Page 1

SERVICE MANUAL

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

SERVICE MANUAL

S00K414BM2S//

COLOUR TELEVISION

Chassis No. UA-1

14BM2, 14BM2S/G

COLOUR TELEVISION

21BM2, 21BM2S/G

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

Ë

Multi 18 Systems

Ë

Full Auto Channel Preset and Auto Channel Skip

Ë

100-CH Program Memory

Ë

High Contrast Picture

Ë

Black Stretch Circuit

Ë

CATV (Hyper Band) Ready

〈Used Frequency Synthesizer Tuner〉

20BM2, 20BM2S/G

MODELS

FEATURE

Ë

Hotel Mode

Ë

On Timer/Sleep Timer/Reminder Timer

Ë

Colour Comb Filter Function (NTSC only)

Ë

Blue Back Noise Mute

Ë

Front AV-In & Rear AV-In/Out Terminals

Ë

AVL Function

Ë

English/Chinese/Malay/France/Russia/Arabic OSD

CONTENTS

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

MODELS 14BM2, 14BM2S/G, 20BM2, 20BM2S/G, 21BM2, 21BM2S/G

» SPECIFICATIONS ...........................................2

» IMPORTANT SERVICE NOTES ......................2

» ADJUSTMENT PRECAUTIONS .....................3

» HOTEL MODE APPLICATION NOTE............15

» TROUBLE SHOOTING TABLE......................15

» SOLID STATE DEVICE BASE DIAGRAM ..... 18

» CHASSIS LAYOUT........................................ 19

» BLOCK DIAGRAM.........................................22

» WAVEFORMS ...............................................25

» DESCRIPTION OF SCHEMATIC DIAGRAM ..27

» SCHEMATIC DIAGRAM

■ MAIN UNIT ...............................................28

■ CRT UNIT.................................................34

The chassis in this receiver is partially hot. Use an isolation transformer between the line cord plug and power

receptacle, when servicing this chassis. To prevent electric shock, do not remove cover. No user – serviceable

parts inside. Refer servicing to qualified service personnel.

SHARP CORPORATION

Page

Page

» PRINTED WIRING BOARD ASSEMBLIES ...36

» REPLACEMENT PARTS LIST

■ ELECTRICAL PARTS............................... 41

■ MISCELLANEOUS PARTS ...................... 46

■ SUPPLIED ACCESSORIES.....................46

■ PACKING PARTS .....................................46

■ CABINET PARTS ..................................... 46

WARNING

1

Page 2

2

2-1 2-2

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

SPECIFICATIONS

Convergence ..............................................................................Self Convergence System

Focus .......................................................................... Electrostatic Focus High Bi-Potential

Sweep Deflection ................................................................................................... Magnetic

Intermediate Frequencies

Picture IF Carrier ............................................................................................... 38.9 MHz

Sound IF Carrier Frequency

5.5 MHz .......................................................................................................... 33.4 MHz

6.0 MHz .......................................................................................................... 32.9 MHz

6.5 MHz .......................................................................................................... 32.4 MHz

Colour Sub-Carrier Frequency..................................................................... 34.47 MHz

Power Input.....................................................................................110 - 240V, AC50/60 Hz

Power Consumption

21BM2 .................................................................................................................... 88 W

20BM2 .................................................................................................................... 87 W

14BM2 .................................................................................................................... 68 W

Audio Power Output Rating..............................................................................5.0W (RMS)

Speaker

Size

21BM2/20BM2 ..............................................................6 × 12 cm Elliptic (2 pcs.)

14BM2.............................................................................5 × 9 cm Elliptic (2 pcs.)

Voice Coil Impedance...........................................................................6 ohms at 400 Hz

Aerial Input Impedance

VHF/UHF ......................................................................................75 ohms Unbalanced

Receiving System .......................................................... CCIR/PAL B/G, D/K, I/SECAM

NTSC 3.58/4.43 MHz (thru AV)

Tuner Ranges

» VHF-Channels...........................................E1 (48.25 MHz) thru E12 (224.25 MHz)

C1 (49.75 MHz) thru C12 (216.25 MHz)

S1 (105.25 MHz) thru S41 (463.25 MHz)

» UHF-Channels ......................................E21 (471.25 MHz) thru E69 (855.25 MHz)

C13 (471.25MHz) thru C57 (863.25 MHz)

Dimensions

21BM2 ............................................................................................... Width: 642.0 mm

Height: 475.0 mm

Depth: 477.0 mm

Weight (approx.): 21.0 kg

20BM2 ............................................................................................... Width: 642.0 mm

Height: 475.0 mm

Depth: 480.0 mm

Weight (approx.): 19.0 kg

14BM2 ............................................................................................... Width: 496.0 mm

Height: 355.0 mm

Depth: 365.0 mm

Weight (approx.):9.2 kg

Cabinet Material ................................................................................................. All Plastics

Specifications are subject to change without prior notice.

IMPORTANT SERVICE NO TES

Maintenance and repair of this receiver should be done by

qualified service personnel only .

SERVICING OF HIGH VOLTAGE SYSTEM AND

PICTURE TUBE

When servicing the high voltage system, remove static charge from it by

connecting a 10k ohm Resistor in series with an insulated wire (such as a

test probe) between picture tube dag and 2nd anode lead. (AC line cord

should be disconnected from AC outlet.)

1. Picture tube in this receiver employs integral implosion protection.

2. Replace with tube of the same type number for continued safety.

3. Do not lift picture tube by the neck.

4. Handle the picture tube only when wearing shatterproof goggles and after

discharging the high voltage completely

X-RAY

This receiver is designed so that any X-Ray radiation is kept to an absolute

minimum. Since certain malfunctions or servicing may produce potentially

hazardous radiation with prolonged exposure at close range, the f ollowing

precautions should be observed:

1. 14BM2 : When repairing the circuit, be sure not to increase the high volt-

age to more than 25.5 kV (at beam 0.1 µA) for the set.

20BM2 : When repairing the circuit, be sure not to increase the high volt-

age to more than 28.0 kV (at beam 0.1 µA) for the set.

21BM2 : When repairing the circuit, be sure not to increase the high volt-

age to more than 28.0 kV (at beam 0.1 µA) for the set.

2. 14BM2 : To keep the set in a normal operation, be sure to make it function on

22.8 kV

± 1.5 kV (at beam 800 µA) in the case of the set. The set has

been factory - Adjusted to the above-mentioned high voltage.

20BM2 : To keep the set in a normal operation, be sure to make it function on

24.5 kV

± 1.5 kV (at beam 1,100 µA) in the case of the set. The set has

been factory - Adjusted to the above-mentioned high voltage.

21BM2 : To keep the set in a normal operation, be sure to make it function on

24.8 kV

± 1.5 kV (at beam 1,100 µA) in the case of the set. The set has

been factory – Adjusted to the above-mentioned high voltage.

If there is a possibility that the high voltage fluctuates as a result of the

repairs, never for get to check for such high voltage after the work.

3. Do not substitute a picture tube with unauthorized types and/or brands

which may cause excess X-ray radiation.

BEFORE RETURNING THE RECEIVER

Before returning the receiver to the user, perform the follo wing safety checks.

1. Inspect all lead dress to make certain that leads are not pinched or that

hardware is not lodged between the chassis and other metal parts in the

receiver.

2. Inspect all protective devices such as non-metallic control knobs, insulating

fishpapers, cabinet backs, adjustment and compartment covers or shields, isolation resistor-capacity networks, mechanical insulators etc.

Page 3

3-1 3-2

3

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

ADJUSTMENT PRECAUTIONS

This model’s setting are adjusted in two different ways: though the I2C bus control and in the

conventional analog manner. The adjustments via the I2C bus control include preset-only

items and variable data.

1. Setting the service mode by the microprocessor.

1 Short JA122 & JA124 for 1 second and release to switch to the service mode position,

and the microprocessor is in input mode. (Adjustment through the I2C bus control). (Use

JWS Key to set as well).

2 Press the CH DOWN / UP key on the remote controller to get ready to select the mode

one by one.

3 Press the CH DOWN / UP key on the remote controller to select the modes reversibly

one by one.

4 Using the VOLUME UP/ DOWN key on the remote controller, the data can be modified.

5 Short JA122 & JA124 for 1 second and release to switch to the normal mode (OFF)

position, and the microprocessor is in out of the service mode.

2. Factory Presetting.

1 Short JA122 & JA124 for 1 second and release to switch to the service mode position

and turn on the main power switch. Initial values are automatically preset, only when a

new EEPROM is used (Judge with the first 4 bytes).

2 The initial data are preset as listed in pages 4, 5 & 6.

3 Make sure the data need modify or not (Initial data).

Note: Once the chassis has been assembly together and ready to be POWER ON for the

FIRST TIME, make sure to short JA122 & JA124 switch to the service mode position first and then turn on the main power switch. (See 2- 1 above).

Precaution: If haven’t done this initiation, it ma y possibly generate e xcessive Beam

current.

3. For reference please check with memory map

(UA1 Series type RH-IX3368CE Attachment)

Ë

SERVICE MODE

(1)In the Service Mode, Key is used to select the mode in the following order.

AGC &

GEOMETRIC

MODE

↓

AGC TAKE OVER POINT (AGC)

↓

VERTICAL SLOPE (V-LIN)

↓

VERTICAL AMP (V-AMP)

↓

VERTICAL SHIFT (V-CENT)

↓

HORIZONTAL SHIFT (H-CENT)

↓

S-CORRECTION (S-COR)

WHITE POINT

ADJ.

MODE

↓

W.P. RED STD. W.T. (DRI-RS)

↓

W.P. GREEN STD. W.T. (DRI-GS)

↓

W.P.BLUE STD. W.P. (DRI-BS)

↓

W.P. RED COOL W.P. (DRI-RC)

↓

W.P. GREEN COOL W.P. (DRI-GC)

↓

W.P. BLUE COOL W.P. (DRI-BC)

↓

W.P. RED WARM W.P. (DRI-RW)

↓

W.P. GREEN WARM W.P. (DRI-GW)

↓

W.P. BLUE WARM W.P. (DRI-BW)

SUB

ADJ.

MODE

↓

MAX VOLUME (SUB-VOL)

↓

SUB CONTRAST (SUB-CON)

↓

SUB COLOUR (SUB-COL)

↓

SUB BRIGHTNESS (SUB-BRI)

↓

SUB TINT (SUB-TINT)

↓

SUB SHARPNESS (SUB-SHP)

↓

MAX HOTEL VOLUME (HTL-VOL)

↓

HOTEL PROGRAM NO (HTL-PRG)

↓

OSD GRB REFERENCE (RGB)

↓

BLACK LEVEL OFFSET R (CUT-R)

↓

BLACK LEVEL OFFSET G (CUT-G)

↓

CATHODE DRIVE LEVEL (CDL)

FORWARD : CH DOWN KEY

REVERSE : CH UP KEY

* ( ) means OSD display.

FORWARD : CH DOWN KEY

REVERSE : CH UP KEY

AGC &

GEOMETRIC

MODE

WHITE POINT

ADJ.

MODE

SUB

ADJ.

MODE

Y-DELAY

ADJ.

MODE

MISC.

OPTION

MODE

IC

OPTION

MODE

OFFSET

ADJ.

MODE

Page 4

4

4-1 4-2

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

Y -DELAY

ADJ.

MODE

↓

Y-D TIME FOR PAL (TV) (DL-PT)

↓

Y-D TIME FOR SECAM (TV) (DL-ST)

↓

Y-D TIME FOR N358 (TV) (DL-3T)

↓

Y-D TIME FOR N443 (TV) (DL-4T)

↓

Y-D TIME FOR B/W (TV) (DL-TV)

↓

Y-D TIME FOR PAL (AV) (DL-PA)

↓

Y-D TIME FOR SECAM (AV) (DL-SA)

↓

Y-D TIME FOR N358 (AV) (DL-3A)

↓

Y-D TIME FOR N443(AV) (DL-4A)

↓

Y-D TIME FOR B/W (AV) (DL-AV)

*(Y-D : Y-DELAY)

OFFSET

ADJ.

MODE

↓

COLOUR OFFSET (PAL) (COL-OP)

↓

COLOUR OFFSET (SECAM) (COL-OS)

↓

COLOUR OFFSET (NTSC358) (COL-O3)

↓

COLOUR OFFSET (NTSC443) (COL-O4)

↓

SHARPNESS OFFSET (PAL) (SHP-OP)

↓

SHARPNESS OFFSET (SECAM) (SHP-OS)

↓

SHARPNESS OFFSET (NTSC358) (SHP-O3)

↓

SHARPNESS OFFSET (NTSC443) (SHP-O4)

IC

OPTION

MODE

↓

VERTICAL SCAN DISABLE(VSD)

↓

BLACK STRETCH (BKS)

↓

AUTO V OLUME LEVELING(AVL)

↓

FAST FILTER IF-PLL(FFI)

↓

ENABLE VERTICAL GUARD (EVG)

↓

EHT TRACKING MODE (EHT)

↓

OVERSCAN SWITCH OFF(OSO)

↓

AUTO COLOUR LIMIT(ACL)

↓

FORCED COLOUR LIMIT(FCO)

MISC.

OPTION

MODE

↓

SOUND SYSTEM M (S-M)

↓

SOUND SYSTEM DK (S-DK)

↓

SOUND SYSTEM I (S-I)

↓

SOUND SYSTEM BG (S-BG)

↓

PLAYBACK SECAM (P-SECAM)

↓

FE (RF) NTSC 3.58 (F-N358)

↓

FE (RF) NTSC 4.43 (F-N443)

↓

FE (RF) SECAM (F-SECAM)

↓

VIDEO MUTE AT IDENT LOSS (VMI)

↓

VIDEO MUTE AT PROGRAM

/SOURCE CHANGE (VMC)

↓

HOTEL MODE (HTL)

↓

REDUCED FM DEMODULATION

GAIN FOR BTSC SIGNAL (BTSC)

↓

A

A

↓

NUMBER OF EXT AV SOURCE (AV)

↓

FM WINDOW SELECTION (FMWS)

↓

SOUND MUTE BIT 0 (SM0)

↓

SOUND MUTE BIT 1 (SM1)

↓

THAI LANGUAGE (THA)

↓

ARABIC LANGUAGE (ARA)

↓

MALAY LANGUAGE (MAL)

↓

CHINESE LANGUAGE (CHI)

↓

FRENCH LANGUAGE (FRE)

↓

RUSSIAN LANGUAGE (RUS)

↓

FORCED V-SYNC SLICING LEVEL(FSL)

↓

SYNC OF OSD (HP2)

↓

TUNER SELECTION (CPT)

↓

B

B

↓

BILINGUAL(BIL)

↓

IF AGC SPEED BIT 0 (AGC0)

↓

IF AGC SPEED BIT 1 (AGC1)

↓

FOA Time Constant-RF (FOA-FE)

↓

FOB Time Constant-RF (FOB-FE)

↓

FOA Time Constant-AV (FOA-AV)

↓

FOB Time Constant-AV (FOB-AV)

USER DATA IN SERVICE MODE

* While SERVICE mode ON, EEPROM DATA will switch to the service data.

Also, once SERVICE mode OFF, EEPROM will switch back to previous USER DATA.

* In the service mode, the user data establish as below,

MODE USER DATA

CONTRAST MIN (1/60)

COLOUR MIN (1/60)

BRIGHTNESS MIN (1/60)

TINT MIN (1/60)

SHARPNESS MIN (1/60)

WHITE TEMP STANDARD

S-VOLUME MIN (1/60)

BLUE BACK OFF

C SYSTEM AUTO

S SYSTEM *1

*1 : For each CH, before

changing service mode

setting.

The flow of Mode lists as following,

* Direct Key-in Step1 Mode

RC COMMAND SERVICE-ITEM

FUNCTION AGC

CONTRAST DOWN V-LIN

COLOUR DOWN V-AMP

BRIGHTNESS DOWN V-CENT

TINT DOWN H-CENT

SHARPNESS DOWN EW / /

SYSTEM HB

BLUEBACK S-COR

TIMER SUB-VOL

CONTRAST UP SUB-CON

COLOUR UP SUB-COL

BRIGHTNESS UP SUB-BRI

TINT UP TINT SUB TINT

SHARPNESS UP SUB-SHP

Page 5

5-1 5-2

5

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

After short JA122 & 124, and turn on the main power switch, read data from E2PROM

address 00H ~ 03H, and compare to the list below, if different, initialize the E2PROM.

Address : Data Address : Data

00H : 55H 02H : 43H

01H : 4FH 03H : A1H

EEPROM ITEMS OSD DATA LENGTH

INITIAL DATA FIX/ADJ

REMARK

AGC TAKE OVER POINT AGC 0~63 14 ADJ

VERTICAL SLOPE V-LIN 0~63 32 ADJ

VERTICAL AMPLITUDE V-AMP 0~63 32 ADJ

VERTICAL SHIFT V-CENT 0~63 32 ADJ

HORIZONTAL SHIFT H-CENT 0~63 32 ADJ

S-CORRECTION S-COR 0~63 0 FIX

WHITE POINT RED STD WHITE TEMP DRI-RS 0~63 32 FIX

WHITE POINT GREEN STD WHITE TEMP DRI-GS 0~63 32 ADJ

WHITE POINT BLUE STD WHITE TEMP DRI-BS 0~63 32 ADJ

WHITE POINT RED COOL WHITE TEMP DRI-RC 0~63 25 ADJ (DRI-RS)-7 *1

WHITE POINT GREEN COOL WHITE TEMP DRI-GC 0~63 32 ADJ (DRI-RS)-7 *1

WHITE POINT BLUE COOL WHITE TEMP DRI-BC 0~63 32 ADJ (DRI-BS)

WHITE POINT RED WARM WHITE TEMP DRI-RW 0~63 32 FIX (DRI-RS)

WHITE POINT GREEN WARM WHITE TEMP DRI-GW 0~63 32 ADJ (DRI-GS)-7

WHITE POINT BLUE WARM WHITE TEMP DRI-BW 0~63 32 ADJ (DRI-BS)-7

MAX VOLUME SUB-VOL 0~63 32 FIX

SUB CONTRAST SUB-CON 0~63 63 FIX

SUB COLOUR SUB-COL 0~63 32 ADJ

SUB BRIGHTNESS SUB-BRI 0~63 32 ADJ

SUB TINT SUB-TINT 0~63 32 ADJ

SUB SHARPNESS SUB-SHP 0~63 32 FIX

MAX HOTEL VOLUME HTL-VOL 0~63 32 FIX

HOTEL PROGRAM NUMBER HTL-PRG

0~99 OR>99FOR NONE

255 FIX

OSD GRB REFERENCE RGB 0~15 15 FIX

BLACK LEVEL OFF-SET R CUT-R 0~15 8 ADJ

BLACK LEVEL OFF-SET G CUT-G 0~15 8 ADJ

CATHODE DRIVE LEVEL CDL 0~15 0(2) FIX *2

Y-DELAY TIME FOR PAL(TV) [YD] DL-PT 0~15 12 FIX

Y-DELAY TIME FOR SECAM(TV) [YD] DL-ST 0~15 15 FIX

Y-DELAY TIME FOR N358 (TV) [YD] DL-3T 0~15 12 FIX

Y-DELAY TIME FOR N443 (TV) [YD] DL-4T 0~15 12 FIX

Y-DELAY TIME FOR B/W (TV) [YD] DL-TV 0~15 12 FIX

Y-DELAY TIME FOR PAL (AV) [YD] DL-PA 0~15 12 FIX

Y-DELAY TIME FOR SECAM (AV) [YD] DL-SA 0~15 15 FIX

Y-DELAY TIME FOR N358 (AV) [YD] DL-3A 0~15 12 FIX

Y-DELAY TIME FOR N443 (AV) [YD] DL-4A 0~15 12 FIX

Y-DELAY TIME FOR B/W (AV) [YD] DL-AV 0~15 12 FIX

COLOUR OFFSET (PAL) COL-OP 0~15 8 FIX

COLOUR OFFSET (SECAM) COL-OS 0~15 8 FIX

COLOUR OFFSET (NTSC358) COL-O3 0~15 4 FIX

COLOUR OFFSET (NTSC443) COL-O4 0~15 4 FIX

SHARPNESS OFFSET (PAL) SHP-OP 0~15 8 FIX

SHARPNESS OFFSET (SECAM) SHP-OS 0~15 4 FIX

Note :

Fixed data, please do not change without specific instruction.

*1:White point RED and GREEN COOL WHITE TEMP for 18000 degree colour TEMP (SMEF

MODELS) MINUS 5. other models (123K degree colour temp) still same MINUS 7.

*2:CDL initial data=2 for all 20” & 21” only.

EEPROM ITEMS OSD DATA LENGTH

INITIAL DATA FIX/ADJ

REMARK

SHARPNESS OFFSET (NTSC358) SHP-O3 0~15 12 FIX

SHARPNESS OFFSET (NTSC443) SHP-O4 0~15 8 FIX

VERTICAL SCAN DISABLE VSD

0(DISABLE)/1(ENABLE)

0 FIX

BLACK STRETCH BKS

0(DISABLE)/1(ENABLE)

1 FIX

AUTOMATIC VOLUME LEVELING AVL

0(DISABLE)/1(ENABLE)

1 FIX

FAST FILTER IF-PLL FFI

0(DISABLE)/1(ENABLE)

0 FIX

ENABLE VERTICAL GUARD (RGB BLANKING) EVG

0(DISABLE)/1(ENABLE)

1 FIX ONLY BLK

EHT TRACKING MODE (HCO) EHT

0(DISABLE)/1(ENABLE)

1 FIX

OVERSCAN SWITCH OFF OSO

0(DISABLE)/1(ENABLE)

0 FIX

AUTO COLOUR LIMIT ACL

0(DISABLE)/1(ENABLE)

0 FIX

FORCED COLOUR LIMIT FCO

0(DISABLE)/1(ENABLE)

0 FIX

SOUND SYSTEM M S-M

0(DISABLE)/1(ENABLE)

0 FIX

SOUND SYSTEM DK S-DK

0(DISABLE)/1(ENABLE)

1 FIX

SOUND SYSTEM I S-I

0(DISABLE)/1(ENABLE)

1 FIX

SOUND SYSTEM BG S-BG

0(DISABLE)/1(ENABLE)

1 FIX

PLAYBACK SECAM P-SECAM

0(DISABLE)/1(ENABLE)

1 FIX

FE (RF) NTSC 3.58 F-N358

0(DISABLE)/1(ENABLE)

0 FIX

FE (RF) NTSC 4.43 F-N443

0(DISABLE)/1(ENABLE)

1 FIX

FE (RF) SECAM F-SECAM

0(DISABLE)/1(ENABLE)

1 FIX

VIDEO MUTE AT IDENT LOSS VMI

0(DISABLE)/1(ENABLE)

1 FIX

VIDEO MUTE AT PROGRAM/SOURCE CHANGE

VMC

0(DISABLE)/1(ENABLE)

1 FIX

HOTEL MODE HTL

0(DISABLE)/1(ENABLE)

0 FIX

REDUCED FM DEMODULATOR GAIN FOR BTSC SIGNAL

BTSC

0(DISABLE)/1(ENABLE)

0 FIX

NUMBER OF EXTERNAL AV SOURCE AV

0 FOR1 AV/1 FOR 2AV

1 FIX

FM WINDOW SELECTION FMWS

0(DISABLE)/1(ENABLE)

0 FIX

SOUND MUTE BIT 0 SM0

0(DISABLE)/1(ENABLE)

1 FIX

SOUND MUTE BIT 1 SM1

0(DISABLE)/1(ENABLE)

0 FIX

THAI LANGUAGE THA

0(DISABLE)/1(ENABLE)

0 FIX

ARABIC LANGUAGE ARA

0(DISABLE)/1(ENABLE)

1 FIX

MALAY LANGUAGE MAL

0(DISABLE)/1(ENABLE)

1 FIX

CHINESE LANGUAGE CHI

0(DISABLE)/1(ENABLE)

1 FIX

FRENCH LANGUAGE FRE

0(DISABLE)/1(ENABLE)

1 FIX

RUSSIAN LANGUAGE RUS

0(DISABLE)/1(ENABLE)

1 FIX

FORCED V-SYNC SLICING LEVEL FSL

0(DISABLE)/1(ENABLE)

0 FIX

SYNC OF OSD HP2

0(DISABLE)/1(ENABLE)

0 FIX

TUNER SELECTION (0:SHARP/ALPS;1:MURATA)

CPT

0(DISABLE)/1(ENABLE)

0 FIX

BILINGUAL BIL

0(DISABLE)/1(ENABLE)

0 FIX

IF AGC SPEED BIT 0 AGC0

0(DISABLE)/1(ENABLE)

1 FIX

IF AGC SPEED BIT 1 AGC1

0(DISABLE)/1(ENABLE)

0 FIX

PHI-1 TIME CONSTANT (RF) FOA-FE

0(DISABLE)/1(ENABLE)

0 FIX

PHI-1 TIME CONSTANT (RF) FOB-FE

0(DISABLE)/1(ENABLE)

0 FIX

PHI-1 TIME CONSTANT (OFF AIR) FOA-AV

0(DISABLE)/1(ENABLE)

1 FIX

PHI-1 TIME CONSTANT (OFF AIR) FOB-AV

0(DISABLE)/1(ENABLE)

1 FIX

Page 6

6

6-1 6-2

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

MCL1 MCL2

CH-No. Fv (MHz) SOUND SYS CH-No. Fv (MHz) SOUND SYS

0 0 590.25 B/G

1 48.25 B/G 1 46.25 B/G

2 62.25 B/G 2 64.25 B/G

3 77.25 D/K 3 86.25 B/G

4 175.25 B/G 4 95.25 B/G

5 182.25 B/G 5 138.25 B/G

6 183.25 D/K 6 175.25 B/G

7 191.25 D/K 7 182.25 B/G

8 196.25 B/G 8 189.25 B/G

9 199.25 M 9 196.25 B/G

10 210.25 B/G 10 209.25 B/G

11 224.25 B/G 11 216.25 B/G

12 471.25 B/G 12 B/G

13 487.25 I 13

14 503.25 B/G 14

15 575.25 B/G 15

16 583.25 B/G 16

17 599.25 B/G 17

18 621.25 M 18 527.25 B/G

19 639.25 D/K 19 847.25 B/G

20 703.25 B/G 20 48.25 B/G

21 735.25 I 21 175.25 B/G

22 767.25 B/G 22 210.25 B/G

23 815.25 B/G 23 224.25 B/G

24 855.25 I 24 575.25 B/G

25 855.25 B/G 25 599.25 B/G

26 55.25 M 26 767.25 B/G

27 83.25 M 27 183.25 M

28 183.25 M 28 193.25 M

29 193.25 M 29 112.25 B/G

30 217.25 M 30 168.25 B/G

31 471.25 M 31

32 477.25 M 32 294.25 B/G

33 693.25 M 33 463.25 B/G

34 34 174.95 B/G

35 112.25 B/G 35 175.55 B/G

36 168.25 B/G 36

37 37 599.25 B/G

38 294.25 B/G 38

39 463.25 B/G 39

40 40

41 647.25 B/G 41

42 663.25 B/G 42

43 679.25 B/G 43

44 174.95 B/G

45 175.55 B/G

INITIAL SETTING

(1)In service mode, After execute select POS 1, store the following tuning data in E2PROM.

SHIPPING SETTING & CHECKING

(1)The following default data has been factory-set for the E2PROM.

ITEMS DATA SETTING

LAST PROGRAM/CHANNEL 1

FLASHBACK PROGARM/CH 1

DIGIT 1

C-SYSTEM AUTO

S-SYSTEM *1

SKIP OFF

AFC ON

VOLUME 1

CONTRAST 60 (MAX)

COLOUR 0 (CENTER)

BRIGHTNESS 0 (CENTER)

TINT 0 (CENTER)

SHARPNESS 0 (CENTER)

WHITE TEMP STAND ARD

REMINDER TIMER In-active, "--:--"

ON TIMER In-active, "--:--"

OFF TIMER In-active, "--:--"

LAST POWER POWER-ON

LANGUAGE *1

BLUE BACK MUTE OFF

HOTEL MODE OFF

0 CHANNEL SKIP ON

*1: Please refer defaults for LANGUAGE and SOUND SYSTEM per MODEL as follows,

*Note for OSD type

*OSD Lang. must be set in service mode, but it's better to write in E2PROM.

Language quantities are 6 as below:

English/Chinese/French/Arabic/Malay/Russian

MODEL

Magnetic filed (V,H) nT

Background Lang. S-SYS

F -10,000 40,000 12,300°K ENGLISH B/G

G 30,000 20,000 18,000°K ARABIC B/G

*G (Africa) -10,000 40,000 12,300°K ENGLISH B/G

Y 10,000 40,000 12,300°K ENGLISH B/G

FACTORY SETTINGS BY MODELS

(Reference: Geomagnetism Adjustment)

MODEL LANGAUGE SOUND SYSTEM

3 ENGLISH B/G

4 ARABIC B/G

Page 7

7-1 7-2

7

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

PIF ADJUSTMENT

NO. Adjustment part Adjusting procedure and conditions Waveform and others

1

Fig. 1

2 RF-AGC

TAKE OVER

POINT

ADJUSTMENT

(I2C BUS

CONTROL)

1. Receive "PAL COLOUR BAR" signal.

» Signal Strength: 57 ±1 dBµV (75 ohm open)

2. Connect the oscilloscope to TP201 (Tuner’s

AGC Terminal) as shown in Fig. 3.

3. Call "AGC" mode in service mode. Adjust the

"AGC" bus data to obtain the Tuner output pin

drop 0.1 V below maximum voltage.

4. Change the antenna input signal to

63~67dBµV , and mak e sure there is no noise .

5. Turn up the input signal to 90~95 dBµV to be

sure that there is no cross modulation beat.

Note:

For the 50 ohm signal strength

gauge, when not using 50/75

impedance adapter, signal

strength is 52

±1 dBµV(75 ohm

open), instead of 57

±1 dBµV

(75 ohm open).

Precaution:

The loss of using impedance

adapter

» Bias box: About 4.5 V

Oscilloscope

0.1V

TV Set

Bias box

TP201

+

+

–

–

TUNER IFT

(PRESET)

1. Get the tuner ready to receive the E-9 CH signal, but with no signal input.

Adjust the PLL data.

2. Connect the sweep generator's output cable

to the tuner antenna. (RF SWEEP)

3. Adjust the sweep generator's to 80dBµV.

4. Connect the response lead (use LOW IMPEDANCE probe with wave detector; see Fig.1) to

the tuner's IF output terminal. (This terminal

must have the probe alone connected).

5. Set the RF AGC to 0 - 6 V with no saturation

with the waveform.

6. Adjust the tuner IF coil to obtain the waveform

as shown in Fig. 2.

Note:Be sure to keep the tuner cover in posi-

tion during this adjustment.

E-9 CH

P C

10k

100k

1n60

75ohm

IF OUT

-1.5+/-0.8dB

1000p

Oscilloscope

Fig. 2

Fig. 3

PURITY ADJUSTMENT

NO. Adjustment part Adjusting procedure and conditions Waveform and others

1

PURITY

ADJUSTMENT

1. Receive the GREEN-ONLY signal. Adjust the

beam current to ~700 µA (21" & 20")/~500 µA

(14").

2. Degauss the CRT enough with the degausing

coil.

Note: Follow the Job Instruction Sheet to ad-

just the magnetic field.

Vertical Bv : +0.030 mT

(0.30 gauss)

Horizontal Bh : +0.020 mT

(0.20 gauss)

(Reference: page 8/21)

3. Maintain the purity magnet at the zero magnetic field and keep the static convergence

roughly adjusted.

4. Observe the points a, b as shown in Fig. 4-1

through the microscope. Adjust the landings

to the rank A requirements.

5. Orient the raster rotation to 0 eastward.

6. Tighten up the deflection coil screws.

» Tightening torque: 108 ± 20 N (11 ±2 kgf)

7. Make sure the CRT corners landing meet the

A rank requirements. If not, stick the magnet

sheet to correct it.

Note: This adjustment must be done after

warming up the unit for 30 minutes

or longer with a beam current over

700

µA. (21" & 20")

(For 14", the beam current should be

over 500

µA).

Note: Set the service mode by JA122 &

JA124 (short) then press factory process R/C RGB key to change to RGB

mono colour mode.

* For the following colours press R/C RGB key

to change.

* Press R/C RGB key for 1 second

in NORMAL MODE, the colour

will change to RGB mono colour

mode.

a

b

A

B

A

B

A = B

A = B

Rank "A"

(on the right of the CRT)

Rank "A"

(on the left of the CRT)

Green only

Blue only

Red only

Signal colour

screen cleared

Fig. 4-1

Fig. 4-2

Fig. 4-3

Text Key "R.G.Cy"" Key can be

directly use to change to other

colours screen.

Page 8

8

8-1 8-2

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

RGB

BGR

R

G

B

R

G

B

B

G

R

B

G

R

RGB

BGR

Lacquer

Wedge "a"

Wedge

"b"

Wedge

"c"

About

100°

About

100°

4-pole magnet

6-pole magnet

CRT neck

20c

m

(21")

Lacquer

Purity magnet

40

cm

(14")

CONVERGENCE ADJUSTMENT

NO. Adjustment part Adjusting procedure and conditions Waveform and others

1

CONVERGENCE

ADJUSTMENT

(To be done

after the purity

adjustment.)

1. Receive the “Crosshatch Pattern” signal.

2. Using the remote controller, call NORMAL

mode.

Static convergence

1. Turn the 4-pole magnet to a proper opening

angle in order to superpose the blue and red

colours.

2. Turn the 6-pole magnet to a proper opening

angle in order to superpose the green colour

over the blue and red colours.

Dynamic convergence

1. Adjust the convergence on the fringes of the

screen in the following steps.

a) Fig. 5-1: Drive the wedge at point “a” and

swing the deflection coil upward.

b) Fig. 5-2: Drive the wedge at points “b” and

“c” and swing the deflection coil

downward.

c) Fig. 5-3: Drive the “c” wedge deeper and

swing the deflection coil rightward.

d) Fig. 5-4: Drive the “b” wedge deeper and

swing the deflection coil leftward.

2. Fix all the wedges on the CRT and apply glass

tape over them.

3. Apply lacquer to the deflection yoke lock screw ,

magnet unit (purity, 4-pole, 6-pole magnets)

and magnet unit lock screw.

Finally received the Red-only and Blue-only

signals to make sure there is no other colours

on the screen.

Fig. 5-2

Fig. 5-1

Fig. 5-3

Fig. 5-4

Fig. 5-5

Fig. 5-6

1. Call “SUB-BRI” in service mode. (Receive

Crosshatch pattern with 5 black level windows)

2. Adjust the “SUB BRIGHT” bus data in order

that the line 1, 2 and 3 have the same darkness

wherelse line 4 is slightly brighter than line 1,

2 and 3 and finally line 5 will be the brighter

than line 4.

1. Switch TV to VIDEO mode, BLUE BACK OFF,

with NO VIDEO signal.

2. Press R/C to set Picture Normal condition.

3. Connect the oscilloscope to Red OUT from

IC801.(TP851 (14")/TP852 (20"/21"))

Range : 1 V/Div (DC)

Sweep : 5 msec/Div

4. Adjust SCREEN VR, so that the tip of signal

reach 3.0 ±0.1 Vdc.

CRT CUT-OFF , BACKGROUND AND SUB-CONTRAST ADJUSTMENT

NO. Adjustment part Adjusting procedure and conditions Waveform and others

1

2

SUBBRIGHTNESS

ADJUSTMENT

(I

2

C BUS

CONTROL)

1, 2 and 3 are in same black level.

CRT CUTOFF

ADJUSTMENT

(I

2

C BUS

CONTROL)

Fig. 6

3

WHITE

BALANCE

SERVICE

MODE

ADJUSTMENT

(I

2

C BUS

CONTROL)

1. Receive the “WHITE” pattern with BURST signal.

2. Press R/C to set Picture NORMAL condition.

3. Connect the DC miliammeter between TP602

(-) and TP603 (+).

4. Check Beam current should be around 1,100 µA

(20"&21") (14" around 800 µA).

5. Set it to service mode and adjust the DRI-GS,

& DRI-BS data to have a colour temperature

of 12,300°K or 7,500°K (white).

* Note .

6. Receive “WHITE” pattern, WITH BURST signal,

and set BRIGHTNESS Y by generator, to ** 10

cd/m2 (MINOLTA CA-100) by reducing

LUMINATE Y signal.

7. Adjust “CUT-R” & “CUT-G” to get desired colour

temperature. Then go back NORMAL mode

(HIGH BRIGHT**) to check colour temperature.

If out 14” back to (1)

Note: This adjustment must be done after

warming up the unit for 30 minutes

or longer with a beam current over

700

µA . (20"&21")

(For 14", the beam current should be

over 500

µA)

* Adjust DRI-GC/GW, DR-BC/BW as following

data, after finishing DRI-BS and DRI-GS data

adjustment.

DRI-RW=32 (FIXED), DRI-GW=”DRI-

GS”-7*, DRI-BW=”DRI-BS”-7*

DRI-RC=25, DRI-BC=”DRI-BS”,

DRI-GC=”DRI-GS”-7*

Refer to Page ????.

* 12,300°K X : 0.272

Y : 0.275

* 18,000°K X : 0.255

Y : 0.255

(MINOLTA COLOUR ANALYZER

CA-100)

*Note: Above Data can be UP/

DOWN by Volume key.

LOW HIGH

14" 10 cd/m2 200 cd/m2

20"/21" 10 cd/m2 120 cd/m2

* 12,300°K DRI-GW=”DRI-GS”-7

DRI-BW=”DRI-BS”-7

* 18,000°K DRI-GC=”DRI-GS”

DATA-5

DRI-RC=27

4

MAXIMUM

BEAM CHECK

1. Receive the “Monoscope Pattern” signal.

2. Press R/C to set Picture NORMAL condition.

3. Connect the DC miliammeter between TP603

(+) and TP602 (–).

(Full Scale: 3 mA Range)

4. Beam current must be within 1,100 ±100µA

(21") 800 ± 100 µA(14") .

1 V

3.0Vdc

0

1 2 3 4 5

Fig. 7

Page 9

9-1 9-2

9

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

HORIZONTAL, VERTICAL, DEFLECTION LOOP AND FOCUS ADJUSTMENT

NO. Adjustment part Adjusting procedure and conditions Waveform and others

1

2

3

4

5

V-SLOPE

(I

2

C BUS

CONTROL)

V-SHIFT-50

(I

2

C BUS

CONTROL)

V-AMP 50

(I2C BUS

CONTROL)

S-CORRECTION

(I2C BUS

CONTROL)

H-SHIFT (50)

(H-CENTER)

(I

2

C BUS

CONTROL)

1. Receive Monoscope Pattern Signal.

2. Call the “V-LIN” mode.

3. Increase or decrease “V-LIN” by Volume key till

the horizontal line in the center of monoscope is

just at the position where the blanking starts.

1. Call the “V-CENT” mode.

2. Increase or decrease “V-CENT” by Volume key

till the picture is centered.

1. Call the “V-AMP” mode.

2. Increase or decrease “V- AMP” b y Volume key

to set overscan of 9.5% typical.

Adjustment Spec 9.5% range +1% -0%.

FIXED DA TA, NO NEED TO ADJUST.

1. Call the “H-CENT” mode.

2. Increase or decrease “H-CENT” by V olume ke y

to center the picture horizontal.

PAL CHROMA ADJUSTMENT

NO. Adjustment part Adjusting procedure and conditions Waveform and others

1 SUB COLOUR

(I

2

C BUS

CONTROL)

1. Receive the “PAL Colour Bar” signal.

2. Press R/C to set Picture Normal condition.

3. Connect the oscilloscope to Red cathode.

» Range : 20 V/Div . (AC) (Use 10:1 probe)

» Sweep time : 10 µsec/Div.

4. Using the R/C call “SUB COL” in SERVICE

mode. Adjust SUB COLOUR bus data, so that

the 75% White & Red portions of PAL Colour

Bar be at the same level shown as Fig. 8.

5. Clear the SERVICE mode.

1

FOCUS

ADJUSTMENT

1. Receive the “Monoscope Pattern” signal.

2. Press R/C to set Picture NORMAL condition.

3. Adjust the focus control to get the best focusing.

Cy

G

B

W

Y 100%W

75%

Mg R

Fig. 8

NTSC CHROMA ADJUSTMENT

NO. Adjustment part Adjusting procedure and conditions Waveform and others

1 SUB-TINT

(I

2

C BUS

CONTROL)

1. Receive the “NTSC 3.58 Colour Bar” signal thru

AV in.

2. Connect the oscilloscope to TP853 (Pin (5) of

P882) BLUE-OUT .

» Range : 100 mV/Div. (AC)

(Use Probe 10:1)

» Sweep time: 10 µsec/Div.

3. Call the “SUB-TINT” mode in service mode.

Adjust the “SUB-TINT” bus data to obtain the

waveform shown as Fig. 9.

4. Clear the SERVICE mode.

PROTECTOR OPERATION CHECKING

NO. Adjustment part Adjusting procedure and conditions Waveform and others

1 BEAM

PROTECTOR

1. Receive “Monoscope Pattern” signal.

2. Set CONTRAST MAX.

3. Set BRIGHT MAX.

4. During the Collector & Emitter of Q883/5/7

short, make sure the protector ON and switch

to standby mode.

* Select one of Q883/5/7 to do each

short test.

2H, V

PROTECTOR

1. Receive “Monoscope Pattern” signal.

2. Connect output of Bias Box to D607 cathode

(R606 side).

3. Set voltage of Bias Box to 18V and make sure

the protector is not work.

4. Set voltage of Bias Box to 27V, and make sure

the protector is work.

A/V INPUT AND OUTPUT CHECKING

NO. Adjustment part Adjusting procedure and conditions Waveform and others

1 VIDEO AND

AUDIO OUTPUT

CHECK

1. Receive the “PAL Colour Bar” signal (100%

White Color Bar, Sound 400 Hz 100% Mod

C475.)

2. T erminate the Video output with a 75 ohm impedance. Make sure the output is as specified

(1.0 Vp-p ±3 dB).

3. Terminate the Audio output with a 10K ohm

impedance. Make sure the output is as specified (1.76 Vp-p ±3 dB).

2 VIDEO AND

AUDIO INPUT

CHECK

1. Using the TV/A V k e y on the remote controller,

make sure that the modes change in order of

TV , A V1, A V2 & TV again and the video & audio

output are according to the input terminal for

each mode.

3 OTHER

PROTECTOR

1. Once finish rectified Electrolytic Capacitor short

testing in +B line, check all possible damaged

components on +B line.

(Use random selected set for inspection)

W

SAME LEVEL

Y

Cy G Mg R

B

Fig. 9

Page 10

10

10-1 10-2

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

FUNCTION OPERATION CHECKING (VIDEO AND AUDIO)

NO. Adjustment part Adjusting procedure and conditions Waveform and others

1

2

COLOUR KEY

1. Receive “Colour Bar” signal.

2. Set P-Mode to select COLOUR.

3. Press V olume Up/Down k ey to chec k whether

the COLOUR effect is OK or not.

CONTRAST

KEY

1. Receive “Monoscope Pattern” signal.

2. Set P-Mode to select CONTRAST.

3. Press V olume Up/Do wn k ey to check whether

the CONTRAST effect is OK or not.

3

BRIGHTNESS

KEY

1. Receive “Monoscope Pattern” signal.

2. Set P-Mode to select BRIGHTNESS.

3. Press Volume Up/Down key to check whether

the BRIGHTNESS effect is OK or not

4 TINT KEY 1. Receive the “NTSC Colour Bar” signal thru A V

in.

2. Set P-Mode to select TINT.

3. Press Volume Up/Do wn ke y to check TINT, UP

for GREEN direction and DOWN for PURPLE

direction whether is OK or not.

FUNCTION OPERATION CHECKING (VIDEO AND AUDIO)

(Continued)

NO. Adjustment part Adjusting procedure and conditions Waveform and others

9

COLOUR

SYSTEM

1. Receive the “P AL COLOUR BAR” signal, press

the COLOUR SYSTEM key to select modes

except PAL, check the COLOUR is not working properly. Then, select the “PAL” mode.

Check again its colour so that it is working properly.

2. Receive “SECAM COLOUR BAR” signal,

press COLOUR SYSTEM key to select modes

except SECAM, check the COLOUR is not

working properly. Then, select the “SECAM”

mode. Check again its colour so that it is working properly.

3. Receive “NTSC 4.43/3.58 COLOUR BAR” signal thru AV, press COLOUR SYSTEM key to

select modes except N4.43/3.58, check the

COLOUR is not working properly. Then, select the “NTSC 4.43/3.58” mode. Check again

its colour so that it is working properly.

10

SOUND

SYSTEM

1. Receive “PAL-D/K” signal, press the “SOUND

SYSTEM” turn to B/G, I. Check the sound output is not working properly. Select D/K and

check the sound output to make sure it is working properly.

2. Receive “PAL-I” signal, press the “SOUND

SYSTEM” to select B/G, D/K. Chec k the sound

output is not working properly. Select I and

check the sound output to make sure it is working properly.

3. Receive “PAL-B/G” signal, press the “SOUND

SYSTEM” to select I, D/K. Check the sound

output is not working properly. Select B/G and

check the sound output to make sure it is working properly.

5

SHARPNESS

KEY

1. Receive “Monoscope Pattern” signal.

2. Set P-mode to select SHARPNESS.

3. Press Volume Up/Down key to check whether

the SHARPNESS effect is OK or not.

6

CH DISPLAY

COLOUR

1. All Ch (1~99) will have an OSD display of the

channel number in green colour under AFT ON

condition.

7

NORMAL KEY

1. Once in PICTURE Mode, and the NORMAL

key is pressed, all the settings will be present

to normal setting.

(Normal setting value for every mode).

» CONTRAST : MAX

» COLOUR : CENTER

» BRIGHTNESS : CENTER

» TINT : CENTER

» SHARPNESS : CENTER

Note:If nothing is display mean

contrast, colour, bright, tint

or sharpness are all in normal setting.

8

WHITE TEMP

1. Receive “Monoscope Pattern” signal.

2. Set FUNCTION to select WHITE TEMP.

3. Press Volume Up/Down key to check WHITE

TEMP Option, STANDARD:

NORMAL SETTING, WARM for more REDDISH direction changing, COOL for more BLUISH direction changing.

11

NOISE MUTE

CHECKING

1. Receive “PAL COLOUR BAR” signal.

2. T urn up the volume control to maximum, make

sure the sound is heard from the speakers.

Then put the unit in no signal state.

3. Check the sound mute is effective.

4. Finally turn sound level of CTV to minimum.

12

OSD

LANGUAGE

QUANTITY

CHECK

There are six language as below;

English, Russian, Chinese, French, Arabic and

Malay.

Page 11

11-1 11-2

11

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

MEMORY MAP

00 PASS WORD 55 00-FF

01

PASS WORD 4F 00-FF

02

PASS WORD 43 00-FF

03

PASS WORD A1 00-FF

04

05

06

AGC TAKE-OVER 0E 00-3F

07

V-SLOPE 20 00-3F

08

V-AMPLITUDE 20 00-3F

09

V-CENTER 20 00-3F

0A

H-CENTER 20 00-3F

0B

H-SIZE 20 00-3F

0C

EW-PARALLELOGRAM 20 00-3F

0D

EW-PARABOLA/WIDTH 20 00-3F

0E

EW-UPPER CORNER 20 00-3F

0F

EW-LOWER CORNER 20 00-3F

10

EW-TRAPEZIUM 20 00-3F

11

HORIZONTAL-BOW 20 00-3F

12

S-CORRECTION 00 00-3F

13

14

15

16

DRIVE-R (STANDARD) 20 00-3F

17

DRIVE-G (STANDARD) 20 00-3F

18

DRIVE-B (STANDARD) 20 00-3F

19

DRIVE-R (WARM) 20 00-3F

1A

DRIVE-G (WARM) 20 00-3F

1B

DRIVE-B (WARM) 20 00-3F

1C

DRIVE-R (COOL) 19 00-3F

1D

DRIVE-G (COOL) 20 00-3F

1E

DRIVE-B (COOL) 20 00-3F

1F

20

21

22

SUB-VOLUME 3F 00-3F

23

SUB-CONTRAST 3F 00-3F

24

SUB-COLOUR 20 00-3F

25

SUB-BRIGHTNESS 20 00-3F

26

SUB-TINT 20 00-3F

27

SUB-SHARPNESS 20 00-3F

28

HTL-VOLUME 20 00-3F

29

HTL-POSITION FF 00-FF

2A

2B

2C

2D

OSD-REFERENCE 0F 00-0F

2E

CUTOFF LEVEL -OFFSET R 08 00-0F

2F

CUTOFF LEVEL -OFFSET B 08 00-0F

30

CATHODE DRIVE LEVEL 00 00-0F

31

Y-DELAY (TV PAL) 0C 00-0F

32

Y-DELAY (TV SECAM) 0F 00-0F

33

Y-DELAY (TV N358) 0C 00-0F

34

Y-DELAY (TV N443) 0C 00-0F

35

Y-DELAY (TV BW) 0C 00-0F

36

Y-DELAY (AV PAL) 0C 00-0F

37

Y-DELAY (AV SECAM) 0F 00-0F

38

Y-DELAY (AV N443) 0C 00-0F

39

Y-DELAY (AV N358) 0C 00-0F

3A

Y-DELAY (AV BW) 0C 00-0F

3B

COLOUR-OFFSET (PAL) 08 00-0F

3C

COLOUR-OFFSET (SECAM) 08 00-0F

3D

COLOUR-OFFSET (N443) 04 00-0F

3E

COLOUR-OFFSET (N358) 04 00-0F

3F

SHARPNESS-OFFSET (PAL) 08 00-0F

MODEL MODEL

LETTER NO. LETTER NO.

ADDRESS

DATA

MICON EEPROM EEPROM CHASSIS CTV FINAL

LAST INITIAL

(HEX) D7 D6 D5 D4 D3 D2 D1 D0

DEFAULT RANGE

WRITE(CPU) CHECK DATA CHECK TYPE CHECK DATA CHECK TYPE

SETTING DATA

REMARK

40

SHARPNESS-OFFSET (SECAM)

04 00-0F

41

SHARPNESS-OFFSET (N443)

0C 00-0F

42

SHARPNESS-OFFSET (N358)

08 00-0F

43

44

FCO ACL OSO EHT EVG FFI AVL BKS

00-FF

45

SCM N443 N358 PB-SEC BG I DK M

00-FF

46

SM FMWS AV BTSC HTL VMC VMI

00-FF

47

HP2 FSL RUS FRA CHN MLY ARB THA

00-FF

48

AGC BIL OBA

00-FF

49

4A

4B

4C

VOLUME

01 00-3C

4D

CONTRAST

3C 00-3C

4E

COLOUR

1E 00-3C

4F

BRIGHTNESS

1E 00-3C

50

TINT

1E 00-3C

51

SHARPNESS

1E 00-3C

52

53

54

55

POSITION/AV1/AV2

01 00-FF

56

FAV-POS A

0A 00-FF

57

FAV-POS B

14 00-FF

58

FAV-POS C

1E 00-FF

59

FAV-POS D

28 00-FF

5A

5B

5C

POWER

00 00-01

5D

WHITE-TEMP

00 00-02

5E

BLUE BACK

00 00-01

5F

LANGUAGE

00 00-07

60

DIGIT

00 00-01

61

62

SKIP 0 SKIP 1 SKIP 2 SKIP 3 SKIP 4 SKIP 5 SKIP 6 SKIP 7

80 00-FF

63

SKIP 8 SKIP 9 SKIP 10 SKIP 11 SKIP 12 SKIP 13 SKIP 14 SKIP 15

00 00-FF

64

SKIP 16 SKIP 17 SKIP 18 SKIP 19 SKIP 20 SKIP 21 SKIP 22 SKIP 23

00 00-FF

65

SKIP 24 SKIP 25 SKIP 26 SKIP 27 SKIP 28 SKIP 29 SKIP 30 SKIP 31

00 00-FF

66

SKIP 32 SKIP 33 SKIP 34 SKIP 35 SKIP 36 SKIP 37 SKIP 38 SKIP 39

00 00-FF

67

SKIP 40 SKIP 41 SKIP 42 SKIP 43 SKIP 44 SKIP 45 SKIP 46 SKIP 47

00 00-FF

68

SKIP 48 SKIP 49 SKIP 50 SKIP 51 SKIP 52 SKIP 53 SKIP 54 SKIP 55

00 00-FF

69

SKIP 56 SKIP 57 SKIP 58 SKIP 59 SKIP 60 SKIP 61 SKIP 62 SKIP 63

00 00-FF

6A

SKIP 64 SKIP 65 SKIP 66 SKIP 67 SKIP 68 SKIP 69 SKIP 70 SKIP 71

00 00-FF

6B

SKIP 72 SKIP 73 SKIP 74 SKIP 75 SKIP 76 SKIP 77 SKIP 78 SKIP 79

00 00-FF

6C

SKIP 80 SKIP 81 SKIP 82 SKIP 83 SKIP 84 SKIP 85 SKIP 86 SKIP 87

00 00-FF

6D

SKIP 88 SKIP 89 SKIP 90 SKIP 91 SKIP 92 SKIP 93 SKIP 94 SKIP 95

00 00-FF

6E

SKIP 96 SKIP 97 SKIP 98 SKIP 99

00 00-FF

6F

70

71

72

73

74

TUNING FREQUENCY (HIGHER PART)

S-SYS

POS 0

75

TUNING FREQUENCY (LOWER PART)

000:BG

76

S-SYS AFT (auto) C-SYS

001:I

77

TUNING FREQUENCY (HIGHER PART)

O1O:DK

POS 1

78

TUNING FREQUENCY (LOWER PART)

011:M

79

S-SYS AFT (auto) C-SYS

7A

TUNING FREQUENCY (HIGHER PART)

AFT

POS 2

7B

TUNING FREQUENCY (LOWER PART)

0:OFF

7C

S-SYS AFT (auto) C-SYS

1:ON

7D

TUNING FREQUENCY (HIGHER PART) POS 3

7E

TUNING FREQUENCY (LOWER PART)

7F

S-SYS AFT (auto) C-SYS

MODEL MODEL

LETTER NO. LETTER NO.

ADDRESS

DATA

MICON EEPROM EEPROM CHASSIS CTV FINAL

LAST INITIAL

(HEX)

D7 D6 D5 D4 D3 D2 D1 D0

DEFAULT RANGE

WRITE(CPU) CHECK DATA CHECK TYPECHECK DATA CHECK TYPE

SETTING DATA

REMARK

Page 12

12

12-1 12-2

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

80

TUNING FREQUENCY (HIGHER PART) POS 4

81

TUNING FREQUENCY (LOWER PART)

82

S-SYS AFT (auto) C-SYS

83

TUNING FREQUENCY (HIGHER PART) POS 5

84

TUNING FREQUENCY (LOWER PART)

85

S-SYS AFT (auto) C-SYS

86

TUNING FREQUENCY (HIGHER PART) POS 6

87

TUNING FREQUENCY (LOWER PART)

88

S-SYS AFT (auto) C-SYS

89

TUNING FREQUENCY (HIGHER PART) POS 7

8A

TUNING FREQUENCY (LOWER PART)

8B

S-SYS AFT (auto) C-SYS

8C

TUNING FREQUENCY (HIGHER PART) POS 8

8D

TUNING FREQUENCY (LOWER PART)

8E

S-SYS AFT (auto) C-SYS

8F

TUNING FREQUENCY (HIGHER PART) POS 9

90

TUNING FREQUENCY (LOWER PART)

91

S-SYS AFT (auto) C-SYS

92

TUNING FREQUENCY (HIGHER PART) POS 10

93

TUNING FREQUENCY (LOWER PART)

94

S-SYS AFT (auto) C-SYS

95

TUNING FREQUENCY (HIGHER PART) POS 11

96

TUNING FREQUENCY (LOWER PART)

97

S-SYS AFT (auto) C-SYS

98

TUNING FREQUENCY (HIGHER PART) POS 12

99

TUNING FREQUENCY (LOWER PART)

9A

S-SYS AFT (auto) C-SYS

9B

TUNING FREQUENCY (HIGHER PART) POS 13

9C

TUNING FREQUENCY (LOWER PART)

9D

S-SYS AFT (auto) C-SYS

9E

TUNING FREQUENCY (HIGHER PART) POS 14

9F

TUNING FREQUENCY (LOWER PART)

A0

S-SYS AFT (auto) C-SYS

A1

TUNING FREQUENCY (HIGHER PART) POS 15

A2

TUNING FREQUENCY (LOWER PART)

A3

S-SYS AFT (auto) C-SYS

A4

TUNING FREQUENCY (HIGHER PART) POS 16

A5

TUNING FREQUENCY (LOWER PART)

A6

S-SYS AFT (auto) C-SYS

A7

TUNING FREQUENCY (HIGHER PART) POS 17

A8

TUNING FREQUENCY (LOWER PART)

A9

S-SYS AFT (auto) C-SYS

AA

TUNING FREQUENCY (HIGHER PART) POS 18

AB

TUNING FREQUENCY (LOWER PART)

AC

S-SYS AFT (auto) C-SYS

AD

TUNING FREQUENCY (HIGHER PART) POS 19

AE

TUNING FREQUENCY (LOWER PART)

AF

S-SYS AFT (auto) C-SYS

B0

TUNING FREQUENCY (HIGHER PART) POS 20

B1

TUNING FREQUENCY (LOWER PART)

B2

S-SYS AFT (auto) C-SYS

B3

TUNING FREQUENCY (HIGHER PART) POS 21

B4

TUNING FREQUENCY (LOWER PART)

B5

S-SYS AFT (auto) C-SYS

B6

TUNING FREQUENCY (HIGHER PART) POS 22

B7

TUNING FREQUENCY (LOWER PART)

B8

S-SYS AFT (auto) C-SYS

B9

TUNING FREQUENCY (HIGHER PART) POS 23

BA

TUNING FREQUENCY (LOWER PART)

BB

S-SYS AFT (auto) C-SYS

BC

TUNING FREQUENCY (HIGHER PART) POS 24

BD

TUNING FREQUENCY (LOWER PART)

BE

S-SYS AFT (auto) C-SYS

BF

TUNING FREQUENCY (HIGHER PART) POS 25

MODEL MODEL

LETTER NO. LETTER NO.

ADDRESS

DATA

MICON EEPROM EEPROM CHASSIS CTV FINAL

LAST INITIAL

(HEX) D7 D6 D5 D4 D3 D2 D1 D0

DEFAULT RANGE

WRITE(CPU) CHECK DATA CHECK TYPE CHECK DATA CHECK TYPE

SETTING DATA

REMARK

C0

TUNING FREQUENCY (LOWER PART) POS 25

C1

S-SYS AFT (auto) C-SYS

C2

TUNING FREQUENCY (HIGHER PART) POS 26

C3

TUNING FREQUENCY (LOWER PART)

C4

S-SYS AFT (auto) C-SYS

C5

TUNING FREQUENCY (HIGHER PART) POS 27

C6

TUNING FREQUENCY (LOWER PART)

C7

S-SYS AFT (auto) C-SYS

C8

TUNING FREQUENCY (HIGHER PART) POS 28

C9

TUNING FREQUENCY (LOWER PART)

CA

S-SYS AFT (auto) C-SYS

CB

TUNING FREQUENCY (HIGHER PART) POS 29

CC

TUNING FREQUENCY (LOWER PART)

CD

S-SYS AFT (auto) C-SYS

CE

TUNING FREQUENCY (HIGHER PART) POS 30

CF

TUNING FREQUENCY (LOWER PART)

D0

S-SYS AFT (auto) C-SYS

D1

TUNING FREQUENCY (HIGHER PART) POS 31

D2

TUNING FREQUENCY (LOWER PART)

D3

S-SYS AFT (auto) C-SYS

D4

TUNING FREQUENCY (HIGHER PART) POS 32

D5

TUNING FREQUENCY (LOWER PART)

D6

S-SYS AFT (auto) C-SYS

D7

TUNING FREQUENCY (HIGHER PART) POS 33

D8

TUNING FREQUENCY (LOWER PART)

D9

S-SYS AFT (auto) C-SYS

DA

TUNING FREQUENCY (HIGHER PART) POS 34

DB

TUNING FREQUENCY (LOWER PART)

DC

S-SYS AFT (auto) C-SYS

DD

TUNING FREQUENCY (HIGHER PART) POS 35

DE

TUNING FREQUENCY (LOWER PART)

DF

S-SYS AFT (auto) C-SYS

E0

TUNING FREQUENCY (HIGHER PART) POS 36

E1

TUNING FREQUENCY (LOWER PART)

E2

S-SYS AFT (auto) C-SYS

E3

TUNING FREQUENCY (HIGHER PART) POS 37

E4

TUNING FREQUENCY (LOWER PART)

E5

S-SYS AFT (auto) C-SYS

E6

TUNING FREQUENCY (HIGHER PART) POS 38

E7

TUNING FREQUENCY (LOWER PART)

E8

S-SYS AFT (auto) C-SYS

E9

TUNING FREQUENCY (HIGHER PART) POS 39

EA

TUNING FREQUENCY (LOWER PART)

EB

S-SYS AFT (auto) C-SYS

EC

TUNING FREQUENCY (HIGHER PART) POS 40

ED

TUNING FREQUENCY (LOWER PART)

EE

S-SYS AFT (auto) C-SYS

EF

TUNING FREQUENCY (HIGHER PART) POS 41

F0

TUNING FREQUENCY (LOWER PART)

F1

S-SYS AFT (auto) C-SYS

F2

TUNING FREQUENCY (HIGHER PART) POS 42

F3

TUNING FREQUENCY (LOWER PART)

F4

S-SYS AFT (auto) C-SYS

F5

TUNING FREQUENCY (HIGHER PART) POS 43

F6

TUNING FREQUENCY (LOWER PART)

F7

S-SYS AFT (auto) C-SYS

F8

TUNING FREQUENCY (HIGHER PART) POS 44

F9

TUNING FREQUENCY (LOWER PART)

FA

S-SYS AFT (auto) C-SYS

FB

TUNING FREQUENCY (HIGHER PART) POS 45

FC

TUNING FREQUENCY (LOWER PART)

FD

S-SYS AFT (auto) C-SYS

FE

POS 46

FF

MODEL MODEL

LETTER NO. LETTER NO.

ADDRESS

DATA

MICON EEPROM EEPROM CHASSIS CTV FINAL

LAST INITIAL

(HEX) D7 D6 D5 D4 D3 D2 D1 D0

DEFAULT RANGE

WRITE(CPU) CHECK DATA CHECK TYPE CHECK DATA CHECK TYPE

SETTING DATA

REMARK

Page 13

13-1 13-2

13

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

100

POS 46

101

TUNING FREQUENCY (HIGHER PART) POS 47

102

TUNING FREQUENCY (LOWER PART)

103

S-SYS AFT (auto) C-SYS

104

TUNING FREQUENCY (HIGHER PART) POS 48

105

TUNING FREQUENCY (LOWER PART)

106

S-SYS AFT (auto) C-SYS

107

TUNING FREQUENCY (HIGHER PART) POS 49

108

TUNING FREQUENCY (LOWER PART)

109

S-SYS AFT (auto) C-SYS

10A

TUNING FREQUENCY (HIGHER PART) POS 50

10B

TUNING FREQUENCY (LOWER PART)

10C

S-SYS AFT (auto) C-SYS

10D

TUNING FREQUENCY (HIGHER PART) POS 51

10E

TUNING FREQUENCY (LOWER PART)

10F

S-SYS AFT (auto) C-SYS

110

TUNING FREQUENCY (HIGHER PART) POS 52

111

TUNING FREQUENCY (LOWER PART)

112

S-SYS AFT (auto) C-SYS

113

TUNING FREQUENCY (HIGHER PART) POS 53

114

TUNING FREQUENCY (LOWER PART)

115

S-SYS AFT (auto) C-SYS

116

TUNING FREQUENCY (HIGHER PART) POS 54

117

TUNING FREQUENCY (LOWER PART)

118

S-SYS AFT (auto) C-SYS

119

TUNING FREQUENCY (HIGHER PART) POS 55

11A

TUNING FREQUENCY (LOWER PART)

11B

S-SYS AFT (auto) C-SYS

11C

TUNING FREQUENCY (HIGHER PART) POS 56

11D

TUNING FREQUENCY (LOWER PART)

11E

S-SYS AFT (auto) C-SYS

11F

TUNING FREQUENCY (HIGHER PART) POS 57

120

TUNING FREQUENCY (LOWER PART)

121

S-SYS AFT (auto) C-SYS

122

TUNING FREQUENCY (HIGHER PART) POS 58

123

TUNING FREQUENCY (LOWER PART)

124

S-SYS AFT (auto) C-SYS

125

TUNING FREQUENCY (HIGHER PART) POS 59

126

TUNING FREQUENCY (LOWER PART)

127

S-SYS AFT (auto) C-SYS

128

TUNING FREQUENCY (HIGHER PART) POS 60

129

TUNING FREQUENCY (LOWER PART)

12A

S-SYS AFT (auto) C-SYS

12B

TUNING FREQUENCY (HIGHER PART) POS 61

12C

TUNING FREQUENCY (LOWER PART)

12D

S-SYS AFT (auto) C-SYS

12E

TUNING FREQUENCY (HIGHER PART) POS 62

12F

TUNING FREQUENCY (LOWER PART)

130

S-SYS AFT (auto) C-SYS

131

TUNING FREQUENCY (HIGHER PART) POS 63

132

TUNING FREQUENCY (LOWER PART)

133

S-SYS AFT (auto) C-SYS

134

TUNING FREQUENCY (HIGHER PART) POS 64

135

TUNING FREQUENCY (LOWER PART)

136

S-SYS AFT (auto) C-SYS

137

TUNING FREQUENCY (HIGHER PART) POS 65

138

TUNING FREQUENCY (LOWER PART)

139

S-SYS AFT (auto) C-SYS

13A

TUNING FREQUENCY (HIGHER PART) POS 66

13B

TUNING FREQUENCY (LOWER PART)

13C

S-SYS AFT (auto) C-SYS

13D

TUNING FREQUENCY (HIGHER PART) POS 67

13E

TUNING FREQUENCY (LOWER PART)

13F

S-SYS AFT (auto) C-SYS

MODEL MODEL

LETTER NO. LETTER NO.

ADDRESS

DATA

MICON EEPROM EEPROM CHASSIS CTV FINAL

LAST INITIAL

(HEX) D7 D6 D5 D4 D3 D2 D1 D0

DEFAULT RANGE

WRITE(CPU) CHECK DATA CHECK TYPE CHECK DATA CHECK TYPE

SETTING DATA

REMARK

140

TUNING FREQUENCY (HIGHER PART) POS 68

141

TUNING FREQUENCY (LOWER PART)

142

S-SYS AFT (auto) C-SYS

143

TUNING FREQUENCY (HIGHER PART) POS 69

144

TUNING FREQUENCY (LOWER PART)

145

S-SYS AFT (auto) C-SYS

146

TUNING FREQUENCY (HIGHER PART) POS 70

147

TUNING FREQUENCY (LOWER PART)

148

S-SYS AFT (auto) C-SYS

149

TUNING FREQUENCY (HIGHER PART) POS 71

14A

TUNING FREQUENCY (LOWER PART)

14B

S-SYS AFT (auto) C-SYS

14C

TUNING FREQUENCY (HIGHER PART) POS 72

14D

TUNING FREQUENCY (LOWER PART)

14E

S-SYS AFT (auto) C-SYS

14F

TUNING FREQUENCY (HIGHER PART) POS 73

150

TUNING FREQUENCY (LOWER PART)

151

S-SYS AFT (auto) C-SYS

152

TUNING FREQUENCY (HIGHER PART) POS 74

153

TUNING FREQUENCY (LOWER PART)

154

S-SYS AFT (auto) C-SYS

155

TUNING FREQUENCY (HIGHER PART) POS 75

156

TUNING FREQUENCY (LOWER PART)

157

S-SYS AFT (auto) C-SYS

158

TUNING FREQUENCY (HIGHER PART) POS 76

159

TUNING FREQUENCY (LOWER PART)

15A

S-SYS AFT (auto) C-SYS

15B

TUNING FREQUENCY (HIGHER PART) POS 77

15C

TUNING FREQUENCY (LOWER PART)

15D

S-SYS AFT (auto) C-SYS

15E

TUNING FREQUENCY (HIGHER PART) POS 78

15F

TUNING FREQUENCY (LOWER PART)

160

S-SYS AFT (auto) C-SYS

161

TUNING FREQUENCY (HIGHER PART) POS 79

162

TUNING FREQUENCY (LOWER PART)

163

S-SYS AFT (auto) C-SYS

164

TUNING FREQUENCY (HIGHER PART) POS 80

165

TUNING FREQUENCY (LOWER PART)

166

S-SYS AFT (auto) C-SYS

167

TUNING FREQUENCY (HIGHER PART) POS 81

168

TUNING FREQUENCY (LOWER PART)

169

S-SYS AFT (auto) C-SYS

16A

TUNING FREQUENCY (HIGHER PART) POS 82

16B

TUNING FREQUENCY (LOWER PART)

16C

S-SYS AFT (auto) C-SYS

16D

TUNING FREQUENCY (HIGHER PART) POS 83

16E

TUNING FREQUENCY (LOWER PART)

16F

S-SYS AFT (auto) C-SYS

170

TUNING FREQUENCY (HIGHER PART) POS 84

171

TUNING FREQUENCY (LOWER PART)

172

S-SYS AFT (auto) C-SYS

173

TUNING FREQUENCY (HIGHER PART) POS 85

174

TUNING FREQUENCY (LOWER PART)

175

S-SYS AFT (auto) C-SYS

176

TUNING FREQUENCY (HIGHER PART) POS 86

177

TUNING FREQUENCY (LOWER PART)

178

S-SYS AFT (auto) C-SYS

179

TUNING FREQUENCY (HIGHER PART) POS 87

17A

TUNING FREQUENCY (LOWER PART)

17B

S-SYS AFT (auto) C-SYS

17C

TUNING FREQUENCY (HIGHER PART) POS 88

17D

TUNING FREQUENCY (LOWER PART)

17E

S-SYS AFT (auto) C-SYS

17F

POS 89

MODEL MODEL

LETTER NO. LETTER NO.

ADDRESS

DATA

MICON EEPROM EEPROM CHASSIS CTV FINAL

LAST INITIAL

(HEX) D7 D6 D5 D4 D3 D2 D1 D0

DEFAULT RANGE

WRITE(CPU) CHECK DATA CHECK TYPE CHECK DATA CHECK TYPE

SETTING DATA

REMARK

Page 14

14

14-1 14-2

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

180

POS 89

181

182

TUNING FREQUENCY (HIGHER PART) POS 90

183

TUNING FREQUENCY (LOWER PART)

184

S-SYS AFT (auto) C-SYS

185

TUNING FREQUENCY (HIGHER PART) POS 91

186

TUNING FREQUENCY (LOWER PART)

187

S-SYS AFT (auto) C-SYS

188

TUNING FREQUENCY (HIGHER PART) POS 92

189

TUNING FREQUENCY (LOWER PART)

18A

S-SYS AFT (auto) C-SYS

18B

TUNING FREQUENCY (HIGHER PART) POS 93

18C

TUNING FREQUENCY (LOWER PART)

18D

S-SYS AFT (auto) C-SYS

18E

TUNING FREQUENCY (HIGHER PART) POS 94

18F

TUNING FREQUENCY (LOWER PART)

190

S-SYS AFT (auto) C-SYS

191

TUNING FREQUENCY (HIGHER PART) POS 95

192

TUNING FREQUENCY (LOWER PART)

193

S-SYS AFT (auto) C-SYS

194

TUNING FREQUENCY (HIGHER PART) POS 96

195

TUNING FREQUENCY (LOWER PART)

196

S-SYS AFT (auto) C-SYS

197

TUNING FREQUENCY (HIGHER PART) POS 97

198

TUNING FREQUENCY (LOWER PART)

199

S-SYS AFT (auto) C-SYS

19A

TUNING FREQUENCY (HIGHER PART) POS 98

19B

TUNING FREQUENCY (LOWER PART)

19C

S-SYS AFT (auto) C-SYS

19D

TUNING FREQUENCY (HIGHER PART) POS 99

19E

TUNING FREQUENCY (LOWER PART)

19F

S-SYS AFT (auto) C-SYS

1A0

AV1

1A1

1A2

(auto) C-SYS

1A3

AV2

1A4

1A5

(auto) C-SYS

1A6

1A7

1A8

1A9

1AA

1AB

1AC

1AD

1AE

1AF

1B0

1B1

1B2

1B3

1B4

1B5

1B6

1B7

1B8

1B9

1BA

1BB

1BC

1BD

1BE

1BF

MODEL MODEL

LETTER NO. LETTER NO.

ADDRESS

DATA

MICON EEPROM EEPROM CHASSIS CTV FINAL

LAST INITIAL

(HEX) D7 D6 D5 D4 D3 D2 D1 D0

DEFAULT RANGE

WRITE(CPU) CHECK DATA CHECK TYPE CHECK DATA CHECK TYPE

SETTING DATA

REMARK

Page 15

15-1 15-2

15

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

UA1 HOTEL MODE APPLICATION NOTE

The purpose of this HOTEL MODE is to enable hotel authorized person to store the tuned

programs as hotel channels, current volume as hotel volume (maximum volume), picture and

sound setting. In addition, The user will not be able to select Preset and Channel-setting functions.

How to enable/disable the “Hotel Mode” ?

Ans: a) Select BLUE BACK function (under MENU-FEATURE selection) by R/C,

press the -/— (one/two digit) key and keep pressing it for five second, then you can

see the hotel mode with four digits password.

b) Key in the four digits password starting with number “1”, “3”, “7”, “9”, then the hotel

mode will be ENABLE condition, you can switch on/off the hotel mode by using R/C

(volume up/down) key.

* We recommend:

Before set the hotel mode, it is better to choose CH 1 & set SOUND VOLUME level Up to

75% full scale.

After set hotel mode, starting channel will be always ch 1 & maximum sound level out will

be set to 75% of full scale.

* If you set hotel mode in AV, starting channel will be the last ch which you received before

power off (same as normal operation).

CONDITION:

When using hotel mode, the user can ONLY control PICTURE, SOUND and FEATURE

selection. But, It will return to the previous hotel mode setting condition, after power off.

The user can’t use: — CH-SETTING (OSD become violet) and Preset. Other functions is

allowed to be used.

#1 Ch 1 is your selected

channel for hotel mode.

Input 1, 3, 7 and 9 by R/C key.

Set VOL UP/DOWN by R/C key.

HOTEL MODE ON

PASSWORD ****

TROUBLE SHOO TING TABLE

NO RASTER

Blown out.

Replace the fuse.

Check IC701, D701 and

C707.

Abnormal

YES

ON/OFF ON

NO

Abnormal Normal

The fuse is blown out again.

Does horizontal circuit

oscillate ?

Check IC801, IC751, D605

and Q601.

D1001 (Power LED Red)

turns on or turns ON/OFF.

Check T701 pin (7) voltage

(Approx. 310V at 220V AC)

Check F701.

Normal

Check Secondary Main+B

T701 pin (17) voltage

(Approx. 115V)

Normal

Normal Abnormal

Normal

Check CRT connector

K1-K5 bias.

Check

IC801.

Check

C787.

Checking the

protector circuit.

Check R615 and R618.

D1001 (Power LED Green)

turns on.

Check D758, IC702, IC753

and R712.

Check R701, R707 and

D709.

NO

Page 16

16

16-1 16-2

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

TROUBLE SHOO TING TABLE (Continued) TROUBLE SHOOTING TABLE (Continued)

NEITHER VERTICAL NOR

HORIZONTAL SYNCHRONIZATION

CIRCUIT TO BE CHECKED:

Sync. Separator Circuit.

NO VERTICAL SCAN

Check R503, R504, R506,

R513, C517 and D501.

DEFECTIVE VERTICAL AMP.

AND VERTICAL LINEARITY

Readjust Vertical Size.

(Bus Data)

Check pins (16), (17) and

(34) of IC801.

Check IC501 Bias pins (3)

and (6).

Normal Abnormal

Vertical Linearity and Size

are abnormal.

Check pins (21) and (22) of

IC801.

Check C503, C507 and

power supply circuit.

NO PICTURE, NO SOUND

No snow noise.

Does signal appear at pin (40) of

IC801 ?

Noise increases but no signal is

received.

Check the tuner supply voltage LB must

be approx. 5V. BT must be approx. 33V

and CH preset data check.

Check the tuner AGC

at TP201.

Does noise or

signal appear at

pin (38) of IC801 ?

Check IC801 and

its related circuit.

Check Q205 and

its related circuit.

Does noise or signal

appear at pins (23)

and (24) of IC801.

Check pin (1) of

SF201, Tuner and

related circuit.

Check pin (37) of

IC801 and related

circuit.

Check pin (27) of

IC801, Tuner and

related circuit.

Does the noise level increase at max.

Contrast, Brightness and Sound controls ?

CIRCUITS TO BE CHECKED:

Tuner.

PIF.

Automatic Gain Control.

(5V), (33V) Power Source.

AbnormalNormal

Normal

YES

YES

YES

NO

NO

NO

Check pin (38) of

IC801.

Does signal appear at pin

(44) of IC801 ?

NO SOUND

Check IC801.

Check C356 and

peripheral circuit.

CIRCUITS TO BE CHECKED:

» Sound system pins (28) and

(44) of IC801.

» Sound Detector Circuit.

» Sound Switch and Att.

Control.

» Audio Output Circuit.

Does signal appear at pins

(6) and (8) of IC301 ?

Check P301 connector of

IC301 and peripheral circuit.

Check Q301, pins (4) and (6)

of IC801 and peripheral

circuit.

Does signal appear at pin (28)

of IC801?

YES

YES

(Signal)

YES

NO

NO

NO

Page 17

17-1 17-2

17

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

TROUBLE SHOOTING TABLE (Continued)

NO SPECIFIC COLOUR

Is some colour produced in

B/W broadcast reception ?

Is the white balance properly

adjusted ?

Readjust the white balance.

The picture colour is yellow.The picture colour is magenta.The picture colour is cyan.

Check Q870, Q885 and its

adjacent circuits (for 20"&21").

Check Q871, Q883 and its

adjacent circuits (for 14").

Check Q871, Q883 and its

adjacent circuits (for 20"&21").

Check Q870, Q885 and its

adjacent circuits (for 14").

Check Q872, Q887 and its

adjacent circuits.

Check IC801 and Bias

control circuit.

Normal

NO SPECIFICATION COLOUR

“PAL/SECAM”

(NO COLOUR SYNCHRONIZATION)

NO YES

YES

NO

Check IC801, R801, R802,

R803, D804, D805, D806

and Q801.

Check X1001(12 MHz).

Page 18

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

SOLID STATE DEVICE BASE DIAGRAM

TOP VIEW

85

14

M24C04W

64 33

132

IX3368CE

SIDE VIEW

BASE

COLLECTOR

EMITTER

2SC1815

43

12

FX0008GE D601A

COLLECTOR

JC

BASE EMITTER

2SC2735

BASE

COLLECTOR

EMITTER

123

PST573J

2SC2482

COLLECTOR

2R

BASE EMITTER

SE115N

COLLECTOR

:BR:

BASE EMITTER

B709A

+ ~ ~ -

DX0386CE

BCE

2SD1877(14")

2SD2586(20" & 21")

1

3

TA48M033

ANODE

(RED)

CATHODE

(COMMON)

ANODE

(GREEN)

PX0423CE

STRF6653(14")

STRF6654(20" & 21")

123

KA7808

KA7805

EMITTER

BF421

BF422

24

135

TDA8357

BASE

COLLECTOR

9

LA7016

TDA7056A

18

Page 19

CHASSIS LAYOUT : 14BM2S/G

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

19

Page 20

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

CHASSIS LAYOUT : 20BM2S/G

20

Page 21

CHASSIS LAYOUT : 21BM2S/G

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

21

Page 22

1234567891011 12 13 14 15 16 17 18 19 20

A

B

C

D

E

F

G

H

I

J

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

22~23

MAIN UNIT BLOCK DIAGRAM

Page 23

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

BLOCK DIAGRAM

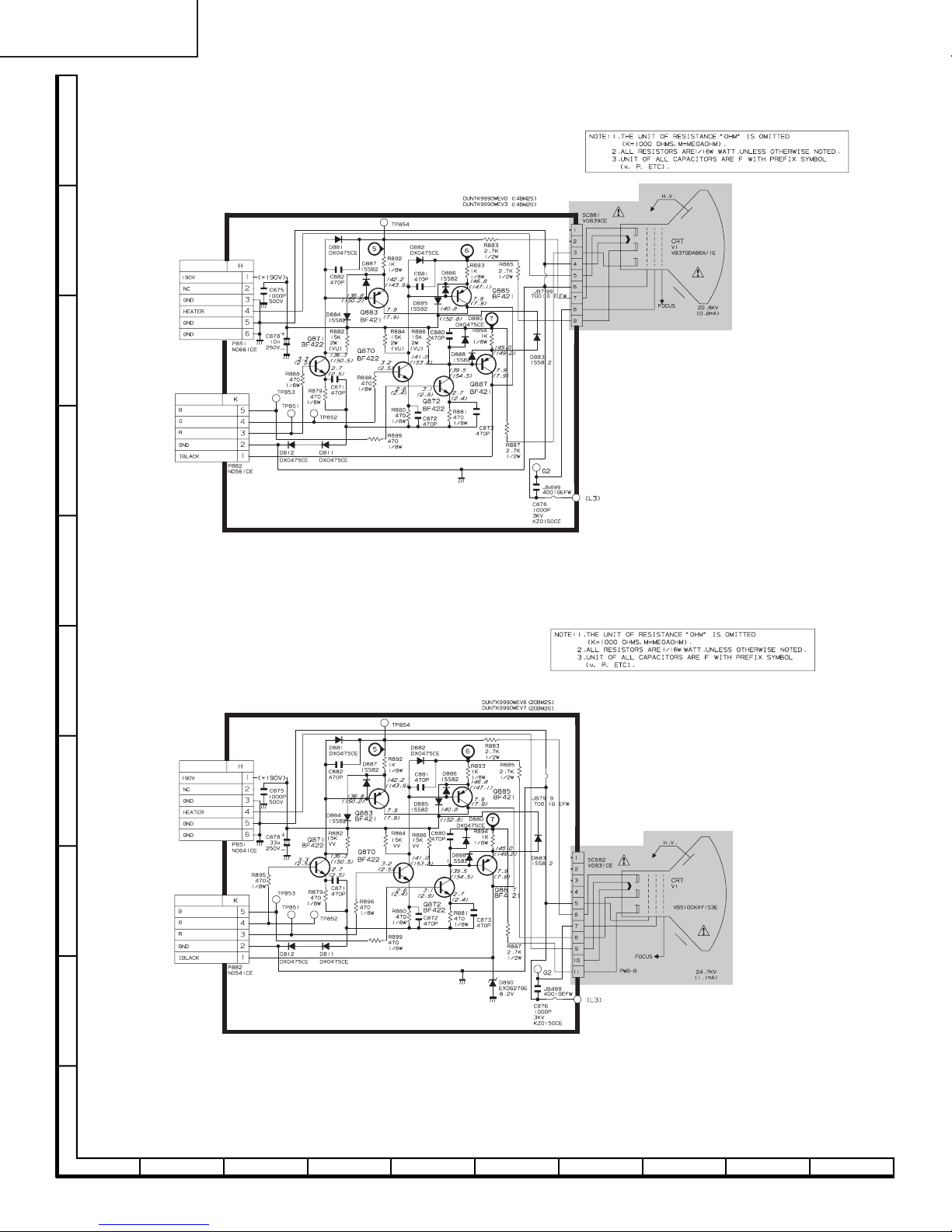

CRT UNIT BLOCK DIAGRAM : 14BM2S/G

CRT UNIT BLOCK DIAGRAM : 20BM2S/G/21BM2S/G

24

Page 24

WA VEFORMS

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

1 1.00Vp-p 14"

1.12Vp-p 21" & 20"

6 66.0Vp-p 14"

80.0Vp-p 21" & 20"

2 2.50Vp-p 14"

3.17Vp-p 21" & 20"

7 72.0Vp-p 14"

87.2Vp-p 21" & 20"

3 2.55Vp-p 14"

3.11Vp-p 21" & 20"

8 3.00Vp-p 14"

3.11Vp-p 21" & 20"

4 3.35Vp-p 14"

3.11Vp-p 21" & 20"

9 1.85Vp-p 14"

1.93Vp-p 21" & 20"

5 68.0Vp-p 14"

83.8Vp-p 21" & 20"

0 150Vp-p 14"

133Vp-p 21" & 20"

q 8.40Vp-p 14"

8.48Vp-p 21" & 20"

y 1,050Vp-p 14"

980Vp-p 21" & 20"

w 1.30Vp-p 14"

1.17Vp-p 21" & 20"

u 2.40Vp-p 14"

2.60Vp-p 21" & 20"

e 0.98Vp-p 14"

0.91Vp-p 21" & 20"

i 500Vp-p 14"

510Vp-p 21" & 20"

25

r 43.0Vp-p 14"

48.0Vp-p 21" & 20"

t 190.0Vp-p 14"

130.5Vp-p 21" & 20"

Page 25

DESCRIPTION OF SCHEMATIC DIAGRAM

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

SAFETY NOTES:

1. DISCONNECT THE AC PLUG FROM THE AC OUTLET BEFORE

REPLACING PARTS.

2. SEMICONDUCTOR HEAT SINKS SHOULD BE REGARDED AS

POTENTIAL SHOCK HAZARDS WHEN THE CHASSIS IS OPERATING.

IMPORTANT SAFETY NOTICE:

PARTS MARKED WITH “å” ( ) ARE IMPORTANT FOR

MAINTAINING THE SAFETY OF THE SET. BE SURE TO REPLACE THESE PARTS WITH SPECIFIED ONES FOR MAINTAINING THE SAFETY AND PERFORMANCE OF THE SET.

SERVICE PRECAUTION:

THE AREA ENCLOSED BY THIS LINE (

CONNECTED WITH AC MAINS VOLTAGE.

WHEN SERVICING THE AREA, CONNECT AN ISOLATING TRANSFORMER BETWEEN TV RECEIVER AND AC LINE TO ELIMINATE

HAZARD OF ELECTRIC SHOCK.

) IS DIRECTLY

NOTES:

1. The unit of resistance “ohm” is omitted.

(K = 1000 ohms, M = Meg ohm).

2. All resistors are 1/16 watt, unless otherwise noted.

3. Unit of all capacitors are F with prefix symbol (

µ,

P, ETC) .

VOLTAGE MEASUREMENT CONDITIONS:

1. Voltage in parenthesis measured with no Signal.

2. Voltages without parenthesis measured with PAL Colour-Signal.

3. All the voltages in each point are measured with high impedence

volt-meter.

WAVEFORM MEASUREMENT CONDITIONS:

1. Colour bar generator signal of 1.8V peak to peak applied at Base

of Video Buffer Amp. Q203.

2. Approximately 4.0 V AGC bias.

27

Page 26

1234567891011 12 13 14 15 16 17 18 19 20

A

B

C

D

E

F

G

H

I

J

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

28~29

MAIN UNIT : 14BM2S/G

Page 27

1234567891011 12 13 14 15 16 17 18 19 20

A

B

C

D

E

F

G

H

I

J

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

30~31

MAIN UNIT : 20BM2S/G

Page 28

1234567891011 12 13 14 15 16 17 18 19 20

A

B

C

D

E

F

G

H

I

J

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

32~33

MAIN UNIT : 21BM2S/G

Page 29

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

CRT UNIT : 14BM2S/G

J

I

H

G

F

CRT UNIT : 20BM2S/G

E

D

C

B

A

12345678910

34

Page 30

CRT UNIT : 21BM2S/G

J

I

H

G

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

F

E

D

C

B

A

12345678910

35

Page 31

1234567891011 12 13 14 15 16 17 18 19 20

A

B

C

D

E

F

G

H

I

J

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

36~37

PRINTED WIRING BOARD ASSEMBLIES

PWB-A: MAIN Unit (Wiring Side)

Page 32

1234567891011 12 13 14 15 16 17 18 19 20

A

B

C

D

E

F

G

H

I

J

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

38~39

PWB-A: MAIN Unit (Chip Parts Side)

Page 33

14BM2, 14BM2S/G

20BM2, 20BM2S/G

21BM2, 21BM2S/G

J

I

H

G

F

E

D

C

B