Page 1

1st Edition

21S-FX10L

SERVICE MANUAL

S2912521SFX10L

COLOUR TELEVISION

Chassis No. GA8S

Chassis No. GA6

MODEL

In the interests of user safety (Required by safety regulations in some countries) the set should be restored to its original

condition and only parts indentical to those specified should be used.

CONTENTS

IMPORTANT SERVICE SAFETY PRECAUTION ................................................................................................... 1-1

LOCATION OF USER’S CONTROL ...................................................................................................................... 2-1

INSTALLATION AND SERVICE INSTRUCTIONS ................................................................................................. 3-1

SERVICE MODE ..................................................................................................................................................... 4-1

ADJUSTMENT METHOD ........................................................................................................................................ 5-1

WAVEFORMS ......................................................................................................................................................... 6-1

CHASSIS LAYOUT ................................................................................................................................................. 7-1

BLOCK DIAGRAM .................................................................................................................................................. 8-1

DESCRIPTION OF SCHEMATIC DIAGRAM .......................................................................................................... 9-1

SCHEMATIC DIAGRAMS ......................................................................................................................................10-1

PRINTED WIRING BOARD ASSEMBLIES ........................................................................................................... 11-1

Parts Guide

21S-FX10L

Page

ELECTRICAL SPECIFICATIONS

POWER INPUT............................AC 110-220 V, 50/60 Hz

POWER RATING .....................................................92W

PICTURE SIZE .............................1,239 cm

CONVERGENCE ............................................. Magnetic

SWEEP DEFLECTION .................................. .. Magnetic

FOCUS ......................................................... Electrostatic

INTERMEDIATE FREQUENCIES

Picture IF Carrier Frequency ...................... 45.75 MHz

Sound IF Carrier Frequency ...................... 41.25 MHz

Color Sub-Carrier Frequency ......................42.17 MHz

(Nominal)

AUDIO POWER

OUTPUT RATING... ...................... 3.0 W(RMS) x 4pcs

2

(192sq inch)

SPEAKER

SIZE ........................................................ 9 x 5cm, 4pcs

VOICE COIL IMPEDANCE .................32 ohm at 400 Hz

ANTENNA INPUT IMPEDANCE

VHF/UHF ........................................75 ohm Unbalanced

TUNING RANGES

VHF-Channels ................................................. 2 thru 13

UHF-Channels ................................................14 thru 69

CATV Channels ............................................. 1 thru 125

(EIA, Channel Plan U.S.A.)

Specifications are subject to change without

prior notice.

SHARP CORPORATION

This document has been published to be used for after

sales service only.

The contents are subject to change without notice.

Page 2

21S-FX10L

TV21S-FX10LService Manual21S-FX10LMarketE

CHAPTER 1. IMPORTANT SERVICE SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY PRECAUTION

Service work should be performed only by qualified service technicians who are

thoroughly familiar with all safety checks and the servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

3. Semiconductor heat sinks are potential shock

hazards when the chassis is operating.

4. The chassis in this receiver has two ground systems

which are separated by insulating material. The nonisolated (hot) ground system is for the B+ voltage

regulator circuit and the horizontal output circuit. The

isolated ground system is for the low B+ DC voltages

and the secondary circuit of the high voltage

transformer.

To prevent electrical shock use an isolation

transformer between the line cord and power

receptacle, when servicing this chassis.

SERVICING OF HIGH VOLTAGE SYSTEM

AND PICTURE TUBE

When servicing the high voltage system,

remove the static charge by connecting a

10k ohm resistor in series with an insulated

wire (such as a test probe) between the picture tube ground and the anode lead. (AC

line cord should be disconnected from AC

outlet.)

1. Picture tube in this receiver employs integral

implosion protection.

2. Replace with tube of the same type number for

continued safety.

3. Do not lift picture tube by the neck.

4. Handle the picture tube only when wearing

shatterproof goggles and after discharging the high

voltage anode completely.

X-RADIATION AND HIGH VOLTAGE LIMITS

1. Be sure all service personnel are aware of the

procedures and instructions covering X-radiation.

The only potential source of X-ray in current solid

state TV receivers is the picture tube. However, the

picture tube does not emit measurable X-Ray

radiation, if the high voltage is as specified in the

"High Voltage Check" instructions.

It is only when high voltage is excessive that Xradiation is capable of penetrating the shell of the

picture tube including the lead in the glass material.

The important precaution is to keep the high voltage

below the maximum level specified.

2. It is essential that servicemen have available at all

times an accurate high voltage meter.

The calibration of this meter should be checked

periodically.

3. High voltage should always be kept at the rated value

−no higher. Operation at higher voltages may cause

a failure of the picture tube or high voltage circuitry

and;also, under certain conditions, may produce

radiation in exceeding of desirable levels.

4. When the high voltage regulator is operating properly

there is no possibility of an X-radiation problem.

Every time a color chassis is serviced, the brightness

should be tested while monitoring the high voltage

with a meter to be certain that the high voltage does

not exceed the specified value and that it is regulating

correctly.

5. Do not use a picture tube other than that specified

or make unrecommended circuit modifications to the

high voltage circuitry.

6. When trouble shooting and taking test

measurements on a receiver with excessive high

voltage, avoid being unnecessarily close to the

receiver.

Do not operate the receiver longer than is necessary

to locate the cause of excessive voltage.

1 – 1

Page 3

IMPORTANT SERVICE SAFETY PRECAUTION

(Continued)

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user, perform

the following safety checks.

1. Inspect all lead dress to make certain that leads are

not pinched or that hardware is not lodged between

the chassis and other metal parts in the receiver.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators, etc.

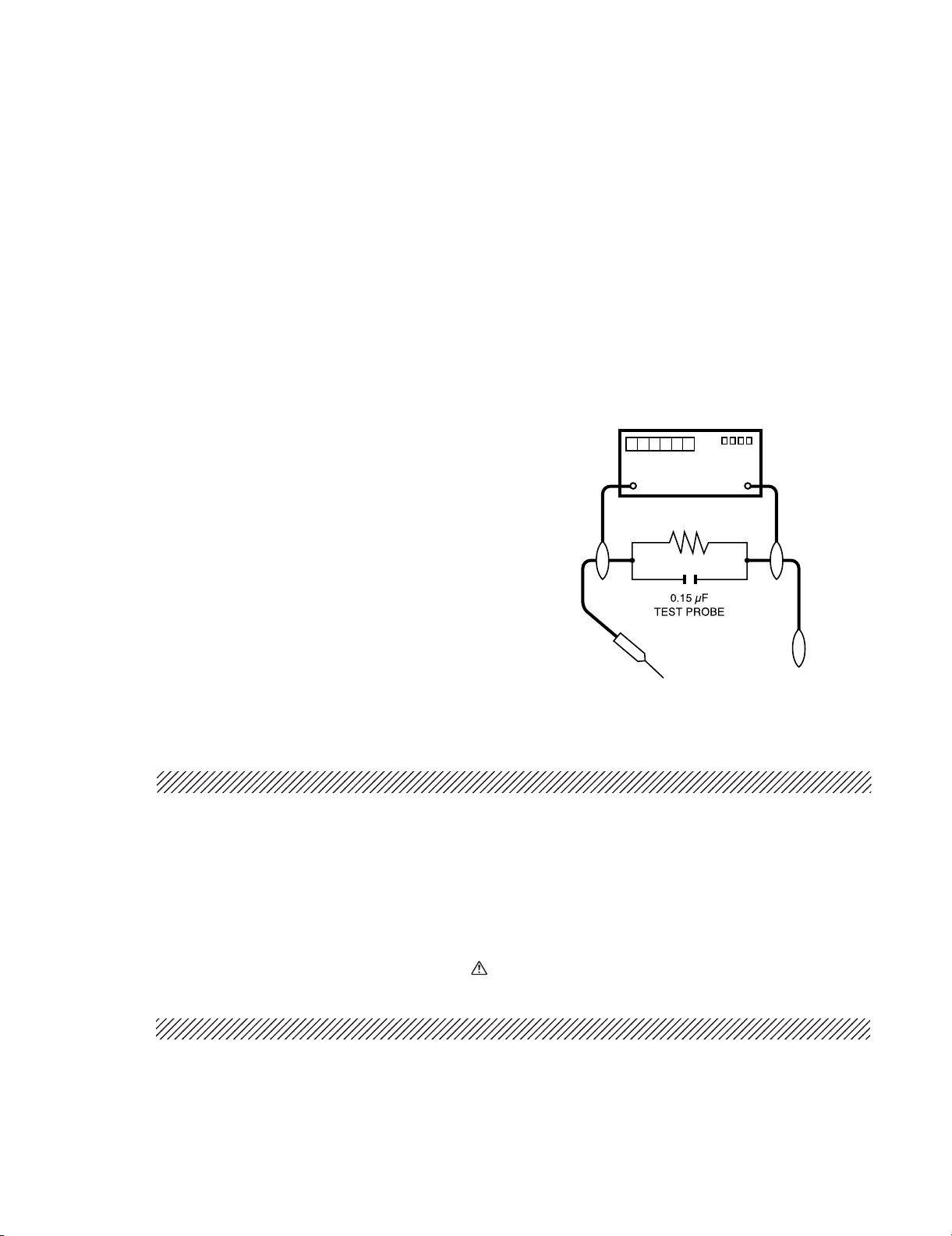

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

•

Plug the AC cord directly into a 110~220 volt AC

outlet, (Do not use an isolation transformer for this

test).

•

Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15μF capacitor in series

with all exposed metal cabinet parts and a known

earth ground, such as electrical conduit or electrical

ground connected to earth ground.

•

Use an AC voltmeter having with 5000 ohm per volt,

or higher, sensitivity to measure the AC voltage drop

across the resistor.

21S-FX10L

•

Connect the resistor connection to all exposed metal

parts having a return to the chassis (antenna, metal

cabinet, screw heads, knobs and control shafts,

escutcheon, etc.) and measure the AC voltage drop

across the resistor.

AII checks must be repeated with the AC line cord

plug connection reversed. (If necessary, a nonpolarized adapter plug must be used only for the

purpose of completing these check.)

Any current measured must not exceed 0.5 milliamp.

Any measurements not within the limits outlined

above indicate of a potential shock hazard and

corrective action must be taken before returning the

instrument to the customer.

DVM

AC SCALE

1.5k ohm

10W

SAFETY NOTICE

Many electr ical and mechanical parts in television

receivers have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by "

and shaded areas in the Replacement Parts Lists and

Schematic Diagrams.

TO EXPOSED

METAL PARTS

For continued protection, replacement parts must be

identical to those used in the or iginal circuit. The use of

substitute replacement parts which do not have the same

safety characteristics as the factory recommended

replacement parts shown in this service manual, may

create shock, fire, X-radiation or other hazards.

"

CONNECT TO

KNOWN EARTH

GROUND

1 – 2

Page 4

21S-FX10L

TV21S-FX10LService Manual21S-FX10LMarketE

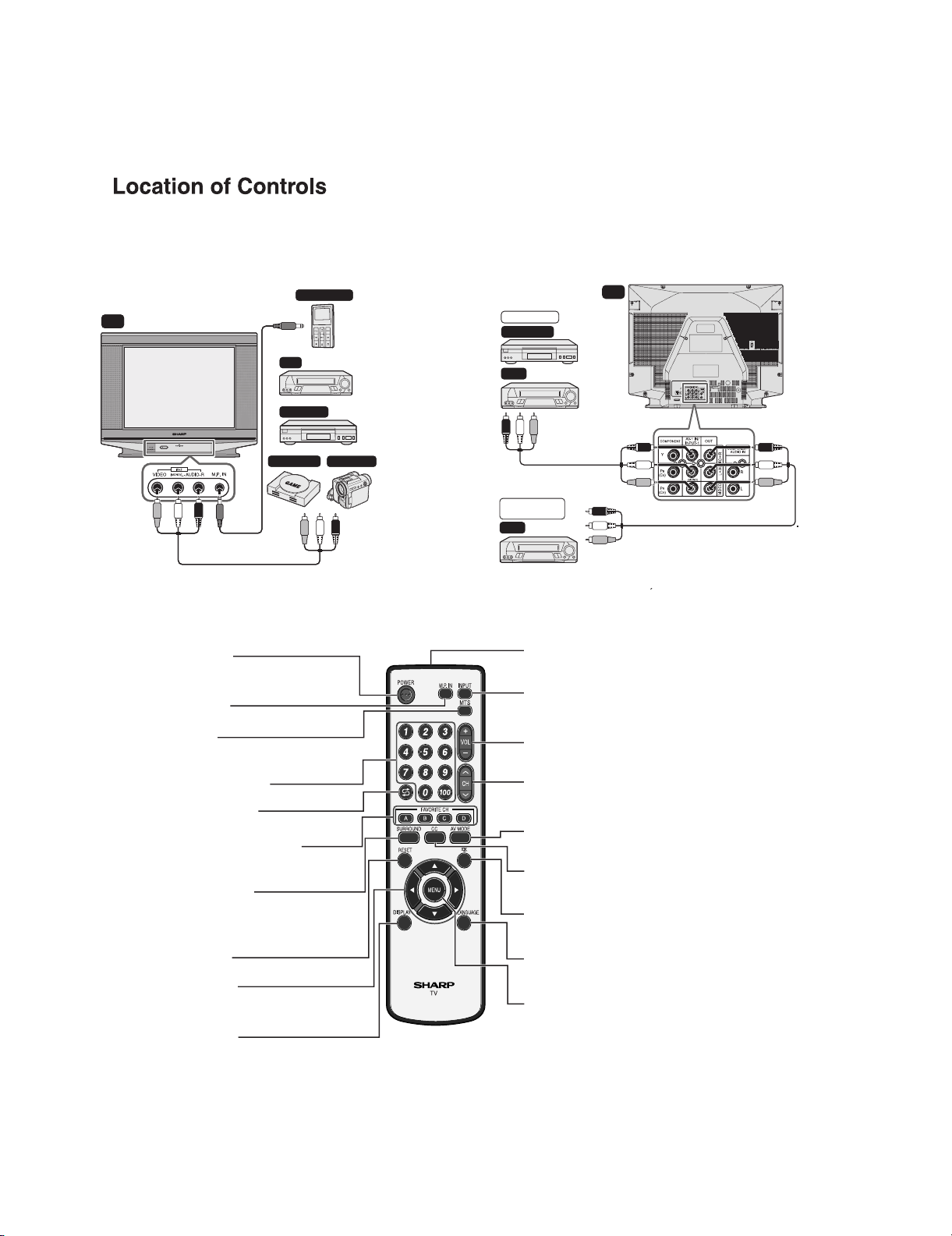

CHAPTER 2. LOCATION OF USER'S CONTROL

[1] LOCATION OF USER'S CONTROL

FRONT AV & REAR AV CONTROLS

:wol

Y

e

l

i

:e

hW

o

o

:wol

:wol

T

T

leY

leY

ihW

ihW

R

R

VT

VT

OEDIV

OEDIV

:et

:et

T

T

T

T

:de

:de

(

(

)L

)L

UA

UA

o

o

OID

OID

(

(

R

R

)

UA

)

UA

o

o

OID

OID

V

V

D

D

V

V

i

i

d

d

l

b

l

b

y

l

oM

y

l

oM

a

e

a

e

r

P

i

r

P

i

e

e

C

C

R

R

a

a

r

P

r

P

e

l

V

e

l

V

y

D

y

D

emaGo

emaGo

e

e

e

e

dr

dr

ocmaC

ocmaC

r

r

t

eR

d

:

F

D

R

CV

OE

IVoT

D

AoT

)L(OIDU

AoT

cabyalPro

k

reyalPDV

t

o

t

u

VT

(OIDU

)R

e

o

iV/oiduAoT

d

slani

mre

e

/

e

/

duAo

duAo

o

o

iV

i

iV

i

T

T

o

o

d

d

i

t

i

t

s

s

n

n

e

e

a

a

mr

tuo

mr

tuo

l

l

REMOTE CONTROL FUNCTION

POWER

Turns the TV on or to Standby

mode.

M.

P. I N

Switches M.P. IN mode on or off.

MTS

Allows reception of stereo or

billingual (TV sound).

Number buttons

FLASHBACK

Returns to previously viewed channel.

FAVORITE CHANNELS

BUTTONS (A/B/C/D)

Operate the Favorite Channel.

SURROUND

Switches between ÒOFFÓo r Ò 10 Ó

(during receiving signal stereo).

RESET

Resets all settings.

8 /9 /; /:

Selects the MENU items,

adjusts the volume and selects

the channel.

DISPLAY

Displays the channel and timer settings

on the screen.

ceRroF

gnid

ro

E

gnitid

dna

CV

R

Infrared transmitter window

Aim this window at the infrared

sensor window on your TV set.

INPUT

Switches between TV broadcasts

and AV input programs.

VOLUME UP/DOWN

Adjusts the volume.

Used for MENU setup.

CHANNE

L UP/DOWN

Selects the channel.

Used for MENU setup.

AV MODE

Switches between MOVIE,

MUSIC and NEWS.

CC

Switches between Closed Caption

service type.

MUTE

Mutes the sound and restores sound

to previous level.

LANGUAGE

Changes the on-screen display

language.

MENU

Calls the MENU screen.

To Audio/Video

in terminals

2 – 1

Page 5

TV21S-FX10LService Manual21S-FX10LMarketE

CHAPTER 3. INSTALLATION AND SERVICE INSTRUCTIONS

INSTALLATION AND SERVICE INSTRUCTIONS

Note: (1) When performing any adjustments to resistor controls and transformers use non-metallic

screwdrivers or TV alignment tools.

(2) Before performing adjustments, the TV set must be on at least 15 minutes.

21S-FX10L

CIRCUIT PROTECTION

The receiver is protected by a 3.15A fuse (F701),

mounted on PWB-A, wired into one side of the AC

line input.

X-RADIATION PROTECTOR CIRCUIT TEST

After service has been performed on the horizontal

deflection system, high voltage system, B+ system,

test the X-Radiation protection circuit to ascertain

proper operation as follows:

1. Apply 110~220V AC using a variac transformer for

accurate input voltage.

2. Allow for warm up and adjust all customer controls

for normal picture and sound.

3. Receive a good local channel.

4. Connect a digital voltmeter to C602 +ve and make

sure that the voltmeter reads 20 ±1.1V.

5. Apply external 28.5V DC at C602 +ve by using an

external DC supply, TV must be shut off.

6. To reset the protector, unplug the AC cord and make

a shor t circuit between C602 -ve and C602 +ve.

Now make sure that normal picture appears on the

screen.

7. If the operation of the horizontal oscillator does not

stop in step 5, the circuit must be repaired before the

set is returned to the customer.

HIGH VOLTAGE CHECK

High voltage is not adjustable but must be checked

to verify that the receiver is operating within safe

and efficient design limitations as specified checks

should be as follows:

1. Connect an accurate high voltage meter between

ground and anode of picture tube.

2. Operate receiver for at least 15 minutes at 110~220V

AC line voltage, with a strong air signal or a properly

tuned in test signal.

3. Enter the service mode and set Y-mute ON by using

Service R/C.

4. The voltage should be approximately 26kV (at zero

beam).

If a correct reading cannot be obtained, check circuitry

for malfunctioning components. After the voltage test,

make Y-mute off to the normal mode.

3 – 1

Page 6

21S-FX10L

TV21S-FX10LService Manual21S-FX10LMarketE

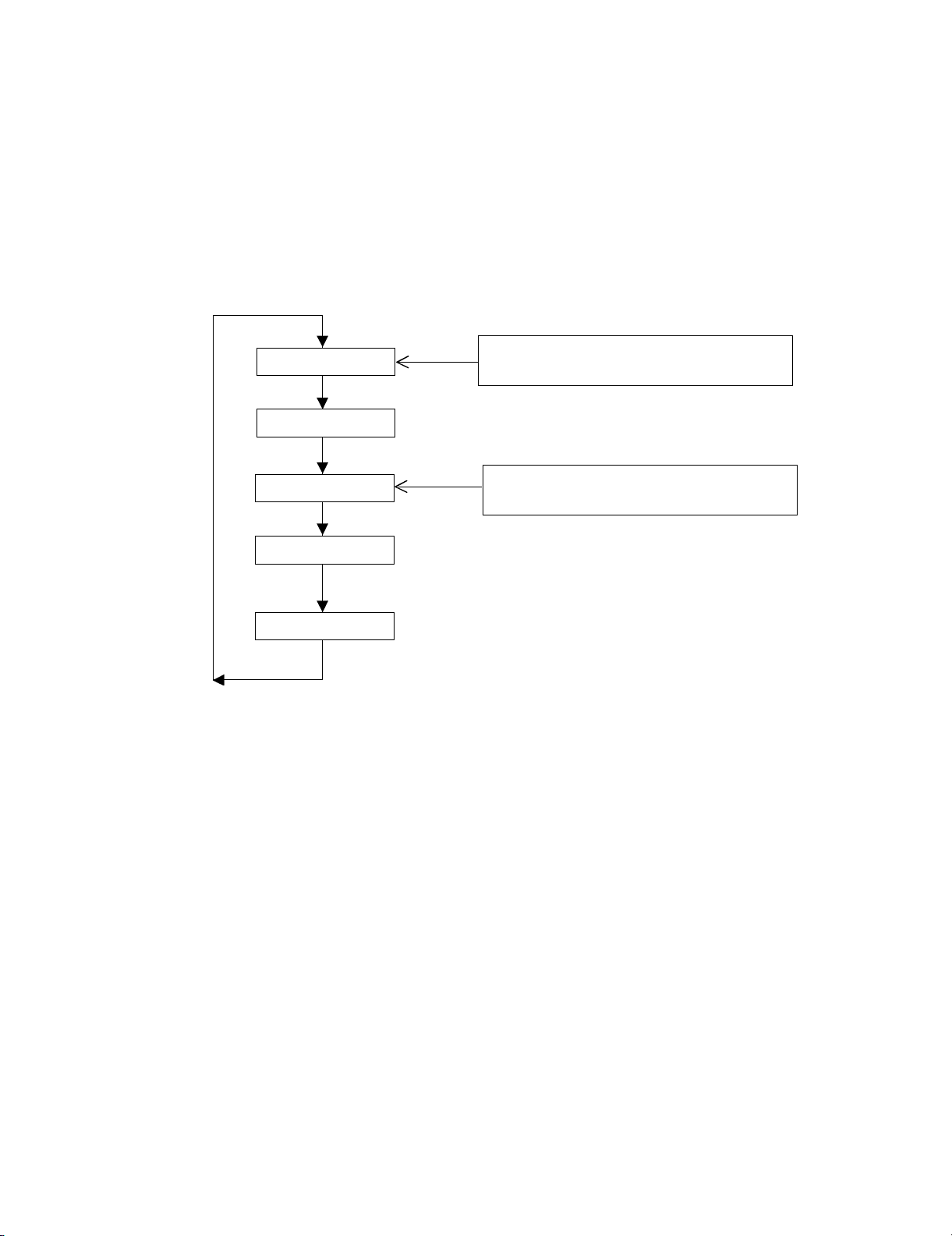

CHAPTER 4. SERVICE MODE

1. Service mode is switched by SERVICE key, CH UP + VOL DOWN when reset.

2. Service mode is c ancelled by SERVICE key during Service mode.

3. Service mode can be switched to the following 5 modes via MENU k ey:

SERVICE MODE

Adjustment mode

Setting mode

Confirmation mode

Option mode

NVM Edit mode

4䋮During Service mode, AFT operation is prohibited. The setting data for PLL is always set to fo data.

5䋮During Service mode, the following user data are set to default value and stored as last memory.

PICTURE䋯TINT䋯COLOR䋯BRIGHT䋯SHARP䋯COLOR TEMP.

BASS䋯TREBLE䋯BALANCE䋯MTS䋯FAO䋯SPEAKER䋯ENERG Y SAVE

6䋮During Service mode, OSD display for ON/OFF is toggled via [CH CALL] key.

䊶At display OFF condition, if changing adjustment data, channel, input source, it remains display OFF.

䊶At display OFF condition, if changing adjustment item, it returns to display ON.

7䋮During Service mode, the following operation are prohibited.

CLOSED CAPTION䋯No si gnal BLUE SCREEN

8䋮During Service mode, sound is muted(only MTSIC) except when selecting the following items.

V24, M01

First mode of service when entering by

SERVICE key.

First mode of service when entering by

2 local keys.

4 – 1

Page 7

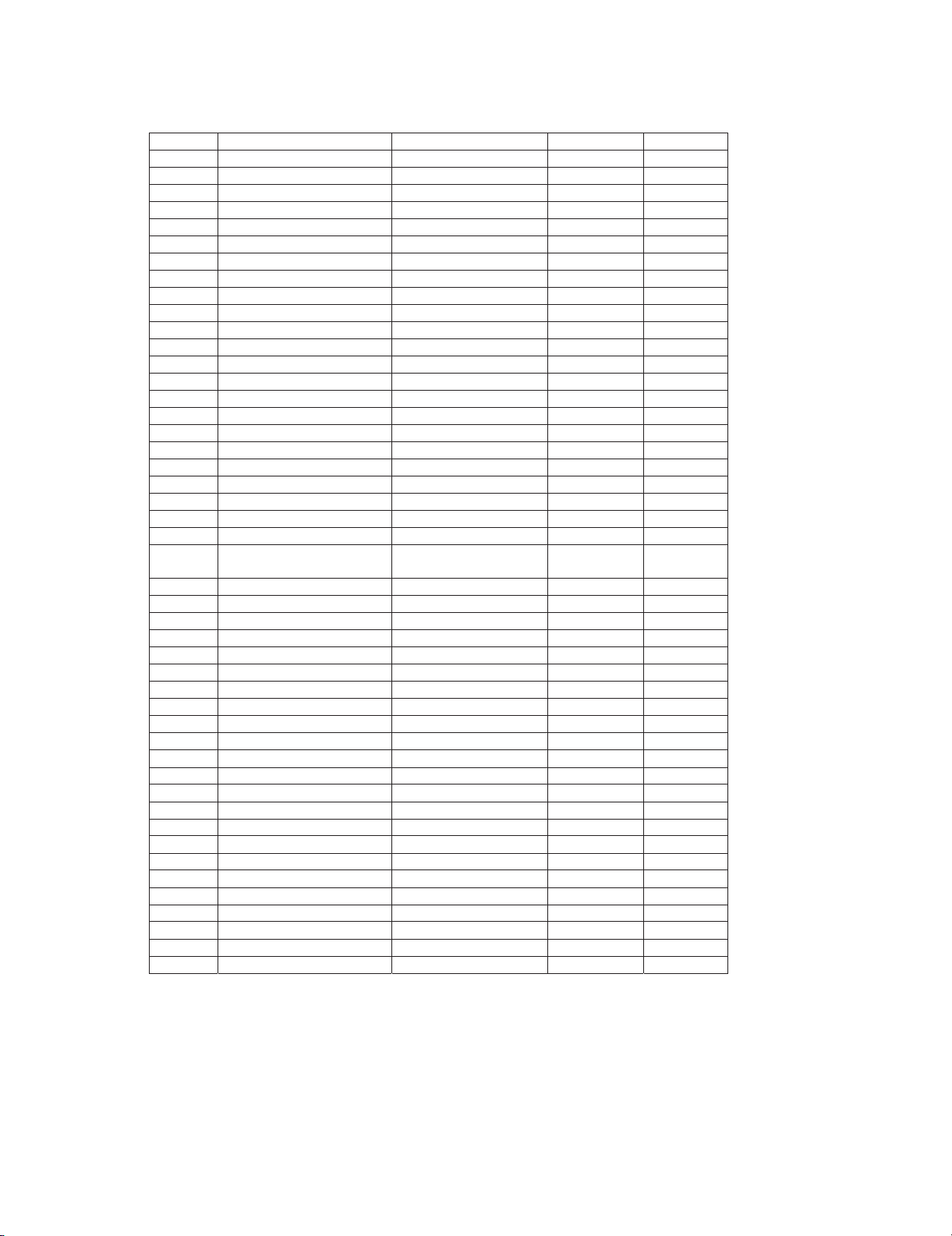

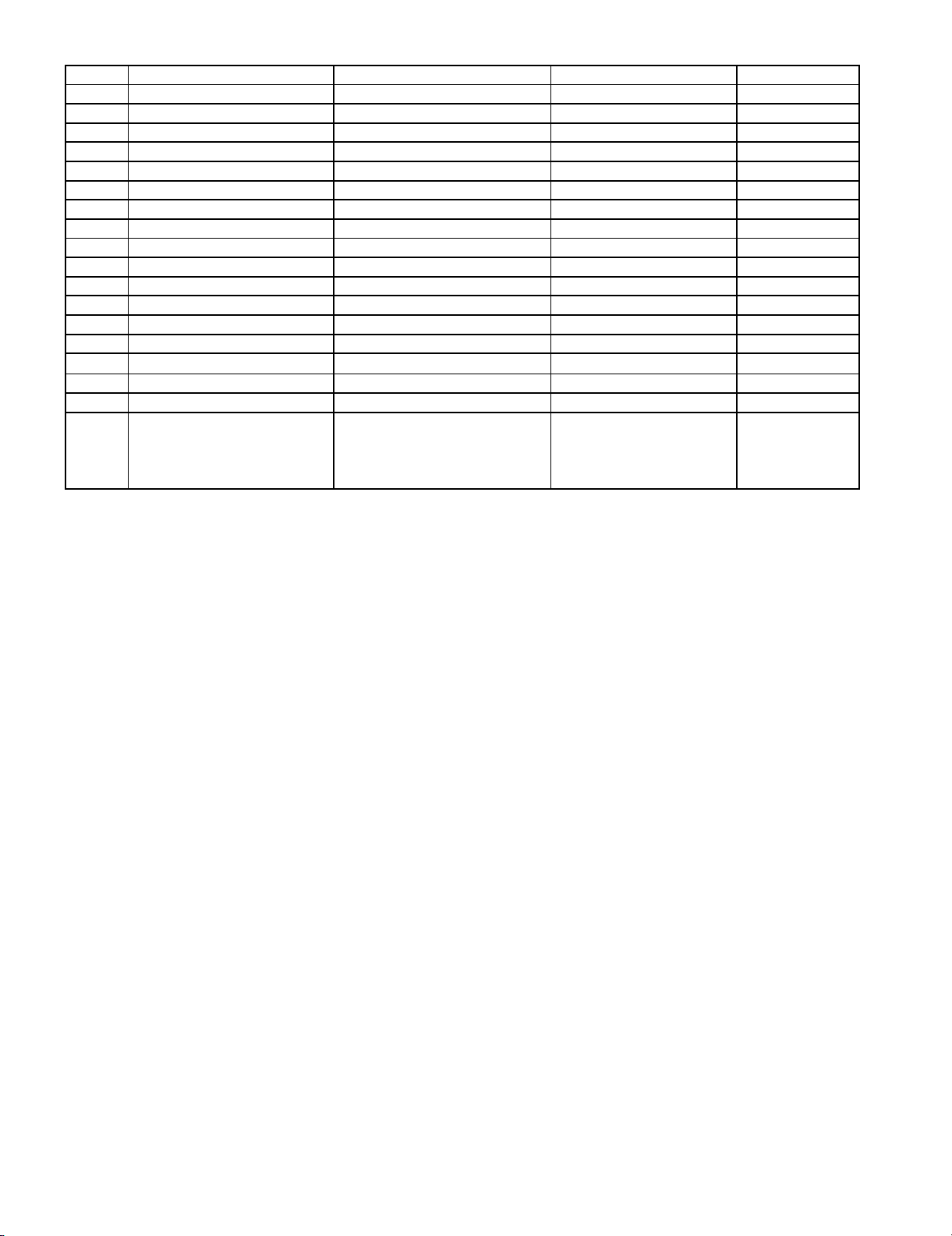

Adjustment Mode Items

Data Service Mode Function Range Default Data

V01 SUB-CON CONTRAST 0~127 127

V02 SUB-TINT TINT 0~127 64

V03 SUB-COL COLOR 0~127 64

V04 SUB-BRI BRIGHT 0~255 128

V05 SUB-SHP-PRE VIDEO-TONE(PRE) 0~63 41

V06 SUB-SHP-OVER VIDEO-TONE(OVER) 0~63 41

V07 V-SHIFT V-SHIFT 0~7 4

V08 H-SHIFT H-PHASE 0~31 16

V09 RF-AGC RF-DELAY 0~127 127

V10 V-SIZE V-SIZE 0~63 32

V11 V-SHIFT50 V-SHIFT(OFFSET) -7~+7 0

V12 H-SHIFT50 H-PHASE(OFFSET) -15~+15 0

V13 V-SIZE50 V-SIZE(OFFSET) -31~+31 0

V14 VIF-VCO VIF-VCO 0~63 32

V15 R-CUT R-CUTOFF 0~255 127

V16 G-CUT G-CUTOFF 0~255 127

V17 B-CUT B-CUTOFF 0~255 127

V18 R-DRI R-DRIVE 0~127 64

V19 B-DRI B-DRIVE 0~127 64

V20 SUB-COLOR-YUV COLOR 0~127 64

V21 SUB-TINT-YUV BASEBAND-TINT 0~127 64

V22 CC-POS CC-POS 0~255 32

V23 SCREEN CUT OFF CUT OFF 0~2 0

V24 SUB-VOL A-ATT

V25 H-VCO H-VCO 0~7 4

V26 S-TRAP S-TRAP ADJ 0~127 64

V27 VS-CORRECT VS-CORRECTION 0~63 36

V28 VS-CORRECT50 VS-CORRECTION -13~+13 0

V29 V LINEARITY V-LINEARITY 0~63 35

V30 V LINEARITY50 V-LINEARITY -13~+13 0

V31 PARABOLA E/W PARABOLA 0~63 32

V32 PARABOLA50 E/W PARABOLA -13~+13 0

V33 TRAPEZIUM E/W TRAPEZIUM 0~63 32

V34 TRAPEZIUM50 E/W TRAPEZIUM -13~+13 0

V35 H-SIZE E/W H-SIZE 0~63 32

V36 H-SIZE50 E/W H-SIZE -13~+13 0

V37 UPPER CORNER E/W UPPER CORNER 0~63 32

V38 UPPER CORNER50 E/W UPPER CORNER -13~+13 0

V39 LOWER CORNER E/W LOWER CORNER 0~63 32

V40 LOWER CORNER50 E/W LOWER CORNER -13~+13 0

V41 ANGLE ADJ ANGLE ADJ 0~63 31

V42 ANGLE ADJ50 ANGLE ADJ -13~+13 0

V43 BOW ADJ BOW ADJ 0~63 31

V44 BOW ADJ50 BOW ADJ -13~+13 0

V45 S-TRAP ADJ START S-TRAP ADJ 0~127 25

V46 S-TRAP STOP S-TRAP ADJ 0~127 95

M01 MTS-ATT DIRECT OUT LEVEL ADJ 0~15 10

㩷㩷㩷㩷Note 䋱䋩 V23 = "1" … HORIZONTAL MODE

V23 = "2" … Y-MUTE MODE

㩷㩷㩷㩷Note 䋲䋩 V24䋺These registers are set to maximum value.

0~127 (O20=0)

0~255 (O20=1)

21S-FX10L

127

255

4 – 2

Page 8

21S-FX10L

(

g

(

(

H-VCO

1. When there is H-VCO auto adjustment key input at item

2. H-FREE (1chip) is set to 1.

3. H-OUT (1chip) is set by intelligent monitor output.

4. IM input becomes TIM input.

5. H-VCO (1chip) data is changed so that the number is 126 inside 8ms interval.

6. When adjustment is completed, OSD display and H-VCO auto adjustment data of EERPOM are updated.

7. H-FREE

RF-AGC

1. If there is RF-AGC auto adjustment key input at item RF-AGC, auto adjustment will be implemented.

2. AGC-OUT (MONITOR(1chip)is set by intelligent monitor output.

3. IM input becomes AD input.

4. RF-AGC(1chip) is decreased from current RF-AGC value to 0, the maximum AFT input voltage is obtained.

5. RF-AGC(1chip) is increased until at the point of AFT input voltage is (max. 0.3V), adjustment is completed.

6. When adjustment is completed, OSD display and RFGC auto adjustment status in EEPROM are updated.

7. Intelli

AUTO ADJUSTMENT

H-VCO, auto adjustment will be implemented.

1chip), intelligent monitor output, IM input mode are recovered.

ent monitor output, IM input mode are recovered.

PIF-VCO

1. If there is PIF-VCO auto adjustment key input at item PIF- VCO, auto adjustment will be implemented.

2. VIF-DEF (1chip) is set to 1.

3. AFT output (1chip) is set by intelligent monitor output.

4. IM input becomes AD input.

5. VIF-VCO (1chip) is changed so the input voltage becomes 2.5V.

6. When adjustment is completed, OSD display and PIF-VCO auto adjustment status in EEPROM are updated.

7. VIF-DEF

1chip)intelligent monitor output, IM input mode are recovered.

S-TRAP

1. If there is S-TRAP auto adjustment key input at item S-TRAP, auto adjustment will be implemented.

2. S-TRAP OUTPUT is set by intelligent monitor output.

3. IM input becomes AD input.

4. S-Trap (1chip) is set to the value of V45(S-TRAP ADJ Start).

5. S_Trap_Result is set to the value of V45(S-TRAP ADJ Start).

6. S-Trap (1chip) is increased until the minimum input voltage becomes minimum.

7. Wait 20ms before sampling the new_ AD_data.

8. When adjustment is completed, OSD display and S-TRAP auto adjustment status in EEPROM are updated.

9. S-TRAP

1chip)intelligent monitor output, IM input mode are recovered.

4 – 3

Page 9

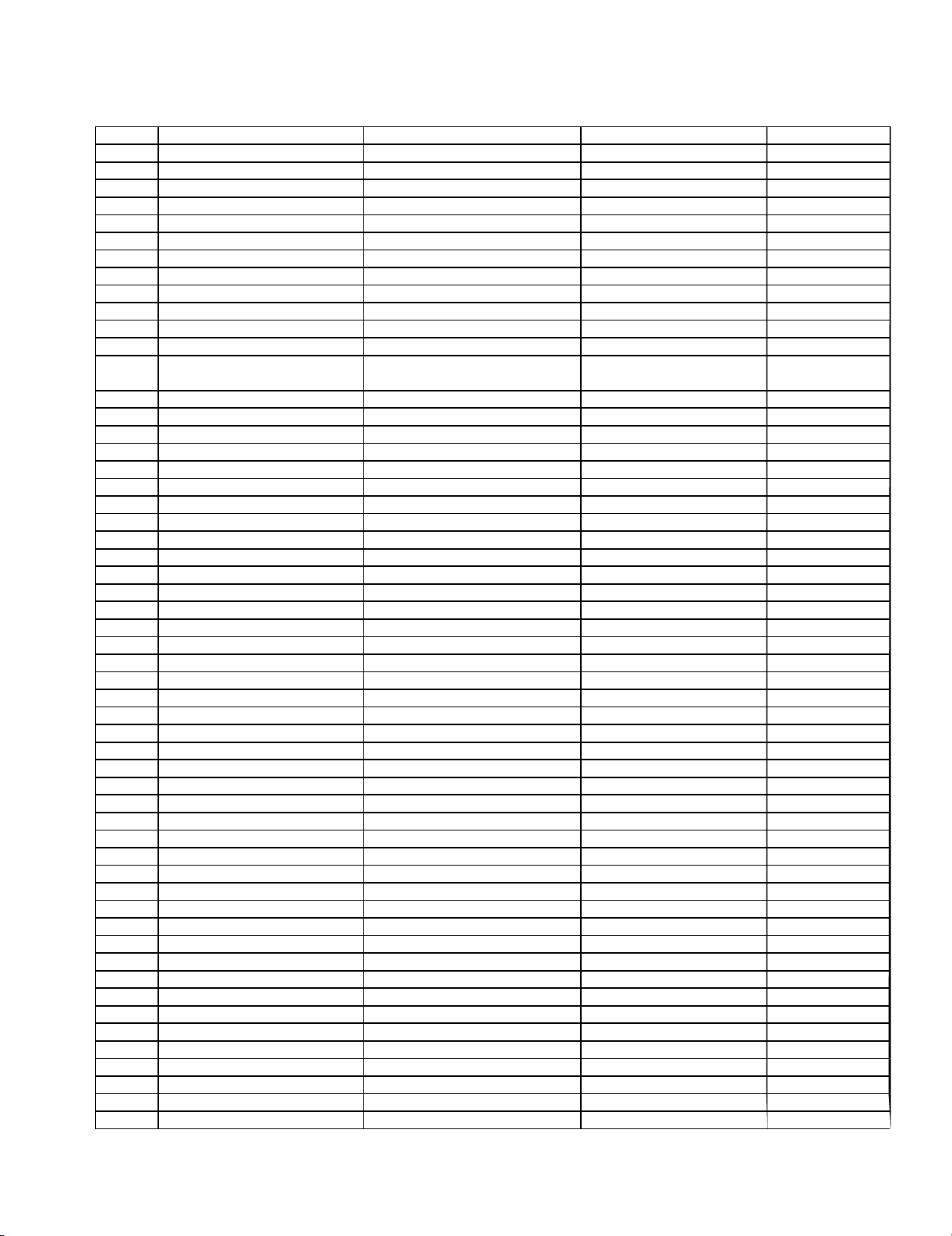

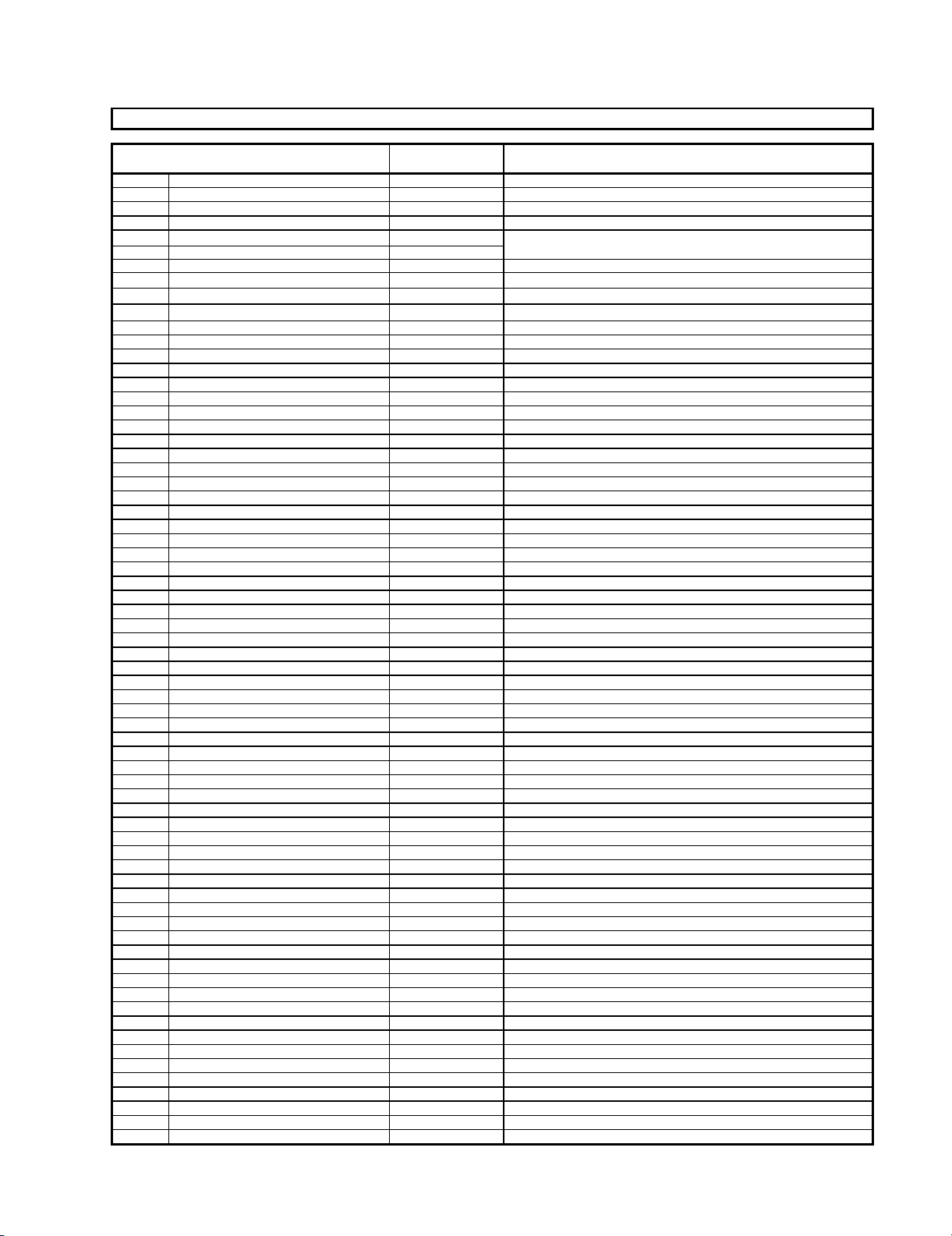

Setting Mode Items

A

R

V

21S-FX10L

Data Service Mode Range Default Data

F01 ABCL-Gain 0/1 0

F02 SHP-AV-PRE -16~+16 0

F03 SHP-YUV-PRE -16~+16 0

F04 SHP-P-PRE -31~+31 0

F05 SHP-N3-PRE -31~+31 0

F06 SHP-AV-OVER -16~+16 0

F07 SHP-YUV-OVER -16~+16 0

F08 SHP-P-OVER -31~+31 0

F09 SHP-N3-OVER -31~+31 0

F10 SHP ANT-ON II OFFSET -15~0 -10

F11 RGB-CLIP 0/1 0

F12 E-SAVE 0~63 30

F13 FAO-VOL A-ATT

F14 VIF-G 0~7 5

F15 YDL-TV 0~7 5

F16 YDL-TV-P 0~7 5

F17 YDL-TV-N3 0~7 5

F18 YDL-AV 0~7 5

F19 YDL-AV-P 0~7 5

F20 YDL-AV-N3 0~7 5

F21 YDL-YU

F22 TINT-AV -32~+32 6

F23 COL-AV -32~+32 0

F24 COL-P -31~+31 24

F25 COL-N3 -31~+31 0

F26 R-R -32~+32 3

F27 R-B -32~+32 -2

F28 B-R -32~+32 -8

F29 B-B -32~+32 6

F30 GAMM

F31 BS-D 0~3 0

F32 BS-C 0~3 0

F33 SL-TV 0~7 2

F34 SL-AV 0~7 2

F35 SL-YUV 0~7 0

F36 AFC2 0/1 0

F37 VD-TV 0~7 5

F38 VD-AV 0~7 7

F39 VD-YUV 0~7 1

F40 AS-TV 0/1 1

F41 AS-AV 0/1 1

F42 AS-YUV 0/1 0

F43 FBP-TV 0/1 0

F44 FBP-AV 0/1 0

F45 FBP-YUV 0/1 0

F46 C.Clip Level 0/1 0

F47 CP 0/1 1

F48 CC LEVEL 0~31 0

F49 OSD POS-H 0~31 0

F50 OSD POS-V50 1~55 38

F51 OSD POS-V60 1~50 23

F52 OFFSET-ADJ-COLO

F53 OFFSET-ADJ-TINT -32~+32 2

F54

F55 R-CUT-YU

WAIT㩺 MD㩺 TIMER

V 0~7 0

Function

ABCL-G

VIDEO-TONE (PRE)

VIDEO-TONE (PRE)

VIDEO-TONE (PRE)

VIDEO-TONE (PRE)

VIDEO-TONE (OVER)

VIDEO-TONE (OVER)

VIDEO-TONE (OVER)

VIDEO-TONE (OVER)

VIDEO-TONE

EXTRGB-CLIP

CONTRAST(OFFSET)

VIF-GAIN

Y-DELAY

Y-DELAY

Y-DELAY

Y-DELAY

Y-DELAY

Y-DELAY

Y-DELAY

TINT(OFFSET)

COLOR(OFFSET)

COLOR(OFFSET)

COLOR(OFFSET)

R-DRI(OFFSET)

R-DRI(OFFSET)

B-DRI(OFFSET)

B-DRI(OFFSET)

GAMMA

BS-DISCHARGE

BS-CHARGE

S-SLICE DOWN

S-SLICE DOWN

S-SLICE DOWN

AFC2-G

VSYNC-DET

VSYNC-DET

VSYNC-DET

AUTO-SLICE

AUTO-SLICE

AUTO-SLICE

FBP VTH

FBP VTH

FBP VTH

C.CLIP LEVEL

CP

CC LEVEL

OSD POS

OSD POS

OSD POS

COLOR

TINT

(SLOW MODE)

R-CUT (OFFSET)

0~127 (O20=0) 120

0~255 (O20=1) 246

0~3 1

-32~+32 10

0/1 1

-63~+63 0

4 – 4

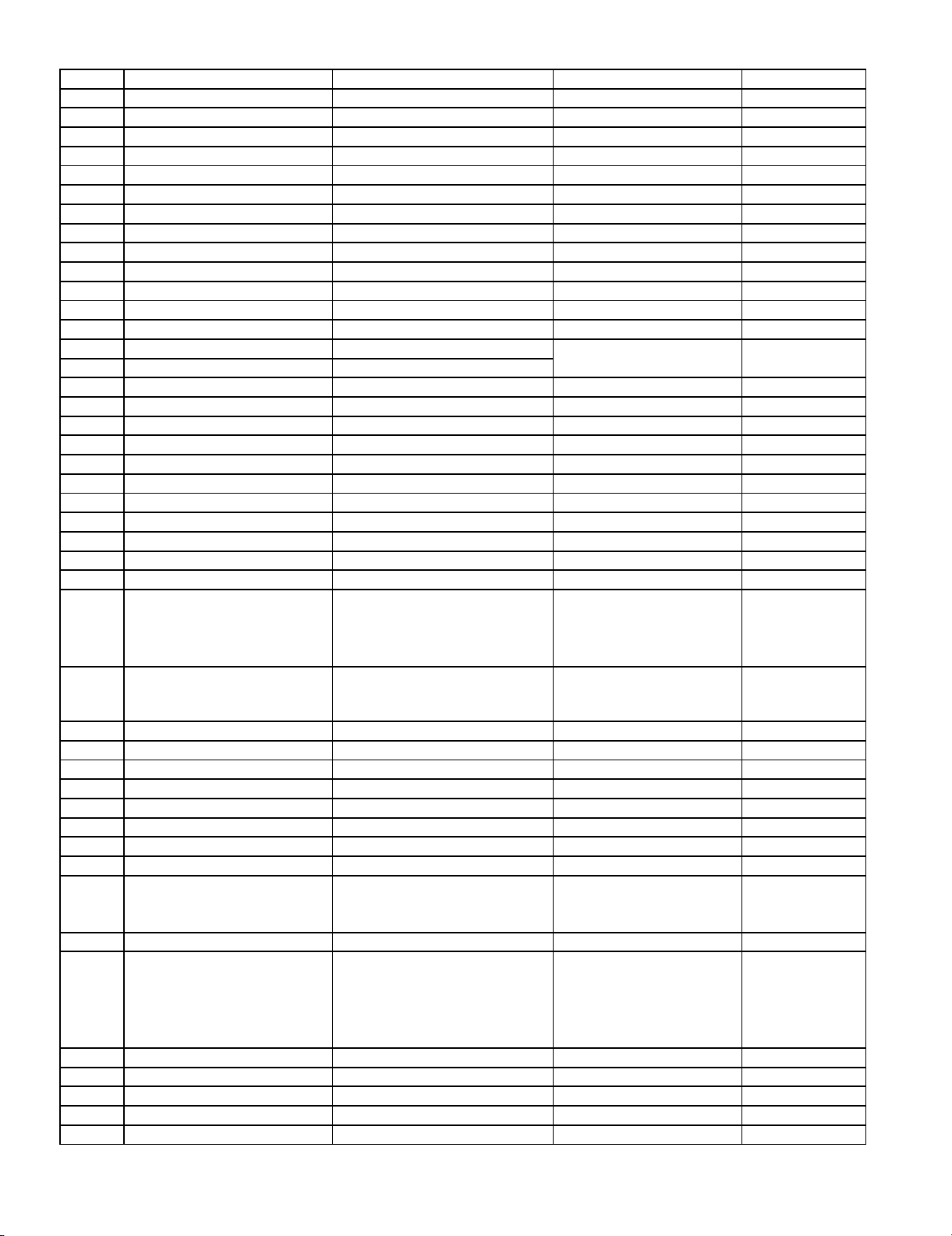

Page 10

21S-FX10L

V

T

T

T

T

T

T

T

F56 G-CUT-YU

F57 B-CUT-YUV -63~+63 0

F58 R-DRI-YUV -63~+63 0

F59 B-DRI-YUV -63~+63 0

F60 CONTRAST OFFSE

F61 CONTRAST YUV OFFSE

F62 BRIGHT OFFSET -63~+63 0

F63 BRIGHT AV2 OFFSET -15~+15

F64 BRIGHT YUV OFFSE

F65 TRAP

F66 TRAP-P

F67 TRAP-N3

F68 AFC1-Gain-TV 0~3 0

F69 AFC1-Gain-AV 0~3 3

F70 AFC1-Gain-YUV 0~3 3

F71 OM-DE

F72 䌂䌓䋭䌇䌡䌩䌮

F73 C-ANGLE

F74 䌖䋭䌄䌌

F75 䌕䋭䌄䌌

F76 AS-SPEED-DN

F77 AS-SPEED-UP

F78 CR-PEDESTEL-ADJ

F79 CB-PEDESTEL-ADJ

F80 SIF-BPF-WIDE

F81 SIF-BPF-WIDE-LOW 0/1 0

F82 SIF-BPF-WIDE-HIGH 0/1 0

G-CUT (OFFSET)

B-CUT (OFFSET)

R-DRI (OFFSET)

B-DRI (OFFSET)

CONTRAST(OFFSET)

CONTRAST(OFFSET)

BRIGHT (OFFSET)

BRIGHT (OFFSET)

BRIGHT (OFFSET)

TRAP-FINE

TRAP-FINE

TRAP-FINE

AFC1-G

AFC1-G

AFC1-G

OM-Det

BS-Gain

C.ANGLE

V-DL Fine

U-DL Fine

AS-SPEED-DN

AS-SPEED-UP

Cr Pedestal Adj.

Cb Pedestal Adj.

SIF BPF WIDE

SIF BPF WIDE LOW

SIF BPF WIDE HIGH

-63~+63 0

-63~+63 0

-63~+63 0

+1

-63~+63 0

0~3 2

0~3 2

0~3 2

0/1 0

0/1 0

0/1 0

0~3 0

0~3 0

0/1 0

0/1 0

0~15 8

0~15 8

0~7 3

0: 11XX (AUTO)

F83 COL-SYSTEM COL-SYSTEM

1: 0011 (PAL-M)

2: 0111 (PAL-N)

3: 0110 (N358)

3

F84 Pow-Storage 0/1 1

F85 SIF45 GAIN DOWN

F86 S-TRAP OFF

F87 BASS OFFSET

F88 MID1 OFFSE

F89 MID2 OFFSE

F90 MID3 OFFSE

F91 TREBLE OFFSET

F92 AVL LEVEL

CONTRAST/BRIGHTNESS INCREASE

GRADUALLY

SIF45 GAIN DOWN

S-Trap

BASS

AUDIO EQ MID1

AUDIO EQ MID2

AUDIO EQ MID3

TREBLE

AUDIO AVL LEVEL

0/1 0

0/1 1

-4~+4 0

-4~+4 0

-4~+4 0

-4~+4 0

-4~+4 0

0~3 0

0:fixto0

F93 AVL OPTION AVL ON

1:fixto1

2: AVL in SOUND MENU

F94 AU-ATT AMP

AU ATTOUT GAIN

0 (0dB)/1(3dB) 0

0: 10%

1: 30%

2: 50%

3: 70%

4: 90%

F96 R MTX UP

F97 MATRIX ADJ

F98 SAP LEVEL

F99 STEREO SENS

F100 SAP SENS

R MTX UP

MATRIX ADJ

SAP LEVEL

STEREO SENS

SAP SENS

0/1 0

0~3 0

0/1 0

0/1 0

0/1 0

2

3F95 OSD LEVEL OSD LEVEL

4 – 5

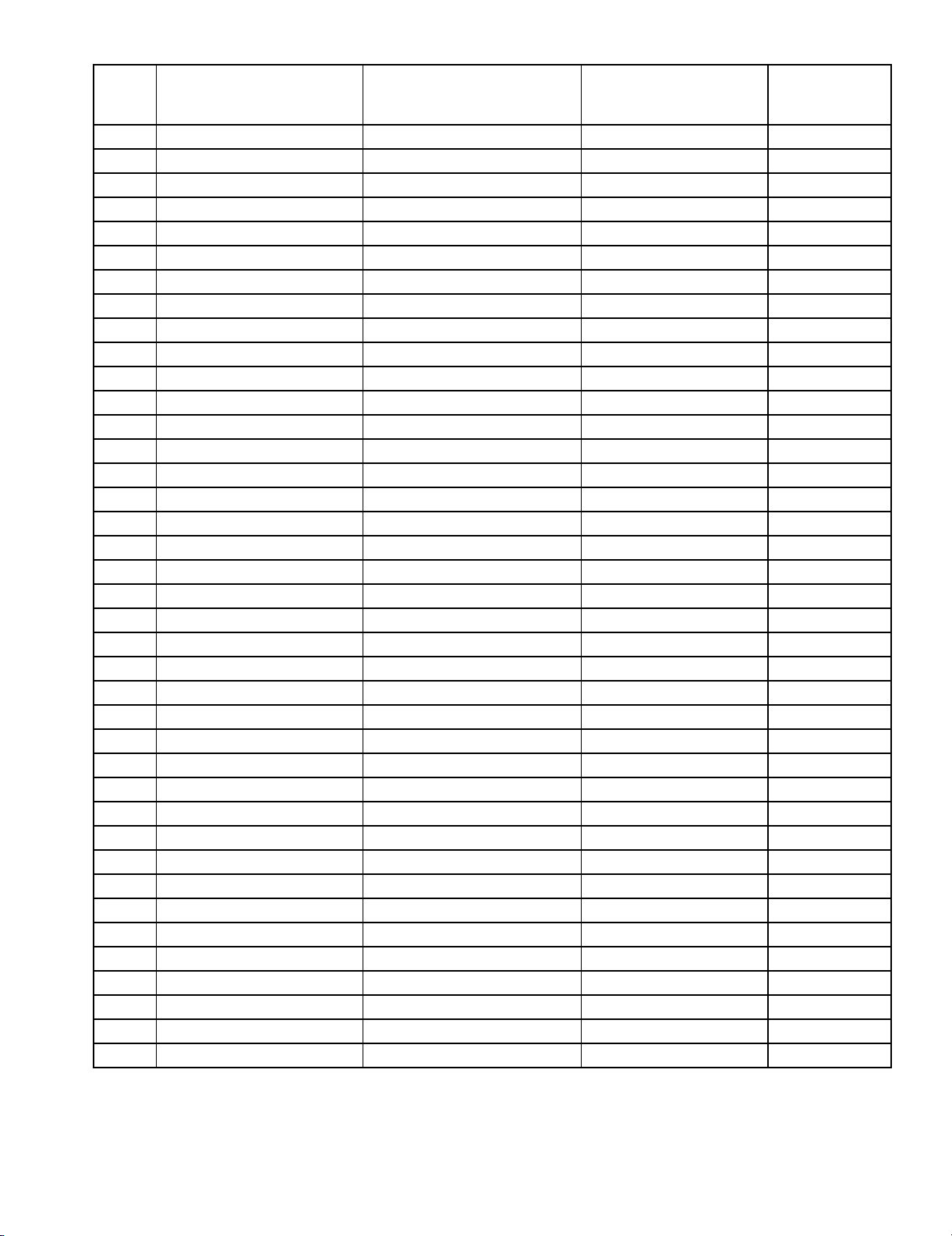

Page 11

21S-FX10L

F101 MER 0~255 70

F102 MEL1

F103 MEL2

F104 MEL3

F105 MEL4

F106 MEL5

F107 MEL6

F108 S-St-Point

F109 S-Sp-Point

F110 S-Step

F111 CONT NEWS

F112 CONT MUSIC

F113 CONT MOVIE

F114 BRIGHT NEWS

F115 BRIGHT MUSIC

F116 BRIGHT MOVIE

F117 COL NEWS

F118 COL MUSIC

F119 COL MOVIE

F120 SHARP NEWS

F121 SHARP MUSIC

F122 SHARP MOVIE

F123 SURR NEWS

F124 SURR MUSIC

F125 SURR MOVIE

F126 TREBLE NEWS

F127 TREBLE MUSIC

F128 TREBLE MOVIE

F129 BASS NEWS

F130 BASS MUSIC

F131 BASS MOVIE

F132 EQ BASS NEWS

F133 EQ BASS MUSIC

F134 EQ BASS MOVIE

F135 EQ MID1 NEWS

F136 EQ MID1 MUSIC

F137 EQ MID1 MOVIE

F138 EQ MID2 NEWS

F139 EQ MID2 MUSIC

F140 EQ MID2 MOVIE

S-BOOSTER FREQ.

CHARACTERISTIC CONTROL

S-BOOSTER LEVEL1

S-BOOSTER LEVEL2

S-BOOSTER LEVEL3

S-BOOSTER LEVEL4

S-BOOSTER LEVEL5

S-BOOSTER LEVEL6

S-BOOSTER START POINT

S-BOOSTER STOP POINT

S-BOOSTER STEP

CONTRAST SETTING- NEWS

CONTRAST SETTING- MUSIC

CONTRAST SETTING- MOVIE

BRIGHTNESS SETTING- NEWS

BRIGHTNESS SETTING- MUSIC

BRIGHTNESS SETTING- MOVIE

COLOUR SETTING- NEWS

COLOUR SETTING- MUSIC

COLOUR SETTING- MOVIE

SHARPNESS SETTING- NEWS

SHARPNESS SETTING- MUSIC

SHARPNESS SETTING- MOVIE

SURROUND SETTING- NEWS

SURROUND SETTING- MUSIC

SURROUND SETTING- MOVIE

TREBLE SETTING- NEWS

TREBLE SETTING- MUSIC

TREBLE SETTING- MOVIE

BASS SETTING- NEWS

BASS SETTING- MUSIC

BASS SETTING- MOVIE

EQ BASS SETTING- NEWS

EQ BASS SETTING- MUSIC

EQ BASS SETTING- MOVIE

EQ MID1 SETTING- NEWS

EQ MID1 SETTING- MUSIC

EQ MID1 SETTING- MOVIE

EQ MID2 SETTING- NEWS

EQ MID2 SETTING- MUSIC

EQ MID2 SETTING- MOVIE

0~255 150

0~255 156

0~255 163

0~255 165

0~255 170

0~255 180

0~60

0~60

0~60

0~60

0~60

0~60

-30~+30

-30~+30

-30~+30

-30~+30

-30~+30

-30~+30

-30~+30

-30~+30

-30~+30

0(OFF)/1(ON)

0(OFF)/1(ON)

0(OFF)/1(ON)

-10~+10

-10~+10

-10~+10

-10~+10

-10~+10

-10~+10

-10~+10

-10~+10

-10~+10

-10~+10

-10~+10

-10~+10

-10~+10

-10~+10

21

60

7

40

50

60

0

0

0

0

0

+10

-10

0

5

0

0

0

-10

0

+5

-5

0

+10

0

0

0

0

0

0

0

0

0-10~+10

4 – 6

Page 12

21S-FX10L

F141 EQ MID3 NEWS

F142 EQ MID3 MUSIC

F143 EQ MID3 MOVIE

F144 EQ TRE NEWS

F145 EQ TRE MUSIC

F146 EQ TRE MOVIE

F147 S-BOOST NEWS

F148 S-BOOST MUSIC

F149 S-BOOST MOVIE

F150 CORNER UP-LOW EN EW CNUPLOW EN 1

F151 BOW/ANGLE-ON/OFF BOW/ANGLE 1

F152 SHP-NR-OFFSET VIDEO TONE 0

F153 V-FREE60 V-FREE60 1

F154 TAKEOFF TV TAKE-OFF 0

F155 STRAP OFFSET S-TRAP ADJ 0

F156 RGB MUTE TIME 0

F157 H-BLK LEFT H-BLK LEFT 0

EQ MID3 SETTING- NEWS

EQ MID3 SETTING- MUSIC

EQ MID3 SETTING- MOVIE

EQ TRE SETTING- NEWS

EQ TRE SETTING- MUSIC

EQ TRE SETTING- MOVIE

S-BOOSTER SETTING- NEWS

S-BOOSTER SETTING- MUSIC

S-BOOSTER SETTING- MOVIE

-10~+10

-10~+10

-10~+10

-10~+10

-10~+10

-10~+10

0(OFF)/1(ON)

0(OFF)/1(ON)

0(OFF)/1(ON)

0/1

0(OFF)/1(ON)

-15~0

0/1

0/1

-16~+16

0~8

0~7

F158 H-BLK RIGHT H-BLK RIGHT 00~7

0: 5ms

F159 H-STOP DELAY H-START

1: 10ms

2: 15ms

3: 20ms

0

0

0

0

0

0

0

1

1

1

4 – 7

Page 13

Y

TV21S-FX10LService Manual21S-FX10LMarketE

CHAPTER 5. ADJUSTMENT METHOD

ADJ ITEM: BUS SET UP (1ST & 2ND STAGE SERVICE DATA)

21S-FX10L

SERVICE ITEMS

V05

V06

V20

V21 SUB-TINT-YUV

V27

V29 V LINEARIT

V43 BOW ADJ

F02

F03

F06

F07

F13

SUB-SHP-PRE

SUB-SHP-OVER

SUB-COLOR-YUV

VS-CORRECT

SHP-AV-PRE

SHP-YUV-PRE

SHP-AV-OVER

SHP-YUV-OVER

FAO-VOL

34

18

41

54

35 ADJUST IF NECESSARY

37

32

-10

-14

-10

-14

81

F14 VIF-G

F20 YDL-AV-N3

F22 TINT-AV

F23 COL-AV

-16

+10

F26 R-R +7

F27

F28

F29

F30

F33

R-B

B-R

B-B

GAMMA

SL-TV

-20

+9

F36 AFC2

F37

VD-TV

F38 VD-AV

F39 VD-YUV 0

F49

F50

F51

F52

F53

F55

F56

F58

F59

F61

OSD POS-H

OSD POS-V50

OSD POS-V60

OFFSET-ADJ-COLOR

OFFSET-ADJ-TINT

R-CUT-YUV

G-CUT-YUV

R-DRI-YUV

B-DRI-YUV

CONTRAST YUV OFFSET

13

48

32

+3

+9

-2

-24

-1

+1

+6

F63 BRIGHT AV2 OFFSET +4

F64 BRIGHT YUV OFFSET +17

F65 TRAP 0

F80 SIF-BPF-WIDE 1

F85 SIF45 GAIN DOWN 1

F86 S-TRAP OFF 0

F92 AVL LEVEL 1

F94 AU-ATT AMP 1

F111 CONT NEWS 50

F112 CONT MUSIC 60

F117

F119

F120

F122

F126

F128

F129

F131

F132

F133

F134

F136

F137

F138

F139

F141

F143

F144

F145

F146

F156

F158

COL NEWS

COL MOVIE

SHARP NEWS

SHARP MOVIE

TREBLE NEWS

TREBLE MOVIE

BASS NEWS

BASS MOVIE

EQ BASS NEWS

EQ BASS MUSIC

EQ BASS MOVIE

EQ MID1 MUSIC

EQ MID1 MOVIE

EQ MID2 NEWS

EQ MID2 MUSIC

EQ MID3 NEWS

EQ MID3 MOVIE

EQ TRE NEWS

EQ TRE MUSIC

EQ TRE MOVIE

RGB MUTE TIME

H-BLK RIGHT

-6

+6

-6

+6

-1

+2

+1

+1

+1

+1

-2

+1

+2

-1

+5

+2

REMARK21S-FX10L

TO IMPROVE

7

4

0

3

1

1

1

2

0

0

0

0

1

3

5 – 1

Page 14

21S-FX10L

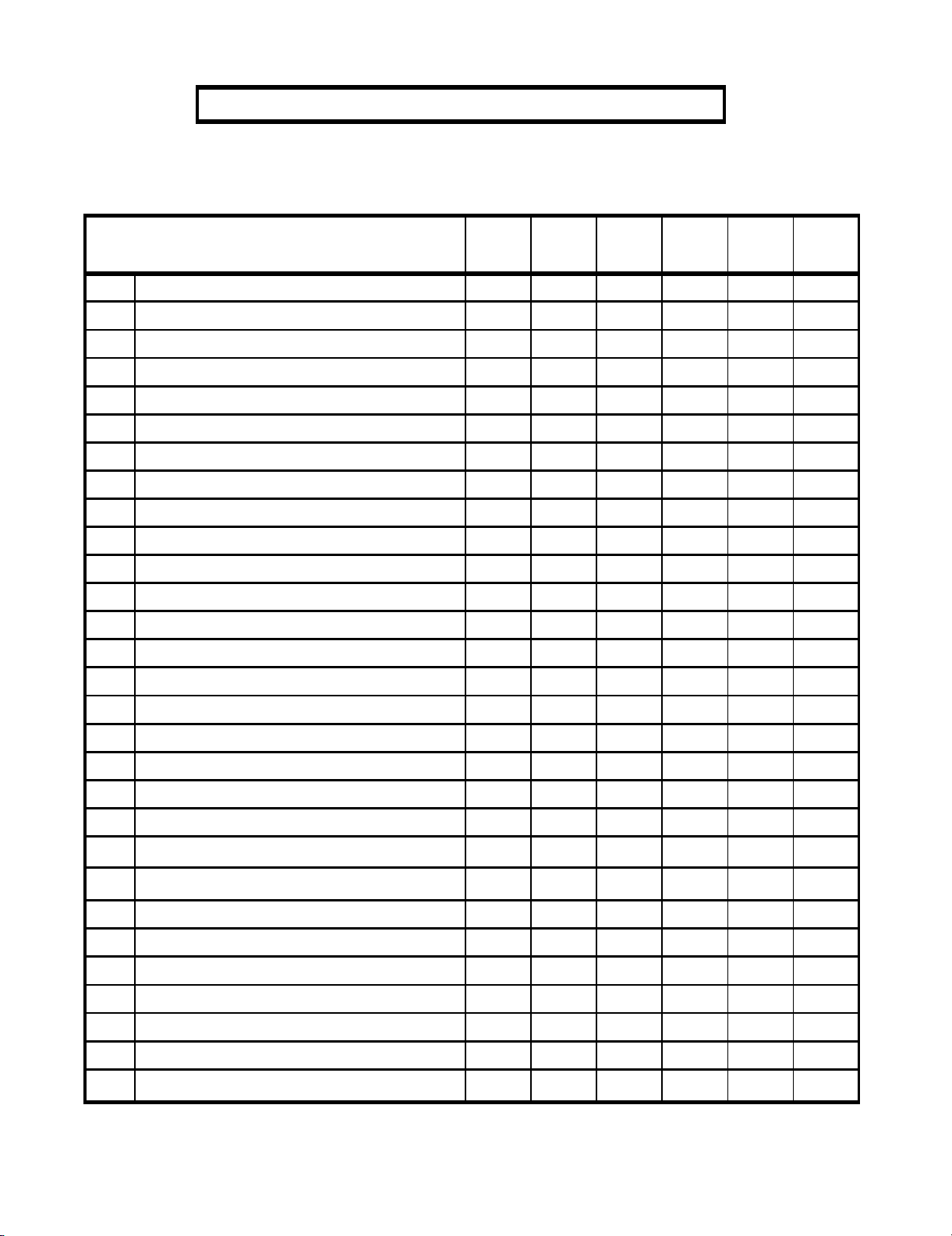

ADJ ITEM: OPTION SET UP (3RD STAGE SERVICE DATA)

SERVICE ITEMS

21S-FX10L

O01 LNA TUNER 0

O02 FAO 1

O03 PON-CH 1

O04

ANTENNA BOOSTER

0

O05 AV 1

O06 AV2 1

O07 MTS 1

O08 COMPONENT 2

O09 TONE-CTRL 2

O10 AUTO-OFF 1

O11 LAST POWER 0

O12 SETUP-FLAG 1

O13 AV MODE 1

O14 MP-IN 1

O15 S-BOOSTER 0

O16 FORCE-COL 0

O17 INIT-LANG 1

O18 LANG-SEL 1

O19 ARROW-KEY 1

O20

VOL-TABLE

AUTO-JUDGEMENT

O21

O22 WHITE-OUT

O23

H-SYNC JUDGE

O24 CHSET COLOR

O25 DEMO

O26 FLAT

0

1

0

1

0

1

1

O27 F/R-AV 3

O28 SPEAKER 1

O29 VOL-CURVE 1

5 – 2

Page 15

T

E

S

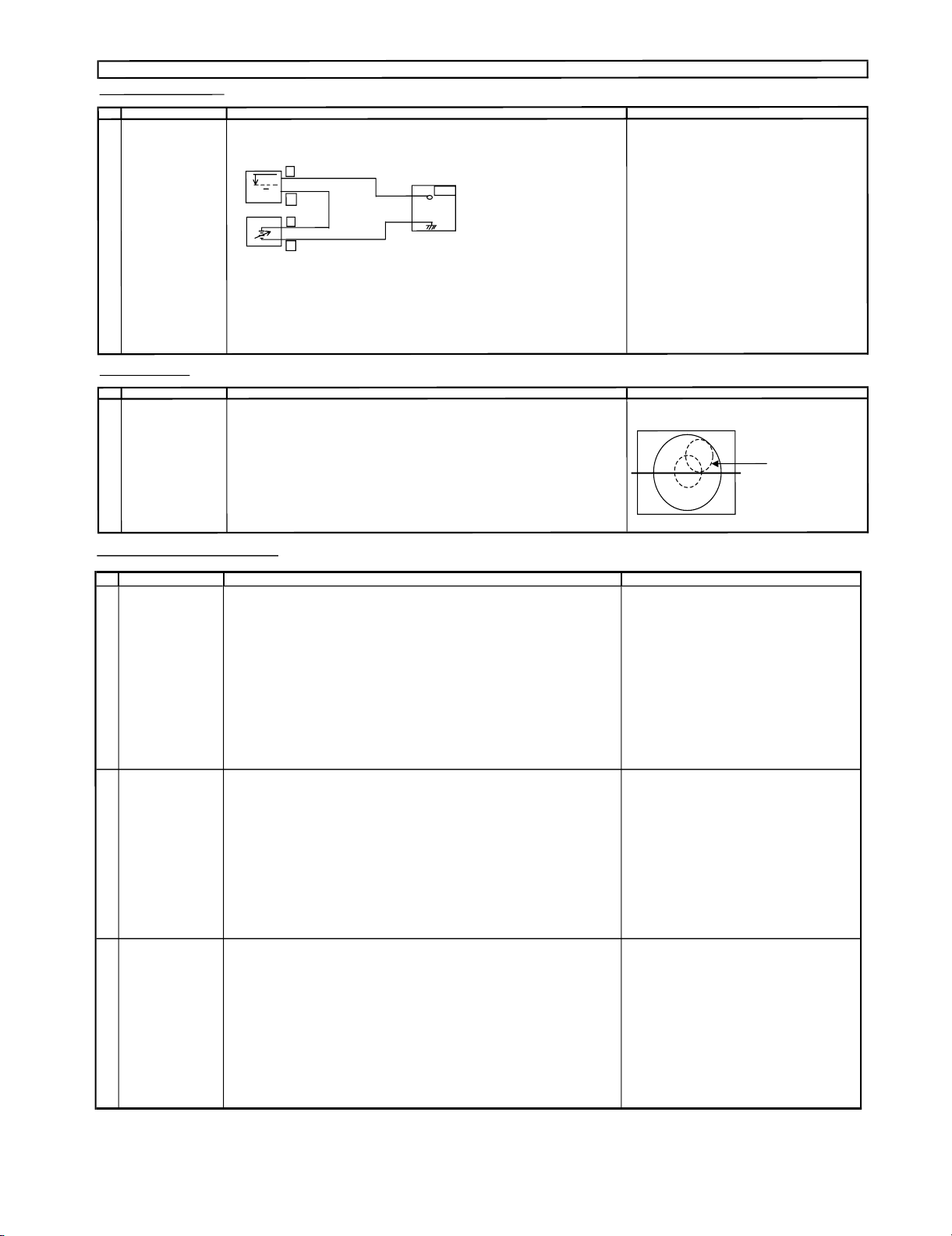

ADJUSTMENT PRECAUT

CHECKING

T

DJUSTMEN

PIF A

T

TMENT POIN

ADJUS

NO

1

CUS ADJUSTME

FO

NO

1 FOCUS (1) Receive

RF-AGC

KE OVER P

A

T

USTMENT (2) Connect t

ADJ

(I2C BUS CONTROL) figure 3-1

UTO & MANUAL

(A

N

USTMENT POIN

J

AD

(1) Recei

OINT

DJ)

A

(3) Call V0

(4) Ch

i

(5)T

modulationbeat.

T

(2) Press RESET to set Picture N

(3) Adjust the focus control to get the bes

ke sure TV Set is in "NORMAL CON

ION :Ma

ADJUSTMENT CONDITION/PROCEDUR

ve the "US 10 CH HALF Color B

Strength: 56 ± 1dBμV (75 ohm open)

Signal

he oscillos

.

0.1V

Bias Box : about 4.5V

9 i

outputpindrop 0.1V b

ge the antenna inpu

n

a

e.

onois

n

s

rn uptheinput s

u

S

U

e

cop

OSCILLO

+

-

+

-

Fig. 3

n service mode. Adjust the V09busdatatoobtain theT

elow maximum voltage.

t

ignal to 9

ION HEAD Signal

4CHL

ar" signal

oJA402(Tuner's AGC Terminal) as shown in

t

SCOPE

BIAS BOX

-1

signal to 63 ~67dBμV, and makes

~95dBμVto be sure that the

0

ADJUSTMENT

(NTSC60Hz).

ORMAL condition.

focusing.

t

.

402

JA

SET

V

T

re i

NDITION / PROCE

CO

u

re the

n

s

uner

re

o cross

DU

DITION" b

E

R

fore switch to Service Mode for Adj

e

for Auto ADJ

*

1)Receive "NTSC C

gnal strength :56±1dBμV(75ohmo

i

s

ervice mode.

1) Go to s

to servic

2) Go

"Auto-AGC" key and confirm the OK display

on the screen

)Ifappear red display w

3

ep and pleas

t

s

4) Proceed step 4 & 5 i

stment.

u

WAVEFORM OR OTHERS

nal

sig

UR BAR"

O

L

O

data V09 , press R/C to operate

e

gn, inc

i

th NG s

i

e repeat step 2.

n

WAVE

.

mode

manual

FORM OR REMARK

Focusing Poin

of ce

monoscope pattern)

21S-FX10L

en).

p

rease data some

dedgeof

an

ter

n

t(middle

H-VCO, VIF-VCO & S-TRAP fo ADJUSTMENT

NO

ADJUSTMENT POINT

1 H-VCO ADJ

(I2C BUS CONTROL)

(AUTO & MANUAL ADJ)

(Manual Adj)

(1) In No signal (RASTER) condition.

(2) Go to service mode, choose service data

(3) Connect oscilloscope to IC801 pin13 (H-OUT)

become 15.735 ± 0.2KHz.

(Auto Adj)

(1) In No signal (RASTER) condition.

(2) Go to service mode.

(3) Choose service data V25,bypressingR/C

at screen.

(4) If appear "NG" pls repeat step 3.

2 VIF-VCO ADJ

(I2C BUS CONTROL)

(AUTO & MANUAL ADJ)

(Manual Adj)

(1) In No signal (RASTER) condition.

(2) Go to service mode, choose service data V14

(3) Connect oscilloscope to IC801 pin7 (AFT)

2.5 ± 0.5 V DC (Checking spec : 2.50 ± 1.5 V)

(Auto Adj)

(1) In No signal (RASTER) condition.

(2) Go to service mode, choose service data V14.

(3) Press the R/C "AUTO PIF-VCO"

(4) If appear "NG" pls repeat step 3.

3

S-TRAP fo ADJ

(Manual ADJ

)

(I2C BUS CONTROL) (1) In No signal (RASTER) condition.

(AUTO & MANUAL ADJ)

(2) Go to service mode, choose service data V26.

(3) Connect oscilloscope to TP 801 or IC801 pin 30

ADJUSTMENT CONDITION / PROCEDURE

V25.

,adjV25 until freq

"AUTO H-VCO" key, OSD will appear "OK"

, adj V14 until voltage become

key, OSD will appear "OK" at screen.

, adj V26 until voltage become Min (below 5 V).

WAVEFORM OR OTHERS

*NOTE:

This adjustment must be done after aging

at least 3 minutes.

(Auto Adj)

(1) In No signal (RASTER) condition.

(2) Go to service mode, choose service data

V26.

(3) Press the R/C "AUTO S-TRAP" key, OSD will appear "OK" at screen.

(4) If appear "NG" pls repeat step 3.

5 – 3

Page 16

21S-FX10L

HORIZONTAL ,V

NO

1

E

A

DJUSTMENT POINT

V-SHIFT

(I2C BUS CONTRO

2

V-SIZE

(I2C BUS CONTROL)

(to be done after V-shift adj)

3

V-LINEARITY

(I2C BUS CONTROL)

4

VS CORRECTION

(I2C BUS CONTR

5 H-SHIFT

(I2C BUS CONTRO

6 H-SIZE

(I

2C BUS CO

RTICAL,DEFLECTION LOOP ADJUSTMENT (1)

ADJUSTMENT CO

(1) Receive US4 CH LION HEAD Signal (NTSC 60 Hz)

L)

(2) Choose the service data

(3) Adjust V

07

Note: B line (Monoscope middle lin

to the A mark (Tubem

(1) Receive US4 CH LIO

(

2) Choose the service data

(3

)AdjustV10

C

V07

.

to align the center of the screen to the geometric center of CRT.

e) m

iddle mark),refer t

N HEAD Signal (NTSC 60 Hz

V10

.

bus data until the overscan become

aution 1: Pls aging TV more th

(1) Receive US4 CH LION HEAD Signal (NTSC 60 Hz).

(2) Choose the servic

edata

V

29.

(3 )Already preset. (Adjust this unless the linearity is achieved.)

(1) Receiv

O

L)

e US4 CH LION HEAD Signal (NTSC60Hz).

(2) Choose the servic

e data

V27.

(3 )Already preset. (Adjust this unless the linearity is achieved.)

(1) Receiv

L)

NTROL)

e US4 CH LION HEAD Signal (NTSC 60 Hz

(2) Choose the service da

(3) Adjust the

(4)Ifcannotmakeitto

(1) Receive US

(2) Choose the service data

(

3) Adjust

V35 bus data until the overscan becomes

ta

V08

s data t

A=B

.

oh

ave a balance posi

, adjust fr

V08 bu

4CHLIONHEAD Signal (NTSC 60 Hz).

V35

NDITION / PROCEDURE

.

u

s

tsameornearesthigher

o the attach drawing

).

10 ± 2.

5%.

an 10 minutes before adjustment

).

tion to spec of

A=B

om the best point so that

10 ± 2.5 %.

position

.

(as attach

drawing).

A slightly smaller than

W

Figure

AVEFORM OR OTHERS

A

OK

B

OK NG

AB

B

.

7

PARABOLA

(I2C BUS CON

(1) Receive CrossHatch Pattern Signal (NTSC 60 Hz).

TROL)

(2) Choose the service data

V31

Adjust the 2nd vertical line from the right end of the crosshatch pattern

so that the middle 4 blocks are straight.

(3) Ma

ke sure both left / right of 2nd vertical line at optimum point

5 – 4

Page 17

HOR

NO

8

IZONTAL ,

ADJ

UPPER

(I2C BUS CO

V

ERTICAL,DEFLECTION

USTMENT POINT

C

ORNER

(1) Receive CrossHatch Pattern Signal (NTSC 60 Hz).

NTROL) (2) Choose the service data V37

(3) Adjust the 2nd upper vertical line from the right end of the crosshatch pattern

so that the upper l

(4)

M

ake sure both left / right of 2nd vertical line at optimum point

LO

OP ADJUSTM

ine

E

NT (2)

ADJUSTMENT CONDITION / PRO

are straight.

C

EDUREWA

21S-FX10L

VEFORMOROTHERS

9 LOWER CO

(I2C BUS CONTROL) (2) Choose the service data V39

10 BOW-AD

(I2C BUS CONTROL) (2) Choose the service dat

11

(I2C BUS CO

12 TRAPEZIUM (1) Receive CrossHatch Pattern Signal (NTSC 60 Hz).

(I2C BUS CON

13 FINAL INSPECTION OF (1) Receive CrossHatch Pattern Signal (NTSC 60Hz).

RNER (1) Receive CrossHatch Pattern Signal (NTSC 60 Hz).

(3) Adjust the 2nd lower vertical line from the right end of the cr

so that the bottom line are straight.

(4) Make sure both left / right of 2nd vertical line at optimum point

J (1) Receive CrossHat

(3) Set V43

ANGLE ADJ (1) Recei

NTROL) (2) Choose the service data V41

(3) Adjust the 2nd vertical line from the end of the crosshatch pattern line is straight

(4) Make sure both left / right of 2nd vertical line at optimum point

TROL) (2) C

ADJUSTM

E

NT (2) Please make sure picture distort

hoose the service data

(3) Adjust the 2nd vertical line from the right end of the crosshatch pattern

so t

hat the D1 (center area of the second vertical line - edge of screen)

and D2 (top area of the second vertical line - edge of screen) are

(4)Makesurebothleft / right of 2nd vertical li

TOP / BOTTOM at LEFT / RIGHT corner.

(3) If NG, please RE-ADJUST follow step

ch Pattern Signal (NTSC 60 Hz).

a

to 32

V

ve CrossHatch Pattern Signal (NTSC 60 Hz).

V33

43

ne at optimum point

ion (overall picture quality) must be balance at optimum point

7

to

13 or

osshatch pattern

sam

e.

adjust at NG position to get best picture quality

D2

D1

A

1

B1

A2

D1

A1 A2

A1 B1 B2

C1 C2

B2

D1

D2

~

~

~

~

~

~

=D

D2

D1

2

C

1

O

VERA

LL P

I

C

BALANCE AT OPTIMUM

&RIGHT)

T

URE QUALI

T

YMUSTBE

P

OIN

T

C2

(LEFT

5 – 5

Page 18

21S-FX10L

CLOSED CAP

NO

SCREEN, WHI

NO

TION ADJUSTMEN

ADJUSTMENT POINT

1

CLOSED CAPTION (1) Recei

SET UP (2) Go to service mode, choose service data V22

TE BALANCE, SUB

A

DJUSTMENT POINT

1

2

SCR

EEN

ADJUSTMENT

(I2C

BUS CONTROL)

WHITE BALANCE AD

(to

be done after s

adj) (as d

(I2C BUS CONTROL)

(CH 23 50IRE become: 1

WINDOW PATT

T

ve US4 CH LION HEAD Signal (NT

(3) Adjust the V22 bus data tohaveab

(4) After the left and right s

-BRIGHTN

ESS &

(1) Set t

he se

rvice d

a) V01 : 127

b) V04

c) V15

d) V16 : 127 G-cutoff upE9

e) V17:127 G

f) V18 : 64

g) V19 : 64 B-cutoff down

(2) Receive the window pattern or US4 CH LION

(3) Go to service mode, get in Y-mute b

(4)Adjustthe Screen so that cut-off line appear in low bright, then judge that whethe

the cut-off data appear in Red or Green or Bluecolor, in this conditionbetwe

V16=G-CUTOFF & V17= B-CUTOFF, fix the data of the

other two cut-off line s

(5)T

u

rn the s

creen VR of FBT so that cut-off linej

Next dis

ab

le the Y-Mute so that the picture appear in n

J (1)WHITE (HIGH BEAM)

creen First use Minolta Color Analyzer CA100, let the gun pointat Dark White position

ERN) Adj the

rawing attach), Adj

p

oint at White position ( as drawing attac

50 cd/m2. White Dark

V18(R DRIVE) , V19(B DRI

y

mmetrical t

SUB-C

ONTRAST ADJUSTMENT(1)

ata before adjus

othatcu

V

04 until LUMINANCE Y become 5 cd/m2,thenlet thegun

10700° X : 0.278 , Y : 0.280

(2) DARK WHITE (LOW BEAM)

Let t

he gun point at Dark White position, ifthe color temperature data shift away from

the data adjus

Please fix t

ad

*

t

ed in

Item 1

h

e first colour appear

jtheother twos

* Repeat step 1 & 2 to get a re

Screen adj

o

t

hat to

o

btai

ADJUSTMENT CONDIT

SC 60 H

a

l

ance position tos

hen

V

22 data reduce 5 step

A

DJUSTMENT

t CRT cutoff as fol

:127 R-cutoff up A9

:127 R-cutoff down69

y

R/

C and set V23 to "1"

t-off l

ine color become white

h

), Adj V01 until LUMINANCE Y

VE) until the axis of color temperature become

ustment,adjust V15,

s in Screen a

nthe similar axis as

gulated position

ION / PROCEDURE

z)

.

pec ofA=B

CON

DITION / PROCEDURE WAVE

lows:

H

EA

DSignal (NT

ust

disappea

dj item

ab

SC 60

colorappear in cut-off line and adj the

.

r and use R/C t

ormal mode

V

16,

V

1

7.

step (4) is fi

xed,

o

v

e

Hz)

r

en

V15 = R-CUTOFF,

oset

V

23 to "0".

N

OTE:

Servic

edata

-cutoff down 19

B

-cuto

ff up 99

*

Not

e:

WAVE

FORM OR OTHERS

AB

FORM OR OTHERS

R/C key (Hex)

5

9

White

5

0%

W

HITE

Use RF CH

2

3

5

0

IRE window pattern

5 – 6

Page 19

SCREEN, WHITE BALANCE, SUB-BRIGHTNESS & SUB-CONTRAST ADJUSTMENT(2)

T

E

S

T

E

S

NO

ADJUSTMENT POINT

ADJUSTMENT CONDITION / PROCEDURE

3 SUB-BRIGHTNESS (1) In CH 23 50IRE window pattern signal condition.

(to be done after screen, (2) Using Minolta Color Analyzer CA-100, let the gun point at

white balance adj) (as attach drawing), adjust V04 Bus data until

BRIGHTNESS Y

Dark White position

(I2C BUS CONTROL)

4

SUB-CONTRAST (1) In CH 23 50IRE window pat

(to be done after screen,

(2) Using Minolta Color Analyzer CA-100, let the gun point at

tern sign

al condition.

W

white balance adj, (as attach drawing), adjust V01 Bus data until BRIGHTNESS Y

sub-brightness adj)

(I2C BUS CONTROL)

** NOTE: Allowable Data for V01 >=90, even Y can't match the spec

5 BEAM CURRENT CHECK (1) Receive US 4 CH LION HEAD Signal (NTSC 60 Hz).

(2)

Press R/C to set Picture NORMAL condition.

(3) Connect the DC miliammeter between TP 603 ( +)&TP602(-)

(Full Scale: 3m

(4) Beam current must be within :

A Range).

1000 ± 100μA

= 1.5cd/m2

hite

po

s

ition

= 150cd/m2

21S-FX10L

WAVEFORM OR OTHERS

US14

Dark White

US14

White

NTSC CHROMA ADJUSTMENT

NO ADJUSTMENT POIN

1 SUB-TINT

(I2C BUS CONTROL)

2S

M

NO ADJ

UB COLOR (1) R

(I2C BUS CON

(to be done after

sub tint adj) R

S LEVEL ADJUSTMEN

USTMENT PO

MS LEVEL (1) R

1

TMENT

ADJUS

(I2C BUS CONTRO

TROL) (3) Connec

T

IN

L) (3) Se

(1) Receive the "US 10 CH HALF Color Bar" signal.

(2) Connect the oscilloscope to JA410 or TP853 B

ange : 500mV/Div (AC) (Use Probe 10:1)

R

Sweep time : 10μsec/Div

(3) Select the servicedata V02 . On Y-mute using the R/C.

(4) Adjust the V02 (Sub tint) data to obtain the waveform as shown in Figure 1.

*REMARK : PLEASE MAKE SUR

(2)

(4) Select the service data V03. Adjust the

(5) Fig 1.2 waveforms shows that the 75% white & red portions of color bar at the sa

*REMARK

(2)

(4) Adjust the bus data

e (TP853) must be in stepping level)

(B-Amp Bas

eceive the "US 10 CH HALF Color

Make the image normal

t the oscilloscope to JA401 (TP851) RED-OUT.

ange : 500mV/Div (AC) ( Use Probe 10:1)

Sweep time : 10μsec/Div

adjustment showninFig. 1-2.

: PLEASE

ceive the "US 10 CH HALF Color Bar" signal.

e

onnect the oscillosc

C

the sound

t

volume c

530m (+

ADJUSTMENT CONDITION / PROCEDUR

LUE-OUT

USE RF SIGNAL DURING SUB TINT ADJUSTMENT

E

r" signal.

a

B

with the remote controlle

V03 (Sub color) data to obt

MAKE SURE USE R

ope to IC3003

ontrol

unti

M01

18m,-35m) Vr

F SIGNAL DURING SUB COLO

ADJUSTMENT C

pin 17 ( C3014 -VE).

more than 1.

he voltage of IC3003 pin 17 (C3014 -VE) become as follows:

t

l

s

m

r.

ain the waveform

NDITION / PROCEDUR

O

1

UR ADJUSTMENT

me level

WAVEFORM OR REMARK

Fig 1-1

Cy

100% WHITE

Y

W

Fig 1-2

WAVEFORM OR REMARK

G

R

B

Mg

5 – 7

Page 20

21S-FX10L

PROTECTOR OPERATION CHECKING

ADJUSTMENT POINT

NO

1 H, V PROTECTOR

2 OTHER PROTECTOR (1) Once finish rectified Electrolytic Capacitor short testing in+Bline,

INPUT & OUTPUT CHECKING

A/V

ADJUSTMENT POINT

NO

1 VIDEO AND AUDIO

OUTPUT CHECK (2) Terminate the Video output with a 75 ohm

2 VIDEO

3 COMPONENT IN

AND AUDIO

INPUT CHECK TV, COMPONENT, INPUT1,INPUT2 & TV again and the video & audio output are according

CHECK

(1) Receive US 4 CH

(2) Connect outputofBiasBoxto

(3) Set voltage of Bias Box to 18V and make sure the protectorisnot working.

(4) Set voltage of Bias Box to

and picture disappear.

(5)PullouttheACcordatle

been reset) for the set to recover from protector mode

check all possible damaged components on +B line.

(Use random selected set

(1) Receive the "US 10 CH HALF Color Bar" signal.

( At signal is standard Color Bar Y/C=1/1, 87.5% Mod.)

Make sure the output is as specified

(3) Terminate the Audio output with a 47K ohm impedance.

( 400 Hz 100 % M

(a)Goto feature menu, set the FAO to OFF

Make sure the O/P is as specified (2.5 Vp-p ± 0.5Vp-p).

(b)Gotofeat

1) Using the INPUT key on the remote controller, make sure that the modes change in order of

(

o the input terminal for each mode.

t

(2) Video cross-talk INPUT t

(1) Connect YUV & Audio signal t

(2) Using the INPUT key on the remote controller, press it until the modes change to COMPONENT,

ure menu, set the FAO t

Make sure the O/P is as specified (1.2 Vp-p ± 0.3Vp-p).

a) When connect INPUT1 input, check TV also

b) When connect INPUT2 input, check TV also

confirm output is appear.

ADJUSTMENT CONDITION / PROCEDURE

LION HEAD Sign

od. 47 k , VOL Max. )

al (NTSC 60 Hz).

D602 cathode (C602 posit

8.5V.Makesur

2

ast 4 second before plugging in again (to make sure

for inspection)

oTV

e the protector isfunctioned, horizontal oscilation stop

ADJUSTMENT CONDITION / PROCEDURE

mpedance. NOTE: When FAO is set to ON, SPEAKER will

i

(1.0Vp-p±3dB). is disabled

oON

checking :

o Component In terminal and Audio terminal.

ive).

-COM has

W

AVEFORM OR OTHERS

WAVEFORM OR OTHERS

automatically turn OFF. TV volume control

5 – 8

Page 21

FUNCTION OPERATION CHECKING (VIDEO & AUDIO) (1)

T

S

E

21S-FX10L

NO ADJUSTMENT POIN

PICTURE Key (1) Receive "US 4 CH LION HEAD Signal (NTSC 60 Hz)" signal.

1

(2) Press to Menu mode, then select Picture Mode and set to select CONTRAST.

(3) Press Volume Up/Down key to check whether the CONTRAST effect is OK or not.

2 COLOUR Key (1) Receive the "US 10 CH HALF Color Bar" signal

(2) Press to Menu mode, then select Picture Mode and set to select COLOUR.

(3) Press Volume Up/Down key to check whether the COLOUR effect is OK or not.

3 BRIGHTNESS Key (1) Receive "US 4 CH LION HEAD Signal (NTSC 60 Hz)" signal.

(2) Press to Menu mode, then select Picture Mode and set to select BRIGHTNESS.

(3) Press Volume Up/Down key to check whether the BRIGHTNESS effect is OK or not

4 TINT Key

5 SHARPNESS Key (1) Receive "US 4 CH LION HEAD Signal (NTSC 60 Hz)" signal.

6 SURROUND (1) Receive "music" sound signal.

(1) Receive the "US 10 CH HALF Color Bar" signal

(2) Press to Menu mode, then select Picture Mode and select TINT.

(3) Press Volume Up/Down key to check TINT, UP for GREEN direction and

DOWN for RED direction whether is OK or not.

(2) Press to Menu mode, then select Picture Mode and set to select SHARPNESS.

(3) Press Volume Up/Down key to check whether the SHARPNESS effect is OK or NOT.

(2) Set MENU, then go into SOUND MENU to select SURROUND.

(3) Press VOLUME UP/DOWN key to check SURROUND effect.

ADJUSTMENT CONDITION / PROCEDUR

WAVEFORM OR REMARK

7 BALANCE (1) Receive mono-tone signal.

(2) Set MENU, then go into SOUND MENU to select BALANCE

(3) Press VOLUME UP/DOWN key to check whether the left to right BALANCE effect is OK or not

8 EQUALIZER (1) Receive "music" sound signal.

(2) Set MENU, then go into SOUND MENU to select EQUALIZER.

(3) Press VOLUME UP/DOWN key to check EQUALIZER effect is OK or not

5 – 9

Page 22

21S-FX10L

T

S

E

ERATION C

FUNCTION O

NO ADJUSTMENT POIN

11 RESET KEY

P

HECKING (VIDEO & AUDIO)

(1) Once in Picture Mode,and the RESET key is pressed,

all the settings will be present to normal setting. (Norm

MOVIE MODE

PICTURE 60 PICTURE 60

COLOUR +6 COLOUR 0

BRIGHTNESS 0 BRIGHTNESS 0

TINT 0 TINT 0

SHARP

ROFF

PICTURE N

COLOR TEMP Mid COLOR TEMP Mid

NEWS MODE

PICTURE 50

UR

COLO

BRIGHTNESS

TINT 0

SHARP -6

PICTURE NR OFF

COLOR TEMP Mid

(2) Once in Audio Menu,and the NORM

all the settings will be present to normal setting (Normal setting of the selected AV mode)

MOVIE MODE

SURROUND OFF SURROUND

BALANCE

AVL

NEWS MODE

SURROUND OFF

BALANCE 0

AVL ON

(2)

ADJUSTMENT CONDITION / PROCEDUR

al setting of selected AV mode) In RESET Mode, when press RESETkey,

MUSIC MODE

+6 SHARP

PICTURE NR OFF

-6

0

AL key is pressed,

MUSIC MODE

BALANCE 0

0

AVL

N

O

0

OFF

ON

*Note:

will appear RESET OSD and all setting

ill set to normal of the AV mode selected.

w

WAVEFORM OR REMARK

12 COLOR TEMP

the NORMAL key is pressed,

(3) Once in Equalizer Menu

all the settings will be present to normal setting (Normal setting

*Bar indacator display 0~20

MOVIE MODE

100 11 100 12 100 9

300 11 300 11 300 10

1K 10 1K 8 1K 11

3K 12 3K 10 3K 11

8K 12 8K 15 8K 9

(1) Receive US 4 C

et FUNCTIONtoselectWHITE TEMP.

S

(2)

olume Up/Down key t

(3) Press V

RMAL SETTING, WARM for more REDDISH direction ch

NO

more BLUISH direction

and

MUSIC MODE

H LION HEAD Signal (NTSC 60 Hz).

check WHITE TEMP Option, STANDARD:

o

changing.

NEWS MODE

of the selected AV mode)

anging, COOL

for

5 – 10

Page 23

CHECKING FUNCTION OPERATION (VIDEO & AUDIO) (3)

T

E

S

21S-FX10L

NO ADJUSTMENT POIN

15 M.P-IN CHECKING (1) Turn up the volume control to maximum, make sure

16 NOISE MUTE (1) Receive mono-tone signal.

17 OSD LANGUAGE (1) Check OSD LANGUAGE qua

18 MTS CHECKING (1) Receive stereo channel.

19 CLOSED CAPTION

SHOCK TEST CHECKING.

NO

CHECKING (2) Turn up the volume contr

QUANTITY CHECK

CHECKING (2) Press R/C "CC" button, and the it w

ADJUSTMENT POINT

1 SHOCK TEST (1) Hit at the top of TV set for two time.

(2) Make sure M.P IN feature is set to O

(

3) Plug in stereo c

(4)

'MP IN' OSD will appear at bottom right corner TV screen, RF channel sound will be switched to

M.P IN sound.

(5) Check the sound is normal

heard from the speakers. Then put the unit in no signal state.

(

3) Check the sound mute is ef

(4) Finally turn sound level of CTV to minimum.

MODEL QUANTITY ENGLISH SPANISH

2

1S-FX10L

(2) Press R/C "MTS" button, and the sound will change from STEREO to SAP to MONO.

(3) Check the sound to make sure it is working accordingly.

(1) Receive closed caption channel.

(3) Check the closed caption to m

(2) Chec

able in M.P IN terminal

2

kTV

set n

ot damage and TV operation operate correctly.

ADJUSTMENT CONDITION / PROCEDUR

N

ol to ma

ximum, make sur

fective.

ntity and type for respective model.

OO

ill change from OFF to CC1 to CC2 to TEXT1 to TEXT2.

a

ke sure it is working accor

ADJUSTMENT CONDITION / PROCEDURE WAVEFORM OR OTHERS

the sound is heard from speakers *For model with MP In feature

WAVEFORM OR REMARK

e the sound is

dingly.

5 – 11

Page 24

21S-FX10L

(1)1.94 Vp-p

Horiz. Rate

(2)4.54 Vp-p

Horiz. Rate

(3)3.68 Vp-p

Horiz. Rate

(4)4.22 Vp-p

Horiz. Rate

(5)3.14 Vp-p

Horiz. Rate

(6)4.92 Vp-p (7)5.88 Vp-p

Horiz. Rate

(8)1.35 Vp-p

Vert. Rate

(9)2.81 Vp-p

Horiz. Rate

(10)37.80 Vp-p

Horiz. Rate

(11)1076 Vp-p

Horiz. Rate

(12)64.28 Vp-p

Vert. Rate

(13)5.96 Vp-p

Vert. Rate

(14)148.00 Vp-p

Horiz. Rate

(15)498.00 Vp-p

-

(16)122.00 Vp-p

Horiz. Rate

Vert. Rate

(18)107.00 Vp-p

Horiz. Rate

(17)92.0 Vp-p

Horiz. Rate

TV21S-FX10LService Manual21S-FX10LMarketE

CHAPTER 6. WAVEFORMS

6 – 1

Page 25

TV21S-FX10LService Manual21S-FX10LMarketE

CHAPTER 7. CHASSIS LAYOUT

21S-FX10L

H

G

F

E

21S-FX10L

D

C

B

A

1

2

3

54

6

7

8

109

7 – 1

Page 26

21S-FX10L

A

C

B

D

E

F

G

H

2

109

8

7

6

54

3

1

TV21S-FX10LService Manual21S-FX10LMarketE

CHAPTER 8. BLOCK DIAGRAM

8 – 1

Page 27

21S-FX10L

1110

12

13

14

15

16

17

18

19

8 – 2

Page 28

21S-FX10L

H

G

21S-FX10L

F

E

D

C

B

A

1

2

3

54

6

7

8

109

8 – 3

Page 29

TV21S-FX10LService Manual21S-FX10LMarketE

CHAPTER 9. DESCRIPTION OF SCHEMATIC DIAGRAM

DESCRIPTION OF SCHEMATIC DIAGRAM

21S-FX10L

NOTES:

1. The unit of resistance "ohm" is omitted.

Ω

=1000Ω,M=MΩ)

(K=k

2. All resistors are 1/16 watt, unless otherwise noted.

3. All capacitors are

μμ

(P=pF=

4. (G) indicates

5.

indicates line isolated ground.

VOLTAGE MEASUREMENT CONDITIONS:

1. All DC voltages are measured with DVM connected

between points indicated and chassis ground, line

voltage set at 120V AC and all controls set for normal

picture unless otherwise indicated.

2. All voltages measured with 1000

signal.

F)

μ

F, unless otherwise noted.

±

2% tolerance may be used.

μ

V B & W or Color

WAVEFORM MEASUREMENT CONDITIONS:

1.

Photographs taken on a standard gated color bar

signal, the tint setting adjusted for proper color. The

wave shapes at the red, green and blue cathodes of

the picture tube depend on the tint, color level and

picture control.

2.

indicates waveform check points (See chart,

waveforms are measured from point indicated to

chassis ground.)

AND SHADED ( ) COMPONENTS

= SAFETY RELATED PARTS.

MARK= X-RAY RELATED PARTS.

DRGANNES MARQUES ET HACHRES ( ):

PIECES RELATIVES A LA SECURITE.

MARQUE : PIECS RELATIVE AUX RAYONS X.

This circuit diagram is a standard one, printed circuits

may be subject to change for product improvement

without prior notice.

9 – 1

Page 30

21S-FX10L

TV21S-FX10LService Manual21S-FX10LMarketE

CHAPTER 10. SCHEMATIC DIAGRAM

H

G

F

E

D

C

B

A

1

2

3

54

6

7

8

109

10 – 1

Page 31

21S-FX10L

1110

12

13

14

15

16

17

18

19

10 – 2

Page 32

21S-FX10L

H

G

F

E

D

C

B

A

1

2

3

54

6

7

8

109

10 – 3

Page 33

TV21S-FX10LService Manual21S-FX10LMarketE

CHAPTER 11. PRINTED WIRING BOARD ASSEMBLIES

H

G

21S-FX10L

F

E

D

C

B

A

1

2

PWB-A : MAIN UNIT ( Wiring Side )

3

54

6

7

8

109

11 – 1

Page 34

21S-FX10L

H

G

F

E

D

C

B

A

1

2

PWB-A : MAIN UNIT ( Chip Parts Side )

3

54

6

7

8

109

11 – 2

Page 35

21S-FX10L

H

G

F

E

D

C

B

A

1

2 109

PWB-B : CRT UNIT (Wring Side )

3

54

6

7

8

11 – 3

Page 36

21S-FX10L

H

G

F

E

D

C

B

PWB-B : CRT UNIT ( Chip Parts Side )

A

1

2 109

3

54

11 – 4

6

7

8

Page 37

PartsGuide

21S-FX10L

PARTS GUIDE

[1] PICTURE TUBE

[2] PRINTED WIRING BOARD

ASSEMBLIES ( NOT REPLACEMENT ITEM )

[3] MAIN UNIT

[4] CRT UNIT

MODEL

CONTENTS

No. XXXXXXXXXXXX

NO.S2912521SFX10L

XXXXXXXX

21S-FX10L

[5] SUPPLIED ACCESSORIES

[6] CABINET PARTS

[7] PACKING PARTS ( NOT REPLACE-

MENT ITEM 0

INDEX

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these

parts with specified ones for maintaining the safety and performance of the set.

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 38

21S-FX10L

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PAR T

RANK

[1] PICTURE TUBE

!

!

VB51QGT420X2E R SEMI-ITC Picture Tube

RCILGA172WJZZ R Degaussing Coil

QEARCA052WJZZ AG R Ground-Part

[2] PRINTED WIRING BOARD ASSEMBLIES ( NOT REPLACEMENT ITEM )

DUNTKE907WEA0 - - MAIN Unit

DUNTKE908WEA0 - - CRT Unit

[3] MAIN UNIT

TU201 RTUNQA037WJZZ R Tuner

!

IC301 VHILA42102+-1 R LA42102+-1

IC501 VHILA78041+-1 AE R LA78041+-1

!

IC701 VHISTRW6553-1 AM R I.C.

!

IC702 RH-FXA003WJZZ R I.C.

IC703 VHISE125N++-F R I.C.

IC751 VHIPQ05RDA1-1 R I.C.

IC801 RH-IXC541WJZZQ R I.C.

IC1003 VHIM24C08W6-1Y AE R IM24C08W

IC3001 VHIMM1501XN-1Y R I.C.

IC3002 VHIMM1501XN-1Y R I.C.

IC3003 VHILA72703V-1Y R I.C.

IC3004 VSIMXC/C//-1Y R I.C.

IC3005 VHIMM1501XN-1Y R I.C.

IC3006 VHIMM1501XN-1Y R I.C.

Q201 VS2SC2735//1EY R 2SC2735//1E

Q601 VS2SC2235Y/1E+ AE R 2SC2235

Q602 VS2SC6090++1E AG R 2SC6090

Q603 VS2SC3198-G-1+ AA R 2SC3198

Q604 VS2SC3928AR-1Y AB R 2SC3928AR

Q605 VS2SD1913R/-1 R 2SD1913R/

Q671 VS2SA1266-G-1+ R 2SA1266-G

Q672 VS2SC3198-Y-1+ R 2SC3198-Y

Q752 VS2SD468-C/-1+ AD R 2SD468

Q753 VS2SD468-C/-1+ AD R 2SD468

Q754 VS2SD468-C/-1+ AD R 2SD468

Q762 VS2SC3928AR-1Y AB R 2SC3928AR

Q764 VS2SC3928AR-1Y AB R 2SC3928AR

Q801 VS2SC3928AR-1Y AB R 2SC3928AR

Q802 VS2SA1530AR-1Y AB R 2SA1530AR

Q803 VS2SA1530AR-1Y AB R 2SA1530AR

Q1002 VS2SC3928AR-1Y AB R 2SC3928AR

Q1003 VS2SC3928AR-1Y AB R 2SC3928AR

D201 VHEZJ33C+++1EY AA R Zener Diode , 33V

D203 VHDHSS4148+-1Y AA R Diode

D392 RH-DX0445CEZZ AE R Diode , DX0445CE

D503 VHEZJ5R1B++1EY AB R

D505 RH-DXA094WJZZY AC R Diode , DXA094WJ

D510 RH-DX0302CEZZY AE R Diode , DX0302CE

D602 VHD1SS244//-1Y AB R Diode , 1SS244

D603 RH-EXA572WJZZY AA R Zener Diode , 27V

D606 RH-DX049WJZZY AC R Diode , DX049WJ

D609 RH-DX0321CEZZY AE R Diode , DX0321CE

D610 RH-DX0255CEZZ AE R Diode , DX0255CE

D611 RH-DXA006WJZZ AE R Diode , DXA006WJ

D670 RH-DXA049WJZZY AE R Diode , DXA049WJ

!

D701 RH-DX0476CEZZ AG R Diode , DX0476CE

D706 RH-DX0066GEZZY AC R Diode , DX0066GE

D709 RH-DX0066GEZZY AC R Diode , DX0066GE

D714 VHDHSS4148+-1Y AA R Diode

D716 VHEZJ2R0B++1EY AA R Zener Diode , 2V

D750 VHEZJ5R1A++1EY AB R Zener Diode , 5.1V

D751 RH-DXA044WJZZ R Diode , DXA044WJ

D752 RH-DX0247CEZZ AE R Diode , DX0247CE

D754 VHEZJ5R1B++1EY AB R Zener Diode , 5.1V

D757 VHEZJ8R2B++1EY AB R Zener Diode , 8.2V

D762 VHDHSS4148+-1Y AA R Diode

D763 VHDHSS4148+-1Y AA R Diode

D764 VHDHSS4148+-1Y AA R Diode

D801 VHDHSS4148+-1Y AA R Diode

D806 RH-EXA520WJZZY AB R Zener Diode

D807 RH-EXA535WJZZY AC R Zener Diode

D808 RH-EXA535WJZZY AC R Zener Diode

D809 RH-EXA535WJZZY AC R Zener Diode

D898 VHDHSS4148+-1Y AA R Diode

D1001 RH-PX0013PEZZ AC R Photodiode

D1002 VHEZJ11A+++1EY AA R Zener Diode , 10.71V

D1005 VHDHSS4148+-1Y AA R Diode

D1006 RH-EXA520WJZZY AB R Zener Diode

D1008 VHDHSS4148+-1Y AA R Diode

D1009 RH-EXA520WJZZY AB R Zener Diode

D1081 RH-DX0066GEZZY AC R Diode , DX0066GE

VA701 RH-VXA182WJZZ R Varistor

X801 RCRSAA075WJZZ AF R Crystal

NR701 RH-HXA013WJZZ R

Zener Diode , 5.1V

DESCRIPTION

2

Page 39

21S-FX10L

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PAR T

RANK

[3] MAIN UNIT

L203 QJUM-0001AJFWY R Jumper wire

L204 VP-XF2R2K0000Y AB R Peaking 2.2μH

L602 RCILP0223CEZZ+ AD R Coil

L603 RCILZ1005CEZZ AD R Coil

L605 RCILZA095WJZZ

L701 RCILFA187WJZZ AD R Coil

L801 VP-DF100K0000Y AB R Peaking 10μH

L802 VP-CF100K0000Y AB R Peaking 10μH

L803 VP-CF220K0000Y AB R Peaking 22μH

L804 QJUM-0001AJFWY R Jumper wire

L805 QJUM-0001AJFWY R Jumper wire

L807 QJUM-0001AJFWY R Jumper wire

L808 VP-CF100K0000Y AB R Peaking 10μH

L3001 QJUM-0001AJFWY R Coil

SF201 RFILCA055WJQZS R Coil

T602 RTRNFA143WJZZ R H-Volt Transformer

T603 RTRNZA058WJZZ AD R Transformer

T702 RTRNWA305WJZZ R Transformer

C202 VCEA0A1AW108M+ AC R 1000 10V Electrolytic

C203 VCKYCY1HF103ZY AA R 0.01 50V Ceramic

C204 VCEA0A1HW105M+ AB R 1 50V Electrolytic

C206 VCEA0A1HW106M+ AB R 10 50V Electrolytic

C207 VCKYCY1HF103ZY AA R 0.01 50V Ceramic

C208 VCKYCY1HF103ZY AA R 0.01 50V Ceramic

C209 VCKYCY1HF103ZY AA R 0.01 50V Ceramic

C210 VCKYCY1HF103ZY AA R 0.01 50V Ceramic

C211 VCCCCY1HH390JY AA R 39p 50V Ceramic

C212 VCCCCY1HH390JY AA R 39p 50V Ceramic

C301 VCEA0A1EW476M+ AB R 47 25V Electrolytic

C302 VCEA0A1HW224M+ AB R 0.22 50V Electrolytic

C303 VCKYCY1HB102KY AA R

C304 VCEA0A1HW224M+ AB R 0.22 50V Electrolytic

C305 VCKYCY1HB102KY AA R 1 50V Ceramic

C306 VCEA0A1CW336M+ AC R 33 16V Electrolytic

C308 VCEA0A1EW477M+ AD R 470 25V Electrolytic

C309 VCFYFA1HA474J+ AE R 0.47 50V Mylar

C310 VCFYFA1HA474J+ AE R 0.47 50V Mylar

C314 VCEA0A1HW475M+ AB R 4.7 50V Electrolytic

C370 VCEA0A1CW106M+ AC R 10 16V Electrolytic

C371 VCE9GA1HW225M+ AB R 2.2 50V Electrolytic

C372 VCE9GA1HW225M+ AB R 2.2 50V Electrolytic

C390 VCEA0A1CW106M+ AC R 10 16V Electrolytic

C391 VCKYPA2HB102K+ AA R 1000p 500V Ceramic

C393 VCEA0A1EW228M+ AD R 2200 25V Electrolytic

C394 VCE9GA1HW225M+ AB R 2.2 50V Electrolytic

C395 VCEA0A1HW225M+ AB R 2.2 50V Electrolytic

C451 VCEA0A1CW477M+ AC R 470 16V Electrolytic

C501 VCFYFA1HA104J+ AE R 0.10 50V Mylar

C505 VCEA0A1HW107M+ AB R 100 50V Electrolytic

C508 VCFYAA2AA224J+ AD R 0.22 100V Mylar

C509 VCKYPA1HB103K+ AB R 10p 50V Ceramic

C511 VCEA0A1HW477M+ AB R 470 50V Electrolytic

C513 RC-EZA332WJZZ+ AD R Capacitor

C514 VCFYSA1JB473J+ R Capacitor

C515 VCEACA1HC335J+ AC R 3.3 50V Electrolytic

C601 VCQYTA1HM563J+ AB R 0.56 50V Mylar

C602 VCEA0A1HW475M+ AB R 4.7 50V Electrolytic

C604 VCEA0A2EW336M+ AD R 33 250V Electrolytic

C608 VCQYTA2AA103K+ R 0.1 100V Mylar

C610 VCEA0A1EW226M+ AB R 22 25V Electrolytic

C613 RC-FZA178WJZZ R

C615 RC-FZ0357CEN1 R

C617 VCFPVC3ZA163H AD R 16 1.8KV Metalized Polypro Film

C618 VCQPPC2JB473J R

C619 RC-KZ0033CEZZ+ AC R 0.01 250V Ceramic

VCFPKH2ED394J R

C635

C650 VCKYPA2HB101K+ AB R 100p 500V Ceramic

C670 VCEA0A1HW476M+ AB R 47 50V Electrolytic

C671 VCKYPA1HB102K+ AA R 1 50V Ceramic

C672 VCKYPA1HB103K+ AB R 10p 50V Ceramic

C701 RC-FZ029SCEZZ AD R 220 275V Metalized Plastic Film

C702 RC-KZ0029CEZZ+ AC R 0.01 250V Ceramic

C703 RC-KZ0029CEZZ+ AC R 0.01 250V Ceramic

C704 RC-KZ0029CEZZ+ AC R 0.01 250V Ceramic

C705 RC-EZA229WJZZ AM R 220 400V Electrolytic

C709 VCEA0A1HW104M+ AB R 50V Mylar

C710 VCQYTA1HM103J+ AB R 50V Mylar

C711 VCKYPA1HB332K+ AB R 3300p 50V Ceramic

C719 VCEA0A1VW226M+ AB R 22 50V Electrolytic

C743 VCKYPH3DB561K AC R 560p 2KV Ceramic

C744 VCFYSA1HB105J+ R Capacitor

C750 VCKYPA2HB102K+ AA R 1000p 500V Ceramic

C751 RC-KZ0102GEZZ AC R 2kV Ceramic

C752 VCKYPH3DB561K AC R 560p 2KV Ceramic

C753 RC-EZA235WJZZ AD R 160V Electrolytic

1 50V Ceramic

DESCRIPTION

3

Page 40

21S-FX10L

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PAR T

RANK

[3] MAIN UNIT

C755 VCEA0A1CW226M+ AB R 22 16V Electrolytic

C756 VCEA0A1EW228M+ AE R 2200 25V Electrolytic

C757 VCEA0A1CW226M+ AB R 22 16V Electrolytic

C758 VCEA0A1CW476M+ AB R 47 16V Electrolytic

C760 VCEA0A1CW476M+ AB R 47 16V Electrolytic

C761 VCEA0A1CW226M+ AB R 22 16V Electrolytic

C767 RC-EZB478WJZZ R

C784 RC-KZ1018CEZZ AC R 2KV Ceramic

C803 VCKYCY1HB104KY AA R 0.10 50V Ceramic

C804 VCEA0A1HW474M+ AB R 0.47 50V Electrolytic

C805 VCKYCY1HB153KY AA R 0.15 50V Ceramic

C806 VCEA0A1CW476M+ AB R 47 16V Electrolytic

C807 VCKYCY1HB103KY AA R 0.01 50V Ceramic

C811 VCFYFA1HA224J+ AA R 0.22 50V Mylar

C812 VCKYCY1HB104KY AA R 0.10 50V Ceramic

C813 VCKYCY1HB104KY AA R 0.10 50V Ceramic

C814 VCKYCY1HB153KY AA R 0.15 50V Ceramic

C815 VCCCCY1HH470JY AA R 47p 50V Ceramic

C816 VCEA0A1HW474M+ AB R 0.47 50V Electrolytic

C818 VCEA0A1CW227M+ AB R 220 16V Electrolytic

C819 VCKYCY1HB103KY AA R 0.01 50V Ceramic

C824 VCKYCY1CF105ZY AB R 1 16V Ceramic

C825 VCEA0A1HW474M+ AB R 0.47 50V Electrolytic

C826 VCEA0A1HW335M+ AB R 3.3 50V Electrolytic

C828 VCEA0A1HW474M+ AB R 0.47 50V Electrolytic

C830 VCKYCY1HB103KY AA R 0.01 50V Ceramic

C831 VCEA0A1AW477M+ AB R 470 10V Electrolytic

C833 VCEA0A1HW105M+ AB R 1 50V Electrolytic

C834 VCKYCY1HB104KY AA R 0.1 50V Ceramic

C836 VCCCCY1HH680JY AA R 68 50V Ceramic

C838 VCEA0A1CW477M+ AC R 470 16V Electrolytic

C839 VCKYCY1HB103KY AA R 0.01 50V Ceramic

C840 VCKYCY1CF105ZY AB R 1 16V Ceramic

C841 VCKYCY1CB393KY AB R 3.9 16V Ceramic

C842 VCKYCY1CF105ZY AB R 1 16V Ceramic

C843 VCEA0A1HW475M+ AB R 4.7 50V Electrolytic

C844 VCEA0A1HW105M+ AB R 1 50V Electrolytic

C845 VCEA0A1HW105M+ AB R 1 50V Electrolytic

C1001 VCEA0A1AW107M+ AB R 100 10V Electrolytic

C1002 VCCCCY1HH101JY AA R 100p 50V Ceramic

C1003 VCEA0A1CW107M+ AB R 100 16V Electrolytic

C1004 VCKYCY1CF474ZY AB R 0.47 16V Ceramic

C1007 VCEA0A1CW476M+ AC R 47 16V Electrolytic

C1008 VCKYCY1HF103ZY AA R 0.01 50V Ceramic

C1013 VCKYCY1HF103ZY AA R 0.01 50V Ceramic

C1016 VCKYCY1EF104ZY AA R 0.1 25V Ceramic

C1017 VCKYCY1HB221KY AA R 220 50V Ceramic

C1018 VCEA0A1HW105M+ AB R 1 50V Electrolytic

C1019 VCKYCY1HB102KY AA R 1 50V Ceramic

C1020 VCKYCY1HB561KY AA R 560 50V Ceramic

C1021 VCKYCY1EF104ZY AA R 0.1 25V Ceramic

C1043 VCKYCY1HB103KY AA R 0.01 50V Ceramic

C1081 VCQYTA1HM104J+ AA R 0.1 50V Mylar

C1850 VCEA0A1HW106M+ AB R 10 50V Electrolytic

C1858 VCKYCY1HB683KY AA R 0.68 50V Ceramic

C1859 VCKYCY1HB472KY AA R 4.7 50V Ceramic

C1860 VCCCCY1HH220JY AA R 22p 50V Ceramic

C1861 VCKYCY1HB683KY AA R 0.68 50V Ceramic

C1862 VCKYCY1HB472KY AA R 4.7 50V Ceramic

C1864 VCKYCY1HB683KY AA R 0.68 50V Ceramic

C1865 VCKYCY1HB683KY AA R 0.68 50V Ceramic

C1866 VCKYCY1HB683KY AA R 0.68 50V Ceramic

C1867 VCKYCY1EB123KY AA R 0.12 25V Ceramic

C1868 VCKYCY1HF103ZY AA R 0.01 50V Ceramic

C1869 VCKYCY1HB472KY AA R 4.7 50V Ceramic

C1870 VCKYCY1HB682KY AA R 6.8 50V Ceramic

C1871 VCKYCY1HB122KY AA R 1.2 50V Ceramic

C1872 VCKYCY1HB683KY AA R

C1873 VCKYCY1EB123KY AA R 0.12 25V Ceramic

C1874 VCKYCY1HB103KY AA R 0.01 50V Ceramic

C1875 VCKYCY1HB472KY AA R 4.7 50V Ceramic

C1876 VCKYCY1HB682KY AA R 6.8 50V Ceramic

C1877 VCKYCY1HB122KY AA R 1.2 50V Ceramic

C3003 VCEA0A1CW106M+ AC R 10 16V Electrolytic

C3004 VCEA0A1CW106M+ AC R 10 16V Electrolytic