15 V S-CORR 50 1 CHIP

0 ~ 63 E/W PAR 50 1 CHIP E/W PARABORA 39

0 ~ 63 HP SUB VOL SOR/SPA VOLUME 63

OSD IC DATA SETTING

V S-CORRECTION

V S-CORRECTION

NORMAL:ON

INITIAL

DATA

8

9

#1 Whiles selecting SERVICE MODE 1, MICOM Version Information, SOFTWARE V ersion Informa-

tion, check some iformation will be displayed.

#2 60 Hz Adjustment Value is programmed from ± 50 Hz Adjustment value.

EEPROM SETTING DATA EEPROM SETTING DATA EEPROM SETTING DATA

V-SIZE +9 V-POSITION -3 E/W PARABOLA -20

V-LINEARITY 0 H-POSITION +3 E/W CORNER -2

VS-CORRECTION +1 H-SIZE +2 TRAPEZIUM -11

#3 While adjusting SECAM R-Y, SECAM B-Y and S BLACK of 1 chip is set to 1.

#4 While choosing PIFVCO MODE and RF AGC set to "0 0" and PIFVCO is set to "1".

5-1 5-2

29WF50

Page 4

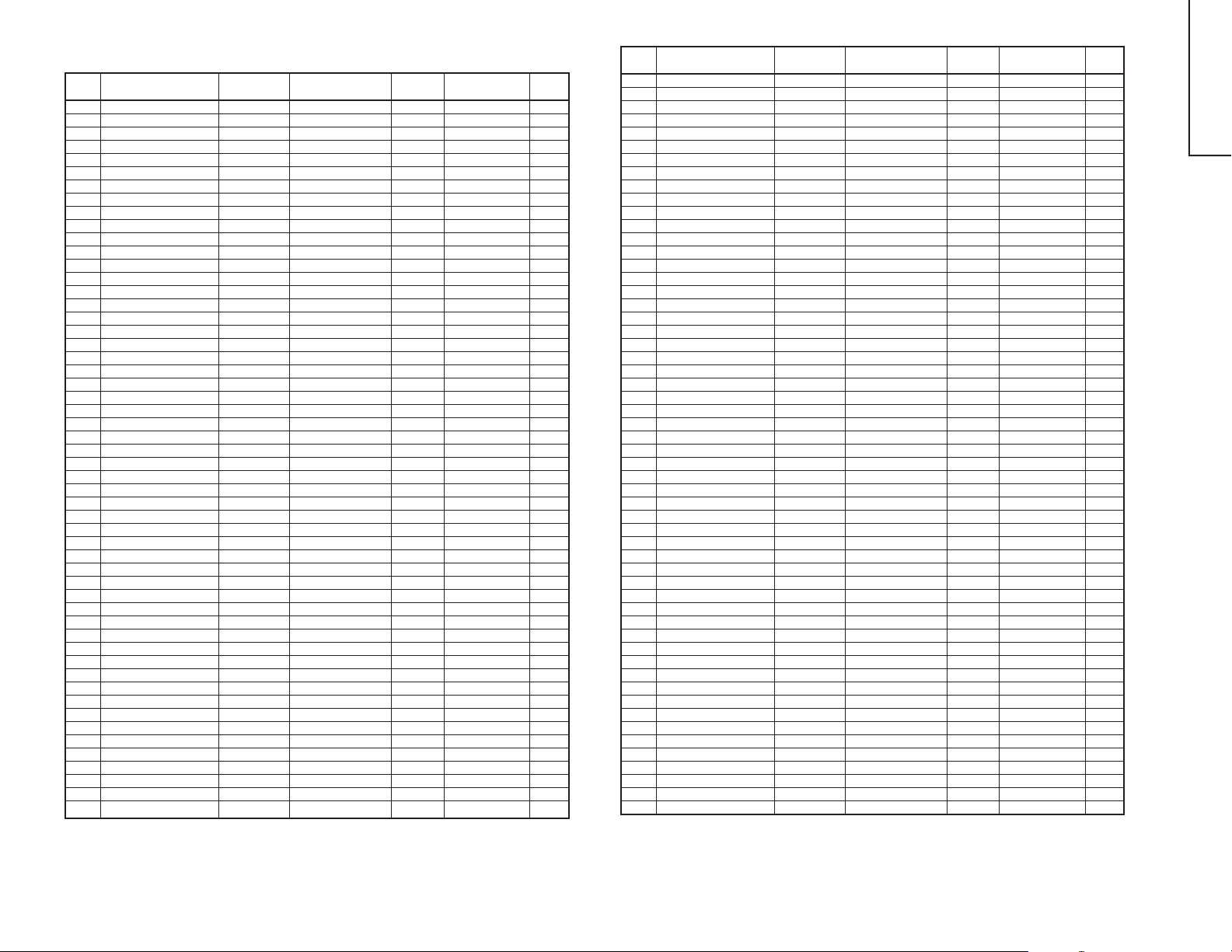

2. SERVICE MODE 2

NO. EEPROM ITEM

1 WPS 0 ~ 1 WPS 1 CHIP WPS 1

2 SUB CONTRAST 0 ~ 127 S CONT 1 CHIP CONTRAST 127

3 NTSC PHASE (NT) 0 ~ 3 N-PNT 1 CHIP NTSC PHASE 0

4 NTSC PHASE (PAL/SEC.) 0 ~ 3 N-P PS 1 CHIP NTSC PHASE 0

5 NTSC PHASE (DVD) 0 ~ 3 N-PD 1 CHIP NTSC PHASE 3

6 SUB SHARPNESS (TV) 0 ~ 63 S SHARP T 1 CHIP SHARPNESS 32

7 SUB SHARPNESS (AV) 0 ~ 63 S SHARP A 1 CHIP SHARPNESS 20

8 SUB SHARPNESS (DVD) 0 ~ 63 S SHARP D 1 CHIP SHARPNESS 10

9 RGB MUTE 0 ~ 1 RGB MUTE 1 CHIP RGB MUTE OFF

10 RGB CONTRAST 0 ~ 63 RGB CONT 1 CHIP RGB CONTRAST 32

11 Y-DL (NTSC-M) 0 ~ 3 YNM 1 CHIP Y-DL 1

12 Y-DL (PAL-B/G) 0 ~ 3 YPB 1 CHIP Y-DL 1

13 Y-DL (PAL-I) 0 ~ 3 YPI 1 CHIP Y-DL 3

14 Y-DL (PAL-D/K) 0 ~ 3 YPD 1 CHIP Y-DL 3

15 Y-DL (SECAM-B/G) 0 ~ 3 YSB 1 CHIP Y-DL 0

16 Y-DL (SECAM-D/K) 0 ~ 3 YSD 1 CHIP Y-DL 3

17 Y-DL (B/W) 0 ~ 3 YBW 1 CHIP Y-DL 0

18 Y-DL (NTSC-AV) 0 ~ 3 YNA 1 CHIP Y-DL 0

19 Y-DL (PAL-AV) 0 ~ 3 YPA 1 CHIP Y-DL 0

20 Y-DL (SECAM-AV) 0 ~ 3 YSA 1 CHIP Y-DL 0

21 Y-DL (B/W-AV) 0 ~ 3 YBA 1 CHIP Y-DL 0

22 SUB COLOUR 0 ~ 31 SUB COL 1 CHIP SUB-COLOUR 16

23 VSM GAIN AVM1 0 ~ 7 V-GAIN 1 1 CHIP VSM GAIN 3

24 VSM GAIN AVM2 0 ~ 7 V-GAIN 2 1 CHIP VSM GAIN 5

6

25 VSM GAIN AVM3 0 ~ 7 V-GAIN 3 1 CHIP VSM GAIN 7

26 BASE BAND TINT 0 ~ 31 B-B TINT 1 CHIP BASE BAND TINT 16

27 SECAM GP-PHASE 0 ~ 3 S G-PHASE 1 CHIP S SP-PHASE 1

28 SECAM ID-SENS 0 ~ 1 S ID-SENS 1 CHIP S ID-SENS 0

29 SECAM ID-MODE 0 ~ 1 S ID-MODE 1 CHIP S ID-MODE 0

30 PIF FREQ 0 ~ 7 P FREQ 1 CHIP PIF FREQ 3

31 P/N-ID 0 ~ 1 PN ID 1 CHIP P/N-ID 0

32 YS/YM MODE 0 ~ 1 YSM MODE 1 CHIP YSM MODE 1

33 RGB ABCL 0 ~ 1 RGB ABCL 1 CHIP RGB ABCL 1

34 DC RESTORATION 0 ~ 3 DC REST 1 CHIP

35 BLACK STRETCH 0 ~ 3 B ST 1 CHIP BLACK STRETCH 1

36 ABL START POINT 0 ~ 3 ABL ST 1 CHIP

37 ABL GAIN 0 ~ 3 ABL GA 1 CHIP ABL GAIN 2

38 AKB MODE 0 ~ 63 AKB MODE 1 CHIP AKB MODE 0

39 COLOUR 0 ~ 1 COL G 1 CHIP COLOUR 1

40 V AGC 0 ~ 1 V AGC 1 CHIP V AGC 0

41 V RAMP REF 0 ~ 1 V RAMP 1 CHIP V RAMP 1

42 VSM PHASE 0 ~ 1 VSM PHASE 1 CHIP VSM PHASE 0

43 BASS LEVEL ON 0 ~ 3 BA LV SUR/SPA BASS LEVEL 3

44 BASS OFF AVM1 SP1 0 ~ 4 #1 BA OFF 1 SP1 SUR/SPA BASS SW, LEVEL 4

45 BASS OFF AVM2 SP1 0 ~ 4 #1 BA OFF 2 SP1 SUR/SPA BASS SW, LEVEL 4

46 BASS OFF AVM3 SP1 0 ~ 4 #1 BA OFF 3 SP1 SUR/SPA BASS SW, LEVEL 4

47 BASS OFF AVM1 SP2 0 ~ 4 #1 BA OFF 1 SP2 SUR/SPA BASS SW, LEVEL 4

48 BASS OFF AVM2 SP2 0 ~ 4 #1 BA OFF 2 SP2 SUR/SPA BASS SW, LEVEL 4

49 BASS OFF AVM3 SP2 0 ~ 4 #1 BA OFF 3 SP2 SUR/SPA BASS SW, LEVEL 4

50 BASS OFF AVM1 SP3 0 ~ 4 #1 BA OFF 1 SP3 SUR/SPA BASS SW, LEVEL 4

51 BASS OFF AVM2 SP3 0 ~ 4 #1 BA OFF 2 SP3 SUR/SPA BASS SW, LEVEL 4

52 BASS OFF AVM3 SP3 0 ~ 4 #1 BA OFF 3 SP3 SUR/SPA BASS SW, LEVEL 4

53 BASS OFF AVM1 SP4 0 ~ 4 #1 BA OFF 1 SP4 SUR/SPA BASS SW, LEVEL 4

54 BASS OFF AVM2 SP4 0 ~ 4 #1 BA OFF 2 SP4 SUR/SPA BASS SW, LEVEL 4

DATA LENGTH

OSD IC DATA SETTING

DC RESTORATION

ABL START POINT

INITIAL

DATA

3

3

NO. EEPROM ITEM

55 BASS OFF AVM3 SP4 0 ~ 4 #1 BA OFF 3 SP4 SUR/SPA BASS SW, LEVEL 4

56 AGC SW 0 ~ 1 AGC SW SUR/SPA AGC SW ON

57 AGC ADJ 0 ~ 3 AGC AD SUR/SPA AGC ADJ 2

58 FM LEVEL #2 FM L NICAM FM LEVEL +1

59 IGR LEVEL #2 IGR L NICAM IGR LEVEL +2

60 NICAM B/G LEVEL #3 BG L NICAM NICAM B/G LEVEL -1

61 NICAM 1 LEVEL #3 I L NICAM NICAM I LEVEL +4

62 NICAL D/K LEVEL #3 DK L NICAM NICAM D/K LEVEL -1

63 LOWER ERROR 0 ~ 255 L ERR NICAM LOWER ERROR 35

64 UPPER ERROR 0 ~ 255 U ERR NICAM UPPER ERROR 70

65 IGR GAIN (9873H) #4 IGR G NICAM IGR GAIN (9873H) 0

66 NICAM SPEED 0 ~ 3 N SPEED NICAM N SPEED 2

67 INTER/EXTER 0 ~ 1 IN/EX NICAM INTER/EXTER 0

68 AUTO MUTE 0 ~ 1 AM NICAM AUTO MUTE ON

69 AGC SW ON/OFF 0 ~ 1 AGC SW NICAM AGC SW OFF

70 AGC GAIN 0 ~ 31 AGC G NICAM AGC GAIN 16

71 SYAKIT VOLUME 1 0 ~ 21 SVOL 1 SYAKIT SVOLUME 1 0

72 SYAKIT VOLUME 2 0 ~ 3 SVOL 2 SYAKIT SVOLUME 2 0

73 SYAKIT LOU 0 ~ 1 SLOU SYAKIT SLOU 1

74 SYAKIT ATT 0 ~ 7 SATT SYAKIT SATT OUT 0

75 SYAKIT BASS 0 ~ 13 SBASS SYAKIT S-BASS 6

76 SYAKIT TREBLE 0 ~ 13 STRE SYAKIT S-TREBLE 6

77 MAX LEVEL SYAKIT 1 0 ~ 5 S1MA 3

78 MAX LEVEL SYAKIT 2 0 ~ 5 S2MA 4

79 MAX LEVEL SYAKIT 3 0 ~ 5 S3MA 6

80 START LEVEL SYAKIT 1 0 ~ 63 S1ST 17

81 START LEVEL SYAKIT 2 0 ~ 63 S2ST 21

82 START LEVEL SYAKIT 3 0 ~ 63 S3ST 20

83 WIDE LEVEL SYAKIT 1 0 ~ 7 S1W1 6

84 WIDE LEVEL SYAKIT 2 0 ~ 7 S2W1 3

85 WIDE LEVEL SYAKIT 3 0 ~ 7 S3W1 3

86 STOP LEVEL SYAKIT 1 0 ~ 5 S1SP 1

87 STOP LEVEL SYAKIT 2 0 ~ 5 S2SP 1

88 STOP LEVEL SYAKIT 3 0 ~ 5 S3SP 1

89 BASS MAX SYAKIT 1 0 ~ 15 SBASS1 12

90 BASS MAX SYAKIT 2 0 ~ 15 SBASS2 11

91 BASS MAX SYAKIT 3 0 ~ 15 SBASS3 10

92 TREBLE MAX SYAKIT 1 0 ~ 15 STRE1 12

93 TREBLE MAX SYAKIT 2 0 ~ 15 STRE2 11

94 TREBLE MAX SYAKIT 3 0 ~ 15 STRE3 10

95 BASS AVM1 SP1 #6 BASS 1 SP1 -5

96 BASS AVM2 SP1 #6 BASS 2 SP1 +2

97 BASS AVM3 SP1 #6 BASS 3 SP1 +5

98 BASS AVM1 SP2 #6 BASS 1 SP2 -5

99 BASS AVM2 SP2 #6 BASS 2 SP2 0

100 BASS AVM3 SP2 #6 BASS 3 SP2 +5

101 BASS AVM1 SP3 #6 BASS 1 SP3 -5

102 BASS AVM2 SP3 #6 BASS 2 SP3 0

103 BASS AVM3 SP3 #6 BASS 3 SP3 +10

104 BASS AVM1 SP4 #6 BASS 1 SP4 -5

105 BASS AVM2 SP4 #6 BASS 2 SP4 -2

106 BASS AVM3 SP4 #6 BASS 3 SP4 +6

107 TREBLE AVM1 SP1 #6 TRE 1 SP1 -5

108 TREBLE AVM2 SP1 #6 TRE 2 SP1 0

109 TREBLE AVM3 SP1 #6 TRE 3 SP1 +5

110 TREBLE AVM1 SP2 #6 TRE 1 SP2 -5

DATA LENGTH

OSD IC DATA SETTING

6-1 6-2

INITIA

DATA

29WF50

Page 5

NO. EEPROM ITEM

EEPROM

111 TREBLE AVM2 SP2 #6 TRE 2 SP2 +2

112 TREBLE AVM3 SP2 #6 TRE 3 SP2 +8

113 TREBLE AVM1 SP3 #6 TRE 1 SP3 -10

114 TREBLE AVM2 SP3 #6 TRE 2 SP3 +1

115 TREBLE AVM3 SP3 #6 TRE 3 SP3 +5

116 TREBLE AVM1 SP4 #6 TRE 1 SP4 -10

117 TREBLE AVM2 SP4 #6 TRE 2 SP4 +3

118 TREBLE AVM3 SP4 #6 TRE 3 SP4 +6

119 BASS MODE AVM1 SP1 ON/OFF #7 BA MO 1 SP1 OFF

120 BASS MODE AVM2 SP1 ON/OFF #7 BA MO 2 SP1 OFF

121 BASS MODE AVM3 SP1 ON/OFF #7 BA MO 3 SP1 ON

122 BASS MODE AVM1 SP2 ON/OFF #7 BA MO 1 SP2 OFF

123 BASS MODE AVM2 SP2 ON/OFF #7 BA MO 2 SP2 OFF

124 BASS MODE AVM3 SP2 ON/OFF #7 BA MO 3 SP2 ON

125 BASS MODE AVM1 SP3 ON/OFF #7 BA MO 1 SP3 OFF

126 BASS MODE AVM2 SP3 ON/OFF #7 BA MO 2 SP3 OFF

127 BASS MODE AVM3 SP3 ON/OFF #7 BA MO 3 SP3 ON

128 BASS MODE AVM1 SP4 ON/OFF #7 BA MO 1 SP4 OFF

129 BASS MODE AVM2 SP4 ON/OFF #7 BA MO 2 SP4 OFF

130 BASS MODE AVM3 SP4 ON/OFF #7 BA MO 3 SP4 ON

131 CONTRAST AVM1 #8 CONT 1 55

132 CONTRAST AVM2 #8 CONT 2 57

133 CONTRAST AVM3 #8 CONT 3 60

134 CONTRAST AVM1 FL #8 CONT 1 FL 55

135 CONTRAST AVM2 FL #8 CONT 2 FL 57

7

136 CONTRAST AVM3 FL #8 CONT 3 FL 60

137 COLOUR AVM1 #9 COL 1 0

138 COLOUR AVM2 #9 COL 2 0

139 COLOUR AVM3 #9 COL 3 +10

140 COLOUR AVM1 FL #9 COL 1 FL 0

141 COLOUR AVM2 FL #9 COL 2 FL 0

142 COLOUR AVM3 FL #9 COL 3 FL +10

143 SHARP AVM1 #10 SHARP 1 -5

144 SHARP AVM2 #10 SHARP 2 0

145 SHARP AVM3 #10 SHARP 3 0

146 SHARP AVM1 FL #10 SHARP 1 FL -5

147 SHARP AVM2 FL #10 SHARP 2 FL 0

148 SHARP AVM3 FL #10 SHARP 3 FL 0

149 γ- POINT AVM1 #11 G-POINT 1 3

150 γ- POINT AVM2 #11 G-POINT 2 2

151 γ- POINT AVM3 #11 G-POINT 3 1

152 γ- POINT AVM1 FL #11 G-POINT 1 FL 3

153 γ- POINT AVM2 FL #11 G-POINT 2 FL 2

154 γ- POINT AVM3 FL #11 G-POINT 3 FL 1

155 SEARCH SPEED #12 S SPE 450

156 OSD 0 ~ 127 OSD-H 2

157 BUZZ 0 ~ 1 BUZZ 1 CHIP BUZZ 0

158 AV AFC 0 ~ 1 AV AFC 1

159 TEXT H 0 ~ 63 TEXT H TEXT 30

160 TEXT V 0 ~ 63 TEXT V TEXT 30

161 NVM NVM EEPROM

DATA LENGTH

OSD IC DATA SETTING

INITIAL

DATA

INITIAL SETTING

(1) Execute MCL 1/2 key to set the following data in EEPROM.

STTM

R/C CODE MCL 4(171:Abh)

TV-CH. CH-No. Fv (MHz) S-SYSTEM

0

1 Thai Local CH-3 55.25 PAL B/G

2 Thai Local CH-5 175.25 PAL B/G

3 Thai Local CH-7 189.25 PAL B/G

4 Thai Local CH-9 203.25 PAL B/G

5 Thai Local CH-11 217.25 PAL B/G

6 Thai Local CH-29 535.25 PAL B/G

7

8

9

10

11 STTM Factory CH-E2 48.25 PAL B/G

12 STTM Factory CH-E4 62.25 PAL B/G

13 STTM Factory CH-E8 196.25 PAL B/G

14 STTM Factory CH-E10 210.25 SECAM B/G

15 STTM Factory CH-E12 224.25 PAL B/G

16 STTM Factory CH-E21 471.25 PAL B/G

17 STTM Factory CH-E69 855.25 PAL B/G

18

19

20

21 STTM Factory CH-E12 223.95 PAL B/G

22 STTM Factory CH-E12 224.55 PAL B/G

23 STTM Factory CH-E12 223.85 PAL B/G

24 STTM Factory CH-E12 224.65 PAL B/G

25 STTM Factory CH-E12 223.75 PAL B/G

26 STTM Factory CH-E12 224.75 PAL B/G

27

28

29

30

31 STTM Factory CH-J1 91.25 NTSC M

32 STTM Factory CH-J3 103.25 NTSC M

33 STTM Factory CH-J4 171.25 NTSC M

34 STTM Factory CH-J6 183.25 NTSC M

35 STTM Factory CH-J8 193.25 NTSC M

36 STTM Factory CH-J10 205.25 NTSC M

37 STTM Factory CH-J12 217.25 NTSC M

38 STTM Factory CH-J38 621.25 NTSC M

39

29WF50

40

41

7-1 7-2

Page 6

SHIPPING SETTING AND CHECKING

(1) The following default data has been factory-set for the E2PROM.

ITEMS DATA SETTING

R/C 238(EEh)

S-SYSTEM B/G

LANGUAGE THAI

SELECT

# FACTORY-SET 8 OPERATE MCL2

LAST POWER ON

LAST TV/AV MODE TV

LAST CH CH1

FLASH BACK CH1

FAVORITE CH1 CH10

FAVORITE CH2 CH20

FAVORITE CH3 CH30

FAVORITE CH4 CH40

1 DIGIT/2 DIGIT 2 DIGIT

VOLUME 0

H/P-VOLUME 0

ROTATION 0

SAVE OFF

AV MODE 2

BALANCE 0

BLUE BACK OFF

8

AUTO SELECT ON

# SERVICE MODE DATA

ITEM DATA SETTING

MODE 1 2 3

CONTRAST # # #

COLOUR # # #

BRIGHT 0 0 0

TINT 0 0 0

SHARPNESS # # #

PEICTURE NR OFF OFF OFF

WHITE TEMP 0 0 0

SHAKIT OFF OFF OFF

BASS + # # #

SOR/SPA OFF OFF OFF

LEVEL 0 0 0

BASS # 0 #

TREBLE # 0 #

FACTORYSET 9

VM ON

TEXT 1

LNA OFF

ON TIMER OFF

ON TIMER CH NO SETTING

ON TIMER VOLUME NO SETTING

REMINDER OFF

AFT ALL CH ON

COLOUR SYSTEM ALL CH AUTO

SKIP ALL CH OFF

NICAM ON/OFF ALL CH ON

NICAM STEREO MODE ALL CH STEREO

NICAM BILINGUAL MODE ALL CH M1

NICAM MONO MODE ALL CH MONO

IGR ON/OFF ALL CH ON

IGR STEREO MODE ALL CH STEREO

IGR BILINGUAL MODE ALL CH MAIN

MONO BILINGUAL MODE SOUND1

SOFT STANDARD DYNAMIC

ITEM DATA SETTING

No.

Adjustment point

Tuner IFT

1

(PRESET)

TU200

2 RF-AGC

TAKE OVER

POINT

ADJUSTMENT

(I2C BUS

CONTROL)

3 PIF VCO COIL

ADJUSTMENT

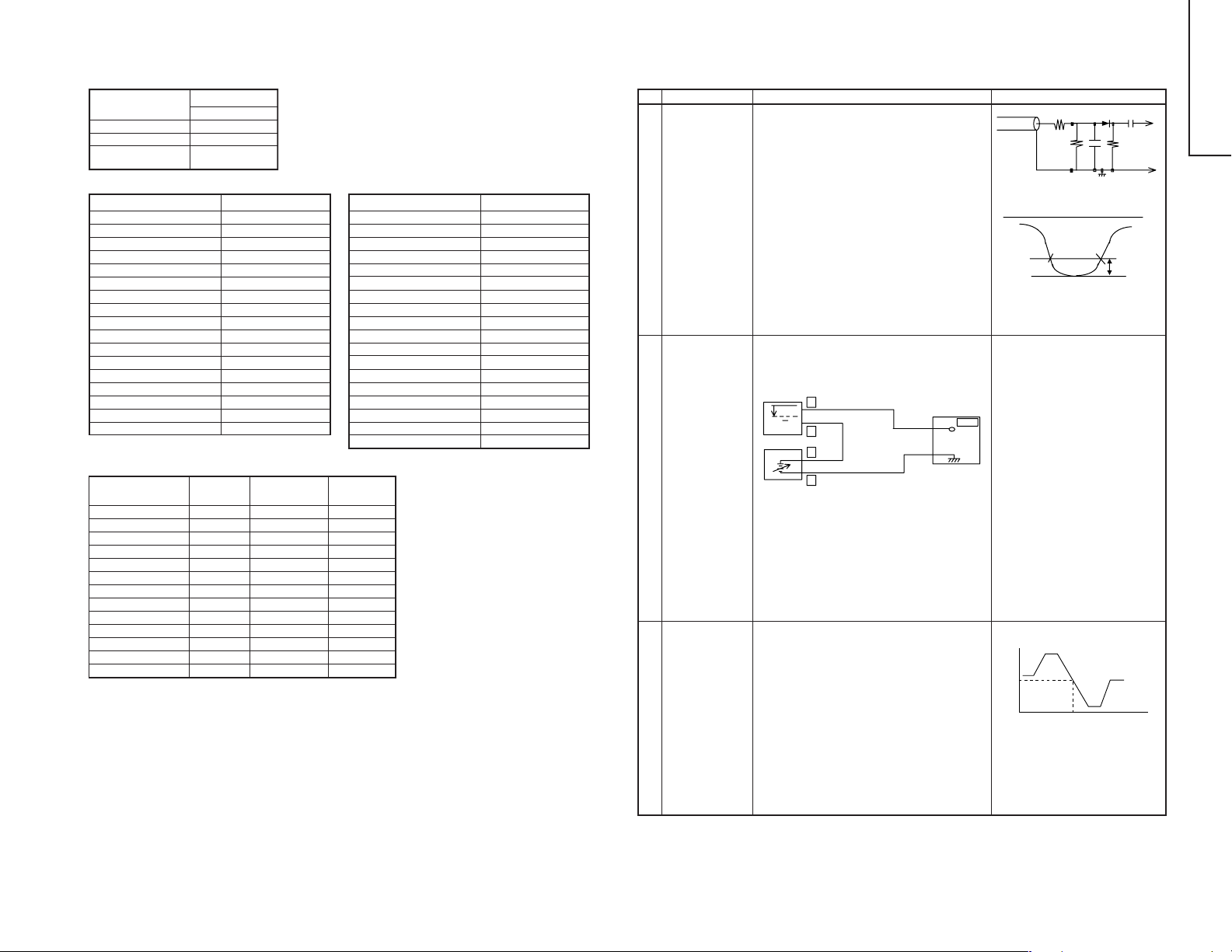

SERVICE ADJUSTMENT

PIF ADJUSTMENT CHECKING

Adjustment Condition / Procedure Waveform or others

1. Get the tuner ready to receive the CH. E-10

signal, but with no signal input.

Adjust the PLL data.

2. Connect the sweep generator’s output cable

to the tuner antenna. (RF SWEEP)

3. Adjust the sweep generator’s to 80dBµV.

4. Connect the response lead (use LOW IMPEDANCE probe with wave detector ; see Fig.1)

to the tuner’s IF output terminal. (This terminal

must have the probe alone connected).

5. Set the RF AGC to 0 - 6 V with no saturation

with the waveform.

6. Adjust the tuner IF coil to obtain the waveform

as shown in Fig. 2.

Note: Be sure to keep the tuner cover in position

during this adjustment.

1. Receive the PAL Colour bar signal.

Signal Strength: 54 ± 1 dbµV (75Ω open)

2. Connect the oscilloscope to TP201 (Tuner’s

AGC Terminal) as shown in Fig. 3.

Oscilloscope

+

0.1V

–

+

–

Bias Box : about 4.5V

BIAS Box

TP201

TV SET

Fig. 3

3. Call "RF-AGC" mode in service mode. Adjust

the "RF-AGC" bus data to obtain the Tuner output pin drop 0.1 ~ 1.0 V below maximum voltage.

4. Change the antenna input signal to 63 ~

67 dBµV, and make sure there is no noise.

5. Turn up the input signal to 90 ~ 95 dBµV to be

sure that there is no cross modulation beat.

1. Do not receive any signal.

2. Connect the digital voltmeter to TP803 (pin (54)

of IC800) in the main unit.

3. Call the "PIF VCO" Mode at the service mode.

4. Verify that it is turned counterclockwise to 0V

and adjust T800 to make DC voltage of TP803

become 2.5 ± 0.1 V in the range.

Oscilloscope

Note:

Precaution:

DC voltage at TP803

5V

2.5V

Down

Adjust T800 to B point, between B'

and B". (Point A and C is NG.)

* Turn the coil counterclockwise for

the up direction and clockwise for

the down direction.

10k

100k

P C

For the 50Ω signal strength

gauge, when not using 50/75

impedance adapter, signal

strength is 52 ± 1 dBµV (75Ω

open), instead of 54 ± 1 dBµV

(75Ω open).

The loss of using impedance

adapter.

Fig. 1

E-9 CH

Fig. 2

BB"CUPB’A

1n60

29WF50

1000p

IF OUT

75ohm

-1.5+/-0.8dB

8-1 8-2

Page 7

9

No.

Adjustment point

1 SUB VOL

(BUS

ADJUSTMENT)

2 NOISE MUTE

CHECKING

No.

Adjustment point

1 VCO COIL

T2300

(SX68KF7)

SOUND ADJUSTMENT

Adjustment Condition / Procedure Waveform or others

1. Receive PAL Colour Bar signal.

Signal content: 400 Hz 100% Mod.

2. Connect the probel of the meter (*) to (SI) connector.

3. Select the SUB-VOL in the service mode.

4. Adjust the SUB-VOL data to make the meter

indicate 5.0 Vrms (at L-CH)

Adjustment value: 5.0± 0.3 Vrms

-0.05 Vrms

1. Receive the PAL Colour Bar signal.

2. Turn up the volume control to maximum, make

sure the sound is heard from the speakers.

Then put the unit in no signal state.

3. Check the sound mute is effective.

4. Finally turn sound level of CTV to minimum.

Note:The setting below is automatically set when the SUB-VOL

is selected in the service mode.

* SURROUND OFF

* S-NORMAL state

* S-VOL Max

* Bass + OFF

SIF(NICAM/IGR) ADJUSTMENT

Adjustment Condition / Procedure Waveform or others

1. Receive the PAL Colour Bar signal.

(Set the receiving frequency at AFT OFF VHF

high frequency.)

2. Connect the digital voltmeter to TP2300 or pin

(1) of SC200 (in the main unit).

3. Verify that it is turned counterclockwise to 0V

and clockwise to 5V , and adjust T2300 to make

the DC voltage of TP2300 become 2.5 ± 0.1 V

in the range.

* Single-unit adjustment

Vcc 5 ± 0.1V

IF input frequency 38.9MHz ± 10kHz. Control it

under these conditions.

Adjust T2300 to make the DC voltage of TP2300

(in the NICAM unit) become 2.5 ± 0.1V.

After single-unit adjustment, check the practical

setup.

Align the receiving frequency to the select channel frequency. (AFT OFF)

The checked voltage must be2.5 ± 1.0V.

(Take care that ± 1.0 is considered for the Vcc

difference between the single unit and unit, Fo

difference and so on, but is not the adjustment

precision.)

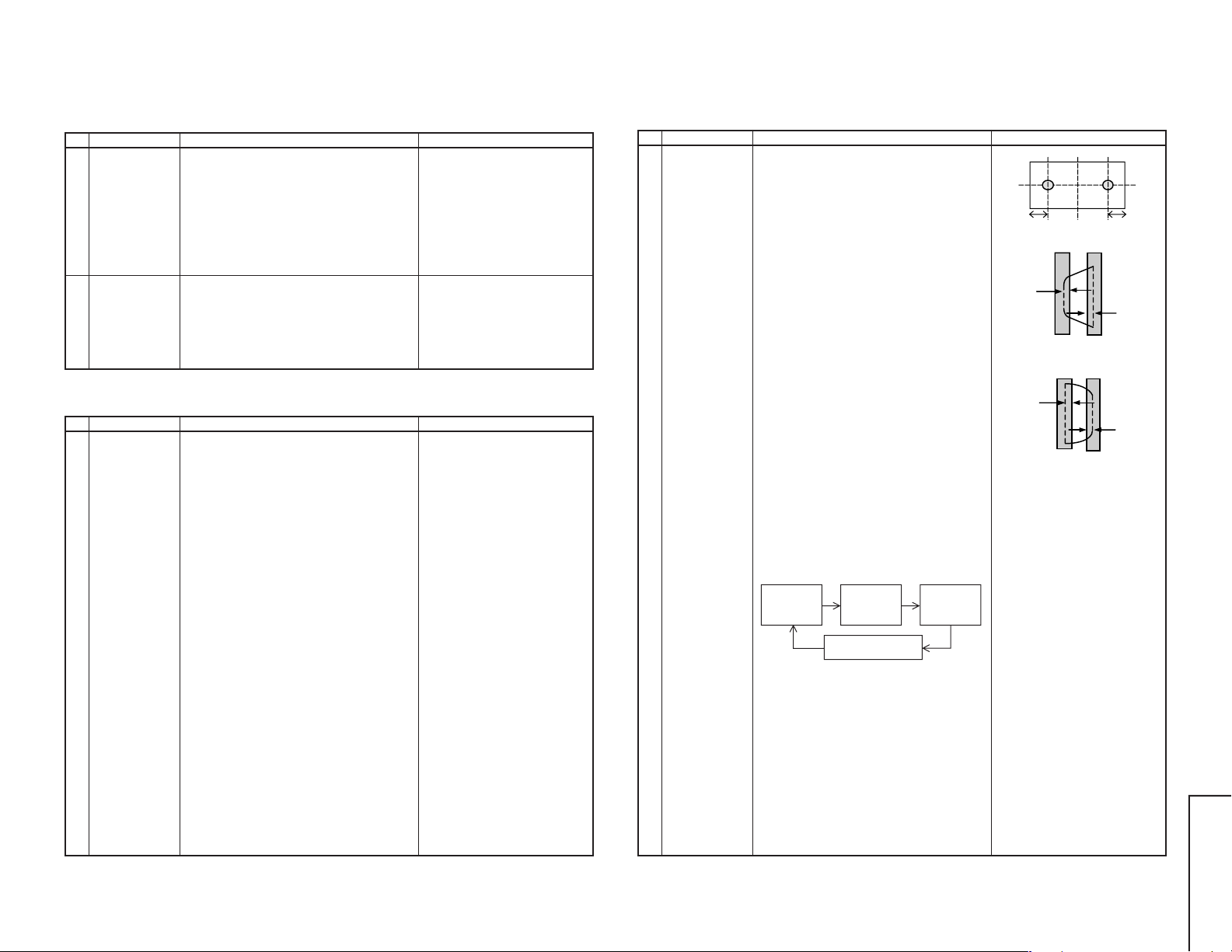

No.

Adjustment point

1 PURITY

ADJUSTMENT

PURITY ADJUSTMENT

Adjustment Condition / Procedure Waveform or others

1. Select the green monocolour screen with remote controller, and set the beam current to

1.6mA with the contrast control.

2. Degauss the CRT enough with the degaussing coil.

Note: Follow the job instruction sheet to ad-

just the magnetic field.

*BH = 0

*Bv = refer to the job intructions sheet.

3. The purity magnet must be previously set at

the zero magnetic field and the convergence

must be roughly adjusted.

With P-Mag, adjust it to the center: rank A.

4. Observe the points a, b, as shown in Fig.4-1

through the microscope. Move DY fore and aft

to set the landing at the point (rank A).

5. If the a/b balance is poor, compensate it to the

center "Rank AB".

6. Align it to zero, keeping the raster rotation in

the east direction.

7. Tighten up the deflection coil screws.

Tightening torque : 180 ± 20N (18 ± 2Kgf)

8. Checking the CRT corner area, bond the magnet sheet to set the landing at Rank A for compensation.

Note: Apply the adjustment after aging with the

beam current 1,600 ± 50µA or more for

30 minutes or more.

Note: Select the service mode, and press the

monocolour key of R/C for process, and

the monocolour screen (green) will be

selected.

* Every push of the monocolour key, changes the

screen as follows.

Monocolour

Screen

GREEN

* Adjustment for uniformity is change to another

content. Please refer to the following page.

Monocolour

Screen

BLUE

Monocolourscreen

Release

Monocolour

Screen

RED

a

90 mm 90 mm

Fig. 4-1

A

Fig. 4-2 Rank A (On the right of CRT)

A

Fig. 4-3 Rank A (On the left of CRT)

* Continuosly press the

monocolour key 1 second or

more, and the monocolour mode

will be selected without the service mode.

b

A=B

B

B

A=B

29WF50

9-1 9-2

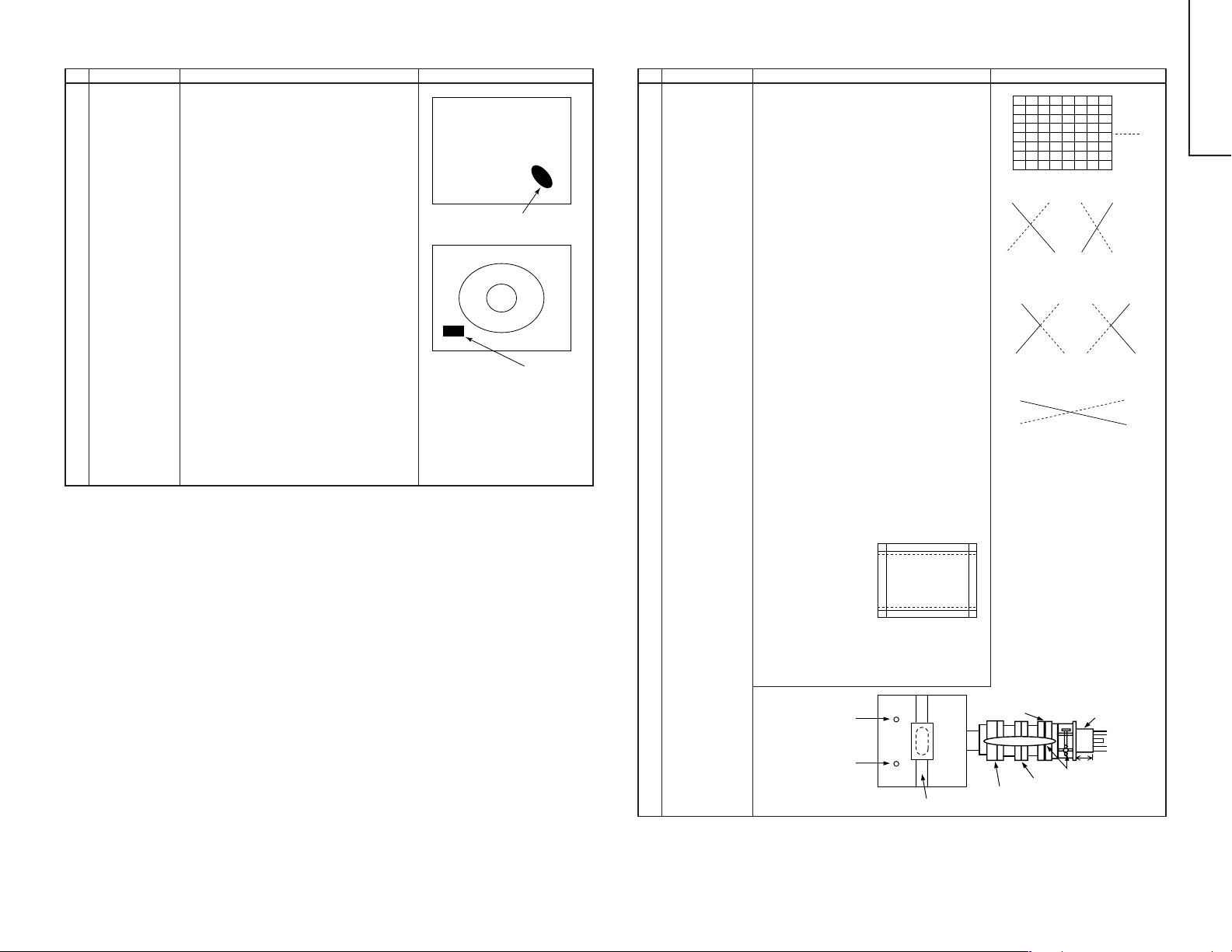

Page 8

10

No.

Adjustment point

1 UNIFORMITY

ADJUSTMENT

(To perform

after the purity

and convergence

adjustment)

UNIFORMITY ADJUSTMENT

Adjustment Condition / Procedure Waveform or others

Before adjustment begin, Horizontal magnetic

field=0G, Vertical magnetic field = 0.1G.

Make sure degauss it.

North Direction Red Uniformity

1. Horizontal mf = Set to monocolour screen Red

and adjust to +0.25G.

2. Pay attention to the edge of CRT, if the landing is poor, adjust by attaching the compensation magnet at the back of CRT . Refer to Fig.5.

South Direction Red Uniformity

1. Horizontal mf = Set to monocolour screen Red

and adjust to -0.25G.

2. Pay attention to the edge of CRT, if the landing is poor, adjust by attaching the compensation magnet at the back of CRT.

The same method is applied for adjustment of

monocolour screen Blue for blue uniformity, and

changing both the magnetic field for north and

south direction.

* During the pasting of compensation magent,

use the crosshatch pattern signal.

Make sure there is no blur or bend lines occur.

If the blur or bend lines are serious, adjust the

location of compensation magnet to make it

better.

(CRT surface)

(CRT back)

Compensation magnet

Miss landing

Fig.5

No.

Adjustment point

CONVER-

1

GENCE ADJ

(To be done

after the purity

adjustment.)

CONVERGENCE ADJUSTMENT

Adjustment Condition / Procedure Waveform or others

(1)Receive E-2CH (the Crosshatch pattern).

(2)Using the remote controller, call NORMAL

mode.

Static Convergence Adjustment

1. Overlap blue and red with the open-/closing

angle and rotation of the 4 pole magnet.

2. Overlap green on blue and red with the open/closing angle and rotation of the 6 pole magnet.

Dynamic Convergence Adjustment

1. Fix the wedges in a position so that the deflection yoke neck is at the center of top bottom and left right. (Straight line and without

any blur horizontal / vertical line)

2. Adjust the Red, Blue, upper and lower of the

center y axis on the screen by using the Volume (YH,YHC) at the deflection yoke.

Refer to Fig. 6-2 and Fig. 6-3

3. If the Horizontal Red. Blue (XV) on the screen

center X axis is shifted, correct the Red. Blue

(XV) by adjusting the balance coil on the deflection yoke.

Refer to Fig.6-4.

4. After confirm that there is no problems on the

entire screen, bond wedge on CRT and glass

tape on it. Fastening the screws of DY and

magnet unit (purity, 4-pole and 6 pole), then

coat the lacquer paint on DY fastening screw

and magnet unit fastening screw.

Note:In case of poor convergence adjustment

on the top and bottom of the screen, adjust DY by swing rightward and leftward.

Refer to Fig.6-1

Y axis

B

R

Fig. 6-2

Adjust by YHC

B

R

Fig. 6-3

Adjust by YH

Fig. 6-4

Adjust by Balance Coil

29WF50

X axis

RB

RB

B

Adjust by swing DY

Note:For CRT drawing, please refer to following

page.

YHC

YH

10-1 10-2

Fig. 6-1

Balance Coil

6-Pole Magnet

Purity Magnet

Lacquer

4-Pole Magnet

CRT Neck

25 ± 0.5mm

Page 9

11

No.

Adjustment point

1 DYNAMIC

FOCUS

ADJUSTMENT

L1680

(in the power

unit)

2

FOCUS

ADJUSTMENT

FBT FOCUS

VR

FOCUS ADJUSTMENT

Adjustment Condition / Procedure Waveform or others

1. Receive E-5CH (Monoscope pattern).

2. With the remote controller, make it normal.

3. Connect the oscilloscope to the pin (8) of

T1680.

4. Turning L1680, adjust the amplitude of the

horizontal frequency waveform to 1,000Vp-p.

1,000 – 50Vp-p

V-FREQ

1. ReceiveE-5CH (Monoscope pattern).

2. With the remote controller, make it normal.

3. Adjust the focus VR-1(F1) to make the horizontal line around "575" on the bottom left of

the screen as fine as possible.

4. Adjust the focus VR-2(F2) to make the vertical line around "575" on the bottom left of the

screen as fine as possible.

5. Repeat item 3 once again to adjust the focus.

Approx. 1,000Vp-p

No.

Adjustment point

2 WHITE

BALANCE

BACKGROUND

(CUT OFF

BKGD)

2

I

C BUS

ADJUSTMENT

(AV SIGNAL)

CUT OFF, BKGD, SUB-CONT ADJUSTMENT

Adjustment Condition / Procedure Waveform or others

1. Receive E-5CH (Monoscope pattern).

2. Select P-NORM with the remote controller.

3. Connect the beam ammeter between TP1601

and TP1602.

4. Coarsely adjust the beam current to approx.

1.8mA with R1633 (Sub-Contrast VR)

5. Receive the window pattern signal with AV input.

(PAL burst is generated with the signal generator.)

6. With the data of G-drive and B-drive, adjust

the colour temperature 12,300°K of the white

peak to white.

7. Adjust the right dark area of the window to

12,300°K with R-cut off, G-cut off and B-cut

off.

8. Readjust the colour temperature at the white

peak.

9. Check 12,300°K at the low white.

Note : Apply this adjustment after aging with the

beam current 1,600 ± 50µA or more for

30 min or more.

(On the white or green monocolour

screen.)

* The colour temperature is based on the ship-

ment initial setting table.

Note1:

R CUT OFF UP "1" KEY

DOWN "4" KEY

G CUT OFFUP "2" KEY

DOWN "5" KEY

B CUT OFF UP "3" KEY

DOWN "6" KEY

Data up/down is possible with the

above comparison.

* 12,300°K X : 0.272

Y : 0.275

(With Monolta colour thermometer

CA-100)

Note2:

G-DRIVE UP "7" KEY

DOWN "

B-DRIVE UP "8" KEY

DOWN "0" KEY

Data up/down is possible with the

above comparison.

" KEY

No.

Adjustment point

CRT CUTOFF

1

(CUT OFF

BKGD)

SERVICE

MODE I

DATA

ADJUSTMENT

CUT OFF, BKGD, SUB-CONT ADJUSTMENT

Adjustment Condition / Procedure Waveform or others

2

C BUS

1. Receive E-5CH (Monoscope pattern).

2. Select P-NORM with the remote controller.

3. Turn on the service SW, and select the CUT

OFF BKGD mode.

4. Select the screen VR 0/10.

5. Press "-/--" key of the remote controller to select the horizontal centering mode.

6. Turn the screen VR clockwise, and adjust the

first lightinghorizontal centering raster to slightly

light.

7. Adjust the CUT OFF data of two other colours,

and coarsely adjust the horizontal centering

to become white. (Note 1)

8. Turn the screen VR in the opposite direction

to the point where the horizontal centering

raster goes out.

Note 1: Apply the adjustment after aging with

the beam current 1,600 ± 50µA or

more for 30 min or more.

9. Press "-/--" key of the remote controller to select the normal mode.

11-1 11-2

* Before doing the adjustment,

make sure the R/G/B-cut and B/

G-Drive is at initial values.

On the monocolour screen of white

or green.

3 WHITE

BALANCE

BACKGROUND

(CUT OFF DVD

BKGD)

2

C BUS

I

ADJUSTMENT

(DVD SIGNAL)

4 MAX BEAM

R1759

1. Receive the window pattern with DVD signal

(component signal).

2. Apply the adjustment in the same manner as

2 (5) and the subsequence above. (12,300°K)

(G-DRIVE, B-DRIVE, R-CUT OFF, G-CUT

OFF, B-CUT OFF)

Apply the adjustment after the end of 2.

1. Receive E-5CH (Monoscope pattern) with

standard mode.

2. Make the image normal with the remote controller. (AV mode: DYNAMIC)

3. Connect the beam ammeter between TP1601

and TP1602.

Ammeter full scale-3mA range

Connect the - side of the ammeter to TP1602.

Connect the + side of the ammeter to TP1601.

4. Adjust the beam current to 1.8mA ± 20µA with

R1759 (sub-contrast VR).

Note: Apply the adjustment after aging with the

beam current 1,600 ± 50µA or more for 30

min or more.

(On the white or green monocolour screen.)

Note : Use the window pattern of

the signal generator for

adjustment.

(PAL, colour burst is generated with

signal generator)

29WF50

Page 10

12

No.

Adjustment point

5 SUB-

CONTRAST

(SUB-CONT)

2

C BUS

I

ADJUSTMENT

(AV SIGNAL)

6 SUB-

CONTRAST

(SUB-CONT

DVD)

I2C bus

adjustment

(DVD Signal)

7 SUB-

BRIGHTNESS

ADJUSMENT

(SUB BRI)

2

(I

C BUS

CONTROL)

(AV SIGNAL)

SUB-

8

BRIGHTNESS

(SUB BRI

DVD)

2

C bus

I

adjustment

(DVD SIGNAL)

CUT OFF, BKGD, SUB-CONT ADJUSTMENT

Adjustment Condition / Procedure Waveform or others

1. Receive the window pattern signal with AV input.

2. Make the image normal with the remote controller. (AV mode: DYNAMIC)

3. Select the SUB-CONTRAST adjustment mode

with the remote controller, and adjust 50%

white to 165 ± 10 cd.

1. Select the DVD mode.

2. Receive the signal of the DVD signal generator. (Component signal) (Window pattern)

3. Make the picture normal with the remote controller. (AV mode: DYNAMIC)

4. Select the SUB-CONTRAST adjustment mode

(DVD) with the remote controller, and adjust

50% white to 165 ± 10 cd.

1. Receive the window pattern signal with AV input.

2. Make the image normal with the remote controller. (AV mode: DYNAMIC)

3. Select the sub-bright adjustment mode with the

remote controller, and adjust the right dark

white area of the window pattern to 5.5 ± 0.5

cd.

1. Select the DVD mode.

2. Receive the signal of the DVD signal generator. (Component signal) (Window pattern)

3. Make the picture normal with the remote controller. (AV mode: DYNAMIC)

4. Select the SUB-BRIGHT adjustment mode

(DVD) with the remote controller, and adjust

the right dark white area of window pattern to

5.5 ± 0.5 cd of window pattern.

Note:

Use "Y" of Minolta colour

analyzer CA-100 in adjustment.

Note:

Use the PAL window pattern of

the signal generator for adjustment.

(PAL and colour burst are provided.)

Note:

Window pattern

50%white for SUB-CONT

* When E-2CH (Crosshatch pat-

tern) or equivalent signal is

receiived.

1. Make the image normal with the

remote controller.

2. Adjust the 3rd (1 thru 5 from the

left) black of the window pattern

to sink.

CUT OFF POINT

Dark white for

SUB-BRIGHT

HORIZONTAL, VERTICAL, DEFLECTION LOOP AND ADJUSTMENT

No.

Adjustment point

1 V-AMP 50

V-LINE 50

V-S CORR50

V-CENT50

Adjustment Condition / Procedure Waveform or others

Adjust the overscan to 8.5%. (E-5)

Adjust the linearity to the best.

Already preset. (Adjust this unless the linearity is

achieved.)

The receiving channel in ( ) are the

following signals.

(E-2) : Crosshatch (50Hz)

(E-5) : Monoscope (50Hz)

Align the center of the screen to the geometric

center of CRT. (E-5)

H-CENT50

Align the center of the screen to the geometric

center of CRT. (E-5)

H-SIZE50

E/W-P AR50

Adjust the overscan to 8.5%. (E-5)

Adjust the 2nd vertical line from the left end of

crosshatch pattern so that the middle 4 blocks

EW-COR50

are straight. (E-2) (refer to Fig.7-1)

Adjust the 2nd vertical line from the left end of

Fig.7-1

crosshatch pattern so that the top are straight.(E-

2) (Refer to Fig.7-2)

TRAPE50

Adjust the 2nd vertical line from the left end of

crosshatch pattern so that the D1 (centre area of

the second vertical line-edge of screen) and D2

(top area of the second vertical line-edge of

screen) are same. (Refer to Fig.7-3)

V-ENT

H-ENT

OTHER

Already preset.

Already preset.

On the items of V-AMP60, V-LINE60, V-S

CORR60, V-CENT60, H-CENT60, H-SIZE60,

Fig.7-2

D2

D1

EW-P AR60, EW-COR60 andTRAPE60, the compensation data is automatically input if the 50Hz

mode adjustment is done.

2

C BUS

I

ADJUSTMENT

Attention:

Don't change 50 Hz mode data after adjust

60 Hz mode data. Because 60 Hz mode

data follow 50 Hz mode data automatically.

However, if it is largely deviated

when it is checked in the 60Hz

mode, readjust it in the 60Hz mode.

Fig.7-3

PAL CHROMA ADJUSTMENT

No.

Adjustment point

1 SUB COLOUR

2

C BUS

(I

CONTROL)

(RF signal)

Adjustment Condition / Procedure Waveform or others

1. Receive the E-10CH (PAL Colour Bar).

2. Make the picture normal with the remote con-

75%W

Y

100%W

troller.

3. Connect the oscilloscope to TP802 (pin (4) of

KY) (Use Probe10:1)

Range : 2V/Div

Sweep time : 20µ sec/Div

Cy G

4. Set the "SUB-COL" adjustment mode with the

remote controller, and vary the sub colour data

to make 75% W of the PAL colour bar and RED

Fig. 8

at the same level for adjustment shown in Fig.

8.

Mg

R

B

29WF50

12-1 12-2

Page 11

No.

Adjustment point

1 SUB-TINT

(SUB TINT)

2

C BUS

(I

CONTROL)

(AV SIGNAL)

NTSC CHROMA ADJUSTMENT

Adjustment Condition / Procedure Waveform or others

1. Select the sub-tint adjustment mode (automatic

Y cut) to receive the NTSC colour bar signal

with AV input.

2. Connect the oscilloscope to TP801.

Range : 50mV/Div (AC)

(Use Probe 10:1)

Sweep time : 10µsec/Div

3. Vary the sub tint data to adjust the waveform

to be gained as shown in Fig 9.

TP801………………(KY) 6 pin

A

B

C

W Y Cy G Mg R B Blk

A=B=C

Fig.9

FUNCTION OPERATION CHECKING (1) (VIDEO & AUDIO)

No.

Adjustment point

CONTRAST

1

Key

2 COLOUR Key 1. Receive the Colour Bar signal.

Adjustment Condition / Procedure Waveform or others

1. Receive the Monoscope Pattern signal.

2. Press to Menu mode, then select Picture Mode

and set to select CONTRAST .

3. Press Volume Up/Down key to check whether

the CONTRAST effect is OK or not.

2. Press to Menu mode, then select Picture Mode

and set to select COLOUR.

3. Press Volume Up/Down key to check whether

the COLOUR effect is OK or not.

13

No.

Adjustment point

1 SECAM

BLACK LEVEL

R-Y/B-Y

2

C BUS

I

ADJUSTMENT

SECAM CHROMA ADJUSTMENT

Adjustment Condition / Procedure Waveform or others

1. Receive "SECAM colour bar" signal.

2. Select SECAM black level adjustment R-Y

mode.

3. Connect the oscilloscope to pin(20) of

IC800(TP802/R out).

• Range : 10mV/Div.

•Sweep time : 20 µsec/Div.

(Use Probe 10:1)

4. Vary R-Y data to minimize the offset between

the non-signal line and signal line as shown in

Fig.10-1(b)

5. Select SECAM black level adjustment B-Y

mode.

6. Reconnect the oscilloscope to TP801...(KY)

6pin

• Range : 10mV/Div.

• Sweep time : 20 µsec/Div.

(Use Probe 10:1)

7. Vary B-Y data to minimize the offset between

the non-signal line and signal line as shown in

Fig.10-2(b)

Fig. 10-1(a)

Fig. 10-1(b)

Fig. 10-2(a)

OFF SET

OFF SET

3 BRIGHTNESS

Key

4 TINT Key 1. Receive the NTSC Colour Bar signal thru AV

5 SHARPNESS

Key

6 NORMAL Key 1. Once in PICTURE Mode, and the NORMAL

7 WHITE TEMP 1. Receive the Monoscope Pattern signal.

1. Receive the Monoscope Pattern signal.

2. Press to Menu mode, then select Picture Mode

and set to select BRIGHTNESS.

3. Press Volume Up/Down key to check whether

the BRIGHTNESS effect is OK or not.

input.

2. Press to Menu mode, then select Picture Mode

and set to select TINT.

3. Press Volume Up/Down key to check TINT , UP

for GREEN direction and DOWN for RED direction whether is OK or not.

1. Receive the Monoscope Pattern signal.

2. Press to Menu mode, then select Picture Mode

and set to select SHARPNESS.

3. Press Volume Up/Down key to check whether

the SHARPNESS effect is OK or not.

key is pressed, all the settings will be present

to normal setting.

(Normal setting value for every mode, refer on

page 8.)

2. Set FUNCTION to select WHITE TEMP .

3. Press Volume Up/Down key to check WHITE

TEMP Option, STANDARD: NORMAL SETTING, WARM for more REDDISH direction

changing, COOL for more BLUISH direction

changing.

Note:

If nothing is display mean contrast,

colour, brightness, tint, sharpness

are all in normal setting.

29WF50

Fig. 10-2(b)

13-1 13-2

Page 12

FUNCTION OPERATION CHECKING (2) (VIDEO & AUDIO)

No.

Adjustment point

8 COLOUR

SYSTEM

Adjustment Condition / Procedure Waveform or others

1. Receive the "PAL COLOUR BAR" signal,

press the COLOUR SYSTEM key to select

modes except PAL, check the COLOUR is not

working properly. Then, select the "P AL" mode.

Check again its colour so that it is working

properly.

2. Receive "SECAM COLOUR BAR" signal,

press COLOUR SYSTEM key to select modes

except SECAM, check the COLOUR is not

working properly. Then, select the "SECAM"

mode. Check again its colour so that it is working properly.

3. Receive “NTSC 3.58” signal, press COLOUR

SYSTEM key to select modes except

NTSC3.58, check the COLOUR is not working properly. Then, select the “NTSC 3.58”

mode. Check again its colour so that it is working properly.

4. Receive “NTSC 4.43/3.58 COLOUR BAR” signal thru AV, press COLOUR SYSTEM key to

select modes except N4.43, check the COLOUR is not working properly. Then, select the

“NTSC 4.43” mode. Check again its colour so

that it is working properly.

PROTECTOR OPERATION CHECK

No.

Checking Item

H.V Protector 1. Receive E-5CH (Monoscope pattern).

1

Other

2

protectors

Adjustment Condition / Procedure Waveform or others

2. Connect the bias box to the cathode side

(R1662 side) of D1621.

3. Set the voltage of the bias box at 15V, and

verify that the protector does not operate.

4. Set the voltage of the bias box at 24V, and

verify that the protector does operate.

Correspondence for short circiut of smoothening

electrolysis of +B line and so on.

To check the operation of the protector and so

on, take care for the breakage, deterioration and

so on of each element.

29WF50

Reference Approx. 17.7 V as ordinary.

14

SOUND

9

SYSTEM

10

HEADPHONE

OUTPUT

CHECKING

1. Receive “PAL-D/K” signal, press the “SOUND

SYSTEM” to select B/G, I. Check the sound

output is not working properly. Select D/K and

check the sound output to make sure it is working properly.

2. Receive “PAL-I” signal, press the “SOUND

SYSTEM” to select B/G, D/K. Check the sound

output is not working properly. Select I and

check the sound output to make sure it is working properly.

3. Receive “PAL-B/G” signal, press the “SOUND

SYSTEM” to select I, D/K. Check the sound

output is not working properly. Select B/G and

check the sound output to make sure it is working properly.

1. Receive the PAL Colour Bar signal with sound

400 Hz, 100% modulation (± 50kHz Dev)

2. Maximum volume, and check the headphone

output with 400 Hz sound and no sound out

from speaker.

(Ref: Output Level of Headphone is as Follow-

ing:)

SUB-VOL Adj. H/P Output (Open)

63 1.0 Vp-p

40 500 mVp-p

14-1 14-2

Page 13

29WF50

CHASSIS LAYOUT

H

G

F

E

D

C

B

A

654321

20

Page 14

BLOCK DIAGRAM-1

H

CRT Unit

G

F

29WF50

E

D

C

B

A

654321

21

Page 15

29WF50

BLOCK DIAGRAM-2

PWB-A MAIN Unit -1/2

H

G

F

29WF50

E

D

C

B

A

22

87109654321

23

1716 19181514131211

Page 16

29WF50

BLOCK DIAGRAM-3

PWB-A MAIN Unit -2/2

H

G

F

29WF50

E

D

C

B

A

24

87109654321

25

1716 19181514131211

Page 17

29WF50

BLOCK DIAGRAM-4

29WF50

H

POWER Unit

G

F

E

D

C

B

A

26

87109654321

1716 19181514131211

27

Page 18

29WF50

BLOCK DIAGRAM-5

H

G

F

NICAM Unit

E

D

C

B

A

654321

28

Page 19

BLOCK DIAGRAM-6

H

G

F

29WF50

OPERATION Unit

E

D

C

B

A

654321

29

Page 20

29WF50

WAVEFORMS

30

Page 21

29WF50

SCHEMATIC DIAGRAM: MAIN-1 Unit

H

G

F

29WF50

E

D

C

B

A

32

87109654321

33

1716 19181514131211

Page 22

29WF50

SCHEMATIC DIAGRAM: MAIN-2 Unit

H

G

F

29WF50

E

D

C

B

A

34

87109654321

35

1716 19181514131211

Page 23

29WF50

SCHEMATIC DIAGRAM: POWER Unit

H

G

F

29WF50

E

D

C

B

A

36

87109654321

37

1716 19181514131211

Page 24

29WF50

SCHEMATIC DIAGRAM: CRT Unit

H

G

F

E

D

C

B

A

654321

38

Page 25

SCHEMATIC DIAGRAM: NICAM Unit

H

G

F

29WF50

E

D

C

B

A

654321

39

Page 26

29WF50

SCHEMATIC DIAGRAM: OPERATION Unit

H

G

F

E

D

C

B

A

654321

40

Loading...

Loading...