Page 1

SERVICE MANUAL

21 SYSTEM

COLOUR TELEVISION

Chassis No. 2IA- M

MODEL

In the interests of user-safety (Required by safety regulations in some countries ) the set should be

restored to its original condition and only parts identical to those specified should be used.

21N52-E1

ELECTRICAL SPECIFICATIONS

Power Input

Power Consumption

Convergence

......

Focus

Sweep Deflection

Intermediate Frequencies

Picture IF Carrier

Sound IF Carrier

6.5MHz .........................................

6.0MHz .........................................

5.5MHz .........................................

4.5MHz .........................................

Colour Sub-Carrier

PAL/NTSC

SECAM

NTSC

Audio Power Output Rating

Speaker

Size .............................

Voice Coil Impedance

................................ 110-240VAC

50/60Hz (Auto)

................................. 107w

..................

Bi-Potential, Uni-Potential Electrostatic

................................

................................

.....................................

............................

............................................

Self Converging System

Magnetic

38.9M Hz

. 32.9MHz

.

33.4MHz

.

34.4MHz

34.47M Hz

34.494/34.65MHz

35.32MHz

2.5W x 2 (Max.)

........

.

8cm x 4cm Oval x 2 pcs

.............

8 ohms at 400 Hz

Specifications are subject to change without prior

notice.

Aerial Input Impedance ,......, 75 ohm Unbalanced

Receiving Channels

PAL-B/G, SECAM-B/G

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..

VHF

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UHF

.......................,...............

CATV

PAL-D/K, SECAM-D/K

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VHF

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UHF

PAL-l

. . . . . . . . . . . . . . . . . . . . .

VHF

UHF ..................

NTSC-M

VHF

. . . . . . . . . . . . . . . . . . . . . . . . . . .

UHF

. . . . . . . . . . . . . . . . . . . . . . . . . . .

....................................

CATV

Receiving Frequency

. . . . . . . . . . . . . . . . . . . . . . . . .

VHF

UHF . . . . . . . . . . . . . . . . . . . . . . . . .

(IRELAND):

(U.K., H.K.): 21 thru 69

(US):

(JAPAN):

(US): 14 thru 83

(JAPAN): 13 thru 62

48.25 thru 301.25 MHz

471.25 thru 885.25 MHz

E2 thru

21 thru 69

S1 thru S3,

M1 thru M10

U1 thru U10

R1 thru

21 thru 69

B thru J

2 thru 13

1 thru 12

A-6 thru A-1,

A thru W,

El2

R12

AA

WARNING

The chassis in this receiver is partially hot. Use an isolation transformer between the line cord plug and

power receptacle, when servicing this chassis.

To prevent electric shock, do not remove cover. No user qualified service personnel.

serviceable parts inside. Refer servicing to

SHARP CORPORATION

Page 2

CONTENTS

Page

l

l

IMPORTANT SERVICE NOTES

l SERVICE ADJUSTMENT

SHOOTING TABLE

LAYOUT DIAGRAM

........................

........................

.................................

........................

........................ REPLACEMENT PARTS LIST

2

3

15

20

l

PRINTED WIRING BOARD ASSEMBLIES

l

SCHEMATIC DIAGRAMS

AND WAVEFORMS

DIAGRAM

.

.................................

.....................................

........................

IMPORTANT SERVICE NOTES

Maintenance and

service personnel on

SERVICING OF HIGH VOLTAGE SYSTEM AND PICTURE TUBE

When servicing the high voltage system,

connecting a 10 kohm Resistor in series with an insulated wire (such as a test

probe) between picture tube

disconnected from AC outlet.)

1.

Picture tube in this receiver employs integral implosion protection.

Replace with tube of the same type number for continued safety.

2.

Do not lift picture tube by the neck.

3.

Handle the picture tube only when wearing shatterproof goggles and after discharging the

4.

high voltage completely.

air of this receiver should be done by qualified

y.

remove static charge from it by

and

anode lead. (AC line cord should be

........

Page

21

.

33

37

X-RAY

This receiver is designed so that any X-Ray radiation is kept to an absolute

minimum.

Since certain malfunctions or servicing may produce potentially

hazardous radiation with prolonged exposure at close range, the following

precautions should be observed:

When repairing the circuit, be sure not to increase the high voltage to more than 27.3kV, (at

1.

cut-off) for the set.

To keep the set in a normal operation, be sure to make it function on

2.

1

in the case of the set.

The set has been factory

If there is a possibility that the high voltage fluctuates as a result of the repairs, never

forget to check for such high voltage after the work,

DO not substitute a picture tube with unauthorized types and/or brands which may cause

3.

excess X-ray radiation.

-Adjusted to the above-mentioned high voltage.

(at beam

BEFORE RETURNING THE RECEIVER

Before returning the receiver to the user, perform the

2. Inspect all protective devices such as non-metallic control knobs, insulating fishpapers,

lead dress to make certain that leads are not pinched or that hardware is not

lodged between the chassis and other metal parts in the receiver.

cabinet backs, adjustment and compartment covers or shields, isolation resistor-capacity

networks, mechanical insulators etc.

following

checks.

2

Page 3

SERVICE ADJUSTMENT

ADJUSTMENT

TUNER

COILS

The tuner has been factory preset (no

adjustment is needed).

Set

voltage at

Connect sweep generator’s output to the test

point of tuner, by using a

in

band.

DC cut probe.

I

Connection Diagram of

* NOTE:

The sweep generator’s probe should be

grounded closely to the tuner test point.

Output level of sweep generator:

Connect response lead (low impedance probe

with detector) to the collector of

unit).

To

test

1

DC Cut

(in IF

To

Apply DC

RF

Apply DC

terminal.

Connect

and

Adjust the tuner IF coils to obtain the

waveform as shown figure below.

NOTE:

For the adjustment, keep the tuner covered

with its lid.

to pin

(about,

ohm resistor between base of

line.

of

P = 38.9 MHz

(in IF unit).

to the tuner

A A A

Connection Diagram of Low Impedance Probe

(with Detector).

P-DETECTOR COIL:

This coil (in IF unit) has been factory

preset (no adjustment is needed).

Connect sweep generator’s output to pin

of

l

Probe in use:

l

Sweep output level:

PI F AGC:

Apply 4.5V DC to pin

Have AFT muted.

AFT is muted if pin

Connect response lead to

The response lead in use should be a direct

probe with a resistor of

of IF unit is grounded.

1

DC cut probe

of

ohms included.

To

test point

Adjust so that “Plland

Adjust T1202 so that 38.9 MHz signal is at

maximum

* Adjust

waveform is of

voltage so that the output

are at the same /eve/.

P

MHz)

1

Direct Probe.

3

Page 4

AFT COIL ROUOGH ADJUSTMENT:

ADJUSTMENT

(Continued)

Connect sweep generator’s output to pin

of IF unit.

l

Probe in use:

l

Sweep output level:

Connection Diagram of

Apply

DC

Connect response lead to pin

DC Cut Probe.

to TP1203 (pin

of IF unit.

(The response lead should be a direct probe

with a 1 Ok ohm resistor included.)

l

Tune off AFT Mute.

Adjust T1201 to align the marker with the

base line.

of

Align the IF marker with the

base line.

To

I

To pin

AFT COIL: T1201

Before this adjustment, the AFT coil

(rough adjustment) must have been

completed.

Receive “PAL COLOUR BAR” signal with

bar generator.

Signal strength: Over

Connect oscilloscope to

l

Oscilloscope range:

l

Sweep time:

l

Synchronization:

Horizontal sync.

Connect the output of

Generator) to the tuner IF output terminal

across a capacitor of 1

l

output frequency:

MHz

MHz

l

output level:

Adjustment error:

* When the preset switch is set at U or V

position, AFT is turned off.

Below

(Standard Signal

5 kHz

MHz kHz.

l

Adjust the sweep generator’s sweep range

to obtain normal S-curve on the oscilloscope

screen.

l Adjust the IF

voltage so that the

curve’s amplitude be approx.‘lVp-p.

Set the preset switch at V position and adjust

FINE button (Up or Down) of tuning control so

that the output waveform suffers no beating.

Set the preset switch at NORMAL position.

Adjust

so that no beating is caused at

the output waveform.

Finely adjust to make zero the beating

.

Page 5

OVERALL WAVEFORM

ADJUSTMENT (Continued)

Set VT voltage at

in

band.

Connect sweep generator’s output to the test

point of tuner.

l

Probe in use:

l

Sweep output level:

DC cut probe

Connect response lead to

The response lead in use should be a direct

probe with a resistor of 1 Ok ohms included.

RF

Apply

DC to the tuner

terminal.

PI F

Apply

DC to pin

of

in IF

unit.

Connect a

parallel to

ohm damping resistor in

(in IF unit).

NOTE:

Cut the resistor’s leads as short as possible.

Turn off AFT:

AFT is turned off if pin

of

in IF unit is

grounded.

CUT-IN CONTROL: R218

Adjust IF

waveform is of

voltage so that the output

Check that the overall waveform is as shown in

Figure below.

I

Receive “PAL COLOUR BAR” signal with

bar generator.

l

Signal strength:

(with

terminated)

Connect DC voltmeter to the tuner

terminal

(Full scale:

Turn

so that the voltmeter reads the

maximum output.

4 Slowly turn

in the opposite direction

until the voltmeter begins to decrease its

reading; then stop turning of

TRAP:

Receive “NTSC COLOUR BAR” signal with

bar generator.

l

Signal strength:

Connect

l

Voltage range:

l

Sweep time:

l Synchronization: Horizontal sync.

I

Adjust

waveform’s

Over 55dB, Below

to

so that the oscilloscope

beat be minimum.

Set the signal strength at

and

check that no noise appears.

Receive “MONOSCOPE PATTERN” signal, and

check that no noise appears.

l

Signal strength:

Set the signal strength at

to

and

check that there appears no crossmodulation

beating.

l

control value:

(with

1

terminated)

5

Page 6

ADJUSTMENT (Continued)

SOUND DETECTOR

COIL: T1301

This coil (in IF unit) has been factory

preset (no adjustment is basically

needed).

Connect

l The probe in use should be a

probe.

l

Apply 4.5V DC to pin

Connect DC voltmeter to pin

(Full scale:

AUDIO MUTE CHECKING

Receive “PAL COLOUR BAR” signal.

Set the Sound control at maximum position.

Stop reception of “PAL COLOUR BAR” signal.

(Pull out the antenna)

Check that no output of

from the speaker.

output to pin

output level:

of

MHz

of

of

Hz signal is heard

DC cut

AUDIO-MUTE ON:

Have pin

value then available on the voltmeter

It should be approx. 4.5V.

AUDIO-MUTE OFF:

Remove the grounding at pin

Adjust T301 so that the voltmeter indicates the

same value as in step 4 above.

of IF unit grounded, and read the

of IF unit.

6

Page 7

VIDEO CIRCUIT ADJUSTMENT

CRT CUT-OFF ADJUSTMENT

l

l

l

l

l

l

Red Bias control

Green Bias control

Screen control (a part of

Green Drive control

Note:

Prior to this adjustment, warm up the unit

with the beam current of more than 700uA for

more than

minutes.

Receive “MONOSCOPE PATTERN” signal with

pattern generator.

Set Red Bias control at

Set Green Bias control at

position.

position.

Set Blue Bias control at MIN position.

Set Green Drive control at CENTER position.

Set Blue Drive control at CENTER position.

Turn the

key on the remote controller.

Set the Screen control at MIN position.

Connect the oscilloscope to

(red

cathode).

Turn

(service switch) at the horizontal

line position.

Adjust Sub-Brightness control

blanking pulse level of

to obtain a

at

Disconnect the oscilloscope

Slowly turn the Screen control clockwise until

the horizontal raster appears slightly, and

stop it.

one of the three

(red, blue,

green) appears first as the Screen control is

turned. So, touching off the Bias control

belonging to the first

use and move

the other two controls so that the horizontal

raster becomes white.

the Screen control counterclockwise until

the horizontal raster disappears, and stop it.

WHITE BALANCE AND BACK GROUND

l

l

l

Prior to this adjustment, warm up the unit

with the beam current of more than 700pA for

more than

I. Receive “MONOSCOPE PATTERN” signal with

pattern generator..

Set the Contrast control and Brightness

control at MAX position.

Connect ammeter to TP601 and

(Full scale: 3

Green Drive control

minutes.

SUB-CONTRAST CONTROL: R436

* Note:

Prior to this adjustment, warm up the unit

with the beam current of more than 700uA for

more than

Receive “MONOSCOPE PATTERN” signal with

pattern generator..

Set the Contrast and Brightness controls at

MAX position.

minutes.

.

Adjust Sub-Contrast control so that the beam

current becomes

(rough adjustment).

Adjust Green Drive control and Blue Drive

control so that the

(High beam:

temperature is at

Adjust the Contrast control and Brightness

control so that the beam current is

is at 9300°K. If the temperature is not at

go back to “CRT CUT-OFF

ADJUSTMENT” and repeat the adjustment.

Connect beam ammeter to TP601

and

(Full scale: 3

Adjust Sub-Contrast control so that the beam

current becomes

7

Page 8

CIRCUIT ADJUSTMENT “PAL”

PAL

l

. T801:

Note: PIFIAFTIAGC adjustments should have

been completed before starting this adjustment.

Receive the “PAL COLOUR BAR” signal with

bar generator.

Connect the following resistance matrix to pins

3 and 4 of the connector (K), to which an

ADJUSTMENT

1 H-delay amp. control

1 H-delay phase control

is connected.

Resistance Matrix

Set service switch

position to cut-off the Y-signal.

Turn on the “N” key the remote controller.

Adjust the

controller so that the output waveform of

difference signal becomes Z.SVp-p.

Adjust IH-delay amp. control

delay phase control (T801) so that the output

waveform shown in Fig. a is corrected to that

shown in Fig.

Return

to CENTER position.

control key of the remote

at the Video Cut

and 1

W Y

Figure a. Waveform before the adjustment

Figure

G

Waveform after the adjustment

R B

PAL SUB-COLOUR ADJUSTMENT:

Receive the “PAL COLOUR BAR” signal with

bar generator.

Turn on the

Connect oscilloscope to the

cathode).

l

Voltage Range:

l

Sweep time: 20psec/div.

Adjust

red signal have the same level.

key on the remote controller.

(red

so that the white signal (75%) and

W

Same level for the white and red outputs.

8

Page 9

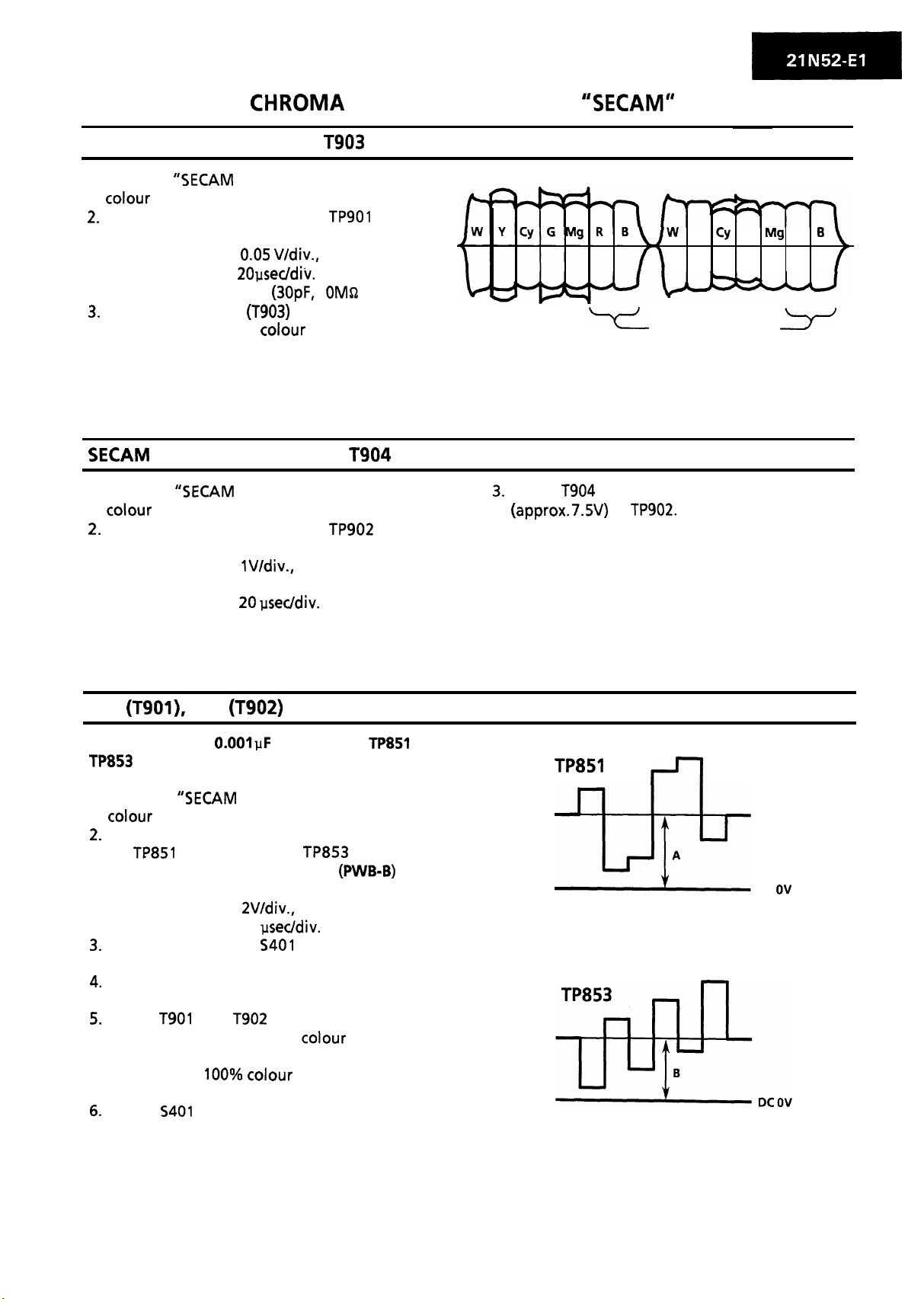

BELL FILTER ADJUSTMENT:

CIRCUIT ADJUSTMENT

I. Receive

COLOUR BAR” signal with

bar generator.

Connect the oscilloscope to TP901 with the

following settings.

l

Voltage Range: 0.05 Wdiv., AC

l

Sweep Time:

l

Probe:

I/I 0

I

or more)

Adjust the Bell Filter (T903) so that the Red and

Blue portions of the

bar signal should

have the same amplitude.

KILLER ADJUSTMENT:

I. Receive

bar generator.

Connect the oscilloscope to

following settings.

l

Voltage Range: IV/div., DC

(Adjust vertical position properly.)

l

Sweep Time:

COLOUR BAR” signal with

with the

Y

G

R

Same amplitude

Adjust T904 to obtain maximum DC voltage

at TP902.

B-Y

Note: Connect a

R-Y

DISCRIMINATOR ADJUSTMENT

capacitor to

and

respectively to filter out interference

noise.

I.

Receive

COLOUR BAR” signal with

generator.

Connect the oscilloscope (with two channels)

to TP851 (R-Y) and the

located on the CRT Socket Unit

(B-Y), both

of the

set.

l

Voltage Range:

l

Sweep Time:

IO

Set service switch

DC

at the Video Cut

position to cut-off the Y-signal.

Set both the Contrast and Brightness controls

to their maximum positions.

Adjust

levels obtained when the

and T902 so that the DC output

control is set

to minimum (black and white level) and those

when set to

saturation become

the same.

Return

to CENTER position.

DC

9

Page 10

SUB-HUE:

I. Receive

2. Connect the oscilloscope to

(B-Y).

3. Turn on the “N” key on the remote controller.

4. Set service switch

at the Video Cut

position to cut-off the Y-signal.

5. Operating the Colour control key on the

remote controller, adjust the B-Y waveform to

6. Adjust Sub-Hue control R835 so that the

waveform is obtained.

7. Return

to CENTER (normal) position.

Same level

Y

G

B-Y

R B

Page 11

ADJUSTMENT OF DEFLECTION LOOP

Note; During the adjustment, keep the unit facing the east.

FOCUS ADJUSTMENT

Receive “MONO SCOPE PATTERN” signal.

Set Contrast and Brightness controls at

CENTER position.

Adjust Focus control to have best focus at the

central area of CRT.

HORIZONTAL CENTERING CONTROL:

This adjustment should be performed

after the purity and convergence

adjustments.

Receive “MONO SCOPE PATTERN” signal.

Adjust

picture is at the position which gives the

relation of A = B .

so that the horizontal center of

Adjust point

VERTICAL LINEARITY CONTROL: R526

Receive “MONO SCOPE PATTERN” signal.

Adjust

picture is at best point.

so that the vertical linearity of

VERTICAL SIZE CONTROL:

Receive “MONO SCOPE PATTERN” signal.

Set the Brightness and Contrast controls at

maximum position.

VERTICAL CENTERING CONTROL:

This adjustment should be performed

after the purity and convergence

adjustments.

Receive “MONO SCOPE PATTERN” signal.

Adjust

picture is at the geometrical center of screen.

so that the vertical center of

Adjust

is at best point.

l Vertical size:

so that the vertical size of picture

(Max. 10%)

Page 12

PURITY ADJUSTMENT

Note: During the adjustment, keep the unit facing the east.

PURITY ADJUSTMENT

Prior to the purity adjustment, warm up the

unit with beam current of more than

a

.

.

Left

,

. . . . . . . .

,

.

. . . .

. . .

. . . . . .

,

,

I

I

,

The beam landing is shifted outwards.

The beam landing is shifted to right.

,

,

, ~~~~~

I

I

I

I

I

I

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. , .

. . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . .

. . . . . . . .

.

.

. . . . . .

. . . . . .

.

. .

Left

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

.

... . . .,..,.......

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . .._ . . . . . . . . . . . . . .

.

.

. . . . . . . . . . . . . .

. . . . .

.

. . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . .

. . . . . . .

. .

. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

.

. . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

Left

,

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. .

.

. . . . . . . . .

. . . . . .

. . . . . . . . . . . . . .

. . .

. . . . . . . . . .

. . . ..‘...........

. . . . . . .

. . . . . .

.

. . . . . . .

. . . . .

,

. . . . .

,

,

.

.

. . . . . .

,

.

.

. . . . . .

. .

I

I

I

,

,

I

I

Figure A.

Figure

Figure

b

Right

. .

.

. . . . .

. . . . . . . . . . . . . . .

. . . . . .

. . . . . . . . .

.

. . . . . . . . . . . . . . . .

. . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

...

. . . . . . . . . . . . . . .

I

,

,

. . . . . .

,

. . .

,

. . .

Right

Right

for

Receive the green signal alone and adjust the

beam current to

Fully

coil.

Before the purity adjustment, it is needed to

roughly adjust the static convergence.

Set the purity magnet at the position which

gives zero

than

Adjustment

Observe the green spots (“a” and

microscope as shown Fig. A, and adjust the

purity magnet so that they are at the

specified landing position.

If the right and left green spots are both

deviated outwards from their landing

positions as shown in Fig. B,’ push the

deflection yoke forwards until their positions

are corrected.

If the beam landing is shifted to

as shown in Figs.

degree of the purity magnet so that the beam

landing is correctly positioned.

Adjust the purity magnet so that the beam

landing is correct at either of the central part,

right and left parts of screen, then check that

the green beams at four corners of screen are

all correctly positioned.

Finally, check that the beam landing at any

pat of screen is satisfactory with the Rank “B”

specifications.

IO. If the green beam is positioned to mix with

the other

backward.

l

Outside of the specified landing:

To front of the deflection yoke.

l

inside of the specified landing:

To back of the deflection yoke.

Set the raster rotation at

the unit facing the east).

Tighten the screws of the deflection coil.

Tightening torque:

minutes.

770

the CRT with the

magnetic field.

adjust the opening

pull the deflection yoke

position (with

kg

2 kg.

with a

or left

The beam landing is shifted to left.

Figure

Page 13

CONVERGENCE ADJUSTMENT

Note: During the adjustment, keep the unit facing the east.

CONVERGENCE ADJUSTMENT

This adjustment should be performed

Wedge “a”

/Wedge

magnet

magnet

after the purity magnet adjustment.

Receive “CROSSHATCH PATTERN” signal.

Set. the Brightness control and Contrast control

at MAX position.

STATIC CONVERGENCE

Adjust the opening degree of the 4-pole

magnet and rotate the magnet to converge

red and blue lines.

Adjust the opening degree of the 6-pole

magnet and rotate the magnet to converge

red, blue and green lines.

DYNAMIC CONVERGENCE

Dynamic convergence (convergence of the

three

is accomplished in the following manner.

fields) at the edges of CRT screen

Purity magnet

\

*..._

\

\

\ :

. -cd-

: \

\

Convergence in Fig. a:

insert

between the deflection yoke

and CRT, and tilt the deflection yoke upward

until the

shown in Fig. a is

corrected.

Convergence in Fig.

Insert wedges

and

between the

deflection yoke and CRT, and tilt the

yoke until the

shown in Fig. b is corrected.

Convergence in Fig.

Insert wedge

deeply between the

deflection yoke and CRT, and tilt the

G

B

deflection yoke to right until the

convergence shown in Fig. c is corrected.

Convergence in Fig.

Insert wedge

deflection yoke and CRT, and tilt the

deflection yoke to left until the

convergence shown in Fig. d is corrected.

l

. . . . . . . . . . . . . ...*.....

. . . . . . .

I .

:

. . . . . . . . . . . . . . . .

.

I

I

I

.

I

, G

Figured.

Stick the three wedges onto the CRT, and

apply glass tapes thereon.

Apply lacquer to the deflection yoke screw,

magnet unit (made of purity,

and

pole magnets) and magnet unit screw.

After the adjustment,

receive either the Red or

the Blue signal and check that there is no mixture

with the other

signal.

Page 14

CRT DISPLAY ADJUSTMENT

Note; During the adjustment, keep the unit facing the east.

SIGN POSITION CONTROL: RI 017

Set the channel number at

Display the channel sign by means of the

channel call of remote control on the screen.

Adjust the sign position by

set

mm away from the CRT edge.

so that it is

CRT edge

Page 15

TROUBLE SHOOTING TABLE

NO RASTER

r

Check

and

1

Check F701.

Check T701 pin (1) voltage

290V DC at

AC).

Check + B voltage

PW).

Blown out.

I

Check D702.

Normal

Check CRT connector

bias.

15

Page 16

CIRCUITS TO BE CHECKED:

l

Tuner.

.

l

Automatic Gain Control.

+

Power Source.

NO PICTURE, NO SOUND

Does the noise level

Contrast, Brightness and Sound controls?

at max.

Noise increases but no signal is

received.

I

Check the tuner

+

biases.

+

must be

must be

must be

preset switch at VHF position.

must be

band switch at UHF position.

Check the tuner

I

Normal Abnormal

with the

with the

and

Picture noise decreases but sound

I

level varies greatly.

I

Does the

(11) of connector- ?

I

appear at pin

16

Page 17

CIRCUITS TO BE CHECKED:

l

l

and its adjacent

circuit.

output circuit.

Specific colours are not produced

in colour broadcast reception.

The picture

cyan.

I

is red or

Is some

I

I

produced in

The picture

magenta.

broadcast

is green or

1

Yes

Is the white balance

Readjust the white balance.

The picture

yellow.

properly

is blue or

17

Page 18

CIRCUITS TO BE CHECKED:

l

l

When change channel does

and its adjacent

circuit.

output circuit.

shading.

,

Is some colour produced

in B/W broadcast

Yes

Yes

Check pins

I

Check

bias.

No

Normal

(20) and (21) of

appears but

abnormal

Check pins (22), (23)

and (27) of

I I

I

bias.

18

Check

and its

Page 19

CIRCUITS TO BE CHECKED:

l

and its adjacent

circuit.

output circuit.

NO SPECIFIC COLOUR

Specific colours are not produced

in

VCR NTSC4.43 reception.

19

Page 20

D

I

I

A

I

I

,

iDI

m

I

n

TUNING SWITCH

,

I

I

I

I

SCREEN

1

Page 21

PRINTED WIRING BOARD ASSEMBLIES

Wiring Side

1

I

2

I

3

I

4

I

5

I

6

Page 22

Wiring Side

I

7

I

8

9

I

Page 23

PRINTED WIRING BOARD ASSEMBLIES (Continued)

I

Wiring Side

23

Page 24

Wiring Side

Wiring Side

Wiring Side

I

7

8

9

I

I

Page 25

PRINTED WIRING BOARD ASSEMBLIES (Continued)

Wiring Side

1

I

2

I

3

I

4

I

5

6

1

25

Page 26

DESCRIPTION OF SCHEMATIC DIAGRAM

SAFETY NOTE:

DISCONNECT THE AC PLUG FROM THE AC OUTLET BEFORE

PARTS.

POTENTIAL SHOCK HAZARDS WHEN THE CHASSIS IS

OPERATING.

SURE TO

REPLACE THESE PARTS WITH SPECIFIED

ONES FOR

SERVICE PRECAUTION:

The area enclosed by this line

with AC Mains Voltage.

When servicing the area, connect an isolating transformer

between TV receiver and AC line to eliminate hazard of

electric shock.

is direct/y connected

SOLID STATE DEVICE BASE DIAGRAMS

NOTE:

The unit of resistance “ohm

Meg ohm).

resistors are

capacitors are

The diodes, whose parts code is not described, are the

All resistors are unless otherwise noted.

watt, unless otherwise noted.

unless otherwise noted P

is omitted

= 1000 ohms,

VOLTAGE MEASUREMENT CONDITIONS:

Voltages without parenthesis measured with

or Color Signal.

The voltage in parenthesis represents the value measured

with no signal.

All the voltages were measured by using a high impedance

voltmeter.

B & W

WAVEFORM MEASUREMENT CONDITIONS:

The co/our bar signal applied to the TP40 1 is 1

The tuner AGC voltage is approximately 4V.

TOPVIEW

I

I

I

I

I

I

I

I

L

I-

BASE

COLLECTOR

GATE

1

---

1

-----

COLLECTOR

BASE

EMITTER

BASE

DRAIN

GATE

SOURCE

E

E

I

1

1

9

1

1

--

--

I

I

I

1

I

I

I

I

I

I

Page 27

. . . . . . . . . . . . . . . . . .

. . .

. .

.

. . . .

. . . . ..‘...................................

. .

. .

. .

. . . . . ... . . .. . .

. . . . .

. . . .

. . . .

. . .

. . . .

. . . . . . . . . .

.

. . . . . ... .

. . . . . . . . . . . . ...* . . . . .

.

. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . .

. .

. .

. .

. .

. . . .

. . ... . . . . ... ... ... .

. . .. .

.

. . . .

. ... .

. .

. . .... . . . . . . .. .

. ... .

. . . . . . . . ..5....... . . . .

.

. .

. . . .

.

. . . . . . . . . . . . ... >

. .. .

. .

. ..

. . . ... ... .

.. .

.

INFRARED REMOTE CONTROLLER CIRCUIT:

CAUTION: This circuit diagram is original one, therefore there may be a slight difference from yours.

1

I

2

3

I

4

I

6

I

Page 28

WAVE FORMS

1

(H)

(H)

(H)

1

(H)

(H)

(H)

(H)

(H)

(H)

5W3-p

(H)

. .

(H)

(H)

(H)

(H)

(H)

(AC 220V)

28

Page 29

SCHEMATIC DIAGRAM: SUB CIRCUIT

29

Page 30

CAUTION:

I

This circuit diagram is original one, therefore there may be a slight difference from yours.

I

30

Page 31

SCHEMATIC DIAGRAM: MAIN CIRCUIT

Page 32

CAUTION: This circuit diagram is original one, therefore there may be a slight difference from yours.

I

I

I

7

I

8

9

10

I

11

I

12

I

32

Page 33

BLOCK DIAGRAM:

MAIN CIRCUIT

1

2

I

3

33

4

I

5 I

6

Page 34

7

8

9

I

10

11

12

I

34

Page 35

BLOCK DIAGRAM: SUB CIRCUIT

1

2

3

4

I

5

I

6

35

Page 36

7

I

8

9

10

11

12

36

Page 37

PARTS LIST

PARTS REPLACEMENT

Ref. No.

I

Part No.

I

I

Description

Code

I I

MOTHER UNIT

Replacement parts which have these special safety characteristics

identified in this manual: electrical components having such

features are identified by

The use of a substitute replacement part which does not have the

same safety characteristics as the factory recommended

replacement parts shown in this service manual may create

shock, fire or other hazards.

in the Replacement Parts Lists.

“HOW TO ORDER REPLACEMENT PARTS”

To have your order filled promptly and correctly, please furnish

the following informations.

2. REF. NO.

4. DESCRIPTION

I I

Description

Ref. No.

I

1. MODEL NUMBER

3. PART NO.

MARK

I

SPARE PARTS-DELIVERY SECTION

Part No.

PICTURE TUBE

R CRT

R

R DegaussingCoil

J

Purity and Static

Convergence

J

Yoke Positioning

(3

used)

PRINTED WIRING BOARD ASSEMBLIES

(

DUNTK6860WEVO

DUNTK6861

DUNTK6862WEVO

DUNTK6859WEVO

DUNTK6863WEVO

DUNTK6374WEVZ

Mother Unit

Control Unit

CRTSocket Unit

AV/S-Output Unit

Powe Unit

R/C Receiver

S-Converter Unit

IF Unit

LED Unit

Code

I

AK

NOTE:

405,

406,

501,

502,

601,

607,

802,

807,

1001,

1002,

1004,

1006,

1009,

1010,

1011,

1012

301

404,

407,

408,

605,

1003

4403

806,

1005

TUNER

THE PARTS

ASSEMBLY BUT NOT INDEPENDENTLY.

1

J Tuner,UHFNHF

INTEGRATED CIRCUITS

J

J

J

Separator, Vertical

Horizontal

Driver

J

R H

i X 1 1 9 4 C E N 1JMicroprocessor

J

J

TRANSISTORS

J

J 2SCl815(GW)

01

01

E J 2SAlOlS(G)

E J 2SAlOlS(Y)

E J

J

BE

AS

and

AM

AM

AC

AC

AC

AD

37

Page 38

Ref. No.

Part No.

Description

MOTHER UNIT (Continued)

Code

Ref. No.

Part No.

I

DIODES

(Continued)

J

Description Code

I

AA

I

TRANSISTORS

DIODES

(Continued)

J

E J

E J

J

J

J

AA

J

J

J Zener Diode,

J Zener Diode,

J

J

1 OCEZZ J

1 CEZZ J Zener Diode,

J

AA

AD

AA

AA

AD

J

J

J

PACKAGED Cl

J

J Resistor Array

COILS

J 68uH

J

J 100pH

J

Diode,

ITS

AA

AL

AC

A%

Page 39

Ref. No.

Part No.

Description

Code

Ref. No. Part No.

Description

Code

MOTHER UNIT (Continued)

COILS

CERAMIC FILTERS

(Continued)

R

J

J 27pH

J 22pH

J 1uH

J 12pH

J 1pH

J 100pH

J

J

J 5.6/6.OMHzTrap

J Osc.,503kHz

J Osc.,4MHz

AK

AC

CONTROLS

J

J lOk(B) Sub-Brightness,

J lOOk(B)SContrast

J ZOOk(B)VerticalSize

J

J 20k(B) Sub-Colour

CEZZ J

Vertical Linearity,

Sub-Hue

DL-Amp.

CAPACITORS

J 4.7

07M J

J

J

J 1

J 4.7

Tantalum AC

Electrolytic AC

Electrolytic

Electrolytic

Electrolytic AC

Electrolytic AD

Electrolytic

Tantalum AD

Electrolytic

Electrolytic AD

Electrolytic AC

DELAY LINES

J DelayLine

J

TRANSFORMERS

J

1

J

J

R H-DriveTrans.

R FlybackTrans.

J Delay Phase

J

J

R CH-SignOscCoil

AC

AD

AD

AD

AH

AD

AD

AD

Cl

EW477M

J

J

J

J 820~ 2kV Ceramic

500VCeramic AA

Polyester

Polyester

Mylar

Electrolytic AC

Electrolytic

Electrolytic AD

Electrolytic

Electrolytic AD

Electrolytic

AC

AA

AD

AD

Page 40

Ref. No.

Part No.

Description

Code

Ref. No.

Description Code

639

~622

DUNTK6860WEVO

MOTHER UNIT (Continued)

RESISTORS

J 47

J

J

J

R 3.9

J

J 1 k

J

J

J

J

SWITCHES

J Service,

Vertical Center

MISCELLANEOUS PARTS

J

FuseResistor A0

FuseResistor A0

Fuse Resistor A0

Cement

Fuse Resistor

Metal Oxide AA

FuseResistor A0

Metal Oxide A0

Metal Oxide AA

AA

AC

DUNTK6861

CONTROL UNIT

DIODES

QSW-ROOOSPEZZ R S-Wide,

CONTROL

SWITCHES

J Sound Up,

J Stand-by

J lSS119

R lOk(B)

Sound Down,

Channel Down,

P-Control,

P-Control Level Up,

P-Control Level Down,

System,

Power

J

AK

DUNTK6281

CRT SOCKET UNIT

TRANSISTORS

J

COIL

J

CONTROLS

J

J 300(B)

Red Bias,

AC

Green Bias,

Blue Bias

AC

Blue Drive

Page 41

Ref. No.

Part No.

Description

Code

Ref. No. Part No.

Description

Code

DUNTK6281

CRT SOCKET UNIT (Continued)

CAPACITORS

J

J

RESISTORS

J 2.7k

J

MISCELLANEOUS PART

25OVElectrolytic AD

J CRTSocket

AD

AA

AA

AK

DIODES

J

COILS

J 33pH

J 15vH

J 8.2pH

CERAMIC FILTERS

J

J

AA

INTEGRATED CIRCUITS

J Sound

J SoundOutput( AK

P/-l J

TRANSISTORS

01

VSZSC181 SGW-1 J

E J

UNIT

Sound Output(L)

AH

AL

AC

VCEAGAlCW477M J 470

VCEAGAlCW107M J

EW477M J

CAPACITORS ,

Electrolytic AC

Electrolytic AD

J

J

Electrolytic AD

Electrolytic

RESISTORS

J

J

Electrolytic

FuseResistor

FuseResistor

MISCELLANEOUS PART

J 2SC1815(Y)

J

AC

J

AH

Page 42

Ref. No.

Description

Code

Ref. No.

Part No.

Description

Code

704,

746

D708,

D709

714,

D743,

DUNTK6859WEVO

POWER UNIT

INTEGRATED CIRCUITS

TRANSISTORS

1 1 CEZZ J

J

J

E J

J

J

DIODES

J

J

J

J

J

J lSS119

J

J

J RU3AMVl

J

J

J

Diode

J

J

Ax

AA

AC

AD

AC

AC

AA

AK

AA

AK

C702,

703,

704,

705,

707,

715,

716

7

744

729

1

TRANSFORMER

R

CAPACITORS

J 0.22 AC250V

J

AC250V Ceramic AC

J 0.0015

J 330

J 0.033 630VMylar

J

J

J 47

J

J 82p

J

J

J

J 0.012

J 0.0068

J

K J

J

J 470

J

2kV Ceramic

1OOVElectrolytic AC

AH

Polyester

Ceramic AA

AS

Ceramic AC

Electrolytic AC

Ceramic AA

Electrolytic

Mylar

Ceramic

Mylar

Mylar

Ceramic AA

Electrolytic AD

Electrolytic

AA

AA

AA

AA

AD

AA

L702

L704

L705

PACKAGED CIRCUIT

J

COILS

J

J

J

J

J 100pH

J 3.3uH

R

AK

AL

745

C742

J 470

J lOOOp2kV Ceramic AC

J 390 25OVElectrolytic AN

J

Electrolytic AD

Electrolytic

Electrolytic

Page 43

Ref. No.

Part No.

Description

Code

Ref. No. Part No.

Description

Code

R709,

710,

714

R722,

760

R724

R725,

726

R740,

R746

R747,

748

R749,

R750,

751,

752,

753,

R754,

756

DUNTK6859WEVO

POWER UNIT (Continued)

RESISTORS

J

Cement AC

J 2.7

J

J 120k3W

J

J 68k

J 47

5

J 39k

J

J

I J

J 330

J

J

J 47

J

J 390

1 J J 820

J

J 8.2M 1/2WSolid

J 1

J

J 10k

J

J

J 6.8

J J 330

J 22k

J

Cement

Carbon

Carbon

Fuse Resistor

Carbon

Carbon

Carbon

Metal Oxide

Carbon

Carbon

Carbon

Carbon

Carbon

Carbon

Fuse Resistor

Cement AC

FuseResistor

Cement AC

Carbon

Carbon

AA

AC

AA

A6

704

FB702,

MISCELLANEOUS PART

J Fuse,T3.15A

J FuseHolder

J

J

DUNTK6863WEVO

RECEIVER AND LED UNIT

DIODE

J

MISCELLANEOUS PART

J Infrared R/C Receiver AL

S-CONVERTER UNIT

INTEGRATED CIRCUIT

J S-Converter

DIODES

E J lSS119

COILS

J 18pH

J

AD

AC

AN

AA

CERAMIC FILTERS

J

J

J 2.2k

J

Carbon

1/4WCarbon

Carbon

Carbon

J 12MHzOsc.

J

J 10MHzOsc.

J

AD

RFiLCO

J

J

AD

Page 44

Ref. No.

Part No.

IF UNIT

Code

Ref. No.

Part No.

Description

PACKING PARTS

Code

INTEGRATED CIRCUIT

1

J

TRANSISTORS

E J 2SCI906

J

DIODE

J

TRANSFORMERS

J AFT

J P-DetectCoil

J

J

CERAMIC FILTERS

J

1 OCEZZ J

CAPACITORS

J 330

J 1

Electrolytic AC

AD

AK

Electrolytic

AN

AC

AD

PackingCase

CABINET PARTS LOCATION

MISCELLANEOUS PARTS

\

I

R ACCord

R

SUPPLIED ACCESSORIES

ACCESSORIES

R Infrared Remote

Controller

ACCESSORIES

1

Dry Battery,

Size

Service Map.

Terminal

1

CABINET PARTS

1

Not Available

H

H

1

2

3

Cabinet, Front

R Door

R Leg(2 used)

R Window AL

R Speaker Decoration

R Speaker Decoration

R

R Push Latch

R Cabinet, Rear

R

Front

AN

AC

Printed in Japan

Loading...

Loading...