Page 1

MODEL: HP

OPERATING INSTRUCTION

AND PARTS MANUAL

HP-5030D

For technical assistance or the SHARK dealer nearest you

visit our website at www.shark-pw.com

97-6133

Page 2

Page 3

Introduction 4

Important Safety Information 4-5

Installation 5,7

Component Identification 6

Starting and Operating Instructions 7

Preventative Maintenance 7

Maintenance and Service 8-9

Field Service of Fuel Pump 9

Machine Assembly Exploded View 10

Machine Assembly Exploded View Parts List 11

Burner Assembly, Exploded View 12

Burner Assembly Exploded View Parts Lists 13

Troubleshooting 14-15

CONTENTS

Preventative Maintenance 16

Warranty

Model Number ______________________________

Serial Number ______________________________

Date of Purchase ____________________________

The model and serial numbers will be found on a decal attached

to the machine. You should record both serial number and date of

purchase and keep in a safe place for future reference.

97-6133 • Rev. 5/07

3

Page 4

WARNING

WARNING

INTRODUCTION & IMPORTANT SAFETY INFORMATION

WARNING

All information in this manual is based on the latest

product information available at the time of printing.

This machine is designed to heat water from a cold

water pressure washer. Maximum water flow is 5 GPM

and maximum pressure is 3000 PSI. Flow rate of 3

GPM will achieve an average temperature of about

180°F. Temperature is dependent on inlet water temperature and water flow rate.

PRESSURE WASHER

We reserve the right to make changes at any time

without incurring any obligation.

Owner/User Responsibility:

The owner and/or user must have an understanding of

the manufacturer’s operating instructions and warnings

before using this hot water generator. Warning information should be emphasized and understood. If the

OPERATOR’S MANUAL

operator is not fluent in English, the manufacturer’s instructions and warnings shall be read to and discussed

with the operator in the operator’s native language by

the purchaser/owner, making sure that the operator

comprehends its contents.

Owner and/or user must study and maintain for future

reference the manufacturers’ instructions.

This manual should be considered a permanent

part of the machine and should remain with it

if machine is resold.

When ordering parts, please specify model

and serial number.

IMPORTANT SAFETY

INFORMATION

CAUTION: To reduce the risk of

CAUTION

READ OPERATOR’S

MANUAL THOROUGHLY

PRIOR TO USE.

2. All installations must comply with local codes.

Contact your electrician, plumber, utility company

or the selling distributor for specific details.

To comply with the National Electrical Code (NGPA

70) and provide additional protection from risk of

electric shock, this hot water generator is equipped

with a UL approved ground fault circuit interrupter

(GFCI) power cord.

injury, read operating instructions carefully before using.

1. Read the owner’s manual

thoroughly. Failure to follow

in str uctions could ca use

malfunction of the machine

and result in death, serious

bodily injury and/or property

damage.

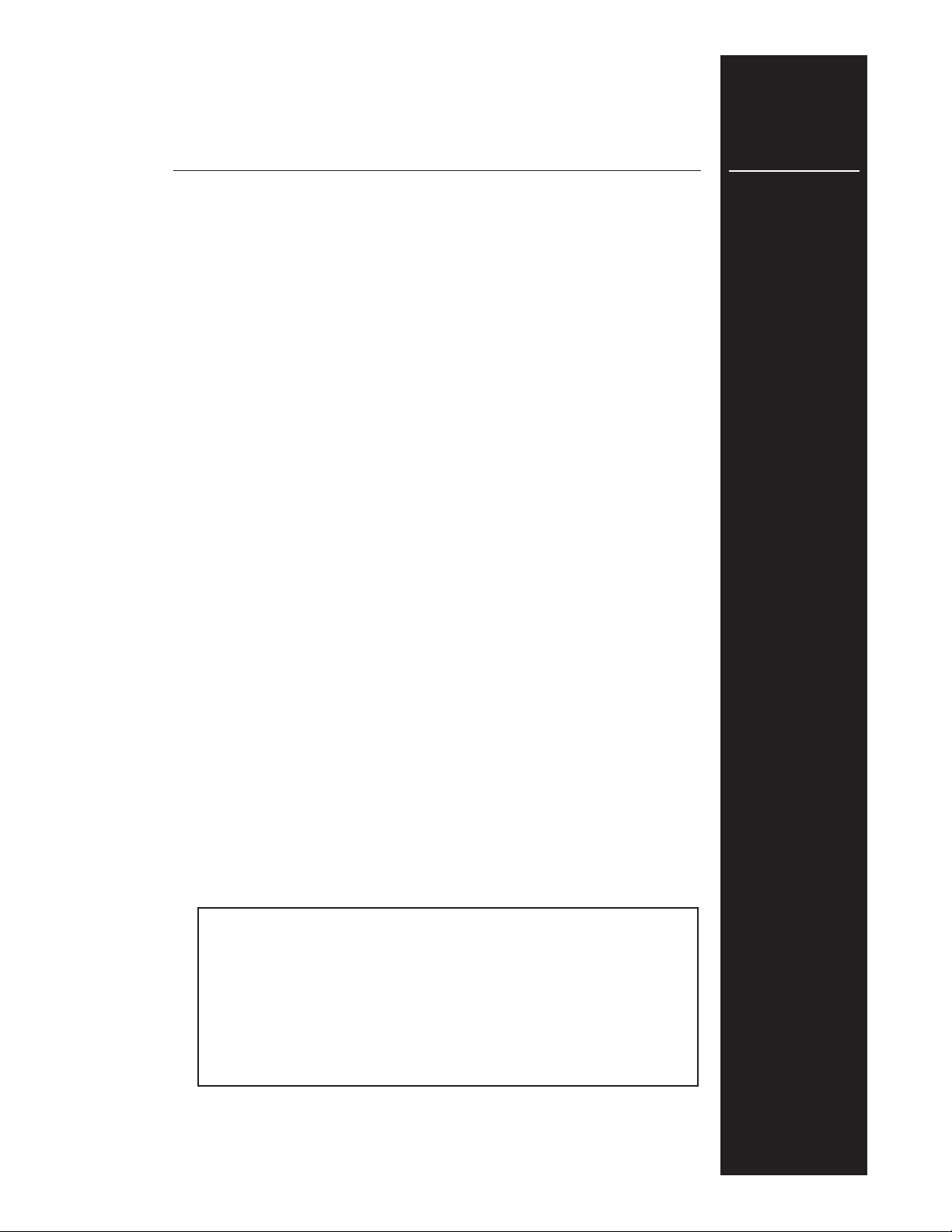

WARNING: Flammable liquids

can create fumes which can

ignite causing property damage

or severe injury.

WARNING: Do not use gasoline, crankcase drainings or oil

RISK OF FIRE.

DO NOT USE WITH

FLAMMABLE LIQUIDS.

containing gasoline, solvents

or alcohol. Doing so will result

in fire and/or explosion.

WARNING: Do not spray flammable liquids. Operate only where an open torch is permitted.

3. This fuel burning machine shall be installed only in

locations where combustible dusts and flammable

gases or vapors are not present.

4. In these oil burning models, use only kerosene,

No. 1 home heating fuel, or diesel fuel.

WARNING: Keep water spray,

wand and high pressure hose

away from electric wiring or

fatal electric shock may result.

Read warning tag on electrical

cord.

KEEP WATER SPRAY

AWAY FROM

ELECTRICAL WIRING.

5. To help protect the operator

from electrical shock, the

machine must be electrically

grounded. It is the responsibility of the owner

to connect this machine to a UL grounded

receptacle of proper voltage and amperage ratings. Do not spray water on or near electrical components. Do not touch machine with wet hands or

while standing in water. Always disconnect power

before servicing.

WARNING: Spray gun kicks back — hold attached

pressure washer with both hands.

6. Grip cleaning wand of attached pressure washer

securely with both hands before starting cleaner.

Failure to do this could result in injury from a whipping wand.

WA R N I N G : High p r e s s u r e

stream of fluid that this equipment can produce can pierce

the skin and its underlying tissues, leading to serious injury

and possible amputation.

HIGH PRESSURE

SPRAY CAN PIERCE

SKIN AND TISSUES.

NOTE: The heating module

does not produce pressure.

Pressure is developed from at-

tached pressure washer.

7. High pressure developed by the attached pressure

washer can cause bodily injury or damage.

4

97-6133 • Rev. 5/07

Page 5

WARNING

WARNING

WARNING

IMPORTANT SAFETY INFORMATION

PRESSURE WASHER

Use caution when operating. Do not point the spray

gun from the attached pressure washer at anyone

or at any part of the body. This machine is to be

used only by qualified operators.

8. Never make adjustments on machine while it is in

operation.

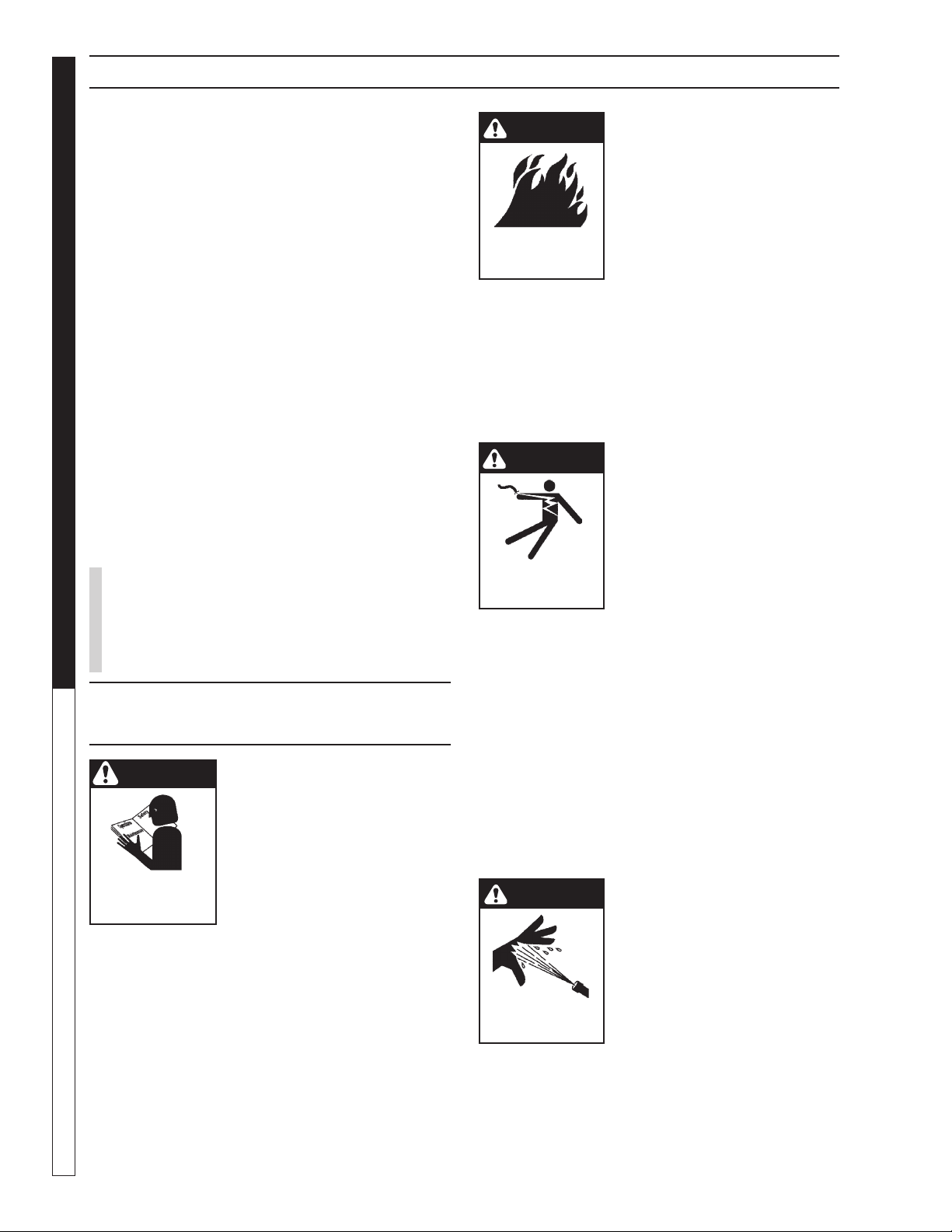

WARNING: High pressure spray

from attached pressure washer

can cause paint chips or other

particles to become airborne

and fly at high speeds.

PROTECTIVE

EYEWEAR AND CLOTH

ING MUST

BE WORN.

9. Eye safety devices must be

-

worn when using this equipment.

WARNING: Risk of asphyxiation

— Use this product only in a

well ventilated area.

10. When the machine is operating, do not cover or place in a

RISK OF

ASPHYXIATION.

USE ONLY IN A WELL

VENTILATED AREA.

closed space where ventilation is insufficient.

WARNING: Risk of fire — Do

not add fuel when the machine

is operating or still hot.

11. Attached pressure washer

with a spray gun should not

be operated with the spray

RISK OF FIRE.

DO NOT ADD FUEL

WHEN OPERATING

MACHINE.

gun in the OFF postion for

extended periods of time as

this may cause damage to

the pump.

Check to make sure burner shuts off when spray

gun trigger is closed.

12. Protect from freezing.

13. To prevent a serious injury, make certain quick

coupler on discharge hose has locked before using

pressure washer.

14. Do not allow acids, caustic or abrasive fluids to

pass through the machine.

15. Inlet water must be from a cold water pressure

washer (3,000 PSI maximum).

16. Do not allow CHILDREN to operate the pressure

washer at any time. THIS MACHINE MUST BE

ATTENDED DURING OPERATION.

17. The best insurance against an accident is precaution and knowledge of the machine.

18. Do not operate this product when fatigued or under

the influence of alcohol or drugs. Keep operating

area clear of all persons.

19. We will not be liable for any changes made to

our standard machines, or any components not

purchased from us.

20. Do not overreach or stand on unstable support.

Keep good footing and balance at all times.

21. Follow the maintenance instructions specified in

the manual.

22. When making repairs disconnect from electrical

source.

23. Turn burner off and open spray gun to allow water

to flow and cool coil to 100°F before turning machine off.

24. Before disconnecting high pressure hose from

machine water outlet, open spray gun to relieve

back pressure in hose.

CAUTION: This machine produces hot water and

must have insulated components attached to protect the operator.

OPERATOR’S MANUAL

5

97-6133 • Rev. 5/07

Page 6

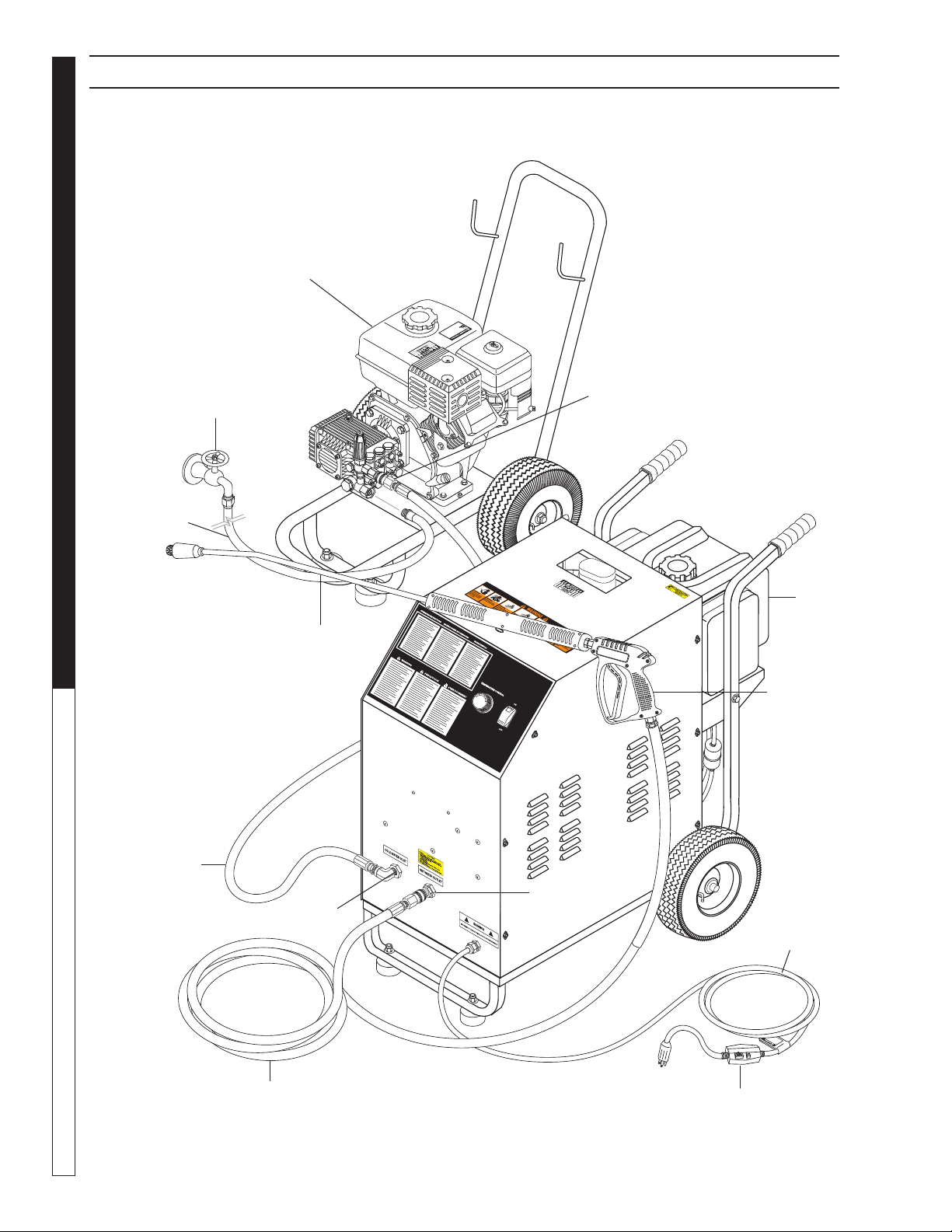

COMPONENT IDENTIFICATION

CAUTI ON HOT WATER:

Must use insulated spray

gun and wand.

Pressure Washer

PRESSURE WASHER

3,000 PSI Maximum

(not included)

OPERATOR’S MANUAL

Garden Hose

(not included)

Fresh Water

Faucet

Insulated Wand

(not included)

Pressure Washer Coupler

Diesel

Fuel

Tank

Insulated

Spray Gun

(not included)

Pressure Washer

6

to Inlet Hose

Inlet

Connection

High Pressure Outlet Hose

(not included)

Outlet

Connection

Power Cord

GFCI

97-6133 • Rev. 5/07

Page 7

INSTALLATION

PRESSURE WASHER

Place machine in a convenient location providing

ample support, drainage and room for maintenance.

Remove bolts from pallet to foot bracket. Install rubber

feet provided as shown in exploded view.

Location:

The location should protect the machine from damaging environmental conditions, such as; wind, rain, and

freezing.

1. This machine should be run on a level surface

where it is not readily influenced by outside sources such as strong winds, freezing temperatures,

rain, etc. It should be located to allow accessibility

for refilling of fuel, adjustments and maintenance.

Normal precautions should be taken by the operator of the machine to prevent moisture from

reaching the electrical controls.

2. It is recommended that a partition be made between the wash area and the machine to prevent

water spray from coming in contact with the

machine. Excess moisture reaching any electric

components or electrical controls will reduce machine life and may cause electrical shorts.

3. During installation of the machine, beware of

poorly ventilated locations or areas where exhaust

fans may cause an insufficient supply of oxygen.

Sufficient combustion can only be obtained when

there is a sufficient supply of oxygen available for

the amount of fuel being burned. If it is necessary

to install a machine in a poorly ventilated area, outside fresh air may have to be piped to the burner

and a fan installed to bring air into the machine.

Placement:

Do not locate near any combustible material. Keep all

flammable material at least 20 feet away.

Allow enough space for servicing the machine.

Local code will require certain distances from floor

and walls. (Two feet away from walls should be adequate.)

Water Source:

The water source for the pressure washer should be

supplied by a minimum 5/8” I.D. garden hose with a

city water pressure of not less than 30 PSI. If the water

supply is inadequate, or if the garden hose is kinked,

the attached pressure washer will run very rough and

the burner will not fire.

Connection:

See Component Identification.

Venting:

Adding exhaust vent pipe to your oil fired burner is

not recommended because restricted air flow causes

carbon build-up, which affects the operation, and increases maintenance on the coil. If a stack must be

used, refrain from using 90° bends. If the pipe can not

go straight up then use only 45° bends and go to the

next size pipe. The overall pipe length must not exceed

6 feet in length. The burner air adjustment must be

performed after vent pipe is installed. Use a smoke

tester for proper air setting.

OPERATOR’S MANUAL

Electrical:

This machine, when installed, must be electrically

grounded in accordance to local codes. Check for

proper power supply using a volt meter.

97-6133 • Rev. 5/07

7

Page 8

OPERATING INSTRUCTIONS

PRESSURE WASHER

STEP 1: Check fuel tank and pump

oil levels on both machines and

connect garden hose to pressure

washer. CAUTION: Only use fresh

water to this machine.

OPERATOR’S MANUAL

Burner

Switch

STEP 4: For hot water washing,

turn the machine burner switch to

the ON position. Adjust thermostat

to desired temperature setting. (The

burner will light automatically.)

STEP 2: Attach high pressure hose

between pressure washer and machine. Turn garden hose water on.

Additional adapters and couplers

may be needed to connect your

brand of pressure washer to the

machine.

STEP 4: Connect the power cord

into the proper electrical outlet,

then push in the GFCI reset button.

Start up attached pressure washer

according to the manufacturers instructions. When a steady stream of

water flows from the spray gun and

wand the machine is ready for cold

water cleaning.

8

97-6133 • Rev. 5/07

Page 9

WARNING

DETERGENTS AND GENERAL OPERATING TECHNIQUES

PRESSURE WASHER

WARNING: Some detergents

may be harmful if inhaled or

ingested, causing severe nausea, fainting or poisoning. The

harmful elements may cause

property damage or severe

injury.

STEP 1: Use detergent designed

specifically for pressure washers.

Household detergents could damage the pump. Prepare detergent

solution as required by the manufacturer. Fill a container with pressure washer detergent. Place the

filter end of detergent suction tube

into the detergent container.

STEP 2: With the motor running,

pull trigger to operate machine.

Liquid detergent is drawn into the

machine and mixed with water.

Apply detergent to work area.

Do not allow detergent to dry on

surface.

IMPORTANT: You must flush the detergent injection system after each use by placing the suction

tube into a bucket of clean water, then run the pressure washer in low pressure for 1-2 minutes.

CLEANING TIPS

Pre-rinse cleaning surface with fresh water. Place detergent suction tube directly into cleaning solution and

apply to surface at low pressure (for best results, limit

your work area to sections approximately 6 feet square

and always apply detergent from bottom to top). Allow

detergent to remain on surface 1-3 minutes. Do not

allow detergent to dry on surface. If surface appears

to be drying, simply wet down surface with fresh water.

If needed, use brush to remove stubborn dirt. Rinse at

high pressure from top to bottom in an even sweeping

motion keeping the spray nozzle approximately 1 foot

from cleaning surface. Use overlapping strokes as you

clean and rinse any surface. For best surface cleaning

action spray at a slight angle.

Recommendations:

• Before cleaning any surface, an inconspicuous

area should be cleaned to test spray pattern and

distance for maximum cleaning results.

• If painted surfaces are peeling or chipping,

use extreme caution as pressure washer may

remove the loose paint from the surface.

• Keep the spray nozzle a safe distance from the

surface you plan to clean. High pressure wash

a small area, then check the surface for damage. If no damage is found, continue to pressure

washing.

CAUTION - Never use:

• Bleach, chlorine and other corrosive chemicals

• Liquids containing solvents (i.e., paint thinner,

gasoline, oils)

• Trisodium phosphate products

• Ammonia products

• Acid-based products

These chemicals will harm the machine and will damage the surface being cleaned.

OPERATOR’S MANUAL

RINSING

It will take a few seconds for the detergent to clear.

Apply safety latch to spray gun. Remove black soap

nozzle from the quick coupler. Select and install the

desired high pressure nozzle. NOTE: You can also stop

detergent from flowing by simply removing detergent

siphon tube from bottle.

9

97-6133 • Rev. 5/07

Page 10

SHUTTING DOWN AND CLEAN-UP

Burner

Switch

PRESSURE WASHER

STEP 1: If using an optional detergent injector,

place the detergent line in

a bucket of water allowing

detergent to be flushed

from system.

OPERATOR’S MANUAL

STE P 2: Tu r n bu r n er

switch off and continue

spraying water, allowing

the water to cool. After

water has cooled to less

than 100°F, turn the attached pressure washer

off.

CAUTION: Always store your pressure washer in a

location where the temperature will not fall below

32°F (0°C). The pump in this machine is susceptible

to permanent damage if frozen. FREEZE DAMAGE

IS NOT COVERED BY WARRANTY.

1. Stop the pressure washer, squeeze spray gun

trigger to release pressure.

2. Detach water supply hose and high pressure

hose.

3. Turn on the machine for a few seconds, until remaining water exits. Turn engine off immediately.

4. Drain the gas and oil from the engine.

5. Do not allow high pressure hose to become

kinked.

6. Store the machine and accessories in a room

which does not reach freezing temperatures.

CAUTION: Failure to follow the above directions will

result in damage to your pressure washer.

When the pressure washer is not being operated or is

being stored for more than one month, follow these

instructions:

1. Replenish engine oil to upper level.

2. Drain gasoline from fuel tank, fuel line, fuel valve

and carburetor.

3. Pour about one teaspoon of engine oil through

the spark plug hole, pull the starter grip several

times and replace the plug. Then pull the starter

grip slowly

until you feel increased pressure which indicates

the piston is on its compression stroke and leave

it in that position. This closes both the intake and

10

exhaust valves to prevent rusting of cylinder.

STEP 3: Turn garden hose

water off. Open the spray

gun to relieve remaining

pressure.

STORAGE

4. Cover the pressure washer and store in a clean, dry

place that is well ventilated away from open flame

or sparks. NOTE: The use of a fuel additive, such

as STA-BIL®, or an equivalent, will minimize the

formulation of fuel deposits during storage. Such

additives may be added to the gasoline in the fuel

tank of the engine, or to the gasoline in a storage

container.

After Extended Storage

CAUTION: Prior to restarting, thaw out any

possible ice from pressure washer hoses,

spray gun or wand.

Engine Maintenance

During the winter months, rare atmospheric conditions

may develop which will cause an icing condition in the

carburetor. If this develops, the engine may run rough,

lose power and may stall. This temporary condition can

be overcome by deflecting some of the hot air from the

engine over the carburetor area. NOTE: Refer to the

engine manufacturer’s manual for service and maintenance of the engine.

97-6133 • Rev. 5/07

Page 11

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

PRESSURE WASHER Troubleshooting Guide

BURNER WILL NOT

LIGHT

Disconnected or short in electrical

wiring

Burner motor thermal protector

tripped

ON/OFF switch defective Check continuity through burner switch.

Heavy sooting on coil and burner,

can cause interruption of air flow

and shorting of electrodes

Improper electrode setting Clean and test according to diagram in

Fuel not reaching combustion chamber

Fuel solenoid malfunction Check by placing screwdriver inside coil

Clogged burner nozzle Replace.

Water not turned on Turn on water to activate burner flow switch.

All wire contacts should be clean and tight.

No breaks in wire.

If tripped, check voltage, connections and

extensions for cause. Check fuel pump

shaft rotation for binding, causing motor to

overheat.

Clean as required.

operator’s manual.

Check fuel pump for proper flow. Check

solenoid flow switch on machines with spray

gun control for proper ON/OFF flow switch.

then turn machine on, open spray gun and

check for magnetic pull.

MACHINE SMOKES

Flow switch malfunction Remove, test for continuity and replace as

needed.

Improper fuel or water in fuel Drain tank and replace contaminated fuel.

Low fuel pressure Adjust fuel pump pressure to specifications.

Air leaks in fuel lines Check fuel lines for leaks or air bubbles.

Tighten or replace as needed.

Plugged or dirty burner nozzle Replace.

Faulty burner nozzle spray pattern Replace nozzle.

Heavy accumulation of soot on coils

and burner assembly

Misaligned electrode Realign electrodes to specifications.

Fuel filter partially clogged Replace as needed.

Obstruction in smoke stack Check for insulation blockage or other for-

Soot build-up on coils Clean coils with soot remover.

Lime build-up in coils Clean inside of coils using coil cleaner.

Remove coils and burner assembly. Clean

thoroughly.

eign objects.

97-6133 • Rev. 5/07

11

Page 12

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

LOW WATER

TEMPERATURE

WATER

TEMPERATURE

TOO HOT

PRESSURE WASHER Troubleshooting Guide

Improper fuel or water in fuel Drain fuel tank and replace with

proper fuel.

Low fuel pressure Increase fuel pressure.

Weak fuel pump Check fuel pump temperature. Re-

place pump if needed.

Fuel filter partially clogged Replace as needed.

Soot build up on coils Clean coils with soot remover.

Lime build up on coils Clean inside of coils using coil

cleaner.

Improper burner nozzle See specifications.

Incoming water to machine warm or hot Lower incoming water temperature.

Fuel pump pressure too high Lower fuel pressure.

Fuel pump defective Replace fuel pump.

Detergent line sucking air Tighten all clamps. Check detergent

line for holes.

Defective high limit switch (thermostat) Replace.

Incorrect fuel nozzle size See Burner Nozzle section.

Insufficient water supplied Check GPM to machine.

Restricted water flow Check nozzle for obstruction, proper

size.

PREVENTATIVE MAINTENANCE

MAINTENANCE SCHEDULE

Machine Clean Daily

Water Lines Check Daily

Fittings Check Daily

Fuel Filter Clean Weekly

Inlet Strainer Clean Weekly

Fuel Nozzle Clean Weekly

Fuel Tank Clean Weekly

Electrodes Adjust Monthly

Fuel Pump Strainer Clean Monthly

12

Electrode Wires Check Monthly

97-6133 • Rev. 5/07

Page 13

PREVENTATIVE MAINTENANCE

PRESSURE WASHER

1. Use clean fuel - kerosene, No. 1 home heating

fuel or diesel. Clean or replace fuel filter every

100 hours of operation. Avoid water contaminated

fuel as it will seize up the fuel pump. De-soot coils

monthly. Use an additive if diesel is being used.

2. Check to see that the attached pressure washer

water pump is properly lubricated.

3. Follow winterizing instructions to prevent freeze

damage to pump and coils.

4. Always neutralize and flush detergent from system

after use.

5. If water is known to be high in mineral content, use

a water softener on your water system, or de-scale

as needed.

6. Do not allow acidic, caustic or abrasive fluids to

be pumped through system.

7. Always use high grade quality cleaning products.

8. Never run attached pressure washer pump dry for

extended periods of time.

9. If machine is operated with smoky or eye burning

exhaust, coils will soot up, not letting water reach

maximum operating temperature. (See section on

Maintenance and Service).

10. Never allow water to be sprayed on or near the

motor or burner assembly or any electrical component.

11. Delime coils as per instructions.

It is advisable, periodically, to visually inspect the

burner. Check air inlet to make sure it is not clogged

or blocked. Wipe off any oil spills and keep equipment

clean and dry.

The areas around the machine should be kept clean

and free of combustible materials, gasoline and other

flammable vapors and liquids.

The flow of ventilating air to the burner must not be

blocked or obstructed in any manner.

MAINTENANCE AND SERVICE

Winterizing Procedure:

Damage due to freezing is not covered by warranty.

Adhere to the following cold weather procedures whenever the washer must be stored or operated outdoors

under freezing conditions.

During winter months, when temperatures drop below 32°F, protecting your machine against freezing

is necessary. Store the machine in a heated room. If

this is not possible use compressed air on the short

hose end. By injecting compressed air, all water will

be blown out of the system. Run anti-freeze through

the system.

97-6133 • Rev. 5/07

Rupture Disk:

For safety, each machine is equipped with a rupture

disk. In the event the pressure of the water should exceed 8000 PSI, the rupture disk will release pressure

and water on to the ground.

When the disk ruptures, it will need to be replaced.

NOTE: Turn burner switch off. Then open spray

gun to cool heating coil or rupture disk will burst

over time.

Adjustable Thermostat:

The adjustable thermostat can be set between 100°F

to 225°F (37.8° to 108°C). The temperature is depen-

dent on water flow and ambient water temperature.

Cleaning of Coils:

In alkaline water areas, lime deposits can accumulate

rapidly inside the coil pipes. This growth is increased

by the extreme heat build up in the coil. The best

prevention for liming conditions is to use high quality

cleaning detergents. In areas where alkaline water is

an extreme problem, periodic use of Deliming Powder will remove lime and other deposits before coil

becomes plugged.

Deliming Coils With A Pressure Washer:

Periodic flushing of coils or optional float tank is recommended.

Step 1 Fill a 5 gallon bucket with 4 gallons of water,

then add 1 lb. of deliming powder. Mix thoroughly.

Step 2 Remove the high pressure nozzle from the

pressure wand and put the wand into the

bucket. Secure the trigger on the spray gun

in the open position.

Step 3 Attach a short section (3-5 ft.) of garden hose

to the attached pressure washer to siphon

solution from the elevated bucket. Start up

pressure washer, allowing solution to be

pumped through pressure washer and into

coils and back into the bucket. Solution should

be allowed to circulate 2-4 hours.

Step 4 After circulating solution flush entire system

with fresh water.

Removal of Soot In Heating Coil:

In the heating process fuel residue, in the form of soot

deposits, may develop between the heating coil pipes

and block air flow which affects burner combustion.

When soot has been detected on visual observation,

the soot on the coil must be cleaned off.

OPERATOR’S MANUAL

13

Page 14

MAINTENANCE AND SERVICE

Fuel:

Use clean fuel oil that is not contaminated with water

and debris. Replace fuel filter and drain tank every

100 hours of operation. Use Kerosene No. 1 or No.

2 Heating Fuel (ASTM D306) or diesel only. NEVER

use gasoline in your burner tank. Gasoline is more

combustible than fuel oil and could result in a serious

explosion. NEVER use crankcase or waste oil in your

PRESSURE WASHER

burner. Fuel machine malfunction could result from

contamination.

Ignition Circuit:

Periodically inspect wires, spring contact and electrodes for condition, security and proper spacing.

(CAUTION: 10,000 VOLTS)

Electrode Setting:

OPERATOR’S MANUAL

Gap

1/8”

3/16”

Side View

(See illustration below)

Electrodes Check : Periodically check wiring connections.

If necessary to adjust electrodes, use diagram.

Burner Nozzle:

Keep the tip free of surface deposits by wiping it with

a clean, solvent-saturated cloth, being careful not to

plug or enlarge the nozzle. For maximum efficiency,

replace the nozzle each season. Select nozzle size

based on the pressure washer you will be using:

Nozzle Pressure Washer GPM

1.50 2 - 3

1.75 3 - 4

2.00 - 2.25 4 - 5

All nozzles should be 45° W

Fuel Control System:

The machine utilizes a fuel solenoid valve located on

the fuel pump to control the flow of fuel to the combustion chamber. This solenoid, which is normally

closed, is activated by a flow switch when water is

flowing through it. When an operator releases the

trigger on the spray gun, the flow of water through the

flow switch stops, turning off the current to the fuel

solenoid. The solenoid then closes, shutting off the

14

supply of fuel to the combustion chamber. Controlling

the flow of fuel in this way gives an instantaneous burn

or no burn situation, thereby eliminating high and low

water temperatures, and combustion smoke normally

associated with machines incorporating a spray gun.

Periodic inspection is recommended to insure that

the fuel solenoid valve functions properly. This can be

done by operating the machine and checking to see

that when the trigger on the spray gun is in the off

position, the burner is not firing.

Fuel Pressure Adjustment:

To adjust fuel pressure, turn the adjusting screw with

a 5/32” allen wrench (located on the fuel pump) clockwise to increase, counterclockwise to decrease. Do

not exceed 200 PSI.

FIELD REPAIR

INSTRUCTIONS

Fuel Pump:

1. Remove the screws 10/32” Allen Head from the

machine hood.

2. Remove louvered hood.

3. With a 9/16” wrench, loosen (DO NOT REMOVE)

the two 3/8” x 3/4” HH NC serrated flange bolts

that secure the front panel.

4. With a 2.5 mm hex head wrench (Allen Wrench),

loosen the three set screws that hold the fuel pump

in the blower motor housing located on Idromatic

Boiler Assembly.

5. Carefully remove the fuel pump (Item #53) from

the blower motor, leaving the flexible zinc fuel line

connected, carefully bend the fuel line and fuel

pump away from the blower motor.

6. Locate the fuel pump/fan motor coupling.

7. Inspect the coupling for damage. The inside

diameter of fuel pump coupling requires flat on

one side to engage fuel pump, and the outside

diameter requires two male notches to engage

the blower motor.

8. Perform a check to see if the fuel pump is turning

freely. Use an open end 7mm wrench or small

adjustable wrench on fuel pump shaft.

9. Spin the fuel pump over in both directions using

the wrench for leverage. When the fuel pump is

turning freely (almost to the point you could turn

it by hand) it is ready to reinstall.

10. Align fuel pump coupler on pump shaft/fan motor.

Slide pump into fan motor. Secure pump with the

three set screws.

97-6133 • Rev. 5/07

Page 15

FIELD REPAIR INSTRUCTIONS

11. Test machine (make sure):

q Blower motor spins

q Fuel is on

q Machine has power to it

q Switch is on

q Flow of water through machine

q Thermostat is turned up

q Flow switch is adjusted properly

12. When unit is operating properly, turn machine off,

tighten front panel, and install hood and 13 self

tapping screws with recess washers.

PRESSURE WASHER

OPERATOR’S MANUAL

97-6133 • Rev. 5/07

15

Page 16

EXPLODED VIEW

16

22

25

46

31

See

PRESSURE WASHER

Burner

Assembly

For

12

Details

27

OPERATOR’S MANUAL

31

33

35

14

10

39

29

28

40

43

41

30

20

19

21

24

18

48

34

23

13

4

43

42

29

6

36

45

38

17

11

3

8

46

2

9

26

47

29

37

44

15

7

1

32

5

16

97-6133 • Rev. 5/07

Page 17

EXPLODED VIEW PARTS LIST

PRESSURE WASHER

ITEM PART NO. DESCRIPTION QTY

1 90-2020 Nut, Cage, 3/8" x 12 Gauge 4

2 90-1996 Screw, 3/8" x 3/4" Whiz Loc 4

3 4-0303 Wheel & Tire, 6" Steel Rim 2

4 4-05089 Thermostat, Adjustable, 240°F 1

5 6-01062 GFCI, 120V 15A, w/36' 12-3

Cord 1

6 6-020240 Switch, Rocker, Carling

w/Green Lens 1

7 6-05152 Strain Relief, Strt, LQ Tite 3231

Small 1

6-05181A

8 90-16 Screw, 8/32" x 3/4" BHSOC 2

9 90-20041 Collar, 5/8" Bore Shaft 3010 2

95-07102225

90-4005

10 95-07200124 Bracket, Fuel Tank, Right 1

11 95-07200125 Frame Assy 1

12 95-07290069 Hood, Cover 1

13 95-07200121 Panel, Front 1

11-1042

14 95-07102287 Strap, Fuel Tank 2

15 2-01015 Bumber, Rubber 1" w/Bolt,

5/16" x 1-1/4" 2

16 11-0101 Label, Warning, Pictorial 1

17 95-07200120 Panel, Back 1

18 2-2007 Nipple, 3/8" x 3/8" NPT ST

Male 1

19 2-2002 Coupler, 3/8" Female, Brass 1

20 2-0031 Elbow, 3/8" Street 1

▲ Locknut, 1/2" 1

▲ Axle 1

▲ Washer, 5/8" 2

▲ Label, Ground 1

ITEM PART NO. DESCRIPTION QTY

21 11-0110 Label, Control Panel 1

22 10-02025A Label, Hot/Caliente, w/Arrows 1

23 10-09004 Decal, Discharge 1

24 10-09003 Decal, Inlet 1

25 11-013 Label (HP) 1

26 90-20061 Nut, 5/16", Eng 2

27 90-19710 Screw, 1/4" x 3/4" HH, NC 4

28 95-07200122 Bracket, Fuel Tank, Left 1

29 90-2018 Nut, Cage, 10/32" x 16 Gauge 13

30 4-0204509 Hose, 3/8" x 9', 2 Wire, 3/8" SW

x 3/8" SOL 1

31 90-1991 Screw, 10/32" x 1/2" 13

32 10-08018 Label, Warning, Service Cord 1

33 2-01103 Grip, 1” Square Handle 2

34 10-08021 Label, Disconnect Pwr Supply 1

35 2-0155 Fastener, Ratchet, Black 2

36 6-05040 Block, Terminal, 8 Pole 1

6-0505

37 90-100461 Screw, 1/4" 1/2" Hex, Black 1

38 90-200490 Nut, 8/32", Keps 2

39 90-200012 Nut, 1/4" Flange 4

40 90-1004 Bolt, 1/4" x 1-1/2" 2

41 90-4000 Washer, 1/4" Flat 2

42 90-19711 Screw, 1/4" x 1/2" HH, NC 4

43 90-200012 Nut, 1/4" Flange 6

44 90-40125 Washer, 3/8" x 1" Steel 2

45 2-0103 Grommet, Rubber, Nozzle

Holder 2

46 9.800-018.0 Label, Tipover Hazard 1

47 90-017 Nut, 10/32” Keps 4

48 9.800-049.0 Label, Cleaning Solution 1

▲ Not Shown

▲ Bar Jumper 2

OPERATOR’S MANUAL

97-6133 • Rev. 5/07

17

Page 18

BURNER ASSEMBLY EXPLODED VIEW

9

4

5

6

PRESSURE WASHER

8

12

31

3

7

11

42

13

56

OPERATOR’S MANUAL

10

58

61

15

59

14

40

37

60

57

62

40

38

17

19

21

30

22

Inlet

49

Outlet

48

49

53

43

41

47

45

41

20

36

24

25

52

46

32

33

34

50

28

23

55

32

26

51

29

27

39

35

50

54

32

33

44

18

44

97-6133 • Rev. 5/07

Page 19

BURNER ASSEMBLY PARTS LIST

PRESSURE WASHER

ITEM PART NO. DESCRIPTION QTY

1 91-010170 Coil, Lavorwash 1

2 7-46140112 Clamp, Electrode 1

3 7-46140004 Electrode 2

4 7-31000017 Elbow 1

5 7-30990015 Ring, Locking 1

6 7-46080002 Slide 1

7 7-46050001 Flange, Burner 1

8 7-31040009 Nozzle, Burner 1.50, 60° 1

9 7-56110098 Cable, High Tension 2

10 7-34050003 Board, Terminal 1

11 7-56130147 Cover, Tank External, SS 1

12 7-56100105 Deflector 1

13 7-56130133 Cover, Burner 1

14 7-46040021 Coil, High 500 1

15 7-56130039 Heater Body 1

16 7-31000015 Connector, 1/8 m 1

17 7-35510013 Pump, Fuel 1

18 7-34140011 Coil, Solenoid 1

19 7-30990012 Coupling, Plastic 1

20 7-33000013 Motor, 110V 60 Cycle 1

21 7-30990028 Fan 1

22 7-34100004 Box, Electric 70 x 70 x 30 1

23 7-46080193 Refractory 1

24 7-46070006 Strip, Coil Fixing 1

25 7-46080162 Rope, Insulating 1

26 7-56130026 Base, Heater 1

27 7-46060013 Nut, Coil Fixing 2

28 7-30040015 Washer, 22 x 39 2

29 7-56090023 Guard, Fan 1

30 7-34000017 Transformer, 110V 60 Cycle 1

31 7-46160005 Tube, Copper 1

32 90-4001 Washer, 5/16" Flat 8

ITEM PART NO. DESCRIPTION QTY

33 90-2001 Nut, 5/16" ESNA 4

34 2-0036 Tee, 1/2" Female, Steel Pipe 1

35 2-0046 Tee, 1/2", Street 1

36 2-0054 Elbow, 1/2" JIC x 1/2” Male 1

37 4-02100000 Fuel Line, 1/4" Push-on, 6"

38 70-121603 Hose Barb 2

39 2-3409 Disk, Rupture Assy, 7000 PSI 1

40 2-9040 Clamp, Hose, UNI, .46-.54 6

41 4-02047714 Hose, 3/8" x 14", 2 Wire,

Pressure Loop 2

42 2-011507 Tank, Encore, 5 Gallon Fuel 1

43 6-021730 Switch, Flow, MV60 1

44 90-20040 Nut, 3/8" Whiz Loc 4

45 2-0053 Elbow, 1/2" JIC x 3/8", 90° 1

46 2-00602 Elbow, 1/2" JIC x 1/2" Fem, 90° 1

47 6-021740 Reed, Replacement, MV60 1

48 2-0006 Nipple, 3/8" x 3/8" Hex, Steel 1

49 2-11039 Connector, 3/8" Anchor 2

50 90-19961 Screw, 3/8" x 1-3/4" HH, NC 4

51 2-1019 Elbow, 3/8" Female 1

52 4-05088 Thermostat, Adjustable, 302°F 1

53 2-0053 Elbow, 1/2" JIC, 3/8", 90° 1

54 95-07290082 Coil, Mount Plate 1

55 90-1006 Bolt, 5/16" x 3/4" 4

56 2-01167 Cap, Fuel Tank, 5 Gallon Fuel 1

57 2-1084 Hose Barb, 1/4" Barb x

1/8" Pipe 1

58 2-99031 Filter, Diesel, Fuel, Disposable 1

59 2-010061 Grommet, Fuel Tank 1

60 7-80320 Valve, Fuel Tank Shut-Off 1

61 4-02100000 Fuel Line, 1/4" Push-On, 36"

62 4-02100000 Fuel Line, 1/4" Push-on 46"

▲ Not Shown

OPERATOR’S MANUAL

97-6133 • Rev. 5/07

19

Page 20

Page 21

SHARK LIMITED NEW PRODUCT WARRANTY

PRESSURE WASHERS

WHAT THIS WARRANTY COVERS

All SHARK PRESSURE WASHERS are warranted by SHARK to the original purchaser to be free from defects in materials

and workmanship under normal use, for the periods specified below. This Limited Warranty is subject to the exclusions shown

below, is calculated from the date of the original purchase, and applies to the original components only. Any parts replaced

under this warranty will assume the remainder of the part’s warranty period. This warranty applies to the original purchaser

and is not transferable.

LIMITED LIFETIME PARTS WARRANTY:

Components manufactured by SHARK, such as frames, handles, and belt guards. Forged brass pump manifold. All heating

coils will have a three year warranty. Internal components (excluding oil seals) on the oil-end of all pressure washer pumps

will have a seven year warranty.

ONE YEAR PARTS AND 90 DAYS LAbOR WARRANTY:

All other components, excluding normal wear items as described below, will be warranted for one year on parts. Warranty on

these parts will be for one year regardless of the duration of the original component manufacturer’s part warranty.

WARRANTY PROVIDED bY OTHER MANUFACTURERS:

Motors, generators, and engines, which are warranted by their respective manufacturers, are serviced through these manufacturers’ local authorized service centers. SHARK cannot provide warranty on these items.

WHAT THIS WARRANTY DOES NOT COVER

This warranty does not cover the following items:

1. Normal wear items, such as nozzles, guns, discharge hoses, wands, quick couplers, seals, filters, gaskets, O-rings,

packings, pistons, pump valve assemblies, strainers, belts, brushes, rupture disks, fuses, pump protectors.

2. Damage or malfunctions resulting from accidents, abuse, modifications, alterations, incorrect installation, improper

servicing, failure to follow manufacturer’s maintenance instructions, or use of the equipment beyond its stated usage

specifications as contained in the operator’s manual.

3. Damage due to freezing, chemical deterioration, scale buildup, rust, corrosion, or thermal expansion.

4. Damage to components from fluctuations in electrical or water supply.

5. Normal maintenance service, including adjustments, fuel system cleaning, and clearing of obstructions.

6. Transportation to service center, shop labor charges, field labor charges, or freight damage.

WHAT YOU MUST DO TO ObTAIN WARRANTY SERVICE

While not required for warranty service, we request that you register your SHARK pressure washer by returning the completed

registration card. In order to obtain warranty service on items, you must return the product to an Authorized SHARK Dealer,

freight prepaid, with proof of purchase, within the applicable warranty period. If the product is permanently installed, you

must notify your Authorized SHARK Dealer of the defect. The Authorized Dealer will file a claim, which must subsequently

verify the defect. In most cases, the part must be returned to SHARK freight prepaid with the claim. For warranty service on

components warranted by other manufacturers, the Authorized Dealer can help you obtain warranty service through these

manufacturers’ local authorized service centers.

LIMITATION OF LIAbILITY

SHARK’S liability for special, incidental, or consequential damages is expressly disclaimed. In no event shall SHARK’S liability

exceed the purchase price of the product in question. SHARK makes every effort to ensure that all illustrations and specifications are correct, however, these do not imply a warranty that the product is merchantable or fit for a particular purpose, or that

the product will actually conform to the illustrations and specifications. THE WARRANTY CONTAINED HEREIN IS IN LIEU

OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE. SHARK does not authorize any other party, including authorized Dealers, to make any representa-

tion or promise on behalf of SHARK, or to modify the terms, conditions, or limitations in any way. It is the buyer’s responsibility

to ensure that the installation and use of SHARK products conforms to local codes. While SHARK attempts to assure that its

products meet national codes, it cannot be responsible for how the customer chooses to use or install the product.

SHARK PRESSURE WASHERS

www.shark-pw.com

97-6133 • Rev. 5/07

PRESSURE WASHER WARRANTY

Page 22

Form #8.914-336.0 / 97-6133 • Revised 5/07 • Printed in U.S.A.

Loading...

Loading...