Shark HNG-4020, HNG-3530, HNG-5030, HNG-3010 Operator's Manual

HNG

OPERATOR’S MANUAL

■ HNG-4020 ■ HNG-3530 ■ HNG-5030

L

D

I

S

E

®

T

SHARK PRESSURE WASHERS ■ 4275 N.W. Pacific Rim Blvd. ■ Camas, WA 98607 ■ USA

For technical assistance or the Shark Dealer nearest you, call 1-800-771-1881.

2

CONTENTS

Introduction................................................................................................................................... 3

Important Safety Information .....................................................................................................3-4

Installation ................................................................................................................................. 4-8

Installation Guide .......................................................................................................................... 5

Start-up ..................................................................................................................................... 8-9

Check List Before Starting .......................................................................................................... 10

Component Identification ............................................................................................................ 11

Operating Instructions ................................................................................................................ 12

Preventatative Maintenance........................................................................................................ 12

General Washing Techniques ................................................................................................12-13

Maintenance & Service............................................................................................................... 13

Heating Coils ......................................................................................................................... 13-14

Propane Gas .............................................................................................................................. 14

Burner Features.......................................................................................................................... 15

Burner Troubleshooting .......................................................................................................... 15-16

Hose & Spray Gun Assembly ..................................................................................................... 17

Exploded View, Left Side ............................................................................................................ 18

Exploded View, Right Side .......................................................................................................... 19

Exploded View, Parts List ...................................................................................................... 20-21

Burner Assembly, Exploded View ............................................................................................... 22

Burner Assembly, Exploded View, Parts List ............................................................................... 23

Control Panel .............................................................................................................................. 24

Control Panel, Parts List ............................................................................................................. 25

Float Tank Assembly ................................................................................................................... 26

Electrical Box, Standard ............................................................................................................. 27

Electrical Box, Time Delay ..................................................................................................... 28-29

Electrical Box, Auto Start ....................................................................................................... 30-31

Troubleshooting ................................................................................................................... 332-33

Basic Facts ................................................................................................................................. 34

Pressure Equivalents.................................................................................................................. 34

Preventative Maintenance Schedule ........................................................................................... 35

Oil Change Record ..................................................................................................................... 35

Warranty

Model Number ______________________________

Serial Number ______________________________

Date of Purchase ____________________________

The model and serial numbers will be found on a decal attached to

the pressure washer. You should record both serial number and

date of purchase and keep in a safe place for future reference.

Shark HNG Manual • Form #97-610 • Revised 2/03a

HNG SERIES PRESSURE WASHER

WARNING

WARNING

WARNING

OPERATOR’S MANUAL

3

INTRODUCTION

Thank you for purchasing a Shark Pressure Washer.

This manual covers the operation and maintenance of

the HNG-402001A, 402007A, 353001A, 353007A,

503001B, 503007B, 503001C, and 503007C washers.

All information in this manual is based on the latest product information available at the time of printing.

Shark, Inc. reserves the right to make changes at any

time without incurring any obligation.

The HNG Series was designed for

maximum use of 4 hours per day,

5 days per week.

Owner/User Responsibility:

The owner and/or user must have an understanding of

the manufacturer’s operating instructions and warnings

before using this Shark pressure washer. Warning information should be emphasized and understood. If the

operator is not fluent in English, the manufacturer’s instructions and warnings shall be read to and discussed

with the operator in the operator’s native language by

the purchaser/owner, making sure that the operator comprehends its contents.

Owner and/or user must study and maintain for future

reference the manufacturers’ instructions

This manual should be considered a permanent

part of the machine and should remain with it if

machine is resold.

When ordering parts, please specify model and

serial number.

IMPORTANT SAFETY

INFORMATION

WARNING: When using this machine basic

precautions should always be followed, including the

following:

CAUTION

READ OPERATOR’S

MANUAL

THOROUGHLY

PRIOR TO USE.

CAUTION: To reduce the risk of

injury, read operating instructions

carefully before using.

1. Read the owner's manual

thoroughly. Failure to follow instructions could cause malfunction of the machine and result

in death, serious bodily injury

and/or property damage.

2. All installations must comply with local codes. Contact your electrician, plumber, utility company or the

selling distributor for specific details.

3. Know how to stop the machine and bleed pressures

quickly. Be thoroughly familiar with the controls.

4. Stay alert. Watch what you are doing.

WARNING: Flammable liquids

can create fumes which can ignite

causing property damage or

severe injury.

5. Risk of explosion - Do not spray

flammable liquids or operate in

RISK OF EXPLOSION:

DO NOT SPRAY

FLAMMABLE

LIQUIDS.

an explosive location. Operate

only where open flame or torch

is permitted.

WARNING: Keep water spray

away from electrical wiring or fatal electric shock may result.

Read warning tag on electrical

cord.

6. To protect the operator from

KEEP WATER SPRAY

AWAY F R OM

ELECTRICAL WIRING.

electrical shock, the machine

must be electrically grounded.

It is the responsibility of the

owner to connect this machine

to a UL grounded receptacle of proper voltage and

amperage ratings. Do not spray water on or near

electrical components. Do not touch machine with

wet hands or while standing in water. Always disconnect power before servicing.

WARNING: Spray gun kicks back. Hold with both hands.

7. Grip cleaning wand securely with both hands before

starting the cleaner. Failure to do this could result in

injury from a whipping wand.

WARNING: Equipment can produce a high pressure stream of

fluid that can pierce skin and its

underlying tissues, leading to

serious injury and possible

amputation.

RISK OF INJECTION

OR SEVERE INJURY

TO PERSONS. KEEP

CLEAR OF NOZZLE.

8. High pressure developed by

these machines can cause

personal injury or equipment

damage. Use caution when operating. Do not direct

discharge stream at anyone or at any part of the

body, or severe injury or death will result. This machine is to be used only by qualified operators.

Shark HNG • Rev. 2/03a

4

HNG SERIES PRESSURE WASHER

OPERATOR’S MANUAL

WARNING

CAUTION: Hot discharge fluid. Do

not touch or direct discharge

stream at persons.

9. Never make adjustments on

machine while in operation.

EXTREMELY HOT:

USE CAUTION WHEN

OPENING LID.

WARNING

WARNING: High pressure can

cause paint chips or other particles to become airborne and fly

at high speeds.

10. Eye safety devices and foot pro-

PROTECTIVE

EYEWEAR AND

CLOTHING MUST

BE WORN.

WARNING

tection must be worn when

using this equipment.

WARNING: Risk of asphyxiation.

Use this product only in a well

ventilated area.

11. When the machine is working,

do not cover or place in a closed

space where ventilation is insuf-

RISK OF

ASPHYXIATION.

USE ONLY IN A WELL

VENTILATED AREA.

ficient.

12. Machines with spray guns

should not be operated with the

trigger in the off position for extensive periods of time

as this may cause damage to the pump.

13. Protect from freezing.

14. Be certain all quick coupler fittings are secured

before using pressure washer.

15. Do not allow acids, caustic, or abrasive fluids to pass

through the pump.

16. Inlet water must be cold and clean fresh water.

17. To reduce the risk of injury, close supervision is necessary when a machine is used near children. Do

not allow children to operate the pressure washer.

This machine must be attended during operation.

18. The best insurance against an accident is precaution and knowledge of the machine.

19. Do not operate this product when fatigued or under

the influence of alcohol or drugs. Keep operating area

clear of all persons.

20. Do not replace LP tank while machine is running.

Serious injury could result.

Shark HNG • Rev. 2/03a

WARNING

WARNING: Use only vapor fuel.

21. This equipment is designed to

run on vapor fuel. Do not use

liquid fuel. Have a qualified serviceman install and service

your equipment.

RISK OF FIRE.

DO NOT USE WITH

FLAMMABLE LIQUIDS.

22. Never expose a spark or flame

where unburned gas may be

present.

23. Never attempt to light pilot unless pilot manual valve

has been shut off for 5 minutes.

24. A conversion kit, as supplied by the manufacturer,

shall be used to convert natural gas to propane.

25. L.P. gases are heavier than air and will spill out on

the floor. Therefore always provide adequate space

and ventilation around these machines. Install

machine 18" above the floor.

26. Shark will not be liable for any changes made to our

standard machines, or any components not purchased from Shark.

27. Do not overreach or stand on unstable support. Keep

good footing and balance at all times.

28. Follow maintenance instructions specified in the

manual.

29. When making repairs disconnect from electrical

source and shut off gas valve.

WARNING

30. Turn burner off and cool to

100° F before turning machine

off.

31. Extinguish any open flame and

test all joints with a soap solution. If odor persists, call your

RISK OF EXPLOSION:

IF GAS SMELL

PRESENT TURN

OFF SUPPLY

gas supplier immediately.

32. Not suitable for connection

to Type B gas vent if the stack

temperature exceeds 243° C

(470° F).

33. A draft hood shall be installed if this machine is

going to be permanently installed and vented to the

outside of the building.

INSTALLATION

Place machine in a convenient location providing ample

support, drainage and room for maintenance (see page 5).

Location:

The location should protect the machine from damaging

environmental conditions, such as wind, rain and freezing.

1. The machine should be run on a level surface where

it is not readily influenced by outside sources such

as strong winds, freezing temperatures, rain, etc. The

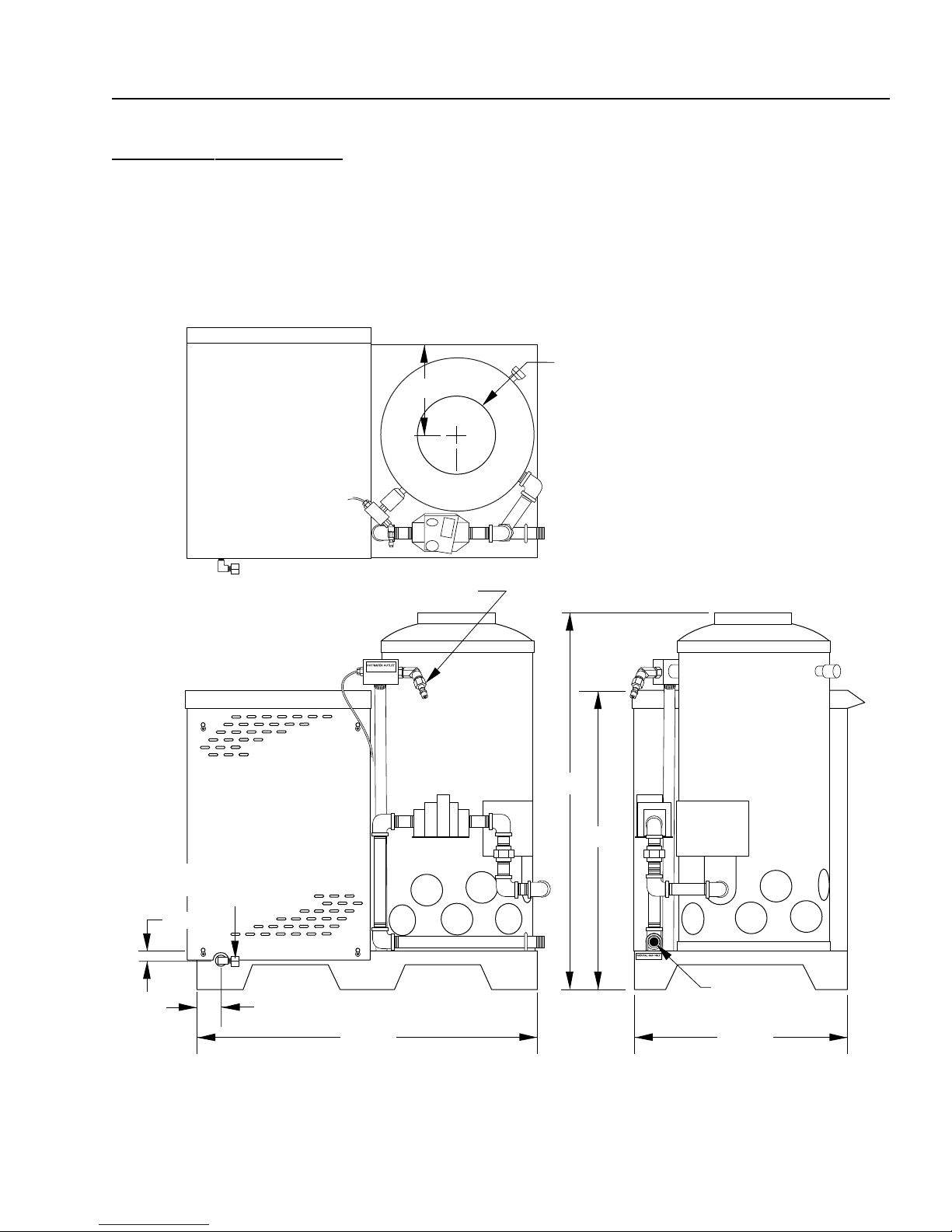

HNG SERIES PRESSURE WASHER

INSTALLATION GUIDE

HNG

9.57" I.D.

11-3/4"

OPERATOR’S MANUAL

5

Fresh Water

In 1.0" GHF

1-1/4"

3.0"

High Pressure Out

44-1/4"

49-0"

38-3/8"

Gas In

1-1/2" NPT-M

27-1/2"

Shark HNG • Rev. 2/03a

6

HNG SERIES PRESSURE WASHER

OPERATOR’S MANUAL

machine should be located considering accessibility for the replacing of components and the refilling

of detergents, adjustments and maintenance. Normal precautions should be taken by the operator of

the machine to prevent excess moisture from reaching the power unit or electrical controls.

2. It is recommended that a partition be made between

the wash area and the machine to prevent direct

spray from the spray gun from coming in contact with

the machine. Excess moisture reaching the power

unit or electrical controls will reduce the machine’s

life and may cause electrical shorts.

3. During installation of the machine, beware of poorly

ventilated locations or areas where exhaust fans may

cause an insufficient supply of oxygen. Sufficient

combustion can only be obtained when there is a

sufficient supply of oxygen available for the amount

of fuel being burned. If it is necessary to install a

machine in a poorly ventilated area, outside fresh

air may have to be piped to the burner and a fan

installed to bring the air into the area.

4. Do not locate near any combustible material. Keep

all flammable material at least 20 feet away.

Allow enough space for servicing the machine.

Local code will require certain distances from floor

and walls. (Two feet away should be adequate).

WARNING: Avoid small areas or near exhaust fans.

Gas Codes:

Confer with local gas company and with proper municipal officials regarding any specific code or regulations

governing the installation. The installation must conform

to local codes.

Electrical:

The machine, when installed, must be electrically

grounded in accordance to local codes. Check for proper

power supply using a volt meter; check the serial plate

for the correct requirements.

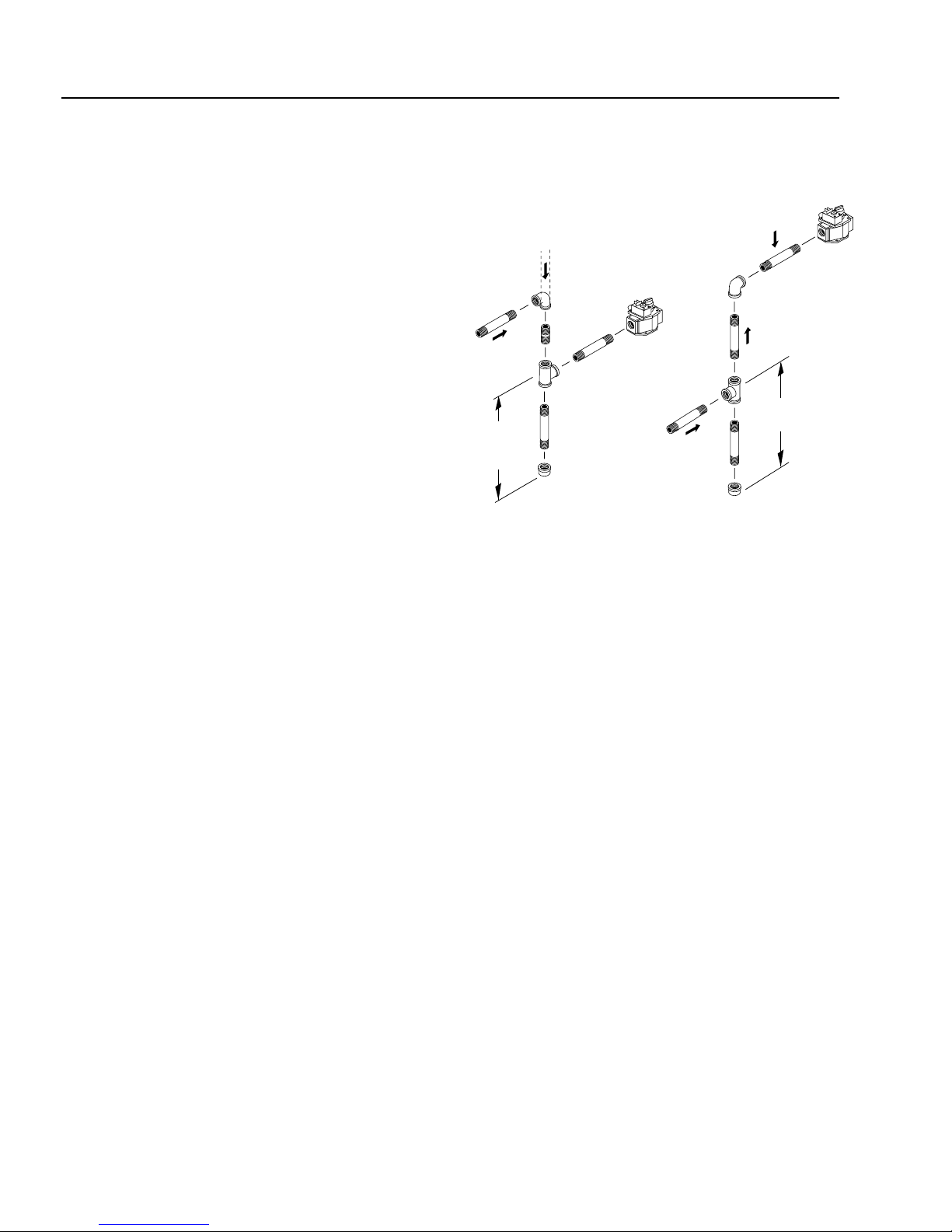

Gas Piping:

Figure 1

Drop

Gas

Valve

3" (7.62 mm)

Minimum

DRIP LEG

Sediment trap (drip leg) must be

installed in the supply line.

Install a union in the gas line adjacent to and upstream

from the control manifold and downstream from the

manual main shut-off valve. A 1/8" NPT plugged tapping

accessible for test gauge connection shall be installed

immediately upstream of the gas supply connection for

the purpose of determining the gas supply pressure to

the burner, and to prevent damage to gas valve.

If a manual gas shut off valve is not in the gas supply line

within six feet of the machine and in an accessible location, one shall be installed.

1/4" Test Port

(6" - 14 W.C.

or 1/2" PSIG)

Gas

Valve

3" (7.62 mm)

Minimum

Shark HNG • Rev. 2/03a

HNG SERIES PRESSURE WASHER

OPERATOR’S MANUAL

7

Figure 2

Manual

Shut-Off Valve

3" (7.62 mm)

Minimum

Flow

Tee

1/8" NPT Plugged

Pressure Gauge

Port Location

Control Manifold

Pipe

Cap

Floor Level

Union

To

Gas Valve

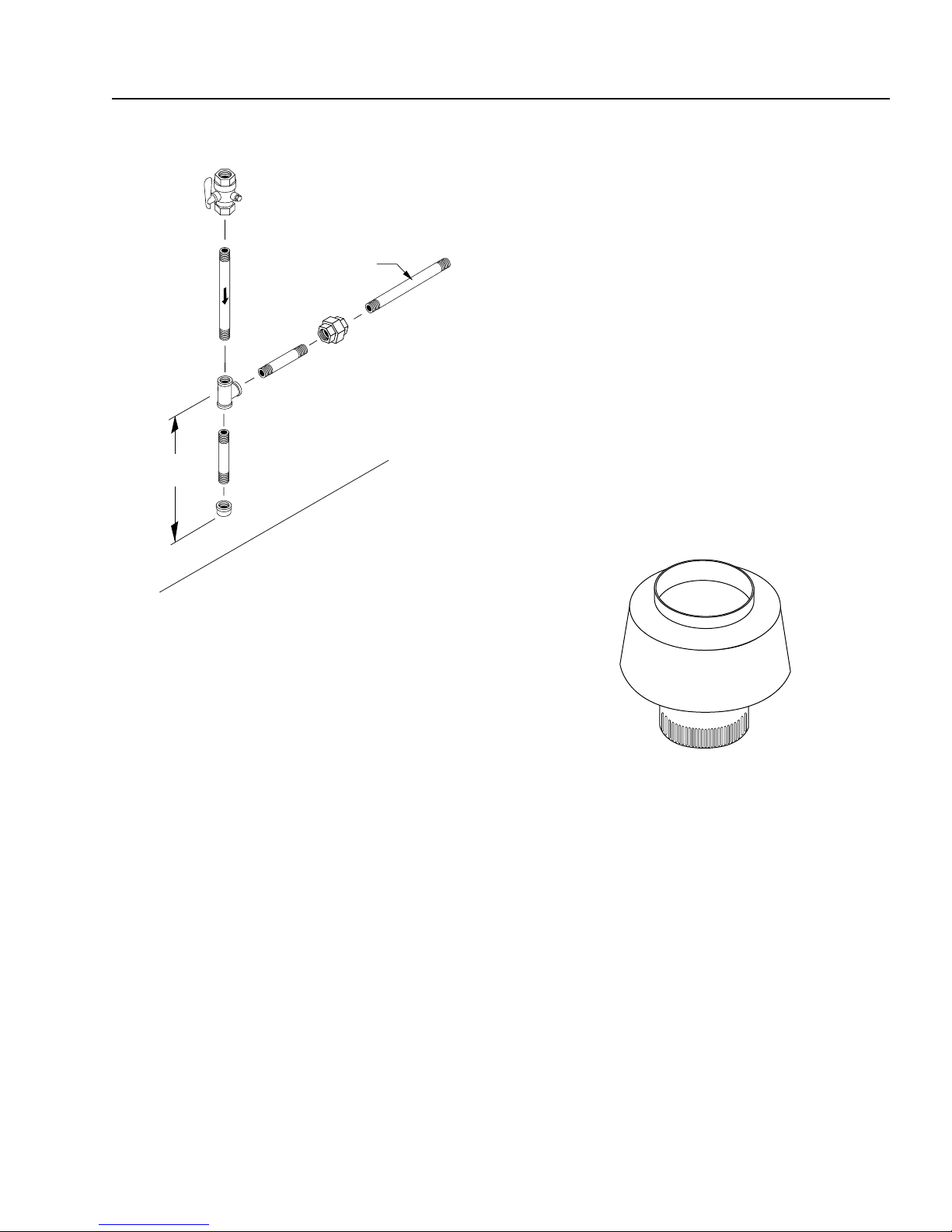

Input - BTU Per Hour Draft Hood & Flue Pipe Size

250,000 - 320,000 8 inch

320,000 - 410,000 9 inch

410,000 - 600,000 10 inch

600,000 - 750,000 12 inch

NOTE: If the flue pipe exceeds 10 ft. in length, or contains more than two elbows, use next size larger pipe

and draft hood or the burner will not ignite. No movable

flue pipe damper should be used on any installation.

Draft Diverter:

Install the draft diverter above the heating coil. The

diverter enhances the draft through the burner by severing the chimney effect created in sections of furnace pipe

positioned below. It also helps prevent freezing of the

coil due to wind chill factors.

Figure 3

Optional

UNION LOCATION

The following pipe and stack sizes are just recommendations. Always consult a local plumber and venting contractor for local codes and regulations during installation.

Distance From Regulator Pipe Size

0 - 59' 1" 1 PS

50' - 100' 1-1/2" 1 PS

100' - 200' 1-3/4" 1 PS

Natural Gas

Distance From Regulator Pipe Size

0 - 50' 1-1/2" 1 PS

50' - 100' 2" 1 PS

100' - 200' 2-1/2" 1 PS

Venting:

If the machine is used indoors, regulations or ventilation

concerns may call for a chimney or furnace pipe.

When venting the machine, if the machine is to be in an

enclosed area with a chimney on it, be sure the chimney

is the same size as the stack on the machine. Poor draft

will cause the machine to soot and not operate efficiently.

When placing the machine for installation, position the

stack to be as straight as possible and to protrude through

the roof of the building at a proper location and at sufficient height to eliminate down-draft. The chimney of a

gas fired machine shall be installed with a down-draft

diverter located about 3 ft. above machine.

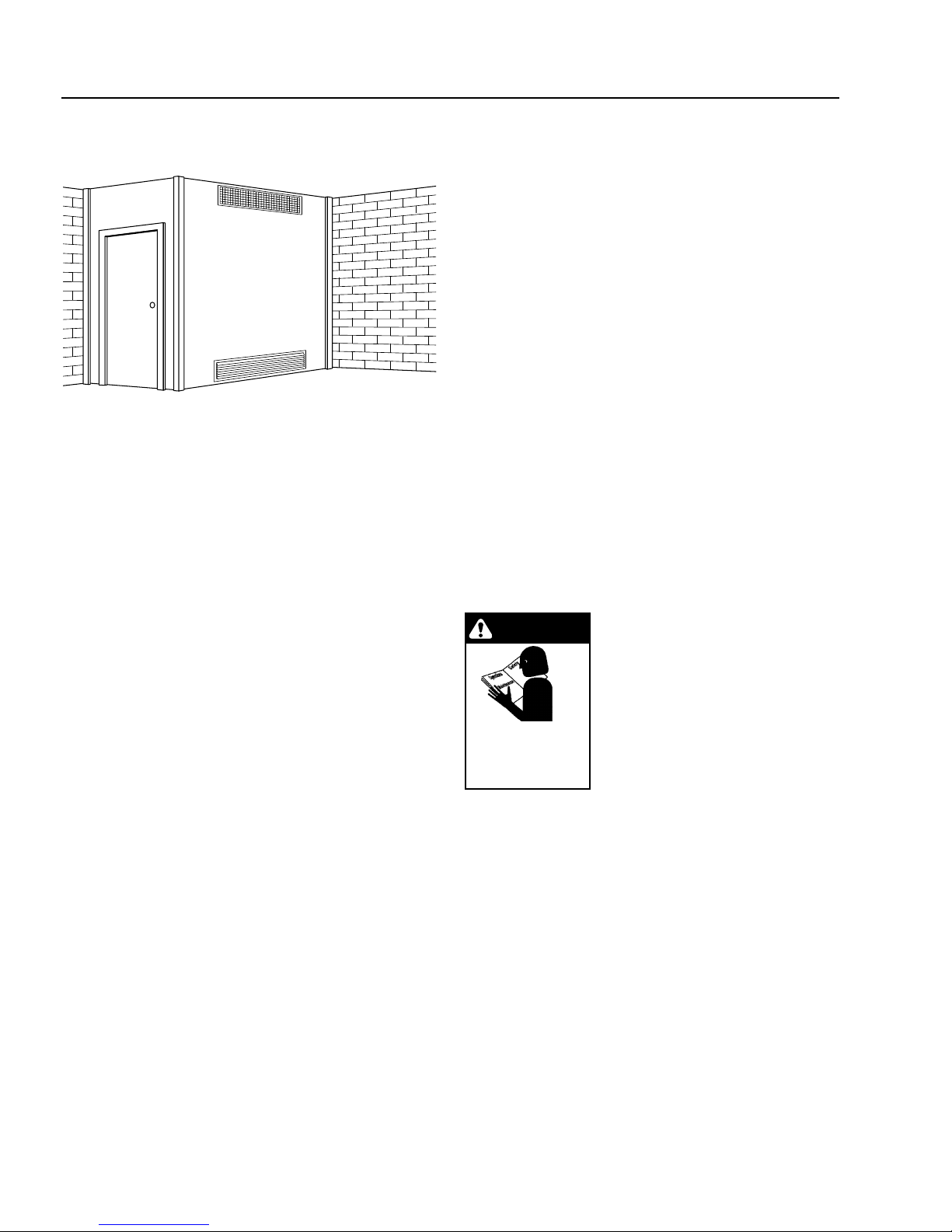

When the heating appliance is installed in a tightly closed

room without ventilation openings to the outdoors or other

rooms, provisions shall be made for supplying air for combustion through special openings, one near the floor line

and the other near the ceiling, each to be sized on the

basis of one square inch or more of free area for each

1,000 BTU input per hour (see Figure 4).

When a room is of unusually tight construction and has

a kitchen and/or bathroom ventilating fan, which may be

used for exhausting air outdoors -or has a vented fireplace — it is recommended that combustion air be supplied to the enclosed room through intakes extending to

the outside of the building and terminating in down-turned

fittings. These should be suitably arranged to prevent obstruction from snow or rain, and include a protecting

screen not smaller than 1/4 inch mesh.

Shark HNG • Rev. 2/03a

8

HNG SERIES PRESSURE WASHER

OPERATOR’S MANUAL

Figure 4

Ventilating Air Opening.

1 square inch for each

1000 BTU per hour input.

Illustration showing air openings necessary

to supply air for combustion when installed

in an enclosed room.

Water Source:

The water source for the machine should be supplied by

a 5/8" I.D. garden hose with a city water pressure of not

less than 30 PSI. If the water supply is inadequate, or if

the garden hose is kinked, the machine will run very rough

and the burner will not fire.

Water Connection:

Connect the high pressure hose by pulling the coupler

collar back and then inserting it onto the discharge nipple.

Secure it by pushing the collar forward.

Attach the wand into the spray gun using teflon tape on

the pipe threads to avoid leaks.

Inspection and Testing Gas Piping:

The building structure should not be weakened by installing the gas piping. The piping should not be supported by other piping, but should be firmly supported

with gas hooks, straps, bands or hangers. Butt or lap

welded pipe should not be run through or in an air duct

or clothes chute.

Before turning gas under pressure into piping, all openings from which gas can escape should be closed. Immediately after turning on gas, the system should be

checked for leaks. This can be done by watching the 1/2

cubic foot test dial for 5 minutes for any movement or by

soaping each pipe connection and watching for bubbles.

If a leak is found, make the necessary repairs and repeat the above test.

Shark HNG • Rev. 2/03a

Defective pipes or fittings should be replaced and not

repaired. Never use a flame or fire in any form to locate

gas leaks — use a soap solution.

After the piping and meter have been checked completely,

purge the system of air. DO NOT bleed the air inside an

enclosed room.

During pressure testing of the system at test pressures

in excess of 1/2 PSIG, the appliance and its individual

shut-off valve must be disconnected from the gas supply piping system or damage to the gas valve will occur.

Gas Pressure:

The ideal incoming gas pressure is 11 water column

inches or w.c.i. (minimum 9 w.c.i, maximum 14 w.c.i. or

1/2 PSIG). The correct operating manifold pressure for

natural gas is 3.5 w.c.i. The operating manifold pressure

for propane gas is 10 w.c.i. By adjusting the gas valve

pressure regulator between 3 and 4 w.c.i. a side range

can be achieved for natural gas.

If the desired input rating cannot be obtained within the

above manifold pressure adjusting range, then the next

size larger or smaller burner orifice should be used.

START-UP

WARNING

READ SAFETY

INSTRUCTIONS

INSTALLING OR

TO

SERVICING

PRIOR

MACHINE

operating valves, pressure regulation, and automatic

shut-off valve for proper operation.

2. Install in a suitable dry location. The machine must

be located in an area properly protected from the

weather.

3. Shut off gas and electricity before starting installation or service. Turn back on to test or operate.

4. DO NOT connect appliances before pressure testing the gas piping. Damage to gas valve may result.

(9 - 14 w.c.i. or 1/2 PSIG)

5. DO NOT insert any object other than suitable pipe

or tubing in the inlet or outlet of the gas valve. Internal damage may occur and result in a hazardous

condition.

6. DO NOT grip gas valve body with a pipe wrench or

vise. Damage may result causing gas leakage. Use

inlet or outlet bosses or a special body wrench.

7. DO NOT short the gas valve terminals.

WARNING: Read and follow instructions carefully when installing or servicing machine. Failure

to do so may result in damage to

property or personal injury.

1. Installation or servicing of gas

appliances and controls must

.

only be performed by qualified

personnel. After installation or

servicing, test manual valve,

HNG SERIES PRESSURE WASHER

8. DO NOT allow any flame to impinge on the regulator vent tubing if supplied. It may clog and cause

gas valve malfunction.

9. DO NOT use the gas cock to adjust gas flow.

10. If main burner fails to shut off, turn off gas supply.

11. Keep all combustible materials away from gas appliances. DO NOT allow lint or dust to collect in burner

area.

12. Dials must only be operated by hand. Never use pliers, wrenches or other tools to turn dials.

13. Leak test with a soap solution after installation or

service with the main burner on. Coat pipe and tubing joints, gaskets, etc.

14. If the machine is installed in an enclosed room, care

should be taken to ensure that an adequate supply

of air is available for combustion and ventilation.

(1 sq. inch per 1000 BTU).

OPERATOR’S MANUAL

9

Shark HNG • Rev. 2/03a

10

HNG SERIES PRESSURE WASHER

OPERATOR’S MANUAL

CHECK LIST BEFORE

STARTING:

CAUTION! If “NO” is checked on any of the following

sixteen questions, do not operate this machine.

YES NO

Has gas supply been inspected by an

authorized contractor to meet local codes?

Is machine protected from downdraft and

excessive wind?

Is machine shielded from moisture or water

spray?

Is the voltage correct and are the circuit

breaker and supply cord adequate

according to s pecifications and serial plate

notation?

Is the machine electrically grounded?

Is there ample water su pply?

Have all flammable liquids or gases been

removed from installation location?

Is there adequate gas supply for the BTU

rating of the burner?

Is incoming gas supply press ure between

6 - 14 water column inches or 1/2 PSIG?

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING

If you do not follow these instr uctions exactly, a fire or

explosion may result, causing p roper ty damag e, persona l

injury or loss of life.

A. This appliance has a pilot which must be lighted by hand.

When lighting the pilot, follow these instructions exactly.

B. BEFORE LIGHTING smell all a round the appliance area

for gas. Be sure to smell nex t to the floor because some

gas is heavier tha n air and will settle on the floor.

FOR YOUR SAFETY

"WHAT TO DO IF YOU SMELL GAS"

• Do not try to light any appliance.

• Do no t touch any electrical switch, do not use any phone

in your building.

• Immediately call you r gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

• If you cannot reach your supplier, call the fire department.

C. Use only your hand to push in or turn the gas control

knob. Never use tools. If the knob will not push in or turn

by hand, don't try to repair it; call a qualified service

technician. Forced or attempted repair may result in a fire

or explosion.

Has the proper gas regulator been

installed for pressure and volume?

Is the machine properly vented to allow

adequate air flow?

Are the propane tanks large enough,

according to rating to prevent freezing?

Have gas lines been checked for gas

leaks?

Have gas lines been checked with local

codes?

Have all operators using this machine

been instructed properly & have they read

the manual?

Has the machine been installed acco rding

to operator's manual instructions?

D. Do not use this appliance if any part has be en under

water. Immediately call a qualified service technician to

inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

Shark HNG • Rev. 2/03a

HNG SERIES PRESSURE WASHER

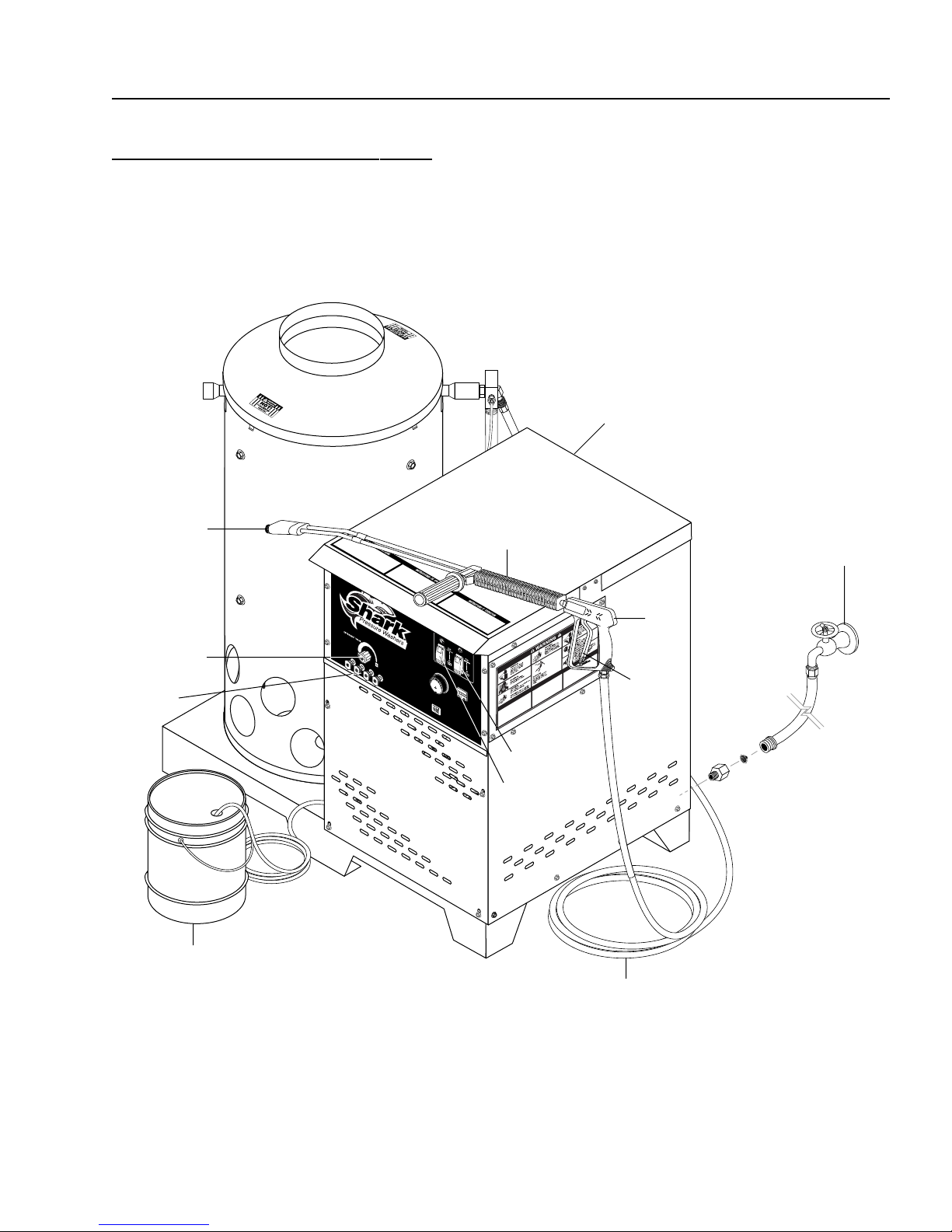

COMPONENT IDENTIFICATION

OPERATOR’S MANUAL

Main Gas

Supply Inlet

11

Wand Quick

Coupler

Detergent

Valve

Pressure

Nozzle

Detergent Bucket

(optional)

Spray

Wand

Pump

Switch

Burner

Switch

Trigger

High Pressure

Hose

Water Supply

(not included)

Spray

Gun

Shark HNG • Rev. 2/03a

12

HNG SERIES PRESSURE WASHER

OPERATOR’S MANUAL

OPERATING INSTRUCTIONS

WARNING

READ OPERATOR’S

THOROUGHLY

MANUAL

4. Connect the water supply hose to the inlet connec-

5. Have an electrician connect power supply into junc-

6. Turn on the main gas supply.

7. Partially depress and turn control knob to the “OFF”

8. Wait five minutes to allow gas, which may have ac-

9. Turn gas cock dial to “PILOT” position.

10. Depress the control knob all the way and hold it in.

11. Release dial and turn to full "ON".

12. Attach the desired high pressure nozzle into the wand

13. Push "ON" switch, or turn to pump position and pull

14. To activate the gas control valve for hot water, push

15. To apply detergent, open the detergent valve counter-

TO USE .

PRIOR

tor and turn the water on. Check for water leaks and

tighten as needed.

tion box according to information shown on the serial plate.

position (see fig.5 on page 14).

cumulated in the main burner compartment, to escape.

After five (5) seconds, depress the red ignitor until

you hear a loud click. Repeat 3 or 4 times if necessary until pilot is lit. If pilot does not remain lit, repeat

the operation allowing a longer period of time before

releasing the gas valve knob. After the pilot lights,

continue to hold the control knob down for about one

(1) minute before releasing.

NOTE: Sufficient time must be allowed for a proper

size pilot flame to heat the thermocouple and hold

the safety magnet in a locked-up position. Also, time

must be allowed for air to escape from the lines during the first operation.

quick coupler by pulling the coupler collar back and

then inserting the nozzle and securing it by pushing

the coupler collar forward.

the trigger on the spray gun allowing cold water to

flow.

the burner switch to the "ON" position and pull the

trigger on the spray gun.

clockwise making sure that the detergent pick up

tube is in the detergent solution and not sucking air.

WARNING: STOP! Read operators manual before operating this

machine.

1. Failure to read operation and

warning instructions may result

in personal injury or property

damage.

2. Turn all switches off.

3. Review installation instructions.

16. To Stop: Turn the burner switch "OFF" and place

the detergent pick up tube into fresh water. Open

the detergent valve and spray gun allowing detergent lines to be flushed and the burner to cool. Otherwise coil damage will result.

17. After water has cooled, push or turn pump switch to

OFF position. If the machine is going to be off for an

extended period of time, put the gas cock dial on the

gas valve into the “OFF” position.

18. Turn water off. Prevent from freezing.

PREVENTATIVE

MAINTENANCE

1. Check to see that the water pump is properly lubricated.

2. Follow winterizing instructions to prevent freeze damage to the pump and coils.

3. Always neutralize and flush detergent from system

after use.

4. If water is known to be high in mineral content, use a

water softener in your water system or descale as

needed.

5. Do not allow acidic, caustic or abrasive fluids to be

pumped through system.

6. Always use high grade quality Shark cleaning

products.

7. Never run pump dry for extended periods of time.

8. Periodically delime coils as per instructions.

It is advisable, periodically, to visually inspect the burner.

Check air inlet to make sure it is not clogged or blocked.

Wipe off any oil spills and keep this equipment clean

and dry.

The areas around the Shark washer should be kept clean

and free of combustible materials, gasoline and other

flammable vapors and liquids.

The flow of combustion and ventilating air to the burner

must not be blocked or obstructed in any manner.

GENERAL WASHING

TECHNIQUES

If dirt comes off relatively easy and no grease and oil are

present, cleaning with cold water will normally suffice.

However, when grease and oil are present, hot water

will greatly speed up the process.

Clean with the spray nozzle a foot or so from the surface

being cleaned. For more difficult cleaning, move the

nozzle in closer.

Shark HNG • Rev. 2/03a

Loading...

Loading...