Page 1

SMT Series

Hot Water - Electric Start - Diesel

Service Manual

Pressure Washer Trailer

MODEL: SMT-354037E

1.103-841.0

WARNING:

This product and accessories may contain a chemical known to the

State of California to cause cancer and birth defects or other

reproductive harm.

For more information about this regulation: www.P65Warnings.ca.gov

9.800-504-0-E 01/05/18

Page 2

Machine Data Label

Model Number: _____________________________________________

Serial Number: ______________________________________________

Date of Purchase: ____________________________________________

The model and serial numbers will be found on a decal attached to the

pressure washer. Record both serial number and date of purchase.

PATENT PENDING

Introduction

Thank you for purchasing this Pressure Washer. We reserve the right to make changes at any time

without incurring any obligation.

Owner/User Responsibility:

The owner and/or user must have an understanding of the manufacturer’s operating instructions and

warnings before using this pressure washer. Warning information should be emphasized and

understood. If the operator is not fluent in English, the manufacturer’s instructions and warnings

shall be read to and discussed with the operator in the operator’s native language by the

purchaser/owner, making sure that the operator comprehends its contents. Owner and/or user must

study and maintain for future reference the manufacturers’ instructions.

Save These Instructions

This manual should be considered a permanent part of the machine and should remain with it if

machine is resold. When ordering parts, please specify model and serial number. Use only identical

replacement parts.This machine is to be used only by trained operators.

Notice

This trailer is equipped to meet applicable U.S. Federal safety standards. Check local and state

requirements regarding brakes and any additional equipment that may be required. Any modifications

or additions including load equalizing hitches, without written factory consent: usage in an

abnormal manner including overloading voids all manufacturers’ warranties and liability.

WARNING: This Owner's Manual contains safety information and instructions for your trailer. You

must read this manual before loading or towing your trailer.

You must follow all safety precautions and instructions.

AVERTISSEMENT: Ce manuel de l'utilisateur contient des informations en matière de sécurité et des

instructions pour la remorque. Lire le présent manuel avant de charger ou de remorquer la remorque.

Suivre toutes les précautions de sécurité et les directives.

2

Shark SMT Operator’s Manual 9.800-504.0 - E

Page 3

Table of Contents

Machine Data Label. . . . . . . . . . . . . . . . . . . . . . . . . .2

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Safety

Important Safety Information. . . . . . . . . . . . . . . . . . .4

Reporting Safety Defects . . . . . . . . . . . . . . . . . . . . .6

Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Important Trailer Safety Information . . . . . . . . . . . .7

Tire Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Understanding Tire Pressure and Load Limits . . . . .7

Tow Vehicles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Safety Chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Load-Carrying Capacity . . . . . . . . . . . . . . . . . . . . .10

Proper Weight Distribution & Tongue Weight. . . . .11

Tongue Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Caster Operations. . . . . . . . . . . . . . . . . . . . . . . . . .12

Trailer Brake Operations. . . . . . . . . . . . . . . . . . . . .13

What to Check And How To Check . . . . . . . . . . . .14

Tire Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Ball Coupler Hitches . . . . . . . . . . . . . . . . . . . . . . . .14

Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Maintenance

Preventative Maintenance . . . . . . . . . . . . . . . . . . .23

Maintenance And Service. . . . . . . . . . . . . . . . . . . .23

Unloader Valves . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Winterizing Procedure. . . . . . . . . . . . . . . . . . . . . . .23

High Limit Hot Water Thermostat . . . . . . . . . . . . . .23

Pumps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Cleaning of Coils. . . . . . . . . . . . . . . . . . . . . . . . . . .23

Fuel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Burner Nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Oil Burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Electrode Setting. . . . . . . . . . . . . . . . . . . . . . . . . . .25

Fuel Pressure Adjustment. . . . . . . . . . . . . . . . . . . .25

Removal of Soot and Heating Coil . . . . . . . . . . . . .25

Hub Inspection Removal-

Replacement And Adjustments. . . . . . . . . . . . . .26

Torque Wrench Method . . . . . . . . . . . . . . . . . . . . .27

Posi-lube Lubrication Procedure. . . . . . . . . . . . . . .27

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Pressure Washer Preventive Maintenance. . . . . . .30

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . .30

Trailer Maintenance Schedule . . . . . . . . . . . . . . . .31

Pump And Engine Oil Change Record . . . . . . . . . .31

Operations

Trailer Component Identification. . . . . . . . . . . . . . .15

Accessory Assembly Instructions . . . . . . . . . . . . . .16

Assembly Instructions. . . . . . . . . . . . . . . . . . . . . . .17

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Operating Instructions. . . . . . . . . . . . . . . . . . . . . . .19

Detergents & General

Operating Techniques. . . . . . . . . . . . . . . . . . . . .20

Cleaning Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Shutting Down And

Clean-Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Rinsing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Shark SMT Operator’s Manual 9.800-504.0 - E

3

Page 4

Safety

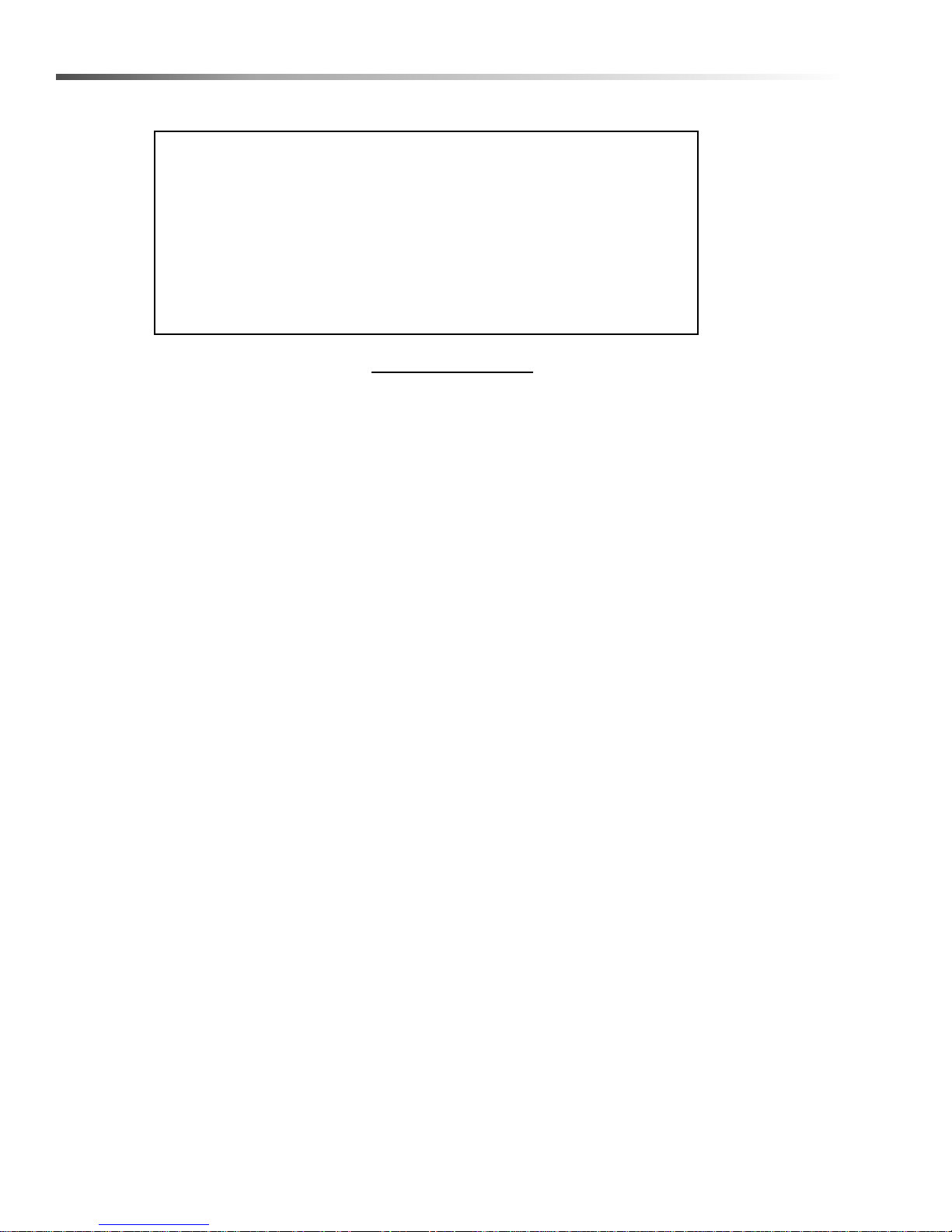

WARNING

READ OPERATOR’S

MANUAL THOROUGHLY

PRIOR TO USE.

OPERATIONS

SAFETY

MAINTENANCE

DANGER

KEEP WATER

SPRAY AWAY FROM

ELECTRICAL WIRING.

WARNING

RISK OF EXPLOSION:

OPERATE ONLY WHERE

OPEN FLAME OR TORCH

IS PERMITTED

WARNING

RISK OF FIRE.

DO NOT ADD FUEL

WHEN OPERATING

MACHINE.

WARNING

USE

PROTECTIVE

EYEWEAR, GLOVES

AND FOOTWEAR

WHEN OPERATING.

Important Safety Information

WARNING: T o reduce the risk of

injury, read operating instructions carefully before using.

AVERTISSEMENT: Pour réduire

le risque de blessures, lire

attentivement les instructions

de fonctionnement avant l'utilisation.

1.Read the owner's manual thor-

oughly. Failure to follow instructions could cause malfunction of the machine and

result in death, serious bodily injury and/or property

damage.

2. Know how to stop the machine and bleed pressure

quickly. Be thoroughly familiar with the controls.

3. Stay alert — watch what you are doing.

DANGER: Keep wand, hose, and

water spray away from electric

wiring or fatal electric shock

may result.

AVERTISSEMENT: Garder la

lance, le boyau et le jet d'eau à

l'écart de tout câblage

électrique ou des chocs

électriques mortels pourraient

survenir.

4. To protect the operator from electrical shock, the

machine must be electrically grounded.

WARNING: Flammable liquids

can create fumes which can

ignite, causing property damage

or severe injury.

AVERTISSEMENT: Des liquides

inflammables peuvent produire

des vapeurs qui peuvent

s'enflammer, causant ainsi des

dommages à la propriété ou des

blessures graves

WARNING: Risk of explosio n — Operate only where

open flame or torch is permitted.

AVERTISSEMENT: Risque d'explosion - Utiliser

uniquement dans des endroits où l'utilisation d'une

flamme nue ou d'une torche est permise.

5. In oil burning models, use only kerosene, No. 1

home heating fuel, or diesel. If diesel is used, add a

soot remover to every tankful.

WARNING: Risk of fire — Do not

add fuel when the product is

operating or still hot.

AVERTISSEMENT: Risque

d'incendie - Ne pas ajouter de

carburant pendant que la

machine fonctionner ou est

encore chaude.

WARNING: Do not use gasoline

crankcase draining or oil

containing gasoline, solvents or alcohol. Doing so

will result in fire and/or explosion.

AVERTISSEMENT: Ne pas utiliser d'e ssence, de

drainage du carter de moteur ou d'essence

contenant de l'huile, de solvants ou de l'alcool.

Agir de la sorte risquerait de créer un incendie et/

ou une explosion.

6. Operate only in locations where combustible dusts

and flammable gases or vapors are not present.

Do not store or use gasoline near this machine.

7. Do not allow acids, caustic or abrasive fluids to

pass through the pump.

8. Never run pump dry or leave spray gun closed

longer than 1-2 minutes.

9. Keep operating area clear of all persons.

WARNING: High pressure spray

can cause paint chips or other

particles to become airborne

and fly at high speeds. T o av oid

personal injury, eye, hand and

foot safety devices must be

worn.

AVERTISSEMENT: Un jet haute

pression peut écailler la

peinture ou provoquer

l'émission d'autres particules dans l'air et leur

projection à hautes vitesses. Po ur év it er les

lésions corporelles, une protection des yeux, du

visage, des mains et des pieds doit être portée lors

de l'utilisation de cet équipement.

10. Always wear properly rated eye protection such as

safety goggles or face shield while spraying.

4

Shark SMT Operator’s Manual 9.800-504.0 - E

(Safety glasses do not provide full protection.)

Page 5

Safety

WARNING

EAR PROTECTION

MUST BE WORN

WARNING

HOT DISCHARGE FLUID:

DO NOT TOUCH OR

DIRECT DISCHARGE

STEAM AT PERSONS.

WARNING

RISK OF INJURY.

HOT SURFACES

CAN CAUSE BURNS

WARNING

TRIGGER GUN KICKS

BACK — HOLD WITH

BOTH HANDS

WARNING

RISK OF INJECTION

OR SEVERE INJURY

TO PERSONS. KEEP

CLEAR OF NOZZLE.

WARNING

PROCTECT FROM

FREEZING

WARNING: This machine

exceeds 85 dB. Appropriate ear

protection must be worn.

AVERTISSEMENT: Cette

machine excède 85 dB et une

protection de l'ouïe appropriée

doit être portée.

WARNING: Hot discharge fluid.

Do not touch or direct discharge

stream at persons or animals.

AVERTISSEMENT: Liquide de

décharge chaud. Ne pas toucher

ou décharger directement le jet

vers des personnes ou des

animaux, car cela risquerait de

causer des blessures graves ou

même la mort.

WARNING: This machine produces hot water and

must have insulated components attached to

protect the operator.

AVERTISSEMENT: Cette machine produit de l'eau

chaude et doit comporter des composants isolés

attachés pour protéger l'opérateur.

WARNING: Risk of injury. Hot

surfaces can cause burns. Use

only designated gripping areas

of spray gun and wand. Do not

place hands or feet on noninsulated areas of the pressure

washer.

AVERTISSEMENT: Risque de

blessures. Les surfaces chaudes

peuvent causer des brûlures.

Utiliser uniquement les zones de prise désignées

du pistolet pulvérisateur et de la lance. Utiliser

uniquement les zones de prise désignées du

pistolet pulvérisateur et de la lance.

11. To reduce the risk of injury, close supervision is

necessary when a machine is used near children.

Do not allow children to operate the pressure

washer. This machine must be attended during

operation.

WARNING: Grip cleaning wand

securely with both hands

before starting. Failure to do

this could result in injury from a

whipping wand.

A VERTISSEMENT: Agripper la

lance de nettoyage avec les

deux mains avant de

commencer. Le non-respect de

cette consigne pourrait mener à

des blessures causées par le

mouvement violent de la lance.

12. Never make adjustments on machine while in

operation.

13. Be certain all quick coupler fittings are secured

before using pressure washer.

WARNING: High pressure

developed by these machines

will cause personal injury or

equipment damage. Keep clear

of nozzle. Use caution when

operating. Do not direct

discharge stream at people or

animals, or severe injury or

death will result.

AVERTISSEMENT: La haute

pression générée par ces machines causera des

lésions corporelles ou des dommages à

l'équipement. Ne pas décharger directement le jet

vers des personnes ou des animaux, car cela

risquerait de causer des blessures graves ou

même la mort Se tenir à l'écart de la buse. Faire

preuve de prudence lors de l'utilisation.

WARNING: Protect machine

from freezing.

AVERTISSEMENT: Protéger la

machine contre le gel.

14.To keep machine in best

operating conditions, it is

important you protect machine

from freezing. Failure to protect

machine from freezing could

cause malfunction of the machine

and result in death, serious bodily injury, and/or

property damage. Follow storage instructions

specified in this manual.

Shark SMT Operator’s Manual 9.800-504.0 - E

5

Page 6

Safety

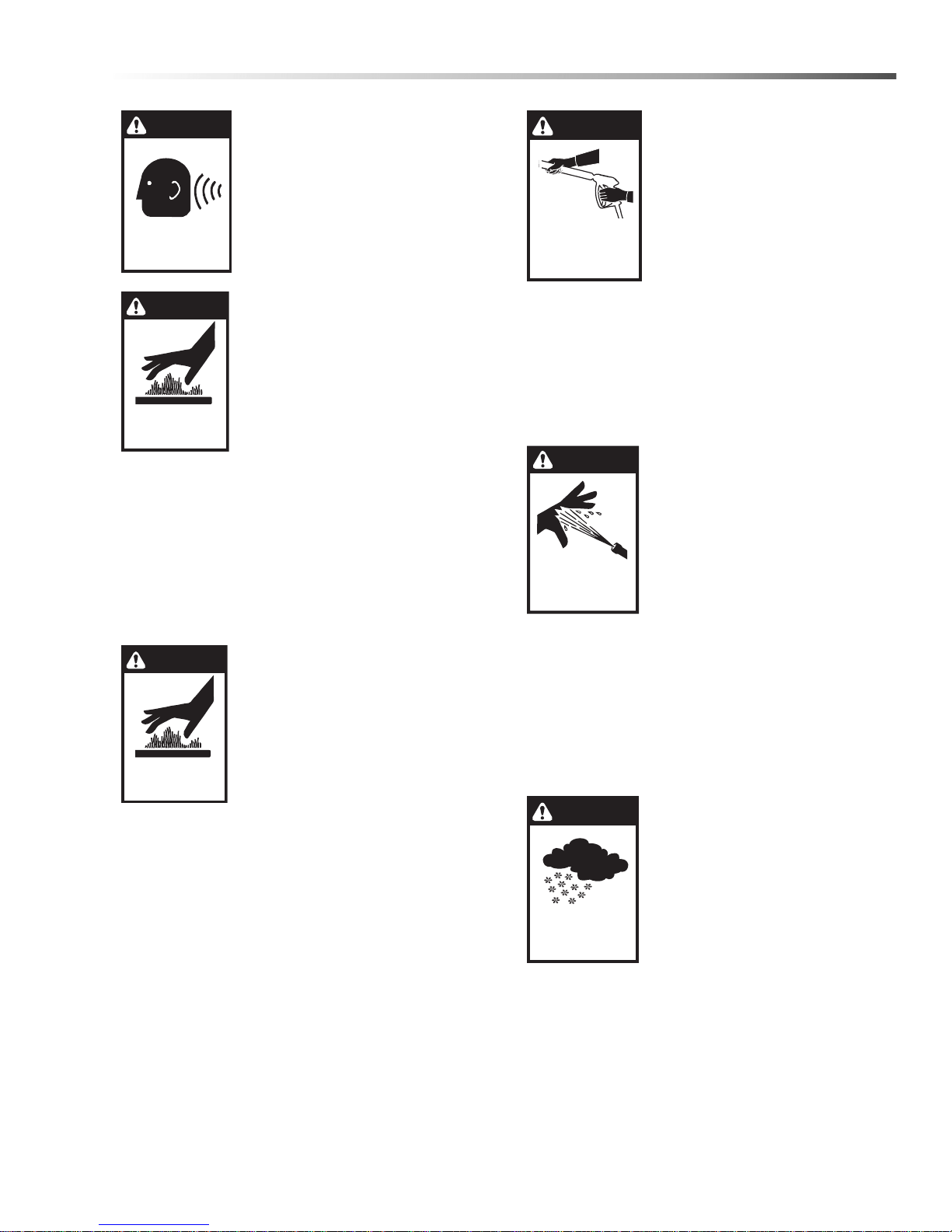

WARNING

RISK OF INJURY

FROM FALLS WHEN

USING LADDER.

WARNING

IF CONNECTED

TO A POTABLE

WATER SUPPLY,

PROTECT AGAINST

BACKFLOW.

DANGER

RISK OF

ASPHYXIATION.

USE THIS PRODUCT

ONLY IN A WELL

VENTILATED AREA.

15. Running this product indoors can result in death

due to carbon monoxide, a poison gas you cannot

see or smell. Never operate indoors, even if

windows and doors are open. Only use outdoor

and far away from windows, doors, and ope nin g s

or vents.

16. Manufacturer will not be liable for any changes

made to our standard machines or any components not purchased from us.

17. The best insurance against an accident is

precaution and knowledge of the machine.

WARNING: Be extre mely careful

when using a ladder, scaffolding or any other relatively

unstable location. The cleaning

area should have adequate

slopes and drainage to reduce

the possibility of a fall due to

slippery surfaces.

A VER TISSEMENT: Faire preuve

d'une extrême prudence au

moment d'utiliser une échelle, des échafaudages

ou toute autre surface relativement instable. La

zone de nettoyage doit avoir une pente et un

drainage adéquats pour réduire la possibilité d'une

chute due à une surface glissante.

18. Do not overreach or stand on unstable support.

Keep good footing and balance at all times.

19. Do not operate this machine when fatigued or

under the influence of alcohol, prescription medications, or drugs.

WARNING: If connection is

made to a potable water

system, the system shall be

protected against backflow.

AVERTISSEMENT: Si une

connexion est établie avec un

réseau d'eau potable, le réseau

doit être protégé contre le

retour d'eau.

20.Inlet water must be clean fresh

water and no hotter then 90°F.

DANGER: Risk of asphyxiation.

Use this product only in a well

ventilated area.

DANGER: Risque d'asphyxie.

Utiliser ce produit uniquement

dans un endroit bien ventilé.

Follow the maintenance

instructions specified in the

manual.

Suivre les instructions d'entretien

spécifiées dans le manuel.

Reporting Safety Defects

If you believe that your trailer has a defect which could

cause a crash or could cause injury or death, you

should immediately inform the National Highway T raffic

Safety Administration (NHTSA) in addition to notifying

Kärcher.

If NHTSA receives similar complaints, it may open an

investigation, and if it finds that a safety defect exists in

a group of trailers, it may order a recall and remedy

campaign. However, NHTSA cannot become involved

in individual problems between you, your dealer or

Kärcher.

To contact NHTSA, you may either call the Auto Safety

Hotline toll-free at 1-888-327-4236 (TTY: 1-800-424-

9153) or write to:

NHTSA

1200 New Jersey Avenue, SE

West building

Washington, DC 20590

You can also obtain other information about motor

vehicle safety from, http://www.safecar.gov.

Checklist

Before Every Trip:

• Tire pressure and tire condition

• Wheel lugs*

• Bearing lube and tightness

• Hitch

• Safety chains

• 12V running lights

• Distribution and security

• Caster up in travel position

6

Shark SMT Operator’s Manual 9.800-504.0 - E

Page 7

Important Trailer Safety Information

* Check lug nuts for tightness before initial trip, at 10

miles, 25 miles and 50 miles. Recheck every 3 months

or 3000 miles.

NOTE: Checking all of the above steps before every

trip is key for safety.

Referencing the Utility Trailer in this

Manual

All references to the trailer or component parts to either

left or right are made with the assumption that you are

standing behind the trailer facing forward. Your left

hand or right hand is the equivalent on the trailer.

Tire Safety

The most common cause of trailer tire failure is underinflation. Therefore, it is important that you always

maintain the specified air pressure as indicated by the

tire manufacturer on the tire's side-walls. This information can also be found on the tire label or the air

pressure molded on the tire side-wall.

The most important things you can do to maintaining

proper tire pressure are observe all tire and trailer

maximum carrying capacities, avoid road hazards, and

inspect the tires for cuts, slashes and other irr eg ular i ties. These practices, along with other care and maintenance, can improve handling, help protect you and

others from avoidable breakdowns and accidents,

improve fuel economy, and increase the life of your

tires.

Make tire safety a regular part of your trailer maintenance routine. The time you spend is minimal

compared to the amount of time, inconvenience, and

potential safety hazards that can occur from a flat tire or

failure.

exceeding the load limits of the tires or the trailers other

components. These labels indicate the manufacturer’s

information including:

• Recommended tire size.

• Recommended tire inflation pressure.

• The maximum weight the trailer is designed to

carry.

• Gross vehicle weight rating of the trailer.

• Gross axle weight rating of the trailer.

Understanding Tire Pressure and Load

Limits

Tire inflation pressure is the level of air in the tire that

provides it with the load-carrying capacity and affects

the overall performance of the trailer. The tire inflation

pressure is a number that indicates the amount of air

pressure that is inside the tire. It is measured in pounds

per square inch (PSI). The tire must be inflated to the

air pressure as designated on the labels. Also listed on

the labels is the air pressure in kilo Pascals (kPa),

which is a metric measurement. Tire manufacturers

determine the air pressure to maximize the amount of

weight the tires can safely carry. The proper tire

pressure for your trailer tires is referred to as the

"recommended cold inflation pressure." It is difficult to

obtain the recommended tire pressure if your tires are

not cold when the reading is taken because the air will

expand when it is warmed by towing down the road,

thus increasing the air pressure inside. If air is added to

a tire that is low the air pressure should never exceed

the recommended pressure.

It is important to check your trailer’s tire pressure at

least once a month for the following reasons:

Most tires will naturally lose air ov er time .

Basic Tire Maintenance

Properly maintained tires improve the load-carrying

capability of your trailer. You can help avoid flat tires

and tire failures by maintaining proper tire pressure,

observing tire and trailer capacity limits, avoiding road

hazards, and inspecting your tires regularly.

Identifying Your Recommended Tire

Pressure and Maximum Load Carrying

Capacity for Your Trailer

Both the tire placard and the VIN label are permanently

attached on top of the frame of your trailer and have the

required information printed on them. They also list th e

maximum load that can be placed on the trailer without

Shark SMT Operator’s Manual 9.800-504.0 - E

Tires can lose air suddenly if dr iven o ver an obje ct that

punctures or cuts the tire. Sometimes a sharp blow

from a pothole or curb can knock the tire loose from the

rim causing immediate deflation.

7

Page 8

Important Trailer Safety Information

Maintaining Proper Tire Pressure

Locate the recommended tire pressure on the trailer's

tire information placard or owner's manual.

Record the tire pressure of all tires. If the tire pressure

is too high in any of the tires, slowly release air by

gently pressing on the tire valve stem with the edge of

your tire gauge until you get the correct pressure.

If the tire pressure is too low, note the difference

between the measured tire pressure and the corr ect tire

pressure. These "missing" pounds of pressure are what

you will need to add.

Add the missing pounds of air pressure to each tire that

is under inflated.

Check all tires to make sure they have the same air

pressure.

If you have been towing your trailer and think that a tire

is under inflated, fill it to the recommended cold inflation

pressure indicated on your trailer's tire label placard or

the VIN label. You can also check the sidewall of the

tire for a correct tire inflation pressure. Your tire will

have a slightly lower air pressure because the tire is

warm when you are inflating it, but it will be much better

than to continue to tow it with the under inflation it may

have had. Once the trailer has been parked long

enough to allow the tires to cool down, recheck the tire

pressure and add additional air to return the tire

pressure to the recommended level.

Never Tow the Trailer Before Checking

• Coupler and latch assembly show no signs of

wear or damage.

• Coupler hitch and hitch ball are of the same

size.

• Coupler and safety chains are safely secured to

the hitch.

• Check all fasteners for proper tightness.

• Load is securely tied down to the trailer.

• Wheel lug nuts are properly tightened to the

right torque.

• Wheel bearings are properly adjusted and

maintained.

• Load is within the maximum load carrying

capacity of trailer.

• Tires are properly inflated and are r oad worthy.

• All trailer lighting is working properly.

IMPORTANT: The load must be distributed equally

on the bed of the trailer if possible. Heavy, concentrated loads may cause damage or possible failure

of the trailer.

WARNING: Loads place on the trailer must be

securely tied to the trailer. Always use appropriate

tie downs designed to restrict loads from moving

when properly attached. Failure to do so will allow

shifting of the load causing potential trailer failure

and/or loss of the load and personal injury.

Tire Size

To maintain the trailer's carrying capacity and safety,

purchase only the same size tires as what were originally supplied on the trailer.

Safety Tips

Slow down if you have to go over a pothole or other

object in road.

Do not run over curbs and try not to strike the curb

when parking.

For a free brochure visit:

www.nhtsa.dot.gov

IMPORTANT: Before towing this trailer be sure to

read the instructions and warnings supplied in this

manual. Also read the information supplied with

your tow vehicle so you know and understand it's

limitations.

AVERTISSEMENT: Les charges placées sur la

remorque doivent être solidement attachées à la

remorque. Toujours utiliser des arrimage s

appropriés conçus pour empêcher les charges de

bouger lorsqu'elles sont bien attachées. Le nonrespect de cette consigne permettra le mouvement

de la charge, entraînant une défaillance potentielle

de la remorque et/ou une perte de la charge et des

lésions corporelles.

This trailer is equipped to meet all applicable feder al

safety standards in effect the day of manufacture.

Check local and state requirements regarding any additional equipment that may be required.

The addition of optional equipment to your trailer may

in- crease the total weight of your trailer package to

where it now exceeds the maximum load carrying

capacity of the trailer.

8

Shark SMT Operator’s Manual 9.800-504.0 - E

Page 9

Important Trailer Safety Information

Tow Vehicles

WARNING: Serious injury or property damage can

result if the total weight of your loaded trailer

exceeds the capacity of the hi tc h an d /o r yo ur to w

vehicle.

AVERTISSEMENT: Des blessures graves ou de

dommages à la propriété peuvent survenir sir le

poids total de la remorque chargée excède la

capacité de l'attelage et/ou du véhicule

remorqueur.

It is very important that you know and understand the

towing capabilities of your tow vehicle. This is especially true with the braking abilities of the tow vehicle.

You should check with your authorized dealer to see

what the capabilities are for the total towing load and

the maximum allowable tongue weight for the vehicle

you plan on using for towing.

It is also important that the lighting system in the tow

vehicle has sufficient capacity support the additional

load the trailer lighting will add to the system. A heavy

duty flasher may be required to make your turn signals

function properly.

Trailer Ball & Couplers

WARNING: Failure to properly engage the hitch ball

in the coupler ball socket and securely lock the

coupler latch mechanism can cause the trailer to

become detached from the tow vehicle while traveling, which may cause serious injury or property

damage.

AVERTISSEMENT: Le non-respect d'engager

correctement la boule d'attache dans la cavit é de la

boule de l'attelage et de verrouiller solidement le

mécanisme du loquet de l'attelage pourrait mener

la remorque à se détacher du véhicule remorqueur

pendant le déplacement, ce qui pourrait cau ser des

blessures graves ou des dommages à la propriété.

Ball diameter for which rating (GVWR) shall not exceed

the gross trailer weight marked on the trailer coupler.

The hitch balls have the rated load they are capable of

towing stamped Into the top of the ball.

Make sure the ball that you use to tow your trailer has

the same capacity rating as the coupler.

Do not use a different size ball than the size the coupler is

designed to use.

Class Coupler Ball Diameter

II 3,500# GVWR 2”

III 5,000# GVWR 2”

IV 8,000# GVWR 2”

Hitch Coupler T roubleshooting

If the coupler becomes damaged it must be repaired or

replaced before towing. When the coupler is placed on

the ball, the latch should close firmly. Keep the latch

mechanism lightly oiled and clean. Items to check for

are as follows:

1. Latch does not grasp ball securely:

• Check the ball size. Make sure the ball and

coupler are the same size.

2. Latch does not snap into full latch position:

• Check adjustment. Latch mechanism may be

too tight.

• Check to see that the coupler housing has not

been damaged, keeping the ball hitch from

fitting completely into the housing as designed.

3. Keep the tongue blocked up when not in use so the

coupler and mechanism are not in the ground

being exposed to dirt and moisture.

4. Apply a small amount of an automotive grease to

the ball before hitching coupler to prevent wear of

the two parts during towing.

5. Make sure the latch safety pin is in position before

towing.

Coupler & Ball Engagement

If the coupler and towing ball resist attempts to make

engagement, do not force latch assembly. Instead,

check the ball diameter to verify that it conforms to

Society of Automotive Engineers (SAE) specifications.

Standard two-inch diameter ball should be within the

limits of 2.000-inches to 1.970-inches. Balls larger than

2.000- inches will not readily fit the coupler. A two-piece

coupler ball is not recommended.

If the coupler becomes damaged it must be repaired or

replaced before towing. When the coupler is placed on

the ball, the latch should close firmly. Keep the latch

mechanism lightly oiled and clean.

Improper engagement of the coupler and ball can

cause damage if the vehicles separate in transit, thus,

caution must be exercised to insure a secure hook-up.

Lower the coupler onto the ball with the coupler latch in

the vertical position. Continue to lower the trailer

tongue until the jack clears the ground, then flip the

coupler latch to its locked (horizontal) position. At this

point visually observe that the ball is fully engaged in

the ball hitch. An even better check to make sure the

two are fully engaged is to raise the tongue of the trailer

again using the jack. Raise until the ball hitch connection starts to raise the rear of the tow vehicle. If the

connection was not properly made, the ball and socket

will separate as the tongue of the trailer is raised.

Shark SMT Operator’s Manual 9.800-504.0 - E

9

Page 10

Important Trailer Safety Information

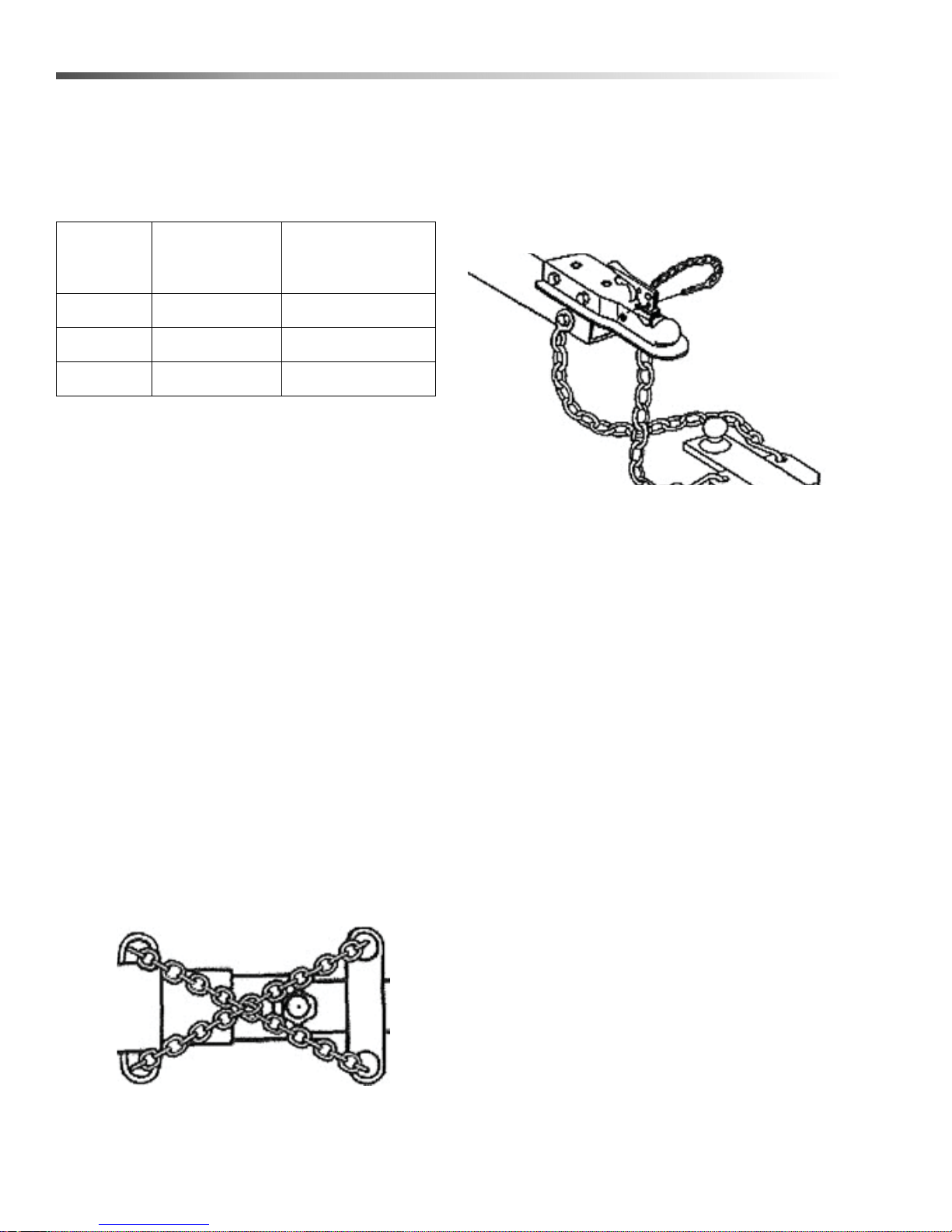

Safety Chains

Listed in the chart below are the dif ferent class sizes of

safety chains and the rated load each chain must be

capable of withstanding.

TRAILER

CLASS

I to 2,000 2,000

II 2,000 to 3,500 3,500

III 3,500 to 5,000 5,000

WARNING: Failure to properly attach safety chains

between the trailer and tow vehicle can result in a

runaway trailer.

AVERTISSEMENT: Le non-respect de fixer

correctement les chaînes de sécurité entre la

remorque et le véhicule remorqueur peut mener à

l'emballement de la remorque.

WARNING: To avoid accidents, before trailering:

• Hitch only to ball size marked on coupling.

• Ball clamp must capture ball and lever or hand

wheel is fully clamped.

• Cross safety chains under coupling.

• Allow only enough slack for turns.

AVERTISSEMENT: Pour éviter les accidents avant

de procéder à un remorquage :

• Atteler uniquement à une boule dont la taille

correspond à celle indiquée sur l'attelage.

• La boule de serrage doit capturer la boule et le

levier ou le volant à main est complètement

serré.

• Croiser les chaînes de sécurité sous l'attelage.

• Laisser suffisamment de jeu pour permettre la

rotation libre.

TRAILER

WEIGHT GVWR

IN LBS.

MINIMUM BRAKING

STRENGTH IN LBS.

The safety chains on your trailer are an added

insurance that it will not become detached from the tow

vehicle. All safety chains are provided with an added

clasp to keep them from becoming accidentally

detached from the tow vehicle. Your trailer hitch on the

tow vehicle should have two attaching holes or rings for

attaching the safety chains, preferably one on each

side of the ball hitch. Crisscross the chains under the

tongue, the chain on the left side of the trailer tongue

attached to the right side of the ball hitch, the chain on

the right side of the trailer tongue attached to the left

side of the ball hitch.

This prevents the trailer tongue from dropping to the

road should the coupler or ball hitch fail. The chains

should be rigged as tight as possible with just enough

slack to allow tight turns to be made. This can be

accomplished by twisting the chain hook in a clockwise

or counterclockwise direction thus twisting the link

spacing and making the chain shorter. Also by keeping

your chains as short as possible you prevent them from

dragging on the road and wearing the chain links. If for

any reason you find it necessary to replace a safety

chain, use only original equipment.

Load-Carrying Capacity

Located on the front left-hand side of the frame, (either

the inside or the outside) is the VIN (Vehicle Identification Number) tag. It will show the GVWR (Gross Vehicle

Weight Rating) which is the maximum load that can be

applied to the tires on the trailer. The GVWR and the

carrying capacity of the trailer are based on the tire size

installed on the trailer.

Bottom View

10

Shark SMT Operator’s Manual 9.800-504.0 - E

The GVWR is the maximum carrying capacity of the

trailer with its respective tires. It may not necessarily

equal the total GVWR of the trailer less the empty

weight of the trailer because there may be anoth er

controlling factor such as frame strength that reduces

the carrying capacity to what is listed on the VIN tag.

Page 11

Important Trailer Safety Information

TIRE AND LOADING INFORMATION

RENSEIGNEMENTS SUR LES PNEUS ET LE CHARGEMENT

The weight of cargo should never exceed

XXXX kg or XXXX lbs

TIRE SIZE COLD TIRE PRESS.

REAR XXXXXXX XXX KPA (XX PSI)

INTER XXXXXXXXX

FRONT XXXXX

SPARE XXXXX

SEE OWNER’S

MANUAL FOR

ADDITIONAL

INFORMATION

VOIR LE MANUAL

DE L’USAGER

POUR PLUS DE

RENSEIGNEMENTS

MANUFACTURED BY: KARCHER NORTH AMERICA INC. DATE OF MFG.:XX/XXXX

GAWR (EACH AXLE)

V.I.N. : TYPE : TRAILER

TRX-XXXX

WITH TIRES RIMS AT COLD

XXXX KG (XXXX LB) XXXX XXXX XXX KPA (XX PSI) SINGLE

THIS VEHICLE CONFORMS TO ALL APPLICABLE U.S. FEDERAL MOTOR VEHICLE SAFETY STANDARDS

IN EFFECT ON THE DATE OF MANUFACTURE SHOWN ABOVE.

XXXXXXXXXXXXXXXXX

GVWR (XXXX KG (XXXX LB)

The tire label will list the tire size that was installed on

the trailer as original equipment when it was sold to

you, the consumer. It also lists the maximum carrying

capacity of the trailer.

IMPORTANT: The total weight of the load must

never exceed the weight of cargo listed on the tire

label and/or the maximum load carrying capacity

listed on the VIN tag on your trailer. The GVWR

(Gross Vehicle Weight Rating) listed is the

maximum total weight of the trailer with accessories and all cargo allowable to be carried on the

tires that are installed on the trailer.

WARNING: Fishtailing caused from improper

tongue weight on the tow vehicle hitch ball can

cause loss of control of the tow vehicle and

resulting serious injury or property damage.

AVERTISSEMENT: Une embardée causée par un

poids de l'attelage inapproprié sur la boule

d'attache du véhicule remorqueur peut causer une

perte de contrôle du véhicule remorqueur e t causer

des blessures graves et des dommages à la

propriété.

CAUTION: The maximum load applied to the trailer

must never exceed the carrying capacity of the

trailer as stated on the VIN label and/or the tire

placard. Doing so may cause failure of one or more

component parts of the trailer causing potential

damage to the trailer and/ or a potential accident.

All concentrated loads must be spread over as

large an area as possible to eliminate potential

damage to the decking.

des dommages potentiels à la remorque et/ou un

accident potentiel. To utes les charges concent rées

doivent être réparties sur une surface aussi large

que possible pour éliminer tout dommage potentiel

au patio.

Shown below is an example of the tire label that is

placed on your trailer showing the items just discussed

above. Once you have familiarized yourself with the

information supplied on the example tire label and VIN

tag, check the tire size and capacity of your trailer as

shown on the VIN tag on your trailer.

Proper Weight Distribution & Tongue

Weight

Ensuring that your trailer has the proper GVWR is very

important. Once that has been established and you

have the load on the trailer it is equally important that

you have proper weight distribution.

Tongue Weight

The tongue weight on your trailer is 10%-15% of the

total weight of the trailer and all the cargo that it is

carrying. This is the amount of weight that is then transferred to the tow vehicle through the ball hitch.

Example: The total weight of the trailer with load is 800

pounds. The tongue weight should not be less than 80

pounds (10%).

Too light of tongue weight can cause the trailer to “fishtail” (sway Weight Rating) as you travel down the

highway . This creates excessive strains on the tow

vehicle, hitch and on the trailer itself. It can very easily

lead to an accident.

To adjust for too light of a tongue weight the load must

be shifted for-ward with respect to the axle. This will

increase the weight that is transferred to the tongue.

Adjustments should be made until the tongue weight

falls within 10% -15% recommended range. Likewise, if

you have too much tongue weight adjust the weight

backwards with respect to the axle until the tongue

weight falls in the recommended range

T ow vehicles var y on how much tongue weight they can

support for proper towing.

ATTENTION: La charge maximale appliquée à la

remorque ne doit jamais excéder la capacité de

charge de la remorque comme mentionné sur

l'étiquette NIV et/ou le flanc du pneu. Agir de la

sorte risquerait de causer une défaillance d'une ou

plusieurs composantes de la remorque, causant

Shark SMT Operator’s Manual 9.800-504.0 - E

11

Page 12

Important Trailer Safety Information

Quick release

pin

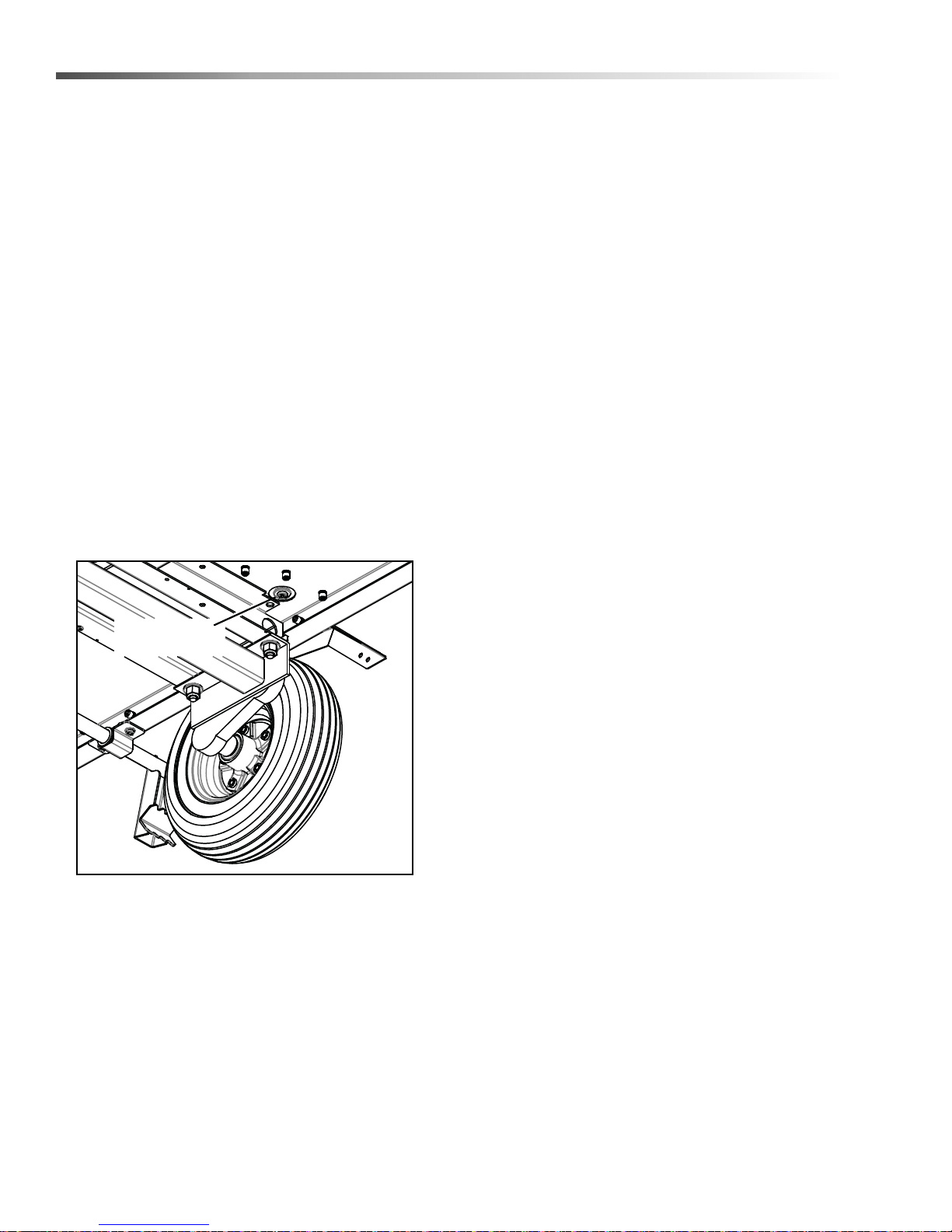

Caster Operations

This trailer has a caster for manual transporting while

using the pressure washer and to keep the trailer

tongue off the ground when not trailering.

WARNING: The caster must be in the up position

when trailering the unit.

AVERTISSEMENT: La roulette doit se trouver en

position verticale lorsque l'appareil est remorqué.

STEP 1: Release the quick release pin by rotating it

clock wise. Pull Quick release pin from receptacle.

Rotate the caster clockwise.

STEP 2: Insert quick release pin in receptacle. Lock

quick release pin in place by rotating pin counter clockwise. Reverse step to lower caster.

NOTE: Before towing, diesel shut-off valve must be in

the OFF position.

12

Shark SMT Operator’s Manual 9.800-504.0 - E

Page 13

Trailer Brake Operations

WARNING: To avoid injury, the trailer brake must

be set when operating the pressure washer or

when not in use.

AVERTISSEMENT: Pour éviter les blessures, le

frein de la remorque doit être appliqué lors de

l'utilisation de la laveuse à pression ou lorsqu'elle

n'est pas utilisée.

Important Trailer Safety Information

To set the brake, press down on the brake pedal until it

engages on the back tires.

To release the brake, push the center of the brake to

release see that it has disengaged from the back tire.

CAUTION: This brake has a spring mechanism that

will return brake to its dis-engaged state. Make sure

foot or hand is moved out of the pinch point area.

ATTENTION: Ce frein comprend un mécanisme à

ressort qui retournera le frein à sa position de

désengagement. Garder les pieds et les mains à

l'écart de la zone du point de pincement.

Shark SMT Operator’s Manual 9.800-504.0 - E

13

Page 14

What to Check And How To Check

34

WEAR PATTERN CAUSE ACTION

ACTION

Center

Wear

Over

Inflation

Adjust pressure

to particular

load per tire

catalog.

Edge

Wear

Under

Inflation

Adjust pressure

to particular

load per tire

catalog.

Side Wear

Loss of

camber or

overloading

Make sure load

doesn't exceed

axle rating.

Align at alignment shop.

Toe Wear

Incorrect

toe-in

Align at alignment shop.

Cupping

Out of

balance

Check bearing

adjustment and

balance tires.

Flat

Spots

Wheel

lockup & tire

skidding

Avoid sudden

stops when

possible and

adjust brakes.

Tire Pressure

Proper air pressure for your tires is printed on the

sidewall. Check pressure while tires are cold. Do not

raise or lower pressure to meet load. Pressure other

than recommended pressure will lead to excessive tire

wear or tire failure. Balancing recommended.

Wheels

Check wheels for hole elongation or “out of round”. This

condition can be caused by lug nuts not being tight or

being too tight. Trailer wheels can be damaged by

chuck holes or curb jumping. You may not be aware of

the road shock to the wheels without periodic checks.

Replace any wheel that is bent. Replace any wheel if

you see elongation of the bolt holes.

Wheel Lugs

Wheel lug nuts must be tightened with a torque wrench.

Refer to the chart below for proper torque.

1. Start all bolts or nuts by hand to

prevent cross threading.

2. Tighten bolts or nuts following

sequence at right.

3. The tightening of the fasteners

should be done in stages.

Following the recommended sequence, tighten

fasteners per wheel torque chart below.

1

2

5

Tires

Before mounting tires onto wheels make certain that

the rim size and contour is approved for the tire as

shown in the Tire and Rim Association Yearbook or the

tire manufacturer’s catalog. Also make sure the tire will

carry the rated load. If the load is not equal on all tires

due to trailer weight distribution, use the tire rated for

the heaviest wheel position.

NOTE: The capacity rating molded into the sidewall

of the tire is not always the proper rating for the tire if

used in a trailer application. Use the following

guideline:

1. L T and ST tires: use the capacity rating molded into

the tire.

2. Passenger Car Tires: Use the capacity rating

molded into the tire sidewall divided by 1.10.

Use tire mounting procedures as outlined by the

Rubber Manufacturer’s Asso ciation or th e tire manufa cturers.

NOTE: Tire wear should be checked frequently

because once a wear pattern becomes firmly

established in a tire it is difficult to stop, even if

the underlying cause is corrected.

4. Wheel nuts/bolts should be torqued before first

road use and after each wheel removal. Check and

re-torque after the first 10 miles, 25 miles and

again at 50 miles. Check periodically thereafter.

Wheel Torque Requirements

WHEEL

SIZE

1st Stage 2nd Stage 3rd Stage

16" 20 - 25 50 - 60 80-90

Ball Coupler Hitches

Coupler assembly includes a latch lever and latch lever

safety pin or hitch pin. Be sure the latch lever is locked

and the pin properly secured before moving your trailer .

The pin can be engaged fully only if ball is properly

TORQUE SEQUENCE

seated in the coupler.

14

Shark SMT Operator’s Manual 9.800-504.0 - E

Page 15

T railer Component Identification

(Optional)

Control Panel

Chemical Injector

Battery Box

Spray Gun

Trigger

Water Inlet

Safety Chains

Wand

Nozzle Quick Coupler

Hitch Channel

Gasoline Tank

Hose and Wand Storage

Diesel Tank

Discharge Manifold

and Temperature Switch

Pump & Unloader Valve

VIN Plate

High Pressure

Outlet

High Pressure Hose

Operations

Pump — Delivers a specific GPM to the high pressure

nozzle which develops pressure.

Spray Gun — Controls the application of water and

detergent onto cleaning surface with trigger device.

Includes safety latch.

Detergent Injector — Allows you to siphon and mix

detergents.

Wand — Must be connected to the spray gun.

High Pressure Hose — Connect one end to water

pump high pressure discharge nipple and the other end

to spray gun.

Shark SMT Operator’s Manual 9.800-504.0 - E

Rupture Disk— Secondary pressure release in the

unlikely event the unloader valve fails. Not shown.

Unloader Valve — Safety device which, when the

spray gun closes, prevents over pressurization.

NOTE: If trigger on spray gun is released for more

than 2 minutes, water will leak from the pump

protector. Warm water will discharge from pump

protector onto floor. This system prevents internal

pump damage.

15

Page 16

Operations

Handle

Bolt

Washer

Nut

Rod

Tab

Accessory Assembly Instructions

Handle Installation

Safety Rod installation

Align the 4 holes in the handle with the holes in the

back plate, install the fasteners and washers supplied.

(See Hose Box and Fuel Tank pages for fastener part

numbers.)

NOTE: Fastener assembly torque to install handle:10

ft-lbs (due to hollow tube handle.)

Slide the rod through both holes in the tabs. To secure

rod, bend both tabs up slightly, until the rod does not

move freely. (See Hose Box and Fuel Tank pages for

fastener part numbers.)

16

Shark SMT Operator’s Manual 9.800-504.0 - E

Page 17

Assembly Instructions

Inlet

Connector

High Pressure

Hose

Discharge

Nipple

Detergent

Hose

Detergent

Injector

(Option)

Safety

Latch

Dipstick

Gasoline

Tank

Red

Black

Diesel Fuel

Tank

Operations

STEP 1: Attach a 5/8" garden hose to

inlet connector. Minimum flow should

be 5 gpm.

STEP 4: Check oil level on sight

glass on backside of pump. Oil

should be visible one-half way up

sight glass (10-40W non-detergent).

The oil level can also be checked by

using the dipstick on the top of the

pump.

STEP 2: Attach high pressure hose

to discharge nipple using quick

coupler. Lock coupler securely into

place by pulling back coupler collar

and inserting it onto discharge nipple,

then pushing collar forward to lock in

place.

NOTE: If using detergent injector,

attach detergent injector to

discharge nipple using quick

coupler. Attach high pressure hose

to other end of detergent injector.

STEP 5: Fill gasoline tank and check

engine oil.

Fill diesel tank with diesel fuel.

CAUTION: Do not confuse diesel

fuel and gasoline when filling

tanks. Keep proper fuel in proper

tanks.

A TTE NTION: Ne pas confondre du

carburant diesel et l'essence au

moment de remplir les réservoirs.

NOTE: Diesel Fuel Shut-off must

be in the ON position prior to

turning on burner.

STEP 3: Attach wand to spray gun

using teflon tape on threads to

prevent leakage. Attach swivel

connector on discharge hose to

spray gun using teflon tape on

threads. Attach swivel connector on

high pressure hose to spray gun

using teflon tape on threads. Engage

safety latch to prevent from triggering

gun.

NEG

POS

STEP 6: On electric start models,

you will need to install a battery

making sure that the red cable is

attached to the positive terminal. Use

a Group U1 garden tractor style type

of battery rated for 300 CCA (battery

not included).

NOTE: Battery is required for

burner to operate.

CAUTION: These machines are

intended to be protected from

outside environments.

ATTENTION: Ces machines sont

conçues pour être protégées

contre l'environnement extérieur.

CAUTION: Risk of injury. Disconnect battery ground terminal

before servicing.

A TTENTION: Risque de blessures.

Débrancher la borne de mise à la

terre de la batterie avant de

procéder à des opérations d'entretien.

Shark SMT Operator’s Manual 9.800-504.0 - E

17

Page 18

Operations

Installation

Place machine in a convenient location providing

ample support, draining and room for maintenance.

This machine is intended for outdoor use. Machine

must be stored indoors when not in use.

Location

The location should protect the machine from

damaging environmental conditions, such as wind, rain,

and freezing.

1. This machine should be run on a level surface

where it is not readily influenced by outside

sources such as strong winds, freezing temperatures, rain, etc. It should be located to allow accessibility for refilling of fuel, adjustments and

maintenance. Normal precautions should be taken

by the operator of the machine to prevent moisture

from reaching the electrical controls.

2. It is recommended that a partition be made

between the wash area and the machine to

prevent water spray from coming in contact with

the machine. Excess moisture reaching any

electric components or electrical controls will

reduce machine life and may cause electrical

shorts.

Placement

Do not locate near any combustible material. Keep all

flammable material at least 20 feet away.

Allow enough space for servicing the machine.

Local code will require certain distances from floor and

walls. (Two feet away from walls should be adequate.)

Water Source

The water source for the pressure washer should be

supplied by a minimum 5/8" I.D. garden hose with a city

water pressure of not less than 5 GPM. If the water

supply is inadequate, or if the garden hose is kinked,

the attached pressure washer will run very rough and

the burner will not fire.

Connection

Connect the wand, nozzle, hose and spray gun (where

applicable). On pipe thread connection s, us e Teflon

tape to avoid water leaks. (See Component Identification).

3. During installation of the machine, beware of

poorly ventilated locations or areas where exhaust

fans may cause an insufficient supply of oxygen.

Sufficient combustion can only be obtained when

there is a sufficient supply of oxygen available for

the amount of fuel being burned. If necessary to

install a machine in a poorly ventilated area

outside, fresh air may have to be piped to the

burner and a fan installed to bring air into the

machine.

Avoid small locations or areas near exhaust fans.

18

Shark SMT Operator’s Manual 9.800-504.0 - E

Page 19

High Pressure Hose

Safety Latch

Trigger

Nozzle Quick Coupler

Operating Instructions

SenDEC

TACH/HOU

R

1/10

Burner

Switch

Operations

STEP 1: Turn water on.

STEP 2: Follow engine manual

provided to start engine.

WARNING:

Starter cord kickback

(rapid retraction) can result in

bodily injury. Kickback will pull

hand and arm toward engine

faster than you can let go. Always

relieve spray gun pressure before

pulling starter cord. Pull starter

cord slowly until resistance is felt,

then pull rapidly

AVERTISSEMENT: Le retour du

cordon de lancement (rétraction

rapide) peut causer des lésions

corporelles. La rétraction rapide

de la corde du démarreur (recul)

attire la main et le bras vers le

moteur plus vite qu'il n'est

possible de lâcher la corde.

Toujours réduire la pression du

pistolet pulvérisateur avant de

tirer sur le cordon de lancement.

Tirer lentement sur le cordon de

lancement jusqu'à ce qu'une

résistance soit sentie, puis tirer

rapidement.

STEP 3: After engine has started,

turn Burner Switch ON. Grip spray

gun handle securely and pull

trigger. Burner should ignite.

NOTE: High pressure nozzle must be inserted at

end of wand to obtain high pressure. To apply

detergent, read operator's manual.

Shark SMT Operator’s Manual 9.800-504.0 - E

19

Page 20

Operations

WARNING

High

Pressure

Hose

Detergent

Injector

(Option)

Detergents & General

Operating Techniques

WARNING: Some detergents may

be harmful if inhaled or ingested,

causing severe nausea, fainting or

poisoning. The harmful elements

may cause property damage or

severe injury.

AVERTISSEMENT: Certains

détergents peuvent être dangereux

s'ils sont inhalés ou ingérés,

provoquant de fortes nausées,

desévanouissements et

l'empoisonnement. Les éléments dangereux peuvent

causer des dommages à la propriété ou des blessures

graves.

STEP 1: Connect high pressure hose to injector with quick

coupler (check to make sure locking coupler sleeves are in

proper position before applying water pressure. If using

detergent injector, connect it to discharge nipple on

machine.

STEP 2: Use detergent designed

specifically for pressure washers.

Household detergents could damage

the pump. Prepare detergent solution

as required by the manufacturer. Fill a

container with pressure washer detergent. Place the filter end of detergent

suction tube into the detergent

container.

STEP 3: Apply safety latch to spray

gun trigger. Turn variable pressure

control handle until discharge water

exits both tubes. Secure black

detergent nozzle into quick coupler

if you have a single wand.

NOTE: Detergent cannot be applied using Red, Yellow,

Green or White nozzles.

STEP 4: With the engine running, pull trigger to operate

machine. Liquid detergent is drawn into the machine and

mixed with water. Apply detergent to work area. Do not

allow detergent to dry on surface.

Thermal Pump Protection

If you run the engine on your pressure washer for 3-5

minutes without pressing the trigger on the spray gun,

circulating water in the pump can reach high temperatures. When the water reaches this temperature, the pump

protector engages and cools the pump by discharging the

warm water onto the ground. This thermal device prevents

internal damage to the pump

.

Cleaning Tips

Pre-rinse cleaning surface with fresh water. Place

detergent suction tube directly into cleaning solution and

apply to surface at low pressure (for best results, limit your

work area to sections approximately 6 feet square and

always apply detergent from bottom to top). Allow

detergent to remain on surface 1-3 minutes. Do not allow

detergent to dry on surface. If surface appears to be

drying, simply wet down surface with fresh water. If

needed, use brush to remove stubborn dirt. Rinse at high

pressure from top to bottom in an even sweeping motion

keeping the spray nozzle approximately 1 foot from

cleaning surface. Use overlapping strokes as you clean

and rinse any surface. For best surface cleaning action

spray at a slight angle.

Recommendations:

• Before cleaning any surface, an inconspicuous

area should be cleaned to test spray pattern and

distance for maximum cleaning results.

• If painted surfaces are peeling or chipping, use

extreme caution as pressure washer may remove

the loose paint from the surface.

• Keep the spray nozzle a safe distance from the

surface you plan to clean. High pressure wash a

small area, then check the surface for damage. If

no damage is found, continue to pressure

washing.

CAUTION - Never use

• Bleach, chlorine and other corrosive chemicals

• Liquids containing solvents (i.e., paint thinner,

gasoline, oils)

• Tri-sodium phosphate products

• Ammonia products or Acid-based products

ATTENTION: Ne jamais utiliser :

• Eau de Javel, produits à base de chlore et autres

produits chimiques corrosifs

• Liquides contenant des solvants (c.-à-d. diluant à

peinture, essence, huiles, etc.)

• Produits à base de tripolyphosphate de sodium

• Ammoniac ou produits à base d'acide

These chemicals will harm the machine and will damage

the surface being cleaned.

20

Shark SMT Operator’s Manual 9.800-504.0 - E

Page 21

Rinsing

It will take a few seconds for the detergent to clear.

Apply safety latch to spray gun. Remove black soap

nozzle from the quick coupler. Select and install the

desired high pressure nozzle. NOTE: You can also

stop detergent from flowing by simply removing

detergent siphon tube from bottle.

Shutting Down And

Clean-Up

SenDEC

Operations

1/10

R

TACH/HOU

STEP 1: Remove detergent suction

tube from container and insert into

1 gallon of fresh water. Turn

variable pressure wand handle for

low pressure or connect the black

detergent nozzle. Pull trigger on

spray gun and siphon water for one

minute.

STEP 4: Turn garden hose water

off. Open the spray gun to relieve

remaining pressure.

STEP 2: T urn burner switch of f and

continue spraying water, allowing

the water to cool. After water has

cooled to less than 100°F, turn off

engine. Protect from freezing.

STEP 5: Lock trigger gun safety

lever to prevent unintentional

pulling of trigger.

STEP 3: Turn off water supply.

Shark SMT Operator’s Manual 9.800-504.0 - E

21

Page 22

Operations

Drain Plug

Storage

CAUTION: Always store your pressure washer in a

location where the temperature will not fall below

32°F (0°C). The pump in this machine is susceptible

to permanent damage if frozen. FREEZE DAMAGE

IS NOT COVERED BY WARRANTY.

ATTENTION: Toujours entreposer la laveuse à

pression dans un endroit où la températur e ne sera

pas inférieure à X °C (X °F). La pompe sur cette

machine est susceptible de subir des dommages si

elle est exposée au gel. LES DOMMAGES DUS AU

GEL NE SONT PAS COUVERTS PAR LA

GARANTIE.

1. Stop the pressure washer, squeeze spray gun

trigger to release pressure.

2. Detach water supply hose and high pressure hose.

3. Turn on the machine for a few seconds, until

remaining water exits. Turn motor off immediately.

4. Drain the fuel from the fuel tank.

When the pressure washer is not being operated or is

being stored for more than one month, follow these

instructions:

1. 1.Replenish pump oil to upper level.

2. 2.Drain fuel from fuel tank, fuel line and filter.

3. 3.Cover the pressure washer and store in a clean,

dry place that is well ventilated away from open

flame or sparks.

After Extended Storage

CAUTION: Prior to restarting, thaw out any

possible ice from pressure washer hoses, spray

gun or wand.

ATTENTION: Avant de redémarrer, faire fondre la

glace se trouvant sur les boyaux, le pistolet

pulvérisateur ou la lance de la laveuse à pression.

5. Do not allow high pressure hose to become kinked.

6. Store the machine and accessories in a room

which does not reach freezing temperatures.

CAUTION: Failure to follow the above directions

will result in damage to your pressure washer.

ATTENTION: Le non-respect des directives cidessus entraînera des dommages à la laveuse à

pression.

22

Shark SMT Operator’s Manual 9.800-504.0 - E

Page 23

Maintenance

Preventative Maintenance

1. Use clean fuel — kerosene, No. 1 home he at ing

fuel or diesel fuel. Clean or replace fuel filter every

100 hours of operation. Avoid water contaminated

fuel as it will seize up the fuel pump. De-soot coils

monthly. Use an additive if diesel is being used.

2. Check to see that the attached pressure washer

water pump is properly lubricated.

3. Follow winterizing instructions to prevent freeze

damage to pump and coils.

4. Always neutralize and flush detergent from system

after use.

5. If water is known to be high in mineral content, use

a water softener on your water system, or descale

as needed.

6. Do not allow acidic, caustic or abrasive fluids to be

pumped through the system.

7. Always use high grade quality cleaning products.

8. Never run attached pressure washer pump dry for

extended periods of time.

9. If machine is operated with smoky or eye burning

exhaust, coils will soot up, preventing water from

reaching maximum operating temperature. (See

section on Maintenance and Service).

10. Never allow water to be sprayed on or near the

motor or burner assembly or any electrical component.

11. Descale coils as per instructions.

It is advisable, periodically, to visually inspect the

burner. Check air inlet to make su re it is not clogged or

blocked. Wipe off any oil spills and keep equipment

clean and dry.

The areas around the pressure washer should be kept

clean and free of combustible materials, gasoline and

other flammable vapors and liquids.

The flow of ventilating air to the burner must not be

blocked or obstructed in any manner.

Maintenance And Service

Unloader Valves

Unloader valves trap pressure in the line when a shutoff spray gun is closed. Machines with unloader valves

are preset and tested at the factory before shipping.

Tampering with the factory settings may cause

personal injury and/or property damage and will void

the manufacturer's warranty.

Winterizing Procedure

Damage due to freezing is not covered by warranty.

Adhere to the following cold weather procedures

whenever the washer must be stored or operated

outdoors under freezing conditions.

During winter months, when temperatures drop below

32°F, protecting your machine agai nst free zing is

necessary. Store the machine in a heated room. If this

is not possible then mix a 50/50 solution of anti -fr e ez e/

water or windshield washer fluid with water in a 5 gallon

bucket. Place a short section of garden hose into the

bucket and connect it to the machine. Elevate the

bucket and turn the pump on to siphon the anti-freeze

through the machine. If compressed air is available, an

air fitting can be screwed into the inlet connector and by

injecting compressed air, all water will be blown out of

the system.

High Limit Hot Water Thermostat

For safety, each machine is equipped with a high limit

control switch. In the event the temperature of the water

should exceed its operating temperature, the high limit

control will turn the burner off until the water cools.

Pumps

Use only 10-40W weight non-foaming oil. Change oil

after first 50 hours of use. Thereafter, change oil every

year or at 500 hour intervals. Oil level should be

checked by using the dipstick found on the top of the

pump or by the red dot visible through the oil gauge

window. Oil should be maintained at that level.

Shark SMT Operator’s Manual 9.800-504.0 - E

Cleaning of Coils

In alkaline water areas, lime deposits can accumulate

rapidly inside the coil pipes. This growth is increased by

the extreme heat build up in the coil. The best prevention for liming conditions is to use high quality cleaning

detergents. In areas where alkaline water is an extreme

problem, periodic use of descale powder will remove

lime and other deposits before coil becomes plugged.

23

Page 24

Maintenance

Descaling Coils With A Pressure Washer

Periodic flushing of coils is recommended.

1. Fill a 5 gallon bucket with 4 gallons of water, then

add 1 lb. of descaling powder.

Mix thoroughly.

2. Remove the high pressure nozzle from the

pressure wand and put the wand into the bucke t.

Secure the trigger on the spray gun into the open

position.

3. Attach a short section (3-5 ft.) of garden hose to

the attached pressure washer to siphon solution

from the elevated bucket. Start up pressure

washer, allowing solution to be pumped through

pressure washer and into HPB coils and back into

the bucket. Solution should be allowed to circulate

2-4 hours.

4. After circulating solution flush entire system with

fresh water.

Fuel

Use clean fuel oil that is not contaminated with water

and debris. Replace fuel filter and drain tank every 100

hours of operation.

Use No. 1 or No. 2 Heating Oil (ASTM D306) only.

NEVER use gasoline in your burner tank. Gasoline is

more combustible than fuel oil and a serious explosion

could result. NEVER use crankcase or waste oil in your

burner . Fuel unit malfunction could re sult from co ntamination.

Fuel Control System

These machines utilize a fuel solenoid valve located on

the fuel pump to control the flow of fuel to the combustion chamber. This solenoid valve, which is normally

closed, is activated by a flow switch when water is

flowing through it. When an operator releases the

trigger on the spray gun, the flow of water through the

flow switch stops, turning off the current to the fuel

solenoid. The solenoid then closes, shutting off the

supply of fuel to the combustion chamber. Controlling

the flow of fuel in this way allows for an instantaneous

burn or no burn situation, thereby eliminating high and

low water temperatures, and combustion smoke

normally associated with machines incorporating a

spray gun.

CAUTION: Periodic inspection is recommended to

insure that the fuel solenoid valve functions

properly. This can be done by operating the

machine and checking to see that when the trigger

on the spray gun is in the off position, the burner is

not firing.

ATTENTION: Une inspection périodique est

recommandée pour assurer que l'électrovalve

d'alimentation en carburant fonctionne

correctement. Cela peut être effectué en utilisant la

machine et en s'assurant que le brûleur n'est pas

allumé lorsque le pistolet pulvérisateur se trouve

en position d'arrêt.

Burner Nozzle

Keep the tip free of surface deposits by wiping it with a

clean, solvent-saturated cloth, being careful not to plug

or enlarge the nozzle. For maximum efficiency, replace

the nozzle each season.

Initial Air Adjustments

Allow sufficient air to obtain a clean burning flame by

loosening the lock screws and moving the air shutter

and if necessary the bulk air band.

Reduce the air supply until the flame tips appear

slightly smoky then increase the air just enough to

cause the flame tips to appear absolutely clean.

Oil Burner

Air Adjustment: The oil burner on this machine is

preset for operation at altitudes below 500 feet. If

operated at higher altitudes, it may be necessary to

adjust the air band for a #1 or #2 smoke spot on the

Bacharach scale.

To adjust, start machine and turn burner ON. Loosen

two locking screws found on the air band and close air

band until black smoke appears from burner exha u st

vent. Note air band position. Next, slowly open the air

band until white smoke just starts to appear. Turn air

band halfway back to the previously noted position.

Tighten locking screws.

For higher altitudes, the air band opening may need to

be increased; for lower altitude, the .air band may need

to be decreased.

24

Shark SMT Operator’s Manual 9.800-504.0 - E

For higher humidity, the air band opening may need to

be increased; for lower relative humidity, the .air band

may need to be decreased.

Page 25

Operations

(For EHASR Only)

For higher ambient temperatures the air band opening

may need to be increased; for lower ambient temperatures, the air band opening may need to be decreased.

Adjust to your operating location's environment asneeded for best smoke spot and performance

compliant with local, state, and federal regulations

Electrode Setting

SR Series Gage

KNA Part Number 8.717-379.0

CAUTION: If white smoke appears from burner

exhaust vent during start-up or operation,

discontinue use and readjust air bands.

ATTENTION: Si de la fumée blanche s'échappe de

l'évacuation du brûleur pendant le démarrage ou le

fonctionnement, cesser d'utiliser et réajuster les

bandes d'air.

NOTE: If a flue is installed, have a professional

serviceman adjust your burner for a #1 or #2 smoke

spot on the Bacharach scale.

Fuel Pressure Adjustment

To adjust fuel pressure, First install a pressure gage

into the port just after the pump fuel exit. Turn the

adjusting screw (located at the regulator port)

clockwise to increase, and counterclockwise to

decrease. Do not exceed 200 psi or lower the pressure

below 130 PSI, when checked at the post-pump

pressure port.

The fuel pressure may need to be adjusted due to

altitude. For every 500 ft altitude above sea level, the

boiling point of water goes down 1 °F. At high altitude

environments, this boiling point change may require the

heat input to be lowered so the water input does not

turn to steam earlier than at the factory settings and

activate the pressure sensors and pressure relief

equipment when the unit is operated and much higher

altitudes from factory settings or local dealer site

settings. Check with your dealer before making local

site fuel pressure adjustments.

Also, as ambient temperature changes seasonally, the

fuel temperature in the feed tank and air temperature

inlet can impact fuel flow. In more extreme temperatures, this local-site adjustment may also require

different fuel nozzles for fuel inlet temperatures tha t are

at seasonal extremes (higher or lower) in locations

where the temperature changes are beyond moderate

temperatures of between 40°F and 90°F. Colder

temperatures will make for a thicker flow and less fine a

fuel spray while hotter temperatures will make for a

thinner flow a more fine spray with the same nozzle.

Consider alternate nozzle configurations from the

baseline factory-supplied nozzle for operating in such

temperature extremes if performance is not meeting

needs with air band and fuel pressure settings alone.

NOTE: When changing fuel pump, a by-pass plug

must be installed in return line port or fuel pump will

not prime.

Removal of Soot and Heating Coil

In the heating process, fuel residue in the form of soot

deposits may develop on the heating coil and block air

flow which will affect burner combustion. When soot

has been detected on visual observation, the soot on

the coil must be washed off after following the coil

removal steps.

1. Remove the top wrap by unscrewing the four

screws from the sides and lift the top wrap off.

2. Remove Insulation.

3. Remove the two pipe nipples and associated

fittings.

4. Lift the coil out of the outer wrap.

CAUTION: The coil weighs about 80 lbs. Use proper

lifting techniques.

ATTENTION: La bobine pèse environ 80lb. Utiliser

des techniques de levage appropriées.

5. Clean, repair and replace the coil by reversing the

above steps.

Coil Reinstallation

Reinstall by reversing the above steps 5 through 1.

NOTE: The 12 VDC burner systems can draw as

much as 18 amps. For such motors to run properly,

the battery and engine charging system must b e kept

in good condition, and the engine must run fast

enough to adequately charge the battery. Do not

throttle down the engine for any length of time.

Shark SMT Operator’s Manual 9.800-504.0 - E

25

Page 26

Maintenance

Hub Inspection RemovalReplacement And Adjustments

A. Removal of Hub

1. Remove wheel

2. Remove grease cap

3. Remove cotter pin or bend tang washer on PosiLube

4. Unscrew the spindle nut counter clockwis e

5. Remove spindle washer

6. Remove hub from spindle

B. Seal Inspection and Replacement

1. Seals should be replaced each time the hub is

removed.

2. Pry the seal out of the hub with a screwdriver.

3. Tap new seal into place.

C. Bearing Maintenance, Adjustments, and

Replacement

D. Bearing Adjustment

Feel and Drag Method

Tighten slotted nut until hub drags slightly whe rotated.

(Rotating the hub while tightening the nut seats the

bearing.) Loosen the slotted nut 1/6 turn (1 hex) to align

nut slot with the cotter pin hole. Wheel should turn

freely. Insert new cotter pin through nut and spindle. If

necessary loosen, never tighten, nut to align slot with

the hole in the spindle. Bend one leg of cotter pin over

the end of the spindle and the other leg over the nut.

Tap legs slightly to set. Cotter pin must be tight. If

equipped with Posi-Lube, bend tang back into position.

1. Inspect for corrosion and wear.

2. If any rust or wear exists on the bearing then

remove and replace.

3. If bearings are found to be in good condition, then

cleaning and repacking the grease is all that is

needed.

NOTE: Do not spin bearings with compressed air.

4. Hand pack each bearing individually using a

premium lithium base wheel bearing grease.

5. Reinstall the hub, reversing the procedure above

using the bearing adjustment procedures below.

6. If you have the Posi–Lube system refer to the

“Posi-Lube Lubrication Procedure”.

26

Shark SMT Operator’s Manual 9.800-504.0 - E

Page 27

Torque Wrench Method

Make sure nut is loose. T ighten nut with tor que wrench

to an initial torque of 50 ft. lbs. Loosen nut from initial

torque and fingertighten. Insert new cotter pin through