Page 1

27DV-S100

27DV-CS10

SERVICE MANUAL

S81Z627DV-S10

TV/VCR/DVD COMBINATION

Chassis No. B00A

27DV-S100

MODELS

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

CONTENTS

» IMPORTANT SERVICE SAFETY PRECATION ....................................................................................... 2

» SAFETY PRECAUTIONS ........................................................................................................................ 6

» ELECTRICAL SPECIFICATIONS ............................................................................................................ 7

» LOCATION OF USER'S CONTROL ........................................................................................................ 8

» DISASSEMBLY AND REASSEMBLY..................................................................................................... 12

» INSTALLATION AND SERVICE INSTRUCTIONS ................................................................................. 16

» PRECAUTIONS IN REASSEMBLING ................................................................................................... 22

» FUNCTION OF MAJOR MECHANICAL PARTS.................................................................................... 23

» ADJUSTMENT, REPLACEMENT AND ASSEMBLY OF MECHANICAL UNITS.................................... 25

» ADJUSTMENT OF THE VCR ELECTRICAL CIRCUITRY..................................................................... 45

» TEST MODE OF DVD SECTION........................................................................................................... 47

» TROUBLESHOOTING........................................................................................................................... 50

» CHASSIS LAYOUT................................................................................................................................. 72

» IC FUNCTION LIST OF DVD SECTION ................................................................................................ 74

» BLOCK DIAGRAM OF TV SECTION.....................................................................................................94

» BLOCK DIAGRAM OF VCR SECTION .................................................................................................. 96

» BLOCK DIAGRAM OF DVD SECTION................................................................................................ 106

» OVERALL SCHEMATIC DIAGRAM ..................................................................................................... 108

» DESCRIPTION OF SCHEMATIC DIAGRAM....................................................................................... 110

» PRINTED WIRING BOARD ASSEMBLIES.......................................................................................... 143

» REPLACEMENT PARTS LIST ............................................................................................................. 155

» PACKING OF THE SET ....................................................................................................................... 185

27DV-CS10

Page

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

1

Page 2

27DV-S100

27DV-CS10

IMPORTANT SERVICE SAFETY PRECAUTION

Ë Service work should be performed only by qualified service technicians who are thoroughly

familiar with all safety checks and servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

3. Semiconductor heat sinks are potential shock hazards

when the chassis is operating.

4. The chassis in this receiver has two ground systems

which are separated by insulation material. The nonisolated (hot) ground system is for the +B voltage

regulator circuit and the horizontal output circuit.The

isolated ground system is for the low +B DC v oltages

and the secondary circuit of the high voltage

transformer .

To prevent electrical shock use an isolation

transformer between the line cord and power

receptacle, when servicing this chassis.

CAUTION: FOR CONTINUED

PROTECTION AGAINST A

RISK OF FIRE, REPLACE

6.3A 125V

ONLY WITH SAME TYPE 6.3A125V FUSE.

SERVICING OF HIGH VOLTAGE SYSTEM

AND PICTURE TUBE

When servicing the high voltage system,

remove the static charge by connecting a

10k ohm resistor in series with an insulated

wire (such as a test probe) between the

picture tube ground and the anode lead. (A C

line cord should be disconnected from AC

outlet.)

1. Note that the picture tube in this receiver employs

integral implosion protection.

2. Replace with tube of the same type number for

continued safety.

3. Do not lift picture tube by the neck.

4. Handle the picture tube only when wearing

shatterproof goggles and after discharging the high

voltage anode completely.

X-RADIATION AND HIGH VOLTAGE LIMITS

1. Be sure all service personnel are aware of the

procedures and instructions covering X-radiation. The

only potential source of X-ray in current solid state

TV receivers is the picture tube. Howev er, the picture

tube does not emit measurable X-Ray r adiation if the

high voltage is as specified in the “High V oltage Check”

instructions.

It is only when high voltage is excessive that Xradiation is capable of penetrating the shell of the

picture tube including the lead in glass material. The

important precaution is to keep the high voltage below

the maximum level specified.

2. It is essential that servicepersonel have available at

all times an accurate high voltage meter.

The calibration of this meter should be checked

periodically.

3. High voltage should always be kept at the rated v alue

-no higher. Operation at higher voltages may cause

a failure of the picture tube or high voltage circuitry

and;also,under certain conditions, may produce

radiation that exceeds specifications.

4. When the high voltage regulator is operating properly

there is no possibility of an X-radiation problem. Every

time a color chassis is serviced, thebrightness should

be tested while monitoring the high voltage with a

meter to be certain that the high voltage does not

exceed the specified value and that it is regulating

correctly.

5. Do not use a picture tube other than that specified or

make unrecommended circuit modifications to the

high voltage circuitry.

6. When trouble shooting and taking test measurements

on a receiver with excessiv e high voltage , av oid being

unnecessarily close to the receiver.

Do not operate the receiver longer than is necessary

to locate the cause of excessive voltage.

2

Page 3

IMPORTANT SERVICE SAFETY PRECAUTION

2

2

(Continued)

27DV-S100

27DV-CS10

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user, perform

the following safety checks.

1. Inspect all lead dress to make certain that leads are

not pinched or that hardware is not lodged between

the chassis and other metal parts in the receiver.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators, etc.

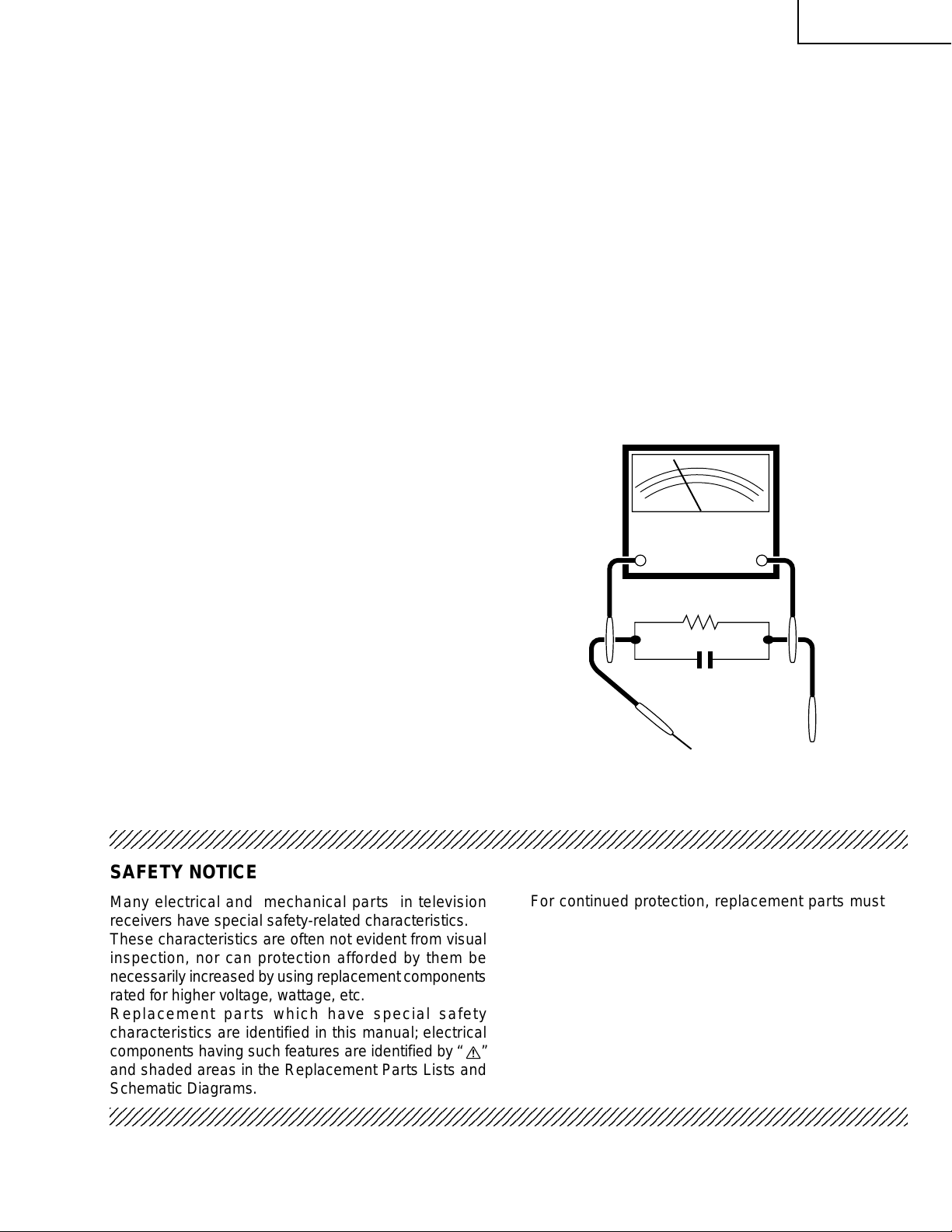

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

» Plug the AC cord directly into a 120 volt AC outlet,

(Do not use an isolation transformer for this test).

» Using to clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in series with

all exposed metal cabinet parts and a known earth

ground, such as electrical conduit or electrical ground

connected to earth ground.

» Use an AC voltmeter having with 5000 ohm per volt,

or higher, sensitivity to measure the A C v oltage drop

across the resistor.

» Connect the resistor connection to all exposed metal

parts having a return to the chassis (antenna, metal

cabinet, screw heads, knobs and control shafts,

escutcheon, etc.) and measure the AC voltage drop

across the resistor.

AII check must be repeated with the AC line cord

plug connection reversed. (If necessary, a nonpolarized adapter plug must be used only for the

purpose of completing these check.)

Any current measured must not exceed 0.5 milliamp.

Any measurements not within the limits outlined

above are indicative of a potential shock hazard and

corrective action must be taken before returning the

instrument to the customer.

AC

VOLTMETER

1.5k ohm

10W

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

CONNECT TO

KNOWN EARTH

GROUND

SAFETY NOTICE

Many electrical and mechanical parts in television

receivers have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have special safety

characteristics are identified in this manual; electrical

components having such features are identified by “ å”

and shaded areas in the Replacement Parts Lists and

Schematic Diagrams.

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

For continued protection, replacement parts must be

identical to those used in the original circuit. The use of

a substitute replacement parts which do not have the

same safety characteristics as the factory recommended

replacement parts shown in this service manual, may

create shock, fire, X-radiation or other hazards.

3

Page 4

27DV-S100

27DV-CS10

PRECAUTIONS A PRENDRE LORS DE LA REPARATION

Ë

Ne peut effectuer la réparation qu’ un technicien spécialisé qui s’est parfaitement

accoutumé à toute vérification de sécurité et aux conseils suivants.

AVERTISSEMENT

1. N’entreprendre aucune modification de tout circuit.

C’est dangereux.

2. Débrancher le récepteur avant toute réparation.

3. Les déversoirs thermiques à semi-conducteurs

peuvent présenter un danger de choc électrique

lorsque le réceqteur est en marche.

4. Le châssis de ce récepteur a deux systèmes de mise

à la terre qui sont séparés par un matériau isolant.

Le système de mise à la terre non-isolée (chaud) est

pour le circuit du régulateur de tension +B et le circuit

de sortie horizontale. Le système de mise à la terre

isolé est pour les basses tensions C. C . +B et le circuit

secondaire du transformateur de haute tension.

PRECAUTION: POUR LA

PROTECTION CONTINUE

CONTRE LES RISQUES

6.3A 125V

D'INCENDIE, REMPLACERLE

FUSIBLEPAR UN FUSIBLE DE

MEME TYPE 6.3-125V .

REPARATION DU SYSTEME A HAUTE

TENSION ET DU TUBE-IMAGE

Lors de la réparation de ce systéme, supprimer la

charge statique en branchant une résistance de 10

k en série a vec un fil isolé (comme une sonde

d’essai) entre la mise à la terre du tube-image et le

fil d’anodel. (Le corden d’alimentation doit être retiré

de la prise murale.)

1. Il est à noter que le tube-image de ce récepteur est

intégralement protégé contre l’implosion.

2. Par mesure de sécurité, changer le tube-image pour

un tube du même numéro de type.

3. Ne pas lever le tube-image par son col.

4. Ne manipuler le tube-image qu’en porant des lunettes

incassables et qu’après avoir déchargé totalement

la haute tension.

LIMITES DES RADIATIONS X ET DE LA

HAUTE TENSION

1. Tout le personnel réparateur doit être instruit des

instructions et procédés relatifs aux radiations X.

Le tube-image, seule source de rayons X dons les

téleviseurs transistorisés, n’émet pour tant pas de

rayons mesur ables si la haute tension est mainten ue

à un niveau préconisé dans la section “Vérification

de la haute tension”.

C’est seulement quand la haute tension est excessiv e

que les rayons X peuv ent entrer dans l’enveloppe du

tube-image y compris le conducteur de verre. Il est

important de maintenir la haute tension en-dessous

du niveau spécifié.

2. Il est essentiel que le réparateur ait sous la main un

voltmètre à haute tension qui doit être périodiquement

étalonné.

3. La haute tension doit toujours être maintenue à la

valeur de régime-et pas plus haute. L’opér ation à des

tensions plus élevées peut entraîner une panne du

tube-image ou du circuit à haute tension et, dans

certaines conditions, peut entraîner une radiation

dépassant les niveaux préscrits.

4. Quand le régulateur à haute tension fonctionne

correctement, il n’y a aucun problème de radiation X.

Chaque fois qu’un châssis couleurs est réparé, la

luminosité doit être examinée bout en contrôlant la

haute tension à l’aide d’un voltmètre pour s’assurer

que la haute tension ne dépasse pas la valeur

spécifiée et qu’elle soit correctement réglée.

5. Ne pas utiliser un tube-image autre que celui spécifié

et ne pas effectuer de modifications déconseillées

du circuit à haute tension.

6. Lors de la recherche des pannes et des mesures

d’essai sur un récepteur qui présente une haute

tension excessive, éviter de s’approcher inutilement

du récepteur.

Ne pas faire fonctionner le récepteur plus longtemps

que nécessaire pour localiser la cause de la tension

excessive.

4

Page 5

27DV-S100

2

2

27DV-CS10

PRECAUTIONS A PRENDRE LORS DE LA REPARATION

(Suite)

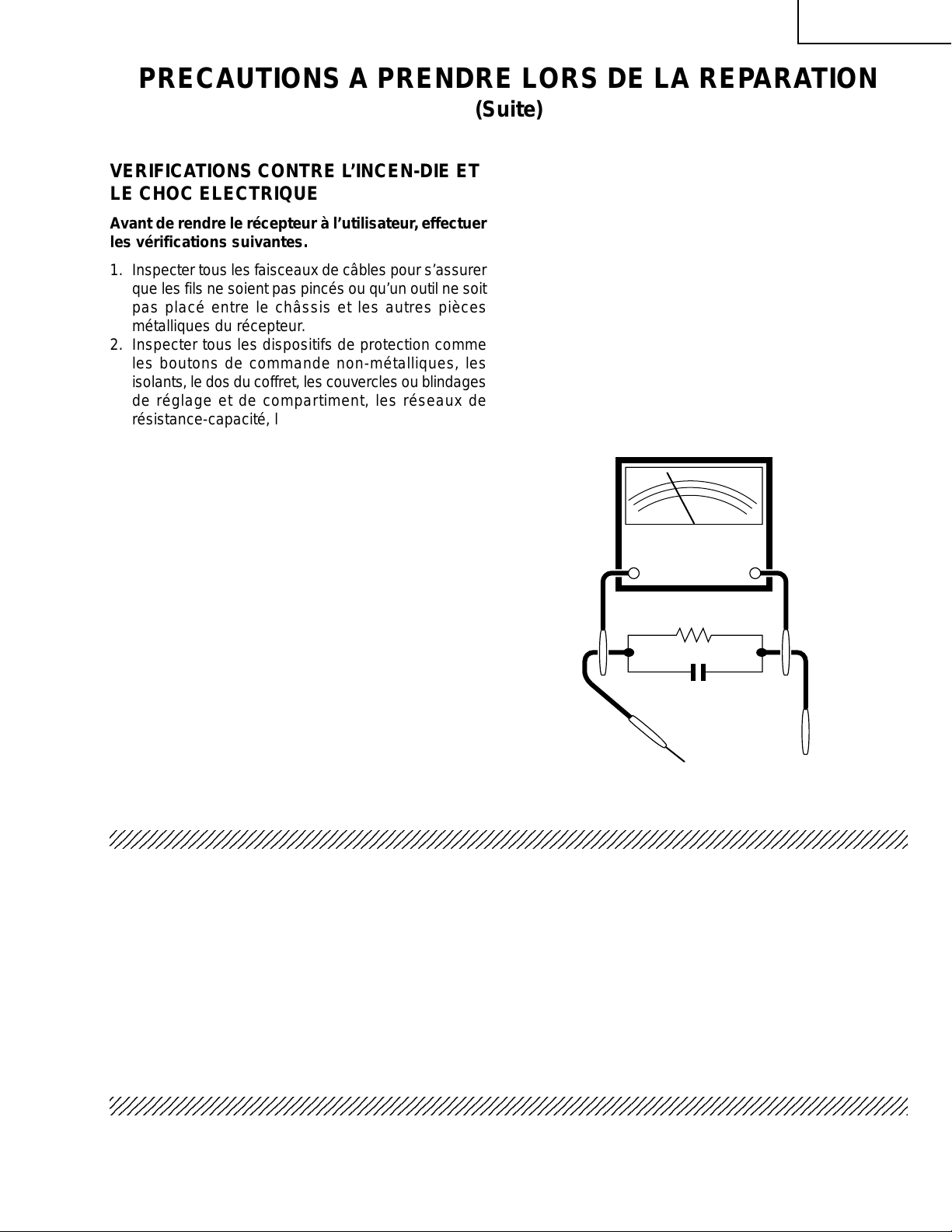

VERIFICATIONS CONTRE L’INCEN-DIE ET

LE CHOC ELECTRIQUE

Avant de rendre le récepteur à l’utilisateur, effectuer

les vérifications suivantes.

1. Inspecter tous les faisceaux de câbles pour s’assurer

que les fils ne soient pas pincés ou qu’un outil ne soit

pas placé entre le châssis et les autres pièces

métalliques du récepteur.

2. Inspecter tous les dispositifs de protection comme

les boutons de commande non-métalliques, les

isolants, le dos du coffret, les couvercles ou blindages

de réglage et de compar timent, les réseaux de

résistance-capacité, les isolateurs mécaniques, etc.

3. S’assurer qu’il n’y ait pas de danger d’électrocution

en vérifiant la fuite de courant, de la facon suivante:

» Brancher le cordon d’alimentation directem-ent à une

prise de courant de 120V. (Ne pas utiliser de

transformateur d’isolation pour cet essai).

» A l’aide de deux fils à pinces, brancher une résistance

de 1,5 k 10 w atts en parallèle avec un condensateur

de 0,15µF en série avec toutes les pièces métalliques

exposées du coffret et une terre connue comme une

conduite électrique ou une prise de terre branchée à

la terre.

» Utiliser un voltmètre CA d’une sensibilité d’au moins

5000 /V pour mesurer la chute de tension en tr avers

de la résistance.

» Toucher avec la sonde d’essai les pièces métalliques

exposées qui présentent une voie de retour au

châssis (antenne, coffret métallique, tête des vis,

arbres de commande et des boutons, écusson, etc.)

et mesurer la chute de tension CA en-travers de la

résistance.

Toutes les vérifications doivent être refaites après

avoir inversé la fiche du cordon d’alimentation. (Si

nécessaire, une prise d’adpatation non polarisée peut

être utilisée dans le but de terminer ces vérifications.)

Tous les courants mesurés ne doivent pas dépasser

0,5 mA.

Dans le cas contraire, il y a une possibilité de choc

électrique qui doit être supprimée avant de rendre le

récepteur au client.

Voltmètre CA

1.5k ohm

10W

0.15µF

SONDE D'ESSAI

AUX PIECES

METALLIQUES

EXPOSEES

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

BRANCHER A UNE

TERRE CONNUE

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans

les téléviseurs présentent des caractéristiques spéciales

relatives à la sécurité, qui ne sont souvent pas évidentes

à vue. Le degré de protection ne peut pas être

nécessairement augmentée en utilisant des pièces de

remplacement étalonnées pour haute tension,

puissance, etc.

Les pièces de remplacement qui présentent ces

caractéristiques sont identifiées dans ce manuel; les

pièces électriques qui présentent ces particularités sont

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

identifiées par la marque “ å “ et hachurées dans la

liste des pièces de remplacement et les diagrammes

schématiques.

Pour assurer la protection, ces pièces doivent être

identiques à celles utilisées dans le circuit d’origine.

L’utilisation de pièces qui n’ont pas les mêmes

caractéristiques que les pièces recommandées par

l’usine, indiquées dans ce manuel, peut provoquer des

électrocutions, incendies, radiations X ou autres

accidents.

5

Page 6

27DV-S100

27DV-CS10

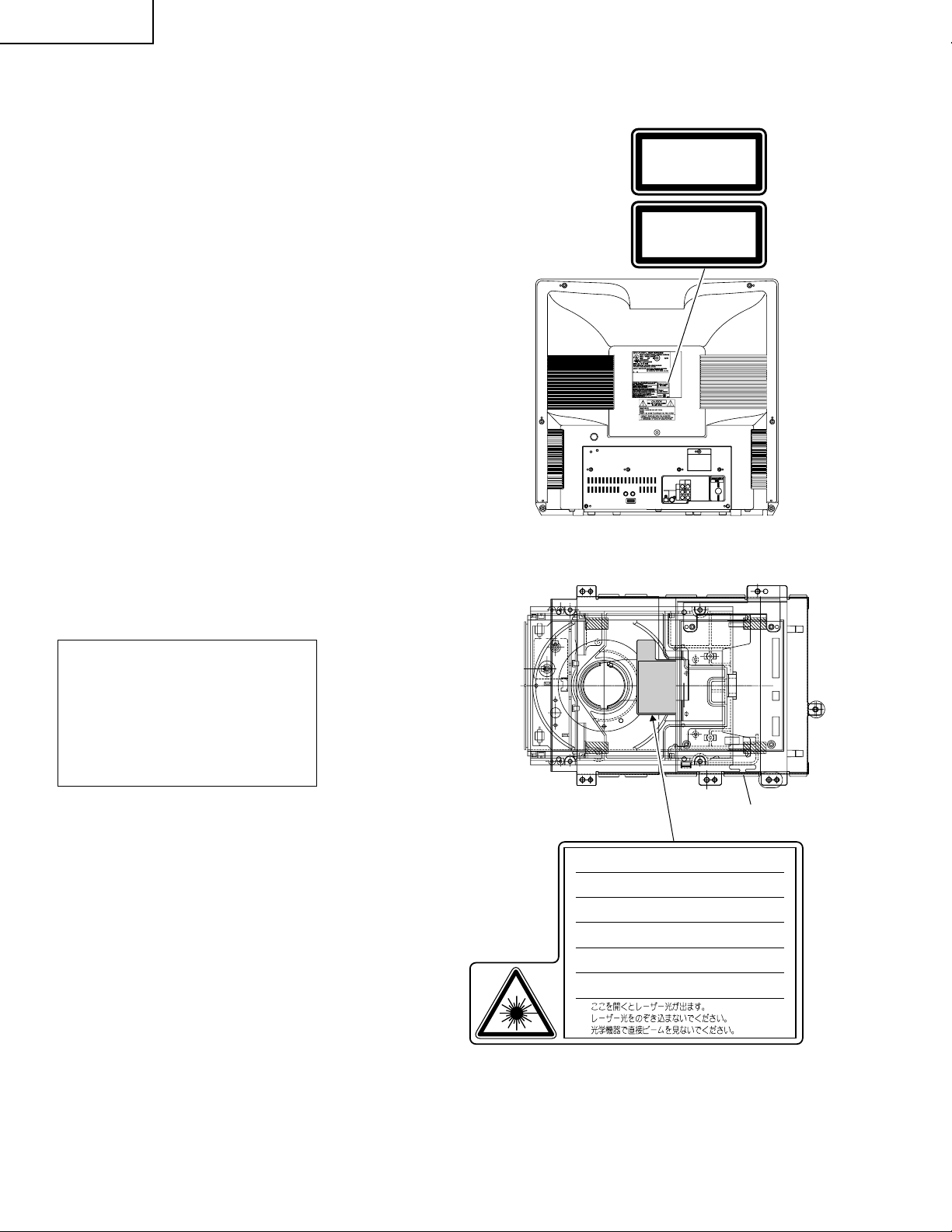

SAFETY PRECAUTIONS

Precaution to be taken when replacing and servicing

the Laser Pickup.

The product is a Class 1 Laser Product.

However Laser component is capable of emitting

radiation exceeding the limit for Class 1. It is important

that following precautions are observed during servicing

to protect your eyes against e xposure to the laser beam.

1. When the cabinet is removed, interlock is defeated

(if equipped), the power is turned on without a disk

in position, Do not look into the pickup lens.

2. The laser power output of the pickup unit and

replacement service par ts are all factory pre-set

before shipment.

Do not attempt to re-adjust the laser pickup unit

during replacement or servicing.

PRODUIT LASER

DE CLASSE 1

CLASS 1

LASER PRODUCT

3. Under no circumstances stare into the pickup lens

at any time.

4. Caution-Use of controls or adjustment or

performance of procedures other than those

specified herein may result in hazardous radiation

exposure.

» LASER SPECIFICATIONS

Laser Diode Properties

Material : AIGalnP

Wave length

D VD: 645~660nm

CD : 770~810nm

Emission Duration : Continuous

Laser output : Max. 0.6 mW

(Top View)

CAUTION-WHEN OPEN. DO NOT STARE INTO BEAM

OR VIEW DIRECTLY WITH OPTICAL INSTRUMENTS.

VARNONG-NÄR DENNA DEL ÄR ÖPPNAD. STIRRA EJ IN I STRÅLEN

OCH BETRAKTA EJ STRÅLEN MED OPTISKA INSTRUMENT.

ADVARSEL-VED ÅBNING. SE IKKE IND I

STRÅLEN-HELLER IKKE MED OPTISKE INSTRUMENTER.

VARO! AVATTAESSA OLET ALTTIINA. ÄLÄ TUIJOTA

SÄTEESEEN ÄLÄKÄ KATSO SITÄ OPTISEN LAITTEEN LÄPI.

VARNING-NÄR DENNA DEL ÄR ÖPPNAD. STIRRA EJ IN I STRÅLEN

OCH BETRAKTA EJ STRÅLEN GENOM OPTISKT INSTRUMENT.

ADVARSE-NÅR DEKSEL ÅPNES. STIRR IKKE INN I STRÅLEN

ELLER SE DIREKTE MED OPTISKE INSTRUMENTER.

(Back of product)

DVD Unit

NOTE:

Laser beam is emitted when this is open.

Do not stare into the beam.

Do not view the beam through any optical instrument,

either.

6

Page 7

ELECTRICAL SPECIFICATIONS

TV SECTION

POWER INPUT: 120 V AC 60 Hz

POWER RATING: 165 W

PICTURE SIZE

Width: 37.8 cm

Height: 38.7 cm

Depth: 37.5 cm

CONVERGENCE: Magnetic

SWEEP DEFLECTION: Magnetic

FOCUS: Hi-Bi-Potential Electrostatic

INTERMEDIATE FREQUENCIES

Picture IF Carrier Frequency: 45.75 MHz

Sound IF Carrier Frequency: 41.25 MHz

Color Sub-Carrier Frequency: 42.17 MHz (Nominal)

AUDIO POWER OUTPUT RATING: 3 W + 3 W (at 10% Distortion)

SPEAKER

Size: 8 cm (3-1")

Voice Coil Impedance: 16 ohm at 400 Hz

VHF/UHF ANTENNA INPUT IMPEDANCE: 75 ohm unbalanced

TUNING RANGES

VHF-Channels: 2 thru 13

UHF -Channels: 14 thru 69

CATV Channels: 1,14 thru 125 (EIA, Channel Plan)

27DV-S100

27DV-CS10

VCR SECTION

Video Recording System: Rotary Two-Head Helical Scanning

Number of Video Heads: 4 pcs.

Video Signal Standard: NTSC Color System

Maximum Recording Time: (SP)120 min (with T-120)

DVD SECTION

Playback-compatible discs: DVD (regional code "1"/"ALL"), Video CD (NTSC),

Operating Temperature: 5°C to 40°C (41°F to 104°F)

Storage Temperature: -20°C to 60°C (-4°F to 140°F)

Format: VHS Standard

Tape Width: 12.7mm (1/2inch)

Tape Speed: (SP)33.35mm/sec (1.31 i.p.s)

(LP)16.68mm/sec (0.66 i.p.s)

Play back only

(EP)11.12 mm/sec (0.44 i.p.s)

(EP)360 min (with T-120)

Video Input: 0.5 to 2.0 Vp-p, 75 ohm unbalanced

Audio Input: -8 dB, 47k ohm unbalanced (0 dB-0.775 Vrms)

CD, DA, MP3, Music CD

Signal system: NTSC

Specifications are subject to change without prior notice.

7

Page 8

27DV-S100

27DV-CS10

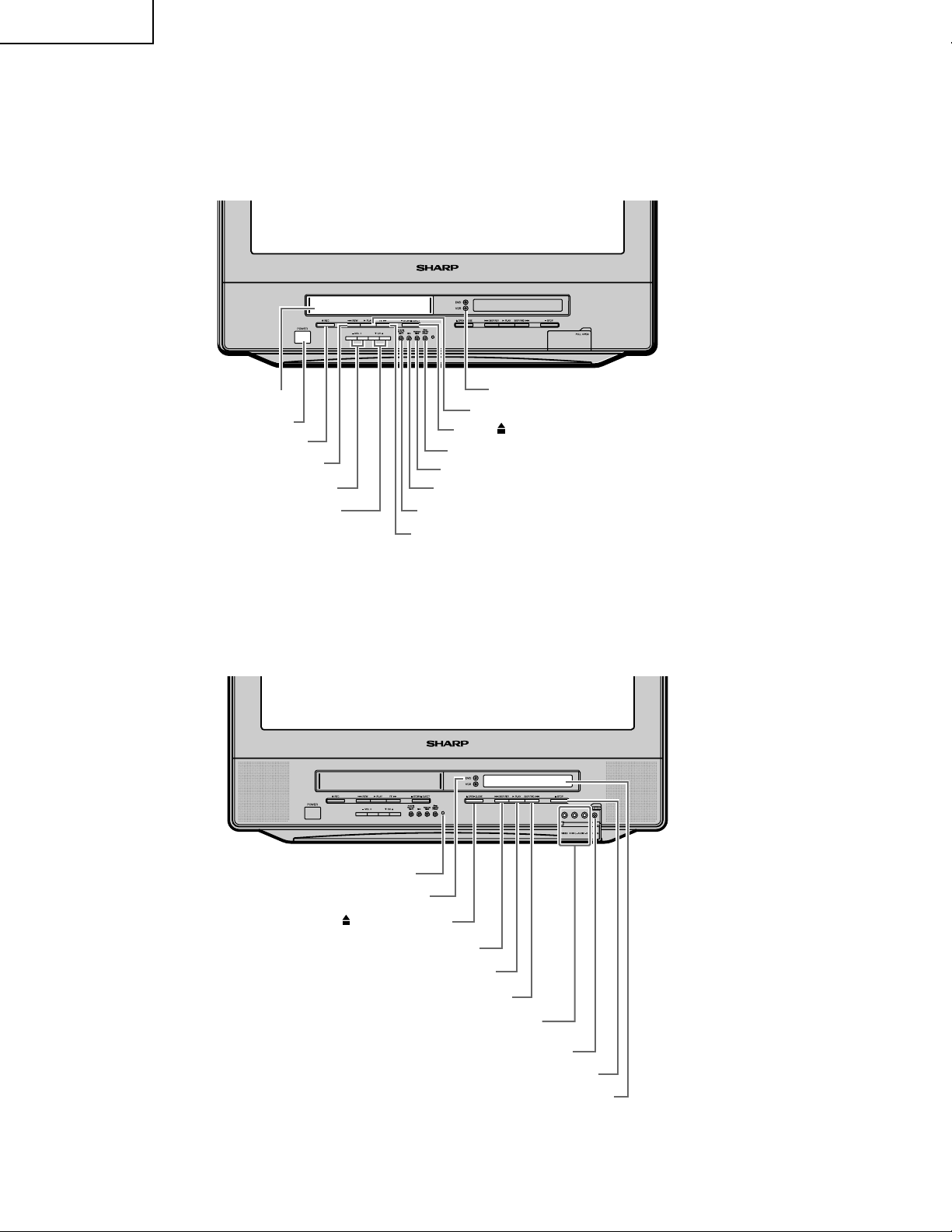

LOCATION OF USER'S CONTROL

Front (TV/VCR controls)

Cassette

compartment

POWER button

»

REC button

ÈREW (rewind) button

VOL + / – (UP/DOWN) buttons

' / " (UP/DOWN) buttons

CH

Front (DVD controls)

VCR mode indicator

|PLAY button

Ë

STOP/ EJECT button

TAMPER PROOF indicator

PROGRAM TIMER indicator

REC indicator

POWER/WAKE-UP TIMER indicator

è

FF (fast forward) button

Sensor area for Remote Control

DVD mode indicator

OPEN-CLOSE button

|È

SKIP/REV (reverse) button

|PLAY button

|

SKIP/FWD (forward) è

VIDEO / L-AUDIO-R terminals

Ë Insert the headphones (not supplied) into the headphone jack to listen to audio.

button

(Inside the cover)

PHONES (Headphone jack)

Ë

STOP button

8

Disc tray

Page 9

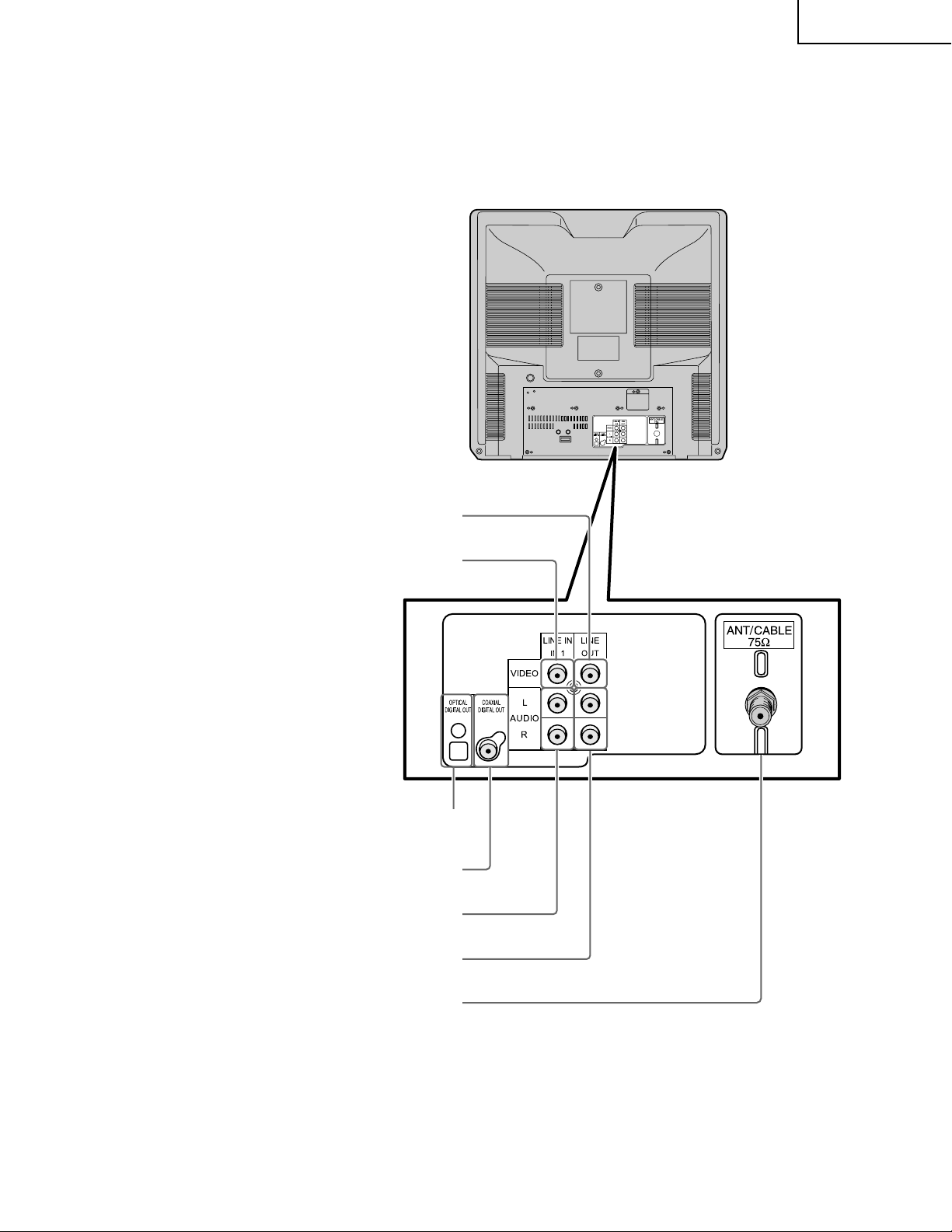

Rear

27DV-S100

27DV-CS10

LOCATION OF USER'S CONTROL (Continued)

Video output terminal

Video input terminal

DVD OPTICAL DIGITAL output terminal

DVD COAXIAL DIGITAL output terminal

Audio input terminals

Audio output terminals

ANT/CABLE terminal (75Ω)

9

Page 10

27DV-S100

27DV-CS10

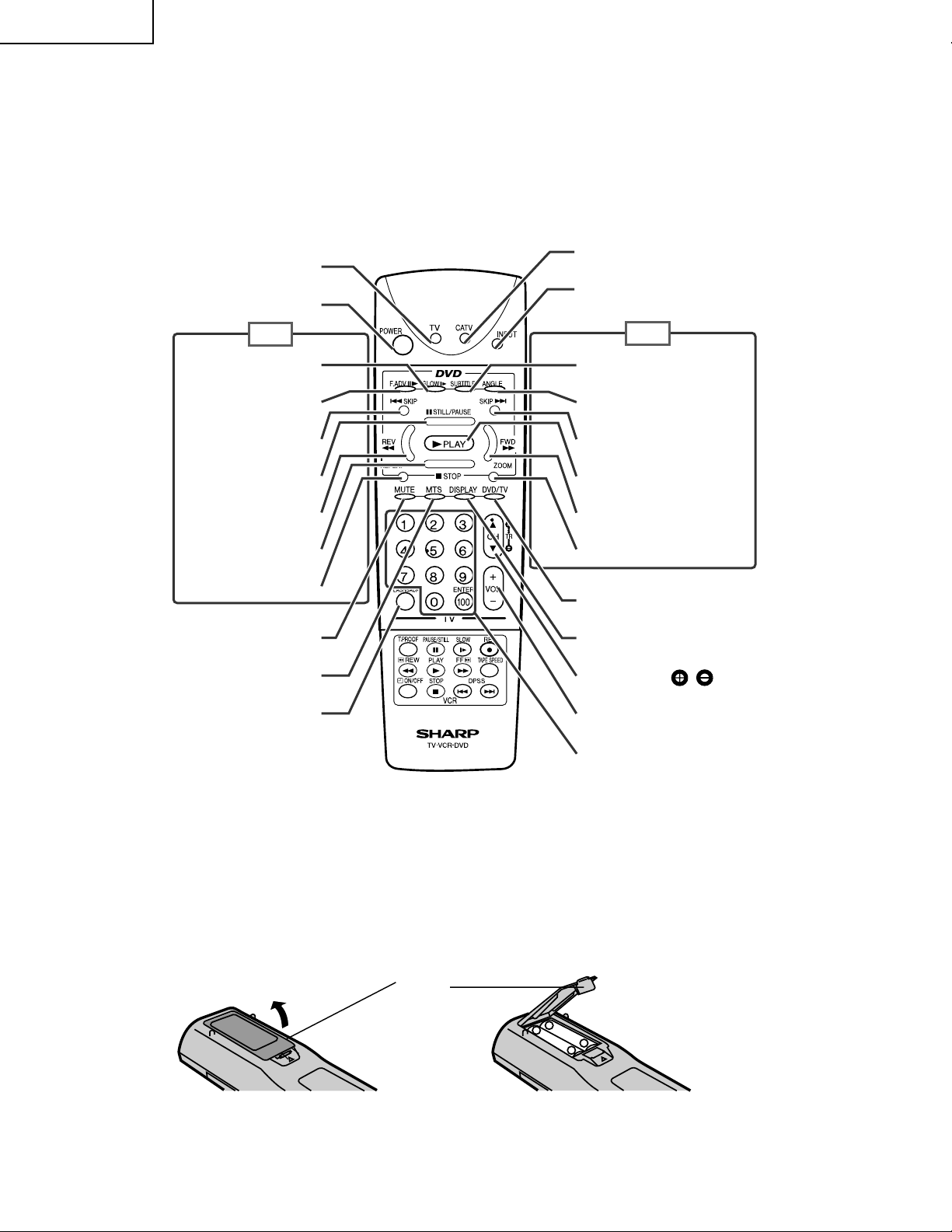

Remote Control Unit (Cover closed)

LOCATION OF USER'S CONTROL (Continued)

TV

POWER

DVD

SLOW

F.ADV

SKIP (REV)

STILL/PAUSE

REV (reverse)

STOP

REPEAT

MUTE

MTS

CATV

INPUT

DVD

SUBTITLE

ANGLE

SKIP (FWD)

PLAY

FWD (forward)

ZOOM

DVD/TV

DISPLAY

CH '/", TR /

FLASHBACK

Ë Using Your Remote Control With Your unit

After installing the batteries, press TV to switch to the TV mode. (If you can change the channel of the TV by

pressing CH '/" or CHANNEL SELECT buttons,you are in TV mode.)

+

/

VOL

CHANNEL SELECT buttons

–

Loading the Batteries

Ë Before using the unit, prepare the Remote Control.

To use the Remote Control, insert batteries first.

Insert the batteries

Battery

Pull up

• With your thumbnail, pull up the slit as indicated by the arrow to remove the back cover. Insert two batteries

(size “AA”). Be sure to match the battery

Cover

–

+

±/— terminals with the ±/— marks inside the compartment.

+

–

10

Page 11

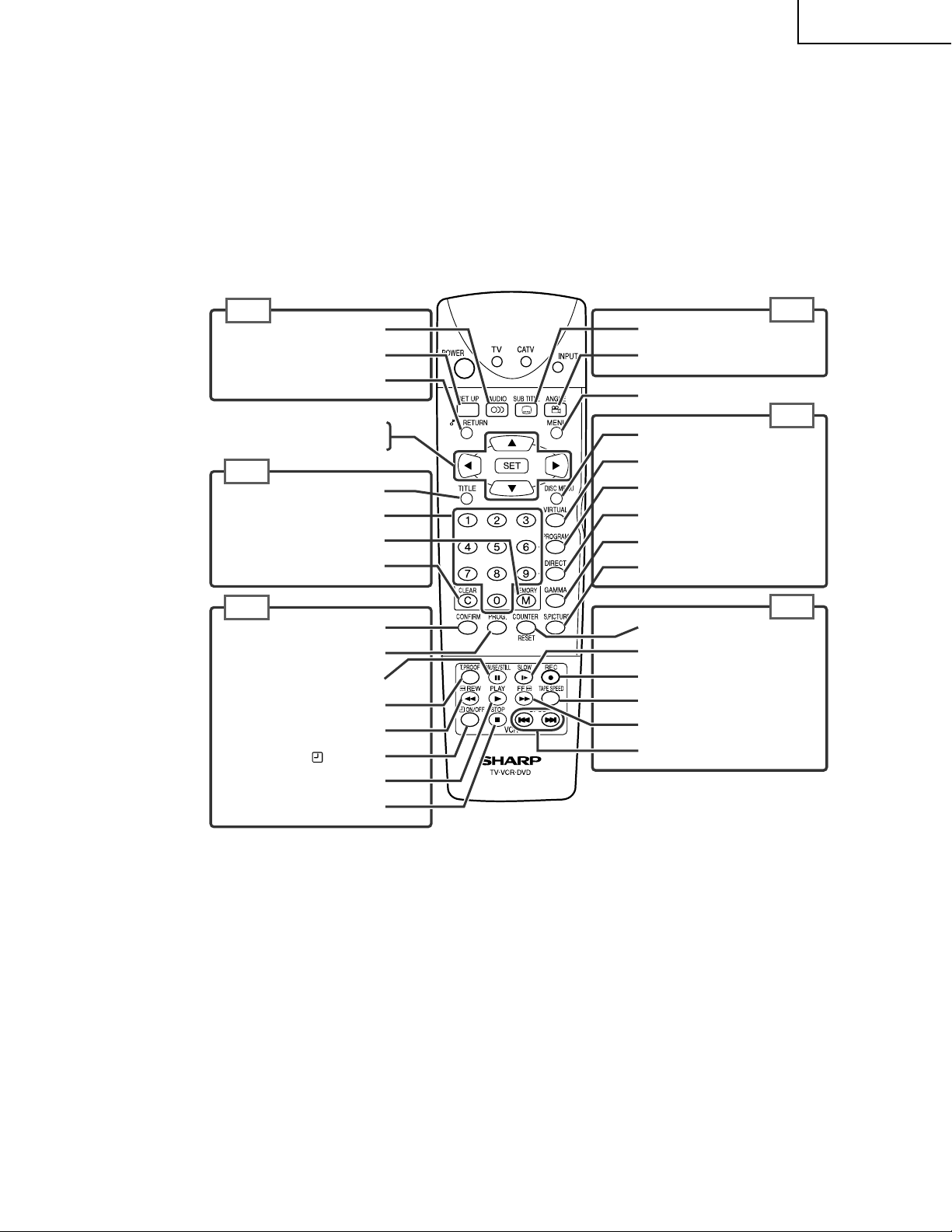

LOCATION OF USER'S CONTROL (Continued)

Remote Control Unit (Cover open)

27DV-S100

27DV-CS10

DVD

RETURN

CURSOR

DVD

NUMBER buttons

MEMORY

VCR

CONFIRM

PAUSE/STILL

T.PROOF

REW (rewind)

AUDIO

SET UP

SET

TITLE

CLEAR

PROG.

ON/OFF

PLAY

STOP

DVD

SUBTITLE

ANGLE

MENU

DVD

DISC MENU

VIRTUAL

PROGRAM

DIRECT

GAMMA

S.PICTURE

VCR

COUNTER RESET

SLOW

REC (record)

TAPE SPEED

FF (fast forward)

DPSS

11

Page 12

27DV-S100

27DV-CS10

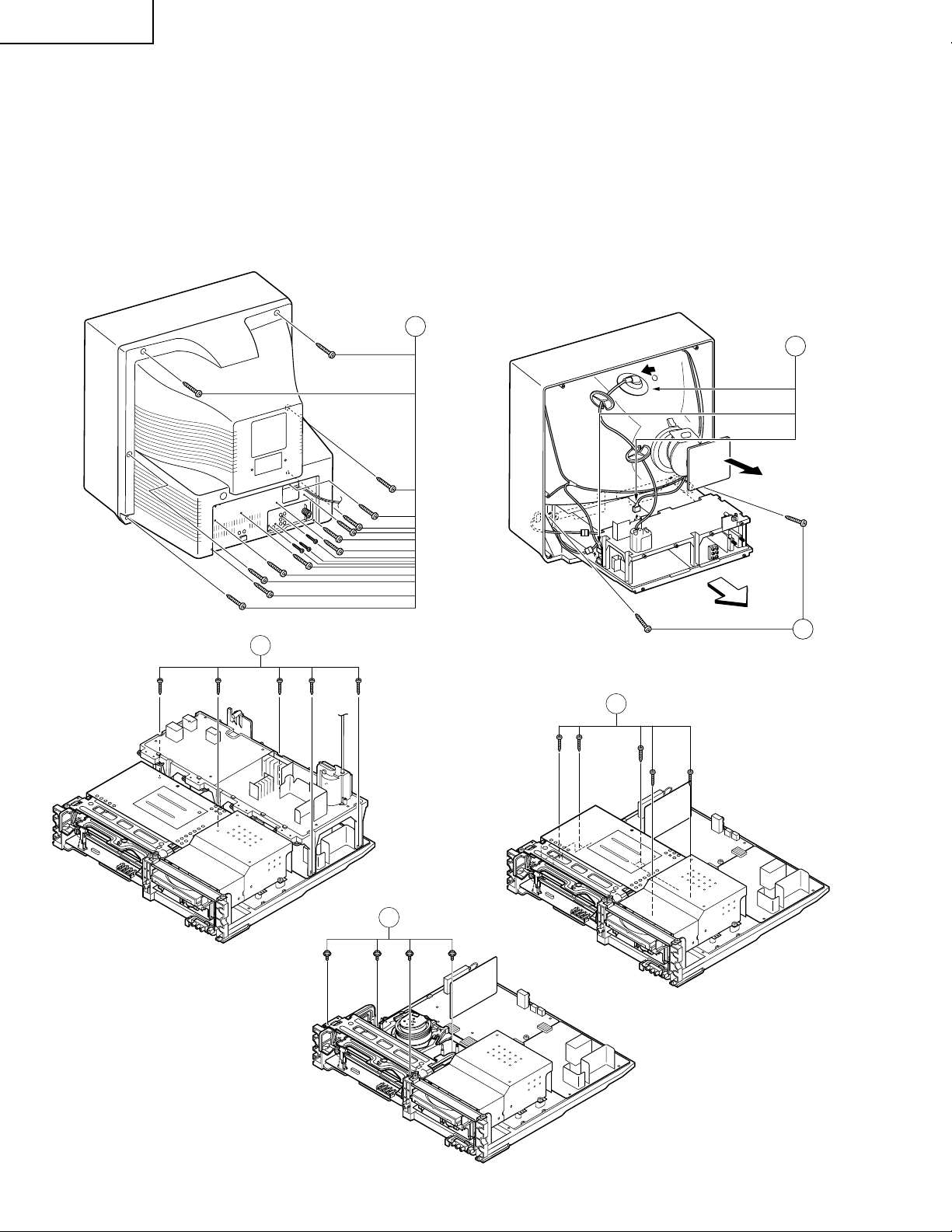

DISASSEMBLY AND REASSEMBLY

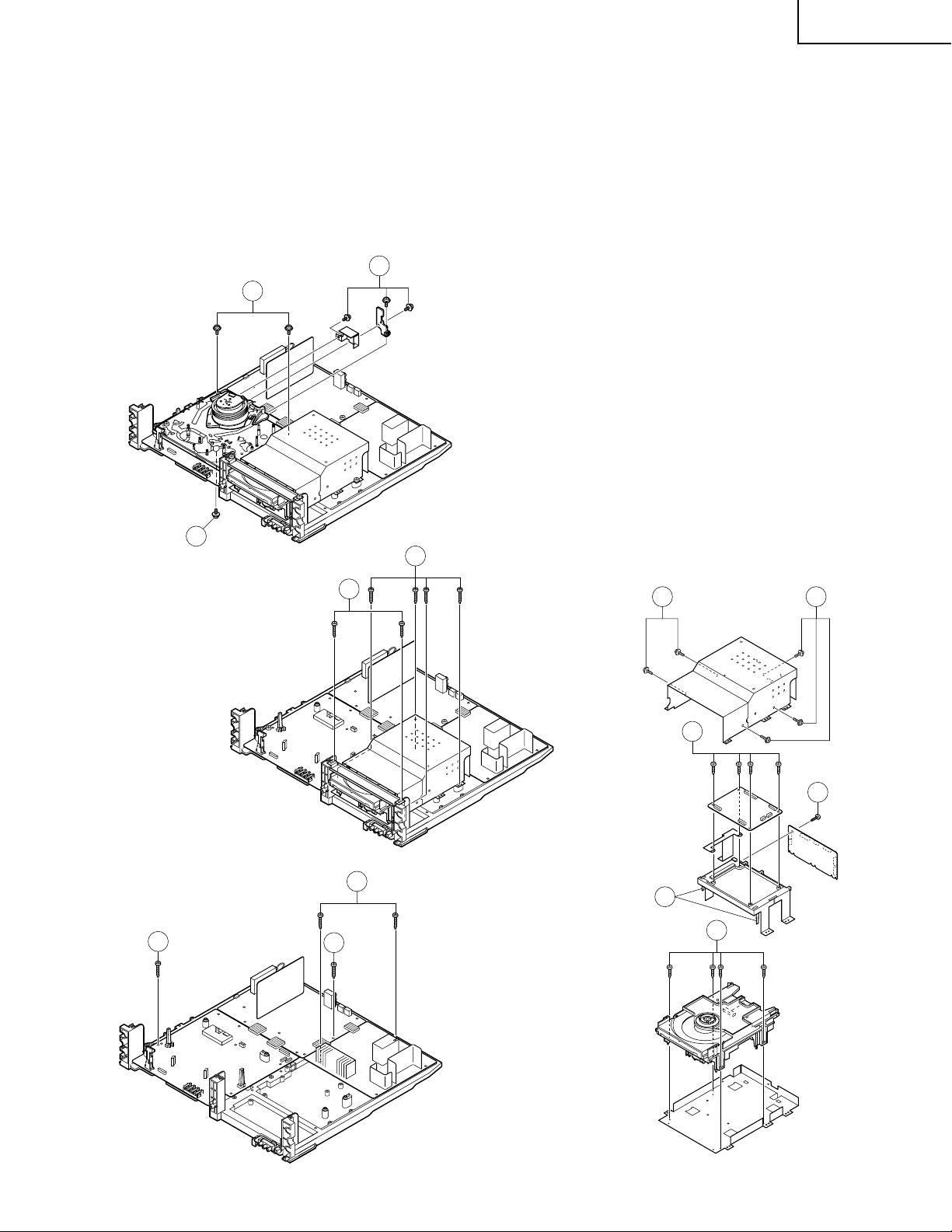

1. Remove the 16 rear cover fixing screws and detach the rear cover.

2. Take out the anode cap, CRT PWB, connectors OO, K and M, coating earth, speaker connectors SE, connector

DC and others.

3. Remove the 2 main chassis fixing screws and take out the main chassis.

4. Remove the 5 fixing screws from the sub-chassis f or the VCR power/deflection PWB and detach this sub-chassis.

5. Remove the 5 VCR shielding case fixing screws and detach the shielding case.

6. Remove the 4 cassette housing fixing screws and detach the cassette housing.

1

2

OO

OO

DC

DC

SE

K

M

M

3

4

5

6

12

Page 13

27DV-S100

27DV-CS10

7. Remove the 2 mechanism chassis bracket fixing screws and the head amplifier shielding case fixing screw.

8. Remove the 3 mechanism chassis fixing screws and detach the mechanism chassis from the main PWB.

9. Remove the 2 DVD mechanism unit reinforcement fixing screws and detach this reinforcement.

10.Remove the 4 DVD mechanism unit fixing screws and detach the DVD mechanism unit.

11.Remove the 1 main PWB fixing screws and detach the main PWB.

12.Remove the 1 TV signal PWB fixing screw and detach the TV signal PWB.

13.Remove the 2 TV power PWB fixing screws and detach the TV power PWB.

7

8

» DVD section

14.Remove the 5 DVD shielding case fixing screws and

detach the DVD shielding case.

15.Undo the 4 hooks from the chassis for the DVD main

and sub PWBs, and detach this chassis.

16.Remove the 4 DVD main PWB fixing screws and

detach the DVD main PWB.

17.Remove the DVD sub PWB fixing scre w , undo the hook

and detach the DVD sub PWB.

18.Finally remove the 4 DVD mechanism fixing screws

and detach the DVD mechanism.

8

10

9

14 14

11

12

16

17

13

15

18

13

Page 14

27DV-S100

27DV-CS10

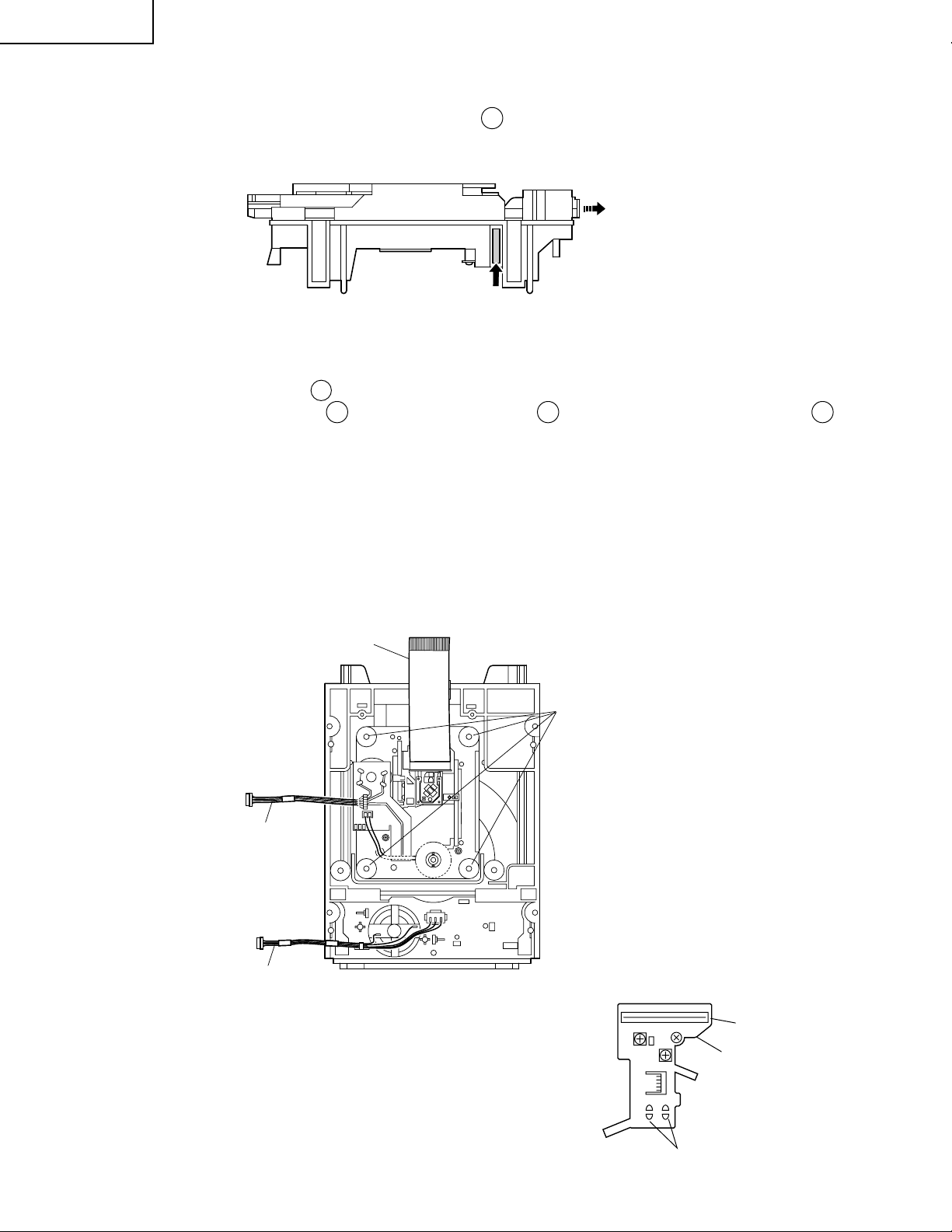

REPLACEMENT OF MAIN PARTS

<Take out disk>

1. Remove the mechanism with angle from the set (refer to 17 on PARTS LIST (See page 183)).

2. It is in such cases as the thin driver, and it is pushed in slowly, and a tra y is dra wn in the arrow direction the slide

rack on the left of the base chassis.

3. Take out disk.

Front Side

<Disassembling and assembling the mechanism chassis>

1. After setting the mechanism chassis to the angle state, ground it to prevent the electrostatic discharge damage

of the pickup.

2. Remove the DVD shield (lower) 5 (refer to the illustration on PARTS LIST (See page 183)).

3. Remove the DVD main PWB unit 35 , and loosen the 4 screws 56 to remove the DVD main PWB unit 35 .

(Pickup relay FFC isn’t removed.) (refer to the illustration on PARTS LIST (See page 183))

4. Remove screws fixing the base chassis (located at the back right and at front left when facing the set).

5. With the pickup FFC connected, turn over the base chassis and short (solder) two short lands on the pickup

interface PWB in order to prevent the electrostatic discharge damage of the pickup.

6. Remove the pickup FFC from the main PWB.

7. Remove the pickup FFC from the pickup interface PWB.

8. Remove the traverse mounting screws to remove the traverse chassis ass’y.

Note: After assembly and wiring, remove the solder joint of the short land. If short-circuited, a disk is not played

back.

Pickup FFC

Sled Motor Lead Wire

Loading Motor Lead Wire

<Replacing the pickup and the spindle motor>

Since the pickup optical axis and turntable inclination of DVD are adjusted

with higher accuracy than of CD/MD, make a replacement as a mechanism

service chassis ass’y (refer to Parts List).

Traverse Fixing Screw

Pickup FFC

Pickup interface PWB

14

Short Land

Page 15

27DV-S100

BA

XB

XB

SE

ZA

XC

ZA

OC

DB

AR

DB

DD

DA

DC

DF

27DV-CS10

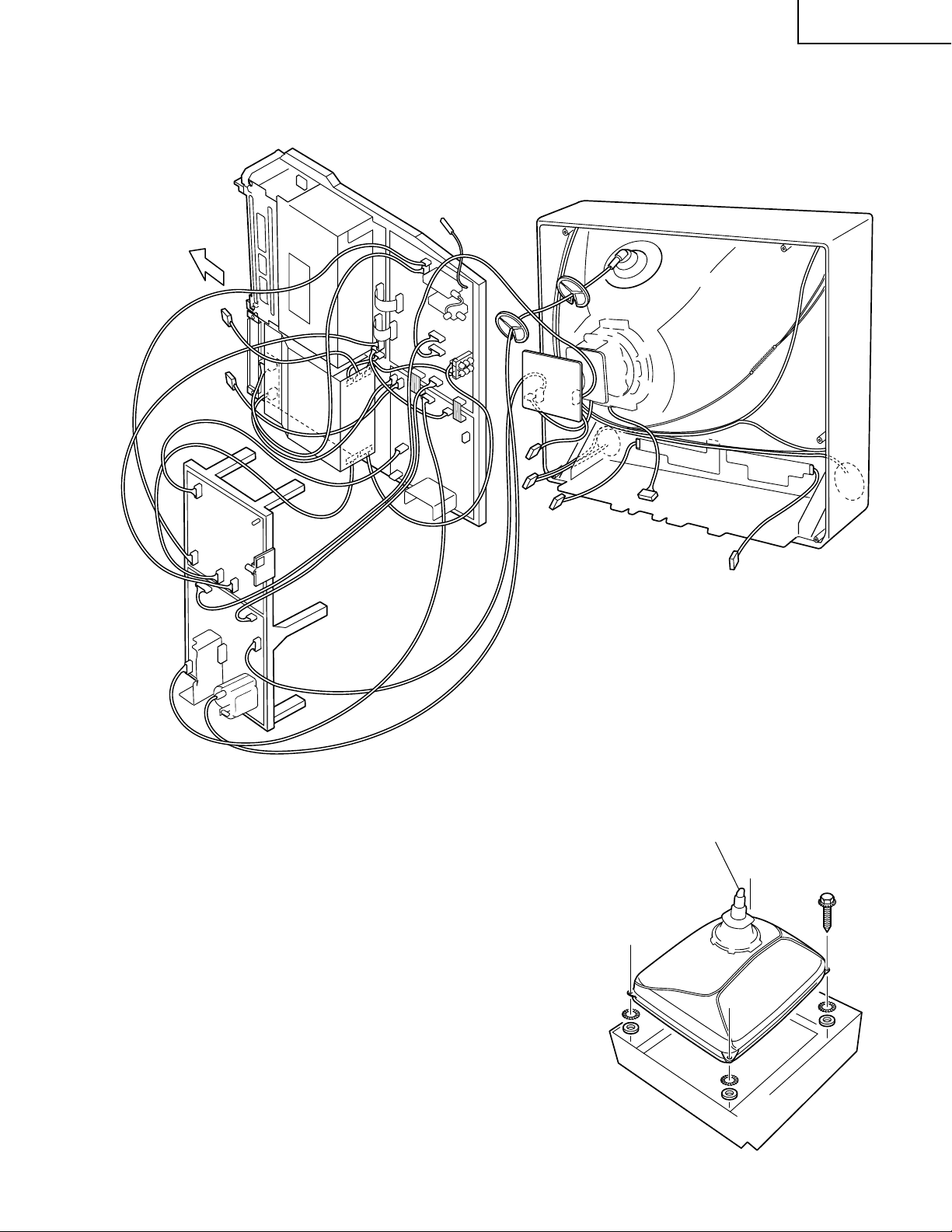

For servicing the TV’s component units, undo the lead dressing holders and place the main chassis upright as shown

below. Connect necessary leads for quick servicing.

OO

FRONT

SC

SA

AR

SA

DC

AR

SE

EB

AR

ZA

ZA

SB

OC

OC

DB

DB

DE

ZA

ZA

DF

DF

DC

DC

DB

DB

DA

DA

DD

DD

WA

SB

DA

GBN

XB

XB

DF

BA

BA

SE

SE

XB

XB

EB

M

XC

XC

GA

OR

XC

GBN

PU

N(H)

M

DC

SE

DC

K

OO

SC

DD

OC

WA

BA

GA

Remove the four screws from the cathode ray tube, and detach

the cathode ray tube (weighing 35 kg or so).

» The cathode ray tube has a high-tension static charge and a

high vacuum. Handle it with enough care on the following

occasions.

N

K

For disposal of the cathode ray tube

1) The high-voltage electrode, which is covered with the anode

cap atop the cathode ray tube, may have a high-tension static

charge. Before detaching the anode cap, be sure to get this

electrode fully discharged.

2) The cathode ray tube has a high vacuum inside. Crack the tip

of the air vent on the neck socket of the cathode ray tube in

order to get the tube out of vacuum.

OO

Get the air vent tip cracked to let in air.

~

~

~

~

15

Page 16

27DV-S100

27DV-CS10

INSTALLATION AND SERVICE INSTRUCTIONS

Note: (1) When performing any adjustments to resistor controls and transformers use non-metallic scre wdriver

or TV alignment tools.

(2) Before performing adjustment, TV set must be on at least 15 minutes.

CIRCUIT PROTECTION

The receiver is protected by a 6.3A fuse (F701), mounted

on PWB-A, wired into one side of the AC line input.

X-RADIATION PROTECTOR CIRCUIT

TEST

After service has been performed on the horizontal

deflection system, high voltage system, or +B system,

test the X-Radiation protector circuit to ascertain proper

operation as follows:

1. Apply 120V AC using a variac transformer for accurate

input voltage.

2. Allow for warm up and using the remote controller,

set the brightness level and contrast level to

maximum.

3. Check the voltage of test point TP653. (It’s voltage

should be about 11.1V DC.)

4. Apply external 14.5V DC at TP653 by using an

external DC supply . The increased v oltage will cause

the horizontal oscillator to stop and the TV to shut

off.

5. To re-star t the oscillator, remove the external DC

power supply and short together TP651 and TP652.

Once the TV set operates normally again, remove

the short between TP651 and TP652.

HIGH V OL T AGE CHECK

High voltage is not adjustable b ut must be checked

to verify that the receiver is operating within safe

and efficient design limitations as specified checks

should be as follows:

1. Connect an accurate high voltage meter between

ground and anode of Picture tube.

2. Operate receiver for at least 15 minutes at 120V AC

line voltage, with strong air signal or properly tuned

in test signal.

3. Set to Ser vice mode on, “Mute” and bus data 1(Ymute on).

4. The voltage should be approximately 29.2kV (at zero

beam). If a correct reading cannot be obtained, chec k

circuitry for malfunctioning components.

After the voltage test, “Mute” and b us data “0” (Y-mute

off).

16

Page 17

27DV-S100

27DV-CS10

The R-series SHARP TV/VCR COMBINATION have most of the analog setup adjustments eliminated. Coil and

variable resistor adjustments are now performed digitally by using the remote controller or set’s volume and

channel change function buttons.

Note: There are still a few analog adjustments in the R-series such as 120V adjust, focus, master screen

voltage and coils in the picture I/F detector circuit.

Follow the steps below , whenever service adjustment is required. See “T ab le-B” to determine, if service

adjustments are required.

1. Service mode

Before putting unit into the service mode, check that

customer adjustments are in the normal mode, use

the reset function in the video adjust menu to ensure

customer controls are in their proper (reset) position.

To enter the service mode

Plug in a television set, during push S2507 (CH-up).

When successfuly entered, the service mode will be

displayed as shown in Figure A.

To exit service mode

Turn off the power or unplug the set.

2. Adjustment Item selection

Once in the service mode, press the channel up or

channel down button on the remote controller or at

the set (Table-A). Select the item y ou wish to adjust.

3. Data number selection

Press the volume up or down button to adjust the

data number in the upper right hand side of the

screen.

Figure A.

17

Page 18

27DV-S100

27DV-CS10

ITEM

SUB COTRAST(*1) PICTURE 20 00 - 31 Adjustment is required of each set.

TINT (*1) TINT 30 00 - 47 Adjustment is required of each set.

SUB COLOR (*1) COLOR 18 00 - 31 Adjustment is required of each set.

BRIGHTNESS (*1) BRIGHT 55 00 - 95 Adjustment is required of each set.

SHARPNESS SHARP 15 00 - 47 Fix at "8"

V-POSITION (*1) V POSITION 95 00-127 Adjustment is required of each set.

H-POSITION (*1) H POSITION 17 00 - 31 Adjustment is required of each set.

R CUT-OFF (*1) R CUT-OFF 64 00-255 Adjustment is required of each set.

G CUT-OFF (*1) G CUT-OFF 64 00-255 Adjustment is required of each set.

B CUT-OFF (*1) B CUT-OFF 64 00-255 Adjustment is required of each set.

G GAIN (*1) G GAIN 64 00-127 Adjustment is required of each set.

B GAIN (*1) B GAIN 64 00-127 Adjustment is required of each set.

Y-γ CURVE Y-γ CURVE 00 00 - 03 Fix at "03"

VSM PHASE VSM PHASE 01 00 - 03 Fix at "02"

APACON PEAK f0 APA PEAK f0 01 00 - 07 Fix at "01"

DC RESTRATION RATE DC REST 21 00 - 63 Fix at "07"

DC RESTRATION LIMIT DC REST LMT 00 00 - 03 Fix at "02"

BLACK STRETCH POINT BLK STRETCH 03 00 - 07 Fix at "00"

APL VS BPS APL VS BPS 01 00 - 03 Fix at "01"

B.L.C B.L.C 01 00 - 01 Fix at "00"

DYNAMIC ABL POINT DY ABL POINT 04 00 - 07 Fix at "06"

DYNAMIC ABL GAIN DY ABL GAIN 04 00 - 07 Fix at "03"

ABL POINT ABL POINT 03 00 - 07 Fix at "07"

ABL GAIN ABL GAIN 03 00 - 07 Fix at "04"

Y-DL Y-DL 01 00 - 01 Fix at "01"

TOF-Q TOF-Q 04 00 - 07 Fix at "04"

VSM GAIN VSM GAIN 01 00 - 03 Fix at "02"

OSD SL OSD SL 00 00 - 01 Fix at "00"

C-DECODE C-DECODE 161 00-255 Fix at "153"

DVD BR-OFF DVD BR-OFF 30 30 - 70 Fix at "50"

PICTURE HEIGHT V AMP 22 00-127 Adjustment is required of each set.

V-LINEARITY V-LINEARITY 22 00 - 31 Adjustment is required of each set.

V-S CORRECTION V-S CORRECT 40 00 - 63 Fix at "47"

PICTURE WIDTH H AMP 30 00 - 63 Adjustment is required of each set.

E-W PARABOLA E-W PARABOLA 19 00 - 63 Adjustment is required of each set.

E-W CORNER E-W CORNER 18 00 - 31 Adjustment is required of each set.

TRAPEZIUM TRAPEZIUM 55 00-127 Adjustment is required of each set.

AGC AGC 01 00 - 01 Fix at "01"

Y-MUTE MUTE 00 00 - 02 00=NORMAL, 01=NO-Y, 02=NO-VERTICAL

ENERGY SAVE ENERGY SAVE 21 00 - 63 Fix at "21"

TEXT BOX TEXT BOX 8 00 - 31 Adjustment is required of each set.

TEXT PICTURE TEXT PICTURE 20 00 - 80 Fix at "20"

CCD LEVEL CCD LEVEL 04 00 - 20 Fix at "10"

OPTION (VCR) OPTION (VCR) 39 00-255 Fix at "39"

OPTION (TV) OPTION (TV) 31 00-127 Fix at "127"

MTS INPUT LEVEL INPUT LEVEL 07 00 - 15 Adjustment is required of each set.

MTS VCO MTS VCO 37 00 - 63 Adjustment is required of each set.

MTS FILTER FILTER 30 00 - 63 Adjustment is required of each set.

WIDE BAND DETECT WIDE BAND 35 00 - 63 Adjustment is required of each set.

SPECTRAL DETECT SPECTRAL 22 00 - 63 Adjustment is required of each set.

H COMP H COMP 03 00 - 07 Fix at "03"

V COMP V COMP 03 00 - 07 Fix at "03"

CCD POSITION CCD POSITION 38 00 - 63 Fix at "38"

OSD DISPLAY INITIAL

RANGE SETTING DATA

(*1) Set the adjustment value to tuner input instead of the adjustment at DVD input (play).

Table-A

PART ADJUSTMENT

REPLACED NECESSARY UNNECESSARY

IC2001 X Data is stored in IC2003.

IC401 X

IC2003 X

CRT X Adjust items related to picture tube only.

The adjustment is needed to compensate for characteristics

of parts including IC401.

Initial setting values are written from IC2001. Adjust for best

results.

NOTE

Table-B

18

Page 19

Ë

SERVICE ADJUSTMENT

Screen Adjustment

1. Select a good local channel.

2. Enter the service mode and select the service

adjustment item "COLOR" and set the data value to

"0" to set the color level to minimum. You may skip

this step, if you selected a B/W picture or monoscope

pattern.

3. Select service adjustment item "MUTE" and adjust

the data value to "1", this turns off the luminance

signal (Y-mute).

4. Adjust the master screen control until raster darkens

to the point where raster is barely seen.

5. Adjust service adjustments item "R-CUT OFF" red

"G-CUT OFF" green and "B-CUT OFF" blue to obtain

a good grey scale with normal whites at low brightness

level.

6. Select the service adjustment item "MUTE" and reset

data to "0". Select service adjustment item "COLOR"

and reset data to obtain normal color level.

White Balance Adjustment

1. Select a good local channel.

2. Enter the service mode and select the service

adjustment item "COLOR" and set to "0" (minimum

color). "COLOR" does not have to be adjusted if you

selected a B/W picture or monoscope pattern.

3. Alternately adjust the service adjustment data of "G

GAIN" and "B GAIN" until a good grey scale with

normal whites is obtained.

4. Select the ser vice adjustment item "COLOR" and

adjust data to obtain normal color level.

Picture Adjustment

1. Select a good local channel.

2. Make sure the customer picture control is maximum.

3. Enter the service mode and select the service

adjustment item "PICTURE".

4. Adjust the data value to achieve normal contrast

range.

Tint Adjustment

1. Select a good local channel.

2. Set customer tint control to center of it’s range.

3. Enter the service mode and select the service

adjustment item "TINT".

4. Adjust "TINT" data value to obtain normal flesh tones.

Color Adjustment

1. Select a good local channel.

2. Make sure the customer color control is set to center

position .

3. Enter the service mode and select the service

adjustment item "COLOR".

4. Adjust "COLOR" data value to obtain normal color

level.

27DV-S100

27DV-CS10

Brightness Adjustment

1. Select a good local channel.

2. Make sure the customer brightness control is set to

center position.

3. Enter the service mode and select the service

adjustment item "BRIGHT".

4. Adjust "BRIGHT" data value to obtain normal

brightness level.

Vertical Phase Adjustment

1. Receive a good local channel.

2. Enter the service mode and select "V-POSITION".

3. Adjust data value so that picture is approximate

center.

Vertical-Size Adjustment

1. Receive a good local channel.

2. Enter the service mode and select "V-AMP".

3. While observing the top and bottom of the screen,

adjust the data value to proper vertical size.

Side Pincushion Adjustment

1. Receive a good local channel or crosshatch pattern

signal.

2. Set to standard setting mode.

3. Enter the service mode and select "E-W P ARABOLA".

4. Adjust the data so that the outer most line on the

screen be straight.

Corner Distortion Adjustment

1. Receive a good local channel or crosshatch pattern

signal.

2. Set to standard setting mode.

3. Enter the service mode and select "E-W CORNER".

4. Adjust the data so that the vertical lines should be

straight.

Trapezoidal Distortion Adjustment

1. Receive a good local channel or crosshatch pattern

signal.

2. Set to standard setting mode.

3. Enter the service mode and select "TRAPEZIUM".

4. Adjust the data so that the leftmost and rightmost

vertical lines are parallel to each other.

Horizontal Position Adjustment

1. Receive a good local channel or crosshatch pattern

signal.

2. Set to standard setting mode.

3. Enter the service mode and select "H-POSITION".

4. Adjust so that the left and right overscans are equal

to each other.

19

Page 20

27DV-S100

27DV-CS10

Horizontal Size Adjustment

1. Receive a good local channel or crosshatch pattern

signal.

2. Set to standard setting mode.

3. Enter the service mode and select "H-AMP".

4. Adjust the data to obtain the best horizontal size.

Caption Position Adjustment

(Horizontal)

1. Receive a good local channel.

2. Enter the service mode and select "TEXT BOX".

3. A black text box appears on the screen. (see Figure

B below)

4. Adjust the data value so that text box is positioned in

the center of the screen.

White Balance Adjustment of Component Signal Input

1. Feed the B/W pattern signal via the component signal

input from signal generator.

2. Set "Y-MUTE" bus data to "01" to get the Y signal

mute.

3. Select a luminance-short gun, and adjust the bus data

of "R CUT-OFF", "G CUT-OFF" and "B CUT-OFF" to

have the luminance at the white level.

4. Adjust the "G GAIN" and "B GAIN" setting to obtain

the specified white level.

Sub-brightness Adjustment of Component Signal Input

1. Feed the B/W pattern signal via the component signal

input from signal generator.

2. Make sure the customer brightness control is set to

center position.

3. Enter the service mode and select "BRIGHT".

4. Adjust the data value to obtain normal br ightness

level.

20

Page 21

Ë

MTS ADJUSTMENT

MTS Level Adjustment (for TV tuner)

1. Receive the following monaural signal. Monaural

signal: 300Hz, 245mVrms.

2. Connect the rms voltmeter to pin (39) of IC3001.

3. Enter the service mode and select "INPUT LEVEL".

4. Adjust the data so that the rms voltmeter reads 490

+10/-10mVrms.

MTS VCO Adjustment (for TV tuner)

1. Keep the unit in no-signal state.

2. Connect the frequency counter to pin (39) of IC3001.

3. Connect a capacitor (100uF, 50V) between positive

(+) side of C3005 and ground.

4. Enter the service mode and select "MTS VCO".

5. Adjust the data so that the frequency counter reads

62.94 +0.72/-0.75kHz.

Filter Adjustment (for TV tuner)

1. Feed the following stereo pilot signal to pin (14) of

IC3001. Stereo pilot signal: 9.4kHz, 600mVrms.

2. Enter the service mode and select "FILTER".

3. Adjust the data until "OK" appears in position on the

screen. Make sure the "OK" is displayed almost at

the center of the data range.

27DV-S100

27DV-CS10

Separation Adjustment (for VCR tuner)

1. Connect the rms voltmeter to pin (22) of IC3601 (or

negative (-) side of C1321).

2. Receive the following composite stereo signal 1.

Composite stereo signal: 30% modulation, left

channel only, noise reduction on, 300Hz.

3. Adjust R3601 to become the output level as the

minimum.

4. Receive the following composite stereo signal 2.

Stereo signal: 30% modulation, left channel only ,

noise reduction on, 3kHz.

5. Adjust R3612 to become the output level as the

minimum.

6. Take the above steps 1 thru 5 again for fine

adjustment.

Separation Adjustment (for TV tuner)

1. Connect the rms voltmeter to pin (39) of IC3001.

2. Receive the following composite stereo signal 1.

Composite stereo signal: 30% modulation, left

channel only, noise reduction on, 300Hz.

3. Enter the service mode and select "WIDE BAND".

4. Adjust the data until the AC voltage reading of the

rms voltmeter is minimum.

5. Receive the following composite stereo signal 2.

Stereo signal: 30% modulation, left channel ony,

noise reduction on, 3kHz.

6. Enter the service mode and select "SPECTRAL".

7. Adjust the data until the AC voltage reading of the

rms voltmeter is minimum.

8. Take the above steps 1 thru 7 again for fine

adjustment.

MTS Level Adjustment (for VCR tuner)

1. Receive the following monaural signal. Monaural

signal: 300Hz, 245mVrms.

2. Connect the rms voltmeter to pin (22) of IC3601 (or

negative (-) side of C1321).

3. Adjust R3614 to become the output level as 490

+10/-10mVrms.

21

Page 22

27DV-S100

27DV-CS10

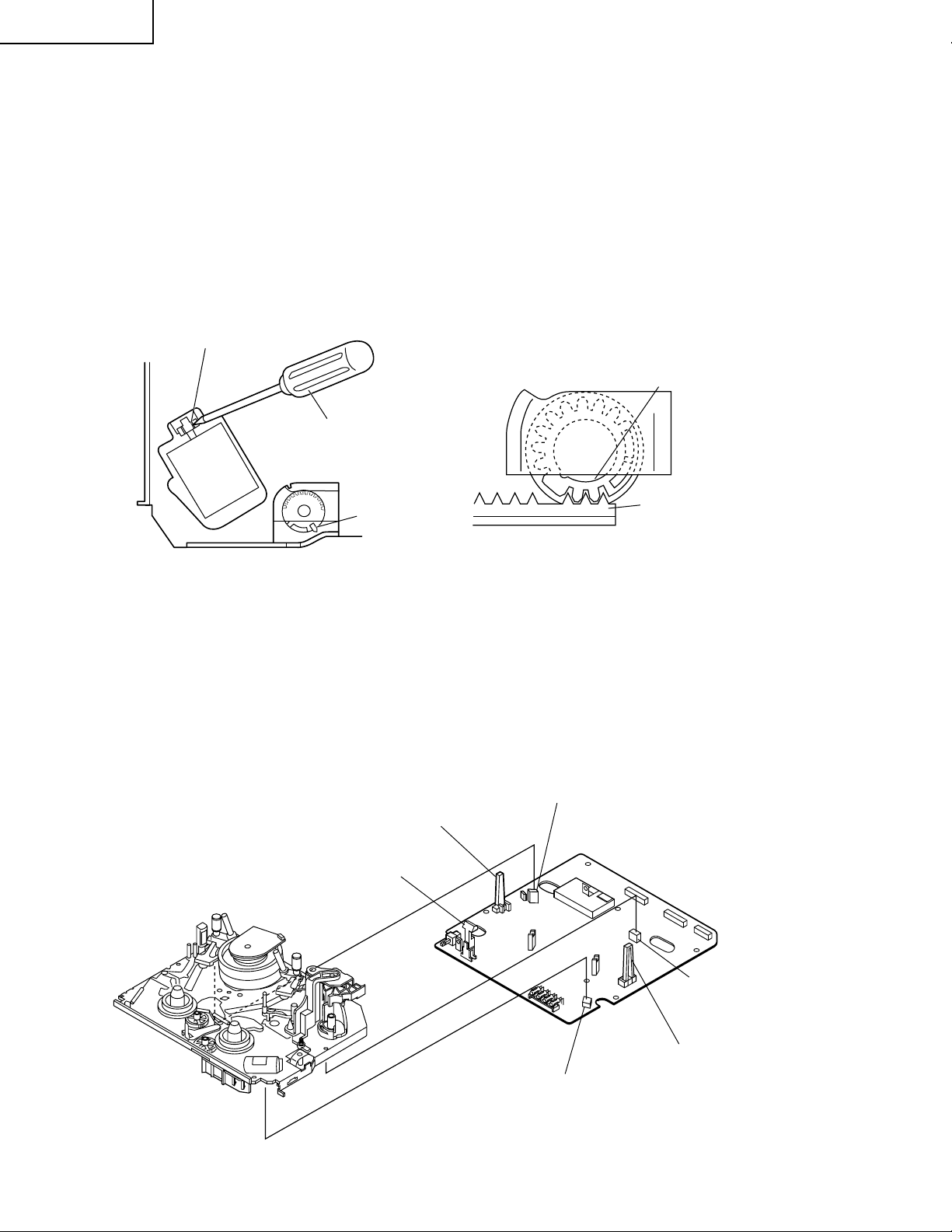

PRECAUTIONS IN REASSEMBLING

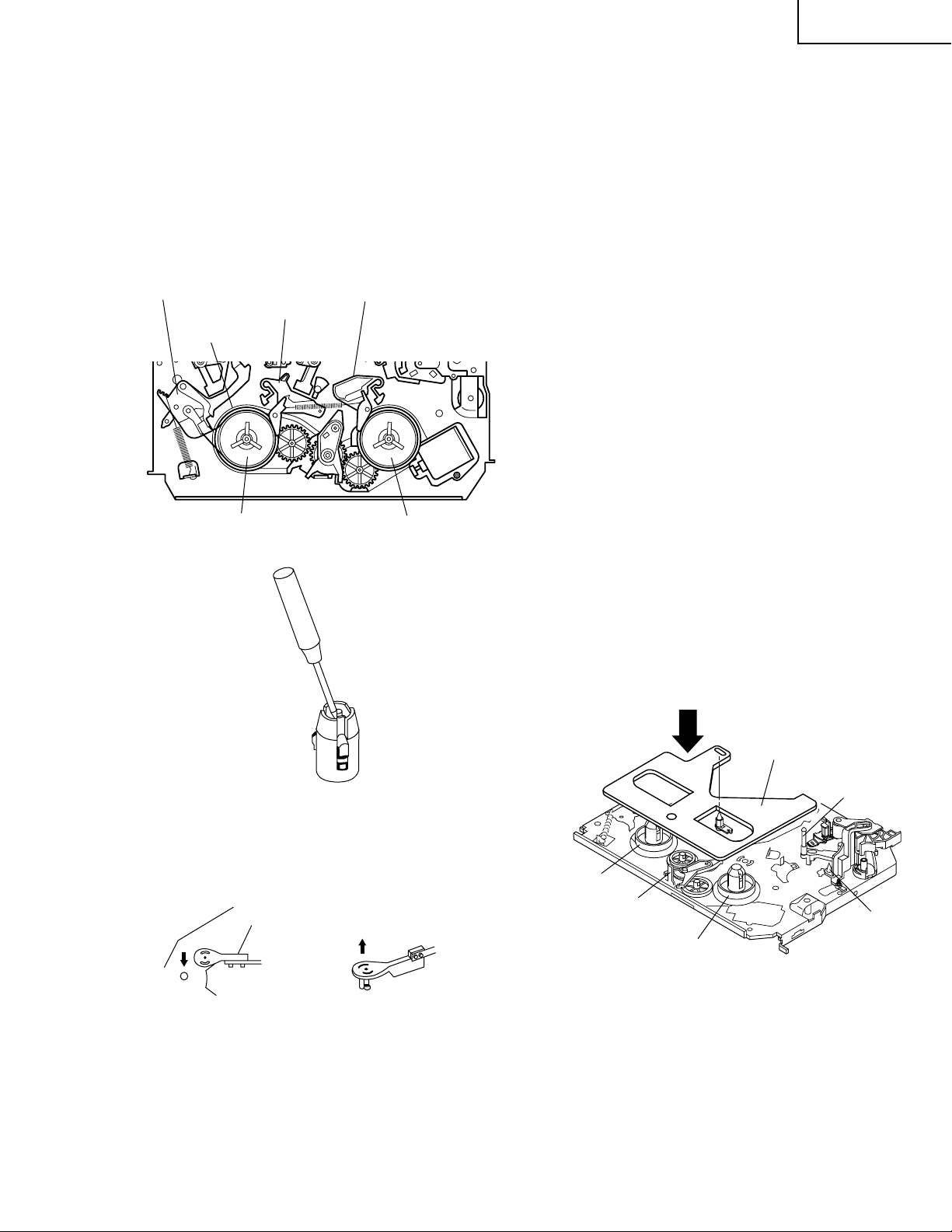

INSTALLING THE CASSETTE HOUSING

When the cassette housing is installed on the mechanism, the initial setting is essential condition.

There are two initial setting methods, namely electrical and mechanical.

1. Electrical initial setting

So as to perform initial setting of mechanism execute

the Step 1 of Installation of cassette housing. After

ascertaining the retur n to the initial setting position

(*1) install the cassette housing. (Conditions: When

mechanism and PWB have been installed)

Pulley feed gear

Screwdriver

Tint mark (*1)

Installing the mechanism on PWB

Lower vertically the mechanism, paying attention to the

mechanism edge, and install the mechanism with due

care so that the parts are not damaged. So as to fix the

mechanism to the main PWB install two housings. (Fit

the antenna cover to one of them. For other, fix the

vicinity of loading motor and solder joint side of main

PWB.) Connect again the FFC cable (AA-MH, AD-ME,

AH-MZ) between the mechanism and the main PWB.

2. Mechanical initial setting

Feed the pulley f eed gear of loading motor with screw

driver. After ascertaining the return to the initial set

position (*1) install the cassette housing in the

specified position. (This method is applied only for

the mechanism.)

Casecon

drive gear

Drive angle of

cassette housing

Parts which need particular care

When installing the mechanism chassis on the PWB

unit, take care so as to prevent deformation due to

contact of mechanism chassis with REC TIP SW.

END SENSOR

REC TIP SW

AE CONNECTOR

AD CONNECTOR

START SENSOR

AL CONNECTOR

22

Page 23

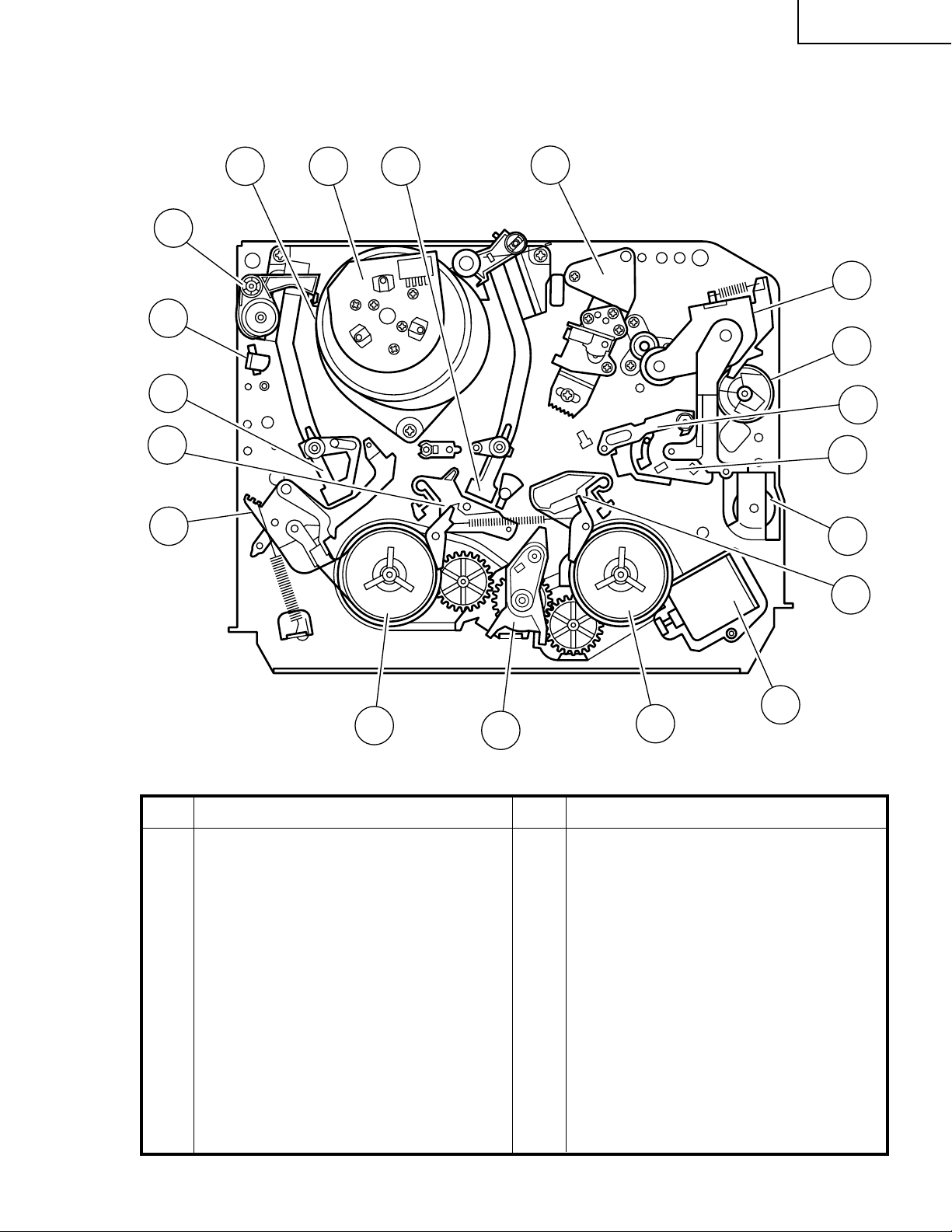

FUNCTION OF MAJOR MECHANICAL PARTS (TOP VIEW)

17

10

11

5

9

14

12

8

16

13

4

6

2

7

3

1

1815

19

27DV-S100

27DV-CS10

No. Function

1 Full erase head

2 Supply pole base ass’y

3 Tension arm ass’y

4 Idler wheel ass’y

5 Pinch drive lever ass’y

6 Supply reel disk

7 Supply main brake ass’y

8 Take-up main brake ass’y

No. Function

11 Reverse guide lever ass’y

12 Casecon drive gear

13 Take-up reel disk

14 Pinch roller lever ass’y

15 Drum ass’y

16 Loading motor

17 Drum motor

18 Take-up pole base ass’y

9 Pinch drive cam

10 A/C Head ass’y

19 Impedance roller ass’y

23

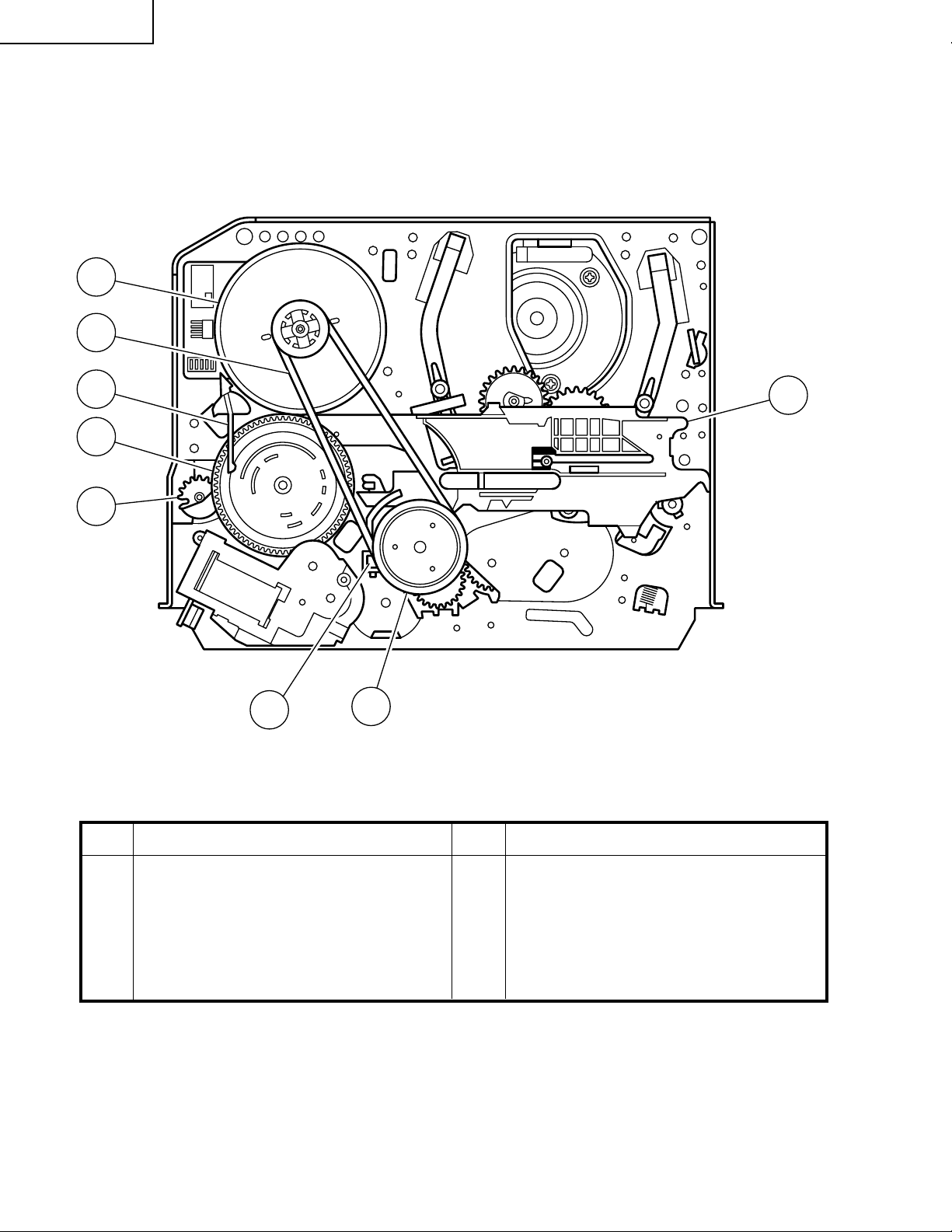

Page 24

27DV-S100

27DV-CS10

FUNCTION OF MAJOR MECHANICAL PARTS (BOTTOM VIEW)

21

22

19

20

12

23

No. Function

26

24

No. Function

12 Casecon drive gear

19 Slow brake

20 Master cam

21 Capstan D.D. motor

22 Reel belt

23 Clutch lever

24 Limiter pulley ass'y

26 Shifter

24

Page 25

27DV-S100

27DV-CS10

ADJUSTMENT, REPLACEMENT AND ASSEMBLY OF

MECHANICAL UNITS

The explanation given below relates to the on-site general service (field service) but it does not relates to the adjustment

and replacement which need high-grade equipment, jigs and skill. For example, the drum assembling, replacement

and adjustment service must be performed by the person who have finished the technical courses.

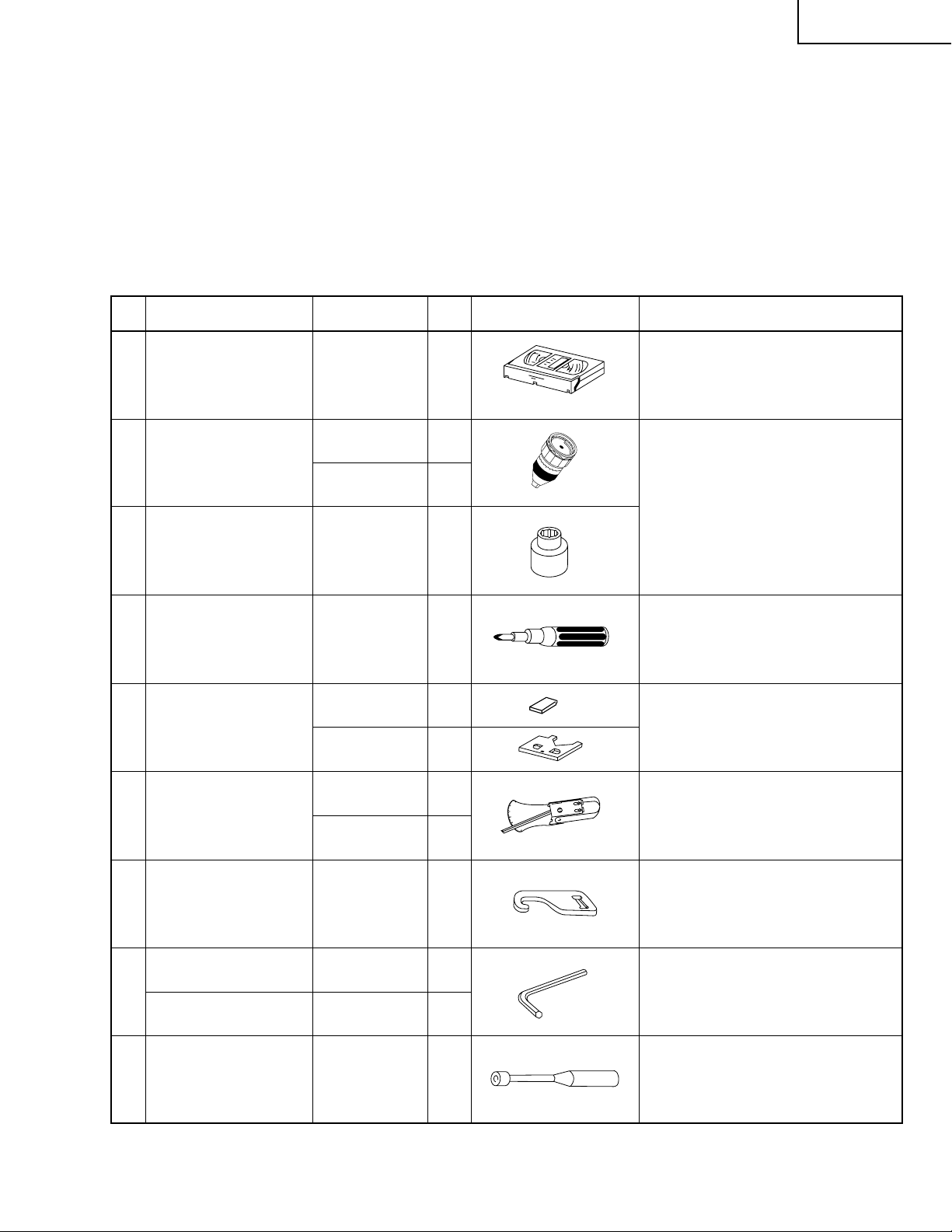

MECHANISM CONFIRMATION ADJUSTMENT JIG

So as to perform completely the mechanism adjustment prepare the following special jigs. So as to maintain the initial

performance of the machine the maintenance and check are necessary. Utmost care must be tak en so that the tape is

not damaged. If adjustment needs any jig, be sure to sue the required jig.

This cassette torque meter is used

1. Torque Cassette Meter JiGVHT-063 CZ

JiGTG0090 CM

2. Torque Gauge

JiGTG1200 CN

3. Torque Gauge Head JiGTH0006 AW

for checking and adjusting the

torque of take-up for measuring

tape back tension.

These Jigs are used for checking

and adjusting the torque of takeup and supply reel disks.

4. Torque Driver JiGTD1200 CB

Master Plane Jig and JiGRH0002 BR

5. Reel Disk Height

Adjusting Jig JiGMP0001 BY

JiGSG2000 BS

6. Tension Gauge

JiGSG0300 BF

Pinch pressing force

7.

measuring jig

Hex Wrench (1.2mm) JiGHW0012 AE

8.

Hex Wrench (1.5mm) JiGHW015 AE

Reverse guide height

9.

adjusting box driver

JiGTDP003 BK

JiGDRiVER11055

AR

When fixing an y part to the

threaded hole using resin with

screw , use the jig. (Specified torque

5 kg)

These Jigs are used for checking

and adjusting the reel disk height.

There are two gauges used for the

tension measurements, 300 g and

2.o kg.

This Jig is used with the tension

gauge. Rotary transformer clearance adjusting jig.

This Jigs are used for loosening or

tightening special hexagon type

screws.

This Jig is used for height adjustment of the reverse guide (for

reverse guide height adjustment).

25

Page 26

27DV-S100

27DV-CS10

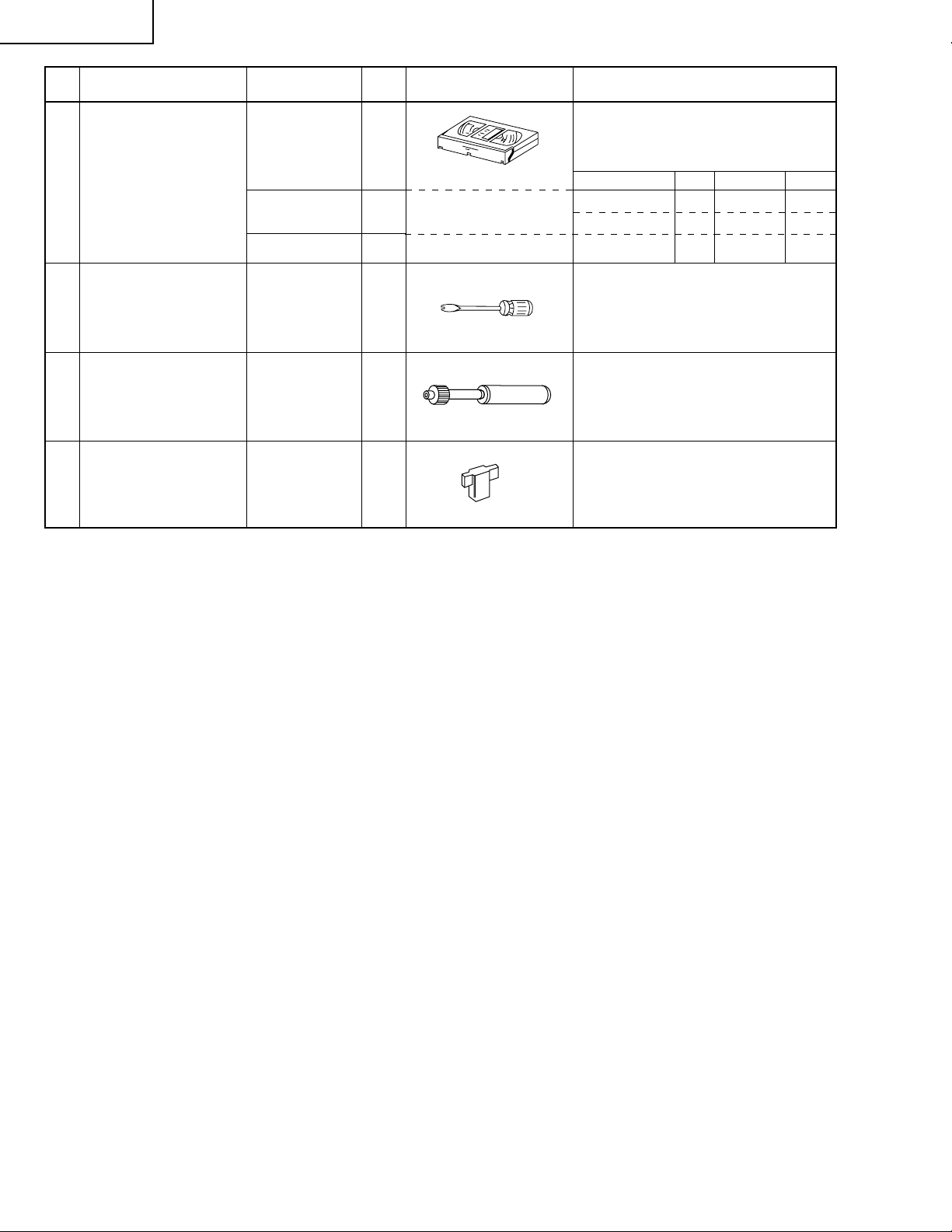

No. Jig Item Part No. Code Configuration Remarks

These tapes are especially used for

electrical fine adjustment.

10. Alignment T ape

Guide roller height

11.

adjustment drive

X value adjustment

12.

gear type screw driver

Reverse Guide Height

13.

Adjusting

VROATSV CD

VROEBZCS

JiGDRiVERH-4 AP

JiGDRiVER-6

JiGRVGH-F18

BM

BU

Video Audio Hi-Fi Audio Track

525 Monoscope 7k — 58µm

NTSC Color Bar 1k — 58µm

525 Monoscope 1k — 19µm

This screwdriver is used for adjusting the guide roller height.

For X value adjustment.

This Jig is used for height

adjustment of the reverse guide.

26

Page 27

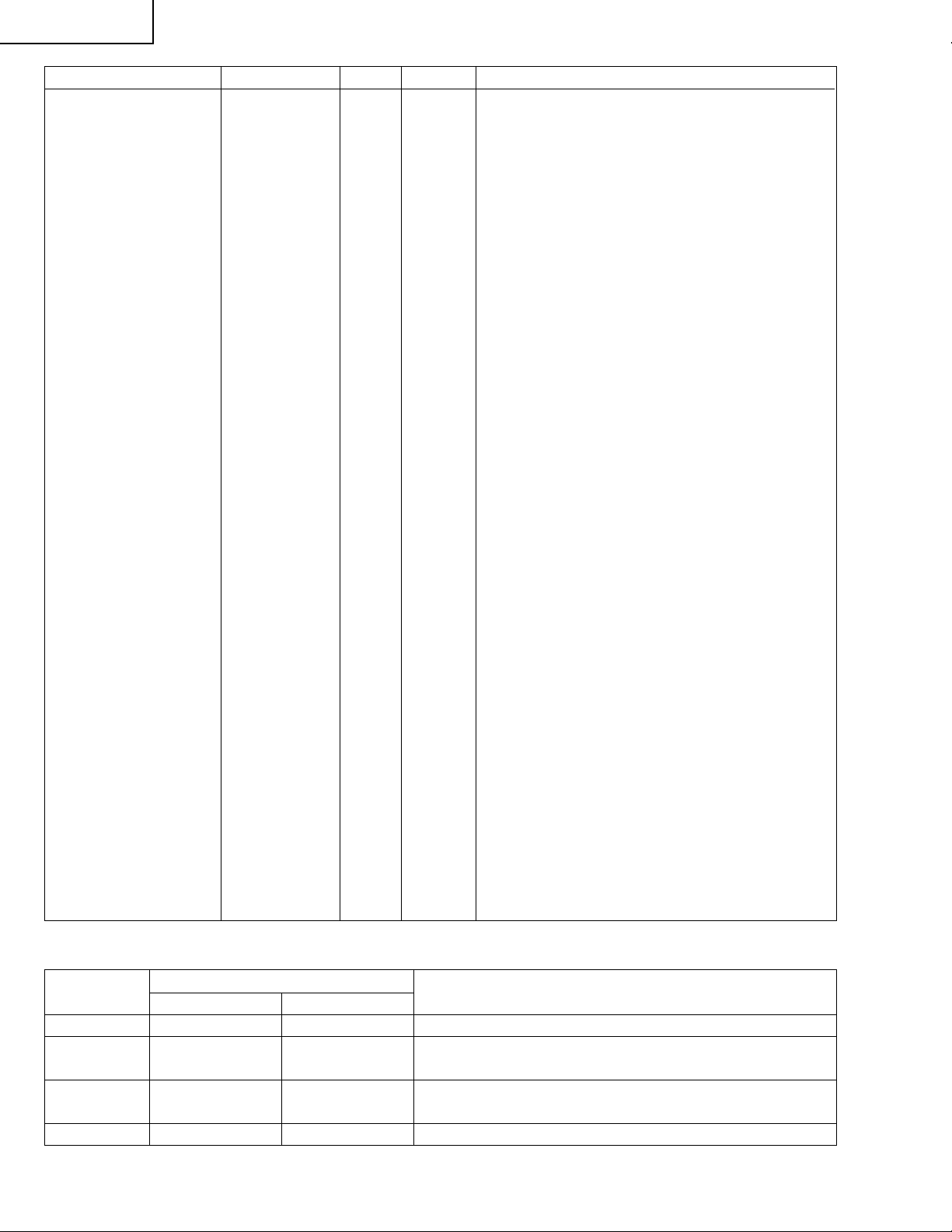

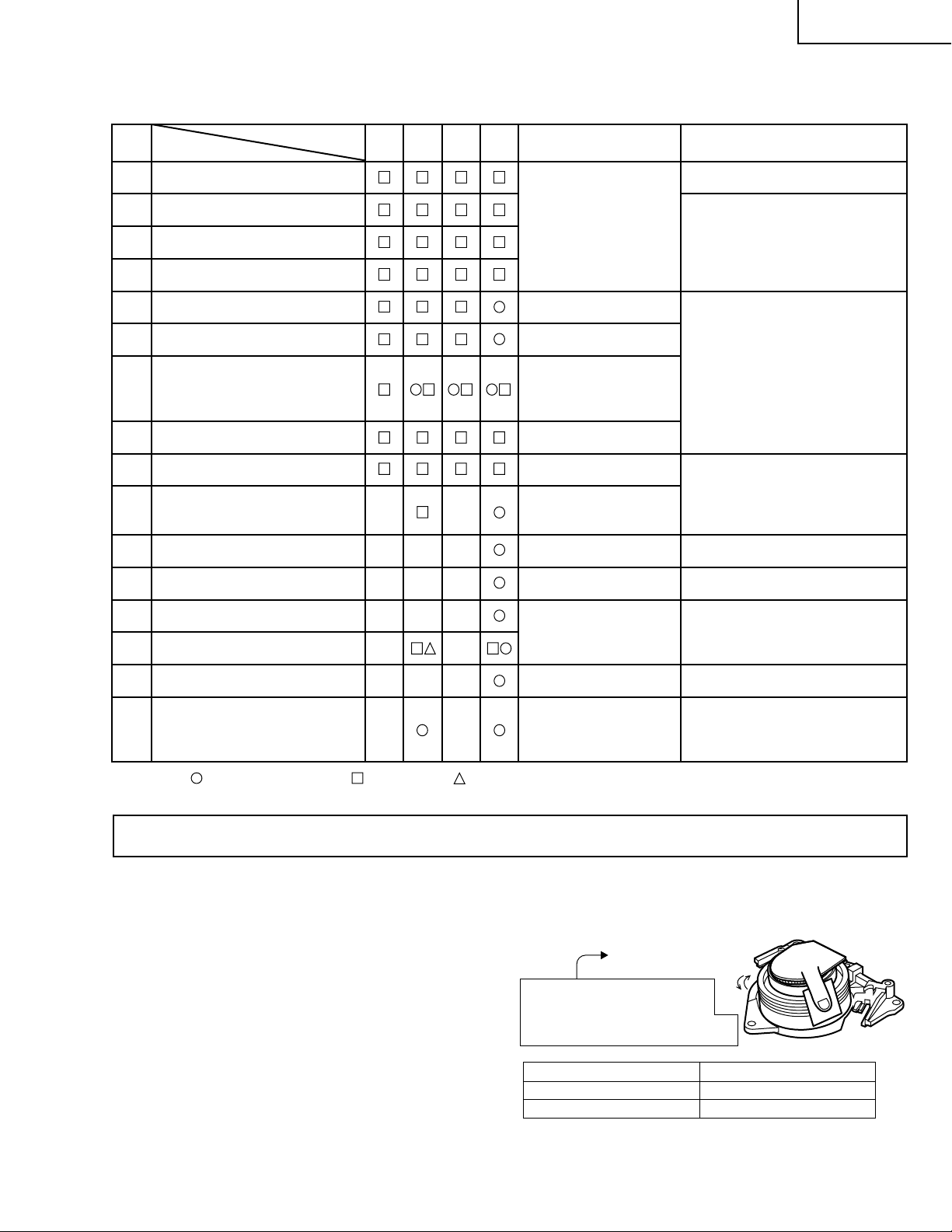

MAINTENANCE CHECK ITEMS AND EXECUTION TIME

NOTE : Part replacement. : Cleaning : Apply grease

<Specified> Cleaning liquid Industrial ethyl alcohol

Maintained

Parts

Remarks

Ref.No.

500

hrs.

1000

hrs.

1500

hrs.

2000

hrs.

Possible symptom

encountered

Guide roller ass’y

Sup guide shaft

Reverse guide

Slant pole on pole base

Full erase head

A/C head

Upper and lower drum ass’y

Capstan D.D. motor

Pinch roller

Reel belt

Tension band ass’y

Loading motor

Idler ass’y

Limiter pulley

Supply/take-up main brake levers

AHC

(Automatic Head Cleaner)

49

—

19

7,8

58

59

63

61

12

34

1

60

46

48

24,25

26

Colour and beating

Small sound or sound

distortion

No tape running,

uneven colour

No tape running, tape

slack

No tape running, tape

slack, no fast forward/

rewind motion

Lateral noises Head

occasionally blocked

Abnormal rotation or significant

vibration requires replacement.

Clean tape contact part with the

specified cleaning liquid.

Clean tape contact area with

the specified cleaning liquid.

Replace the roller of the

cleaner when it wears down.

Just change the AHC roller

assembly for new one.

Screen swaying

Cassette not loaded or

unloaded

No tape running, tape

slack

Tape slack

Clean rubber and rubber

contact area with the specified

cleaning liquid.

Poor S/N ratio, no

colour Poor flatness

of the envelope with

alignment tape

* This mechanism does not need electric adjustment with variable resistor. Check parts. If any deviation is found,

clean or replace parts.

Perform the maintenance with the regular intervals as follows so as to maintain the quality of machine.

27DV-S100

27DV-CS10

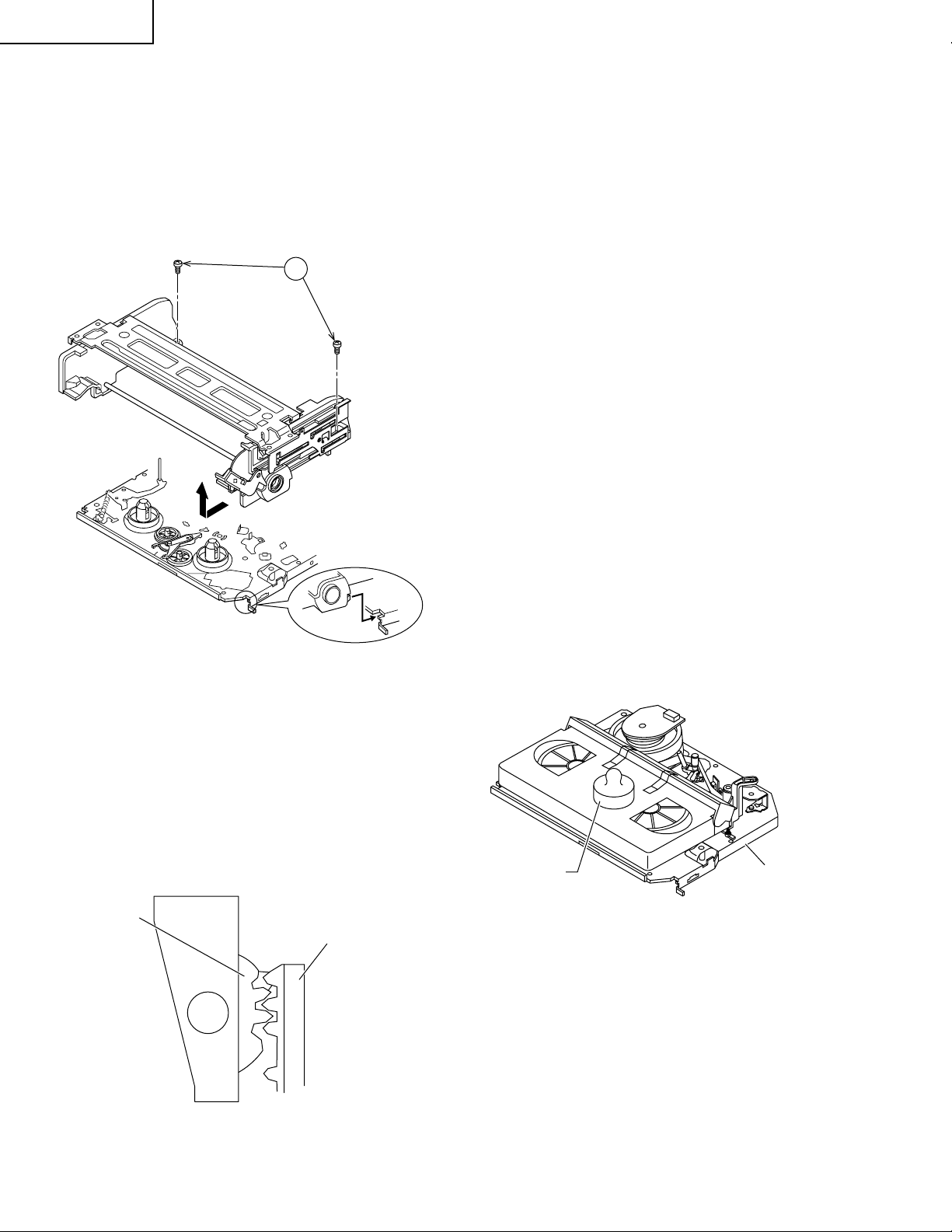

Video head cleaning procedure

1. Apply one drop of cleaning liquid to the cleaning paper with the baby oiler.

2. Gently press the cleaning paper against the video head to fix your finger, and move the upper drum so that each

head is passed to and for 5 times (do not move the cleaning paper).

3. Wipe with the dry cleaning paper.

Notes :

• Use the commercially available ethanol of Class 1 as

cleaning liquid.

• Since the video head may be damaged, do not move

up and down the cleaning paper.

• Whenever the video head is cleaned, replace the

cleaning paper.

• Do not apply this procedure for the parts other than

the video head.

Gently press the cleaning paper to

fix with your finger, and rotate the

upper drum to clean.

Move to and for 5 times for each head.

(Do not move the cleaning paper.)

ZPAPRA56-001E Cleaning Paper

ZOiLR-02-24TE Babe Oiler (Spoit)

Rotate the upper drum

with one hand.

Parts Code Description

27

Page 28

27DV-S100

500g

Mechanism chassis

Weight to prevent

float (500g)

27DV-CS10

REMOVING AND INSTALLING THE CASSETTE HOUSING

• Removal

1. In the cassette removing mode, remove the cassette.

2. Unplug the power cord.

3. Remove in the following numerical order.

a) Remove two screws 1.

b) Slide and pull up the cassette housing control.

1

Figure 1-1.

Notes:

1. When fitting the S/E sensor holder to the cassette

controller frame L/R, take care.

2. Misengagement of teeth of casecon drive gear and

drive angle gear causes malfunction. (The cassette

cannot be set, load and ejection are repeated).

3. In the case when you use the magnet screw driver,

never approach the magnet driver to the A/C head, FE

head, and drum.

4. When installing or removing, take care so that the

cassette housing control and tool do not contact the

guide pin or drum.

5. After installing the cassette housing control once perform cassette loading operation.

TO RUN A TAPE WITHOUT THE CASSETTE

HOUSING CONTROL ASSEMBLY

1. Remove the full-surface panel.

2. Short-circuit R7057 and JUMPER:420.

3. Plug in the power cord.

4. Turn off the power switch.

(The mechanism moves to the cassette mounting

position.)

5. Open the lid of a cassette tape by hand.

6. Hold the lid with two pieces of vinyl tape.

7. Set the cassette tape in the mechanism chassis.

8. Stabilize the cassette tape with a weight (500g) to

prevent floating.

9. Turn on the power switch.

10. Perform running test.

11. After running test, once turn off the power to let the

mechanism move to the cassette mounting position,

then remove the cassette.

• Reassembly

1. Before installing the cassette housing control, shortcircuit R7057 and JUMPER:420 provided on the main

PWB, prug in the power cord, and then press the

STOP/EJECT button. The casecon drive gear turns

and stops when the positioning mark appears. Engage

two teeth of casecon drive gear with the three teeth of

casecon drive angle gear, and set on the mechanism

chassis as shown below.

Casecon

drive gear

Casecon drive

angle gear

Figure 1-2.

2. Install in the reverse order of removal.

Figure 1-3.

Note:

The weight should not be more than 500g.

To take out the cassette tape.

1. Turn off the power switch.

2. Take out the cassette tape.

28

Page 29

27DV-S100

27DV-CS10

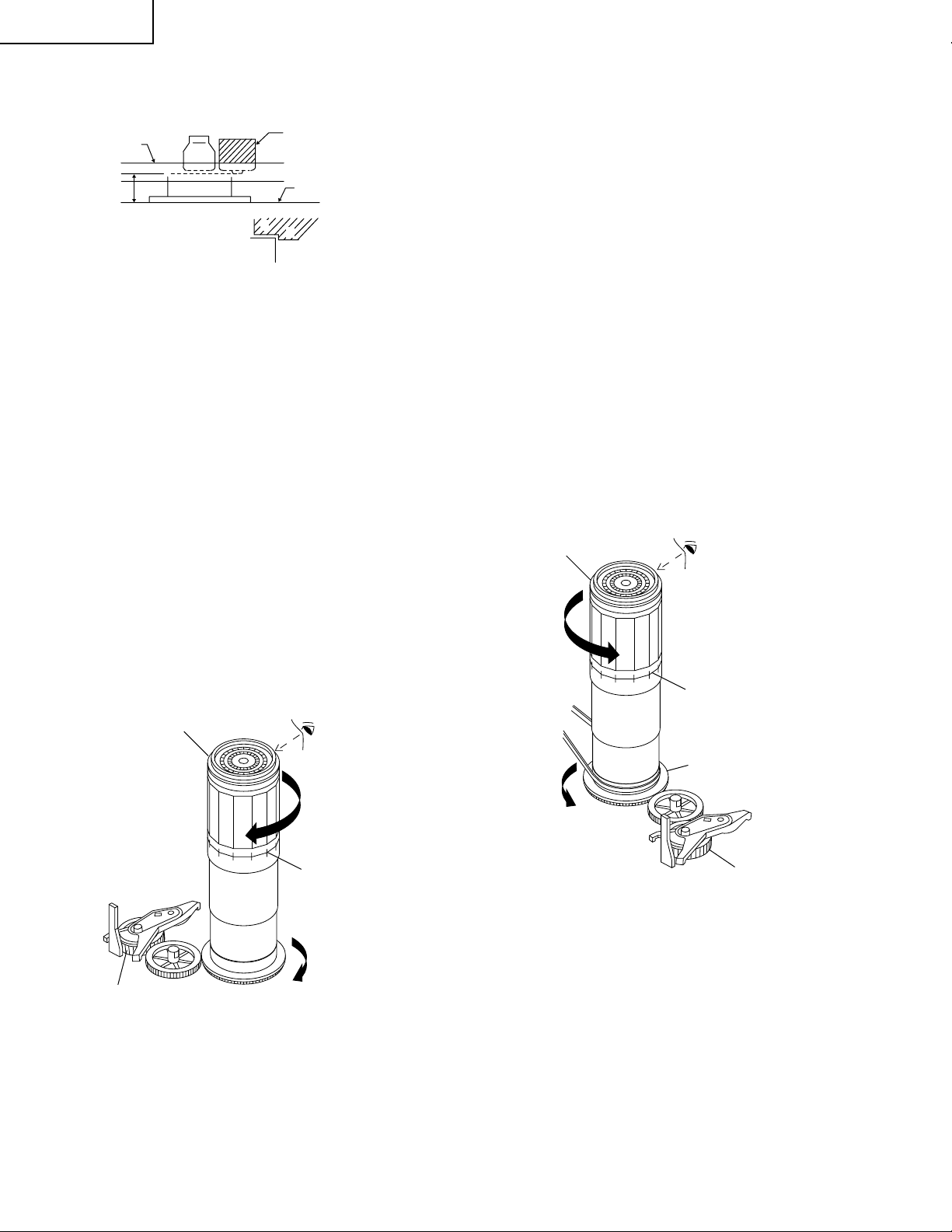

REEL DISK REPLACEMENT AND HEIGHT

CHECK

• Removal

1. Remove the cassette housing control assembly.

2. Pull the tension band out of the tension arm ass'y.

3. Remove the Supply/Take-up main brake ass'y.

4. Open the hook at the top of the reel disk, and remove

the reel disk.

Note:

Take care so that the tension band ass'y and main brake

ass'y (especially soft brake) are not deformed.

Tension arm ass'y

Supply main brake ass'y

Tension band ass'y

Supply reel disk

Take-up main brake ass'y

Take-up reel disk

3. After checking the reel disk height, wind the tension

band ass'y around the reel disk, and insert into the hole

of tension arm ass'y.

4. Assemble the Supply main brake ass'y.

Notes:

1. When installing the reel disk, take due care so that the

tension band ass'y is not deformed and grease does no

adhere.

2. Do not damage the Supply main brake ass'y. Be careful

so that grease does not adhere to the brake surface.

• Reassembly (Take-up reel disk)

1. Clean the reel disk shaft and apply grease (SC-141) to

it.

2. Align the phase of the reel disk to that of the reel relay

gear and to install a new take-up reel disk onto the

shaft.

3. Check the reel disk height and reassemble the take-up

main brake ass'y.

Note:

1. Take care so that the Take-up main brake ass'y is not

damaged. Take care so that grease does not adhere

the brake surface.

2. After reassembly, check the video search rewind back

tension (see page 32), and check the brake torque (see

page 34).

Figure 1-4.

Note:

When the tension band ass'y is pressed in the direction of

the arrow for removal, the catch is hard to be deformed.

Figure 1-5.

• Height checking and adjustment

Note:

1. Set the master plane with due care so that it does not

contact the drum.

2. When putting the master plane, shift the reverse guide

a little in the loading direction. Care must be taken

since excessive shift results in damage.

Master plane

Reverse

guide

Supply reel disk

Cassette lock

release shaft

Take-up reel disk

Position

pin

Figure 1-6.

• Reassembly (Supply reel disk)

1. Clean the reel disk shaft and apply grease (SC-141) to

it.

2. Match the phases of reel disk and reel relay gear, and

set the new reel disk.

Note:

Check that the reel disk is lower than part A but higher than

part B. If the height is not correct, readjust the reel disk

height by changing the poly-slider washer under the reel

disk.

• Problems caused by maladjustments

1. Tapes may get scratched.

29

Page 30

27DV-S100

27DV-CS10

Note:

Whenever replacing the reel disk, perform the height

checking and adjustment.

Master plane

10 ± 0.2mm

Reel disk

Reel disk

Reel disk height

adjusting jig

Mechanism chassis

A

B

Figure 1-7.

CHECKING AND ADJUSTMENT OF TAKEUP TORQUE IN FAST FORWARD MODE

• Remove the cassette housing control assembly.

• After short-circuiting R7057 and JUMPER:420

provided on the main PWB, plug in the power cord,

then turn on the power.

• Setting

1. Set a torque gauge to zero on the scale. Place it on the

take-up reel disk.

2. Press the FF button.

3. To calculate the remaining capacity of the play back

mode, slowly rotate the supply reel disk, and then shift

it into the forward mode.

• Checking

1. Turn the torque gauge slowly (one rotation every 2 to

3 seconds) by hand in the CW direction.

2. Make sure that the indication of torque gauge is not

less than 30mN·m (306gf·cm).

Torque gauge

Notes:

1. Hold the torque gauge by hand so that it is not moved.

2. Do not keep the reel disk in lock state. Do not allow

long-time measurement.

5. CHECKING AND ADJUSTMENT OF

TAKE-UP TORQUE IN REWIND MODE

• Remove the cassette housing control assembly.

• After short-circuiting R7057 and JUMPER:420

provided on the main PWB, plug in the power cord,

then turn on the power.

• Setting

1. Set a torque gauge to zero on the scale. Place it on the

supply reel disk.

2. Press the rewind button.

3. To calculate the remaining capacity, slowly rotate the

take-up reel disk, and then shift it into the rewind mode.

• Checking

1. Turn the torque gauge slowly (one rotation every 2 to

3 seconds) by hand in the CCW direction.

2. Make sure that the indication of torque gauge is not

less than 30mN·m (306gf·cm).

Torque gauge

30mN·m (306gf·cm)

or more

CCW

The gauge is held at

its maximum value.

(Red mark)

30mN·m (306gf·cm)

or more

Idler ass'y

Figure 1-8.

CW

The gauge is held at

its maximum value.

(Red mark)

• Adjustment

1. If the FF winding-up torque is less than the specified

value, clean the capstan D.D. motor pulley, drive belt,

and limiter pulley with cleaning liquid, and check again.

2. If the torque is less than the set value, replace the reel

belt.

• Problems caused by maladjustments

1. Tapes may fail to be wound up near the FF end.

Supply reel disk

Idler ass'y

Figure 1-9.

• Adjustment

1. If the rewind winding-up torque is less than the specified value, clean the capstan D.D. motor pulley, drive

belt, and limiter pulley with cleaning liquid, rewind

again, and check the winding-up torque.

2. If the winding-up torque is still out of range, replace the

drive belt.

• Problems caused by maladjustments

1. Tapes may fail to be wound up near the REW end.

30

Page 31

27DV-S100

27DV-CS10

Notes:

1. Hold the torque gauge by hand so that it is not moved.

2. Do not keep the reel disk in lock state. Do not allow

long-time measurement.

CHECKING AND ADJUSTMENT OF TAKEUP TORQUE IN RECORD/PLAYBACK

MODE

• Remove the cassette housing control assembly.

• After short-circuiting R7057 and JUMPER:420

provided on the main PWB, plug in the power cord.

• Turn off the power switch. (The mechanism moves

to the cassette mounting position.)

• Open the cassette torque meter lid, and fix it with

tape.

• Load the cassette torque meter into the unit.

• Put the weight (500g) on the cassette torque meter.

• Turn on the power switch.

• Press the picture record button, and set EP picture

record mode (x3).

Set value EP6.9 ± 2.5mN·m (70 ± 25gf·cm)

CHECKING AND ADJUSTMENT OF TAKEUP TORQUE IN VIDEO SEARCH REWIND

MODE

• Remove the cassette housing control assembly.

• After short-circuiting R7057 and JUMPER:420

provided on the main PWB, plug in the power cord,

then turn on the power.

• Setting

Press the playback button and rewind button to set the

video search rewinding mode.

• Checking

Place the torque gauge on the supply reel disk, and turn

it counterclockwise very slowly (one rotation every 1 to 2

seconds) and check that the torque is within the set value

14.0 ± 3.9mN⋅m. (144 ± 40gf⋅cm)

Torque gauge

CCW

500g

Cassette torque meter

Figure 1-10.

• Checking

1. Make sure that value is within the setting 6.9 ± 2.5mN·m

(70 ± 25gf·cm).

2. The winding-up torque fluctuates due to variation of

rotation torque of limiter pulley ass'y. Read the center

value of fluctuation as setting.

3. Set the EP record mode (x3) and make sure that the

winding-up torque is within setting.

• Adjustment

If the playback winding-up torque is not within the setting,

replace the limiter pulley assembly.

Note:

When the torque cassette is set, put a weight (500g) to

prevent rise.

When the cassette torque meter is taken out.

Turn off the power switch.

• Problems caused by maladjustments

1. Much maladjusted : Tapes may get scratched.

2. Slightly maladjusted : Tapes may get slack halfway,

resulting in the STOP mode.

: Tapes may get entangled.

Supply reel disk

Figure 1-11.

Note:

Surely put the torque gauge on the reel disk to measure.

If the torque gauge is raised, accurate measurement is

impossible.

• Adjustment

If the rewinding playback winding-up torque is not within

the setting, replace the limiter pulley assembly.

Note:

The winding-up torque fluctuates due to variation of

rotation torque of supply reel disk. Read the center value

of fluctuation as setting.

• Problems caused by maladjustments

1. Much maladjusted : Tapes may get scratched.

2. Slightly maladjusted : Tapes may get slack halfway,

resulting in the STOP mode.

: Images onscreen may get distorted.

: Tapes may get entangled.

: Tapes may became out from

cassette.

31

Page 32

27DV-S100

27DV-CS10

CHECKING THE VIDEO SEARCH REWIND

BACK TENSION

• Remove the cassette housing control assembly.

• After short-circuiting R7057 and JUMPER:420

provided on the main PWB, plug in the power cord,

then turn on the power.

• Checking

1. After pressing the play button, press the rewind button,

and set the video search rewind mode.

2. Place the torque gauge on the take-up reel disk, and

turn it counterclockwise very slowly (one rotation every

2 to 3 seconds) and check that the torque is within the

set value 3.4 ± 1.5mN⋅m (35 ± 15gf⋅cm).

• Problems caused by maladjustments

1. Tapes may get scratched whether much or slightly

maladjusted

Torque gauge

CCW

Tension gauge

Pinch roller

Capstan shaft

Tension gauge adapter

900 - 1,200gf

Figure 1-13.

1. Detach the pinch roller from the capstan shaft.

Do not separate excessively. Or the pinch lever and

pinch double action lever may disengage.

2. Engage the tension gauge adapter with the pinch roller

shaft, and pull in the arrow direction.

3. Gradually return the pinch roller, and measure the

pulling force when the pinch roller contacts the capstan

shaft.

4. Make sure that the measured value is within setting 9.0

N to 11.8 N (900 to 1,200gf).

Take-up reel disk

Figure 1-12.

Note:

Set the torque gauge securely on the take-up reel disk. If

it is not secure, the measurement will be incorrect.

CHECKING THE PINCH ROLLER

PRESSURE

• Remove the cassette housing control assembly.

• After short-circuiting R7057 and JUMPER:420

provided on the main PWB, plug in the power cord,

then turn on the power.

• Checking

Press the play button to set the playback mode.

• Problems caused by maladjustments

1. Much maladjusted : The service life of the capstan

and pinch roller may be shorter.

2. Slightly maladjusted : Images onscreen may get

distorted.

CHECKING AND ADJUSTMENT OF

TENSION POLE POSITION

• Remove the cassette housing control assembly.

• After short-circuiting R7057 and JUMPER:420

provided on the main PWB, plug in the power cord,

then turn off the power.

• Setting

1. Turn off the power switch.

2. Open the cassette tape (T-120), and fix with tape.

3. Set the cassette tape into the unit.

4. Put the weight (500g) on the cassette tape.

5. Turn on the power switch.

6. Make the adjustment with the beginning of a T-120

tape.

500g

Weight to prevent

float (500g)

Figure 1-14.

• Checking

1. Set a cassette tape, push the REC button to place the

unit in the SP record mode. Now check the tension pole

position.

(T-120)

32

Page 33

27DV-S100

90°

90°

Tension pole adjuster

500g

Weight to prevent

float (500g)

Cassette torque

meter

27DV-CS10

2. Visually check to see if the right edge of the tension

pole is within the 2.3 ± 0.25 from the right edge of the

Sup guide shaft.

Sup guide shaft

Tension pole

2.3 ± 0.25

Make the adjustment with the beginning of a T-120 tape.

Figure 1-15.

At left side from the center line

Tension pole adjuster adjusting range

Figure 1-18.

Adjust so that the delta mark of tension pole adjuster is

within 90° range (left, right).

CHECKING AND ADJUSTMENT OF

RECORD/PLAYBACK BACK TENSION

• Remove the cassette housing control assembly.

2.3 ± 0.25

Figure 1-16.

Insert the slotted screwdriver in the tension pole adjuster,

and rotate counterclockwise.

At right side from the center line

2.3 ± 0.25

Figure 1-17.

Insert the slotted screwdriver in the tension pole adjuster,

and rotate clockwise.

• Problems caused by maladjustments

1. Images onscreen may get distorted.

• After short-circuiting R7057 and JUMPER:420

provided on the main PWB, plug in the power cord,

then turn off the power.

• Setting

1. Turn off the power switch.

2. Open the torque cassette meter and fix with tape.

3. Set the cassette tape into the unit.

4. Put the weight (500g) on the cassette torque meter.

5. Turn on the power switch.

Figure 1-19.

• Checking

1. Push the REC button to place the unit in the SP record

mode.

2. At this time ascertain that the back tension is within the

setting (36.5 to 52g·cm) by seeing the indication of

torque cassette meter.

33

Page 34

27DV-S100

27DV-CS10

• Adjustment

1. If the indication of torque cassette meter is lower than

the setting, shift the tension spring engagement to the

part A.

2. If the indication of torque cassette meter is higher than

the setting, shift the tension spring engagement to the

part B.

• Problems caused by maladjustments

1. Much maladjusted : Tapes may get scratched.

2. Slightly maladjusted : Images onscreen may get

distorted.

BA

Tension arm

Tension spring

Figure 1-20.

CHECKING THE BRAKE TORQUE

• Checking the brake torque at the supply side

in the CW direction/CCW direction with respect to the

supply reel disk so that the reel disk and torque gauge

pointer rotate at equal speed, and make sure that the

value is within the setting (CW direction: 4.9 to 13.7mN·m

(50 to 140gf·cm); CCW direction: 2.9 to 9.8mN·m (30 to

100gf·cm).

• Checking the brake torque at the take-up side

Torque gauge

CW

Take-up reel

disk

CCW: 4.9~13.7mN⋅m (50~140gf⋅cm)

CW: 3.9~10.8mN⋅m (40~110gf⋅cm)

CCW

Figure 1-22.

• Remove the cassette housing control assembly.

Torque gauge

CCW

CCW: 2.9~9.8mN⋅m (30~100gf⋅cm)

CW: 4.9~13.7mN⋅m (50~140gf⋅cm)

CW

Supply reel disk

Figure 1-21.

• Remove the cassette housing control assembly.

• After short-circuiting R7057 and JUMPER:420

provided on the main PWB, plug in the power cord,

then turn on the power.

• Setting

1. Set a torque gauge to zero on the scale. Place it on the

supply reel disk.

2. Switch from the FF mode to the STOP mode.

3. Disconnect the power cord.

• Checking

Turn the torque gauge at a rate of about one turn/2 sec

• After short-circuiting R7057 and JUMPER:420

provided on the main PWB, plug in the power cord,

then turn on the power.

• Setting

1. Switch from the FF mode to the STOP mode.

2. Disconnect the power cord.

3. Set a torque gauge to zero on the scale. Place it on the

take-up reel disk.

• Checking

1. Turn the torque gauge at a rate of about one turn/2 sec

in the CCW direction/CW direction so that the reel disk

and torque gauge pointer rotates at equal speed and

make sure that the value is within the setting (CCW

direction: 4.9 to 13.7mN·m (50 to 140gf·cm), CW

direction: 3.9 to 10.8 mN·m (40 to 110gf·cm).

2. Adjustment of the brake torque at the supply side and

the take-up side

• Unless the supply side brake torque or take-up side

brake torque is within the setting, clean the felt surface

of reel disk (supply, take-up) brake lever, check again

the brake torque.

• If value cannot be set within the setting yet, replace the

main brake ass'y or main brake spring.

• Problems caused by maladjustments

1. From the FF or REW to the STOP mode

• Much maladjusted :The brake noise may get louder.

• Slightly maladjusted :Tapes may get slack and

scratched.

34

Page 35

27DV-S100

27DV-CS10

REPLACEMENT OF A/C (Audio/Control)

HEAD

1. Remove the cassette housing control assembly.

2. In unloading state unplug the power cord.

• Removal

1. Remove the screws 123, Azimuth screw, Tilt screw.

2. Unsolder the PWB fitted to the A/C head.

Notes:

1. When replacing, never touch the head. If you touched,

clean with the cleaning liquid.

2. When removing the screw 3, take care so that the

spring may out.

3

Azimuth screw

Spring

2

Figure 1-23.

Tilt screw

Height screw

1

section and A/C head front section) (See the figure be-

low.)

3. Align the left end of gear of A/C head arm with the

punched mark of chassis, tentatively tighten the screws

1 and 2 so as to ensure smooth motion of A/C head

arm. Tentative tightening torque must be 0.15 to 0.20

N·m (1.5 to 2.0kgf·cm).

1

3

Height screw

Left end of A/C head plate gear

2

Punched line mark on chassis

Figure 1-25.

Notes:

1. If the screws 1 and 2 are tighten tentatively too

loose, the azimuth and height of A/C head may change

when they are finally tightened. Therefore care must be

taken.