Page 1

SERVICE MANUAL

S35F420F650///

COLOR TELEVISION

Chassis No. GA-4

20F650

MODEL

In the interests of user-safety (Required by safety regulations in some countries ) the set should be restored to its

original condition and only parts identical to those specified should be used.

CONTENTS

» ELECTRICAL SPECIFICATIONS .........................................................................................................1

» IMPORTANT SERVICE SAFETY PRECAUTION .................................................................................2

» LOCATION OF USER'S CONTROL .....................................................................................................6

» INSTALLATION AND SERVICE INSTRUCTIONS................................................................................7

» SERVICE MODE ..................................................................................................................................8

» ADJUSTMENT METHOD ...................................................................................................................14

» CHASSIS LAYOUT .............................................................................................................................28

» BLOCK DIAGRAM ..............................................................................................................................29

» WAVEFORMS .....................................................................................................................................33

» DESCRIPTION OF SCHEMATIC DIAGRAM......................................................................................34

» SCHEMATIC DIAGRAMS...................................................................................................................35

» PRINTED WIRING BOARD ASSEMBLIES ........................................................................................39

» REPLACEMENT PARTS LIST............................................................................................................43

» PACKING OF THE SET......................................................................................................................49

20F650

Page

ELECTRICAL SPECIFICATIONS

POWER INPUT.................................................... AC 120 V, 60 Hz

POWER RATING .................................................................... 88W

PICTURE SIZE .......................................... 1,239 cm2 (192sq inch)

CONVERGENCE ............................................................. Magnetic

SWEEP DEFLECTION .................................................... Magnetic

FOCUS .................................................. QFP/UNI-B1 Electrostatic

INTERMEDIATE FREQUENCIES

Picture IF Carrier Frequency ..................................... 45.75 MHz

Sound IF Carrier Frequency...................................... 41.25 MHz

Color Sub-Carrier Frequency .................................... 42.17 MHz

(Nominal)

AUDIO POWER

OUTPUT RATING ........................................2.5 W(RMS) x 2pcs

SPEAKER

SIZE ................................................................... 12 x 5 cm, 2pcs

VOICE COIL IMPEDANCE............................. 16 ohm at 400 Hz

ANTENNA INPUT IMPEDANCE

VHF/UHF.....................................................75 ohm Unbalanced

TUNING RANGES

VHF-Channels...............................................................2 thru 13

UHF-Channels ............................................................14 thru 69

CATV Channels...........................................................1 thru 125

(EIA, Channel Plan U.S.A.)

Specifications are subject to change without

prior notice.

SHARP CORPORATION

This document has been published to be used for after

sales service only.

The contents are subject to change without notice.

Page 2

20F650

Ë

IMPORTANT SERVICE SAFETY PRECAUTION

Service work should be performed only by qualified service technicians who are

thoroughly familiar with all safety checks and the servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

3. Semiconductor heat sinks are potential shock

hazards when the chassis is operating.

4. The chassis in this receiver has two ground systems

which are separated by insulating material. The nonisolated (hot) ground system is for the B+ voltage

regulator circuit and the horizontal output circuit. The

isolated ground system is for the low B+ DC voltages

and the secondary circuit of the high voltage

transformer.

To prevent electrical shock use an isolation

transformer between the line cord and power

receptacle, when servicing this chassis.

CAUTION: FOR CONTINUED

PROTECTION AGAINST A

RISK OF FIRE, REPLACE

4A 125V

ONLY WITH SAME TYPE 4A125V FUSE.

SERVICING OF HIGH VOLTAGE SYSTEM

AND PICTURE TUBE

When servicing the high voltage system,

remove the static charge by connecting a

10k ohm resistor in series with an insulated

wire (such as a test probe) between the picture tube ground and the anode lead. (AC

line cord should be disconnected from AC

outlet.)

1. Picture tube in this receiver employs integral

implosion protection.

2. Replace with tube of the same type number for

continued safety.

3. Do not lift picture tube by the neck.

4. Handle the picture tube only when wearing

shatterproof goggles and after discharging the high

voltage anode completely.

X-RADIA TION AND HIGH VOLTAGE LIMITS

1. Be sure all service personnel are aware of the

procedures and instructions covering X-radiation. The

only potential source of X-ray in current solid state

TV receivers is the picture tube. However, the picture

tube does not emit measurable X-Ray radiation, if

the high voltage is as specified in the "High Voltage

Check" instructions.

It is only when high voltage is excessive that Xradiation is capable of penetrating the shell of the

picture tube including the lead in the glass material.

The important precaution is to keep the high voltage

below the maximum level specified.

2. It is essential that servicemen have available at all

times an accurate high voltage meter.

The calibration of this meter should be checked

periodically.

3. High voltage should always be kept at the rated value

−no higher. Operation at higher voltages may cause

a failure of the picture tube or high voltage circuitry

and;also, under certain conditions, may produce

radiation in exceeding of desirable levels.

4. When the high voltage regulator is operating properly

there is no possibility of an X-radiation problem. Every

time a color chassis is serviced, the brightness should

be tested while monitoring the high voltage with a

meter to be certain that the high voltage does not

exceed the specified value and that it is regulating

correctly.

5. Do not use a picture tube other than that specified or

make unrecommended circuit modifications to the

high voltage circuitry.

6. When trouble shooting and taking test measurements

on a receiver with excessive high voltage, avoid being

unnecessarily close to the receiver.

Do not operate the receiver longer than is necessary

to locate the cause of excessive voltage.

2

Page 3

2

2

2

IMPORTANT SERVICE SAFETY PRECAUTION

(Continued)

20F650

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user, perform

the following safety checks.

1. Inspect all lead dress to make certain that leads are

not pinched or that hardware is not lodged between

the chassis and other metal parts in the receiver.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators, etc.

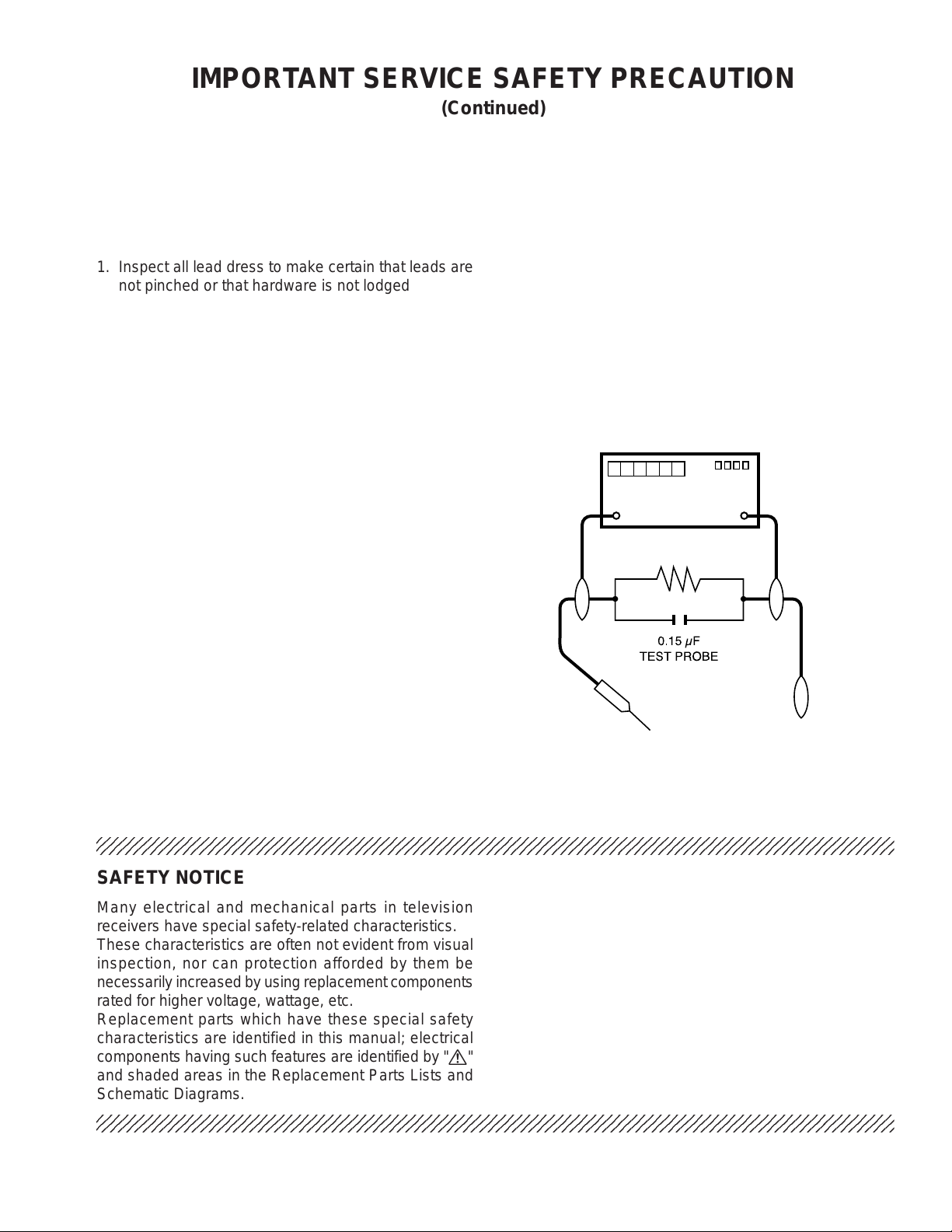

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

• Plug the AC cord directly into a 120 volt AC outlet,

(Do not use an isolation transformer for this test).

• Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in series with

all exposed metal cabinet parts and a known earth

ground, such as electrical conduit or electrical ground

connected to earth ground.

• Use an AC voltmeter having with 5000 ohm per volt,

or higher, sensitivity to measure the AC voltage drop

across the resistor.

• Connect the resistor connection to all exposed metal

parts having a return to the chassis (antenna, metal

cabinet, screw heads, knobs and control shafts,

escutcheon, etc.) and measure the AC voltage drop

across the resistor.

AII checks must be repeated with the AC line cord

plug connection reversed. (If necessary, a nonpolarized adapter plug must be used only for the

purpose of completing these check.)

Any current measured must not exceed 0.5 milliamp.

Any measurements not within the limits outlined

above indicate of a potential shock hazard and

corrective action must be taken before returning the

instrument to the customer.

DVM

AC SCALE

1.5k ohm

10W

TO EXPOSED

METAL PARTS

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

CONNECT TO

KNOWN EARTH

GROUND

SAFETY NOTICE

Many electrical and mechanical parts in television

receivers have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by "å"

and shaded areas in the Replacement Parts Lists and

Schematic Diagrams.

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

For continued protection, replacement parts must be

identical to those used in the original circuit. The use of

substitute replacement parts which do not have the same

safety characteristics as the factory recommended

replacement parts shown in this service manual, may

create shock, fire, X-radiation or other hazards.

3

Page 4

20F650

Ë

PRECAUTIONS A PRENDRE LORS DE LA REPARATION

Ne peut effectuer la réparation qu' un technicien spécialisé qui s'est parfaitement

accoutumé à toute vérification de sécurité et aux conseils suivants.

AVERTISSEMENT

1. N'entreprendre aucune modification de tout circuit.

C'est dangereux.

2. Débrancher le récepteur avant toute réparation.

3. Les déversoirs thermiques à semi-conducteurs

peuvent présenter un danger de choc électrique

lorsque le réceqteur est en marche.

4. Le châssis de ce récepteur a deux systèmes de mise

à la terre qui sont séparés par un matériau isolant.

Le système de mise à la terre non-isolée (chaud) est

pour le circuit du régulateur de tension B+ et le circuit

de sortie horizontale. Le système de mise à la terre

isolé est pour les basses tensions C. C. B+ et le circuit

secondaire du transformateur de haute tension.

PRECAUTION:POUR LA

PROTECTION CONTINUE

CONTRE LES RISQUES

D'INCENDIE, REMPLACER LE

4A 125V

FUSIBLE P AR UN FUSIBLE DE

MEME TYPE 4A-125V.

REP ARATION DU SYSTEME A HAUTE TENSION ET DU TUBE-IMAGE

Lors de la réparation de ce systéme,

supprimer la charge statique en branchant

une résistance de 10 kΩ en série avec un fil

isolé (comme une sonde d'essai) entre la

mise à la terre du tube-image et le fil

d'anodel. (Le corden d'alimentation doit être

retiré de la prise murale.)

1. Il est à noter que le tube-image de ce récepteur est

intégralement protégé contre l'implosion.

2. Par mesure de sécurité, changer le tube-image pour

un tube du même numéro de type.

3. Ne pas lever le tube-image par son col.

4. Ne manipuler le tube-image qu'en porant des lunettes

incassables et qu'après avoir déchargé totalement

la haute tension.

LIMITES DES RADIATIONS X ET DE LA

HAUTE TENSION

1. Tout le personnel réparateur doit être instruit des

instructions et procédés relatifs aux radiations X.

Le tube-image, seule source de rayons X dons les

téleviseurs transistorisés, n'émet pourtant pas de

rayons mesurables si la haute tension est maintenue

à un niveau préconisé dans la section "Vérification

de la haute tension".

C'est seulement quand la haute tension est excessive

que les rayons X peuvent entrer dans l'enveloppe du

tube-image y compris le conducteur de verre. Il est

important de maintenir la haute tension en-dessous

du niveau spécifié.

2. Il est essentiel que le réparateur ait sous la main un

voltmètre à haute tension qui doit être périodiquement

étalonné.

3. La haute tension doit toujours être maintenue à la

valeur de régime-et pas plus haute. L'opération à des

tensions plus élevées peut entraîner une panne du

tube-image ou du circuit à haute tension et, dans

certaines conditions, peut entraîner une radiation

dépassant les niveaux préscrits.

4. Quand le régulateur à haute tension fonctionne

correctement, il n'y a aucun problème de radiation

X. Chaque fois qu'un châssis couleurs est réparé, la

luminosité doit être examinée bout en contrôlant la

haute tension à l'aide d'un voltmètre pour s'assurer

que la haute tension ne dépasse pas la valeur

spécifiée et qu'elle soit correctement réglée.

5. Ne pas utiliser un tube-image autre que celui spécifié

et ne pas effectuer de modifications déconseillées

du circuit à haute tension.

6. Lors de la recherche des pannes et des mesures

d'essai sur un récepteur qui présente une haute

tension excessive, éviter de s'approcher inutilement

du récepteur.

Ne pas faire fonctionner le récepteur plus longtemps

que nécessaire pour localiser la cause de la tension

excessive.

4

Page 5

2

2

PRECAUTIONS A PRENDRE LORS DE LA REPARATION

(Suite)

20F650

VERIFICATIONS CONTRE L'INCEN-DIE ET

LE CHOC ELECTRIQUE

Avant de rendre le récepteur à l'utilisateur, effectuer

les vérifications suivantes.

1. Inspecter tous les faisceaux de câbles pour s'assurer

que les fils ne soient pas pincés ou qu'un outil ne soit

pas placé entre le châssis et les autres pièces

métalliques du récepteur.

2. Inspecter tous les dispositifs de protection comme

les boutons de commande non-métalliques, les

isolants, le dos du coffret, les couvercles ou blindages

de réglage et de compartiment, les réseaux de

résistance-capacité, les isolateurs mécaniques, etc.

3. S'assurer qu'il n'y ait pas de danger d'électrocution

en vérifiant la fuite de courant, de la facon suivante:

» Brancher le cordon d'alimentation directem-ent à une

prise de courant de 120V. (Ne pas utiliser de

transformateur d'isolation pour cet essai).

» A l'aide de deux fils à pinces, brancher une résistance

de 1,5 kΩ 10 watts en parallèle avec un condensateur

de 0,15µF en série avec toutes les pièces métalliques

exposées du coffret et une terre connue comme une

conduite électrique ou une prise de terre branchée à

la terre.

» Utiliser un voltmètre CA d'une sensibilité d'au moins

5000Ω/V pour mesurer la chute de tension en travers

de la résistance.

» Toucher avec la sonde d'essai les pièces métalliques

exposées qui présentent une voie de retour au

châssis (antenne, coffret métallique, tête des vis,

arbres de commande et des boutons, écusson, etc.)

et mesurer la chute de tension CA en-travers de la

résistance.

Toutes les vérifications doivent être refaites après

avoir inversé la fiche du cordon d'alimentation. (Si

nécessaire, une prise d'adpatation non polarisée peut

être utilisée dans le but de terminer ces vérifications.)

Tous les courants mesurés ne doivent pas dépasser

0,5 mA.

Dans le cas contraire, il y a une possibilité de choc

électrique qui doit être supprimée avant de rendre le

récepteur au client.

DVM

ECHELLE CA

1.5k ohm

10W

0.15 µF

SONDE D'ESSAI

AUX PIECES

METALLIQUES

EXPOSEES

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

BRANCHER A UNE

TERRE CONNUE

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans

les téléviseurs présentent des caractéristiques spéciales

relatives à la sécurité, qui ne sont souvent pas évidentes

à vue. Le degré de protection ne peut pas être

nécessairement augmentée en utilisant des pièces de

remplacement étalonnées pour haute tension,

puissance, etc.

Les pièces de remplacement qui présentent ces

caractéristiques sont identifiées dans ce manuel; les

pièces électriques qui présentent ces particularités sont

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

identifiées par la marque "

å " et hachurées dans la

liste des pièces de remplacement et les diagrammes

schématiques.

Pour assurer la protection, ces pièces doivent être

identiques à celles utilisées dans le circuit d'origine.

L'utilisation de pièces qui n'ont pas les mêmes

caractéristiques que les pièces recommandées par

l'usine, indiquées dans ce manuel, peut provoquer des

électrocutions, incendies, radiations X ou autres

accidents.

5

Page 6

20F650

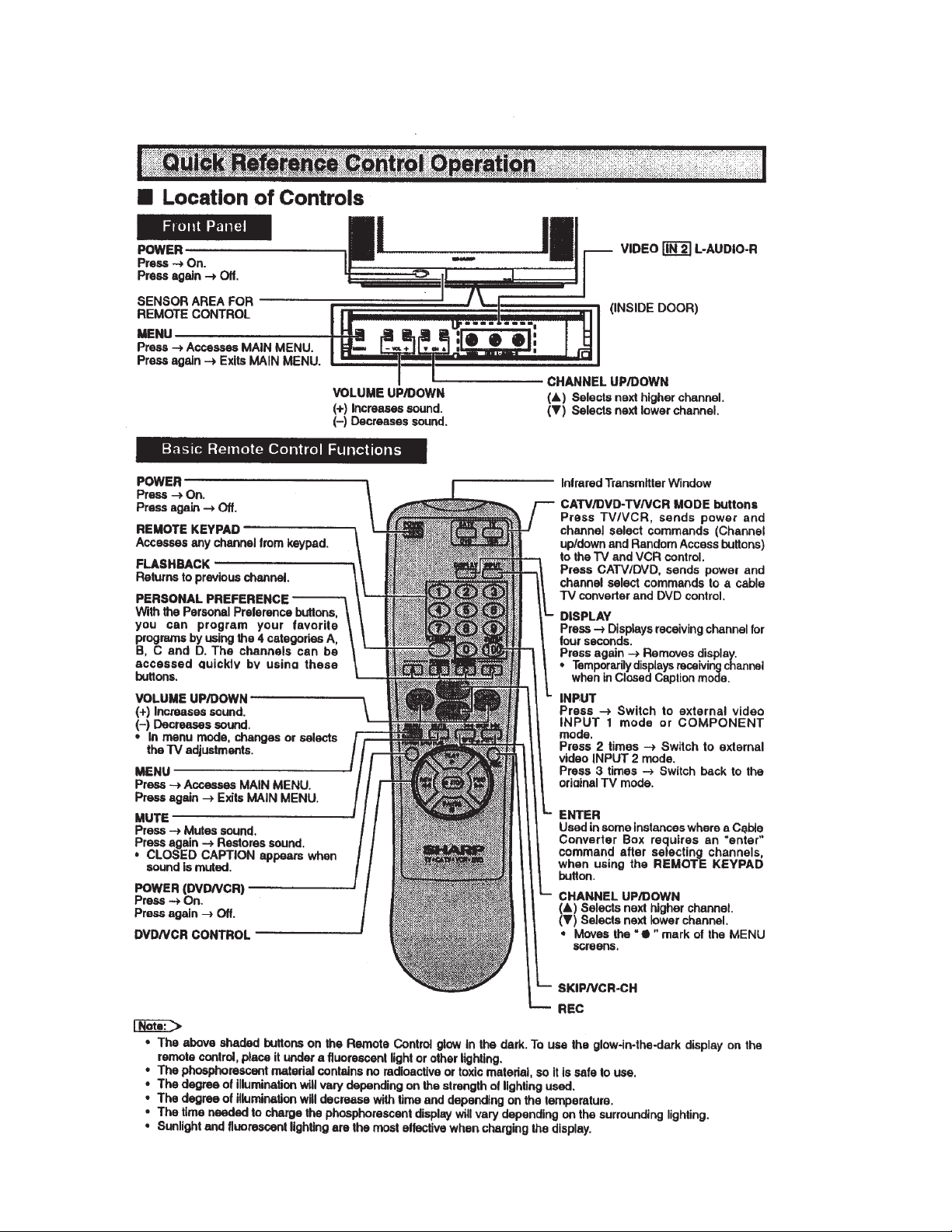

LOCATION OF USER'S CONTROL

6

Page 7

INSTALLATION AND SERVICE INSTRUCTIONS

Note: (1)When performing any adjustments to resistor controls and transformers use non-metallic

screwdrivers or TV alignment tools.

(2)Before performing adjustments, the TV set must be on at least 15 minutes.

20F650

CIRCUIT PROTECTION

The receiver is protected by a 4A fuse (F701),

mounted on PWB-A, wired into one side of the AC

line input.

X-RADIATION PROTECTOR CIRCUIT TEST

After service has been performed on the horizontal

deflection system, high voltage system, B+ system,

test the X-Radiation protection circuit to ascertain

proper operation as follows:

1. Apply 120V AC using a variac transformer for

accurate input voltage.

2. Allow for warm up and adjust all customer controls

for normal picture and sound.

3. Receive a good local channel.

4. Connect a digital voltmeter to P603 pin3 and make

sure that the voltmeter reads 19.8 ±1.1V.

5. Apply external 25.5V DC at P603 pin3 by using an

external DC supply, TV must be shut off.

6. To reset the protector, unplug the AC cord and make

a short circuit between P603 pin1 and P603 pin2.

Now make sure that normal picture appears on the

screen.

7. If the operation of the horizontal oscillator does not

stop in step 5, the circuit must be repaired before the

set is returned to the customer.

HIGH VOLTAGE CHECK

High voltage is not adjustable but must be checked

to verify that the receiver is operating within safe

and efficient design limitations as specified checks

should be as follows:

1. Connect an accurate high voltage meter between

ground and anode of picture tube.

2. Operate receiver for at least 15 minutes at 120V AC

line voltage, with a strong air signal or a properly

tuned in test signal.

3. Enter the service mode and set Y-mute ON by using

Service R/C.

4. The voltage should be approximately 28.7kV (at zero

beam).

If a correct reading cannot be obtained, check circuitry

for malfunctioning components. After the voltage test,

make Y-mute off to the normal mode.

7

Page 8

20F650

SERVICE MODE

Service Mode Overview

1. Service mode is entered by SERVICE key input or CH-UP +VOL-DOWN input during reset.

2. Service mode is cleared by entering SERVICE key command during service mode.

3. If key input port (SERVICE) input is LOW, then it is in service mode.

4. During key input port (SERVICE) input is LOW, clearing service mode by key input SERVICE is disabled.

5. Service mode can be switched to 4 modes as follows by key input MENU;

Adjustment mode

Setting mode

Check mode

Option mode

6. AFT processing is disabled during service mode. PLL setting data is set to fo data.

7. All user data are set to default during service mode. FAO and SPEAKER user settings are of f and on respectively

in service mode. Energy Save is off.

8. Sleep timer, View timer, On timer and OFF timer are inactivated in Service mode.

9. Sound is muting in service mode except at Adjustment Items V20, M01, M03, M04, M05, and M06.

First mode of service mode when SERVICE key is

pressed.

First mode of service mode when local key

CH-UP + VOL-DOWN is pressed after MCU reset.

8

Page 9

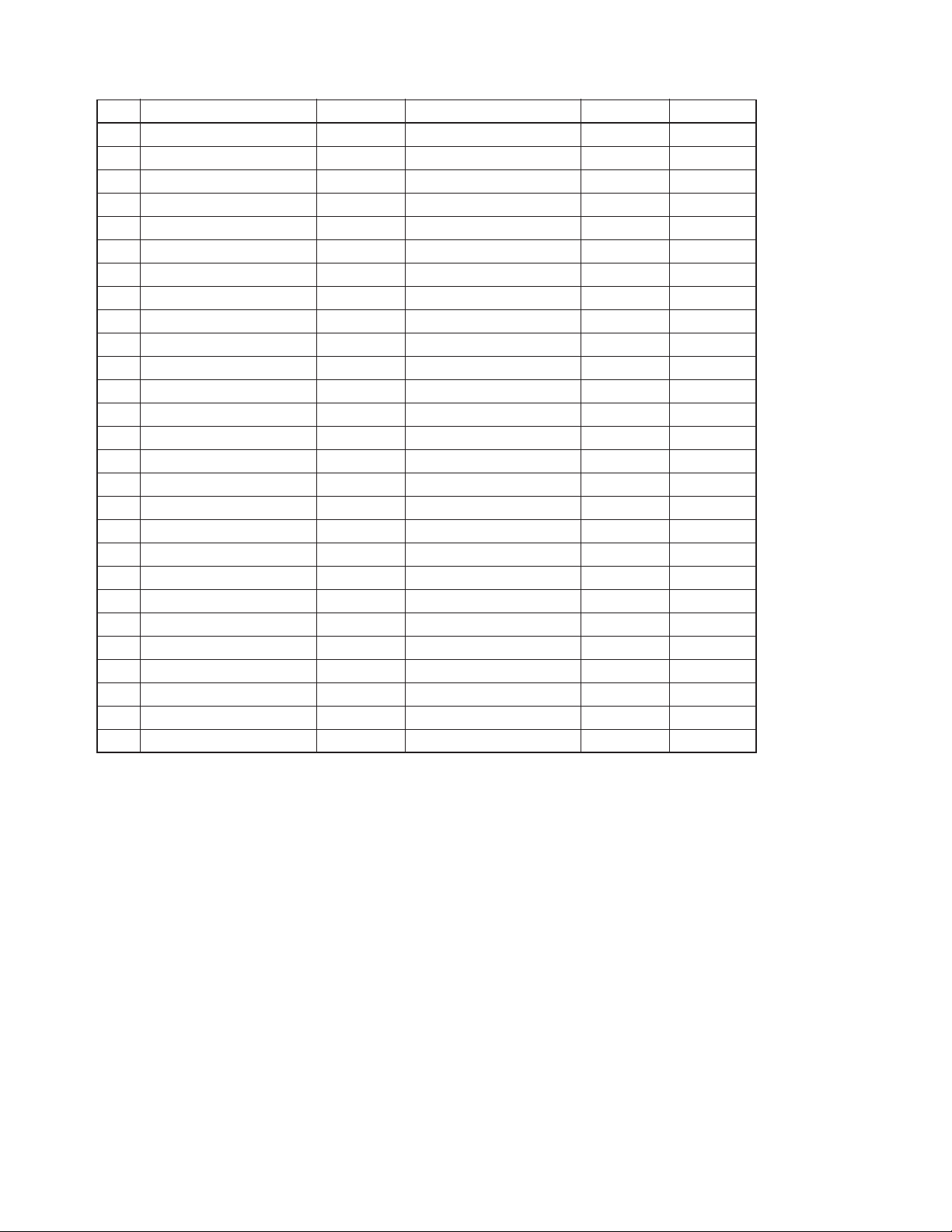

Adjustment Mode Items

No. Item Name IC Register Range Default

V01 SUB-PICTURE 1 Chip CONTRAST 0~127 127

V02 SUB-TINT 1 Chip TINT 0~127 64

V03 SUB-COLOR 1 Chip COLOR 0~127 64

V04 SUB-BRIGHT 1 Chip BRIGHT 0~255 128

V05 SUB-SHARP 1 Chip VIDEO-TONE 0~63 32

V06 V-SHIFT 1 Chip V-SHIFT 0~7 4

V07 H-SHIFT 1 Chip H-PHASE 0~31 16

V08 RF-AGC 1 Chip RF-DELAY 0~127 127

V09 V-SIZE 1 Chip V-SIZE 0~63 32

V10 PIF-VCO 1 Chip VIF-VCO 0~63 32

V11 R-CUTOFF 1 Chip R-CUTOFF 0~255 127

V12 G-CUTOFF 1 Chip G-CUTOFF 0~255 127

V13 B-CUTOFF 1 Chip B-CUTOFF 0~255 127

V14 R-DRIVE 1 Chip R-DRIVE 0~127 64

V15 B-DRIVE 1 Chip B-DRIVE 0~127 64

V16 SUB-COLOR(YUV) 1 Chip COLOR 0~127 64

V17 SUB-TINT(YUV) 1 Chip BASEBAND-TINT 0~127 64

V18 CC-POS MICON CC-POS 0~255 32

V19 SCREEN CUT OFF 1 Chip CUT OFF 0~2 0

V20 SUB-VOL 1 Chip A-ATT 0~127 127

V21 H-VCO 1 Chip H-VCO 0~7 4

M01 MTS-ATT MTS ATT (MTS) 0~15 10

M02 MTS-VCO MTS VCO (MTS) 0~63 32

M03 MTS-FIL TER MTS FILTER (MTS) 0~63 28

M04 MTS-WIDEBAND MTS WIDEBAND (MTS) 0~63 27

M05 MTS-SPECTRAL MTS SPECTRAL (MTS) 0~63 32

M06 SUB-VOL MTS VOL (MTS) 0~63 63

20F650

9

Page 10

20F650

Ë

SELF ADJUSTMENT

H-VCO

1. When there is H-VCO self-adjustment key input for adjustment item H-VCO, self-adjustment is performed.

2. H-FREE(1chip) is set to 1.

3. H-OUT is set by intelligent monitor output.

4. IM input is set as TIM input.

5. H-VCO(1chip) data is changed so that the number of input pulse is 125 inside 8ms interval.

6. When adjustment completed, OSD display and H-VCO self-adjustment status data of EEPROM are updated.

7. H-FREE(1chip), intelligent monitor output and IM input mode are recovered.

RF-AGC

1. When there is RF-AGC self-adjustment key input for adjustment item RF-AGC, self-adjustment is performed.

2. AGC-OUT is set by intelligent monitor output.

3. IM input is set as AD input.

4. By decreasing RF-AGC (1chip) data from current RF-AGC adjustment value to 0, AFT input voltage becomes the

maximum setting value.

5. Increase RF-AGC(1chip) data, when AFT input voltage is at (max. 0.3V) point, adjustment is completed.

6. When adjustment completed, OSD display and RF-AGC self-adjustment status data of EEPROM are updated.

7. Intelligent monitor output and IM input mode are recovered.

PIF-VCO

1. When there is PIF-VCO self-adjustment key input for adjustment item PIF-VCO, self-adjustment is performed.

2. VIF-DEF(1chip) is set to 1.

3. AFC is set by intelligent monitor output.

4. IM input is set as AD input.

5. VIF-VCO(1chip) data is changed so that input voltage becomes 2.5V.

6. When adjustment completed, OSD display and PIF-VCO self-adjustment status data of EEPROM are updated.

7. VIF-DEF(1chip), intelligent monitor output and IM input mode are recovered.

10

Page 11

Setting Mode Items

No. Item Name IC Register Range Default

F01 VIDEO TONE -GAIN (TV) 1 Chips V-TONE 0/1 0

F02 VIDEO TONE -GAIN (AV) 1 Chips V-TONE 0/1 0

F03

VIDEO TONE -GAIN (S-AV)

F04 VIDEO TONE -GAIN(YUV) 1 Chips V-T ONE 0/1 0

F05 ABCL 1 Chips ABCL 0/1 0

F06 BS 1 Chips BS-OFF 0/1 0

F07 ABCL-G 1 Chips ABCL-G 0/1 0

F08 SHP-AV OFFSET VIDEO-TONE(OFFSET) -16~+16 0

F09 SHP-SAV OFFSET VIDEO-TONE(OFFSET) -16~+16 0

F10 SHP-YUV OFFSET VIDEO-TONE(OFFSET) -16~+16 0

F11 RGB-CLIP 1 Chips EXTRGB-CLIP 0/1 0

F12 E-SAVE OFFSET CONTRAST(OFFSET) 0~63 30

F13 FAO-VOL 1 Chips A-ATT 0~127 120

F14 PIF-G 1 Chips VIF-GAIN 0~7 4

F15 Y-DELAY(TV) 1 Chips Y-DELAY 0~7 0

F16 Y-DELAY(AV) 1 Chips Y-DELAY 0~7 0

F17 Y-DELAY(SAV) 1 Chips Y-DELAY 0~7 0

F18 Y-DELAY(YUV) 1 Chips Y -DELAY 0~7 0

F19 TINT-AV OFFSET TINT(OFFSET) -32~+32 0

F20 TINT-SAV OFFSET TINT(OFFSET) -32~+32 0

F21 COL-AV OFFSET COLOR(OFFSET) -32~+32 0

F22 COL-SAV OFFSET COLOR(OFFSET) -32~+32 0

F23 R-DRI(R2) OFFSET R-DRI(OFFSET) -32~+32 0

F24 R-DRI( R) OFFSET R-DRI(OFFSET) -32~+32 0

F25 R-DRI(B) OFFSET R-DRI(OFFSET) -32~+32 0

F26 B-DRI(R2) OFFSET B-DRI(OFFSET) -32~+32 0

F27 B-DRI( R) OFFSET B-DRI(OFFSET) -32~+32 0

F28 B-DRI(B) OFFSET B-DRI(OFFSET) -32~+32 0

F29 V-FREE 1 Chips V-FREE 0/1 0

F30 GAMMA 1 Chips GAMMA 0~3 0

F31 TRAP(TV) 1 Chips TRAP-FINE 0~3 2

F32 TRAP(AV) 1 Chips TRAP-FINE 0~3 2

F33 H-FREE 1 Chips H-FREE 0/1 0

F34 1W(TV) 1 Chips V.WINDOW 0/1 0

F35 1W(AV) 1 Chips V.WINDOW 0/1 0

F36 YLPF 1 Chips YSW-LPF 0/1 1

F37 BS-D 1 Chips BS-DISCHARGE 0~3 0

F38 BS-C 1 Chips BS-CHARGE 0~3 0

F39 SL(TV) 1 Chips S-SLICE DOWN 0~3 0

F40 SL(AV) 1 Chips S-SLICE DOWN 0~3 0

F41 SL(SAV) 1 Chips S-SLICE DOWN 0~3 0

F42 SL(YUV) 1 Chips S-SLICE DOWN 0~3 0

F43 AFC2 1 Chips AFC2-G 0/1 0

F44 VD(TV) 1 Chips VSYNC-DET 0/1 0

F45 VD(AV) 1 Chips VSYNC-DET 0/1 0

F46 AS(TV) 1 Chips AUTO-SLICE 0/1 0

F47 AS(AV) 1 Chips AUTO-SLICE 0/1 0

F48 AS(SAV) 1 Chips AUTO-SLICE 0/1 0

F49 AS(YUV) 1 Chips AUTO-SLICE 0/1 0

F50 FBP(TV) 1 Chips FBP VTH 0/1 0

F51 FBP(AV) 1 Chips FBP VTH 0/1 0

F52 FBP(SAV) 1 Chips FBP VTH 0/1 0

F53 FBP(YUV) 1 Chips FBP VTH 0/1 0

F54 C.CLIP LEVEL 1 Chips C.CLIP LEVEL 0/1 0

1 Chips V-TONE 0/1 0

20F650

11

Page 12

20F650

Setting Mode Items (Continued)

No. Item Name IC Register Range Default

F55 PSW MTS PSW 0/1 0

F56 FAO-VOL MTS VOL 0~63 60

F57 CP PLL CHARGE PUMP 0/1 0

F58 CC LEVEL MICON CC LEVEL 0/1 0

F59 OSD POS MICON OSD POS 0/1 0

F60 OFFSET-ADJ-COL 1 Chips COLOR -32~+32 0

F61 OFFSET-ADJ-TINT 1 Chips TINT -32~+32 0

F62 OFFSET-ADJ-TINT-YUV 1 Chips BASEBAND-TINT -32~+32 0

F63 WAIT MD TIMER 1 Chips SLOW MODE 0/1 1

F64 R-CUT-YUV 1 Chips R-CUT(OFFSET) -63~+63 0

F65 G-CUT-YUV 1 Chips G-CUT(OFFSET) -63~+63 0

F66 B-CUT-YUV 1 Chips B-CUT(OFFSET) -63~+63 0

F67 R-DRI-YUV 1 Chips R-DRI(OFFSET) -63~+63 0

F68 B-DRI-YUV 1 Chips B-DRI(OFFSET) -63~+63 0

F69 CONTRAST OFFSET 1 Chips CONTRAST(OFFSET) -63~+63 0

F70 BRIGHTNESS OFFSET 1 Chips BRIGHT(OFFSET) -63~+63 0

F71

AV2 BRIGHTNESS OFFSET

1 Chips BRIGHT(OFFSET) -15~+15 7

12

Page 13

Option Mode Items

20F650

No

001 DEMO Without DEMO With DEMO 1

002 DOWNLOAD Without V-CHIP OP With V-CHIP OP 1

003 V-CHIP Without V-CHIP With V-CHIP 1

004 SPEAKER Without SPEAKER With SPEAKER 1

005 FAOWithout FAO With FAO 1

006 P.PREF Without P.REF With P.REF 1

007 UNIV+ Without UNIV+ With UNIV+ 1

008 VIEW TIMER Without VIEW TIMER With VIEW TIMER 1

009 EZ-SETUP EZ-SETUP AUTO PRESET 0

010 PON-CH Without POWER-ON With POWER-ON 0

011 FAV-COL FAV-COL COL-TEMP 1

012 COMPONENT Without COMPONENT With COMPONENT 1

013 AV Without AV With A V 1

014 AV2 AV1 system AV2 system 1

015 MTS Without MTS With MTS 1

016 TONE-CTRL Without S-ADJ With S-ADJ 1

017 AUTO-OFF Without AUTO-OFF With AUTO-OFF 1

018 INIT-LANG ENGLISH SPANISH 0

019 SETUP-FLAG NO SET UP AUTO SET UP 1

020 AV-FR

021 AV3/S-IN Without AV3/S-IN With AV3/S-IN 0

022 COMB Without COMB With COMB 0

023 AUTO-INPUT Without AUTO-INPUT With AUTO-INPUT 1

024 CLOCK Without CLOCK With CLOCK 0

025 LED SEMEX MODEL SPC MODEL 0

026 FLAT Not FLAT MODEL FLAT MODEL 1

027 BASS BOOST Without BASS BOOST With BASS BOOST 0

028 DSE Without DSE With DSE 0

029 SRS Without SRS With SRS 0

030 WHITE-OUT Without WHITE-OUT With WHITE-OUT 0

OPTION FUNCTION

01

"0"=NO AV "1"=REAR "2"=FRONT "3"=REAR & FRONT

Default Data

3

Check Mode

Micron mask version, software version and ROM correction function status are displayed in check mode.

13

Page 14

20F650

ADJUSTMENT METHOD

Caution: to get into the service mode, one of the ways is press direct key for service items. the other ways

is short the main chassis JA301 and JA410

There is three stage of Service Mode data

First stage data from V01 ~ M06

to go into second stage of service mode data, press MENU key

Second stage data from F01 ~ F71

to go into third stage of service mode data, press MENU key

Third stage data from 001 ~ 030

Below is the contents of these data

First Stage

Data Service Mode Function Range Default Data

V01 SUB-PICTURE CONTRAST 0~127 127

V02 SUB-TINT TINT 0~127 64

V03 SUB-COLOR COLOR 0~127 64

V04 SUB-BRIGHT BRIGHT 0~255 128

V05 SUB-SHARP VIDEO-TONE 0~63 32

V06 V-SHIFT V-SHIFT 0~7 4

V07 H-SHIFT H-PHASE 0~31 16

V08 RF-AGC RF-DELAY 0~127 127

V09 V-SIZE V-SIZE 0~63 32

V10 PIF-VCO VIF-VCO 0~63 32

V11 R-CUTOFF R-CUTOFF 0~255 127

V12 G-CUTOFF G-CUTOFF 0~255 127

V13 B-CUTOFF B-CUTOFF 0~255 127

V14 R-DRIVE R-DRIVE 0~127 64

V15 B-DRIVE B-DRIVE 0~127 64

V16 SUB-COLOR(YUV) COLOR 0~127 64

V17 SUB-TINT(YUV) BASEBAND-TINT 0~127 64

V18 CC-POS CC-POS 0~255 32

V19 SCREEN CUT OFF CUT OFF 0~2 0

V20 SUB-VOL A-ATT 0~127 127

V21 H-VCO H-VCO 0~7 4

M01 MTS-ATT ATT (MTS) 0~15 10

M02 MTS-VCO VCO (MTS) 0~63 32

M03 MTS-FIL TER FILTER (MTS) 0~63 28

M04 MTS-WIDEBAND WIDEBAND (MTS) 0~63 27

M05 MTS-SPECTRAL SPECTRAL (MTS) 0~63 32

M06 SUB-VOL VOL (MTS) 0~63 63

Auto Adjustment Item

1. H-VCO

2. RF-AGC

3. PIF-VCO

14

Page 15

Second Stage

Data Service Mode Function Range Default Data

F01 VIDEO TONE -GAIN (TV) V-TONE 0/1 0

F02 VIDEO TONE -GAIN (AV) V-TONE 0/1 0

F03 VIDEO TONE -GAIN (S-AV) V-TONE 0/1 0

F04 VIDEO TONE -GAIN(YUV) V-TONE 0/1 0

F05 ABCL ABCL 0/1 0

F06 BS BS-OFF 0/1 0

F07 ABCL-G ABCL-G 0/1 0

F08 SHP-AV VIDEO-TONE(OFFSET) -16~+16 0

F09 SHP-SAV VIDEO-TONE(OFFSET) -16~+16 0

F10 SHP-YUV VIDEO-TONE(OFFSET) -16~+16 0

F11 RGB-CLIP EXTRGB-CLIP 0/1 0

F12 E-SAVE CONTRAST(OFFSET) 0~63 30

F13 FAO-VOL A-ATT 0~127 120

F14 PIF-G VIF-GAIN 0~7 4

F15 Y-DELAY(TV) Y-DELAY 0~7 0

F16 Y-DELAY(AV) Y-DELAY 0~7 0

F17 Y-DELAY(SAV) Y -DELAY 0~7 0

F18 Y-DELAY(YUV) Y-DELAY 0~7 0

F19 TINT-A V TINT(OFFSET) -32~+32 0

F20 TINT-SA V TINT(OFFSET) -32~+32 0

F21 COL-AV COLOR(OFFSET) -32~+32 0

F22 COL-SAV COLOR(OFFSET) -32~+32 0

F23 R-DRI(R2) R-DRI(OFFSET) -32~+32 0

F24 R-DRI( R) R-DRI(OFFSET) -32~+32 0

F25 R-DRI(B) R-DRI(OFFSET) -32~+32 0

F26 B-DRI(R2) B-DRI(OFFSET) -32~+32 0

F27 B-DRI( R) B-DRI(OFFSET) -32~+32 0

F28 B-DRI(B) B-DRI(OFFSET) -32~+32 0

F29 V-FREE V-FREE 0/1 0

F30 GAMMA GAMMA 0~3 0

F31 TRAP(TV) TRAP-FINE 0~3 2

F32 TRAP(AV) TRAP-FINE 0~3 2

F33 H-FREE H-FREE 0/1 0

F34 1W(TV) V.WINDOW 0/1 0

F35 1W(AV) V.WINDOW 0/1 0

F36 YLPF YSW-LPF 0/1 1

F37 BS-D BS-DISCHARGE 0~3 0

F38 BS-C BS-CHARGE 0~3 0

F39 SL(TV) S-SLICE DOWN 0~3 0

F40 SL(AV) S-SLICE DOWN 0~3 0

F41 SL(SAV) S-SLICE DOWN 0~3 0

F42 SL(YUV) S-SLICE DOWN 0~3 0

F43 AFC2 AFC2-G 0/1 0

F44 VD(TV) VSYNC-DET 0/1 0

F45 VD(AV) VSYNC-DET 0/1 0

F46 AS(TV) AUTO-SLICE 0/1 0

F47 AS(AV) AUTO-SLICE 0/1 0

F48 AS(SAV) AUTO-SLICE 0/1 0

F49 AS(YUV) AUTO-SLICE 0/1 0

F50 FBP(TV) FBP VTH 0/1 0

F51 FBP(AV) FBP VTH 0/1 0

F52 FBP(SAV) FBP VTH 0/1 0

F53 FBP(YUV) FBP VTH 0/1 0

F54 C.CLIP LEVEL C.CLIP LEVEL 0/1 0

F55 PSW PSW 0/1 0

F56 FAO-VOL VOL 0~63 60

20F650

15

Page 16

20F650

Second Stage

Data Service Mode Function Range Default Data

F57 CP CHARGE PUMP 0/1 0

F58 CC LEVEL CC LEVEL 0/1 0

F59 OSD POS OSD POS 0/1 0

F60 OFFSET-ADJ-COL COLOR -32~+32 0

F61 OFFSET-ADJ-TINT TINT -32~+32 0

F62 OFFSET-ADJ-TINT-YUV BASEBAND-TINT -32~+32 0

F63 WAIT MD TIMER SLOW MODE 0/1 1

F64 R-CUT-YUV R-CUT(OFFSET) -63~+63 0

F65 G-CUT-YUV G-CUT(OFFSET) -63~+63 0

F66 B-CUT-YUV B-CUT(OFFSET) -63~+63 0

F67 R-DRI-YUV R-DRI(OFFSET) -63~+63 0

F68 B-DRI-YUV B-DRI(OFFSET) -63~+63 0

F69 CONTRAST OFFSET CONTRAST(OFFSET) -63~+63 0

F70 BRIGHTNESS OFFSET BRIGHT(OFFSET) -63~+63 0

F71 AV2 BRIGHTNESS OFFSET BRIGHT(OFFSET) -15~+15 7

Third Stage

Data OPTION FUNCTION DATA = "0" DATA ="1" Default Data

001 DEMO DEMO DISABLE ENABLE 1

002 DOWNLOAD V-CHIP OP DISABLE ENABLE 1

003 V-CHIP V-CHIP DISABLE ENABLE 1

004 SPEAKER SPEAKER DISABLE ENABLE 1

005 F AO F AO DISABLE ENABLE 1

006 P.PREF P.REF DISABLE ENABLE 1

007 UNIV+ UNIV+ DISABLE ENABLE 1

008 VIEW TIMER VIEW TIMER DISABLE ENABLE 1

009 EZ-SETUP EZ-SETUP AUTO PRESET 0

010 * PON-CH POWER-ON DISABLE ENABLE 0

011 FAV-COL FAV-COL COL-TEMP 1

012 COMPONENT COMPONENT DISABLE ENABLE 1

013 AV AV DISABLE ENABLE 1

014 AV2 AV1 AV2 1

015 MTS MTS DISABLE ENABLE 1

016 TONE-CTRL S-ADJ DISABLE ENABLE 1

017 AUTO-OFF AUTO-OFF DISABLE ENABLE 1

018 INIT-LANG ENGLISH SPANISH 0

019 SETUP-FLAG NO SET UP AUTO SET UP 1

020 AV-FR

021 AV3/S-IN AV3/S-IN DISABLE ENABLE 0

022 COMB COMB DISABLE ENABLE 0

023 AUTO-INPUT AUTO-INPUT DISABLE ENABLE 1

024 CLOCK CLOCK DISABLE ENABLE 0

025 LED SEMEX MODEL SPC MODEL 0

026 FLAT FLA T DISABLE ENABLE 1

027 BASS BOOST BASS BOOST DISABLE ENABLE 0

028 DSE DSE DISABLE ENABLE 0

029 SRS SRS DISABLE ENABLE 0

030 WHITE-OUT WHITE-OUT DISABLE ENABLE 0

(Continued)

"0"=NO AV "1"=REAR "2"=FRONT "3"=REAR & FRONT

3

*

*POWER ON BY CH-UP/CH-DOWN KEY

16

Page 17

BUS SET UP

20F650

TINT-OF

B-D(R) B-D(B)

B-D(R2)

–

–

–

C-OF

AS(AV) FAO-VOL CP

17-2

B-C-YUV AV2 Brightness

G-C-YUV

REFER AS BELOW STEP RANGE REFER AS BELOW

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

CONTROL

PRE-ADJUST

REQUIREMENT

–

–

20F650

CONTENT

INPUT

CONDITION

–

V05 F15 F16 F19 F21 F23 F24 F25 F26 F27 F28

SHARP Y-DL(TV) Y-DL(AV) TINT-AV COL-AV R-D(R2) R-D(R) R-D(B)

DATA SETUP FOR FIRST AND SECOND STAGE SERVICE DATA

OSD CHECKING

FUNCTION

OUTPUT

20F650 50 5 2 -7 4 +8 +3 -2 -18 -8 +6

DEF

DATA SETUP FOR FIRST AND SECOND STAGE SERVICE DATA

GAMMA 1W(AV) SL(TV) SL(AV) VD(TV) AS(TV)

F30 F35 F39 F40 F44 F46 F47 F56 F57 F60 F61

20F650 1 1 1 1 1 1 1 58 1 +10 +8

FUNCTION

ADJUSTMENT

PROCEDURE

F62 F66 F67 F71

TI-YUV

20F650 -12 +36 +2 0

FUNCTION

LED FLAT BASS DSE SRS WHITE

CLOCK

DEF

SYMBOL REVISED CONTENT,

HISTORY

OF REVISION

OPTION SET UP

REFER AS BELOW STEP RANGE REFER AS BELOW

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

CONTROL

PRE-ADJUST

REQUIREMENT

20F650

CONTENT

INPUT

CONDITION

001 002 003 004 005 006 007 008 009 010

DEMO DOWNLOAD V-CHIP SP FAO P.PREF UNIV+ VIEW EZ PON-CH

FUNCTION

BUS OPTION FOR THIRD STAGE SERVICE DATA

OSD CHECKING

OUTPUT

17-1

011 012 013 014 015 016 017 018 019 020

009 → “0”=EZ-SETUP “1”=AUTO PRESET

FAV-COL COMP AV AV2 MTS TONE AUTO LAN SETUP AV-FR

DEF “0”=DISABLE “1”=ENABLE

20F650 1 1 1 1 1 1 1 1 0 0

ADJUSTMENT

FUNCTION

BUS OPTION FOR THIRD STAGE SERVICE DATA

PROCEDURE

20F650 1 1 1 1 1 1 1 0 1 3

AV3 COMB A-IN

021 022 023 024 025 026 027 028 029 030

FUNCTION

20F650 0 0 1 0 0 1 0 0 0 0

018 → “0”=ENGLISH “1”=SPANISH

019 → “0”=NO SET UP “1”=AUTO SETUP

025 → “0”=SEMEX SPEC “1”=SPC SPEC

DEF 011 → ”0”=FAV-COL “1”=COL-TEMP

SYMBOL REVISED CONTENT,

HISTORY

OF REVISION

17

Page 18

20F650

AB

V-SIZE

18-2

V09 STEP RANGE 0~63

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

H-POSITION

C CONTROL

2

I

OPTION SET UP, BUS SET UP, CRT PURITY, V-PHASE, +B ADJUST

CONTROL

PRE-ADJUST

REQUIREMENT

US 4 CH LION HEAD

AC120V

CONFIRMATION BY CRT SCREEN

ADJUST THE V09 BUS DATA UNTILL THE OVERSCAN BECOME AS

CONTENT

INPUT

CONDITION

OUTPUT

SPECIFIED BELOW.

CAUTION: - PLEASE AGING TV MORE THAN 10 MINUTES BEFORE

ADJUSTMENT.

ADJUSTMENT

PROCEDURE

[CHECKING SPEC]

OVERSCAN 10 ± 2.5%

SYMBOL REVISED CONTENT,

HISTORY

OF REVISION

18-1

V07 STEP RANGE 0-31

SPEC OF A=B.

1. ADJUST THE V07 BUS DATA TO HAVE A BALANCE POSITION TO

2. IF CANNOT MAKE IT T O A=B, ADJ FROM THE BEST POINT SO THAT

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

C BUS CONTROL

2

I

OPTION SET UP, BUS SET UP , CRT-PURITY

US 4 CH LION HEAD (MONOSCOPE)

PRE-ADJUST

CONTROL

CONTENT

REQUIREMENT

AC 120V, US MAGNETIC FIELD

CONFIRMATION BY CRT SCREEN

INPUT

CONDITION

OUTPUT

B SLIDELY SMALLER THAN A

[CHECKING SPEC]

ADJUSTMENT

PROCEDURE

LEFT AND RIGHT SYMMETRICAL

SYMBOL REVISED CONTENT,

HISTORY

OF REVISION

18

Page 19

CLOSED CAPTION SET UP

A

B

TEXT BOX BLK

V18 STEP RANGE 0~255

20F650

19-2

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

V-PHASE

C CONTROL

2

I

OPTION SET UP, BUS SET UP

CONTROL

PRE-ADJUST

REQUIREMENT

US 4 CH LION HEAD

AC 120V

CONFIRMATION ON CRT DISPLAY.

1) BY SELECTING THE V18, BOX BLK TEXT WILL BE APPEARED.

CONTENT

INPUT

CONDITION

OUTPUT

SPEC OF A=B.

2) ADJUST THE V18 BUS DATA TO HAVE A BALANCE POSITION TO

ADJUSTMENT

PROCEDURE

[CHECKING SPEC]

LEFT AND RIGHT SYMMETRICAL

SYMBOL REVISED CONTENT,

HISTORY

OF REVISION

19-1

V06 STEP RANGE 0-7

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

C CONTROL

2

I

OPTION SET UP, BUS SET UP , CRT-PURITY

PRE-ADJUST

CONTROL

REQUIREMENT

US 4 CH LION HEAD (MONOSCOPE PATTERN)

120V, RF INPUT, ZERO MAGNETIC FIELD

CONFIRMATION ON CRT SCREEN

CONTENT

INPUT

CONDITION

OUTPUT

ADJUST V06 BUS DATA TO HAVE MOST ACCEPTABLE VERTICAL PO-

SITION.

THE MONOSCOPE PATTERN SHOULD BE BALANCE IN VERTICAL

POSITION

NOTE: THE DATA FOR V06 LIMIT AT <= 04, EVEN POSITION GOOD

ENOUGH

ADJUSTMENT

PROCEDURE

19

[CHECKING CONFIRMATION]

SYMBOL REVISED CONTENT,

HISTORY

OF REVISION

Page 20

20F650

PIF-VCO

20-2

V10 STEP RANGE 0~63

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

H-VCO

C CONTROL

2

I

OPTION SET UP, BUS SET UP

CONTROL

PRE-ADJUST

REQUIREMENT

SCREEN

(AT SELF ADJUSTMENT MODE)

1) GO INTO SERVICE MODE, BY SELECTING THE SERVICE DATA V10

2) PRESS THE R/C FOR AUTO PIF-VCO KEY, OSD APPEAR “OK” AT

NO SIGNAL (RASTER) CONDITION

AC 120V

CONFIRMATION ON CRT DISPLA Y (AUTO), IC801 PIN 2 VOLT AGE (MANUAL).

CONTENT

INPUT

CONDITION

OUTPUT

3) IF APPEAR “NG” PLS REPEAT STEP2

AS SPECIFIED BELOW

(AT MANUAL ADJUSTMENT MODE)

1) GO INTO SERVICE MODE, BY SELECTING THE SERVICE DATA V10

2) ADJUST THE DAT A UP/DOWN UNTIL IC801 PIN 2 VOL T AGE BECOME

ADJUSTMENT

PROCEDURE

[CHECKING SPEC]

2.5 ± 0.5 V DC (CHECKING SPEC : 2.50 ± 1.5V)

SYMBOL REVISED CONTENT,

HISTORY

OF REVISION

20-1

V21 STEP RANGE 0-7

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

C CONTROL

2

I

OPTION SET UP, BUS SET UP

PRE-ADJUST

CONTROL

REQUIREMENT

NO SIGNAL (RASTER) CONDITION

AC 120V

IC 801 PIN 11

(MANUAL ADJ)

1) GO TO SERVICE MODE,

2) GO TO SERVICE DATA V21, ADJ UNTIL FREQ AS BELOW

(SELF ADJ)

CONTENT

INPUT

CONDITION

OUTPUT

1) GO TO SERVICE MODE,BY SELECTING THE SERVICE DATA V21

2) PRESS THE R/C TO OPERATE AUTO H-VCO,OSD APPEAR "OK" AT

20

SCREEN

3) IF APPEAR "NG" PLS REPEAT STEP2

ADJUSTMENT

PROCEDURE

0.2 KHz

±

[CHECKING SPEC]

FREQ = 15.735

SYMBOL REVISED CONTENT,

HISTORY

OF REVISION

Page 21

SCREEN

20F650

21-2

V11,V12,V13 STEP RANGE 0-255

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

RF-AGC

C CONTROL

2

I

OPTION SET UP, BUS SET UP

CONTROL

PRE-ADJUST

REQUIREMENT

64, GET IN Y-MUTE BY R/C AND SET V19 TO “1”, PICTURE APPEAR

IN CUT-OFF CONDITION

WINDOW P ATTERN OR US4CH LION HEAD

CONTENT

CONFIRMATION ON CRT DISPLAY

120V

INPUT

CONDITION

OUTPUT

V (FIX)

µ

1) IN SERVICE MODE, SET V04&V11&V12&V13 TO 127; V14&V15 TO

2) ADJUST THE SCREEN SO THAT CUT-OFF LINE APPEAR IN LOW

BRIGHT , THEN JUDGE THAT WHETHER THE CUT-OFF LINE APPEAR

IN RED OR GREEN OR BLUE COLOR, IN THIS CONDITION V11=R-

CUTOFF, V12=G-CUTOFF, V13=B-CUT-OFF, FIX THE DATA OF THE

COLOR APPEAR IN CUTOFF LINE AND USE R/C TO ADJUST THE

OTHER TWO CUT-OFF DATA SO THAT CUT-OFF LINE COLOR BE-

COME WHITE.

3) TURN THE SCREEN VR OF FBT SO THAT CUT-OFF LINE JUST DIS-

ADJUSTMENT

APPEAR AND USE R/C TO SET V19 TO “0”, NEXT DISABLE THE Y-

MUTE SO THAT PICTURE APPEAR IN NORMAL MODE.

PROCEDURE

[VOLTAGE CONFIRMATION]

SYMBOL REVISED CONTENT,

HISTORY

OF REVISION

21-1

V08 STEP RANGE 0-127

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

C CONTROL

2

I

OPTION SET UP, BUS SET UP

PRE-ADJUST

CONTROL

REQUIREMENT

(AT SELF ADJUSTMENT MODE)

1. GO TO SERVICE MODE

US10CH HALF COLOR BAR

RF INPUT

FIELD STRENGTH 56dB

TUNER AGC TERMINAL (TP 201) OR CRT DISPLAY CONFIRMATION

CONTENT

INPUT

CONDITION

OUTPUT

2. GO TO SERVICE DATA V08, PRESS R/C TO OPEARATE AUTO-AGC

KEY AND CONFIRM THE OK DISPLAY ON THE SCREEN.

3. IF APPEAR NG PLS REPEAT STEP 2 AGAIN.

(AT MANUAL ADJUSTMENT MODE)

COME MAXIMUM, THEN DROP 0.1V BELOW MAXIMUM VOLTAGE.

1. ADJUST THE V08 BUS DATA UNTIL AGC TERMINAL VOLTAGE BE-

2. CHANGE THE ANTENNA INPUT SIGNAL TO 63-67 dBµV, AND MAKE

21

SURE THERE IS NO NOISE

THAT THERE IS NO CROSS MODULA TION BEAT.

3. CHANGE THE ANTENNA INPUT SIGNAL T O 90-95 dBµV TO BE SURE

ADJUSTMENT

PROCEDURE

[VOLTAGE CONFIRMATION]

MAX - 0.1V dc

SYMBOL REVISED CONTENT,

HISTORY

OF REVISION

Page 22

20F650

BLACK

US14

WHITE

BLACK

US14

SUB-BRIGHT

22-2

V04 STEP RANGE 0-255

C CONTROL

2

I

ADJUSTMENT

ITEM

CONTROL

ADJUSTMENT

POSITION

WHITE BALANCE

OPTION SET UP, BUS SET UP, SCREEN, WHITE BALANCE

WINDOW PATTERN

120V

CRT SCREEN DISPLAY.

1) LET THE GUN POINT AT BLACK POSITION (AS A TTACH DRAWING),

PRE-ADJUST

CONTENT

REQUIREMENT

INPUT

CONDITION

OUTPUT

ADJUST V04 BUS DATA UNTIL BRIGHTNESS Y=0.5 cd/m2, THEN

STEP DOWN MORE 4 STEP

ADJUSTMENT

PROCEDURE

[VOLTAGE CONFIRMATION]

BRIGHTNESS Y=0.5 cd/m2, THEN STEP DOWN MORE 4 STEP

SYMBOL REVISED CONTENT ,

HISTORY

OF REVISION

22-1

V14,V15,V1 1,V12,V13 STEP RANGE 0-127, 0~255

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

C BUS CONTROL

2

I

OPTION SET UP, BUS SET UP, SCREEN

23CH 501RE WINDOW PATTERN

PRE-ADJUST

CONTROL

CONTENT

REQUIREMENT

120V

CRT SCREEN DISPLAY.

INPUT

CONDITION

OUTPUT

ATTACH), ADJ V04 UNTIL BRIGHTNESS Y BECOME 5 cd/m2, THEN

LET THE GUN POINT AT WHITE POSITION (AS DRA WING ATT ACH),

FIRST LET THE GUN POINT AT BLACK POSITION (AS DRAWING

1) WHITE (HIGH BEAM)

ADJUST V01 UNTIL BRIGHTNESS Y BECOME 150 cd/m2, ADJUST

THE BUS DATA OF V14 (R DRIVE), V15(B DRIVE) UNTIL THE AXIS

OF COLOR TEMPERATURE BECOME X=0.273, Y=0.280

22

AWAY FROM THE DATA ADJUSTED IN STEP 1), ADJUST AGAIN THE

TWO SERVICE DATA WHICH HAVE CHOSEN AT SCREEN ADJUST

LET THE GUN POINT A T BLACK POSITION, IF THE V ALUE SHIFTED

2) BLACK (LOW BEAM)

ADJUSTMENT

SO THAT TO OBTAIN THE SIMILAR AXIS AS ABOVE.

THIS ADJUSTMENT .

*WARNING: DO NOT DISTURB THE MINI STEP GUN DATA DURING

**REPEAT STEP 1), 2) TO GET A REGULATED POSITION.

PROCEDURE

[CHECKING CONFIRMATION]

X=0.273, Y=0.280 (11,600°K + 1 MPCD)

SYMBOL REVISED CONTENT,

HISTORY

OF REVISION

Page 23

US14

WHITE

SUB-TINT

V02 STEP RANGE 0-127

B-AMP BASE (TP853)

MUST BE IN STEPPING

LEVEL

20F650

23-2

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

SUB-PICTURE

C CONTROL

2

I

OPTION SET UP, BUS SET UP, VCO ADJ, RF-AGC

CONTROL

PRE-ADJUST

REQUIREMENT

US 10 CH HALF COLOR BAR PATTERN

120V

CONTENT

INPUT

CONDITION

B-AMP TR BASE (TP853)

CONFIRRM WITH OSCILLOSCOPE

1) GET IN Y-MUTE FUNCTION BY R/C.

2) ADJUST THE V02 BUS DATA TO GET A WAVEFORM AS BELOW.

3) DISABLE THE Y -MUTE

**PLS T AKE NOTE THA T SER VICE MODE DATA F61 NEED TO SET +8

OUTPUT

ADJUSTMENT

PROCEDURE

[CONFIRMATION]

SYMBOL REVISED CONTENT,

HISTORY

OF REVISION

23-1

ADJUSTMENT

ITEM

V01 STEP RANGE 0-127

C BUS CONTROL

2

I

PRE-ADJUST

CONTROL

ADJUSTMENT

POSITION

THE SPEC

ADJUST V01 BUS DATA UNTIL BRIGHTNESS Y=150 cd/m2.

1) LET THE GUN POINT AT WHITE POSITION (AS A TTACH DRAWING),

OPTION SET UP, BUS SET UP , SCREEN, WHITE BALANCE, SUB-BRIGHTNESS

WINDOW PATTERN

120V

CRT SCREEN DISPLAY.

CONTENT

REQUIREMENT

INPUT

CONDITION

OUTPUT

NOTE: ALLOWABLE DATA FOR V01 IS >= 90, EVEN Y CAN’T MATCH

23

ADJUSTMENT

PROCEDURE

[VOLTAGER CONFIRMATION]

BRIGHTNESS Y=150 cd/m2

SYMBOL REVISED CONTENT,

HISTORY

OF REVISION

Page 24

20F650

100% WHITE

WY RBMg

Cy G

X-RAY PROTECTION OPERATING CONFIRMATION

–

24-2

1.1V DC 25.5V

– STEP RANGE –

TP VOLTAGE OPERATION VOLTAGE

±

19.8

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

SUB-COLOR

AFTER ALL ADJUSTMENT FINISHED.

CONTROL

PRE-ADJUST

REQUIREMENT

US 4 CH LION HEAD (MONOSCOPE PATTERN)

AC 120V, RF INPUT

CONTENT

INPUT

CONDITION

CONFIRMATION BY THE CRT

SET THE USER CONTROL TO SHIPMENT POSITION.

OUTPUT

[VOLTAGE CONFIRMATION]

CHECK THE VOL TAGE OF P603 PIN 3 AS SPECIFIED BELOW.

[OPERATION CONFIRMATION]

SUPPLY THE DC VOLTAGE TO P603 PIN 3 AND MAKE SURE THE PRO-

TECTOR IS FUNCTIONED.

HORIZONTAL OSCILATION STOP AND PICTURE DISAPPEAR.

[RECOVER INFORMATION]

PULL OUT THE AC CORD.

[CAUTION]

ADJUSTMENT

PROCEDURE

FROM THE RECOVER CONFIRMATION MENTIONED ABOVE, THE AC

CODE MUST BE PULLED OUT AT LEAST 4 SECOND BEFORE PLUG-

GING IN AGAIN.(IN ORDER TO MAKE SURE THE µ-COM HAS BEEN

RESET.)

[VOLTAGE CONFIRMATION]

SYMBOL REVISED CONTENT,

HISTORY

OF REVISION

24-1

V03 STEP RANGE 0-127

C BUS CONTROL

2

I

OPTION SET UP, BUS SET UP, VCO ADJ, RF-AGC, SUB-PICT, SUB-TNT

US 10 CH HALF COLOR BAR PATTERN

120V

R-AMP TR BASE (TP851)

CONFIRRM WITH OSCILLOSCOPE

ADJUSTMENT

ITEM

CONTROL

ADJUSTMENT

POSITION

PRE-ADJUST

CONTENT

REQUIREMENT

INPUT

CONDITION

OUTPUT

OF COLOR BAR BEAT AT THE SAME LEVEL

1) SET THE V03 BUS DATA TO GET A WAVEFORM AS BELOW

2) THIS WAVEFORM SHOWS THAT THE 75% WHITE & RED PORTIONS

*PLEASE T AKE NOTE THAT SERVICE DATA F60 MUST SET TO +10

24

ADJUSTMENT

PROCEDURE

[CHECKING CONFIRMATION]

SYMBOL REVISED CONTENT,

HISTORY

OF REVISION

Page 25

MS LEVEL ADJUSTMENT

M01 STEP RANGE 0~15

20F650

25-2

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

HIGH VOLTAGE

C BUS CONTROL

2

I

OPTION SET UP, BUS SET UP, VCO ADJ, RF-AGC

MONORAL SIGNAL (400HZ 100% MODULATION)

CONTROL

PRE-ADJUST

CONTENT

REQUIREMENT

–

AC 120V, RF INPUT

IC 3001 39 PIN

INPUT

CONDITION

OUTPUT

COME AS SPECIFIED BELOW.

1) SET THE SOUND VOLUME CONTROL MORE THAN 1.

2) ADJUST BUS DATA OF M01 UNTIL THE VOLTAGE OF 39 PIN BE-

ADJUSTMENT

PROCEDURE

[CHECKING SPEC]

490 ± 10mVrms (CHECKING SPEC :490 ± 20mVrms)

SYMBOL REVISED CONTENT,

HISTORY

OF REVISION

25-1

– STEP RANGE –

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

AFTER ALL ADJUSTMENT FINISHED.

CONTROL

PRE-ADJUST

REQUIREMENT

US 4 CH LION HEAD (MONOSCOPE PATTERN)

AC 120V, RF INPUT

CONTENT

INPUT

CONDITION

HIGH VOLTAGE

CRT ANODE VOLTAGE

SET THE USER CONTROL TO SHIPMENT SETTING POSITION. PUSH

ON Y -MUTE BY R/C CONFIRM THE VOLTAGE OF CRT ANODE BY HIGH

VOLTAGE METER AND MAKE SURE THE READING IS AS BELOW.

OUTPUT

BELOW 30kV

25

ADJUSTMENT

PROCEDURE

[CAUTION POINT]

USE ELECTROSTATIC HI-VOLTAGE METER AND FOLLOW THE UL/

DHHS STANDARD TO MAKE CORRECTION AND CONTROL.

SYMBOL REVISED CONTENT,

HISTORY

OF REVISION

Page 26

20F650

V-CHIP

26-2

— STEP RANGE —

—

AFTER ALL ADJUSTMENT FINISHED.

ADJUSTMENT

ITEM

SEPARTION ADJUSTMENT

CONTROL

ADJUSTMENT

POSITION

PRE-ADJUST

UHF 15 CH (V-CHIP TRANSMISION SIGNAL CH)

AC 120V, RF INPUT

CONTENT

REQUIREMENT

INPUT

CONDITION

1) RECEIVE THE UHF 15 CH.

CONFIRMATION BY THE CRT.

OUTPUT

V-CHIP RATING DISPLAY IS EQUAVALENCE TO TRANSMISSION

2) PUSH THE DISPLAY KEY (R/C), MAKE SURE THAT THE OSD.

RATING.

ADJUSTMENT

PROCEDURE

[VOLTAGE COMFIRMATION]

SYMBOL REVISED CONTENT,

HISTORY

OF REVISION

26-1

M04, M05 STEP RANGE 0~63

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

C BUS CONTROL

2

I

OPTION SET UP, BUS SET UP, VCO ADJ, RF-AGC, MS-LEVEL, MTS-VCO, FILTER

STEREO SIGNAL SIGNAL 1,: MODULATION 30%, L-CH ONLY, NR-ON, 300Hz

SIGNAL 2,: MODULATION 30%, L-CH ONLY, NR-ON, 3kHz

CONTROL

PRE-ADJUST

CONTENT

REQUIREMENT

RF INPUT

IC 3001 39 PIN

INPUT

CONDITION

OUTPUT

BECOME MINIMUM LEVEL.

AGE OF 39 PIN BECOME MINIMUM LEVEL.

1) INPUT SIGNAL 1, ADJUST BUS DATA OF M04 UNTIL THE OF 39 PIN

2) INPUT SIGNAL 2, ADJUST BUS DATA OF M05 UNTIL THE AC VOLT-

3) REPEAT STEP 1) AND 2).

SET THE SOUND VOLUME TO MAXIMUM THEN MAKE SURE THE

26

READING FROM THE SPEAKER TERMINAL MUST BE OVER THE SPEC

AS SPECIFIED BELOW.

ADJUSTMENT

PROCEDURE

[CHECKING SPEC]

SYMBOL REVISED CONTENT,

OVER 25 dB (CHECKING SPEC : OVER 20 dB)

HISTORY

OF REVISION

Page 27

20F650

27-2

TRI-VISION

— STEP RANGE —

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

—

AFTER ALL ADJUSTMENT FINISHED.

PRE-ADJUST

CONTROL

REQUIREMENT

RA TING AND NAME.

(DOWNLOADING CONFIRMATION)

1) RECEIVE THE DOWNLOAD A SIGNAL.

2) SELECT V-CHIP CONTROL MENU THEN ON THE DOWNLOAD.

3) UNPLUG THE AC THEN PLUG AGAIN.

RATING SYS. DOWNLOAD SIGNAL A/B (PRCC SIG) INCLUDED SIGNAL.

AC 120V, RF INPUT

CONFIRMATION BY THE CRT SCREEN

CONTENT

INPUT

CONDITION

OUTPUT

4) BACK TO V-CHIP CONTROL MENU, CHECK THE DOWNLOADED

(UPLOADING CONFIRMATION)

1) RECEIVE THE D

27

ADJUSTMENT

PROCEDURE

[COMFIRMATION]

SYMBOL REVISED CONTENT,

HISTORY

OF REVISION

27-1

Page 28

20F650

H

G

F

CHASSIS LAYOUT

E

D

C

B

A

654321

28

Page 29

654321

A

B

C

D

E

F

G

H

20F650

CRT BLOCK DIAGRAM

29

Page 30

20F650

MAIN BLOCK DIAGRAM

J

I

H

G

F

E

D

C

B

A

12345678910

30

Page 31

20F650

10 11 12 13 14 15 16 17 18 19

31

Page 32

20F650

MTS BLOCK DIAGRAM

J

I

H

G

F

E

D

C

B

A

12345678910

32

Page 33

WAVEFORMS

20F650

33

Page 34

20F650

DESCRIPTION OF SCHEMATIC DIAGRAM

NOTES:

1. The unit of resistance "ohm" is omitted.

(K=kΩ=1000Ω, M=MΩ)

2. All resistors are 1/16 watt, unless otherwise noted.

3. All capacitors are µF, unless otherwise noted.

µµ

(P=pF=

4. (G) indicates ±2% tolerance may be used.

indicates line isolated ground.

5.

VOLTAGE MEASUREMENT CONDITIONS:

1. All DC voltages are measured with DVM connected

between points indicated and chassis ground, line

voltage set at 120V AC and all controls set for normal

picture unless otherwise indicated.

2. All voltages measured with 1000

signal.

F)

µ

V B & W or Color

WAVEFORM MEASUREMENT CONDITIONS:

1.

Photographs taken on a standard gated color bar

signal, the tint setting adjusted for proper color. The

wave shapes at the red, green and blue cathodes of

the picture tube depend on the tint, color level and

picture control.

2.

indicates waveform check points (See chart,

waveforms are measured from point indicated to

chassis ground.)

å

AND SHADED ( ) COMPONENTS

= SAFETY RELATED PARTS.

ç

MARK= X-RAY RELATED PARTS.

å

DRGANNES MARQUES

PIECES RELATIVES A LA SECURITE.

MARQUE ç : PIECS RELATIVE AUX RAYONS X.

This circuit diagram is a standard one, printed circuits

may be subject to change for product improvement

without prior notice.

ET HACHRES ( ):

34

Page 35

654321

A

B

C

D

E

F

G

H

20F650

SCHEMATIC DIAGRAM: CRT Unit

35

Page 36

20F650

SCHEMATIC DIAGRAM: MAIN Unit

J

I

H

G

F

E

D

C

B

A

12345678910

36

Page 37

20F650

10 11 12 13 14 15 16 17 18 19

37

Page 38

20F650

H

G

F

SCHEMATIC DIAGRAM: MTS Unit

E

D

C

B

A

654321

38

Page 39

654321

A

B

C

D

E

F

G

H

20F650

PRINTED WIRING BOARD ASSEMBLIES

PWB-B: CRT Unit (Wiring Side)

39

Page 40

20F650

H

G

F

E

D

C

B

PWB-A: MAIN Unit (Wiring Side)

A

654321

40

Page 41

654321

A

B

C

D

E

F

G

H

20F650

RJ15

Z1 A1

RJ8

FDC2

Z

3

R62

R61

7

4

R613

RJ14

7

R102

RJ16

R1024

RJ1

7

C101

6

1

RJ3

RJ32

R62

6

R62

R61

3

8

R100

R1008

6

R431

R43

2

IC402

C43

9

R100

9

R1003

R1007

R303

R709

R71

4

R1081

Q702

Q701

R70

7

RJ3

R1040

2

R66

RJ30

Q604

R528

0

R52

C519

C518

R504

RJ9

R43

8

RJ21RJ6

R1002

4

R31

R315

C313

R305

8

C30

R307

R308

R1802

R801

Q80

1

2

R1043

4

C100

RJ10R107

IC100

3

2

RJ1

RJ18C1015

R437

3

IC40

R84

6

1

C40

RJ19

C436

IC401

3

Q80

RJ2

R377

R353

R372

R374

R462

R378

R363

R458

C453R362

R461

R108

3

2

Q107

R1079

Q1070

Q1073

R1895

R189

6

D80

1

3

C808

D810

R840R84

R804

C809

D81

R1851

1

R1852

D812R805

R806

R1853

C810

RJ29

7

R80

C814

R1063

R84

2

Q804

7

R81

C100

9

C1011

C1013

R1064

R1065

C1855

R1066

R1074

R103

2

7

R1098R109

R373

IC30

5

R366

R36

5

R433

R1056

Q1002

R108

5

R1078

R108

7

R1849

R82

7

Q805

R821

0

1

R83

C84

R835RJ26

5

R839

C846

8

R82

4

C80

FDC3

R802

2

C80

C806R185

R803

IC80

1

R847

R1062

C81

C815

6

2

C819

R81

R816

R814

R832

5

R81

C823

C826

C757C821

R1061

C1008

D1086

5

R105

R1048

R1047

D108

D1085

9

IC100

1

R1059

R1096

4

R104

R1037

R1076

R1036

R1033

R1034

R1091

R1090

R1038

C186

C1862R1046

4

R1867R1049

R1041

C186

C1863

C205

R1861

R435

R186

2

R434

R384

3

R38

R3006

IC300

2

C3081

4

C83

3

R83

C847RJ

9

C841

C1867

C836

5

R84

C832

R853C853

C833

C831

R844

C830

C828

R185

4

C185

6

R1077

R301

Q1001

R1039

RJ1

1

RJ

5

R21

3

IC100

7

Q202

6

1

R206

Q20

R20

R205

C20

C20

9

8

9

7

R212

C212C189

C213R20

RJ2

7

D20

RJ28

C203

1

R20

R202

1

B

R38

R382

1

FDC1

RJ24

R3009

RJ2

3

RJ1

3

RJ2

5

R44

1

RJ2

0

R439

0

R22

1

C208

0

7

R20

R44

RJ2

C21

0

2

R210

RJ7

R211

R830

2

2

Z

A2

RJ1

PWB-A: MAIN Unit (Chip Parts Side)

41

Page 42

20F650

H

G

F

E

PWB-C: MTS Unit (Wiring Side)

D

C30 43

R3035

R30 30

Q3001

R3028

R3027

Q30 05

R3031

R3032

C

R3018

R3016

B

R3015R3033

R3085

R3083

Q3007

R3017R3036

Q3006

R30 84

R30 82

Q30 02

C3042

R3019

Q3004

R30 29

R3034

R3026

R30 14R3021

R3011

C3036

R3007

R3025

R3005

C3008

C3013

R3008

IC3001

R3012

R3003

C3002

C3035

R3013

R3010

RJ101

R30 04

R3001

C30 31

C30 32

C30 28

C3033C3026

C3025

C3024

C3023

R3002

C3027

A

PWB-C: MTS Unit (Chip Parts Side)

654321

42

Page 43

20F650

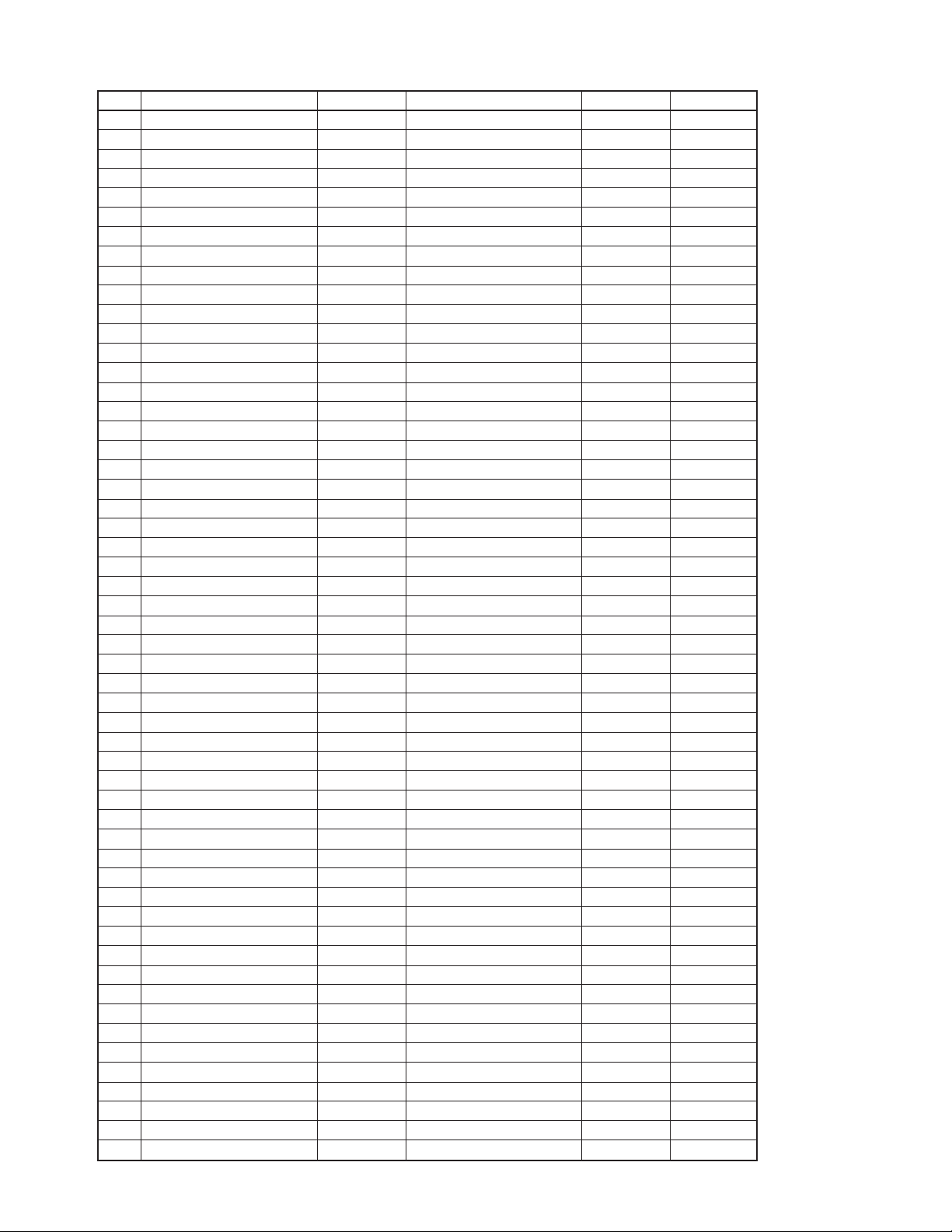

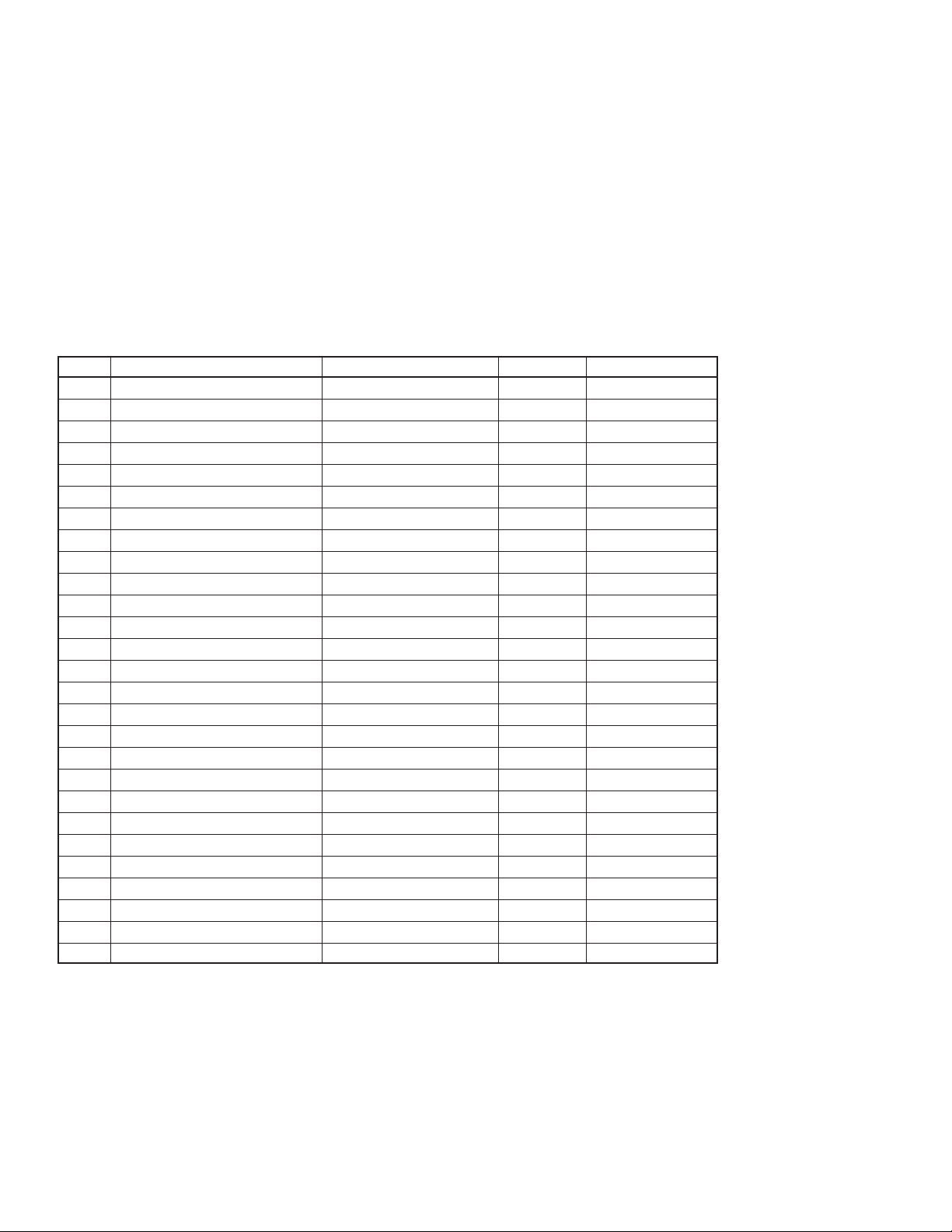

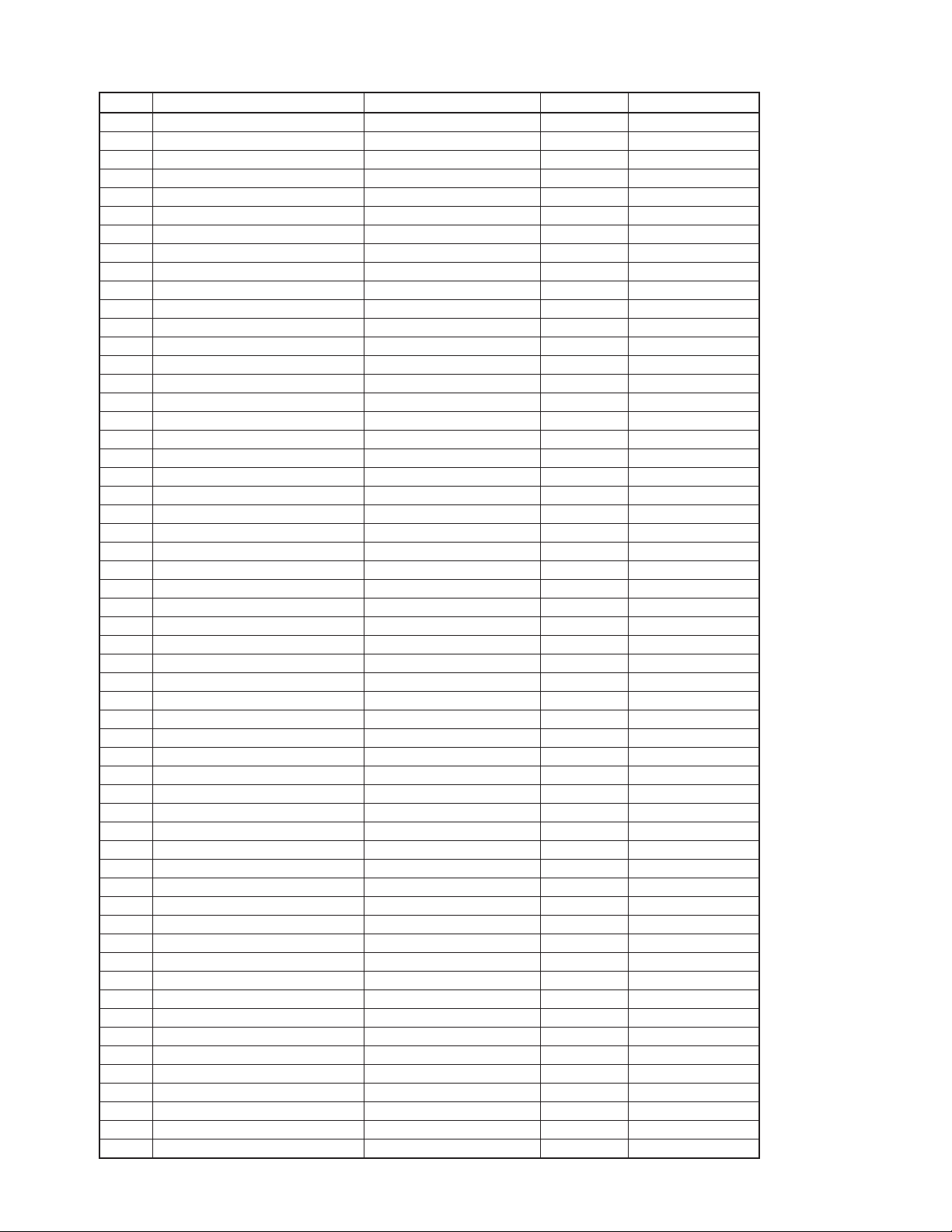

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

REPLACEMENT PARTS LIST

PARTS REPLACEMENT

Replacement parts which have these special safety characteristics identified in this manual ; electrical components having such features are

identified by å and shaded areas in the Replacement Parts Lists and

Schematic Diagrams. The use of a substitute replacement part which

does no have the same safety characteristic as the factory recommended replacement parts shown in this service manual may create

shock, fire or other hazards.

"HOW TO ORDER REPLACEMENT PARTS"

To have your order filled promptly and correctly, please furnish the following informations.

1. MODEL NUMBER 2. REF. NO.

3. PART NO. 4. DESCRIPTION

in USA: Contact your nearest SHARP Parts Distributor to order. For

location of SHARP Parts Distributor, Please call Toll-Free; 1800-BE-SHARP

★ MARK: SPARE PARTS-DELIVERY SECTION

' MARK: X-RAY RELATED PARTS

Ref. No. Part No. ★ Description Code

PICTURE TUBE

å VB51QDK190X4E X Picture Tube

å L706 RCiLGA032WJZZ X Degaussing Coil AR

QEARCA012WJZZ X Grounding Strap AC

PRINTED WIRING BOARD ASSEMBLIES

(NOT REPLACEMENT ITEM)

LISTE DES PIECES

CHANGE DES PIECES

Les pi`eces de rechange qui pr élelesentent ces caract éleristiques sp

éleciales de s élecurit éle, sont identifi élees dans ce manuel : les pi`eces

élelectriques qui pr élesentent ces particularit éles, sont rep éler élee

par la marque å et sont hachur élees dans les listes de pi`eces et dans

les diagrammes sch élematiques.

La substitution d'une pi`ece de rechange par une autre qui ne pr éLesente

pas les m éoemes caract éLeristiques de s élecurit éle que la pi`ece

recommand élee parl'usine et dans ce manuel de service, peut provoquer

une éLelectrocution, un incendie ou toutautre sinistre.

"COMMENT COMMANDER LES PIECES DE RECHANGE"

Pour que votre commande soit rapidement et correctement remplie,

veuillez fournir les renseignements suivants.

1. NUMERO DU MODELE 2. NO. DE REF

3. NO. DE PIECE 4. DESCRIPTION

in CANADA: Contact SHARP Electronics of Canada Limited

Phone (416) 890-2100

★ MARQUE: SECTION LIVRAISON DES PIECES DERECHANGE

' MARQUE: PIECES RELATIVE AUX RAYONS X

Ref. No. Part No. ★ Description Code

Q701 VS2SD601AR/-1Y X 2SD601AR AB

Q702 VS2SD601AR/-1Y X 2SD601AR AB

Q751 VS2SD468-C/-1+ X 2SD468-C AB

Q752 VS2SD468-C/-1+ X 2SD468-C AB

Q753 VS2SC3198-G-1+ X 2SC3198-G AB

Q754 VS2SD468-C/-1+ X 2SD468-C AB

Q801 VS2SD601AR/-1Y X 2SD601AR AB

Q804 VS2SB709AR/-1Y X 2SB709AR AB

Q805 VS2SD601AR/-1Y X 2SD601AR AB

Q1001 VS2SD601AR/-1Y X 2SD601AR AB

Q1073 VS2SD601AR/-1Y X 2SD601AR AB

PWB-A DUNTKD070WEA0 – MAIN Unit —

PWB-B DUNTKA599WEG3 – CRT Unit —

PWB-C DUNTKC574WEA2 – MTS Unit —

DUNTKD070WEA0

PWB-A MAIN UNIT

TUNER

NOTE: THE PARTS HERES SHOWN ARE SUPPLIED AS AN

ASSEMBLY NOT INDEPENDENTLY.

å TU201 VTUVT1T5UF202 X VHF Tuner AP

INTEGRATED CIRCUITS

IC301 VHiAN17821A-1 X AN17821A AH

IC401 VHiMM1501XN-1Y X MM1501XNRE AC

IC402 VHiMM1501XN-1Y X MM1501XNRE AC

å IC501 VHiAN15525A-1 X AN15525A

IC601 VHiKA78R09AP1 X I.C. AC

å IC701 VHiSTRW6753-1 X I.C. AG

å IC702 RH-FXA003WJZZ X PC123Y82 AB

å IC703 VHiSE125N++-F X SE125N AD

IC801 VHiM61251CF1EQ X I.C. AN

IC1001 RH-iXB301WJZZY X I.C.

IC1003 VHiBR24L16F-1Y X BR24L16F-WE2 AF

TRANSISTORS

Q201 VS2SC2735//1EY X 2SC2735 AB

Q601 VS2SC2235Y/1E+ X 2SC2235Y

Q602 VSTT2140+++-F X TT2140+++ AD

Q603 VS2SC3198-G-1+ X 2SC3198-G AB

Q604 VS2SD601AR/-1Y X 2SD601AR AB

D201 RH-EX0676GEZZY X Zener Diode, 33V AB

DIODES

D203 VHD1SS119//-1Y X 1SS119 AA

D393 RH-DX0247CEZZY X DX0247CE

D502 VRD-RA2BE103JY X 10k 1/8W Carbon AA

D503 RH-EX0612GEZZY X Zener Diode, 5.1V AB

D505 RH-DX0441CEZZY X DX0441CE AB

D510 RH-DX0131CEZZY X DX0131CE AB

D601 VHD1SS119//-1Y X 1SS119 AA

D602 VHD1SS244//-1Y X 1SS244 AB

D603 RH-EX0663GEZZY X Zener Diode, 24V

D606 RH-DX0131CEZZY X DX0131CE AB

å D701 RH-DX0476CEZZ X DX0476CE AC

D702 RH-DX0490CEZZY X DX0490CE AB

D703 VHD1SS119//-1Y X 1SS119 AA

D704 RH-EX0650GEZZY X Zener Diode, 18V AB

D705 RH-DX0066GEZZY X DX0066GE AB

D706 RH-DX0066GEZZY X DX0066GE AB

D707 RH-DX0066GEZZY X DX0066GE AB

D708 RH-EX0621GEZZY X Zener Diode AB

D710 VHD1SS119//-1Y X 1SS119 AA

D711 VHD1SS119//-1Y X 1SS119 AA

D713 RH-EX0606GEZZY X Zener Diode AB

D714 VHD1SS119//-1Y X 1SS119 AA

D716 RH-EX0601GEZZY X Zener Diode AB

D751 RH-DXA006WJZZ X DXA006WJ AB

D752 RH-DX0247CEZZ X DX0247CE

D801 RH-EX1393CEZZY X Zener Diode, 5.1V AB

D802 RH-EX0630GEZZY X Zener Diode, 9.1V AB

D803 VHD1SS119//-1Y X 1SS119 AA

D806 VHD1SS119//-1Y X 1SS119 AA

D810 RH-EX0263TAZZY X Zener Diode, 8.1V AB

D811 RH-EX0263TAZZY X Zener Diode, 8.1V AB

43

Page 44

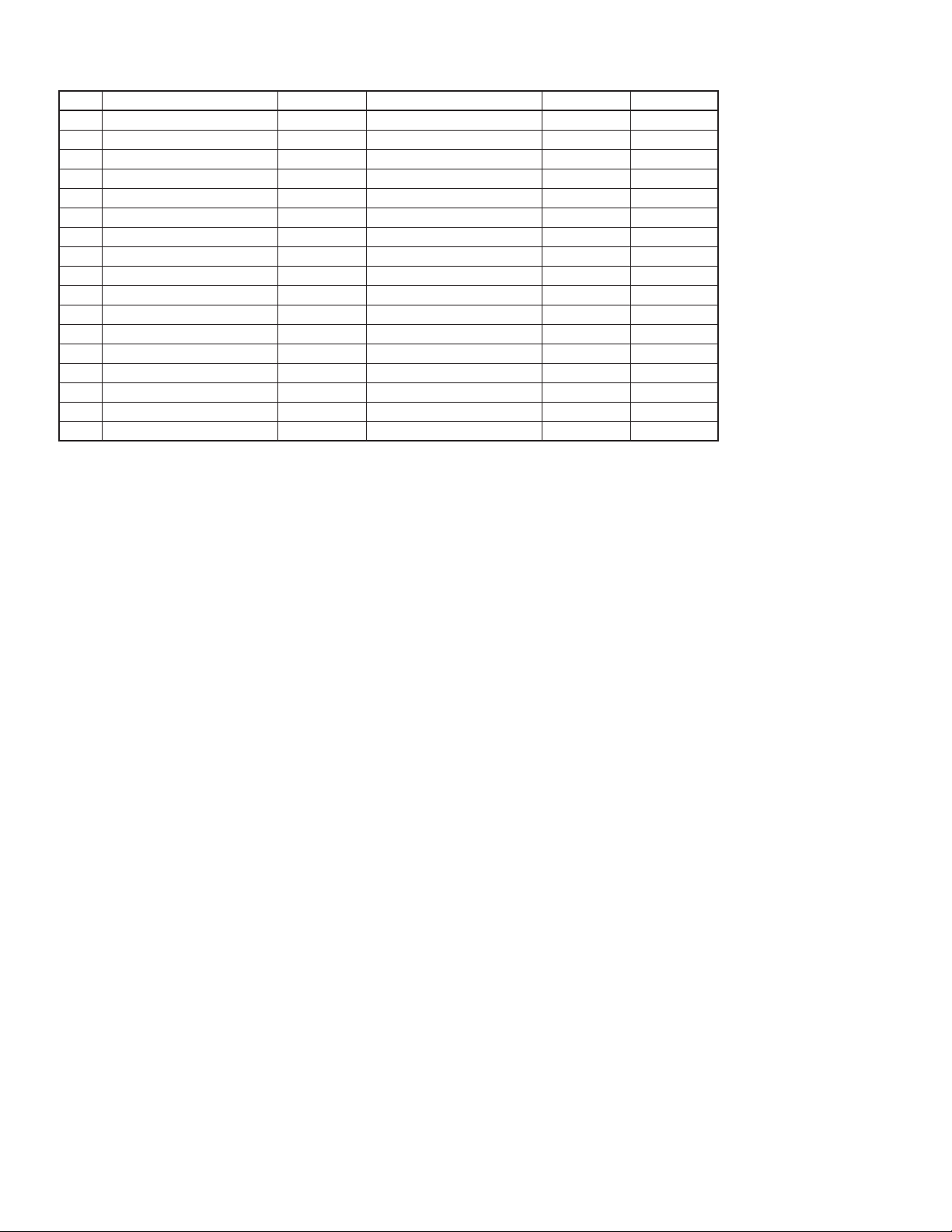

20F650

Ref. No. Part No. ★ Description Code

D812 RH-EX0263TAZZY X Zener Diode, 8.1V AB

D1081 VHD1SS119//-1Y X 1SS119 AA

D1085 RH-EX1393CEZZY X Zener Diode, 5.1V AB

D1086 RH-EX1393CEZZY X Zener Diode, 5.1V AB

D1089 RH-EX1393CEZZY X Zener Diode, 5.1V AB

D1091 VHD1SS119//-1Y X 1SS119 AA

D1094 VHD1SS119//-1Y X 1SS119 AA

D1095 VHD1SS119//-1Y X 1SS119 AA

D1801 VHD1SS119//-1Y X 1SS119 AA

VA701 RH-VXA009WJZZ X Varistor

çå C607 VCFPVC3ZA912H X 9100p 1.8kVM.Polypro AE

PACKAGED CIRCUITS

å PR702 RMPTP0026CEZZ X Packaged Circuit AF

X801 RCRSAA009WJZZ X Crystal, 3.58MHz AC

FILTERS

å C701 RC-FZ029SCEZZ X 0.22 50V

CF201 RFiLC0447CEZZ X Filter AB

CF802 RFiLC0446CEZZ X Filter, 4.5MHz AB

SF201 RFiLC0405CEZZ X Filter AD

å C705 RC-EZA104WJZZ X 470 200V Electrolytic

COILS

L203 VP-DF270K0000Y X Peaking 27µHAB

L204 VP-XF1R2K0000Y X Peaking 1.2µHAB

L602 RCiLP0223CEZZ X Coil 3.3µHAB

å L701 RCiLF0078PEZZ X Coil AF

å L703 RCiLF0078PEZZ X Coil AF

L751 RCiLP0179CEZZ+ X Coil AB

L801 VP-DF100K0000Y X Peaking 10µHAB

å C750 VCKYPA2HB102K+ X 1000p 500V Ceramic AB

L802 VP-DF100K0000Y X Peaking 10µHAB

L803 VP-DF100K0000Y X Peaking 10µHAB

L804 VP-XF150K0000Y X Peaking 15µHAB

L806 VP-DF100K0000Y X Peaking 10µHAB

L807 VP-XF1R5K0000Y X Peaking 1.5µH

L1861 VP-XF8R2K0000Y X Peaking 8.2µHAB

L1862 VP-XF8R2K0000Y X Peaking 8.2µHAB

TRANSFORMERS

çå T602 RTRNFA095WJZZ X H-Volt Transformer AR

å T603 RTRNZA058WJZZ X Transformer AB

å T701 RTRNWA179WJZZ X Transformer

CAPACITORS

C201 VCEA0A1CW476M+X 47 16V Electrolytic AB

C202 VCEA0A0JW108M+ X 1000 6.3V Electrolytic AB

C203 VCKYCY1HF103ZY X 0.01 50V Ceramic AA

C205 VCKYCY1HF103ZY X 0.01 50V Ceramic AA

C206 VCEA0A1HW106M+X 10 50V Electrolytic AB

C207 VCKYCY1HF103ZY X 0.01 50V Ceramic AA

C208 VCKYCY1HF103ZY X 0.01 50V Ceramic AA

C209 VCKYCY1HF103ZY X 0.01 50V Ceramic AA

C210 VCKYCY1HF103ZY X 0.01 50V Ceramic AA

C213 VCKYCY1HB102KY X 1000p 50V Ceramic AA

C301 VCEA0A1CW477M+X 470 16V Electrolytic AB

C304 VCEA0A1CW106M+X 10 16V Electrolytic AA

C308 VCKYCY1HB822KY X 8200p 50V Ceramic AA

C310 VCEA0A1HW105M+X 1 50V Electrolytic AB

C311 VCEA0A1HW105M+X 1 50V Electrolytic AB

C312 VCEA0A1HW335M+X 3.3 50V Electrolytic AA

C313 VCKYCY1HB822KY X 8200p 50V Ceramic AA

C317 VCE9GA1CW106M+X 10 16V Elect.(N.P) AB

C318 VCEA0A1CW107M+X 100 16V Electrolytic AB

C321 VCEA0A1HW335M+X 3.3 50V Electrolytic AA

C322 VCEA0A1HW105M+X 1 50V Electrolytic AB

C391 VCKYPA1HB102K+ X 1000p 50V Ceramic AA

C392 VCQYTA1HM103J+ X 0.01 50V Mylar AB

C393 VCEA0A1EW108M+X 1000 25V Electrolytic AB

C434 VCE9GA1CW106M+X 10 16V Elect.(N.P) AB

C435 VCE9GA1CW106M+X 10 16V Elect.(N.P) AB

C436 VCKYCY1EF104ZY X 0.1 25V Ceramic AA

C437 VCE9GA1HW106M+X 10 50V Elect.(N.P) AB

C438 VCEA0A1CW106M+X 10 16V Electrolytic AA

C439 VCKYCY1HF103ZY X 0.01 50V Ceramic AA

C452 VCE9GA1CW106M+X 10 16V Elect.(N.P) AB

C505 VCEA0A1HW107M+X 100 50V Electrolytic AB

C508 VCFYAA2AA224J+ X 0.22 100V AC

Ref. No. Part No. ★ Description Code

C511 VCEA0A1VW477M+X 470 35V Electrolytic AB

C512 VCKYPA2HB102K+ X 1000p 500V Ceramic AB

C513 RC-EZA332WJZZ+ X Electrolytic

C515 VCEACA1HC335J+ X 3.3 50V Electrolytic AB

C601 VCQYTA1HM563J+ X 0.056 50V Mylar AA

C602 VCEA0A1HW475M+X 4.7 50V Electrolytic AB

C603 VCEA0A1HW105M+X 1 50V Electrolytic AB

C604 VCEA0A2EW336M+X 33 250V Electrolytic AB

C606 VCKYPA2HB102K+ X 1000p 500V Ceramic AB

C608 VCQYTA2AA103K+ X 0.01 100V Mylar

C610 VCEA0A1EW227M+X 220 25V Electrolytic AB

C611 VCFPVC2DB334J X 0.33 200V M.Polypro AB

C642 VCEA0A1EW476M+X 47 25V Electrolytic AB

C643 VCEA0A1CW477M+X 470 16V Electrolytic AB

C650 VCKYPA2HB101K+ X 100p 500V Ceramic AB

C702 RC-KZ0029CEZZ+ X 0.01 250V Cermic AB

C703 RC-KZ0029CEZZ+ X 0.01 250V Cermic AB

C706 VCEA0A1VW226M+X 22 35V Electrolytic AB

C708 VCKYPA1HB471K+ X 470p 50V Ceramic AA

C709 VCEA9M1HW105M+X 1 50V Electrolytic AA

C710 VCFYFA1HA104J+ X 0.1 50V Mylar AB

C711 VCKYPA1HB681K+ X 680p 50V Ceramic AA

C713 RC-KZ016SCEZZ X 470p 250V Ceramic AD

C718 VCKYPA2HB472K+ X 4700p 500V Ceramic AB

C743 VCKYPH3DB561K X 560p 2kV Ceramic AB

C751 RC-KZ0106GEZZ X 3300p 250V Ceramic AB

C752 VCKYPH3DB561K X 560p 2kV Ceramic AB

C753 RC-EZ0724CEZZ X 100 160V Electrolytic AC

C754 RC-EZ0638CEZZ X 33 160V Electrolytic AC

C755 VCQYTA1HM103J+ X 0.01 50V Mylar AB

C756 VCEA0A1EW228M+X 2200 25V Electrolytic

C757 VCKYCY1HB471KY X 470p 50V Ceramic AA

C784 RC-KZ0341CEZZ X 1000p 2kV Ceramic

C801 VCFYFA1HA105J+ X 1 50V Mylar AB

C802 VCKYCY1HF103ZY X 0.01 50V Ceramic AA

C803 VCEA9M1CW476M+X 47 16V Electrolytic AA

C804 VCKYCY1HF103ZY X 0.01 50V Ceramic AA

C805 VCEA0A1HW105M+X 1 50V Electrolytic AB

C806 VCKYCY1HF103ZY X 0.01 50V Ceramic AA

C807 VCEA0A1CW337M+X 330 16V Electrolytic AB

C808 VCKYCY1HF103ZY X 0.01 50V Ceramic AA

C809 VCKYCY1HF103ZY X 0.01 50V Ceramic AA

C810 VCKYCY1HF103ZY X 0.01 50V Ceramic AA

C811 VCEA9M1CW106M+X 10 16V Electrolytic AA

C814 VCKYCY1HF103ZY X 0.01 50V Ceramic AA

C815 VCKYCY1HF103ZY X 0.01 50V Ceramic AA

C816 VCKYCY1EF104ZY X 0.1 25V Ceramic AA

C817 VCEA9M1CW107M+X 100 16V Electrolytic AB

C818 VCEA9M1HW475M+X 4.7 50V Electrolytic

C819 VCCCCY1HH121JY X 120p 50V Ceramic AA

C820 VCEA9M1HW474M+X 0.47 50V Electrolytic AA

C821 VCKYCY1HF153ZY X 0.015 50V Ceramic AA

C822 VCE9GA1HW105M+X 1 50V Elect.(N.P) AB

C823 VCKYCY1EF104ZY X 0.1 25V Ceramic AA

C824 VCEA0A1CW337M+X 330 16V Electrolytic AB

C825 VCE9GA1HW105M+X 1 50V Elect.(N.P) AB

C826 VCKYCY1HF103ZY X 0.01 50V Ceramic AA

C827 VCEA0A1CW476M+X 47 16V Electrolytic AB

C828 VCKYCY1HF103ZY X 0.01 50V Ceramic AA

C829 VCEA9M1CW476M+X 47 16V Electrolytic AA

C831 VCKYCY1EF104ZY X 0.1 25V Ceramic AA

C833 VCKYCY1EF104ZY X 0.1 25V Ceramic AA

C834 VCEA0A1CW107M+X 100 16V Electrolytic AB

C835 VCEA0A1CW106M+X 10 16V Electrolytic AA

C836 VCKYCY1HF103ZY X 0.01 50V Ceramic AA

C837 VCEA9M1HW105M+X 1 50V Electrolytic AA

C839 VCCCCY1HH680JY X 68p 50V Ceramic AA

C840 VCFYFA1HA105J+ X 1 50V Mylar AB

C841 VCCCCY1HH101JY X 100p 50V Ceramic AA

C842 VCEA9M1HW474M+X 0.47 50V Electrolytic AA

C843 VCEA0A1HW105M+X 1 50V Electrolytic AB

C845 VCKYCY1CF224ZY X 0.22 16V Ceramic AA

44

Page 45

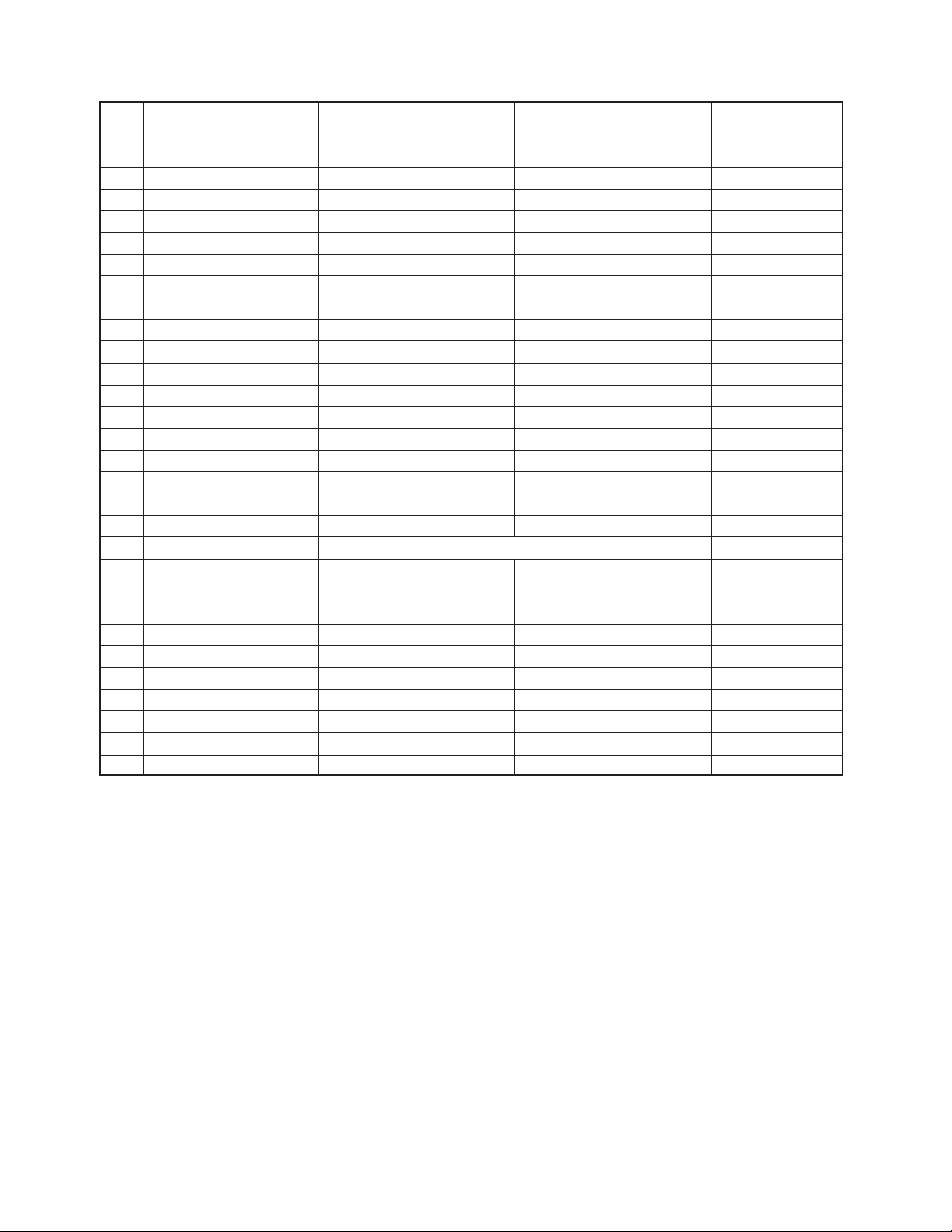

20F650

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

C846 VCKYCY1HF103ZY X 0.01 50V Ceramic AA

C847 VCCCCY1HH220JY X 22p 50V Ceramic AA

C848 VCEA9M1HW105M+X 1 50V Electrolytic AA

C1001 VCEA0A1AW107M+X 100 10V Electrolytic AA

C1003 VCEA0A1CW226M+X 22 16V Electrolytic AB

C1004 VCKYCY1CF474ZY X 0.47 16V Ceramic AB

C1006 VCEA0A1HW225M+X 2.2 50V Electrolytic AB

C1007 VCEA0A1CW107M+X 100 16V Electrolytic AB

C1008 VCKYCY1HF103ZY X 0.01 50V Ceramic AA

C1009 VCKYCY1HF103ZY X 0.01 50V Ceramic AA

C1011 VCKYCY1HB221KY X 220p 50V Ceramic AA

C1012 VCEA0A1HW105M+X 1 50V Electrolytic AB

C1013 VCKYCY1HB102KY X 1000p 50V Ceramic AA

C1014 VCE9GA1HW475M+X 4.7 50V Elect.(N.P) AB

C1015 VCCCCY1HH101JY X 100p 50V Ceramic AA

C1016 VCKYCY1EF104ZY X 0.1 25V Ceramic AA

C1020 VCEA0A0JW477M+ X 470 6.3V Electrolytic AB

C1081 VCQYTA1HM104J+ X 0.1 50V Mylar AB

C1849 VCFYFA1HA223J+ X 0.022 50V Mylar AA

C1855 VCKYCY1HB561KY X 560p 50V Ceramic AA

C1856 VCKYCY1HB102KY X 1000p 50V Ceramic AA

C1861 VCCCCY1HH221JY X 220p 50V Ceramic AA

C1862 VCKYCY1HB102KY X 1000p 50V Ceramic AA

C1863 VCCCCY1HH221JY X 220p 50V Ceramic AA

C1864 VCKYCY1HB102KY X 1000p 50V Ceramic AA

C1868 VCEA9M1CW336M+X 33 16V Electrolytic

RESISTORS

RJ1 VRS-CY1JF000JY X 0 1/16W Metal Oxide AA

RJ3 VRS-CY1JF000JY X 0 1/16W Metal Oxide AA

RJ5 VRS-CY1JF000JY X 0 1/16W Metal Oxide AA

RJ9 VRS-CY1JF000JY X 0 1/16W Metal Oxide AA

RJ10 VRS-CY1JF000JY X 0 1/16W Metal Oxide AA

RJ12 VRS-CY1JF000JY X 0 1/16W Metal Oxide AA

RJ13 VRS-CY1JF000JY X 0 1/16W Metal Oxide AA

RJ14 VRS-CY1JF000JY X 0 1/16W Metal Oxide AA

RJ17 VRS-CY1JF000JY X 0 1/16W Metal Oxide AA

RJ18 VRS-CY1JF000JY X 0 1/16W Metal Oxide AA

RJ19 VRS-CY1JF000JY X 0 1/16W Metal Oxide AA

RJ20 VRS-CY1JF000JY X 0 1/16W Metal Oxide AA

RJ22 VRS-CY1JF000JY X 0 1/16W Metal Oxide AA

RJ25 VRS-CY1JF000JY X 0 1/16W Metal Oxide AA