Page 1

25WF30

SERVICE MANUAL

S21Q425WF30//

COLOUR TELEVISION

Chassis No. NFC

MODEL

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

25WF30

FEATURES

Ë

Ë

100 CH Program Memory

Ë

A V Mode (Standard/ Dynamic/ Soft)

Ë

CATV Hyper Band Ready

Ë

Colour Comb Filter (NTSC)

Ë

ON/OFF Velocity Modulation

Ë

Black Stretch Circuit

Ë

Picture Noise Reduction

Ë

White Temp. Select

Aperture Control

Ë

Bass+

Ë

Multi Language (English/Thai)

Ë

Mono / Bilingual Select

Ë

ON/OFF Reminder Timer

Ë

Power Save Mode

Ë

Rear AV-In 1 & 2, S-Video In, AV Output

(Monitor Out), Headphone and Front AV-In 3

Ë

Component Intput Terminal

CONTENTS

Page

» SPECIFICATIONS .............................................2

» IMPORTANT SERVICE NOTES........................ 2

» ADJUSTMENT PRECAUTIONS........................3

» TROUBLE SHOOTING TABLE .......................13

» CHASSIS LAYOUT..........................................18

» BLOCK DIAGRAM........................................... 19

» WAVEFORMS..................................................27

» DESCRIPTION OF SCHEMATIC DIAGRAM ..28

» SCHEMATIC DIAGRAM

Ë

CRT UNIT.....................................................29

Ë

MAIN UNIT ...................................................30

Ë

POWER UNIT ..............................................34

Ë

OPERATION UNIT .......................................36

» PRINTED WIRING BOARD ASSEMBLIES.....37

» SOLID STATE DEVICE BASE DIAGRAM....... 45

» REPLACEMENT PARTS LIST

Ë

ELECTRICAL PARTS ..................................46

Ë

SUPPLIED ACCESSORIES.........................54

Ë

MISCELLANEOUS PARTS.......................... 54

Ë

PACKING PARTS.........................................54

Ë

CABINET PA RTS .........................................55

» PACKING OF THE SET...................................56

Page

WARNING

The chassis in this receiver is partially hot. Use an isolation transformer between the line cord plug and power

receptacle, when servicing this chassis. To prevent electric shock, do not remove cover. No user – serviceable

parts inside. Refer servicing to qualified service personnel.

SHARP CORPORATION

1

Page 2

25WF30

µµ

µµ

µA) for the set.

µµ

µµ

µA) in the case of the set. The set has been factory

IMPORTANT SERVICE NOTES

discharging the high voltage completely

Maintenance and repair of this receiver should be done by

qualified service personnel only .

SERVICING OF HIGH VOLTAGE SYSTEM AND

PICTURE TUBE

When servicing the high voltage system, remove static charge from it by

connecting a 10k ohm Resistor in series with an insulated wire (such as a

test probe) between picture tube dag and 2nd anode lead. (AC line cord

should be disconnected from AC outlet.)

1. Picture tube in this receiver employs integral implosion protection.

2. Replace with tube of the same type number for continued safety.

3. Do not lift picture tube by the neck.

4. Handle the picture tube only when wearing shatterproof goggles and after

X-RAY

This receiver is designed so that any X-Ray radiation is kept to an absolute

minimum. Since certain malfunctions or servicing may produce potentially

hazardous radiation with prolonged exposure at close range, the following

S1 thru S41

than 33.0 kV (at beam 0

precautions should be observed:

1. When repairing the circuit, be sure not to increase the high voltage to more

2. To keep the set in a normal operation, be sure to make it function on 29.0

Depth : 484 mm

Height : 586.5 mm

If there is a possibility that the high voltage fluctuates as a result of the

repairs, never forget to check for such high voltage after the work.

±1.5 kV (at beam 1,600

– Adjusted to the above-mentioned high voltage.

Weight (Approx): 37 kg

which may cause excess X-ray radiation.

3. Do not substitute a picture tube with unauthorized types and/or brands

BEFORE RETURNING THE RECEIVER

hardware is not lodged between the chassis and other metal parts in the

receiver.

fishpapers, cabinet backs, adjustment and compartment covers or shields, iso-

lation resistor-capacity networks, mechanical insulators and etc.

Before returning the receiver to the user, perform the following safety checks.

1. Inspect all lead dress to make certain that leads are not pinched or that

2. Inspect all protective devices such as non-metallic control knobs, insulating

2-1 2-2

SPECIFICATIONS

5.5 MHz .............................................................................................. 33.16 / 33.4 MHz

Convergence ..............................................................................Self Convergence System

Picture IF Carrier ............................................................................................... 38.9 MHz

Focus ..................................................................... Bi-Potential, Uni-Potential Electrostatic

Sweep Deflection................................................................................................... Magnetic

Intermediate Frequency

PAL ............................................................................................................... 34.47 MHz

Sound IF Carrier

Colour Sub-Carrier

NTSC............................................................................................................ 35.32 MHz

Power Input .................................................................................. AC 110 - 240V, 50/60 Hz

Power Consumption ...................................................................................................158 W

Audio Power Output Rating.......................................................................... 10W × 2 (Max)

Size ...................................................................................................... 6 × 12 cm × 2 pcs.

Receiving Channels

Speaker

PAL-B/G

Aerial Input Impedance ....................................................................... 75 ohm Unbalanced

Specifications are subject to change without prior notice.

VHF .......................................................................................................E2 thru E12

UHF .....................................................................................................E21 thru E69

CATV .......................................................................................................X thru Z + 2,

VHF ...................................................................................... 44.25 MHz thru 423.25 MHz

UHF.................................................................................... 431.25 MHz thru 863.25 MHz

Receiving Frequency

Dimensions ...............................................................................................Width: 622 mm

2

Page 3

SERVICE MODE 2

FORWARD : CH DOWN KEY

REVERSE : CH UP KEY

G-DRIVE

B-DRIVE

3 sec. TIME OUT

INITIAL

DRIVE

DATA

DATA

0 - 127 63

LENGTH

DOWN

4 KEY

5 KEY

6 KEY

F/B KEY

25WF30

0 KEY

Press service/ language for 2 sec,

SERVICE MODE

50Hz ADJ.

SERVICE MODE 1

CUT OFF

1.) In the Service Mode, Key is used to select the mode in the following order.

C bus control and in the

2

RASTER

it will enter into service mode 2.

Press service/ language for 2 sec again,

it will jump back to service mode 1.

Press the MENU button

again at the remote controller,

it will jump back to

MODE

MODE

MODE

SUB 1 ADJ.

60 Hz ADJ.

SUB 2 ADJ.

MODE

MODE

MODE

Service Mode 1.

Press the MENU button

at the remote controller,

it will enter into

Service Mode Option.

OPTION

SERVICE MODE

"—/——"

BKGD

MODE

CUT OFF

CUT OFF/ BKGD MODE

3 sec. TIME OUT

CUT OFF

R-CUT OFF

G-CUT OFF

B-CUT OFF

DATA

INITIAL

DATA

LENGTH

LATERAL MODE

(R, G, B-CUT OFF)

63 - 255 63

UP

KEY

1 KEY

R-CUT OFF

2 KEY

G-CUT OFF

3 KEY

7 KEY

B-CUT OFF

G-DRIVE

8 KEY

B-DRIVE

C bus control include preset-only items

2

ADJUSTMENT PRECAUTIONS

the I2C bus control). (Use JWS Key to set as well).

one by one.

one by one.

service mode.

1 Make a short-circuit JA373 and JA374, enter into the service mode. (Adjustment through

2 Press the CH DOWN / UP key on the remote controller to get ready to select the mode

3 Press the CH DOWN / UP key on the remote controller to select the modes reversibly

4 Using the VOLUME UP/ DOWN key on the remote controller, the data can be modified.

5 When the short circuit between JA373 and JA374 is cut off, it will be released from the

This model’s setting are adjusted in two different ways: though the I

conventional analog manner. The adjustments via the I

and variable data.

1. Setting the service mode by the microprocessor.

2. Factory Presetting.

3-1 3-2

are automatically preset, only when a new EEPROM is used (Judge with the first 4

bytes).

1 Make a short-circuit JA373 and JA374 and turn on the main power switch. Initial values

2 The initial data are preset as listed in page.

FIRST TIME, make sure to make a short-circuit JA373 and JA374 to switch to the

service mode position first and then turn on the main power switch. (See 2-1 above).

Precaution: If haven’t done this initiation, it may possibly generate excessive Beam

current.

3 Make sure the data need modify or not (Initial data).

Note: Once the chassis has been assembly together and ready to be POWER ON for the

3

Page 4

25WF30

SERVICE MODE

DATA

Also, once press the menu button at the remote controller, EEPROM will switch

to SERVICE MODE OPTION.

Once press the menu button again at the remote controller, EEPROM will switch

• While SERVICE MODE 1 on, EEPROM DATA will switch to the service data.

User Data in Service Mode Option

TRAPEZIUM 50 Hz (TRAPE 50)

E/W CORNER 50 Hz (E/W COR 50)

50 Hz ADJ. MODE

back to SERVICE MODE 1.

• In the service option the user data establish as below,

Service Mode Option

E/W PARABOLA 50 Hz (E/W PAR 50)

H-SIZE 50 Hz (H-SIZE 50)

H-POSITION 50 Hz (H-CENT 50)

60 Hz ADJ. MODE

1 COMB OPTION ON/OFF COMB OP OPTION OFF

2 DVD OPTION ON/OFF DVD OP OPTION OFF

3 PAL OPTION ON/OFF PAL OP OPTION ON

4 6.5 M SIF FIX 0 ~ 1 6.5 M 1 CHIP 6.5 M SIF FIX (1) 0

5 ROTATION OPTION ON/OFF ROTA OP OPTION OFF

6 SYAKIT OPTION ON/OFF SYAKIT OP OPTION OFF

7 SPATIALIZER OPTION ON/OFF SPA OP OPTION OFF

8 FLAT OPTION ON/OFF FLAT OP OPTION (ON:FL) OFF

9 SPEAKER 1 ~ 3 SPEAKER OPTION SP1 (1) 1

11 HOTEL POSITION 0 ~ 99 H POSITION OPTION 0

No. EEPROM ITEM DATA LENGTH OSD IC DATA SETTING INITIAL

TRAPEZIUM 60 Hz (TRAPE 60)

E/W CORNER 60 Hz (E/W COR 60)

E/W PARABOLA 60 Hz (E/W PAR 60)

H-SIZE 60 Hz (H-SIZE 60)

10 HOTEL ON/OFF ON/OFF H MODE OPTION OFF

H-POSITION 60 Hz (H-CENT 60)

SUB 2

12 HOTEL VOLUME 0 ~ 60 H VOLUME OPTION 0

13 LANGUAGE OPTION 1 ~ 2 LANG OPTION 2

14 MONO BILINGUAL ON/OFF MO/BIL OPTION OFF

SUB COLOR (SUB COLOR)

SUB COLOR (DVD) (SUB COLOR DVD)

V-ENT (V-ENT)

1 COMB ON

2 DVD ON

No. EEPROM ITEM DATA

H-ENT (H-ENT)

RF AGC (RF AGC)

3 PAL ON

4 6.5 M 1

5 ROTA OFF

6 SYAKIT OFF

SECAM BELL (SCM BELL)

SPRIT/INTER (S/I)

7 SPA OFF

8 FLAT ON

9 SPEAKER 1

11 H POS 0

10 H MODE OFF

12 H VO 0

RF SUB SOUND (RF S-SOUND)

HEAD PHONE (HP SUB VOL)

SUB VOLUME ADJ.

13 LANG 2

COLOR TEMP. (WT)

14 MO / BIL ON

PIFVCO (PIFVCO)

LNA (LNA)

SIF574 (SIF574)

AFC (AFC)

4-1 4-2

V-SIZE 50 Hz (V-SIZE 50)

V-LINEARITY 50 Hz (V-LINE 50)

VS-CORRECTION 50 Hz (VS-CORR 50)

V-POSITION 50 Hz (V-CENT 50)

V-SIZE 60 Hz (V-SIZE 60)

V-LINEARITY 60 Hz (V-LINE 60)

VS-CORRECTION 60 Hz (VS-CORR 60)

V-POSITION 60 Hz (V-CENT 60)

SUB 1

SECAM R-Y (SCM R-Y)

SECAM B-Y (SCM B-Y)

4

BRIGHT (SUB BRI)

BRIGHT (DVD) (SUB BRI DVD)

SUB CONT (SUB CONT)

SUB CONT (DVD) (SUB CONT DVD)

SUB TINT (SUB TINT)

SUB TINT (DVD) (SUB TINT DVD)

FORWARD : CH DOWN KEY

REVERSE : CH UP KEY

Page 5

DATA

INITIAL EEPROM

OSD IC DATA SETTING

DATA LENGTH

3

DC RESTORATION

25WF30

3

ABL START POINT

1 WPS 0 ~ 1 WPS 1 CHIP WPS 1

2 SUB CONTRAST 0 ~ 127 S CONT 1 CHIP CONTRAST 127

NO. EEPROM ITEM

2. SERVICE MODE 2

3 NTSC PHASE (NT) 0 ~ 3 N-PNT 1 CHIP NTSC PHASE 0

4 NTSC PHASE (PAL/SEC.) 0 ~ 3 N-P PS 1 CHIP NTSC PHASE 0

5 NTSC PHASE (DVD) 0 ~ 3 N-PD 1 CHIP NTSC PHASE 3

6 SUB SHARPNESS (TV) 0 ~ 63 S SHARP T 1 CHIP SHARPNESS 10 12

EEPROM

DATA

INITIAL

OSD IC DATA SETTING

DATA LENGTH

7 SUB SHARPNESS (AV) 0 ~ 63 S SHARP A 1 CHIP SHARPNESS 10 20

8 SUB SHARPNESS (DVD) 0 ~ 63 S SHARP D 1 CHIP SHARPNESS 10 20

9 RGB MUTE 0 ~ 1 RGB MUTE 1 CHIP RGB MUTE OFF

11 Y-DL (NTSC-M) 0 ~ 3 YNM 1 CHIP Y-DL 1

10 RGB CONTRAST 0 ~ 63 RGB CONT 1 CHIP RGB CONTRAST 32

12 Y-DL (PAL-B/G) 0 ~ 3 YPB 1 CHIP Y-DL 1

13 Y-DL (PAL-I) 0 ~ 3 YPI 1 CHIP Y-DL 3

14 Y-DL (PAL-D/K) 0 ~ 3 YPD 1 CHIP Y-DL 3

15 Y-DL (SECAM-B/G) 0 ~ 3 YSB 1 CHIP Y-DL 0

16 Y-DL (SECAM-D/K) 0 ~ 3 YSD 1 CHIP Y-DL 3

17 Y-DL (B/W) 0 ~ 3 YBW 1 CHIP Y-DL 0

18 Y-DL (NTSC-AV) 0 ~ 3 YNA 1 CHIP Y-DL 0

19 Y-DL (PAL-AV) 0 ~ 3 YPA 1 CHIP Y-DL 0

20 Y-DL (SECAM-AV) 0 ~ 3 YSA 1 CHIP Y-DL 0

21 Y-DL (B/W-AV) 0 ~ 3 YBA 1 CHIP Y-DL 0

22 SUB COLOUR 0 ~ 31 SUB COL 1 CHIP SUB-COLOUR 16

23 VSM GAIN AVM1 0 ~ 7 V-GAIN 1 1 CHIP VSM GAIN 3

24 VSM GAIN AVM2 0 ~ 7 V-GAIN 2 1 CHIP VSM GAIN 5

25 VSM GAIN AVM3 0 ~ 7 V-GAIN 3 1 CHIP VSM GAIN 7

26 BASE BAND TINT 0 ~ 31 B-B TINT 1 CHIP BASE BAND TINT

27 SECAM GP-PHASE 0 ~ 3 S G-PHASE 1 CHIP S SP-PHASE 1

28 SECAM ID-SENS 0 ~ 1 S ID-SENS 1 CHIP S ID-SENS 0

29 SECAM ID-MODE 0 ~ 1 S ID-MODE 1 CHIP S ID-MODE 0

30 PIF FREQ 0 ~ 7 P FREQ 1 CHIP PIF FREQ 3

31 P/N-ID 0 ~ 1 PN ID 1 CHIP P/N-ID 0

32 YS/YM MODE 0 ~ 1 YSM MODE 1 CHIP YSM MODE 1

33 RGB ABCL 0 ~ 1 RGB ABCL 1 CHIP RGB ABCL 1

34 DC RESTORATION 0 ~ 3 DC REST 1 CHIP

35 BLACK STRETCH 0 ~ 3 B ST 1 CHIP BLACK STRETCH 1

36 ABL START POINT 0 ~ 3 ABL ST 1 CHIP

37 ABL GAIN 0 ~ 3 ABL GA 1 CHIP ABL GAIN 2

38 AKB MODE 0 ~ 63 AKB MODE 1 CHIP AKB MODE 0

39 COLOUR 0 ~ 1 COL G 1 CHIP COLOUR 1

40 V AGC 0 ~ 1 V AGC 1 CHIP V AGC 0

41 V RAMP REF 0 ~ 1 V RAMP 1 CHIP V RAMP 1

42 VSM PHASE 0 ~ 1 VSM PHASE 1 CHIP VSM PHASE 0

43 BASS LEVEL ON 0 ~ 3 BA LV SUR/SPA BASS LEVEL 0

44 BASS OFF AVM1 SP1 0 ~ 4 #1 BA OFF 1 SP1 SUR/SPA BASS SW, LEVEL 4

45 BASS OFF AVM2 SP1 0 ~ 4 #1 BA OFF 2 SP1 SUR/SPA BASS SW, LEVEL 4

46 BASS OFF AVM3 SP1 0 ~ 4 #1 BA OFF 3 SP1 SUR/SPA BASS SW, LEVEL 4

47 BASS OFF AVM1 SP2 0 ~ 4 #1 BA OFF 1 SP2 SUR/SPA BASS SW, LEVEL 4

48 BASS OFF AVM2 SP2 0 ~ 4 #1 BA OFF 2 SP2 SUR/SPA BASS SW, LEVEL 4

49 BASS OFF AVM3 SP2 0 ~ 4 #1 BA OFF 3 SP2 SUR/SPA BASS SW, LEVEL 4

50 BASS OFF AVM1 SP3 0 ~ 4 #1 BA OFF 1 SP3 SUR/SPA BASS SW, LEVEL 4

51 BASS OFF AVM2 SP3 0 ~ 4 #1 BA OFF 2 SP3 SUR/SPA BASS SW, LEVEL 4

52 BASS OFF AVM3 SP3 0 ~ 4 #1 BA OFF 3 SP3 SUR/SPA BASS SW, LEVEL 4

53 BASS OFF AVM1 SP4 0 ~ 4 #1 BA OFF 1 SP4 SUR/SPA BASS SW, LEVEL 4

54 BASS OFF AVM2 SP4 0 ~ 4 #1 BA OFF 2 SP4 SUR/SPA BASS SW, LEVEL 4

8

V S-CORRECTION

9

V S-CORRECTION

5-1 5-2

0 ~ 15 V S-CORR 50 1 CHIP

0 ~ 63 E/W PAR 50 1 CHIP E/W PARABORA 39

0 ~ 63 HP SUB VOL SOR/SPA VOLUME 63

00H 23H 02H 18H

01H 23H 03H A3H

Address Data Address Data

After short JA373 & JA374, and turn on the main power switch, read data from EEPROM Address

00H ~ 03H, and compare to the list below, if different, initialize the EEPROM.

0 MICOM INFO. DISPLAY SERVICE MODE

1 CUT OFF REFER # CUTOFF BKGD

No. EEPROM SETTING

1. SERVICE MODE 1

VS-CORRECTION (50Hz) #2

2 CUT OFF (DVD) REFER # CUTOFFBKGD (DVD)

3 V-SIZE 0 ~ 63 V-SIZE 50 1 CHIP V-SIZE 30

4 V-LINEARITY (50Hz) #2 0 ~ 15 V S-LINE 50 1 CHIP V-LINEARITY 10

5

6 V-POSITION #2 0 ~ 7 V-CENT 50 1 CHIP V-PHASE 5

7 H-POSITION #2 0 ~ 31 H-CENT 50 1 CHIP H-PHASE 11

E/W-PARABOLA (50Hz) #2

8 H-SIZE (50Hz) #2 0 ~ 63 H-SIZE 50 1 CHIP H-SIZE 32

9

H. PHONE SUB VOL. ADJ.

11 TRAPEZIUM (50Hz) #2 0 ~ 31 TRAPE 50 1 CHIP TRAPEZIUM 17

10 E/W CORNER (50Hz) #2 0 ~ 15 E/W COR 50 1 CHIP E/W CORNER 6

12 SECAM R-Y #3 0 ~ 15 SCM R-Y 1 CHIP SR-Y 8

13 SECAM B-Y #3 0 ~ 15 SCM B-Y 1 CHIP SB-Y 8

14 BRIGHT 0 ~ 127 SUB BRI 1 CHIP BRIGHTNESS 80

15 BRIGHT (DVD) 0 ~ 127 SUB BRI DVD 1 CHIP BRIGHTNESS 80

16 SUB CONT 0 ~ 15 SUB CONT 1 CHIP SUB CONT 3

17 SUB CONT (DVD) 0 ~ 15 SUB CONT DVD 1 CHIP SUB CONT 3

18 TINT 0 ~ 127 SUB TINT 1 CHIP TINT 64

19 TINT (DVD) 0 ~ 127 SUB TINT DVD 1 CHIP TINT 16

20 V-SIZE 0 ~ 63 V-SIZE 60 1 CHIP V-SIZE 39

21 V-LINEARITY 0 ~ 15 V-LINE 60 1 CHIP V-LINEARITY 10

22 VS-CORRECTION (60Hz) 0 ~ 15 V S-CORR 60 1 CHIP

23 V-POSITION (60Hz) 0 ~ 7 V-CENT 60 1 CHIP V-PHASE 2

24 H-POSITION (60Hz) 0 ~ 31 H-CENT 60 1 CHIP H-PHASE 14

25 H-SIZE (60Hz) 0 ~ 63 H-SIZE 60 1 CHIP H-SIZE 34

26 E/W PARABOLA (60Hz) 0 ~ 63 E/W PAR 60 1 CHIP E/W PARABORA 19

27 E/W CORNER (60Hz) 0 ~ 15 E/W COT 60 1 CHIP E/W CORNER 4

28 TRAPEZIUM (60Hz) 0 ~ 31 TRAPE 60 1 CHIP TRAPEZIUM 6

29 COLOUR 0 ~ 127 SUB COL 1 CHIP COLOUR 60

30 COLOUR (DVD) 0 ~ 127 SUB COL DVD 1 CHIP COLOUR 60 45

31 V-ENT 0 ~ 7 V-ENT 1 CHIP V-ENT 6

32 H-ENT 0 ~ 7 H-ENT 1 CHIP H-ENT 4

33 RF AGC 0 ~ 63 RF AGC 1 CHIP RF AGC 46

34 SECAM BELL 0 ~ 1 SCM BELL 1 CHIP S BELL 0

35 SPRIT/INTER 0 ~ 1 S/I 1 CHIP SPRIT/INTER 0

36 RF SUB SOUND 0 ~ 127 RF S-SOUND 1 CHIP RF SUB SOUND 96

37 SUB VOLUME 0 ~ 63 SUB VOL SOR/SPA VOLUME 45

38

39 COLOUR TEMP. 0 ~ 1 WT OPTION 1

40 PIF VCO #4 PIFVCO -

41 LNA ON/OFF LNA OPTION OFF

42 SIF574 ON/OFF SIF574 1 CHIP SIF574 OFF ON

tion, check some iformation will be displayed.

43 AFC AFC OFF

#1 Whiles selecting SERVICE MODE 1, MICOM Version Information, SOFTWARE V ersion Informa-

#2 60 Hz Adjustment Value is programmed from ± 50 Hz Adjustment value (± will be informed later)

#3 While adjusting SECAM R-Y, SECAM B-Y and S BLACK of 1 chip is set to 1.

#4 While choosing PIFVCO MODE and RF AGC set to "0 0" and PIFVCO is set to "1".

5

Page 6

25WF30

DATA

INITIAL EEPROM

OSD IC DATA SETTING

DATA LENGTH

111 TREBLE AVM2 SP2 #6 TRE 2 SP2 +2

112 TREBLE AVM3 SP2 #6 TRE 3 SP2 +8

NO. EEPROM ITEM

DATA

INITIAL EEPROM

OSD IC DATA SETTING

DATA LENGTH

113 TREBLE AVM1 SP3 #6 TRE 1 SP3 -10

114 TREBLE AVM2 SP3 #6 TRE 2 SP3 0

115 TREBLE AVM3 SP3 #6 TRE 3 SP3 +5

116 TREBLE AVM1 SP4 #6 TRE 1 SP4 -10

117 TREBLE AVM2 SP4 #6 TRE 2 SP4 +2

118 TREBLE AVM3 SP4 #6 TRE 3 SP4 +6

119 BASS MODE AVM1 SP1 ON/OFF #7 BA MO 1 SP1 OFF

120 BASS MODE AVM2 SP1 ON/OFF #7 BA MO 2 SP1 OFF

121 BASS MODE AVM3 SP1 ON/OFF #7 BA MO 3 SP1 ON

122 BASS MODE AVM1 SP2 ON/OFF #7 BA MO 1 SP2 OFF

123 BASS MODE AVM2 SP2 ON/OFF #7 BA MO 2 SP2 OFF

124 BASS MODE AVM3 SP2 ON/OFF #7 BA MO 3 SP2 ON

125 BASS MODE AVM1 SP3 ON/OFF #7 BA MO 1 SP3 OFF

126 BASS MODE AVM2 SP3 ON/OFF #7 BA MO 2 SP3 OFF

127 BASS MODE AVM3 SP3 ON/OFF #7 BA MO 3 SP3 ON

128 BASS MODE AVM1 SP4 ON/OFF #7 BA MO 1 SP4 OFF

129 BASS MODE AVM2 SP4 ON/OFF #7 BA MO 2 SP4 OFF

130 BASS MODE AVM3 SP4 ON/OFF #7 BA MO 3 SP4 ON

131 CONTRAST A VM1 #8 CONT 1 55

132 CONTRAST A VM2 #8 CONT 2 57

133 CONTRAST A VM3 #8 CONT 3 60

134 CONTRAST AVM1 FL #8 CONT 1 FL 55

135 CONTRAST AVM2 FL #8 CONT 2 FL 57

136 CONTRAST AVM3 FL #8 CONT 3 FL 60

137 COLOUR A VM1 #9 COL 1 0

138 COLOUR A VM2 #9 COL 2 0

139 COLOUR A VM3 #9 COL 3 +10

140 COLOUR AVM1 FL #9 COL 1 FL 0

141 COLOUR AVM2 FL #9 COL 2 FL 0

142 COLOUR AVM3 FL #9 COL 3 FL +10

143 SHARP A VM1 #10 SHARP 1 -5

144 SHARP A VM2 #10 SHARP 2 0

145 SHARP A VM3 #10 SHARP 3 0

146 SHARP AVM1 FL #10 SHARP 1 FL -5

147 SHARP AVM2 FL #10 SHARP 2 FL 0

148 SHARP AVM3 FL #10 SHARP 3 FL 0

149 γ- POINT AVM1 #11 G-POINT 1 3

150 γ- POINT AVM2 #11 G-POINT 2 2

151 γ- POINT AVM3 #11 G-POINT 3 1

152 γ- POINT AVM1 FL #11 G-POINT 1 FL 3

153 γ- POINT AVM2 FL #11 G-POINT 2 FL 2

154 γ- POINT AVM3 FL #11 G-POINT 3 FL 1

155 SEARCH SPEED #12 S SPE 450

156 OSD 0 ~ 127 OSD-H 2

157 BUZZ 0 ~ 1 BUZZ 1 CHIP BUZZ 0

158 AV AFC 0 ~ 1 AV AFC 1

159 TEXT H 0 ~ 63 TEXT H TEXT 30

160 TEXT V 0 ~ 63 TEXT V TEXT 30

161 NVM NVM EEPROM

6-1 6-2

55 BASS OFF AVM3 SP4 0 ~ 4 #1 BA OFF 3 SP4 SUR/SPA BASS SW, LEVEL 4

56 AGC SW 0 ~ 1 AGC SW SUR/SPA AGC SW ON

NO. EEPROM ITEM

57 AGC ADJ 0 ~ 3 AGC AD SUR/SPA AGC ADJ 3 2

58 FM LEVEL #2 FM L NICAM FM LEVEL +1

59 IGR LEVEL #2 IGR L NICAM IGR LEVEL +2

60 NICAM B/G LEVEL #3 BG L NICAM NICAM B/G LEVEL -1

61 NICAM 1 LEVEL #3 I L NICAM NICAM I LEVEL +4

62 NICAL D/K LEVEL #3 DK L NICAM NICAM D/K LEVEL -1

63 LOWER ERROR 0 ~ 255 L ERR NICAM LOWER ERROR 35

64 UPPER ERROR 0 ~ 255 U ERR NICAM UPPER ERROR 70

65 IGR GAIN (9873H) #4 IGR G NICAM IGR GAIN (9873H) 0

66 NICAM SPEED 0 ~ 3 N SPEED NICAM N SPEED 2

67 INTER/EXTER 0 ~ 1 IN/EX NICAM INTER/EXTER 0

68 AUTO MUTE 0 ~ 1 AM NICAM AUTO MUTE OFF ON

69 AGC SW ON/OFF 0 ~ 1 AGC SW NICAM AGC SW OFF

70 AGC GAIN 0 ~ 31 AGC G NICAM AGC GAIN 16

71 SYAKIT VOLUME 1 0 ~ 21 SVOL 1 SYAKIT SVOLUME 1 0

72 SYAKIT VOLUME 2 0 ~ 3 SVOL 2 SYAKIT SVOLUME 2 0

73 SYAKIT LOU 0 ~ 1 SLOU SYAKIT SLOU 1

74 SYAKIT ATT 0 ~ 7 SATT SYAKIT SATT OUT 0

75 SYAKIT BASS 0 ~ 13 SBASS SYAKIT S-BASS 6

76 SYAKIT TREBLE 0 ~ 13 STRE SYAKIT S-TREBLE 6

77 MAX LEVEL SYAKIT 1 0 ~ 5 S1MA 3

78 MAX LEVEL SYAKIT 2 0 ~ 5 S2MA 4

79 MAX LEVEL SYAKIT 3 0 ~ 5 S3MA 6

80 START LEVEL SYAKIT 1 0 ~ 63 S1ST 17

81 START LEVEL SYAKIT 2 0 ~ 63 S2ST 21

82 START LEVEL SYAKIT 3 0 ~ 63 S3ST 20

83 WIDE LEVEL SYAKIT 1 0 ~ 7 S1W1 6

84 WIDE LEVEL SYAKIT 2 0 ~ 7 S2W1 3

85 WIDE LEVEL SYAKIT 3 0 ~ 7 S3W1 3

86 STOP LEVEL SYAKIT 1 0 ~ 5 S1SP 1

87 STOP LEVEL SYAKIT 2 0 ~ 5 S2SP 1

88 STOP LEVEL SYAKIT 3 0 ~ 5 S3SP 1

89 BASS MAX SYAKIT 1 0 ~ 15 SBASS1 12

90 BASS MAX SYAKIT 2 0 ~ 15 SBASS2 11

91 BASS MAX SYAKIT 3 0 ~ 15 SBASS3 10

92 TREBLE MAX SYAKIT 1 0 ~ 15 STRE1 12

93 TREBLE MAX SYAKIT 2 0 ~ 15 STRE2 11

94 TREBLE MAX SYAKIT 3 0 ~ 15 STRE3 10

95 BASS AVM1 SP1 #6 BASS 1 SP1 -5

96 BASS AVM2 SP1 #6 BASS 2 SP1 +2

97 BASS AVM3 SP1 #6 BASS 3 SP1 +5

98 BASS AVM1 SP2 #6 BASS 1 SP2 -5

99 BASS AVM2 SP2 #6 BASS 2 SP2 0

100 BASS AVM3 SP2 #6 BASS 3 SP2 +5

101 BASS AVM1 SP3 #6 BASS 1 SP3 -5

102 BASS AVM2 SP3 #6 BASS 2 SP3 0

103 BASS AVM3 SP3 #6 BASS 3 SP3 +10

104 BASS AVM1 SP4 #6 BASS 1 SP4 -5

105 BASS AVM2 SP4 #6 BASS 2 SP4 -2

106 BASS AVM3 SP4 #6 BASS 3 SP4 +6

110 TREBLE AVM1 SP2 #6 TRE 1 SP2 -5

107 TREBLE AVM1 SP1 #6 TRE 1 SP1 -5

108 TREBLE AVM2 SP1 #6 TRE 2 SP1 0

109 TREBLE AVM3 SP1 #6 TRE 3 SP1 +5

6

Page 7

PROM.

2

ITEM DATA SETTING

VM OFF

TEXT 1

LNA OFF

ON TIMER IN ACTIVE

ON TIMER CH IN ACTIVE

ON TIMER VOLUME IN ACTIVE

REMINDER IN ACTIVE

AFT ALL CH ON

COLOUR SYSTEM ALL CH AUTO

SKIP ALL CH OFF

NICAM ON/OFF ALL CH ON

NICAM STEREO MODE ALL CH STEREO

NICAM BILINGUAL MODE ALL CH M1

NICAM MONO MODE ALL CH MONO

IGR ON/OFF ALL CH ON

IGR STEREO MODE ALL CH STEREO

IGR BILINGUAL MODE ALL CH MAIN

MONO BILINGUAL MODE SOUND1

25WF30

FACTORYSET 9

SHIPPING SETTING AND CHECKING

SELECT

ITEM DATA SETTING

LAST POWER ON

LAST TV/AV MODE TV

LAST CH CH1

FLASH BACK CH1

FAVORITE CH1 CH10

FAVORITE CH2 CH20

FAVORITE CH3 CH30

FAVORITE CH4 CH40

1 DIGIT/2 DIGIT 2 DIGIT

VOLUME 0

H/P-VOLUME 0

ROTATION 0

R/C 238(EEh)

ITEMS DATA SETTING

S-SYSTEM B/G

LANGUAGE THAI

(1) The following default data has been factory-set for the E

STTM

SAVE OFF

SOFT STANDARD DYNAMIC

MODE 1 2 3

AV MODE 2

BALANCE 0

BLUE BACK OFF

AUTO SELECT ON

TINT 0 0 0

BRIGHT 0 0 0

COLOUR # # #

CONTRAST # # #

SHAKIT OFF OFF OFF

SHARPNESS # # #

WHITE TEMP 0 0 0

PEICTURE NR OFF OFF OFF

BASS # 0 #

LEVEL 0 0 0

BASS + # # #

SOR/SPA OFF OFF OFF

TREBLE # 0 #

# SERVICE MODE DATA

INITIAL SETTING

0

1 Thai Local CH-3 55.25 PAL B/G

2 Thai Local CH-5 175.25 PAL B/G

3 Thai Local CH-7 189.25 PAL B/G

4 Thai Local CH-9 203.25 PAL B/G

5 Thai Local CH-11 217.25 PAL B/G

6 Thai Local CH-29 535.25 PAL B/G78

TV-CH. CH-No. Fv (MHz) S-SYSTEM

R/C CODE MCL 4(171:Abh)

(1) Execute MCL 4key to set the following data in EEPROM.

9

10

11 STTM Factory CH-E2 48.25 PAL B/G

12 STTM Factory CH-E4 62.25 PAL B/G

13 STTM Factory CH-E8 196.25 PAL B/G

14 STTM Factory CH-E10 210.25 SECAM B/G

15 STTM Factory CH-E12 224.25 PAL B/G

16 STTM Factory CH-E21 471.25 PAL B/G

17 STTM Factory CH-E69 855.25 PAL B/G18192021 STTM Factory CH-E12 223.95 PAL B/G

7

22 STTM Factory CH-E12 224.55 PAL B/G

23 STTM Factory CH-E12 223.85 PAL B/G

24 STTM Factory CH-E12 224.65 PAL B/G

25 STTM Factory CH-E12 223.75 PAL B/G

26 STTM Factory CH-E12 224.75 PAL B/G27282930

31 STTM Factory CH-J1 91.25 NTSC M

32 STTM Factory CH-J3 103.25 NTSC M

33 STTM Factory CH-J4 171.25 NTSC M

34 STTM Factory CH-J6 183.25 NTSC M

35 STTM Factory CH-J8 193.25 NTSC M

36 STTM Factory CH-J10 205.25 NTSC M

37 STTM Factory CH-J12 217.25 NTSC M

7-1 7-2

38 STTM Factory CH-J38 217.25 NTSC M

Page 8

25WF30

Note:The setting below is automati-

cally set when the SUB-VOL is

selected in the service mode.

* SURROUND OFF

* A V MODE (STANDARD)

* S-NORMAL state

* S-VOL Max

* Bass + OFF

SOUND ADJUSTMENT

Adjustment Condition / Procedure Waveform or others

Signal content: 400 Hz 100% Mod.

nector.

indicate 5.2 Vrms (at L-CH)

1. Receive PAL Colour Bar signal.

2. Connect the probel of the meter (*) to (SI) con-

Adjustment value: 5.0± 0.3 Vrms

3. Select the SUB-VOL in the service mode.

4. Adjust the SUB-VOL data to make the meter

sure the sound is heard from the speakers.

Then put the unit in no signal state.

1. Receive the PAL Colour Bar signal.

2. Turn up the volume control to maximum, make

b

Fig. 4-1

a

90 mm 90 mm

PURITY ADJUSTMENT

Vertical Bv: 0.1G

Horizontal Bh: 0.1G

Adjustment Condition / Procedure Waveform or others

mote controller, and set the beam current of

1,400µA with the contrast control.

3. Check the sound mute is effective.

4. Finally turn sound level of CTV to minimum.

1. Select the green monocolour screen with re-

coil. For the adjustable magnetic field.

2. Degauss the CRT enough with the degausing

A=B

B

A

A=B

B

A

Fig. 4-2 Rank A (On the right of CRT)

netic field and keep the static convergence

roughly adjusted.

With P-MG, adjust it to the center - rank A.

through the microscope. Move DY fore and aft

to set the landing at the point (rank A).

center "Rank AB).

the east direction.

Tightening torqu: 180N ± 20N (11kgf ± 2kgf)

netic sheet to set the landing at Rank A for

3. Maintain the purity magnet at the zero mag-

4. Observe the points a, b, as shown in Fig.4-1

5. If the a/b balance is poor , compensate it to the

6. Align it to zero, keeping the raster rotation in

7. Tighten the defrection coil fastening screw.

compensation.

8. Checking the CRT corner area, bond the mag-

changed to another content.

Please refer to the following

ond in NORMAL MODE, the col-

our will change to RGB mono

Fig. 4-3 Rank A (On the left of CRT)

Note:This adjustment must be done after

warming up the unit for 30 minutes or longer

with a beam current over 1400 ± 50 µA.

colour mode.

* Press R/C RGB key for 1 sec-

Note:Select the service mode, and press the

monocolour key of R/C for process,and the

monocolour screen (green) will be selected.

Every push of the monocolor key changes the

screen as follows.

page.

* Adjustment for uniformity is

RED

ONLY

BLUE

ONLY

Single-colour

screen cleared

ONLY

GREEN

(BUS

ADJUST-

Adjustment point

No.

SERVICE ADJUSTMENT

PIF ADJUSTMENT CHECKING

MENT)

1 SUB VOL

IF OUT

1000p

75ohm

1n60

100k

10k

Oscilloscope

Adjustment Condition / Procedure Waveform or others

signal, but with no signal input.

Adjust the PLL data.

1. Get the tuner ready to receive the CH. E-10

to the tuner antenna. (RF SWEEP)

2. Connect the sweep generator’s output cable

CHECKING

2 NOISE MUTE

E-9 CH

Fig. 1

ANCE probe with wave detector ; see Fig.1)

to the tuner’s IF output terminal. (This terminal

3. Adjust the sweep generator’s to 80dBµV .

4. Connect the response lead (use LOW IMPED-

ADJUSTMENT

Adjustment point

1 PURITY

No.

-1.5+/-0.8dB

Fig. 2

P C

For the 50Ω signal strength

gauge, when not using 50/75

impedance adapter, signal

Note:

strength is 52 ± 1 dBµV (75Ω

Oscilloscope

+

during this adjustment.

Signal Strength: 54 ± 1 dbµV (75Ω open)

must have the probe alone connected).

with the waveform.

as shown in Fig. 2.

5. Set the RF AGC to 0 - 6 V with no saturation

6. Adjust the tuner IF coil to obtain the waveform

Note: Be sure to keep the tuner cover in position

AGC Terminal) as shown in Fig. 3.

1. Receive the PAL Colour bar signal.

2. Connect the oscilloscope to TP201 (Tuner’s

open), instead of 54 ± 1 dBµV

(75Ω open).

The loss of using impedance

adapter.

Precaution:

TP201

0.1V

TV SET

BIAS Box

Fig. 3

–

+

–

Bias Box : about 4.5V

"AG" bus data to obtain the Tuner output pin

3. Call "AG" mode in service mode. Adjust the

BB"CUPB’A

5V

2.5V

DC voltage at TP803

drop 0.1 ~ 1.0 V below maximum voltage.

67 dBµV, and make sure there is no noise.

sure that there is no cross modulation beat.

4. Change the antenna input signal to 63 ~

5. Turn up the input signal to 90 ~ 95 dBµV to be

of IC800) in the main unit.

1. Do not receive any signal.

2. Connect the digital voltmeter to TP803 (pin (54)

3. Call the "PIF VCO" Mode at the service mode.

Down

and adjust T800 to make DC voltage of TP803

become 2.5 ± 0.1 V in the range.

4. Verify that it is turned counterclockwise to 0V

the up direction and clockwise for

Adjust T800 to B point, between B'

the down direction.

and B".

* Turn the coil counterclockwise for

8-1 8-2

Tuner IFT

(PRESET)

TU200

Adjustment point

1

No.

TAKE OVER

POINT

2 RF-AGC

C BUS

2

ADJUSTMENT

(I

CONTROL)

8

ADJUSTMENT

3 PIF VCO COIL

Page 9

B G R

B G R

Fig. 5-1

R G B

R G B

Fig. 5-2

R G B

Fig. 5-3

B G R

Fig. 5-4

Wedge "a"

About

100 Deg.

Wedge "c"

Fig. 5-5

CRT Neck

26 ± 0.5mm

Lacquer

4-Pole Magnet

25WF30

Fig. 5-6

B G R

Adjustment Condition / Procedure Waveform or others

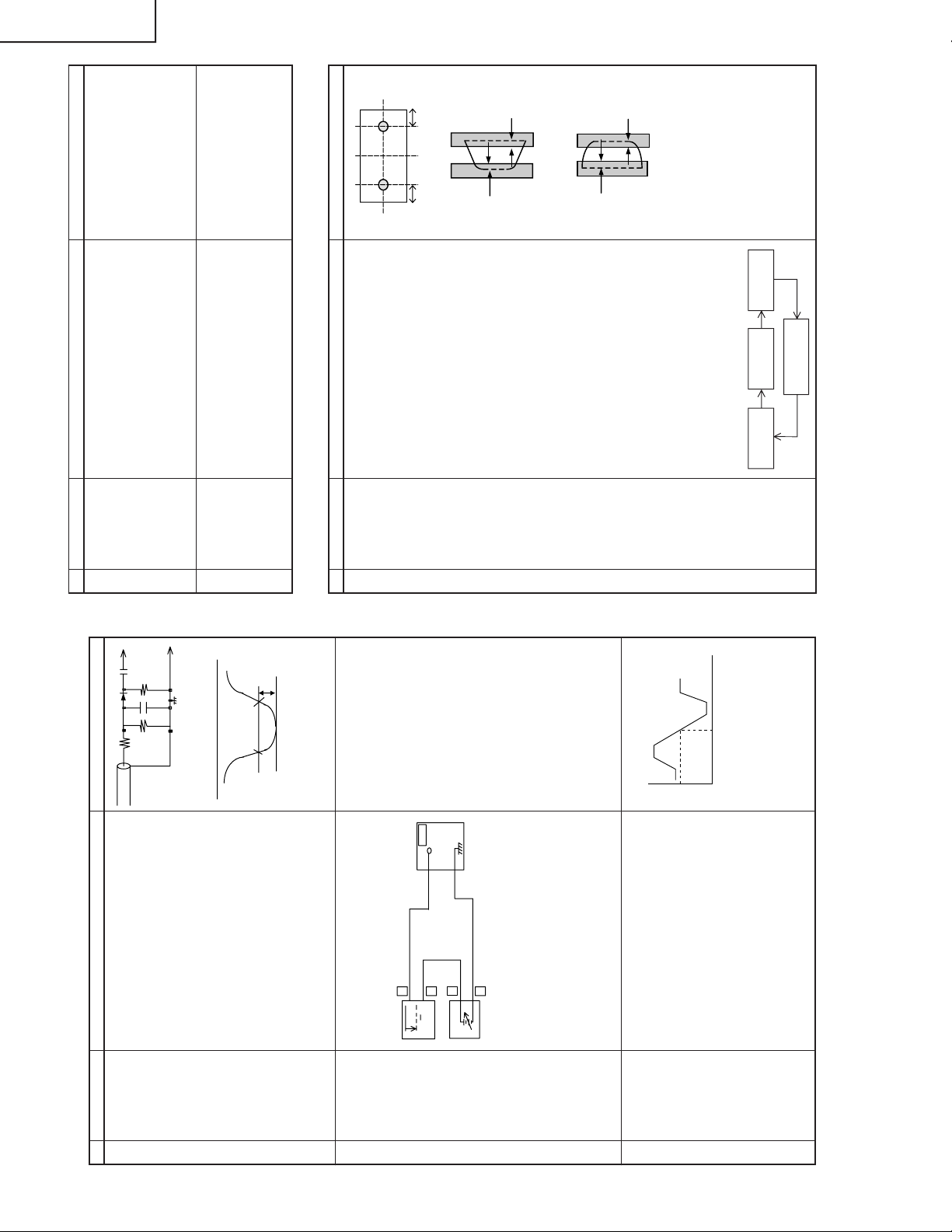

CONVERGENT ADJUSTMENT

mode.

1. Receive the Crosshatch Pattern signal.

2. Using the remote controller, call NORMAL

CONVER-

GENCE

ADJUSTMENT

Adjustment point

1

No.

angle in order to superpose the blue and red

colours.

angle in order to superpose the green colour

Static convergence

1. Turn the 4 - pole magnet to a proper opening

(To be done

after the purity

adjustment.)

over the blue and red colours.

2. Turn the 6 - pole magnet to a proper opening

Dynamic convergence

Drive the wedge at point "a" and swing the

screen in the following steps.

a) Fig. 5-1:

1. Adjust the convergence on the fringes of the

R G B

deflection coil upward.

Drive the wedge at point "b" and "c" and

swing the deflection coil downward.

Drive the "c" wedge deeper and swing the

deflection coil rightward.

Drive the "b" wedge deeper and swing the

b) Fig. 5-2:

c) Fig. 5-3:

deflection coil leftward.

d) Fig. 5-4:

tape over them.

2. Fix all the wedges on the CRT and apply glass

3. Apply lacquer to the deflection yoke lock screw,

Lacquer

About

100 Deg.

magnet unit (purity, 4 - pole, 6 - pole magnets)

and magnet unit lock screw.

Finally received the Red - only and Blue - only

signals to make sure there is no other colours

6-Pole Magnet.

Wedge "b"

on the screen.

Purity Magnet

Miss landing

(CRT surface)

Adjustment Condition / Procedure Waveform or others

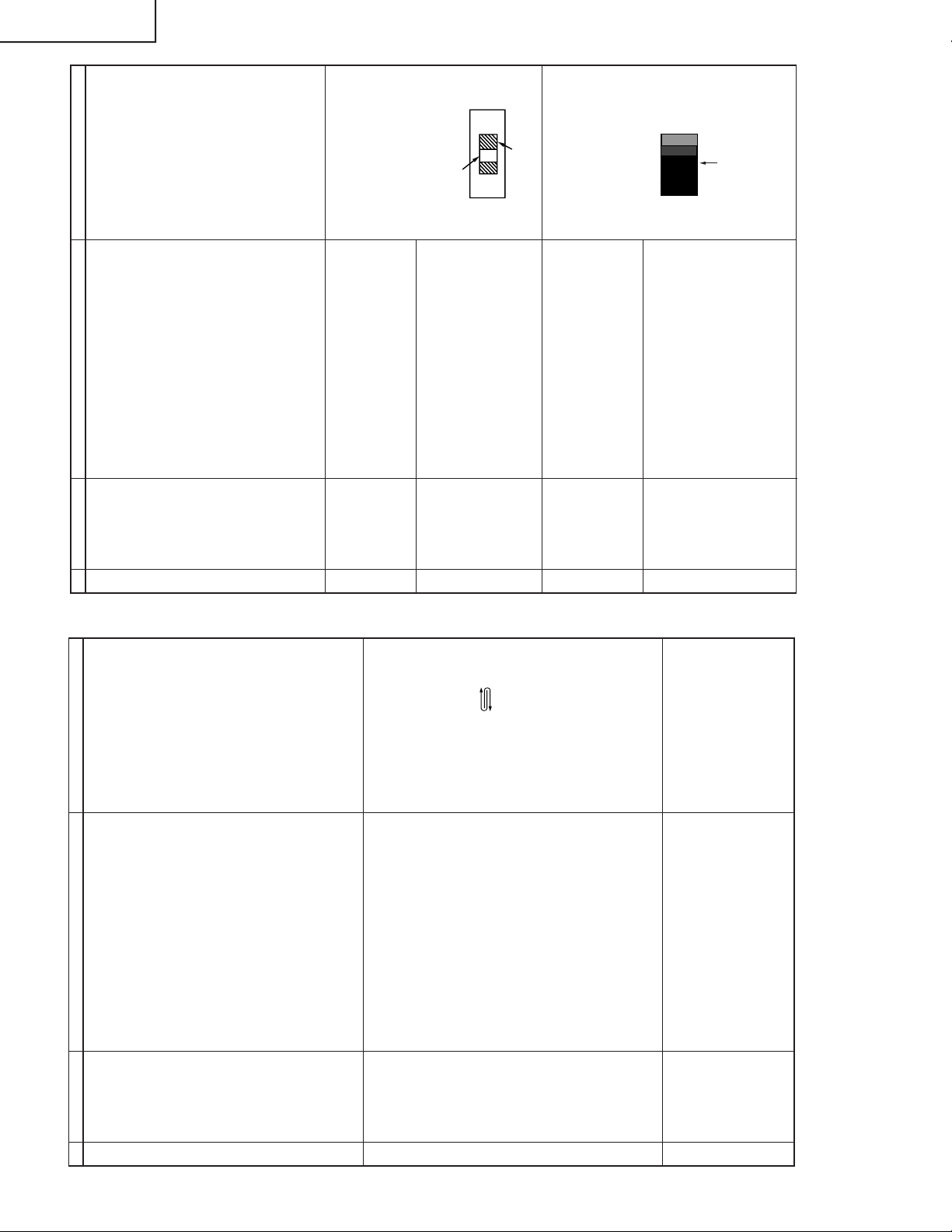

UNIFORMITY ADJUSTMENT

Before adjustment begin,

Horizontal magnetic field =

Vertical magnetic field = 0.1G

Make sure degauss it.

(North direction Red uniformity)

1. Horizontal mf = Set to monocolour screen Red

adjustment

(To perform

after the purity

and conver-

gence

Adjustment point

1 Uniformity

No.

adjustment.)

Compensation magnet

(CRT back)

and adjust to + 0.25G.

ing is poor, adjust by attaching the compen-

sation magnet at the back of the CRT. (Refer

to figure.)

2. Pay attention to the edge of CR T, if the land-

and adjust to - 0.25G.

(South direction Red uniformity)

1. Horizontal mf = Set to monocolour screen Red

2. Pay attention to the edge of CR T, if the land-

ing is poor, adjust by attaching the compen-

sation magnet at the back of the CRT.

monocolour screen Blue for blue uniformity,

and changing both the magnetic field for North

and South direction.)

use the crosshatch pattern.

Make sure there is no blur or bend lines oc-

cur.

If the blur or bend lines are serious, adjust

(The same mothod is aplied for adjustment of

* During the pasting of compensation magnet,

the location of compensation magnet to make

9-1 9-2

it better.

9

Page 10

25WF30

SUB-CONT ADJUSTMENT

Adjustment Condition / Procedure Waveform or others

standard mode.

controller.(AV MODE: DYNAMIC)

& TP1602.

Ammeter full scale-3mA range

TP1602 is connected at the - side of the am-

meter.

TP1601 is connected at the + side of the am-

1. Receive E-5CH "Monoscope pattern" with

2. Make the pictur normal with the remote

3. Connect the beam ammeter between TP1601

meter.

4. Adjust the beam current to 1.6mA ± 20µA with

Use "Y" of Minolta color analyzer

CA-100 in adjustment.

Use the PAL window pattern of

the signal generator for adjust-

ment. (PAL and colour burst are

Note 3:

Note 4:

R1759 (sub-contrast VR).

beam current 1,400±50µA or more for 30 min

or more.

Note : Apply the adjustment after aging with the

(On the white or green monocolor screen)

controller.(AV MODE: DYNAMIC)

1. Receive the window pattern with AV input.

2. Make the picture normal with the remote

3. Select the SUB-CONTRAST adjustment

provided.)

mode with the remote controller, and adjust

50% white to 165 ± 10cd.

1. Select the DVD mode.

50% white for SUB-CONT

Note 5:Window Pattern

tor. (Component signal) (Window pattern)

2. Receive the signal of the DVD signal genera-

3. Make the picture normal with the remote

Dark white for SUB-BRIGHT

tern) or equivalent signal is re-

ceived.

remote controller.

* When E-2 CH (Crosshatch pat-

controller.(AV MODE: DYNAMIC)

mode (DVD) with the remote controller, and

adjust 50% white to 165 ± 10 cd.

4. Select the SUB-CONTRAST adjustment

controller.(AV MODE: DYNAMIC)

1. Receive the window pattern with AV input.

2. Make the picture normal with the remote

left) black of the window pattern

1.Make the image normal with the

2.Adjust the 3rd (1 thru 5 from the

with the remote controller, and adjust the right

dark white area of the window pattern to 5.5

± 0.5 cd.

3. Select the SUB-BRIGHT adjustment mode

CUT OFF POINT

to sink.

tor. (Component signal) (Window pattern)

controller.(AV MODE: DYNAMIC)

(DVD) with the remote controller, and adjust

the right dark white area of the window pat-

1. Select the DVD mode.

2. Receive the signal of the DVD signal genera-

3. Make the picture normal with the remote

tern to 5.5 ± 0.5 cd of window pattern.

4. Select the SUB-BRIGHT adjustment mode

MAX BEAM

R1759

Adjustment point

1

No.

the R/G/B-cut and the B/G-Drive is

at initial value.

* Befor doing adjustment, make sure

C BUS

2

ADJUSTMENT

CONTRAST

2 SUB-

(AV SIGNAL)

(SUB-CONT)

I

SUB3

DOWN "4" KEY

as below.

Note:Data up/Down is possible

R CUT OFFUP "1" KEY

G CUT OFFUP "2" KEY

C BUS

2

ADJUSTMENT

CONTRAST

(SUB-CONT

DVD) I

DOWN "5" KEY

DOWN "6" KEY

B CUT OFF UP "3" KEY

G-DRIVE UP "7" KEY

(DVD SIGNAL)

DOWN " "KEY

DOWN "0" KEY

B-DRIVE UP "8" KEY

* 12,300°K X : 0.272 ± 0.005

C

2

BUS CON-

TROL (AV

SUB-

BRIGHTNESS

4

SIGNAL)

(SUB-BRI) I

SUB-

BRIGHTNESS

(SUB-BRI

5

Y : 0.275 ± 0.005

on the shipment initial setting ta-

(With Monolta colour thermometer

CA-100)

ble.

* The colour temperature is based

Use the window pattern of the

Note2:

C BUS

2

CONTROL

(DVD SIGNAL)

DVD) I

signal generator SX1006 for

adjustment.(PAL, colour burst is

generated with signal genera-

tor.)

10-1 10-2

Adjustment Condition / Procedure Waveform or others

OFF BKGD mode at the service mode.

lect the horizontal centering mode.

first lighting horizontal centering rasterslighly

CUT OFF, BKGD ADJUSTMENT

1. Receive E-5CH "Monoscope Pattern" signal.

2. Select P-NORM with the remote controller.

3. Turn on the service switch, and select the CUT

4. Select the screen VR 0/10.

5. Press "-/--" key of the remote controller to se-

C BUS

2

BKGD)

SERVICE

DATA

MODE I

CRT CUTOFF

(CUTOFF

Adjustment point

1

No.

light.

6. T urn the scteen VR clockwise, and adjust the

7. Adjust the CUT OFF data of two other colors,

ADJUSTMENT

and coarsely adjust the horizontal centering

to become white. (Note 1)

to the point where the horizontal centering

raster goes out.

the beam current 1,600±50µA or more for 30

min or more.

8. Turn the screen VR in the opposite direction

lect the normal mode.

Note 1: Apply the adjustment after aging with

9. Press "-/--" key of the remote controller to se-

and TP1602.

1. Receive E-5CH "Monoscope Pattern" signal.

2. Select P-NORM with the remote controller.

3. Connect the beam ammeter between TP1601

4. Coarsely adjust the beam current to approx.

2

WHITE

BALANCE

BACK-

GROUND

(CUT OFF

2

10

1.6mA with R1759 (Sub-Contrast VR)

(PAL burst is generated with the signal gen-

erator.)

the color temperature 12,300°K of the white

peak to white.

12,300°K with R-cut off, G-cut off and B-cut

off.

5. Receive the window pattern with AV input.

6. With the data of G-drive and B-drive, adjust

7. Adjust the right dark area of the window to

peak.

8. Read just the color temperature at the white

9. Check 12,300°K at the low white.

C

BUS ADJUST-

MENT (AV

SIGNAL)

BKGD) I

the beam current 1,400±50µA or more for 30

min or more. (On the white or green minocolor

screen)

nal (component signal).

item 5 of adjustment 2 and the subsequence

above. (17,000°K ) (G-DRIVE, B-DRIVE, R-

CUT OFF, G-CUT OFF, B-CUT OFF)

Apply the adjustment after the end of adjust-

C BUS

2

(CUT OFF

DVD BKGD)

I

ment 2.

ADJUSTMENT

(DVD SIGNAL)

Note1 : Apply this adjustment after aging with

1. The window pattern is received with DVD sig-

2. Apply the adjustment in the same manner as

WHITE

BALANCE

BACK-

GROUND

3

Page 11

25WF30

Fig. 7

YMgR100% W

75% W

Adjustment Condition / Procedure Waveform or others

PAL CHROMA ADJUSTMENT

troller.

1. Receive the PAL Colour Bar signal.

Adjustment point

1 SUB COLOUR

No.

(ky). (Use Probe10:1)

2. Make the image normal with the remote con-

3. Connect the oscilloscope to pin (4) of TP802

C BUS

2

(I

CONTROL)

Cy G B

Range : 2V/Div

Sweep time : 20µ sec/Div

remote controlller, and vary the sub colour data

to make 75% W of the colour bar and RED at

4. Set the sub colour adjustment mode with the

Fig. 8

A=B=C

W Y Cy G Mg R B

(B-Y)

ABC

(Use Probe 10:1)

the same level for adjustment shown in Fig. 7.

Adjustment Condition / Procedure Waveform or others

Y cut) to receive NTSC colour bar signal.

Range : 20mV/Div (AC)

Sweep time : 20µ sec/Div

to be gained as shown in Fig 8.

NTSC CHROMA ADJUSTMENT

1. Select the sub-tint adjustment mode (automatic

2. Connect the oscilloscope to TP801.

C BUS

2

SUB-TINT

(I

CONTROL)

Adjustment point

1

No.

TP801………………(KY) 6 pin

3. Vary the sub tint data to adjust the waveform

The receiving channel in ( ) are

following signals.

(E-2):Crosshatch(50Hz)

(E-5):Monoscope(50Hz)

Adjustment Condition / Procedure Waveform or others

is achieved.) (E-2)

center of CRT. (E-5)

center of CRT. (E-5)

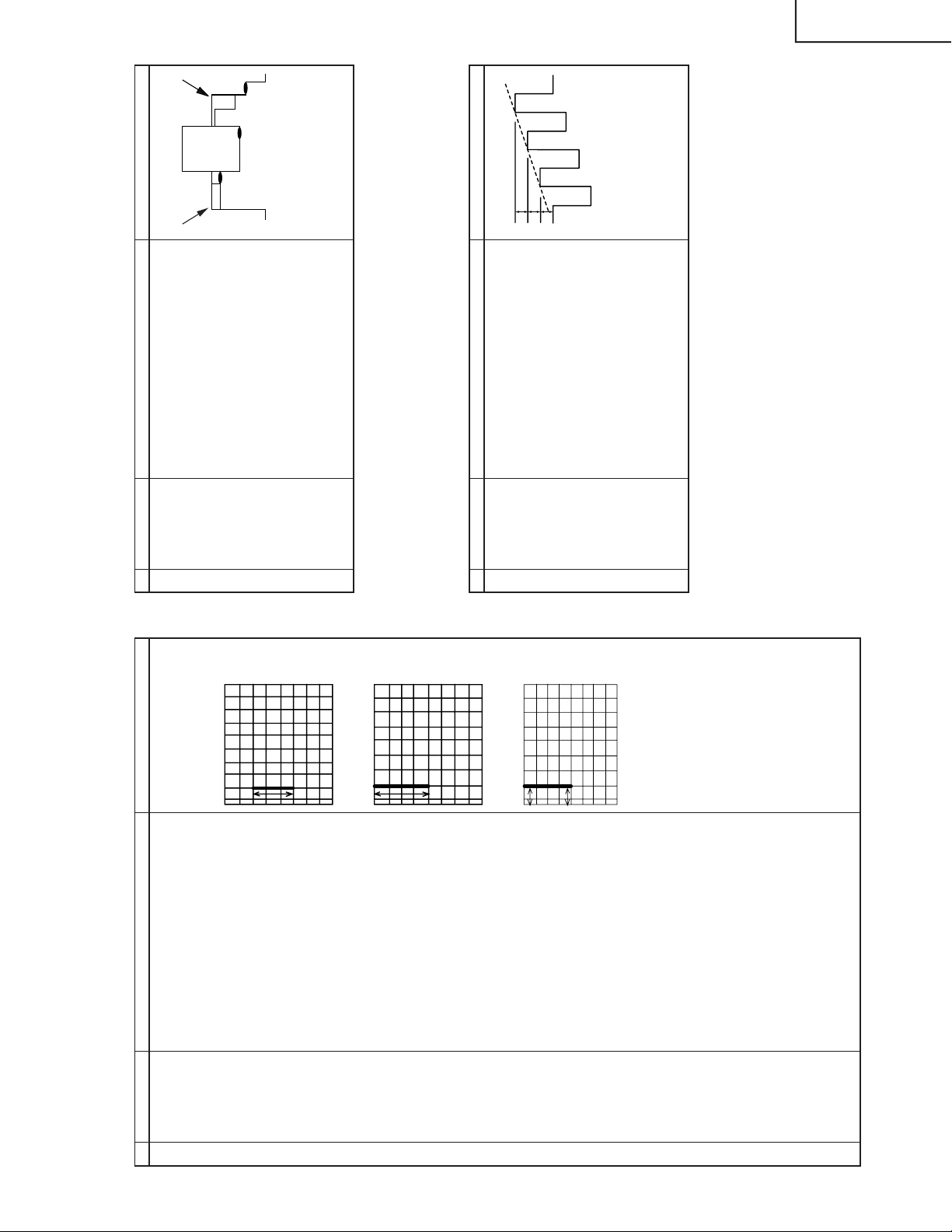

Fig. 6-1

D2

D1

Fig. 6-2

crosshatch pattern so that the midddle 4 blocks

are straight.(E-2) (Refer to Fig.6-1)

crosshatch pattern so that the top are straight.(E-

2) (Refer to Fig.6-2)

crosshatch pattern so that the D1 (center area

of the first vertical line-edge of screen) and D2

(top area of the first vertical line-edge of the

screen) are same. (E-2) (Refer to Fig.6-3)

Fig. 6-3

However, if it is largely deviated

when it is checked in 60Hz mode,

readjust it in the 60Hz mode.

60, V-CENT 60, H-CENT 60, H-SIZE 60, E/W-

PAR 60, E/W-COR 60 and TRAPE 60, the

compensation data is automatically input if the

50Hz mode adjusutment is done.

Do not change 50Hz mode data after adjust 60Hz

mode data.Because 60Hz mode data follow

50Hz mode data automatically.

11-1 11-2

V-AMP 50 Adjust the overscan to 8.5%.(Monoscope)(E-5)

Adjustment point

MAIN SCREEN

1

No.

HORIZONTAL, VERTICAL, DEFLECTION LOOP AND ADJUSTMENT

V-LINE 50 Adjust the linearity to the best. (E-5)

ADJUSTMENT

V S-CORR 50 Already preset. (Adjust this unless the linearity

V-CENT 50 Align the center of the screen to the geometric

H-CENT 50 Align the center of the screen to the geometric

H-SIZE 50 Adjust the overscan to 8.5% ± 0.5%. (E-5)

E/W-PAR 50 Adjust the 2nd vertical line from the left end of

E/W-COR 50 Adjust the 2nd vertical line from the left end of

TRAPE 50 Adjust the 2nd vertical line from the left end of

V-ENT Already preset.

H-ENT Already preset.

OTHER On the items of V-AMP 60, V-LINE 60, V S-CORR

11

C BUS AD-

2

I

JUSTMENT

Page 12

25WF30

Adjustment Condition / Procedure Waveform or others

1.Receive the "PAL COLOUR BAR" signal thru

AV, press the COLOUR SYSTEM key to se-

lect modes except PAL, check the COLOUR

is not working properly. Then, select the "P AL"

mode. Check again its colour so that it is work-

ing properly.

COLOUR SYSTEM key to select modes ex-

cept NTSC3.58, check the COLOUR is not

working properly. Then, select the “NTSC 3.58”

mode. Check again its colour so that it is work-

ing properly.

thru AV, press COLOUR SYSTEM key to se-

lect modes except N4.43, check the COLOUR

2. Receive “NTSC 3.58” signal thru AV, press

is not working properly. Then, select the “NTSC

3. Receive “NTSC 4.43 COLOUR BAR” signal

63 1.0Vp-p

40 500mVp-p

from speaker.

SUB-VOL ADJ H/P Output (Open)

400 Hz, 100% modulation (± 50 kHz Dev)

4.43” mode. Check again its colour so that it

is working properly.

output with 400 kHz sound and no sound out

1. Receive the PAL Colour Bar signal with sound

2. Maximum volume, and check the headphone

Reference Approx. 17.7V as

ordinary.

Adjustment Condition / Procedure Waveform or others

(R1620 side).

the protector is not work.

1.Receive E-5CH "Monoscope Pattern" signal.

2. Connect the Bias Box to D1621 cathode

the protector is work.

3.Set voltage of Bias Box to 15V and make sure

4.Set voltage of Bias Box to 24V, and make sure

ing electrolysis of +B line and so on.

* Correspondence for short circuit of smooth-

PROTECTOR OPERATION CHECKING

To check the operation of the protector and

so on, take care for the breakage, deteriora-

tion and so on of each element.

Adjustment point

SYSTEM

FUNCTION OPERATION CHECKING (2) (VIDEO & AUDIO)

8 COLOUR

No.

OUTPUT

CHECKING

9 HEADPHONE

Adjustment point

H, V PROTEC-

TOR

1

No.

If nothing is display mean contrast,

Notes:

OTHER

PROTECTOR

2

colour, bright, tint, sharpness are

all in normal setting.

12-1 12-2

Adjustment Condition / Procedure Waveform or others

Mode and set to select CONTRAST.

1. Receive "Monoscope Pattern" signal.

CONTRAST

Adjustment point

FUNCTION OPERATION CHECKING (1) (VIDEO & AUDIO)

1

No.

the CONTRAST effect is OK or not.

2. Press to MENU mode, then Select Picture

3. Press V olume Up/Down key to check whether

Key

Mode and set to select COLOUR.

1.Receive "Color Bar" signal.

2 COLOUR Key

the COLOUR effect is OK or not.

2. Press to MENU mode, then Select Picture

3.Press Volume Up/Down key to check whether

Mode and set to select BRIGHTNESS.

1.Receive "Monoscope Pattern" signal.

3 BRIGHTNESS

the BRIGHTNESS effect is OK or not.

2. Press to MENU mode, then Select Picture

3.Press Volume Up/Down key to check whether

in.

1.Receive the "NTSC Colour Bar" signal thru A V

4 TINT Key

Mode and set to selectTINT.

UP for GREEN direction and DOWN for RED

2. Press to MENU mode, then Select Picture

direction whether is OK or not.

3.Press Volume Up/Down key to check TINT,

Mode and set to select SHARPNESS.

1.Receive "Monoscope Pattern" signal.

5 SHARPNESS

the SHARPNESS effect is OK or not.

2. Press to MENU mode, then Select Picture

3.Press Volume Up/Down key to check whether

Key

key is pressed, all the settings will be present

1.Once in PICTURE Mode, and the NORMAL

6 NORMAL Key

12

TEMP Option, STANDARD: NORMAL SET-

TING, WARM for more REDDISH direction

changing, COOL for more BLUISH direction

to normal setting.

(Normal setting value for every mode, refer to

page 7-2.)

2. Set FUNCTION to select WHITE TEMP.

3. Press Volume Up/Down key to check WHITE

7 WHITE TEMP 1. Receive the Monoscope Pattern signal.

changing.

Page 13

No

NO RASTER

Is pin (10) of IC700 in "L" level ?

Yes

Yes (RED)

Does D1200 (Power LED) turn on?

Does horizontal circuit

momentary oscillate?

No

Check the

Yes

Check

(Bus error)

power circuit

consisting of

IC700, Q700

IC750 and

IC602.

protecter circuit

and its related

parts pin (2) of

IC1000 vertical

pulse.

25WF30

A

TROUBLE SHOOTING TABLE (Continued)

Abnormal

Normal

Check CRT connector (KY), (H) bias.

Check D1576 and R1576.

Check R1651,

IC800 and their

peripheral parts.

Check IC850.

See many often

D1200 flashes

in red.

This indicates

which IC to

check up.

D1200 (Power LED) turn on and off.

TROUBLE SHOOTING TABLE

NO VERTICAL SCAN

Abnormal

Check the voltage at pin (6) of IC1501.

Normal Abnormal

Check vertical trigger pulse at pin (26) of IC800.

Normal

Check IC800 and its

peripheral parts.

Check IC1501 and

related circuits.

13

13-1 13-2

Page 14

25WF30

Yes

NO LED LIGHT

TROUBLE SHOOTING TABLE (Continued)

Blown out

Check F3700.

Check F3700.

Normal

Replace the Fuse.

Is the Fuse again blown out?

No

Check the power circuit

consisting of T700, IC700,

Q700 and peripheral parts.

Check IC1000,

IC1002, Q1002,

Q752 and

Q753.

No Yes

Does 5V appear at pin (22) of IC1000?

2000 (ms)500 500

Check the

peripheral circuit

of IC1700,

IC1002, IC1701

and D1751.

500 500 2000 (ms)

Bus-Err

PROM

2

(IC1001)

TROUBLE SHOOTING TABLE (Continued)

E

V/C/D

(IC800)

Bus-Err

2000 (ms)500 500

2000 (ms)500 500

2000 (ms)500 500

2000 (ms)500 500

14-1 14-2

PLL

Bus-Err

(Tuner)

Bus-Err

S-CONTROL

(IC300)

Bus-Err

AV-SWITCH

(IC400)

Bus-Err

OTHER

A

14

Page 15

Check IC850 and

its peripheral

circuit.

Are waveform at pins (7), (8)

and (9) of IC850 normal?

25WF30

B

No snow noise.

B

Abnormal

Check TU200, SF200 and

their related parts.

Check pins (6) and (7) of IC800.

Normal

Noise or signal

appear.

Check Q455 and its

peripheral circuit.

Yes

Is AV1, A V2 or A V3

input normal?

Check IC400 and its

Noise

No

Which does pin (43) of

peripheral circuit.

Signal

IC400 appear, noise or

signal?

Check the

Yes

No Yes No

Is IC800 RGB

out Normal?

Signal

Which does pin (39) of

IC800 appear, noise or

signal?

Check IC800 and

Noise

Check IC400, Q401

peripheral circuits

of screen heater

(FBT) and the CRT.

its peripheral

circuit.

and their peripheral

circuit.

NO PICTURE

TROUBLE SHOOTING TABLE (Continued) TROUBLE SHOOTING TABLE (Continued)

No

Check IC600, L200, TU200

Does the snow noise appear

on the picture tube at max

contrast and brightness

Yes

Snow noise increase.

and etc.

control?

No

Yes

Does 5V appear at pins (6) and (7)

of TU200 (TUNER)?

Check IC1751, L201 and etc.

No

Yes

Does 31V appear at pin (9) of

TU200?

Check TU200, TP201 and etc.

15-1 15-2

15

Page 16

25WF30

C

NO COLOUR

No

Yes

Is only RF signal’s colour abnormal?

NO SPECIFIC COLOUR

Check TU200,

Turn on colour control. Does

Yes

Q455, IC400 and

their peripherals.

Set the colour

No

colour appear?

Turn on colour system forced

switch. Does colour appear?

Yes

Fix cotrol to

coloured

control.

system.

NoYes

Check Q400

No

Is chroma input level at pin (43)

of IC800 proper?

and its

Is SCP signal waveform at pin (30) of

IC800 proper?

peripheral circuit.

No

Yes

Are signal waveforms at TP801

and TP802 proper?

No

Yes

Check D1664

and its

peripheral circuit.

Check IC850.

YesNo

Yes

Is there audio signal at pins (3) and (22)

of IC300?

Is audio output terminal J400

normal ?

NO NORMAL SOUND

No

Check TV sound.

Change the sound system.

Set S-Volume at

maximum.

Do pins (12), (15)

of IC300 work?

Check IC400

and its

peripheral

parts.

No Yes

Is sound normal?

Yes

No

Check IC300.

Is there audio

signal at pins

(46) and (48)

of IC400?

YesNo

PAL, SECAM,

Is there audio

signal at pins (2)

and (5) of IC1300?

No

Check IC301 and

its peripheral

circuit.

Check TU200

and its

peripheral

circuits of no

problem, set

NTSC4.43:

Check X800, pin

(12) of IC800 and

their peripheral circuit.

Yes

Check IC1300 and

the sound

system

inpositon.

its peripheral

parts.

Check IC400

and its

Check IC800 and

its peripheral circuit.

peripheral

circuit.

16-1 16-2

TROUBLE SHOOTING TABLE (Continued) TROUBLE SHOOTING TABLE (Continued)

16

Check TU200

and its

peripheral parts.

Check NICAM

unit and its

peripheral

circuit.

Page 17

25WF30

C

TROUBLE SHOOTING TABLE (Continued)

Fix control to coloured system.

Colour control circuit detective.

Colour saturation control does not

COLOUR PRODUCED

Colour in B/W mode.

No

Yes

Turn on colour system forced

switch. Does colour appear?

No

Turn up and down colour control.

Does colour gain go up and

work.

down?

No

Yes Yes

Turn colour control to minimum.

Does colour disappear?

No

Yes

Is chroma input level at pin (43) of

IC800 proper?

Fix control to

coloured system.

Check IC800.

White

balance:

APG circuit:

Check IC800

Ref. value: 100 ~ 500mVp-p.

Yes No

Can the sub-colour be readjusted

in service mode?

Check RGB

output circuit

of IC800.

and its

peripherals.

Check Q400 and its

peripherals.

Is SCP signal waveform at pin

(30) of IC800 proper?

Yes

Check IC800

and its

peripherals.

SET Sub-

colour.

Are signal waveforms at TP801 and TP802

proper?

NoYes

No

Check D1664 and its

peripherals.

PAL, SECAM, NTSC4.43:

Check X800, pin (12) of IC800 and

their peripherals.

Check IC800.

17-1 17-2

17

Page 18

25WF30

CHASSIS LAYOUT

H

G

F

E

D

C

B

A

654321

18

Page 19

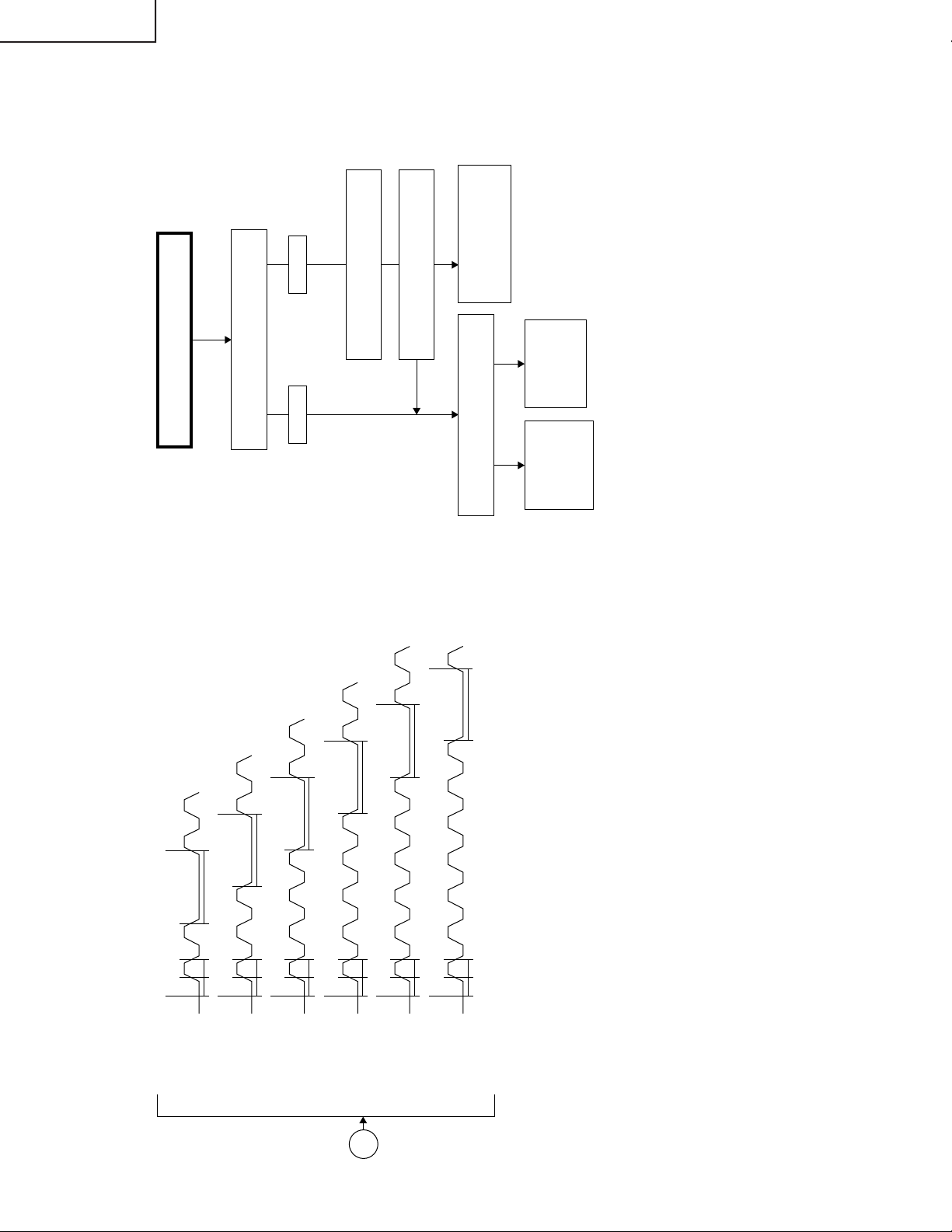

BLOCK DIAGRAM-1

H

G

F

25WF30

E

D

C

B

A

654321

19

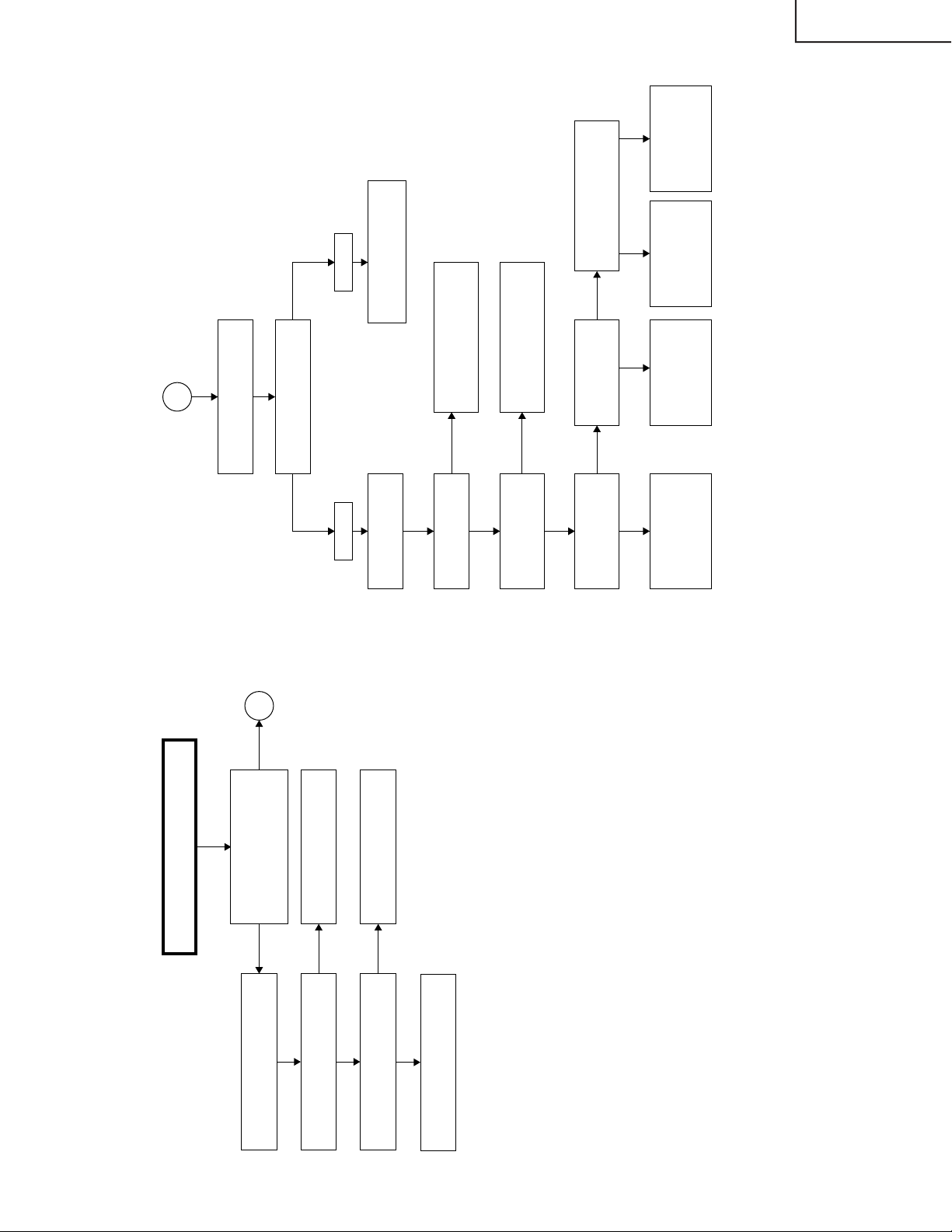

Page 20

25WF30

BLOCK DIAGRAM-2

H

G

F

25WF30

E

D

C

B

A

20

87109654321

21

1716 19181514131211

Page 21

25WF30

BLOCK DIAGRAM-3

H

G

F

25WF30

E

D

C

B

A

22

87109654321

23

1716 19181514131211

Page 22

25WF30

BLOCK DIAGRAM-4

H

G

F

25WF30

E

D

C

B

A

24

87109654321

25

1716 19181514131211

Page 23

25WF30

BLOCK DIAGRAM-5

H

G

F

E

D

C

B

A

654321

26

Page 24

WAVEFORMS

25WF30

Pin 1 Vp-p=2.46v

Pin 4 Vp-p=2.04v

Pin 7 Vp-p=1090v Pin 8 Vp-p=10v Pin 9 Vp-p=4.64v

Pin 2 Vp-p=1.8v Pin 3 Vp-p=1.7v

Pin 5 Vp-p=58.4v

Pin 6 Vp-p=288v

Pin 10 Vp-p=1.0v

Pin 13 Vp-p=3.96v

Pin 16 Vp-p=150.0v Pin 17 Vp-p=150.0v Pin 18 Vp-p=448.0v

Pin 11 Vp-p=1.0v

Pin 14 Vp-p=3.88v Pin 15 Vp-p=150.0v

Pin 12 Vp-p=4.6v

27

Page 25

25WF30

DESCRIPTION OF SCHEMATIC DIAGRAM

SAFETY NOTES:

1. DISCONNECT THE AC PLUG FROM THE AC OUTLET BEFORE

REPLACING PARTS.

2. SEMICONDUCTOR HEAT SINKS SHOULD BE REGARDED AS

POTENTIAL SHOCK HAZARDS WHEN THE CHASSIS IS OPERATING.

IMPORTANT SAFETY NOTICE:

PARTS MARKED WITH “å” ( ) ARE IMPORTANT FOR

MAINTAINING THE SAFETY OF THE SET. BE SURE TO REPLACE THESE PARTS WITH SPECIFIED ONES FOR MAINTAINING THE SAFETY AND PERFORMANCE OF THE SET.

SERVICE PRECAUTION:

THE AREA ENCLOSED BY THIS LINE (

CONNECTED WITH AC MAINS VOLTAGE.

WHEN SERVICING THE AREA, CONNECT AN ISOLATING TRANSFORMER BETWEEN TV RECEIVER AND AC LINE TO ELIMINATE

HAZARD OF ELECTRIC SHOCK.

) IS DIRECTLY

NOTES:

1. The unit of resistance “ohm” is omitted.

(K = 1000 ohms, M = Meg ohm).

2. All resistors are 1/16 watt, unless otherwise noted.

3. All capacitors are µF, unless therwise noted. (P = µµF).

VOLTAGE MEASUREMENT CONDITIONS:

1. Voltage in parenthesis measured with no Signal.

2. Voltages without parenthesis measured with PAL Colour-Signal.

3. All the voltages in each point are measured with high impedence

volt-meter.

WAVEFORM MEASUREMENT CONDITIONS:

1. Colour bar generator signal of 2.5V peak to peak applied at Base

of Video Buffer Amp. Q203.

2. Approximately 4.0 V AGC bias.

28

Page 26

SCHEMATIC DIAGRAM: CRT Unit

H

G

F

25WF30

E

D

C

B

A

654321

29

Page 27

25WF30

SCHEMATIC DIAGRAM: MAIN-1/2 Unit

H

G

F

25WF30

E

D

C

B

A

30

87109654321

31

1716 19181514131211

Page 28

25WF30

SCHEMATIC DIAGRAM: MAIN-2/2 Unit

H

G

F

25WF30

E

D

C

B

A

32

87109654321

33

1716 19181514131211

Page 29

25WF30

SCHEMATIC DIAGRAM: POWER Unit

H

G

F

25WF30

E

D

C

B

A

34

87109654321

35

1716 19181514131211

Page 30

25WF30

SCHEMATIC DIAGRAM: OPERATION Unit

H

G

F

E

D

C

B

A

654321

36

Page 31

PRINTED WIRING BOARD ASSEMBLIES

H

G

F

25WF30

E

D

C

PWB-C: CRT Unit (Wiring Side)

B

A

654321

37

Page 32

25WF30

H

G

F

25WF30

E

D

C

B

A

PWB-A: MAIN Unit (Wiring Side)

38

87109654321

39

1716 19181514131211

Page 33

25WF30

H

G

F

25WF30

E

D

C

B

A

PWB-A: MAIN Unit (Chip Parts Side)

40

87109654321

41

1716 19181514131211

Page 34

25WF30

H

G

F

25WF30

E

D

C

B

A

PWB-B: POWER Unit (Wiring Side)

42

87109654321

43

1716 19181514131211

Page 35

25WF30

H

G

F

E

D

C

B

A

PWB-D: OPERATION Unit (Wiring Side)

654321

44

Page 36

8 5

SOLID STATE DEVICE BASE DIAGRAM

TOP VIEW

SIDE VIEW

1 4

4 3

1 2

EMITTER

BASE

ZR

:BR:

EMITTER

BASE

1 28

56 29

14 8

1 7

BASE

EMITTER

COLLECTOR

1 7 1 9

1 8

FX0008GEM24C08W

D601A

B709A

iX3395CEN2 TDA16846

2SD2581

2SC3207

2SD1830 TA8427

2SC5248

2SA1964

TDA6103Q

M51497L

iX0037

KA78S09P

1 12

1 21

42 22

JC

EMITTER

BASE

1 4

36 25

37 24

48 13

COLLECTOR

iX3422CE

BH3543F MM1437BF

2SC2735

CXA2089Q

1 10

8 5

1 4

24 13

1 12

8 5

1 4

20 11

1 2 3

6 5 4

KA358P

VSiMZ1A

TDA9181T

AN5891K

MiP0253

EMITTER

BASE

COLLECTOR

2SC3198-Y

2SC3198-G

2SC1959-Y

DX0452CE

DX0336CE SE120N

CATHODE

ANODE

1 2 3

1 3

ANODE (RED)

CATHODE (COMMON)

ANODE (GREEN)

A K

COLLECTOR

BASE

EMITTER

PX0414CE PX0274CE AN5277

KA7809

KA7805

SPP11N60C 2SA1266-Y

A K

8 5

8 5

1 4

COLLECTORCOLLECTOR

25WF30

45

Page 37

25WF30

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

Replacement parts which have these special safety characteristics

identified in this manual: electrical components having such features

are identified by "å" in the Replacement Parts Lists.

The use of a substitute replacement part which does not have the

same safety characteristics as the factory recommended replacement parts shown in this service manual may create shock, fire or

other hazards.

"HOW TO ORDER REPLACEMENT PARTS"

To have your order filled promptly and correctly, please furnish the

following informations.

Ref. No. Part No. ★ Description Code

å VB6OLST196X*S Picture Tube

å RCiLG0017KJZZ Degaussing Coil

å RCiLH0012KJZZ Deflection Yoke

å QEARC2517CEZZ R Grounding Strap AK

PARTS LIST

PARTS REPLACEMENT

1. MODEL NUMBER 2. REF . NO.

3. PART NO. 4. DESCRIPTION

MARK ★: SPARE PARTS-DELIVERY SECTION

PICTURE TUBE

PMAGF3092CEZZ R Magnet AL

PMAGG3002CEZZ R Magnet AC

PSPAG0003PEZZ R Spacer AD

PSPAH0035KJ00 Spacer

Q201 VS2SC2735//1E R VS2SC2735 AC

Q316 VS2SB709A//-1 R VS2SB709A AA

Q400 VS2SD601A//-1 R VS2SD601A AC

Q401 VS2SD601A//-1 R VS2SD601A AC

Q402 VS2SD601A//-1 R VS2SD601A AC

Q409 VS2SD601A//-1 R VS2SD601A AC

Q410 VSiMZ1A////-1 R VSIMZ1A AC

Q450 VS2SB709A//-1 R VS2SB709A AA

Q451 VS2SD601A//-1 R VS2SD601A AC

Q452 VS2SD601A//-1 R VS2SD601A AC

Q453 VS2SD601A//-1 R VS2SD601A AC

Q454 VS2SD601A//-1 R VS2SD601A AC

Q455 VS2SD601A//-1 R VS2SD601A AC

Q600 VS2SD601A//-1 R VS2SD601A AC

Q620 VS2SB709A//-1 R VS2SB709A AA

Q800 VS2SB709A//-1 R VS2SB709A AA

Q1000 VS2SD601A//-1 R VS2SD601A AC

Q1001 VS2SD601A//-1 R VS2SD601A AC

Q1002 VS2SD601A//-1 R VS2SD601A AC

Q1004 VS2SB709A//-1 R VS2SB709A AA

Q1066 VS2SD601A//-1 R VS2SD601A AC

Q1300 VS2SB709A//-1 R VS2SB709A AA

Q1301 VS2SD601A//-1 R VS2SD601A AC

Q1320 VS2SD601A//-1 R VS2SD601A AC

Q1321 VS2SD601A//-1 R VS2SD601A AC

Q1322 VS2SB709A//-1 R VS2SB709A AA

Q1325 VS2SD601A//-1 R VS2SD601A AC

Q1401 VS2SD601A//-1 R VS2SD601A AC

Q1402 VS2SD601A//-1 R VS2SD601A AC

Q1403 VS2SB709A//-1 R VS2SB709A AA

Q1404 VS2SD601A//-1 R VS2SD601A AC

Q1405 VS2SB709A//-1 R VS2SB709A AA

Q5400 VS2SD601A//-1 R VS2SD601A AC

Q5401 VS2SD601A//-1 R VS2SD601A AC

Q5402 VS2SB709A//-1 R VS2SB709A AA

Q5403 VS2SD601A//-1 R VS2SD601A AC

Q5404 VS2SB709A//-1 R VS2SB709A AA

Q5406 VS2SD601A//-1 R VS2SD601A AC

PRINTED WIRING BOARD ASSEMBLIES

(NOT REPLACEMENT ITEM)

PWB-A DUNTKA122FMX1 – MAIN Unit —

PWB-B DUNTKA123FMW6 – POWER Unit —

PWB-C DUNTKA075FMX3 – CRT Unit —

PWB-D DUNTKA429WEV0 – OPERATION Unit —

PWB-A DUNTKA122FMX1

MAIN UNIT

TUNER

NOTE: THE PARTS HERE SHOWN ARE SUPPLIED AS AN

ASSEMBLY BUT NOT INDEPENDENTLY.

å TU200 VTUVTST5HD970 VHF Tuner

INTEGRATED CIRCUITS

IC300 VHiAN5891K+-1 R AN5891K AQ

IC301 VHiBH3543F+-1 R BH3543F-E2 AE

IC400 VHiCXA2089Q-1 R CXA2089Q AN

IC600 VHiKA7805AP-1 R KA7805AP AE

IC601 VHiKA7809AP-1 R KA7809AP AE

IC602 VHiKA78S09P-1 R KA78S09P AD

IC605 VHiM51497L/-1 R M51497L AL

IC800 RH-iX3395CEN2 R I.C. AY

IC1000 RH-iX3422CEZZ M37221MA-204SP

IC1001 VHiM24C08B/-1 R M24C08-BN6 AM

IC1002 VHiMM1437BF-1 R I.C. AF

IC1300 VHiAN5277//-1 R AN5277 AN

IC5400 VHiTDA9181T-1* R TDA9181T AU

TRANSISTORS

Q200 VS2SC2735//1E R VS2SC2735 AC

D201 VHD1SS390++-1 R 1SS390++ AB

DIODES AND LED'S

D202 RH-EX0619GEZZ R Zener Diode AA

D203 RH-EX0619GEZZ R Zener Diode AA

D300 RH-EX0619GEZZ R Zener Diode AA

D301 RH-EX0619GEZZ R Zener Diode AA

D302 RH-DX0475CEZZ R Diode AB

D316 RH-DX0475CEZZ R Diode AB

D400 RH-EX0631GEZZ R Zener Diode AA

D401 RH-EX0631GEZZ R Zener Diode AA

D402 RH-EX0631GEZZ R Zener Diode AA

D403 RH-EX0631GEZZ R Zener Diode AA

D404 RH-EX0631GEZZ R Zener Diode AA

D405 RH-EX0619GEZZ R Zener Diode AA

D450 RH-DX0475CEZZ R Diode AB

D451 RH-EX0621GEZZ R Zener Diode AB

D455 RH-EX0631GEZZ R Zener Diode AA

D456 RH-EX0631GEZZ R Zener Diode AA

D457 RH-EX0631GEZZ R Zener Diode AA

D458 RH-EX0631GEZZ R Zener Diode AA

D602 RH-DX0475CEZZ R Diode AB

D603 RH-DX0475CEZZ R Diode AB

D605 RH-DX0475CEZZ R Diode AB

D620 RH-DX0475CEZZ R Diode AB

D621 RH-DX0475CEZZ R Diode AB

D622 RH-DX0475CEZZ R Diode AB

D625 RH-DX0475CEZZ R Diode AB

D626 RH-EX0610GEZZ R Zener Diode AA

D1000 RH-EX0619GEZZ R Zener Diode AA

D1001 RH-EX0619GEZZ R Zener Diode AA

D1002 RH-EX0619GEZZ R Zener Diode AA

D1003 RH-EX0619GEZZ R Zener Diode AA

D1004 RH-EX0619GEZZ R Zener Diode AA

D1005 RH-EX0619GEZZ R Zener Diode AA

D1006 RH-EX0619GEZZ R Zener Diode AA

D1007 RH-EX0619GEZZ R Zener Diode AA

D1008 RH-EX0619GEZZ R Zener Diode AA

46

Page 38

25WF30

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

PWB-A DUNTKA122FMX1

MAIN UNIT (Continued)

D1009 RH-EX0619GEZZ R Zener Diode AA

D1010 RH-EX0619GEZZ R Zener Diode AA

D1011 RH-EX0619GEZZ R Zener Diode AA

D1012 RH-EX0619GEZZ R Zener Diode AA

D1015 RH-EX0619GEZZ R Zener Diode AA

D1016 RH-EX0619GEZZ R Zener Diode AA

D1017 RH-DX0475CEZZ R Diode AB

D1302 RH-DX0475CEZZ R Diode AB

D1303 RH-DX0475CEZZ R Diode AB

D1304 RH-DX0475CEZZ R Diode AB

D1320 RH-DX0475CEZZ R Diode AB

D1321 RH-DX0475CEZZ R Diode AB

PACKAGED CIRCUIT

X800 RCRSB0278CEZZ R Crystal AG

FILTERS

CF201 RFiLC0085CEZZ R Filter AG

CF401 RFiLC0463CEZZ R Filter AD

CF1000 RFiLA0084CEZZ R Filter AE

CF1001 RFiLA0020CEZZ R Filter AD

SF200 RFiLC0444CEZZ R Filter AN

SF201 RFiLC0445CEZZ R Filter AM

COILS AND TRANSFORMERS

L200 VP-DF270K0000 R Peaking 27µHAB

L201 VP-DF270K0000 R Peaking 27µHAB

L202 VP-DF120K0000 R Peaking 12µHAB

L203 VP-XF1R2K0000 R Peaking 1.2µHAB

L205 VP-XF1R2K0000 R Peaking 1.2µHAB

L401 VP-XF120K0000 R Peaking 12µHAB

L600 VP-DF120K0000 R Peaking 12µHAB

L800 VP-DF120K0000 R Peaking 12µHAB

L801 VP-DF6R8K0000 R Peaking 6.8µHAB

L1002 VP-XF1R0K0000 R Peaking 1µHAB

L5400 VP-XF100K0000 R Peaking 10µHAB

L5403 VP-XF120K0000 R Peaking 12µHAB

L5404 VP-XF120K0000 R Peaking 12µHAB

T800 RCiLD0005PEZZ R Detection Coil AF

CAPACITORS

C201 VCKYCY1HF103Z R 0.01 50V Ceramic AA

C202 VCEA0A0JW228M R 2200 6.3V Electrolytic AD

C203 VCKYCY1HF103Z R 0.01 50V Ceramic AA

C204 VCEA0A1HW106M R 10 50V Electrolytic AB

C205 VCKYCY1HF103Z R 0.01 50V Ceramic AA

C206 VCEA0A0JW228M R 2200 6.3V Electrolytic AD

C207 VCKYCY1HF103Z R 0.01 50V Ceramic AA

C210 VCKYCY1HF103Z R 0.01 50V Ceramic AA

C211 VCEA0A1HW225M R 2.2 50V Electrolytic AB

C212 VCKYCY1HF103Z R 0.01 50V Ceramic AA

C213 VCKYCY1HF103Z R 0.01 50V Ceramic AA

C214 VCKYCY1HF103Z R 0.01 50V Ceramic AA

C215 VCKYCY1HF103Z R 0.01 50V Ceramic AA

C216 VCKYCY1HF103Z R 0.01 50V Ceramic AA

C217 VCKYCY1HF103Z R 0.01 50V Ceramic AA

C218 VCKYCY1HF103Z R 0.01 50V Ceramic AA

C219 VCKYCY1HF103Z R 0.01 50V Ceramic AA

C220 VCEA0A1HW224M R 0.22 50V Electrolytic AB

C221 VCQYTA1HM102K R 1000p 50V Mylar AA

C222 VCKYCY1CF104Z R 0.1 16V Ceramic AA

C223 VCKYCY1HF103Z R 0.01 50V Ceramic AA

C226 VCKYCY1HF103Z R 0.01 50V Ceramic AA

C227 VCEA0A1HW475M R 4.7 50V Electrolytic AB

C231 VCCCCY1HH3R0C R 3.0p 50V Ceramic AA

C234 VCKYCY1CF104Z R 0.1 16V Ceramic AA

C300 VCEA0A1CW106M R 10 16V Electrolytic AB

C302 VCKYCY1HF183Z R 0.018 50V Ceramic AA

C303 VCEA0A1HW475M R 4.7 50V Electrolytic AB

C304 VCEA0A1CW106M R 10 16V Electrolytic AB

C305 VCEA0A1CW106M R 10 16V Electrolytic AB

C306 VCEA0A1CW106M R 10 16V Electrolytic AB

C307 VCEA0A1CW106M R 10 16V Electrolytic AB

C308 VCKYCY1HB472K R 4700p 50V Ceramic AA

C309 VCKYCY1HB472K R 4700p 50V Ceramic AA

C319 VCKYCY1CB333K R 0.033 16V Ceramic AA

C320 VCKYCY1CB333K R 0.033 16V Ceramic AA

C321 VCEA0A1CW106M R 10 16V Electrolytic AB

C322 VCQYTA1HM333K R 0.033 50V Mylar AA

C323 VCQYTA1HM333K R 0.033 50V Mylar AA

C326 VCEA0A1CW106M R 10 16V Electrolytic AB

C327 VCEA0A1CW106M R 10 16V Electrolytic AB

C331 VCQYTA1HM103K R 0.01 50V Mylar AB

C332 VCEA0A1HW104M R 0.1 50V Electrolytic AB

C333 VCEA0A1CW106M R 10 16V Electrolytic AB

C334 VCEA0A1CW106M R 10 16V Electrolytic AB

C335 VCEA0A1CW106M R 10 16V Electrolytic AB

C336 VCEA0A1CW106M R 10 16V Electrolytic AB

C337 VCQYTA1HM103K R 0.01 50V Mylar AB

C338 VCEA0A1HW104M R 0.1 50V Electrolytic AB

C339 VCFYFA1HA684J R 0.68 50V M.Polypro AD

C340 VCEA0A1CW106M R 10 16V Electrolytic AB

C341 VCEA0A1CW106M R 10 16V Electrolytic AB

C342 VCKYCY1CF104Z R 0.1 16V Ceramic AA

C343 VCEA0A1CW107M R 100 16V Electrolytic AC

C349 VCEA0A1CW106M R 10 16V Electrolytic AB

C350 VCEA0A1CW106M R 10 16V Electrolytic AB

C352 VCEA0A1CW476M R 47 16V Electrolytic AB

C353 VCEA0A1CW337M R 330 16V Electrolytic AC

C354 VCEA0A1CW337M R 330 16V Electrolytic AC

C355 VCEA0A0JW227M R 220 6.3V Electrolytic AB

C356 VCEA0A0JW477M R 470 6.3V Electrolytic AC

C357 VCKYCY1HF103Z R 0.01 50V Ceramic AA

C358 VCQYTA1HM153K R 0.015 50V Mylar AA

C360 VCQYTA1HM393K R 0.039 50V Mylar AB

C400 VCEA0A1CW107M R 100 16V Electrolytic AC

C401 VCKYCY1HF103Z R 0.01 50V Ceramic AA

C402 VCKYCY1CF474Z R 0.47 16V Ceramic AB

C403 VCEA0A1CW106M R 10 16V Electrolytic AB

C404 VCKYCY1CF104Z R 0.1 16V Ceramic AA

C405 VCEA0A1CW106M R 10 16V Electrolytic AB

C406 VCE9GA1CW106M R 10 16V Elect.(N.P) AB

C407 VCEA0A1CW106M R 10 16V Electrolytic AB

C424 VCEA0A1CW477M R 470 16V Electrolytic AC

C425 VCEA0A1CW476M R 47 16V Electrolytic AB

C426 VCKYCY1HF103Z R 0.01 50V Ceramic AA

C427 VCKYCY1CF104Z R 0.1 16V Ceramic AA

C428 VCEA0A1CW106M R 10 16V Electrolytic AB

C429 VCKYCY1CF104Z R 0.1 16V Ceramic AA

C430 VCEA0A1CW106M R 10 16V Electrolytic AB

C431 VCKYCY1CF104Z R 0.1 16V Ceramic AA

C432 VCKYCY1CF104Z R 0.1 16V Ceramic AA

C433 VCEA0A1CW106M R 10 16V Electrolytic AB

C434 VCEA0A1CW106M R 10 16V Electrolytic AB

C435 VCEA0A1CW106M R 10 16V Electrolytic AB

C436 VCKYCY1HF103Z R 0.01 50V Ceramic AA

C437 VCEA0A1CW476M R 47 16V Electrolytic AB

C438 VCKYCY1CF104Z R 0.1 16V Ceramic AA

C439 VCKYCY1CF104Z R 0.1 16V Ceramic AA

C450 VCKYCY1HB103K R 0.01 50V Ceramic AA

C451 VCEA0A1HW474M R 0.47 50V Electrolytic AB

C452 VCFYFA1HA334J R 0.33 50V Mylar AB

C453 VCEA0A1CW226M R 22 16V Electrolytic AB

C454 VCEA0A1CW106M R 10 16V Electrolytic AB

C455 VCEA0A1HW105M R 1 50V Electrolytic AB

C456 VCEA0A1HW224M R 0.22 50V Electrolytic AB

C457 VCKYCY1CF104Z R 0.1 16V Ceramic AA

C458 VCKYCY1HF103Z R 0.01 50V Ceramic AA

C459 VCEA0A1CW107M R 100 16V Electrolytic AC

C460 VCKYCY1HB822K R 8200p 50V Ceramic AB

C461 VCKYCY1HF103Z R 0.01 50V Ceramic AA

C462 VCCCCY1HH561J R 560p 50V Ceramic AB

C463 VCKYCY1HF103Z R 0.01 50V Ceramic AA

C468 VCKYCY1HF103Z R 0.01 50V Ceramic AA

C469 VCEA0A1HW105M R 1 50V Electrolytic AB

C478 VCKYCY1HB152K R 1500p 50V Ceramic AA

C500 VCKYCY1HB222K R 2200p 50V Ceramic AA

47

Page 39

25WF30

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

PWB-A DUNTKA122FMX1

MAIN UNIT (Continued)

C501 VCEACA1HC224M R 0.22 50V Electrolytic AC

C505 VCFPVC2DB474J R 0.47 200V M.Polypro AE

C600 VCEA0A1HW474M R 0.47 50V Electrolytic AB

C601 VCKYCY1HB822K R 8200p 50V Ceramic AB

C602 VCKYCY1HF103Z R 0.01 50V Ceramic AA

C603 VCEA0A1CW228M R 2200 16V Electrolytic AD

C605 VCQYTA1HM152J R 1500p 50V Mylar AA

C620 VCEA0A1CW476M R 47 16V Electrolytic AB

C621 VCEA0A1CW476M R 47 16V Electrolytic AB

C622 VCEA0A1CW476M R 47 16V Electrolytic AB

C623 VCEA0A1CW476M R 47 16V Electrolytic AB

C624 VCKYCY1CF334Z R 0.33 16V Ceramic AA

C625 VCEA0A1CW476M R 47 16V Electrolytic AB

C630 VCE9GA1CW106M R 10 16V Elect.(N.P) AB

C631 VCEA0A1HW224M R 0.22 50V Electrolytic AB

C632 VCKYCY1HB102K R 1000p 50V Ceramic AA

C633 VCQYTA1HM182K R 1800p 50V Mylar AA

C634 VCEA0A1HW224M R 0.22 50V Electrolytic AB

C635 VCKYCY1HF103Z R 0.01 50V Ceramic AA

C636 VCEA0A1CW476M R 47 16V Electrolytic AB

C637 VCKYCY1HF103Z R 0.01 50V Ceramic AA

C638 VCQYTA1HM473J R 0.047 50V Mylar AA

C639 VCKYCY1HB392K R 3900p 50V Ceramic AA

C640 VCKYCY1HB222K R 2200p 50V Ceramic AA

C800 VCKYCY1HB222K R 2200p 50V Ceramic AA

C801 VCEA0A1HW224M R 0.22 50V Electrolytic AB

C802 VCCCCY1HH100D R 10p 50V Ceramic AA

C803 VCKYCY1HF103Z R 0.01 50V Ceramic AA