Page 1

SERVICE MANUAL

MODEL # ORDER #

RG-232637 1.107-235.0

9.801-589.0

Page 2

Page 3

Exploded View ......................................................................................... 4

Exploded View Parts List ......................................................................... 5

Legacy Axial Pump ...............................................................................6-7

Troubleshooting ....................................................................................... 8

Preventive Manteinance .......................................................................... 9

Oil Change Record ................................................................................ 10

CONTENTS

3

9.801-589.0 • RG-232637 • Rev. 06/14

Page 4

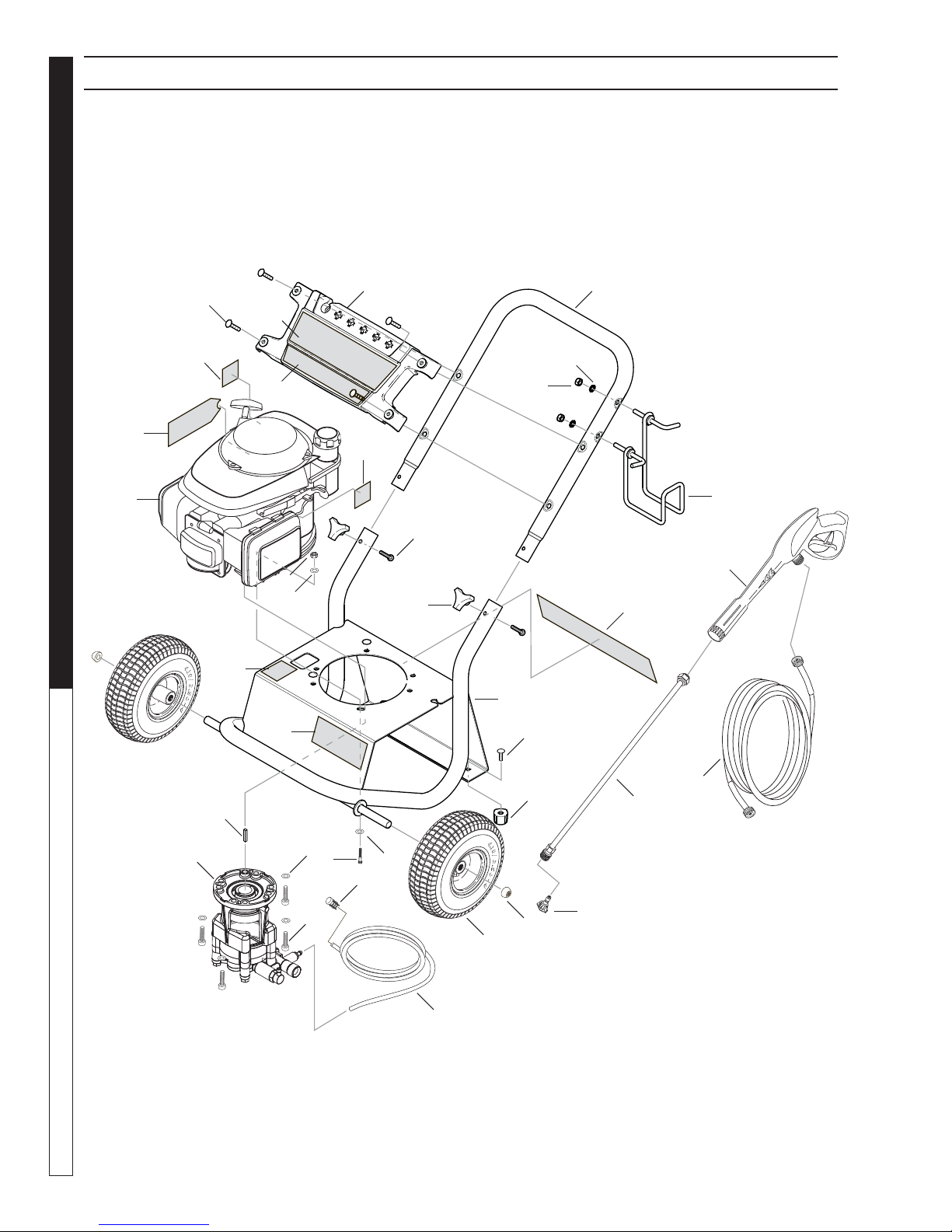

SERVICE MANUAL

EXPLODED VIEW

PRESSURE WASHER

19

2

15

36

16

17

14

21

35

27

20

30

7

6

29

9

13

25

28

26

31

18

3

1

4

5

4

6

8

22

10

23

9.801-589.0 • RG-232637 • Rev. 06/14

12

11

34

32

33

Page 5

EXPLODED VIEW PARTS LIST

PRESSURE WASHER

ITEM PART NO. DESCRIPTION QTY

1 8.920-004.0 Pump, Legacy Axial

2.6 GPM 3000PSI 1

2 9.194-077.0 Engine Honda GC160 1

3 9.194-881.0 Key SQR 3/16" x 1 47/64" 1

4 9.196-033.0 5/16-24 UNF X 1.75

Socket Head Cap Screw 4

5 9.802-813.0 Washer, 5/16"

Split Ring Lock, Zinc 4

6 9.186-010.0 5/16-18 X 1-1/2

GR 5 HHCS Zinc 4

7 9.802-776.0 Nut, 5/16-18, ESNA 4

8 8.718-980.0 Washer, 5/16" Flat,

SAE (780452) 8

9 9.115-099.0 Powder Coated-P1

Frame Black Wrinkle 1

10 9.802-270.0 Wheel & Tire Assy,

10" Steel Rim W/Tube 2

11 9.182-506.0 Cap Black Plastic, 5/8'' 2

12 9.183-405.0 Rubber Dampener 5/16''-18 2

13 9.196-308.0 5/16-18 X 1/2 Carriage Bolt 2

14 8.753-553.0 Label, Rate Specs, Low 1

15 8.751-096.0 Label, Regulation 4442.6 1

16 9.801-587.0 Rating Plate, RG-232637 1

17 8.750-881.0 Shark, Label Name Plate 1

ITEM PART NO. DESCRIPTION QTY

18 8.783-035.0 Label, Operation

Warnings Trilingual 1

19 9.138-313.0 Caution Engine Oil Tag 1

20 9.138-373.0 Open/Closed

Sticker-(GCV 160) 1

21 9.138-377.0 Quick Start Instruction

Guide Sticker 1

22 5.731-652.0 Filter with weight 1

23 6.388-216.0 Hose DN 5 1

24 9.180-004.0 ▲ Motor Oil, SAE-10W 30, 20 oz.

25 9.140-153.0 Powder Coated Handle 1

26 9.142-015.0 Hanger LT Side 1

27 9.802-786.0 Nut, 5/16, Hex, NC 2

28 9.198-003.0 5/16 Internal

L/W .332 ID X .620 2

29 8.767-003.0 1/4-20 Star Knob 2

30 9.196-307.0 1/4-20 x 1-1/2 GR 2 Hex Bolt 2

31 9.112-012.0 Al Bit 101 Trigger Gun 1

32 9.112-533.0 Lance-AL Quick

Connect-Male 3000 psi 1

33 8.751-356.0 Kit, Nozzle (035) 1

8.712-337.0 ▲Nozzle, 0003, Red 1

8.712-338.0 ▲Nozzle, 0015, Yellow 1

8.712-339.0 ▲Nozzle, 0025, Green 1

8.712-340.0 ▲Nozzle, 0040, White 1

8.712-398.0 ▲Nozzle, Black, Soaper 1

34 8.753-423.0 Hose, HP 5ft, 3600PSI M22 1

35 9.134-022.0 Name plate 1

36 9.196-049.0 Nylon Rivet 1

▲ Not Shown

SERVICE MANUAL

5

9.801-589.0 • RG-232637 • Rev. 06/14

Page 6

8.920-004.0

SERVICE MANUAL

PRESSURE WASHER

PUMP EXPLODED VIEW AND PARTS LIST

*

ITEM PART # DESCRIPTION QTY

1 8.762-010.0 Cylinder Head 1

2 9.175-004.0 Valve Assy Horizontal 3

3 2.884-916.0 Valve Complete (Kit 3) 1

4 5.443-448.0 Nipple Chemestry 1

5 6.362-451.0 O-Ring Seal 8.0 x 1.0 1

6 6.362-175.0 O-Ring Seal, 5.28 x 1.78 1

7 7.401-909.0 Sphere 7 G40 - 1.4401 1

8 5.110-714.0 Sleeve 1

9 5.332-258.0 Helical Spring 1

10 9.139-372.0 Nozzle, INS 020/021 Pump 1

11 9.184-018.0 Outlet-Thermal Valve 1

12 6.362-480.0 O-Ring Seal, 12.42 x 1.78 1

13 7.362-507.0 O-Ring Seal 8 x 2 NBR 90 1

14 6.413-403.0 Thermo Valve Tin Coated 1

ITEM PART # DESCRIPTION QTY

15 5.332-290.0 Helical Spring 1

16 9.175-005.0 Unloader Assembly 1

17 4.132-007.0 Drain Plug Replacement 1

18 5.003-062.0 Plate 1

19 9.177-301.0 Hich Pressure Seal 3

20 9.177-310.0 Back Ring 3

21 6.362-833.0 O-Ring Seal 12.5 x 1.73 3

22 9.155-011.0 Housing Low Pressure Seal 3

23 6.363-058.0 Grooved Ring 3

24 9.134-016.0 Spacer 3

25 6.365-393.0 Oil Sealing 12.20x4/6 3

26 9.133-007.0 Piston Guide 1

27 6.362-390.0 O-Ring Seal 15.6 x 1.8 1

28 9.134-019.0 Male Adapter 1

29 9.181-005.0 Filter Seal 1

30 9.155-013.0 Female House Conn 1

31 8.751-121.0 ◆Gooseneck, Hose Adapter 1

(For pump guard or Filters)

32 9.139-370.0 Spare Part List, Piston 1

33 6.362-471.0 O-Ring Seal 80.0x3.0 NBR70 1

◆Not Included

6

9.801-589.0 • RG-232637 • Rev. 06/14

Page 7

PUMP EXPLODED VIEW PARTS LIST (CONT)

8.920-004.0 Housing View

PRESSURE WASHER

SERVICE MANUAL

ITEM PART # DESCRIPTION QTY

1 9.166-016.0 Grooved Ball Bearing 1

2 9.135-018.0 Swash Plate Hor. 1

3 9.165-356.0 Ball Bearing No 6207 1

4 9.177-314.0 Radial Seal 35 x 52 x 7 1

5 9.135-016.0 Oil Housing 1

7

9.801-589.0 • RG-232637 • Rev. 06/14

Page 8

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

ENGINE OPERATES

FOR 15 MINUTES

THEN STOPS

ENGINE LACKS

POWER

ENGINE FALTERS

WATER DRIPPING

FROM UNDER PUMP

OIL DRIPPING

WATER LEAKING

FROM PUMP

PRESSURE WASHER Troubleshooting Guide

PROTECTOR

NO DETERGENT

Not enough gas or engine oil Fill tank with gas. Check oil level.

Vapor lock developed by heat of day Keep gas tank full to avoid vapor locking.

Obstruction in fuel fi lter Clean or replace fuel fi lter.

Dirty air fi lter Replace air fi lter.

Choke is opened too soon Move choke to halfway position until engine

runs smoothly.

Piston packing worn Call local distributor.

O-Ring plunger retainer worn Call local distributor.

Cracked piston Call local distributor.

Oil seal worn or damaged Call local distributor.

Spray gun closed with machine

running 5 minutes or longer

Excess water supply pressure Place a pressure regulator at end of 50'

Detergent suction tube not properly

connected to machine

Detergent is too thick Dilute detergent. For best results, use

Detergent fi lter valve is at lowest

setting

Open spray gun or turn off machine.

garden hose.

Check connection.

manufacturers detergent.

Set detergent fi lter valve to a higher setting.

GARDEN HOSE

CONNECTION

LEAKS

SPRAY WAND

LEAKS

PUMP IS NOISY

Filter on detergent suction tube is

clogged

Damaged or clogged detergent suction tube

A high pressure nozzle is attached. Replace with black detergent nozzle.

Discharge nozzle is obstructed Blow out or remove debris with fi ne needle.

Loose fi ttings Tighten fi ttings.

Missing/worn rubber washer Insert new washer.

Spray wand not properly attached Slide the spray wand into the gun. Turn the

Broken o-ring Call local distributor and order an o-ring.

Pump is sucking air Check that hoses and fi ttings are air tight.

Run warm water through fi lter to remove

debris.

Remove obstruction or replace detergent

suction tube.

wand collar clockwise onto the spray gun

threads until tight.

Turn off machine and purge pump by

squeezing trigger gun until a steady fl ow of

water emerges through nozzle.

8

9.801-589.0 • RG-232637 • Rev. 06/14

Page 9

PREVENTATIVE MAINTENANCE

This pressure washer was produced with the best available materials and quality craftsmanship. However, you

as the owner have certain responsibilities for the correct care of the equipment. Attention to regular preventative maintenance procedures will assist in preserving the performance of your equipment. Contact your dealer

for maintenance. Regular preventative maintenance will add many hours to the life of your pressure washer.

Perform maintenance more often under severe conditions. Check pump oil and engine oil level before fi rst use

of your new pressure washer.

MAINTENANCE SCHEDULE

Inspect Daily

Engine Oil

Air Cleaner/Filter

Engine Fuel Filter 500 hours or 6 months

Spark Plug Maintenance 300 hours or annually

Clean Fuel Tank(s) Annually

Replace Fuel Lines Annually

Replace High Pressure Nozzle Every 6 months

Replace Quick Connects/O-Rings Annually/As needed

Clean Water Screen/Filter Weekly

Replace HP Hose Annually (if there are any signs of wear)

Change First month or 20 hours.

Every 100 hours or every 6 months after fi rst month

Filter Every 50 hours

Inspect Every 50 hours

Clean Monthly

PRESSURE WASHER Troubleshooting Guide

9

9.801-589.0 • RG-232637 • Rev. 06/14

Page 10

OIL CHANGE RECORD

Check pump oil and engine oil level before fi rst use of your new pressure washer.

Date Oil Changed

SERVICE MANUAL

Month/Day/Year

PRESSURE WASHER

Estimated Operating

Hours Since Last

Oil Change

Date Oil Changed

Month/Day/Year

Estimated Operating

Hours Since Last

Oil Change

10

9.801-589.0 • RG-232637 • Rev. 06/14

Page 11

Page 12

Form #9.801-589.0 • RG-232637 • Revised 06/14

Printed in U.S.A. or Mexico

Loading...

Loading...