Page 1

HNG

OPERATOR’S MANUAL

■ HNG-4020 ■ HNG-3530 ■ HNG-5030

L

D

I

S

E

®

T

SHARK PRESSURE WASHERS ■ 4275 N.W. Pacific Rim Blvd. ■ Camas, WA 98607 ■ USA

For technical assistance or the Shark Dealer nearest you, call 1-800-771-1881.

Page 2

2

CONTENTS

Introduction................................................................................................................................... 3

Important Safety Information .....................................................................................................3-4

Installation ................................................................................................................................. 4-8

Installation Guide .......................................................................................................................... 5

Start-up ..................................................................................................................................... 8-9

Check List Before Starting .......................................................................................................... 10

Component Identification ............................................................................................................ 11

Operating Instructions ................................................................................................................ 12

Preventatative Maintenance........................................................................................................ 12

General Washing Techniques ................................................................................................12-13

Maintenance & Service............................................................................................................... 13

Heating Coils ......................................................................................................................... 13-14

Propane Gas .............................................................................................................................. 14

Burner Features.......................................................................................................................... 15

Burner Troubleshooting .......................................................................................................... 15-16

Hose & Spray Gun Assembly ..................................................................................................... 17

Exploded View, Left Side ............................................................................................................ 18

Exploded View, Right Side .......................................................................................................... 19

Exploded View, Parts List ...................................................................................................... 20-21

Burner Assembly, Exploded View ............................................................................................... 22

Burner Assembly, Exploded View, Parts List ............................................................................... 23

Control Panel .............................................................................................................................. 24

Control Panel, Parts List ............................................................................................................. 25

Float Tank Assembly ................................................................................................................... 26

Electrical Box, Standard ............................................................................................................. 27

Electrical Box, Time Delay ..................................................................................................... 28-29

Electrical Box, Auto Start ....................................................................................................... 30-31

Troubleshooting ................................................................................................................... 332-33

Basic Facts ................................................................................................................................. 34

Pressure Equivalents.................................................................................................................. 34

Preventative Maintenance Schedule ........................................................................................... 35

Oil Change Record ..................................................................................................................... 35

Warranty

Model Number ______________________________

Serial Number ______________________________

Date of Purchase ____________________________

The model and serial numbers will be found on a decal attached to

the pressure washer. You should record both serial number and

date of purchase and keep in a safe place for future reference.

Shark HNG Manual • Form #97-610 • Revised 2/03a

Page 3

HNG SERIES PRESSURE WASHER

WARNING

WARNING

WARNING

OPERATOR’S MANUAL

3

INTRODUCTION

Thank you for purchasing a Shark Pressure Washer.

This manual covers the operation and maintenance of

the HNG-402001A, 402007A, 353001A, 353007A,

503001B, 503007B, 503001C, and 503007C washers.

All information in this manual is based on the latest product information available at the time of printing.

Shark, Inc. reserves the right to make changes at any

time without incurring any obligation.

The HNG Series was designed for

maximum use of 4 hours per day,

5 days per week.

Owner/User Responsibility:

The owner and/or user must have an understanding of

the manufacturer’s operating instructions and warnings

before using this Shark pressure washer. Warning information should be emphasized and understood. If the

operator is not fluent in English, the manufacturer’s instructions and warnings shall be read to and discussed

with the operator in the operator’s native language by

the purchaser/owner, making sure that the operator comprehends its contents.

Owner and/or user must study and maintain for future

reference the manufacturers’ instructions

This manual should be considered a permanent

part of the machine and should remain with it if

machine is resold.

When ordering parts, please specify model and

serial number.

IMPORTANT SAFETY

INFORMATION

WARNING: When using this machine basic

precautions should always be followed, including the

following:

CAUTION

READ OPERATOR’S

MANUAL

THOROUGHLY

PRIOR TO USE.

CAUTION: To reduce the risk of

injury, read operating instructions

carefully before using.

1. Read the owner's manual

thoroughly. Failure to follow instructions could cause malfunction of the machine and result

in death, serious bodily injury

and/or property damage.

2. All installations must comply with local codes. Contact your electrician, plumber, utility company or the

selling distributor for specific details.

3. Know how to stop the machine and bleed pressures

quickly. Be thoroughly familiar with the controls.

4. Stay alert. Watch what you are doing.

WARNING: Flammable liquids

can create fumes which can ignite

causing property damage or

severe injury.

5. Risk of explosion - Do not spray

flammable liquids or operate in

RISK OF EXPLOSION:

DO NOT SPRAY

FLAMMABLE

LIQUIDS.

an explosive location. Operate

only where open flame or torch

is permitted.

WARNING: Keep water spray

away from electrical wiring or fatal electric shock may result.

Read warning tag on electrical

cord.

6. To protect the operator from

KEEP WATER SPRAY

AWAY F R OM

ELECTRICAL WIRING.

electrical shock, the machine

must be electrically grounded.

It is the responsibility of the

owner to connect this machine

to a UL grounded receptacle of proper voltage and

amperage ratings. Do not spray water on or near

electrical components. Do not touch machine with

wet hands or while standing in water. Always disconnect power before servicing.

WARNING: Spray gun kicks back. Hold with both hands.

7. Grip cleaning wand securely with both hands before

starting the cleaner. Failure to do this could result in

injury from a whipping wand.

WARNING: Equipment can produce a high pressure stream of

fluid that can pierce skin and its

underlying tissues, leading to

serious injury and possible

amputation.

RISK OF INJECTION

OR SEVERE INJURY

TO PERSONS. KEEP

CLEAR OF NOZZLE.

8. High pressure developed by

these machines can cause

personal injury or equipment

damage. Use caution when operating. Do not direct

discharge stream at anyone or at any part of the

body, or severe injury or death will result. This machine is to be used only by qualified operators.

Shark HNG • Rev. 2/03a

Page 4

4

HNG SERIES PRESSURE WASHER

OPERATOR’S MANUAL

WARNING

CAUTION: Hot discharge fluid. Do

not touch or direct discharge

stream at persons.

9. Never make adjustments on

machine while in operation.

EXTREMELY HOT:

USE CAUTION WHEN

OPENING LID.

WARNING

WARNING: High pressure can

cause paint chips or other particles to become airborne and fly

at high speeds.

10. Eye safety devices and foot pro-

PROTECTIVE

EYEWEAR AND

CLOTHING MUST

BE WORN.

WARNING

tection must be worn when

using this equipment.

WARNING: Risk of asphyxiation.

Use this product only in a well

ventilated area.

11. When the machine is working,

do not cover or place in a closed

space where ventilation is insuf-

RISK OF

ASPHYXIATION.

USE ONLY IN A WELL

VENTILATED AREA.

ficient.

12. Machines with spray guns

should not be operated with the

trigger in the off position for extensive periods of time

as this may cause damage to the pump.

13. Protect from freezing.

14. Be certain all quick coupler fittings are secured

before using pressure washer.

15. Do not allow acids, caustic, or abrasive fluids to pass

through the pump.

16. Inlet water must be cold and clean fresh water.

17. To reduce the risk of injury, close supervision is necessary when a machine is used near children. Do

not allow children to operate the pressure washer.

This machine must be attended during operation.

18. The best insurance against an accident is precaution and knowledge of the machine.

19. Do not operate this product when fatigued or under

the influence of alcohol or drugs. Keep operating area

clear of all persons.

20. Do not replace LP tank while machine is running.

Serious injury could result.

Shark HNG • Rev. 2/03a

WARNING

WARNING: Use only vapor fuel.

21. This equipment is designed to

run on vapor fuel. Do not use

liquid fuel. Have a qualified serviceman install and service

your equipment.

RISK OF FIRE.

DO NOT USE WITH

FLAMMABLE LIQUIDS.

22. Never expose a spark or flame

where unburned gas may be

present.

23. Never attempt to light pilot unless pilot manual valve

has been shut off for 5 minutes.

24. A conversion kit, as supplied by the manufacturer,

shall be used to convert natural gas to propane.

25. L.P. gases are heavier than air and will spill out on

the floor. Therefore always provide adequate space

and ventilation around these machines. Install

machine 18" above the floor.

26. Shark will not be liable for any changes made to our

standard machines, or any components not purchased from Shark.

27. Do not overreach or stand on unstable support. Keep

good footing and balance at all times.

28. Follow maintenance instructions specified in the

manual.

29. When making repairs disconnect from electrical

source and shut off gas valve.

WARNING

30. Turn burner off and cool to

100° F before turning machine

off.

31. Extinguish any open flame and

test all joints with a soap solution. If odor persists, call your

RISK OF EXPLOSION:

IF GAS SMELL

PRESENT TURN

OFF SUPPLY

gas supplier immediately.

32. Not suitable for connection

to Type B gas vent if the stack

temperature exceeds 243° C

(470° F).

33. A draft hood shall be installed if this machine is

going to be permanently installed and vented to the

outside of the building.

INSTALLATION

Place machine in a convenient location providing ample

support, drainage and room for maintenance (see page 5).

Location:

The location should protect the machine from damaging

environmental conditions, such as wind, rain and freezing.

1. The machine should be run on a level surface where

it is not readily influenced by outside sources such

as strong winds, freezing temperatures, rain, etc. The

Page 5

HNG SERIES PRESSURE WASHER

INSTALLATION GUIDE

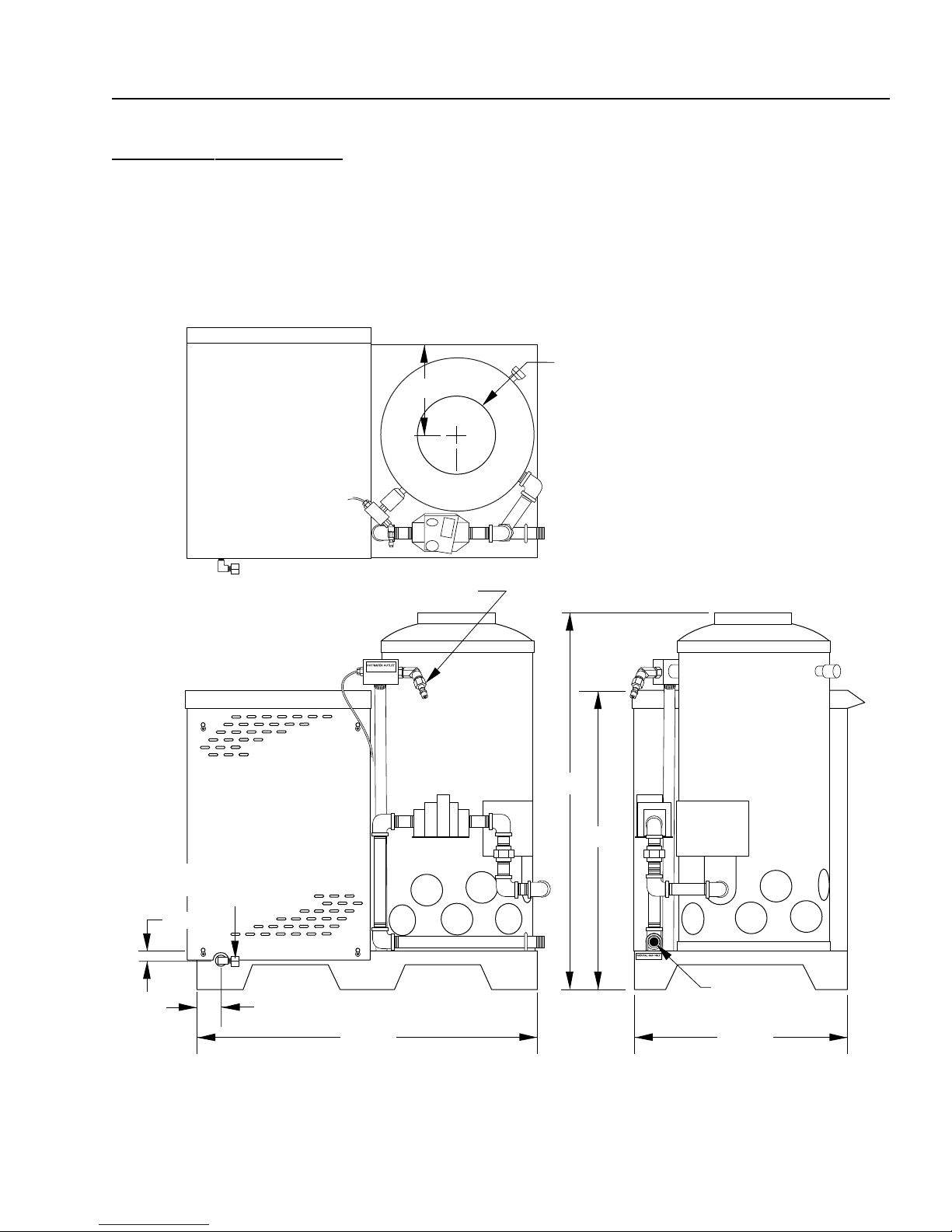

HNG

9.57" I.D.

11-3/4"

OPERATOR’S MANUAL

5

Fresh Water

In 1.0" GHF

1-1/4"

3.0"

High Pressure Out

44-1/4"

49-0"

38-3/8"

Gas In

1-1/2" NPT-M

27-1/2"

Shark HNG • Rev. 2/03a

Page 6

6

HNG SERIES PRESSURE WASHER

OPERATOR’S MANUAL

machine should be located considering accessibility for the replacing of components and the refilling

of detergents, adjustments and maintenance. Normal precautions should be taken by the operator of

the machine to prevent excess moisture from reaching the power unit or electrical controls.

2. It is recommended that a partition be made between

the wash area and the machine to prevent direct

spray from the spray gun from coming in contact with

the machine. Excess moisture reaching the power

unit or electrical controls will reduce the machine’s

life and may cause electrical shorts.

3. During installation of the machine, beware of poorly

ventilated locations or areas where exhaust fans may

cause an insufficient supply of oxygen. Sufficient

combustion can only be obtained when there is a

sufficient supply of oxygen available for the amount

of fuel being burned. If it is necessary to install a

machine in a poorly ventilated area, outside fresh

air may have to be piped to the burner and a fan

installed to bring the air into the area.

4. Do not locate near any combustible material. Keep

all flammable material at least 20 feet away.

Allow enough space for servicing the machine.

Local code will require certain distances from floor

and walls. (Two feet away should be adequate).

WARNING: Avoid small areas or near exhaust fans.

Gas Codes:

Confer with local gas company and with proper municipal officials regarding any specific code or regulations

governing the installation. The installation must conform

to local codes.

Electrical:

The machine, when installed, must be electrically

grounded in accordance to local codes. Check for proper

power supply using a volt meter; check the serial plate

for the correct requirements.

Gas Piping:

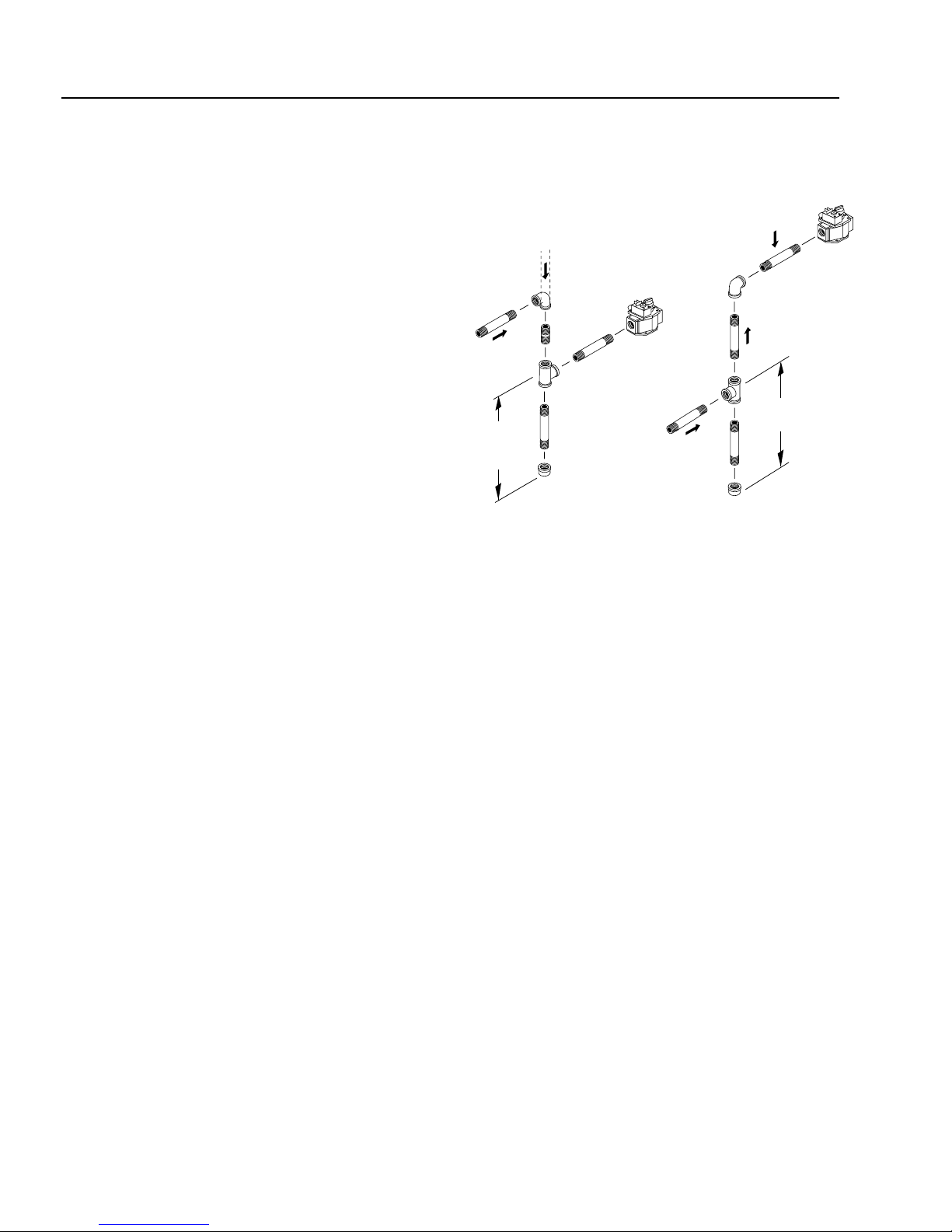

Figure 1

Drop

Gas

Valve

3" (7.62 mm)

Minimum

DRIP LEG

Sediment trap (drip leg) must be

installed in the supply line.

Install a union in the gas line adjacent to and upstream

from the control manifold and downstream from the

manual main shut-off valve. A 1/8" NPT plugged tapping

accessible for test gauge connection shall be installed

immediately upstream of the gas supply connection for

the purpose of determining the gas supply pressure to

the burner, and to prevent damage to gas valve.

If a manual gas shut off valve is not in the gas supply line

within six feet of the machine and in an accessible location, one shall be installed.

1/4" Test Port

(6" - 14 W.C.

or 1/2" PSIG)

Gas

Valve

3" (7.62 mm)

Minimum

Shark HNG • Rev. 2/03a

Page 7

HNG SERIES PRESSURE WASHER

OPERATOR’S MANUAL

7

Figure 2

Manual

Shut-Off Valve

3" (7.62 mm)

Minimum

Flow

Tee

1/8" NPT Plugged

Pressure Gauge

Port Location

Control Manifold

Pipe

Cap

Floor Level

Union

To

Gas Valve

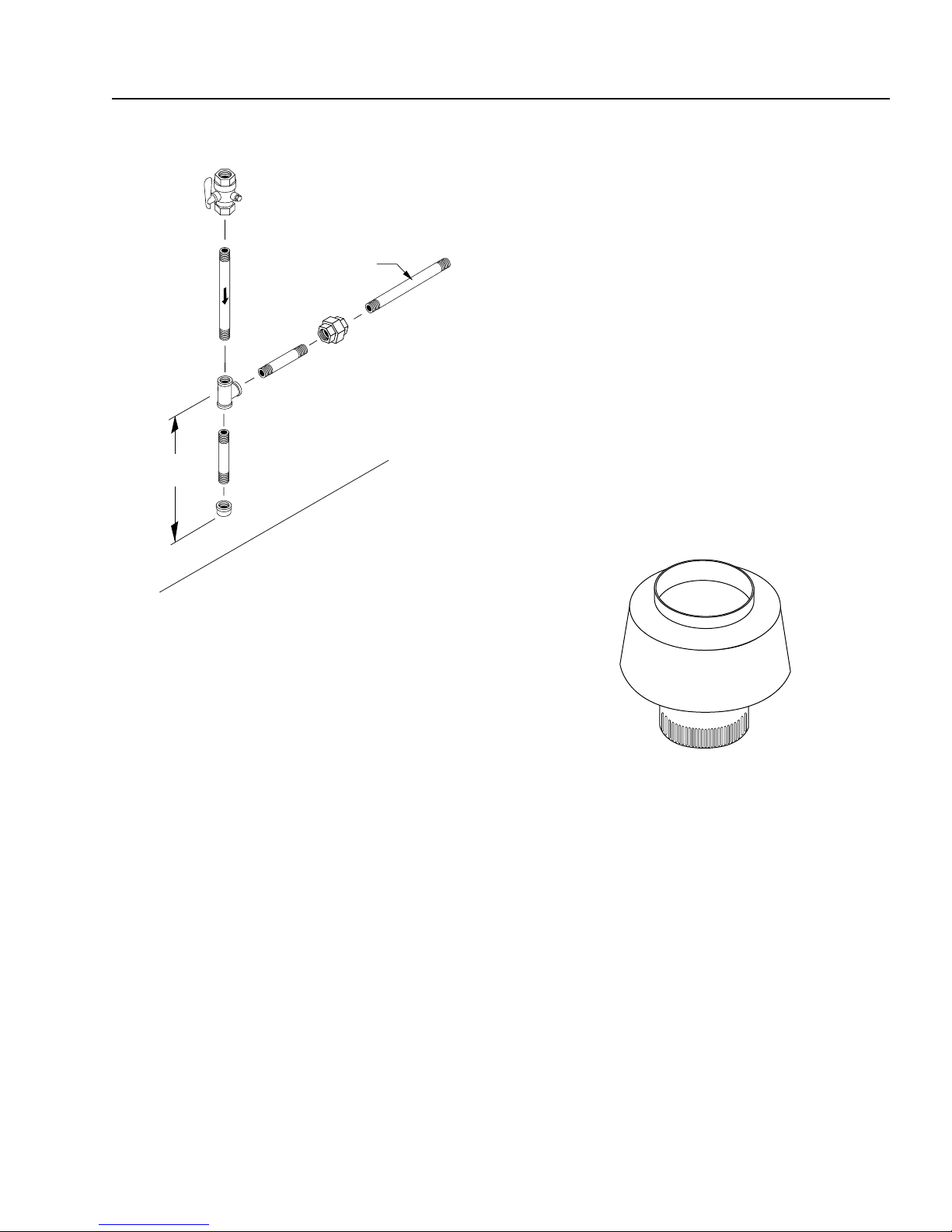

Input - BTU Per Hour Draft Hood & Flue Pipe Size

250,000 - 320,000 8 inch

320,000 - 410,000 9 inch

410,000 - 600,000 10 inch

600,000 - 750,000 12 inch

NOTE: If the flue pipe exceeds 10 ft. in length, or contains more than two elbows, use next size larger pipe

and draft hood or the burner will not ignite. No movable

flue pipe damper should be used on any installation.

Draft Diverter:

Install the draft diverter above the heating coil. The

diverter enhances the draft through the burner by severing the chimney effect created in sections of furnace pipe

positioned below. It also helps prevent freezing of the

coil due to wind chill factors.

Figure 3

Optional

UNION LOCATION

The following pipe and stack sizes are just recommendations. Always consult a local plumber and venting contractor for local codes and regulations during installation.

Distance From Regulator Pipe Size

0 - 59' 1" 1 PS

50' - 100' 1-1/2" 1 PS

100' - 200' 1-3/4" 1 PS

Natural Gas

Distance From Regulator Pipe Size

0 - 50' 1-1/2" 1 PS

50' - 100' 2" 1 PS

100' - 200' 2-1/2" 1 PS

Venting:

If the machine is used indoors, regulations or ventilation

concerns may call for a chimney or furnace pipe.

When venting the machine, if the machine is to be in an

enclosed area with a chimney on it, be sure the chimney

is the same size as the stack on the machine. Poor draft

will cause the machine to soot and not operate efficiently.

When placing the machine for installation, position the

stack to be as straight as possible and to protrude through

the roof of the building at a proper location and at sufficient height to eliminate down-draft. The chimney of a

gas fired machine shall be installed with a down-draft

diverter located about 3 ft. above machine.

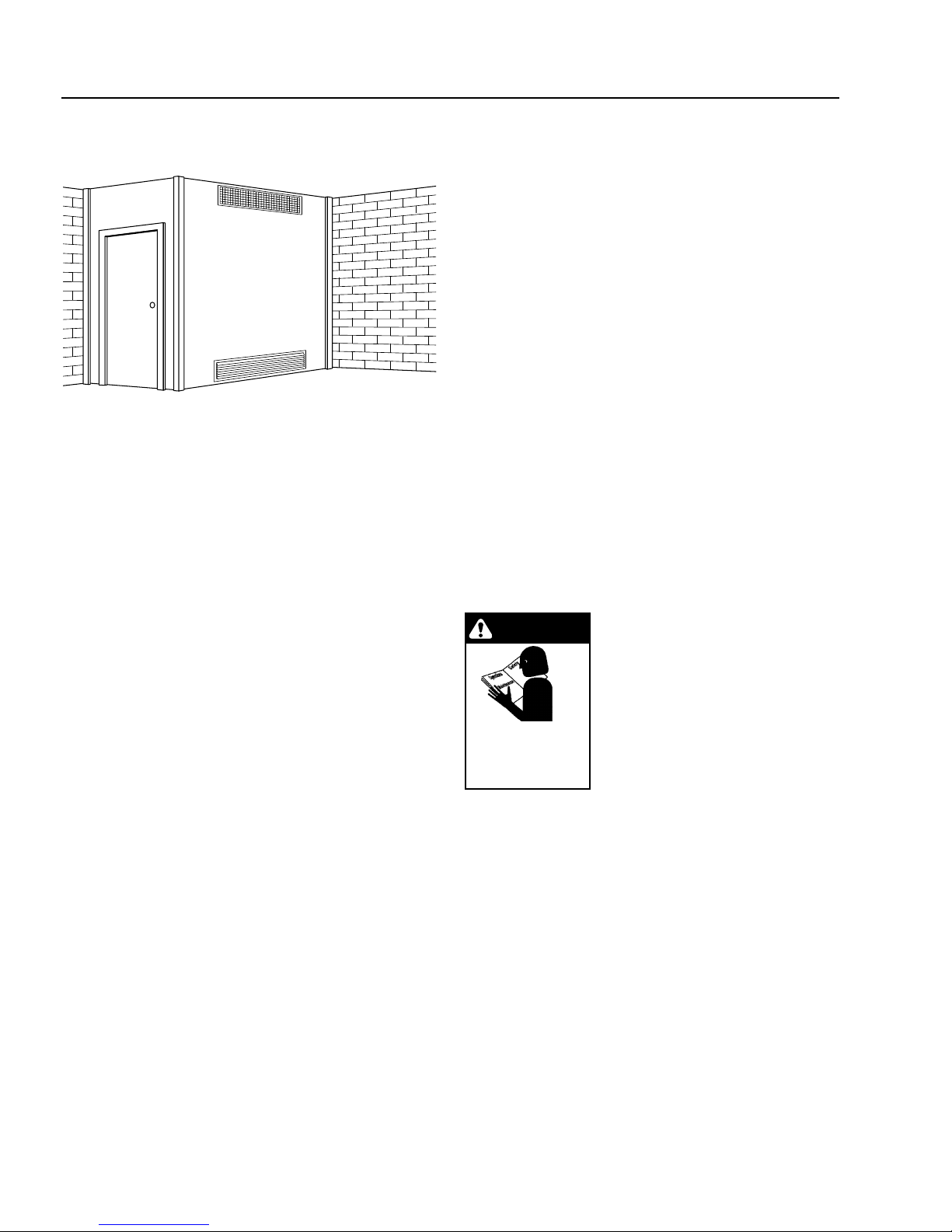

When the heating appliance is installed in a tightly closed

room without ventilation openings to the outdoors or other

rooms, provisions shall be made for supplying air for combustion through special openings, one near the floor line

and the other near the ceiling, each to be sized on the

basis of one square inch or more of free area for each

1,000 BTU input per hour (see Figure 4).

When a room is of unusually tight construction and has

a kitchen and/or bathroom ventilating fan, which may be

used for exhausting air outdoors -or has a vented fireplace — it is recommended that combustion air be supplied to the enclosed room through intakes extending to

the outside of the building and terminating in down-turned

fittings. These should be suitably arranged to prevent obstruction from snow or rain, and include a protecting

screen not smaller than 1/4 inch mesh.

Shark HNG • Rev. 2/03a

Page 8

8

HNG SERIES PRESSURE WASHER

OPERATOR’S MANUAL

Figure 4

Ventilating Air Opening.

1 square inch for each

1000 BTU per hour input.

Illustration showing air openings necessary

to supply air for combustion when installed

in an enclosed room.

Water Source:

The water source for the machine should be supplied by

a 5/8" I.D. garden hose with a city water pressure of not

less than 30 PSI. If the water supply is inadequate, or if

the garden hose is kinked, the machine will run very rough

and the burner will not fire.

Water Connection:

Connect the high pressure hose by pulling the coupler

collar back and then inserting it onto the discharge nipple.

Secure it by pushing the collar forward.

Attach the wand into the spray gun using teflon tape on

the pipe threads to avoid leaks.

Inspection and Testing Gas Piping:

The building structure should not be weakened by installing the gas piping. The piping should not be supported by other piping, but should be firmly supported

with gas hooks, straps, bands or hangers. Butt or lap

welded pipe should not be run through or in an air duct

or clothes chute.

Before turning gas under pressure into piping, all openings from which gas can escape should be closed. Immediately after turning on gas, the system should be

checked for leaks. This can be done by watching the 1/2

cubic foot test dial for 5 minutes for any movement or by

soaping each pipe connection and watching for bubbles.

If a leak is found, make the necessary repairs and repeat the above test.

Shark HNG • Rev. 2/03a

Defective pipes or fittings should be replaced and not

repaired. Never use a flame or fire in any form to locate

gas leaks — use a soap solution.

After the piping and meter have been checked completely,

purge the system of air. DO NOT bleed the air inside an

enclosed room.

During pressure testing of the system at test pressures

in excess of 1/2 PSIG, the appliance and its individual

shut-off valve must be disconnected from the gas supply piping system or damage to the gas valve will occur.

Gas Pressure:

The ideal incoming gas pressure is 11 water column

inches or w.c.i. (minimum 9 w.c.i, maximum 14 w.c.i. or

1/2 PSIG). The correct operating manifold pressure for

natural gas is 3.5 w.c.i. The operating manifold pressure

for propane gas is 10 w.c.i. By adjusting the gas valve

pressure regulator between 3 and 4 w.c.i. a side range

can be achieved for natural gas.

If the desired input rating cannot be obtained within the

above manifold pressure adjusting range, then the next

size larger or smaller burner orifice should be used.

START-UP

WARNING

READ SAFETY

INSTRUCTIONS

INSTALLING OR

TO

SERVICING

PRIOR

MACHINE

operating valves, pressure regulation, and automatic

shut-off valve for proper operation.

2. Install in a suitable dry location. The machine must

be located in an area properly protected from the

weather.

3. Shut off gas and electricity before starting installation or service. Turn back on to test or operate.

4. DO NOT connect appliances before pressure testing the gas piping. Damage to gas valve may result.

(9 - 14 w.c.i. or 1/2 PSIG)

5. DO NOT insert any object other than suitable pipe

or tubing in the inlet or outlet of the gas valve. Internal damage may occur and result in a hazardous

condition.

6. DO NOT grip gas valve body with a pipe wrench or

vise. Damage may result causing gas leakage. Use

inlet or outlet bosses or a special body wrench.

7. DO NOT short the gas valve terminals.

WARNING: Read and follow instructions carefully when installing or servicing machine. Failure

to do so may result in damage to

property or personal injury.

1. Installation or servicing of gas

appliances and controls must

.

only be performed by qualified

personnel. After installation or

servicing, test manual valve,

Page 9

HNG SERIES PRESSURE WASHER

8. DO NOT allow any flame to impinge on the regulator vent tubing if supplied. It may clog and cause

gas valve malfunction.

9. DO NOT use the gas cock to adjust gas flow.

10. If main burner fails to shut off, turn off gas supply.

11. Keep all combustible materials away from gas appliances. DO NOT allow lint or dust to collect in burner

area.

12. Dials must only be operated by hand. Never use pliers, wrenches or other tools to turn dials.

13. Leak test with a soap solution after installation or

service with the main burner on. Coat pipe and tubing joints, gaskets, etc.

14. If the machine is installed in an enclosed room, care

should be taken to ensure that an adequate supply

of air is available for combustion and ventilation.

(1 sq. inch per 1000 BTU).

OPERATOR’S MANUAL

9

Shark HNG • Rev. 2/03a

Page 10

10

HNG SERIES PRESSURE WASHER

OPERATOR’S MANUAL

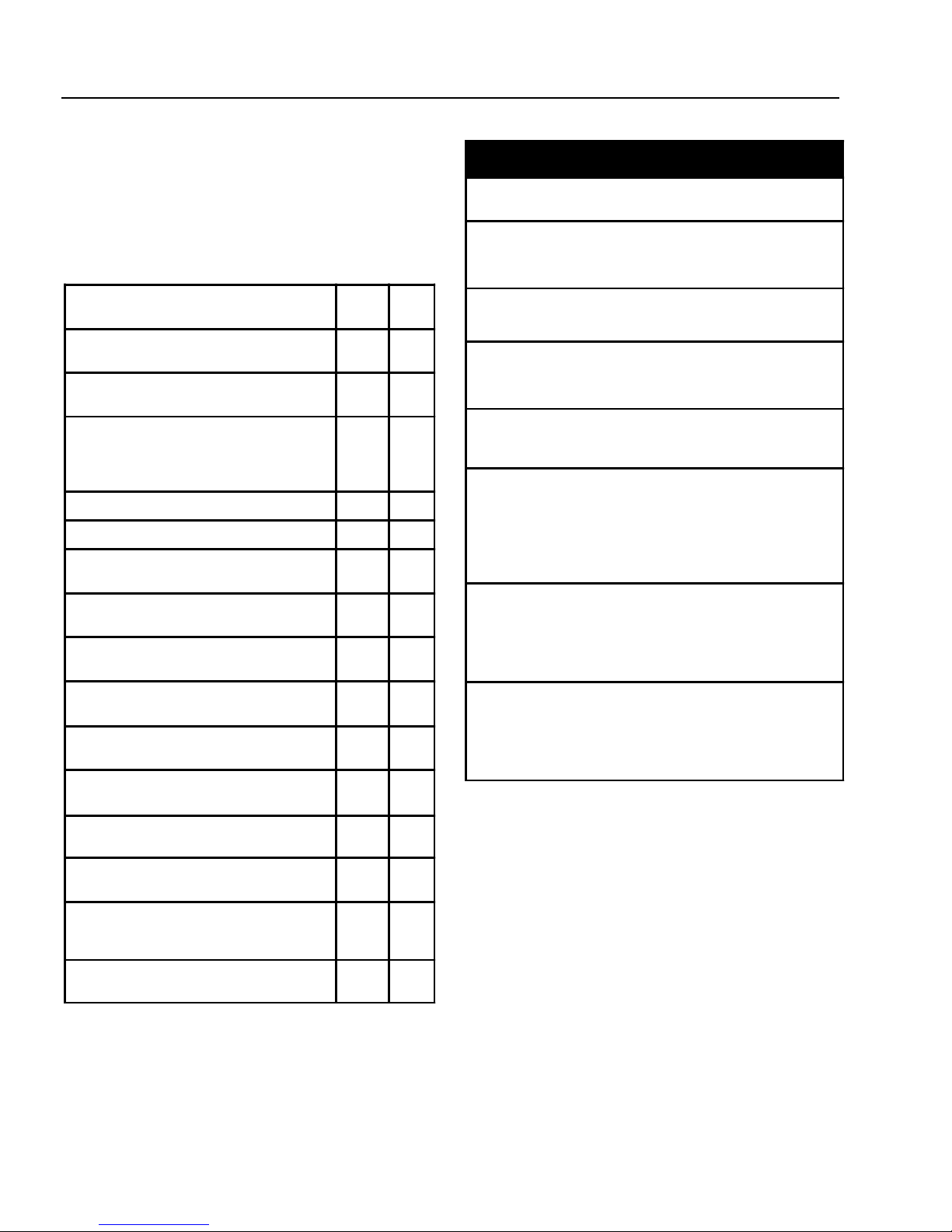

CHECK LIST BEFORE

STARTING:

CAUTION! If “NO” is checked on any of the following

sixteen questions, do not operate this machine.

YES NO

Has gas supply been inspected by an

authorized contractor to meet local codes?

Is machine protected from downdraft and

excessive wind?

Is machine shielded from moisture or water

spray?

Is the voltage correct and are the circuit

breaker and supply cord adequate

according to s pecifications and serial plate

notation?

Is the machine electrically grounded?

Is there ample water su pply?

Have all flammable liquids or gases been

removed from installation location?

Is there adequate gas supply for the BTU

rating of the burner?

Is incoming gas supply press ure between

6 - 14 water column inches or 1/2 PSIG?

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING

If you do not follow these instr uctions exactly, a fire or

explosion may result, causing p roper ty damag e, persona l

injury or loss of life.

A. This appliance has a pilot which must be lighted by hand.

When lighting the pilot, follow these instructions exactly.

B. BEFORE LIGHTING smell all a round the appliance area

for gas. Be sure to smell nex t to the floor because some

gas is heavier tha n air and will settle on the floor.

FOR YOUR SAFETY

"WHAT TO DO IF YOU SMELL GAS"

• Do not try to light any appliance.

• Do no t touch any electrical switch, do not use any phone

in your building.

• Immediately call you r gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

• If you cannot reach your supplier, call the fire department.

C. Use only your hand to push in or turn the gas control

knob. Never use tools. If the knob will not push in or turn

by hand, don't try to repair it; call a qualified service

technician. Forced or attempted repair may result in a fire

or explosion.

Has the proper gas regulator been

installed for pressure and volume?

Is the machine properly vented to allow

adequate air flow?

Are the propane tanks large enough,

according to rating to prevent freezing?

Have gas lines been checked for gas

leaks?

Have gas lines been checked with local

codes?

Have all operators using this machine

been instructed properly & have they read

the manual?

Has the machine been installed acco rding

to operator's manual instructions?

D. Do not use this appliance if any part has be en under

water. Immediately call a qualified service technician to

inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

Shark HNG • Rev. 2/03a

Page 11

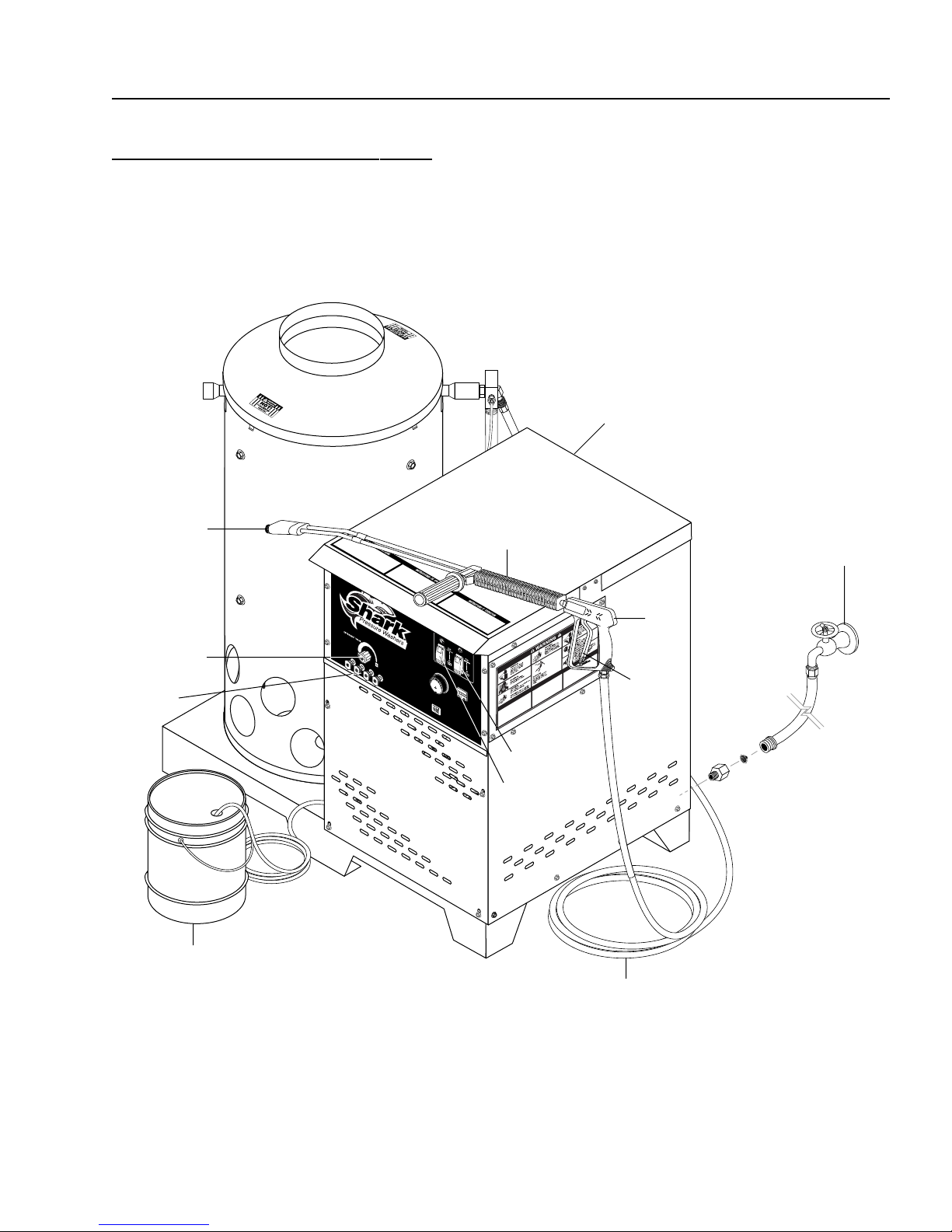

HNG SERIES PRESSURE WASHER

COMPONENT IDENTIFICATION

OPERATOR’S MANUAL

Main Gas

Supply Inlet

11

Wand Quick

Coupler

Detergent

Valve

Pressure

Nozzle

Detergent Bucket

(optional)

Spray

Wand

Pump

Switch

Burner

Switch

Trigger

High Pressure

Hose

Water Supply

(not included)

Spray

Gun

Shark HNG • Rev. 2/03a

Page 12

12

HNG SERIES PRESSURE WASHER

OPERATOR’S MANUAL

OPERATING INSTRUCTIONS

WARNING

READ OPERATOR’S

THOROUGHLY

MANUAL

4. Connect the water supply hose to the inlet connec-

5. Have an electrician connect power supply into junc-

6. Turn on the main gas supply.

7. Partially depress and turn control knob to the “OFF”

8. Wait five minutes to allow gas, which may have ac-

9. Turn gas cock dial to “PILOT” position.

10. Depress the control knob all the way and hold it in.

11. Release dial and turn to full "ON".

12. Attach the desired high pressure nozzle into the wand

13. Push "ON" switch, or turn to pump position and pull

14. To activate the gas control valve for hot water, push

15. To apply detergent, open the detergent valve counter-

TO USE .

PRIOR

tor and turn the water on. Check for water leaks and

tighten as needed.

tion box according to information shown on the serial plate.

position (see fig.5 on page 14).

cumulated in the main burner compartment, to escape.

After five (5) seconds, depress the red ignitor until

you hear a loud click. Repeat 3 or 4 times if necessary until pilot is lit. If pilot does not remain lit, repeat

the operation allowing a longer period of time before

releasing the gas valve knob. After the pilot lights,

continue to hold the control knob down for about one

(1) minute before releasing.

NOTE: Sufficient time must be allowed for a proper

size pilot flame to heat the thermocouple and hold

the safety magnet in a locked-up position. Also, time

must be allowed for air to escape from the lines during the first operation.

quick coupler by pulling the coupler collar back and

then inserting the nozzle and securing it by pushing

the coupler collar forward.

the trigger on the spray gun allowing cold water to

flow.

the burner switch to the "ON" position and pull the

trigger on the spray gun.

clockwise making sure that the detergent pick up

tube is in the detergent solution and not sucking air.

WARNING: STOP! Read operators manual before operating this

machine.

1. Failure to read operation and

warning instructions may result

in personal injury or property

damage.

2. Turn all switches off.

3. Review installation instructions.

16. To Stop: Turn the burner switch "OFF" and place

the detergent pick up tube into fresh water. Open

the detergent valve and spray gun allowing detergent lines to be flushed and the burner to cool. Otherwise coil damage will result.

17. After water has cooled, push or turn pump switch to

OFF position. If the machine is going to be off for an

extended period of time, put the gas cock dial on the

gas valve into the “OFF” position.

18. Turn water off. Prevent from freezing.

PREVENTATIVE

MAINTENANCE

1. Check to see that the water pump is properly lubricated.

2. Follow winterizing instructions to prevent freeze damage to the pump and coils.

3. Always neutralize and flush detergent from system

after use.

4. If water is known to be high in mineral content, use a

water softener in your water system or descale as

needed.

5. Do not allow acidic, caustic or abrasive fluids to be

pumped through system.

6. Always use high grade quality Shark cleaning

products.

7. Never run pump dry for extended periods of time.

8. Periodically delime coils as per instructions.

It is advisable, periodically, to visually inspect the burner.

Check air inlet to make sure it is not clogged or blocked.

Wipe off any oil spills and keep this equipment clean

and dry.

The areas around the Shark washer should be kept clean

and free of combustible materials, gasoline and other

flammable vapors and liquids.

The flow of combustion and ventilating air to the burner

must not be blocked or obstructed in any manner.

GENERAL WASHING

TECHNIQUES

If dirt comes off relatively easy and no grease and oil are

present, cleaning with cold water will normally suffice.

However, when grease and oil are present, hot water

will greatly speed up the process.

Clean with the spray nozzle a foot or so from the surface

being cleaned. For more difficult cleaning, move the

nozzle in closer.

Shark HNG • Rev. 2/03a

Page 13

HNG SERIES PRESSURE WASHER

OPERATOR’S MANUAL

13

If the machine is equipped with a shut-off spray gun and

various nozzle patterns, use the wide patterns for easy

soil removal jobs and the narrow patterns on the more

difficult jobs or for tight areas such as cracks and holes.

In most cases, faster results and better detergent

economy is obtained by applying the detergent and letting it “set” for a few minutes, prior to rinsing. This enables the detergent to do its soil penetrating and loosening work.

Most cleaning work terminates with a high pressure rinse

as part of the normal cleaning procedure. In some cases,

however, the last operation may be application of a detergent (sanitizing, for example). After such work, run

the machine for 20-30 seconds to clear pump and lines.

MAINTENANCE AND SERVICE

Spray Nozzles:

Each machine is equipped with one or more spray

nozzles, depending on the model. Different spray nozzles

are calibrated for each machine, depending on the flow

and pressure of that particular model. Spray nozzles vary

in bore size and angle of spray. Popular spray angles are

0°, 15°, 25°, 40°. When ordering, please specify size and

angle of nozzle. Nozzle size for each machine is located

on the serial plate.

Unloader Valves:

Unloader valves relieve pressure in the line when a spray

gun is closed. Unloader valves are preset and tested at

the factory before shipping. Occasional adjustment of

the unloader may be necessary to maintain correct pressure. For valve adjustment contact your nearest Shark

dealer or call Shark technical support.

Winterizing Procedure:

Damage due to freezing is not covered by warranty.

Adhere to the following cold weather procedures whenever the washer must be stored or operated outdoors

under freezing conditions.

It is necessary to protect your machine against freezing

when temperatures drop below 32° F. Siphoning a small

amount of antifreeze into the system is recommended.

This is done by pouring a 50-50 mix of antifreeze and

water into the float tank and then siphoning 100% antifreeze through the detergent line with the pump on. If

compressed air is available, an air fitting can be screwed

into the float tank strainer fitting, and by injecting compressed air, all water will be blown out of the system.

The use of a draft diverter will prevent the wind chill factor from freezing the coil.

Shark HNG • Rev. 2/03a

Low Pressure Diagnosis:

(Machines with spray gun)

Refer to Troubleshooting Chart for low pressure. If the

trouble is found to be either the unloader or the pump,

your next step is to determine which is the problem. This

can be done by eliminating the unloader from the system and attaching the 50' discharge hose directly to the

pump. If high pressure is developed in this manner, the

pump is good and the unloader needs to be repaired or

replaced. If low pressure is still present, then the pump

needs repairing.

CAUTION: When using this procedure to test components keep the spray gun open at all times.

High Limit Hot Water Thermostat:

For safety, each machine is equipped with an adjustable

thermostat. In the event the temperature of the water

should exceed its operating temperature, the thermostat will turn the burner off until the water cools.

Pumps:

Use only SAE30 weight non-detergent oil. Change oil

after first 50 hours of use. Thereafter, change oil every

three months or at 500 hour intervals. Oil level should be

checked through use of the dipstick found on the top of

the pump or by the red dot visible through the oil gauge

window. Oil should be maintained at that level.

HEATING COILS

To Check Water Heater Coil for Leaks:

With the main burners "OFF" start the pumping unit and

allow it to run for a few minutes. With a drop light or flashlight check the burner compartment. If no leaks are visible, and water is dripping from the coils then it is condensation from the flue gases when the burners are on.

Condensation from Heating Coil:

When cold water is being pumped into the water heater

coils, and the burners are on, condensation will form on

the coils and drip down into the burner compartment,

giving the appearance of a leaking coil, particularly on

cold humid days.

Deliming Coils:

In alkaline water areas, lime deposits can accumulate

rapidly inside the coil pipes. This growth is increased by

the extreme heat build up in the coil. The best prevention

for liming conditions is to use high quality cleaning detergents. In areas where alkaline water is an extreme

problem, periodic use of Shark Deliming Powder (part

#9-028008) will remove lime and other deposits before

coil becomes plugged. (See Instructions below for use

of Shark Deliming Powder.)

Page 14

14

HNG SERIES PRESSURE WASHER

OPERATOR’S MANUAL

Periodic flushing of coils is recommended.

1. Fill a container with 4 gallons of water, then add 1 lb.

of deliming powder. Mix thoroughly.

2. Remove nozzle from spray gun assembly and put

spray gun into container. Secure the trigger on the

spray gun into the open position.

3. Attach a short section (3-5 ft.) of garden hose to

machine to siphon solution from an elevated container, or add mixture to the float tank. Turn pump

switch on allowing solution to be pumped through

coils and back into the container. Solution should be

allowed to circulate 2-4 hours.

4. After circulating solution, flush entire system with

fresh water. Reinstall wand assembly to spray gun.

Gas Valve Regulator Adjustment:

(See Fig. 5)

Adjustment of the built-in regulator isn’t normally necessary, since it is preset at the factory. However, field adjustment may be accomplished as follows:

1. Attach manometer at pressure tap port.

2. Remove regulator adjustment screw cap.

3. With small screwdriver, rotate adjustment screw

clockwise to increase or counterclockwise to decrease gas pressure.

4. Replace regulator adjustment screw cap.

Figure 7

3/8" to 1/2"

Burner

Pilot

Igniter

Line To Gas

Valve

Pilot Burner Adjustment:

1. Remove pilot adjustment cap.

2. Adjust pilot key to provide properly sized flame.

3. Replace pilot adjustment cap.

Rupture Disk:

If pressure from pump or thermal expansion should exceed safe limits, the rupture disk will burst, allowing high

pressure to be discharged through hose to ground. When

the disk ruptures, it will need to be replaced. Torque to

35 ft. lbs.

Figure 5

On/Off

Switch

Inlet

View

Inlet

Pressure

Por t

Line to

Pilot Light

Outlet

Pressure

Port

Gas Valve Adjustment

Manifold Pressure

Adjustment Screw

Under Cap

Outlet

View

PROPANE GAS (Vapor Fuel Only)

General Safety Precautions:

Have a qualified gas service person assist in any gas

burner installation or service. Few maintenance people

or mechanics are knowledgeable in gas controls or related safety practices. Since propane gas is heavier than

air, unburned propane gas will gravitate to the floor rather

than rise out of the stack. Hence, adequate floor space

and good ventilation are especially important with propane systems.

Shark HNG • Rev. 2/03a

Page 15

HNG SERIES PRESSURE WASHER

OPERATOR’S MANUAL

15

Gas Pressure Requirements:

All propane fired machines operate on gas phase only.

They are designed to operate at a pressure of 11 w.c.i.

(between 1/3 and 1/2 of one PSI), and are often operated at even higher pressures when extra heat is needed.

Exterior regulators are needed to control the system. Propane bottles are not included with the machine. A high

pressure regulator should be installed on the propane

bottle and a low pressure regulator attached to the pressure washer.

Propane Cylinder Capacity:

An important consideration with propane systems is the

capacity of the supply cylinder relative to the needs of

the burner. The burner operates on propane as a gas.

As gas is used from the propane cylinder, the liquid in

the cylinder boils to maintain gas pressure. This boiling

process cools the liquid, and in a heavy, continuous-demand situation, the liquid temperature can fall to the point

at which it cannot provide gas as rapidly as is needed. In

this case, it may be necessary to warm the propane cylinder by directing a warm spray, not over 120°, on the

cold cylinder, or by manifolding two propane bottles together to increase total vaporization capacity. It is recommended that a minimum 100 lb. propane bottle be

used on the machine, depending on the length of running time desired.

If the water heater will be exposed to freezing weather,

an antifreeze solution should be circulated through the

coils by whatever means are available for the particular

system the water heater is used on.

BURNER TROUBLESHOOTING

Millivolt System Check:

This machine has a thermopile self-powered combination gas control. Before checking the millivolt system,

the following operations should be performed and observations made:

1. Inspect system for proper wiring.

2. The switch leads and all wire connections should be

cleaned and tightened to eliminate all unnecessary

resistance.

3. Clean and/or adjust pilot for maximum flame impingement on the thermopile.

4. If pilot will not remain lit when gas cock dial is released, check automatic pilot (Step D).

The millivolt system and individual components may be

checked with a DC millivolt meter having a 0-1000 MV

range. Conduct each check as shown in the chart below

by connecting the meter test leads to terminals as indicated. All readings are closed circuit.

BURNER FEATURES

Operated Automatic Valve:

This machine is equipped with a thermopile self-powered combination gas control. This system is designed

as a constant burning pilot. Lighting of the pilot is accomplished by manually lighting the pilot. A thermostat

and flow switch control the main solenoid valve.

Care of Main Burner:

Because condensation from heater coils may drip down

on the burners, scale buildup may occur in the burner jet

orifices.

1. TO REMOVE BURNER MANIFOLD FROM

WATER HEATER COIL:

Turn off the gas at the main burner by turning the

knob to the “OFF” position on the gas valve and main

gas supply.

Disconnect the pilot and ignition lines from the gas

valve. Disconnect union in main burner line. (Remove

the nuts from the U-bolts, item 28 on page 23). Slide

burner manifold out through shell opening.

2. TO CLEAN BURNER JETS:

Select proper size drill for type of gas involved. Use

vise to hold drill and to ream out each jet orifice.

Shark HNG • Rev. 2/03a

TERM

MILLIVOLT

Check

Test

A

B

C

D

TERMINAL

Complete

Thermopile

Resistance

Auto/Pilot

OPERATOR

PANEL

To Te st

System

Output

System

Dropout

TH

TH

TP

TP

Connect

Meter

Leads To

Termina ls

2 & 3 Closed

1 & 2 Open

1 & 3 Closed

1 & 2 Open

Switch

Flow &

Burner

Contacts

TERM

TERM

Meter

Reading

Should

Be

100 MV or

More

Greater

than 250

Less than

35

Between

120 - 30

MV

Page 16

16

HNG SERIES PRESSURE WASHER

OPERATOR’S MANUAL

2 Lead Thermopile

Equivalent

To (CP-2)

To Burner

Flow Switch

Igniter

Gas

Valve

Pilot 2CH-2

or

Equivalent

2 Lead

Thermopile

Connections

C. System Resistance Check

(“C” Reading = Switch contacts CLOSED - Gas Cock

“ON” - Main burner should be ON)

If the “C” Reading is more than that specified

for the system being checked, this indicates the

resistance in the system is excessive and must

be reduced. To correct:

a. Clean and tighten switch leads and connec-

tions.

b. Shorten switch lead wires and/or replace

with heavier gauge wire.

c. Cycle switch rapidly to clean contacts.

D. Automatic Pilot Dropout Check

1. Hold gas cock dial depressed in pilot position until maximum output is observed. Then extinguish

pilot and observe meter.

2. Dropout of automatic pilot magnet (sound should

be audible) should occur between 120 millivolts

and 30 millivolts. If dropout occurs outside these

limits, change the automatic pilot magnet assembly.

A. Complete Millivolt System Check

(“A” Reading = Switch contacts CLOSED - Gas

Cock Dial “ON” - Main burner should come ON).

1. If the reading is more than 100 millivolts and the

automatic valve still does not come on, replace

the automatic valve operator.

2. If the closed circuit reading (“A” Reading) is less

than 100 millivolts, determine cause for low reading - proceed as follows:

B. Thermopile Output Reading Check

(“B” Reading = Switch contacts OPEN - Main burner

OFF).

If the minimum 250 millivolt reading is not obtainable, readjust pilot for maximum millivolt output.

If millivolt reading is still below minimum specified, replace thermopile.

Shark HNG • Rev. 2/03a

Page 17

HNG SERIES PRESSURE WASHER

HOSE & SPRAY GUN ASSEMBLY

ALL MODELS

4

OPERATOR’S MANUAL

3

1

17

5

ITEM PART NO. DESCRIPTION QTY

1 2-2002 Coupler, 3/8" Female 1

2 4-02093450BC Hose 3/8" x 50', 1 Wire Blue,

w/Coupler 1

3 4-01246

4 4-0111341A Wand, V.P. w/Coupler & Nozzles 1

5 4-12805500 Nozzle, SAQCMEG 0005.5,

4-12805515 Nozzle, SAQCMEG 1505.5,

4-12805525 Nozzle, SAQCMEG 2505.5,

Spray Gun, Shut-Off AP-1000

Red (4020, 5030) 1

Yellow (4020, 5030) 1

Green (4020, 5030) 1

1

2

ITEM PART NO. DESCRIPTION QTY

5 4-12805540 Nozzle, SAQCMEG 4005.5,

White (4020, 5030) 1

4-12804000 Nozzle, SAQCMEG 0004, Red

(3530) 1

4-12804015 Nozzle, SAQCMEG 1504, Yellow

(3530) 1

4-12804025 Nozzle, SAQCMEG 2504, Green

(3530) 1

4-12804040 Nozzle, SAQCMEG 4004, White

(3530) 1

Shark HNG • Rev. 2/03a

Page 18

18

HNG SERIES PRESSURE WASHER

HNG

EXPLODED VIEW

LEFT SIDE

73

74

75

76

79

78

13

12

14

74

70

77

For

Detail See

Burner

Assembly

Illus.

72

66

85

71

65

86

67

68

69

Detail See

Assembly

For

Burner

Illus.

90

To

Detergent

Valve

92

56

89

57

53

87

51

55

OPERATOR’S MANUAL

88

For

Detail See

Float Tank

Illus.

7

87

88

50

52

35

36

35

58

48

49

87

6

For Detail

81

80

5

82

See Control

Panel Illus.

Steam

Valve

Option

6

Shark HNG • Rev. 2/03a

Steam

Valve

Option

83

63

62

52

26

61

59

64

84

Page 19

HNG SERIES PRESSURE WASHER

HNG

EXPLODED VIEW

RIGHT SIDE

46

47

OPERATOR’S MANUAL

6

19

52

42

15

26

11

58

41

37

34

38

44

35

29

36

33

27

91

32

43

97

30

28

28

29

22

Steam

Valve

Option

27

25

21

45

60

19

28

13

26

12

14

62

23

17

18

8

20

40

Steam Valve

Option

39

1

2

95

94

93

9

10

7

13

12

12

79

96

79

12

6

90

Shark HNG • Rev. 2/03a

For Internal

Detail See

Electrical Box

Illustrations

50

4

3

6

Page 20

20

HNG SERIES PRESSURE WASHER

HNG

EXPLODED VIEW PARTS LIST

OPERATOR’S MANUAL

ITEM PART NO. DESCRIPTION QTY

1 95-07163028 Box, Electrical 1

2 95-07163113 Panel, Front 1

3 95-07163114 Cover, E-Box Access 1

4 10-07994 Label, Warning 1

5 10-99071 Label, Steam Valve Option 1

6 90-19711 Screw, 1/4" x 1/2" HH NC,

Whiz Loc 42

7 4-02120000 Hose, 3/4" Push-on /ft. 2.33

8 95-07163119 Brace, Panel 1

9 95-071210136 Platform, Motor 3/16" 1

10 95-07121112 Rail, Pump or Generator Combo

(402001, 353001, 503001) 1

95-07163136 Rail, Pump, Legacy Pumps

(402007, 353007, 503007) 1

11 90-2007 Nut, 3/8" Hex, NC 3

12 90-4002 Washer, 3/8" SAE, Flat 22

13 90-2002 Nut, 3/8", ESNA, NC 14

14 90-4007 Washer, 3/8" x 1-1/2", Fender,

SAE 14

15 90-1025 Bolt, 3/8" x 5-1/2", Tap 2

16 90-2020 ▲ Nut, Cage, 3/8" x 12" GA 8

17 5-511113 Bushing, H x 1-1/8" (4020) 1

5-511138 Bushing, H x 1-3/8"

(3530, 5030) 1

18 5-512024 Bushing, H x 24mm 1

19 5-40204401 Pulley, 2AK 44 H (402007) 1

5-40205401 Pulley, 2AK 54 H (402001) 1

5-40504501 Pulley, 2BK 45 H

(353001, 353007, 503007) 1

5-40505701 Pulley, 2BK57H (503001) 1

20 5-40206401 Pulley, 2AK 64 H (402007) 1

5-40208401 Pulley, 2AK 84 H (402001) 1

5-40507001 Pulley, 2BK 70 H

(353007, 503001) 1

5-40505701 Pulley, 2BK57H (503007) 1

5-40508001 Pulley, 2BK 80 H (353001) 1

21 5-602037 Belt, AX37 (402001) 2

5-604036 Belt, BX36 (353001, 503001) 2

5-602034 Belt, AX34 (402007) 2

5-604034 Belt, BX34 (353007, 503007) 2

Shark HNG • Rev. 2/03a

ITEM PART NO. DESCRIPTION QTY

22 5-2304 Pump General, T-1011

(402001) 1

5-2307 Pump, General, TS-2021

(353001, 503001) 1

5-1651 Pump, Legacy, TML-3053

(402007, 353007, 503007) 1

23 1-190029 Cap, Valve, with 1/4" Gauge Port

(402001, 353001, 503001) 1

15-070042532 Cap, Valve, with 1/4" Gauge Port,

Legacy (402007, 353007,

503007) 1

24 90-4002 3/8" Washer (4020, 3530) 1

25 6-021720 Switch, Pressure N/O,

1/4" NPT SS 1

26 2-1042 Tee, 1/2" Street 2

27 2-1076 Bushing, Reducer, 1/2" x 1/4" 1

28 2-1089 Hose Barb, 1/4" Barb x 1/4"

Pipe, 90° 1

(Steam Option) 2

29 2-9040 Clamp, Hose, .46-.54 3

30 2-1037 Tee, 1/4" Branch Male

(Steam Option) 1

32 2-0051 Nipple, 1/2" JIC, 3/8" Pipe 1

33 2-0079 Swivel, 1/2" JIC Fem., 3/8" MAL1

34 2-10712 Tee, 1/2" x 1/2" JIC 51#

(All except 5030) 1

35 2-1105 Swivel, 1/2" JIC Fem, Push-On 4

(5030 - qty 2)

2-11050 Swivel, 3/4" SAE Fem, Push-on

(5030) 2

36 4-02110000 Hose, 1/2", Push-On per/ft. 3

4-02120000 Hose, 3/4" Push-on /ft. (5030) 3

37 5-3208 Unloader, AL-VRT 607,

7.8 GPM @ 4200 PSI 1

38 2-106301 Elbow, 1/2" JIC x 3/8", 45 DGR 1

39 2-0031 Elbow, 3/8", Street

(Steam Option) 1

40 2-00682 Bushing, 3/8" Street

(Steam Option) 1

41 4-02047725 Hose, 3/8" x 25", 2 Wire,

Pressure Loop 1

42 2-0053 Elbow, 1/2" JIC, 3/8", 90° 1

43 5-10401 Motor, 6HP 1PH 1725 RPM

(4020A) 1

5-1013 Motor, 7.5HP 1PH 1725 RPM

(3530A) 1

Page 21

HNG SERIES PRESSURE WASHER

HNG

EXPLODED VIEW PARTS LIST

OPERATOR’S MANUAL

21

ITEM PART NO. DESCRIPTION QTY

43 5-1018 Motor, 10 HP, 3 PH, 230/460V,

1725 RPM (5030B,C) 1

44 6-0108 Cord, Service, SEO, 10/3 /ft.

Coleman (4020A) 9.25

6-0102 Cord, Service, SO, 8/3 /ft.

Coleman (3530A) 9.25

6-01021 Cord, Service, 8/4 /ft.

(5030B) 9.25

6-0105 Cord, Service, 12/4 /ft.

(5030C) 9.25

45 95-07163117 Panel, Side, Left 1

46 95-07163116 Cover, Top 1

47 10-99075 Label, Operating Instructions 1

48 95-07163102 Panel, Rear 1

49 2-0148 Plug, Plastic, 7/8" 1

50 90-2022 Nut, Cage, 1/4" x 16 GA 30

51 6-04110 Box, Junction 3 Hole, 3/4" 1

52 2-1062 Elbow, 1/2" JIC x 1/2", 90° 2

2-10630 Elbow, 3/4" JIC x 1/2" 90°

(5030) 2

53 6-0411 Cover Plate, Junction Box,

2" x 4" 1

11-1042 ▲ Ground Label 1

55 4-02100030 Inlet Hose, 30", Water Supply 1

56 4-02100045 Inlet Hose, 45", Water Supply 1

57 2-00602 Elbow, 1/2" JIC x 1/2" Fem, 90° 1

58 2-1053 Nipple, 1/2" JIC 1/2" MPT Pipe 2

59 2-10942 Swivel, 1/2" MP x 3/4" GHF,

w/Strainer 1

60 10-09003 Label, Cold Water Inlet 1

61 2-1100 Adapter, 1/2" x 1/2" Pipe 1

62 2-0108 Bumper Pad, Engine 18

63 2-01041 Pad, Soft Rub ber, 50 DURO 6

64 95-07163100 Assy, Frame 1

65 2-2007 Nipple, 3/8" x 3/8" NPT ST Male1

66 2-00575 Elbow, 3/8" Steel, Street, 45° 1

67 95-07101226 Block, Discharge, Brass,

1/2" x 1/2" 1

68 2-3408 Disk, Rupture Assy, 8000 PSI 1

69 2-90041 Clamp, Screw, #16 Micro 1

70 4-05088 Thermostat, Adjustable, 302F 1

71 2-0008 Nipple 1/2" Hex, Steel 1

ITEM PART NO. DESCRIPTION QTY

72 4-02130050 Hose, 7/8" Push-On, Conduit,

7338-870 3.33

73 95-07163099 Top, Burner Wrap, 20" 1

74 10-02025A Label, Hot/Caliente w/Arrows

Warning 2

75 7-01415 Insulation, Tank Head, 20",

10" Opening 1

76 90-50045 Clip, Retaining, U-Type 4

77 95-07121220 Coil, Dura, 20" Dia., SCH. 80 1

78 95-07163094 Wrap, Outer Assy, 20" Coil 1

79 90-1016 Bolt, 3/8" x 1", NC HH 8

80 95-07163126 Cover, Control Panel 1

95-07163115 Cover, Control Panel (Remote) 1

81 11-0353 Label, Control Panel 1

11-0354 Label, Control Panel, Remote 1

82 95-07163118 Panel, Side, Right 1

83 4-02021236 Hose, 1/4" x 36", 2 Wire,

Gauge Hose (Steam Option) 1

84 90-20231 Nut, Cage, 1/4" x 12 GA 12

85 2-00681 Bushing, 1/2" x 3/8" Steel 1

86 10-09004 Label, Hot Water Outlet 1

87 2-01411 Bushing, 1" Snap 3

88 2-01081 Plug, Rubber 3

89 2-01037 Grommet, 1-5/16" Rubber 1

90 90-1016 3/8" Bolt 8

91 90-2002 3/8" ESNA 4

92 10-08021 Label, Disconnect Power Supply1

93 90-1030 Bolt, 8mm x 16mm Hex Head 4

94 90-4008 Washer, 5/16" Lock Split Ring 4

95 90-4001 Washer, 5/16" Flat 4

Shark HNG • Rev. 2/03a

Page 22

22

HNG SERIES PRESSURE WASHER

HNG BURNER ASSEMBLY

EXPLODED VIEW

OPERATOR’S MANUAL

21

1

2

15

14

13

10

12

19

10

20

29

23

22

11

31

28

9

Elec.

Ignition

32

24

26

25

3

4

5

32

Elec.

Ignition

6

7

5

9

8

4

5

4

16

18

17

30

Shark HNG • Rev. 2/03a

5

Page 23

HNG SERIES PRESSURE WASHER

HNG BURNER ASSEMBLY

PARTS LIST

OPERATOR’S MANUAL

23

ITEM PART NO. DESCRIPTION QTY

1 7-7021 Jet, Orifice, #54 Natural Gas 44

7-7022 Jet, Orifice 2

2 95-031610/54 Burner Assy,

Square, Small #54 1

95-031610/65 Burner Ring w/Jets "65"

(LP Option) 1

3 2-001359 Bushing, 1" x 3/4", Black, Steel

Hex 1

4 2-00162 Nipple, 3/4" x 3", Black Pipe 3

5 2-00293 Elbow, 3/4", Black, 90° 4

6 2-00164 Nipple, 3/4" x 6", Black Pipe 1

7 2-00163 Nipple, 3/4" x 2", Black 1

8 2-0087 Union, 3/4", Black Pipe 1

9 2-00151 Nipple, 3/4" x Close, Black 2

10 95-07163081 Nipple, 1" NPT x 15", Black,

SCH. 40 2

11 2-00295 Elbow, 1" x 3/4", Reducing

Black 1

12 2-00291 Elbow, 1", Black, 90° 1

13 2-00091 Nipple, 1/2" x 3", Galv. SCH. 80 1

14 95-07121113 PHW/VNG Insulation Retainer

Plate 1

15 90-2999 Screw, #10 x 1/2", TEK 4

16 95-07163097 Cover, Burner Access, 20" Coil 1

17 90-19942 Screw, 10/32" x 3/4", Hex Wash

SL Mach/Blk 2

18 10-99032 Label, Pilot Light Hole 1

10-99077 Label, Pilot Light Warning 1

ITEM PART NO. DESCRIPTION QTY

19 90-2018 Nut, Cage, 10/32" x 16 GA 2

20 7-70162 Ignitor, Piezo #1244-42 1

7-70164 Washer, Panel Adapter, Piezo

1244-26 1

21 90-10131 U-Bolt, 5/16" x 3", Pipe 2

22 7-70237 Pilot, Natural Gas Pilot A3-S,

#77623 1

7-7036 Thermopile, 44" MFG 1

23 7-0150 Tubing, Aluminum, 600/Rl, 1/4"

Dead Soft /in. 36

24 7-7000HC Valve, Gas 7000 MVRHC,

#497701404 1

7-70002 Valve, Gas, 7000 DERHC,

#5N2501531 (Elec Ignition) 1

25 2-3006 Valve, Ball, 1/4" Female x 1/4"

Female, UL Listed #12 1

26 2-1118 Connector, 1/4" Tube x 1/4"

MPT 2

27 95-07163085 ▲ Splash Guard 1

28 90-10130 U-Bolt, 5/16" x 1", Pipe 1

29 10-99077 Label, Pilot Light Warning 1

30 10-02020 Label, Burner Instructions 1

31 10-02024 Label, Natural Gas 1

32 2-001359 Bushing, 1" x 3/4" Blk Steel

(Elec. Ignition) 2

▲ Not Shown

Shark HNG • Rev. 2/03a

Page 24

24

HNG SERIES PRESSURE WASHER

HNG CONTROL PANEL

ALL MODELS

OPERATOR’S MANUAL

7

8

5,6

12

13

11

9

Steam

Valve

Option

15

10

For Internal

Detail See

Electrical Box

Illustrations

3

2

17

11

16

Steam

Valve

1

4

Option

Shark HNG • Rev. 2/03a

18

17

14

Detergent Remote

Operating System

Page 25

HNG SERIES PRESSURE WASHER

HNG CONTROL PANEL

ALL MODELS PARTS LIST

ITEM PART NO. DESCRIPTION QTY

1 4-05088 Thermostat, Adjustable 1

2 6-020240 Switch, Rocker, Carling w/Green

Lens 2

3 6-020241 Switch, Rocker, Carling Red

Actuator (Time Delay) 1

4 4-050822 Hour Meter, HOBBS 1

5 2-0103 Grommet, Rubber, Nozzle

Holder 4

6 Nozzle (See Pg 17) 1

7 2-30152 Valve, Metering, 1/4" Hose 1

8 4-02080000 Tube, 1/4" x 1/2", Clear Vinyl,

per ft. 10

9 2-1905 Strainer, 1/4" w/Check Valve 1

10 2-9040 Clamp, Hose, .46-.543

11 2-30151 Valve, Flow Control/Metering

(Steam Option) 1

12 2-0030 Elbow, 1/4" Street 1

13 2-00330 Elbow, 45° 1/4 Street

(Steam Option) 1

14 6-2020 Switch, Selector, w/Red Lever 3

15 2-1089 Hose Barb, 1/4" Barb x 1/4" Pipe,

90° (Steam Option) 1

16 10-99071 Label, Steam Valve

(Steam Option) 1

17 6-2000 Block, Contact, N/C 3

18 6-2001 Block, Contact, N/O 3

OPERATOR’S MANUAL

25

Shark HNG • Rev. 2/03a

Page 26

26

HNG SERIES PRESSURE WASHER

HNG FLOAT TANK ASSEMBLY

ALL MODELS

OPERATOR’S MANUAL

10

9

3

2

4

6

8

7

5

1

To Outside

Water

Supply

ITEM PART NO. DESCRIPTION QTY

1 11-0602 Label, Shark 1

2 2-0100379 Adapter, 3/4" x 3/4" MT x Insert,

90° 1

3 2-010058 Bulkhead, 3/4" Polypropylene 1

4 2-01164 Tank, Plastic Universal Float 1

5 2-0151 Plug, Float Tank 1

Shark HNG • Rev. 2/03a

To Pump

ITEM PART NO. DESCRIPTION QTY

6 2-1062 Elbow, 1/2" JIC x 1/2", 90 DGR 1

7 2-11041 Connector, 1/2" Anchor 1

8 2-1906 Strainer, 1/2" Basket 1

9 2-3014 Valve, Fluidmaster, 400A, Float 2

10 4-02120000 Hose, 3/4" Push-On 2 ft.

Page 27

HNG SERIES PRESSURE WASHER

2

HNG ELECTRICAL BOX

STANDARD

3

13

7

8

OPERATOR’S MANUAL

16

15

13

27

5 - Remote Only

11

12

ITEM PART NO. DESCRIPTION QTY

1 95-0716028 Box, Electr ical 1

2 95-07163030 Panel, Electrical Box Side 1

90-1999 ▲ Screw, 10/32" x 3/4" 1

11-1042 ▲ Ground Label 1

3 90-1991 Screw,

4 90-2018 Nut, Cage, 10/32" x 16 GA 4

5 6-0517 Strain Relief, 3/4" 3

6 6-60111 Transformer, Micron,

6-02294 Fuse, KTK-R1 600V Midget 2

6-0229810 Fuse, Paper, Buss FNM-8/10,

7 6-0504 Block, Terminal, 4 Pole 1

8 6-4013 Contactor, 120V, CH (5030B) 1

6-4018 Contactor, 120V, CH (353001A,

6-4007 Contactor, 120V, CH (5030C) 1

9 6-5015 Overload, 29.00-42.00 Amp, CH

10/32" x 1/2" BHSOC Blk

(Remote) 1

240/480V-120V, .075 KVA 1

250V Midget TD 1

353007A, 402001A, 402007A) 1

(353001A, 353007A) 1

Shark HNG • Rev. 2/03a

4

20

10

Detergent

Valve

Remote

1

5

14

19

18

17

3

9

6

ITEM PART NO. DESCRIPTION QTY

9 6-5013 Overload, 24.00-32.00 Amp, CH

(5030B) 1

6-5011 Overload, 13.00-19.00 Amp, CH

(5030C) 1

16

10 6-1401590 Valve, Deter., Less Solenoid

(Remote) 1

6-140160 Solenoid Coil, 120V (Remote) 1

11 2-1089 Hose Barb, 1/4" Barb x 1/4" Pipe,

90° (Remote) 2

12 2-9040 Clamp, Hose, .46-.54 2

13 6-021595 Din Rail, 35 mm,

14 6-05041 Block

15 6-03541 Base, Relay, SH2B-05, IDEC

16 6-03621 Relay, 120V, RH2B-UL-AC120

17 7-70151 Ignition, Electronic Control 1

18 6-60121 Transformer, Micron, 120/240V-

19 90-017 Nut, 10/32", Keps 13

20 90-199940 Screw, 10/32" x 1/4" (Remote) 2

Terminal, 16 Pole

(Remote) 3

(Remote) 3

24V, .050 KVA (Elec Ignition) 1

▲ Not Shown

per in.

(Remote)

4

1

Page 28

28

HNG SERIES PRESSURE WASHER

HNG ELECTRICAL BOX

TIME DELAY, EXPLODED VIEW

3

15

7

19

OPERATOR’S MANUAL

19

8

16

15

13

2

5 - Remote Only

11

12

10

Detergent

Valve

13

4

21

16

Remote

1

5

14

20

18

17

3

9

6

Shark HNG • Rev. 2/03a

Page 29

HNG SERIES PRESSURE WASHER

HNG ELECTRICAL BOX

TIME DELAY, EXPLODED VIEW PARTS LIST

OPERATOR’S MANUAL

29

ITEM PART NO. DESCRIPTION QTY

1 95-0716028 Box, Electrical 1

2 95-07163030 Panel, Electrical Box Side 1

90-1999 ▲ Screw, 10/32" x 3/4" 1

11-1042 ▲ Label, Ground 1

3 90-1991 Screw,

4 90-2018 Nut, Cage, 10/32" x 16 GA 4

5 6-0517 Strain Relief, 3/4" 3

6 6-60111 Transformer, Micron,

6-02294 Fuse, KTK-R1 600V Midget

6-02295 Fuse, KTK-R-1/2 600V Midget

6-0229810 Fuse, Paper, Buss FNM-8/10,

7 6-0504 Block, Terminal, 4 Pole 1

8 6-4013 Contactor, 120V, CH (5030B) 1

6-4018 Contactor, 120V, CH(402001A,

6-4007 Contactor, 120V, CH (5030C) 1

9 6-5015 Overload, 29.00-42.00 AMP, CH

6-5013 Overload, 24.00-32.00 Amps, CH

6-5011 Overload, 13.00-19.00 Amps, CH

10/32" x 1/2" BHSOC Blk

(Remote) 1

240/480V-120V, .075 KVA 1

(120-230V Models) 2

(460V Models) 2

250V Midget TD 1

402007A, 353001A, 353007A) 1

(353001A, 353007A) 1

(5030B) 1

(5030C) 1

16

ITEM PART NO. DESCRIPTION QTY

10 6-1401590 Valve, Deter. Less Solenoid

(Remote) 1

6-140160 Solenoid Coil, 120V (Remote) 1

11 2-1089 Hose Barb, 1/4" Barb x 1/4" Pipe,

90° (Remote) 2

12 2-9040 Clamp, Hose, .46-.54 2

13 6-021595 Din Rail, 35 mm, per in. 4

14 6-05041 Block Terminal,16 Pole (Remote)1

15 6-03541 Base, Relay, SH2B-05, IDEC,

(Time Delay) 1

(Remote) 3

16 6-03621 Relay, 120V, RH2B-UL-AC120

(Time Delay) 1

(Remote) 3

17 7-70151 Ignition, Electronic Control 1

18 6-60121 Transformer, Micron, 120/240V-

24V, .050 KVA (Elec. Ignition) 1

19 6-03700 Timer, Multi-Function,

24V-120/240V (Time Delay) 1

20 90-017 Nut, 10/32" Keps 13

21 90-199940 Screw. 10/32" x 1/4" (Remote) 2

▲ Not Shown

Shark HNG • Rev. 2/03a

Page 30

30

HNG SERIES PRESSURE WASHER

HNG ELECTRICAL BOX

AUTO START, EXPLODED VIEW

3

7

19

OPERATOR’S MANUAL

19

16

8

15

13

2

5 - Remote Only

11

12

4

23

10

Detergent

Valve

13

9

20

21

Remote

5

6

14

22

1

18

17

3

Shark HNG • Rev. 2/03a

Page 31

HNG SERIES PRESSURE WASHER

HNG ELECTRICAL BOX

AUTO START, EXPLODED VIEW PARTS LIST

OPERATOR’S MANUAL

31

ITEM PART NO. DESCRIPTION QTY

1 95-0716028 Box, Electrical 1

2 95-07163030 Panel, Electrical Box Side 1

90-1999 ▲ Screw, 10/32" x 3/4" 1

11-1042 ▲ Ground Label 1

3 90-1991 Screw,

4 90-2018 Nut, Cage, 10/32" x 16 GA 4

5 6-0517 Strain Relief, 3/4" 3

6 6-60111 Transformer, Micron,

6-02294 Fuse, KTK-R1 600V Midget

6-02295 Fuse, KTK-R-1/2 600V Midget

6-0229810 Fuse, Paper, Buss FNM-8/10,

7 6-0504 Block, Terminal, 4 Pole 1

8 6-4013 Contactor, 120V, CH (5030B) 1

6-4018 Contactor, 120V, CH

6-4007 Contactor, 120V, CH (5030C) 1

9 6-5015 Overload, 29.00-42.00 AMP, CH

6-5013 Overload, 24.00-32.00 Amp,

6-5011 Overload, 13.00-19.00 Amp,

10/32" x 1/2" BHSOC Blk

(Remote) 1

240/480V-120V, .075 KVA 1

(120-230V Models) 2

(460V Models) 2

250V Midget TD 1

(353001A, 353007A, 402001A,

402007A) 1

(353001A, 353007A) 1

CH (5030B) 1

CH (5030C) 1

16

ITEM PART NO. DESCRIPTION QTY

10 6-1401590 Valve, Deter. Less Solenoid

(Remote) 1

6-140160 Solenoid Coil, 120V (Remote) 1

11 2-1089 Hose Barb, 1/4" Barb x 1/4" Pipe,

90° (Remote) 2

12 2-9040 Clamp, Hose, .46-.54 2

13 6-021595 Din Rail, 35 mm, per in. 4

14 6-05041 Block

15 6-03541 Base, Relay, SH2B-05, IDEC

16 6-03621 Relay, 120V, RH2B-UL-AC120

17 7-70151 Ignition, Electronic Control 1

18 6-60121 Transformer, Micron, 120/240V-

19 6-06880 Timer, Solid State 120V, 5-60 Min.

20 6-035210 Relay, Socket, IDEC (Remote) 1

21 6-036210 Relay, Latch, IDEC (Remote) 1

22 90-017 Nut, 10/32", Keps 13

23 90-199940 Screw 10/32" x 1/4" (Remote) 2

Terminal, 16 Pole (Remote)

(Remote) 2

(Remote) 2

24V, .050 KVA, (Elec. Ignition) 1

(Auto Start) 1

▲ Not Shown

1

Shark HNG • Rev. 2/03a

Page 32

32

HNG SERIES PRESSURE WASHER

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

NO SPARK - NO

PILOT GAS

SPARK - BUT NO

PILOT LIGHT

PILOT GAS - BUT

NO SPARK

PILOT LIT - BUT

MAIN BURNER

WON'T COME ON

PILOT CYCLES

OFF AND ON BY

ITSELF

MAIN BURNER

SHUTS DOWN

LOW OPERATING

PRESSURE

LOW WATER

TEMPERATURE

Shark HNG • Rev. 2/03a

No main power Restore power.

Faulty limit switch Test/replace.

Faulty wiring Test wiring.

No gas s upplied to pilot valve Check for availability of gas.

Manual valves in "OFF" position Turn manual valve and gas cock to full "ON". Check

Faulty pilot valve Test gas valve.

Faulty wiring Test wiring.

Restricted pilot line or clogged pilot orifice Clean pilot tubing and orifices.

Broken or shorted electrode assembly Test/replace.

Faulty wiring Test wiring.

Low pilot flame Check inlet pressure, pilot oriface.

Improper alignment of sensor in pilot flame Adjust alignment - see figure 7, page 14.

Faulty main gas operator in gas control Tes t gas va lve - repair/replace.

Faulty flame sensor Test sensor, wiring - repair/replace.

Faulty pilot valve Test gas valve.

Faulty wiring Test wiring.

Low pilot flame Check inlet pressure, pilot oriface.

Improper alignment of sensor in pilot flame Adjust alignment - see figure 7, page 14.

Faulty main gas operator in gas control Test gas valve - repair/replace.

Faulty flame sensor Test sensor, wiring - repair/replace.

Faulty pressure g auge Install new gau ge.

Insufficient water supply Use larger garden hose. Clean filter washer at water

Old, worn or incorrect spray nozzle Match nozzle number to machine and/or replace with

Belt slippage Tighten or replace. Use correct be lt.

Plumbing or hose leak Check plumbing system for leak s. Retape leaks with

Faulty or misadjusted unloader valve (where

applicable)

Worn packing in pump Install new packing kit.

Fouled or dirty inlet or discharge valves in

pump

Worn inlet or discharge valves Rep lace with valve kit.

Obstruction in spray nozzle Remove obstruction.

Leaking pressure control valve (where

applicable)

Detergent metering valve left open sucking

air or faulty metering valve

Slow motor RPM Check incoming voltage.

Improper size of gas lines See page 7 for sizing of gas lines.

Low gas p ressure Increase gas pressure to machine.

Improper pressure regulator Specify BTU, building gas pressure 11 w.c.i. to

Low gas p ressure Increase gas pressure as described on page 8.

Soot buildup on c oils not allowing heat

transfer

Improper burner noz zle

OPERATOR’S MANUAL

pilot key adjustment.

inlet.

new nozzle.

teflon tape.

Adjust unloader for proper pressure. Install repair kit

when nee ded.

Clean inlet and discharge valve.

Rebuild or replace as needed.

Close and/or replace metering valve.

machine for correct sizing of regulator.

Clean coils.

See serial plate.

Page 33

HNG SERIES PRESSURE WASHER

OPERATOR’S MANUAL

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

WATER

TEMPERATURE

TOO HOT

PRESENCE OF

WATER IN OIL

WATER DRIPP ING

FROM UNDER

PUMP

DETERGENT N OT

DRAWING

PUMP RUNNING

NORMALLY BUT

PRESSURE LOW

ON INSTALLATION

FLUCTUATING

PRESSURE

PUMP NOISY

OIL DRIPPI NG Oil seal worn Check and replace if necessary.

EXCESSIVE

VIBRATION IN

DELIVERY LINE

RELIEF VALVE

LEAKS WATER

Incoming water to machine warm or hot Lower incoming water temperature.

Gas pressure too high See page 13 for specifications for proper gas pressure.

Detergent line sucking air Tighten all clamps. Check detergent lines for holes.

Defective high limit switch Replace.

Incorrect burner nozzle size See serial plate.

Insufficient water supplied Check water GPM to machine.

Restricted water flow Check nozzle for obstruction, proper size.

Oil seal worn Check and replace if necessary.

High humidity in air Check and change oil twice as often.

Piston packing worn Check and replace if necessary.

O-Ring plunger retainer worn Check and replace if necessary.

Air leak Tighten all clamps. Check detergent lines for holes.

Detergent metering valve packing not tight or

packing worn

Filter screen on detergent suction hose

plugged

Dried up detergent plugging metering valve Disassemble and clean thoroughly.

High viscosity of detergent Dilute detergent to specifications.

Restriction behind float tank screen removed Install restriction.

Hole in detergent line(s) Repair hole.

Strainer basket plugged Remove and clean.

Connections on selector valve loose Put teflon tape on all pipe connections.

Detergent solenoid not opening (where

applicable)

Pump sucking air Check water supply and possibility of air seepage.

Valves sticking Check and clean or replace if necessary.

Unloader valve seat faulty Check and replace if necessary.

Nozzle incorrectly sized Check and replace if necessary (See serial plate for

Worn piston packing Check and replace if necessary.

Valves worn Check and replace if necessary.

Blockage in valve Check and replace if necessary.

Pump sucking air Check water supply and air seepage at joints in

Worn piston packing Check and replace if necessary.

Air in suction line Check water supply and connections on suction line.

Broken or weak inlet or discharge valve

springs

Excessive matter in valves Check and clean if necessary.

Worn bearings Check and replace if necessary.

Irregular functioning of the valves Check and replace if necessary.

Relief valve defective Replace or repair.

Tighten nut. Replace valve or packing.

Clean or replace.

Check flow switch, replace detergent solenoid.

proper size).

suction line.

Check and replace if necessary.

33

Shark HNG • Rev. 2/03a

Page 34

34

HNG SERIES PRESSURE WASHER

BASIC FACTS

o

06nodesaB

alumroF 8H3C01H4C

OPERATOR’S MANUAL

enaporPenatuB

UTB000,1xorppAGN.tF.uC1

o

)F7.34-1.13

(tnioPnoitaziropaV

)ropaV(ytivarGcificepS 225.1600.2

)diuqiL(ytivarGcificepS 805.0485.0

)diuqiL(.laGrep.sbL 32.478.4

)ropaV(.tF.uCrepUTB 365.293.3

)diuqiL(.laGrepUTB 745.19230.201

)diuqiL(.bLrepUTB 195.12122.12

)diuqiL(.bLrep.tF.uC 706.835.6

)diuqiL(.laGrep.tF.uC 54.638.13

rebmuNenatcO 52119

thgieWraluceloM 90.4421.85

:tsoCgninnuRetaluclaCoT.tF.uC1=UTB000,1

mrehT1=.tF.uC001

ruoH1=mrehT1

nuRottsoC=mrehTrepsaGfotsoC

saGlarutaNgnisUelpmaxE

:mrehT¢05ta

.tF.uC004

enihcaMUTB000,004

)000,1/000,004(

nuRotruoH/00.2$=¢05x4

sagfotsocx)001/004((

)

PRESSURE EQUIVALENTS

Simply stated, pressure is the force exerted by a gas or liquid attempting to escape from a container. It is useful to

know how strong this “attempt to escape” is. Pressure can be measured with a manometer or with a pressure gauge.

At the lower levels, it is expressed in “water column inches” i.e. 11 w.c.i. Higher pressures are expressed in terms of

the force exerted against a square inch of area, for example, 125 lbs. per square inch (125 psi).

1 water column inch = 50 oz./sq. in. 11 water column inches = 6.35 oz./sq. in.

11 water column inches = 4 lb./sq. in. 1 lb./sq. in. = 27.71 water column inches

1 lb./sq. in. = 2.04" Mercury 1" Mercury = .39 lb./sq. in

1 Std. Atmosphere = 14.73 lbs./sq. in.

Shark HNG • Rev. 2/03a

Page 35

HNG SERIES PRESSURE WASHER

OPERATOR’S MANUAL

35

PREVENTATIVE MAINTENANCE

This pressure washer was produced with the best available materials and quality craftsmanship. However, you as the

owner have certain responsibilities for the correct care of the equipment. Attention to regular preventative maintenance procedures will assist in preserving the performance of your equipment. Contact your Shark, Inc. dealer for

maintenance. Regular preventative maintenance will add many hours to the life of your pressure washer. Perform

maintenance more often under severe conditions.

MAINTENANCE SCHEDULE

Replace Fuel Lines Annually

Pump Oil

Clean Burner Filter Annually

Remove Burner Soot From Heating Coil Annually

Check Belt Tension Monthly

Descale Coil Annually - (more often if required)

Replace High Pressure Nozzle Every 6 months

Replace Quick Connects Annually

Clean Water and Detergent Screen/Filter Weekly

Clean Float/Supply Tank Every 6 months