®

VN920DSP

HIGH SIDE DRIVER

TYPE R

DS(on)

I

OUT

V

CC

VN920DSP 16 mΩ 25 A 36 V

■ CMOS COMPATIBLE INPUT

■ ON STATE OPEN LOAD DETECTION

■ OFF STATE OPEN LOAD DETECTION

■ SHORTED LOAD PROTECTION

■ UNDERVOLTAGE AND OVERVOLTAGE

SHUTDOWN

■ PROTECTION AGAINST LOSS OF GROUND

■ VERY LOW STAND-BY CURRENT

■ REVERSE BATTERY PROTECTION (*)

DESCRIPTION

The VN920DSP is a monolithic device ma de by

using STMicroelectronics VIPower M0-3

Technology, i ntended for dr iving any kind o f load

with one side connected to ground.

Active VCC pin voltage clamp prote cts the device

against low energy spikes (see ISO7637 transient

compatibility table). Active current limitation

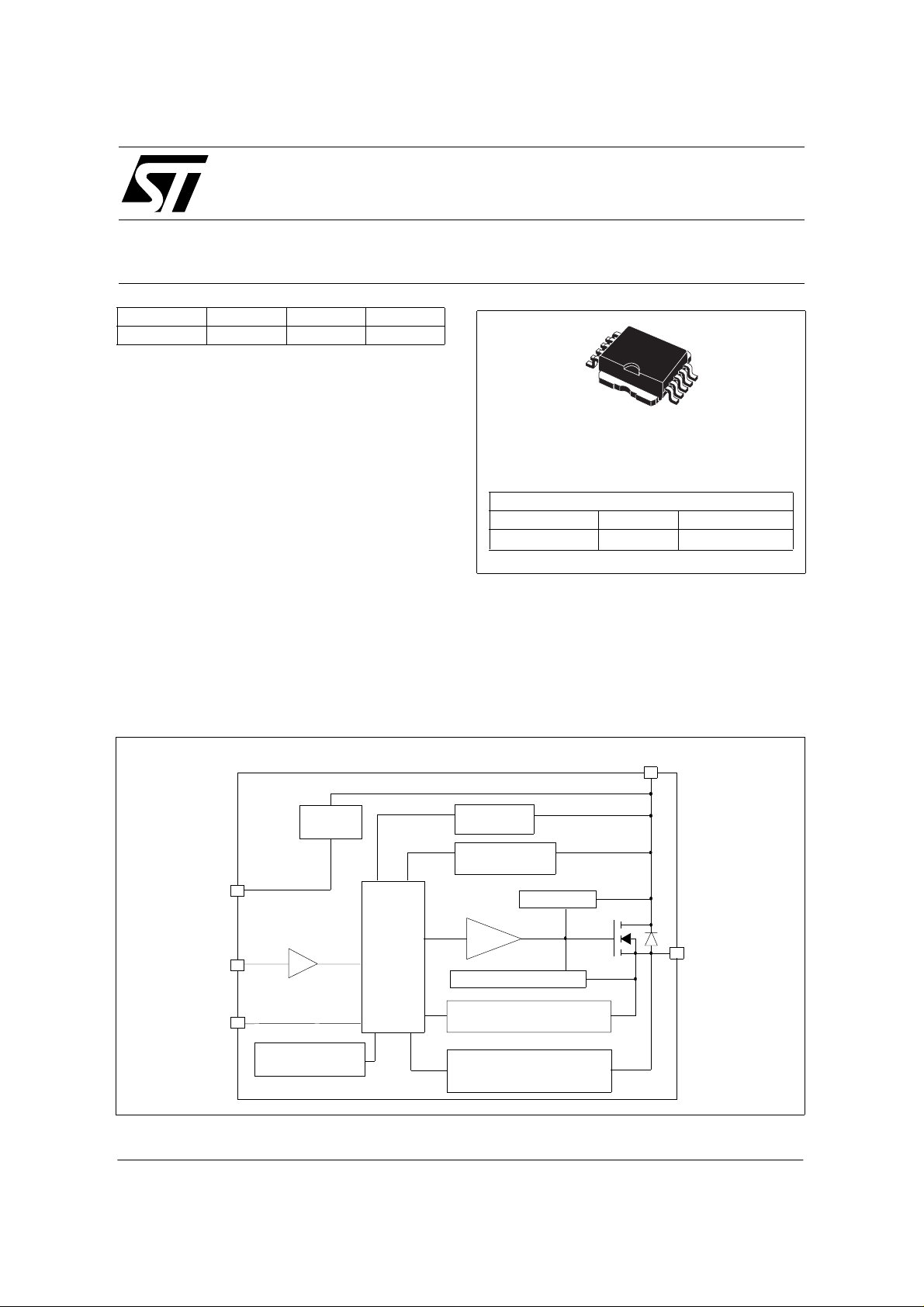

BLOCK DIAGRAM

10

1

PowerSO-10™

ORDER CODES

PACKAGE TUBE T&R

PowerSO-10™

VN920DSP VN920DSP13TR

combined with thermal shutdown and automatic

restart protect the device against overload.

The device detects open load condition both is on

and off state. Output shorted to VCC is detected in

the off state. Device automatically turns off in case

of ground pin disconnection.

V

CC

OVERVOLTAGE

DETECTION

UNDERVOLTAGE

DETECTION

Power CLAMP

DRIVER

CURRENT LIMITER

ON STATE OPENLOAD

DETECTION

OFF STA TE OPENLOAD

AND OUTPUT SHORTED TO V

DETECTION

OUTPUT

CC

GND

INPUT

STATUS

OVERTEMPERATURE

DETECTION

(*) See application schematic at page 8

V

CC

CLAMP

LOGIC

October 20 02 1/17

VN920DSP

ABSOLUTE MAXIMUM RATI NG

Symbol Parameter Value Unit

DC Supply Vol tage 41 V

V

CC

- V

- I

- I

I

V

E

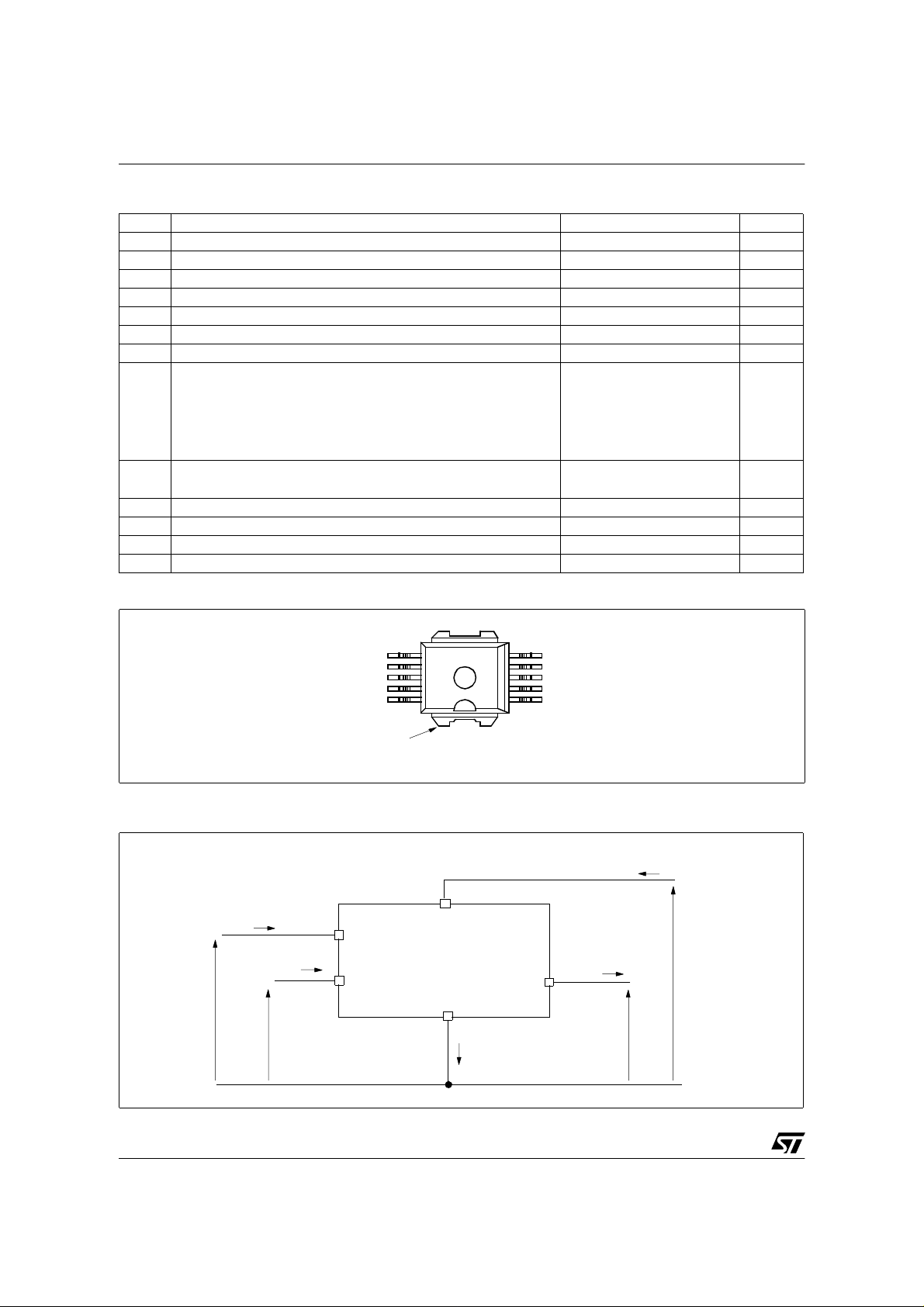

CONNECTION DIAGRAM (TOP VIEW)

Reverse DC Supply Voltage - 0.3 V

CC

DC Reverse Ground Pin Current - 200 mA

GND

DC Output Current Internally Limited A

I

OUT

Reverse DC Ou tput Current - 25 A

OUT

DC Input Curre nt +/- 10 mA

I

IN

DC Status Curr ent +/- 10 mA

STAT

Electro static Discharge (Human Body Model: R=1. 5KΩ; C=100pF)

- INPUT

- CURRENT SENSE

ESD

- OUTPUT

- V

CC

Maximum Switching Energy

MAX

(L=0.25mH; R

Power Diss ip ation TC=25°C 96.1 W

P

tot

Junction Operating Temperature Internally Limited °C

T

j

Case Oper ating Temperature - 40 to 150 °C

T

c

Storage Temperature - 55 to 150 °C

T

stg

=0Ω; V

L

=13.5V; T

bat

=150ºC; IL=45A)

jstart

4000

4000

5000

5000

362 mJ

V

V

V

V

GROUND

INPUT

STATUS

N.C.

N.C.

V

CURRENT AND VOLTAGE CONVENTIONS

I

IN

INPUT

I

STAT

STATUS

V

IN

V

STAT

6

7

8

9

10

11

CC

PowerSO-10™

V

CC

OUTPUT

GND

I

GND

5

4

3

2

1

OUTPUT

OUTPUT

N.C.

OUTPUT

OUTPUT

I

OUT

V

OUT

I

S

V

CC

2/17

1

VN920DSP

THERMAL DATA

Symbol Parameter Value Unit

CC

OV

ON

S

Thermal R esistance Junct ion-case Max 1.3 °C/W

Thermal Resistanc e Junctio n-ambient Max 51.3 (*) °C/W

Operating Supply Voltage 5.5 13 36 V

Undervolt age Shut-down 3 4 5.5 V

Undervolt age Shut-down

hysteresis

0.5 V

Overvolt age Shut-down 36 V

=10A; Tj=25°C

I

OUT

On State Resistance

I

=10A

OUT

I

=3A; VCC=6V

OUT

Off Stat e; V

Supply Current

Off Stat e; V

Tj=25°C

On State; V

Off State Output Current VIN=V

OUT

Off State Output Current VIN=0V; V

Off State Output Current VIN=V

Off State Output Current VIN=V

OUT

OUT

=13V; VIN=V

CC

=13V; VIN=V

CC

OUT

OUT

=0V

=0V;

10

10

=13V; VIN=5V; I

CC

OUT

=0A

=0V 0 50 µA

=3.5V -75 0 µA

OUT

=0V; VCC=13V; Tj =125°C 5 µ A

=0V; VCC=13V; Tj =25°C 3 µ A

16

30

50

25

20

5

R

thj-case

R

thj-amb

(*) When mounted on a standard single-sided FR-4 board with 0.5cm2 of Cu (at leas t 35µ m t hick) .

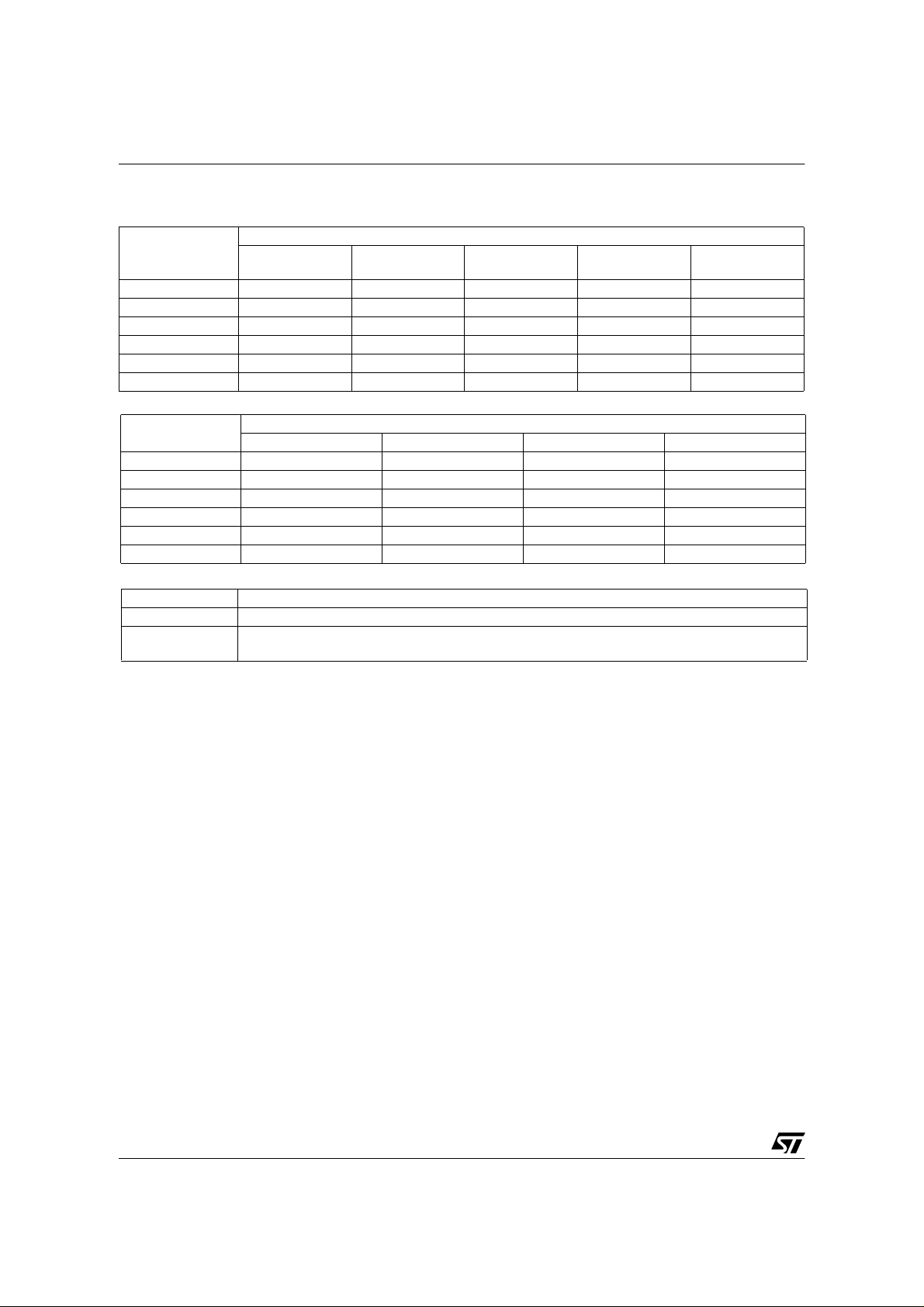

ELECTRICAL CHARACTERISTICS (8V<VCC<36V; -40°C<Tj<150°C unless otherwise specified)

POWER

Symbol Parameter Test Conditions Min Typ Max Unit

V

V

USD

V

USDhyst

V

R

I

I

L(off1)

I

L(off2)

I

L(off3)

I

L(off4)

mΩ

mΩ

mΩ

µA

µA

mA

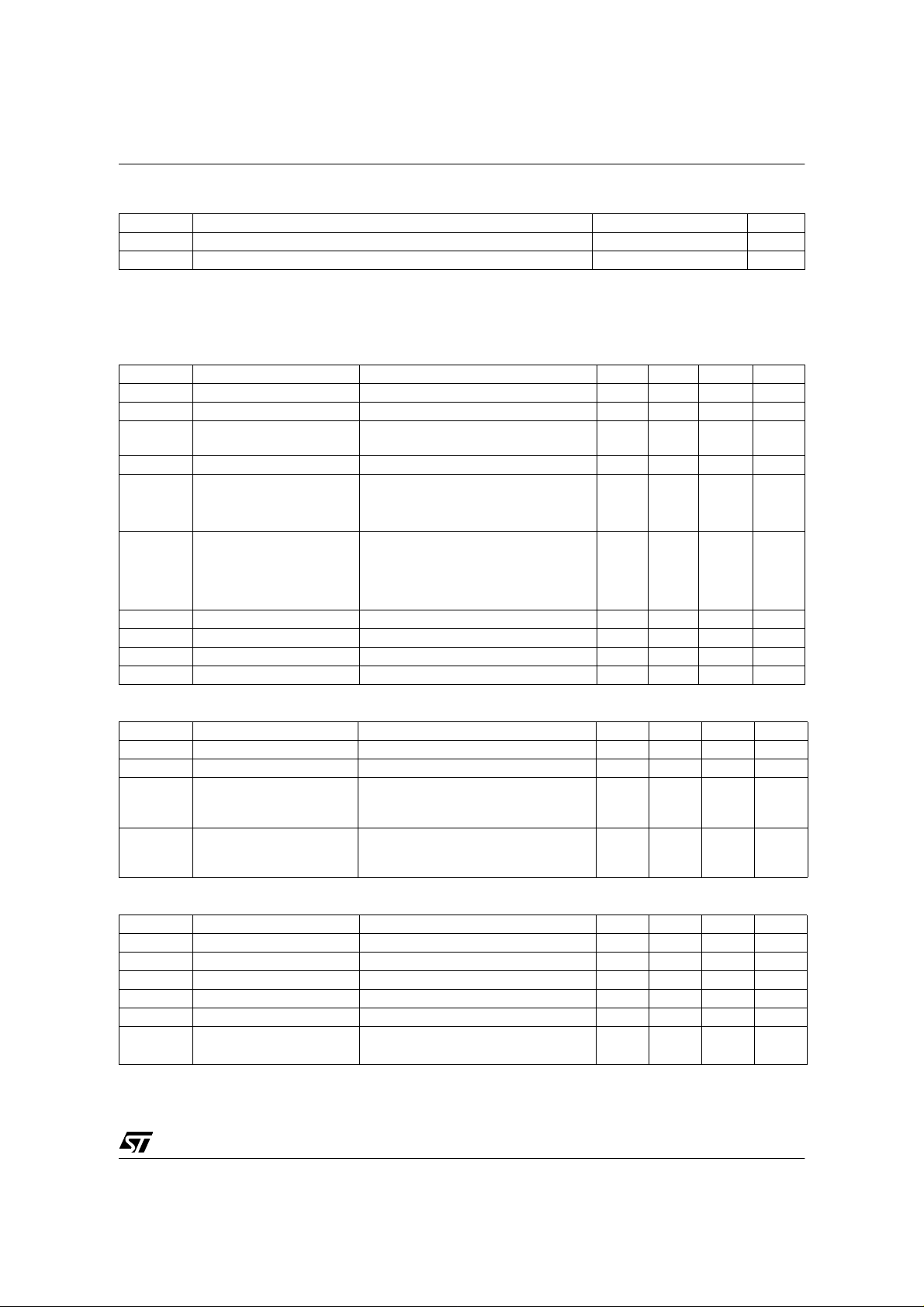

SWITCHING (VCC=13V)

Symbol Parameter Test Conditions Min Typ Max Unit

(on)

(off)

Turn-on Delay Time RL=1.3Ω 50 µs

Turn-off Delay Time RL=1.3Ω 50 µs

/

Turn-on Voltage Slope RL=1.3Ω

See

relative

diagram

/

Turn-off Voltage Slope RL=1.3Ω

See

relative

diagram

dV

dV

t

d(on)

t

d(off)

dt

dt

OUT

OUT

INPUT PIN

Symbol Parameter Test Conditions Min Typ Max Unit

IL

IL

IH

IH

ICL

Input Low Level 1.25 V

Low Level Input Current VIN=1.25V 1 µA

Input High Level 3.25 V

High Level Input Current VIN=3.25V 10 µA

Input Hyst eresis Vo ltage 0.5 V

I

Input Clamp Voltage

IN

I

IN

=1mA

=-1mA

66.8

-0.7

8V

V

I(hyst)

V

V

I

V

I

V/µs

V/µs

V

3/17

1

VN920DSP

ELECTRICAL CHARACTERISTICS (continued)

STATUS PIN

Symbol Parameter Test Conditions Min Typ Max Unit

V

STAT

I

LSTAT

C

STAT

V

SCL

Status Low Output Voltage I

Status Leakage Current Normal Operation V

Status Pin Input

Capacitance

Status Clamp Voltage

PROTECTIONS

Symbol Parameter Test Conditions Min Typ Max Unit

T

T

t

V

demag

TSD

T

hyst

SDL

I

lim

Shut-down Temperature 150 175 200 °C

Reset Temp erature 135 °C

R

Ther ma l Hy steresi s 7 15 °C

Statu s delay in overload

condition

Current limitation

Turn-off Output Clamp

Voltage

=1.6mA 0.5 V

STAT

Normal Operation V

=1mA

I

STAT

I

=-1mA

STAT

T

j>TTSD

=5V 10 µA

STAT

=5V 100 pF

STAT

66.8

-0.7

20 µs

30 45 75

5.5V<V

I

OUT

CC

<36V

75

=2A; VIN=0V; L= 6m H VCC-41 VCC-48 VCC-55 V

8V

V

A

A

OPENLOAD DETECTION

Symbol Parameter Test Conditions Min Typ Max Unit

OL

Openload ON State

Detectio n Threshol d

Openload ON State

Detection Delay

Openload OFF State

Voltage Det ection

Threshold

Openl o ad Detection De lay

at Turn Off

V

> V

OUT

t

DOL(off)

=5V 300 500 700 mA

V

IN

=0A 200 µs

I

OUT

V

=0V 1.5 2.5 3.5 V

IN

1000 µs

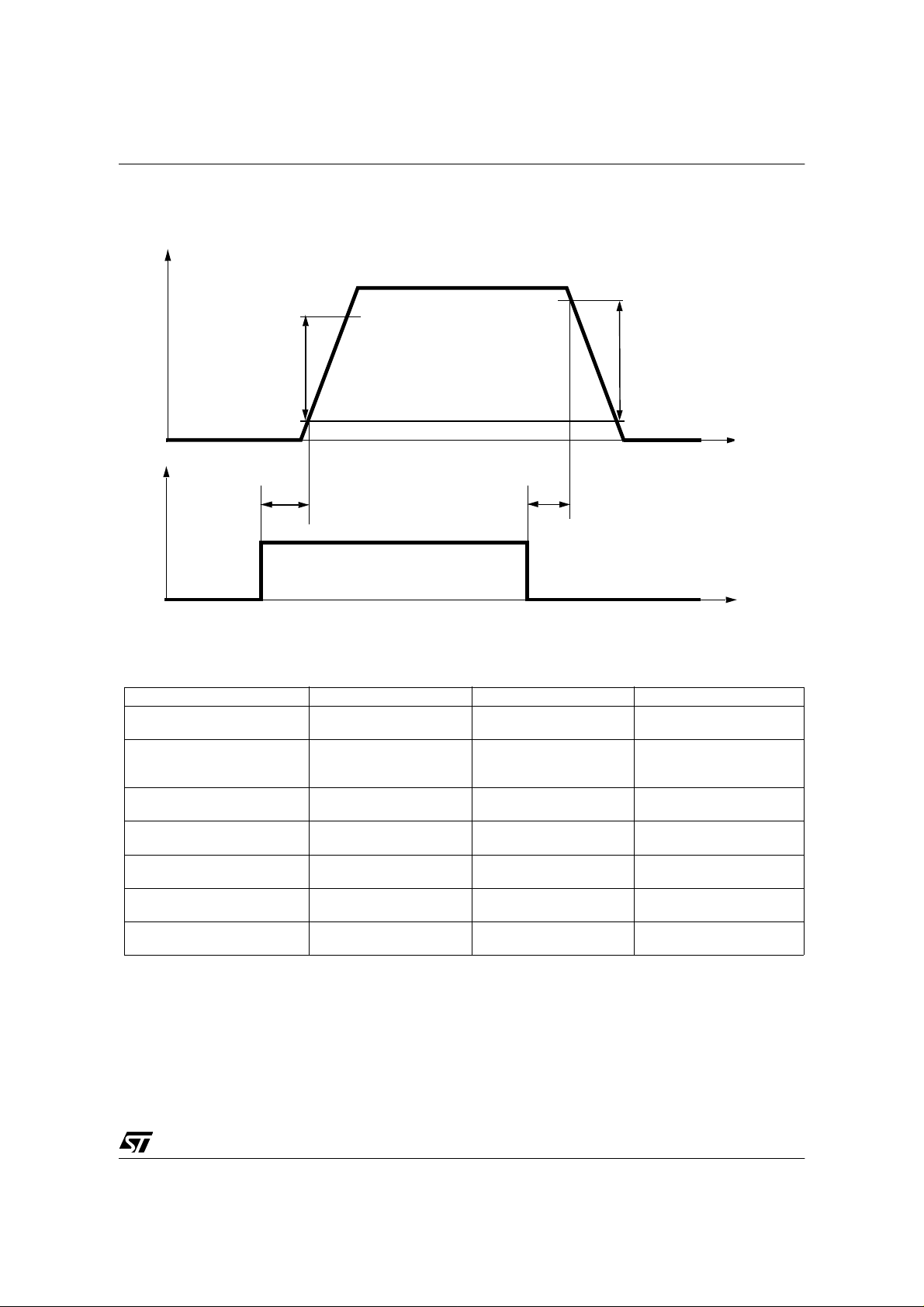

OVERTEMP STATUS TIMING

I

< I

OUT

t

DOL(on)

OL

V

V

IN

STAT

t

SDL

Tj > T

TSD

t

SDL

OL

I

OL

t

DOL(on)

V

t

DOL(off)

OPEN LOAD STATUS TIMING (with external pull-up)

V

IN

V

STAT

4/17

2

Switching time Waveforms

V

OUT

dV

/dt

OUT

(on)

V

IN

t

d(on)

80%

10%

t

d(off)

90%

dV

OUT

/dt

VN920DSP

(off)

t

t

TRUTH TABLE

CONDITIONS INPUT OUTPUT STATUS

Normal Operation

Cur rent Limitation

Overtemperature

Undervoltage

Overvoltage

Output Voltage > V

Output Current < I

OL

OL

L

H

L

H

H

L

H

L

H

L

H

L

H

L

H

L

H

L

X

X

< T

(T

j

> T

(T

j

L

L

L

L

L

L

H

H

L

H

TSD

TSD

H

H

H

) H

) L

H

L

X

X

H

H

L

H

H

L

5/17

VN920DSP

ELECTRICAL TRANSIENT REQUIREMENTS ON VCC PIN

ISO T/R 7637/1

Test Pulse

1 -25 V -50 V -75 V -100 V 2 m s 10 Ω

2 +25 V +50 V +75 V +100 V 0.2 ms 10 Ω

3a -25 V -50 V - 100 V -150 V 0.1 µs 50 Ω

3b +25 V +50 V +75 V +100 V 0.1 µs 50 Ω

4 -4 V -5 V -6 V -7 V 100 ms, 0.01

5 +26.5 V +46.5 V +66.5 V +86.5 V 400 ms, 2

ISO T/R 7637/1

Test P ulse

1CCCC

2CCCC

3aCCCC

3bCCCC

4CCCC

5CEEE

CLASS CONTENTS

C All functions of the devi ce are performed as designed after exposure to disturbance.

E One or more fu nctions of the device is not performed as designed after exposure to disturbance

and canno t be retur ned to proper opera tion without repla cing the device.

I II III IV Delays and

IIIIIIIV

TEST LEVELS

TEST LEVEL S RESULTS

Impedance

Ω

Ω

6/17

Figure1: Waveforms

INPUT

LOAD VOLTAGE

STATUS

V

CC

INPUT

LOAD VOLTAGE

STATUS

V

CC

INPUT

LOAD VOLTAGE

STATUS

NORMAL OPERATION

UNDERVOLTAGE

V

USD

OVERVOLTAGE

V

CC<VOV

V

USDhyst

undefined

VCC>V

VN920DSP

OV

INPUT

LOAD VOLTAGE

STATUS

INPUT

LOAD VOLTAGE

STATUS

T

j

INPUT

LOAD CURRENT

STATUS

OPEN LOAD wi th external pull-up

V

OUT>VOL

V

OL

OPEN LOAD without external pull-up

T

TSD

T

R

OVERTEMPERATURE

7/17

VN920DSP

APPLICATION SCHEMATIC

+5V

µ

R

C

R

prot

prot

+5V

STA T US

INPUT

GND PROTECTION NETWORK AGAINST

REVERSE BATTERY

Soluti on 1: Resistor in the ground line (R

can be us ed with any t ype of load.

The fo llowin g is an indica tion on how to dim ension the

resistor.

R

GND

1) R

2) R

where -I

be foun d in the abs olute max i mum rating se ct i on of the of

≤ 600mV / (I

GND

≥ (−VCC) / (-I

GND

is the DC re vers e grou nd pi n cu rren t an d can

GND

S(on)ma x

)

GND

).

the devic e’s datasheet.

Power Dissipation in R

battery situations) is:

= (-VCC)2/R

P

D

GND

(when VCC<0: during reverse

GND

This resistor can be shared amongst several different

HSD. Please note that the value of this resistor should be

calcul ated with form ula (1) wher e I

sum of the maximum on-state currents of the different

S(on)max

devices.

Please note that if the microprocessor ground is not

common with the device ground then the R

produce a shift (I

and the status output values. This shift will vary

S(on)max

* R

) in the input thresholds

GND

depending on many devices are ON in the case of several

high side drivers sharing the same R

GND

If the calculated power dissipation leads to a large resistor

or several devices hav e to share the sa me resisto r then

the ST suggest to utilize Solution 2 (see below) .

Solution 2:

A resistor (R

D

GND

A diode (D

=1kΩ) sh ould b e insert ed in paral lel to

GND

if the device will be driving an inductive load.

) in the gr ound line.

GND

only). This

GND

becomes t he

GND

.

will

V

CC

D

OUTPUT

GND

R

V

GND

GND

D

GND

This small signal diode can be safely shared amongst

several different HSD. Also in this case, the presence of

j

the ground network wi ll produce a shift (

600mV) in t he

input threshold and the status output values if the

microprocessor ground is not common with the device

ground. This shift will not vary if more than one HSD

shares the same diode/resi stor net w ork.

LOAD DUMP PROTECTION

Dld is necessary (Voltage Transient Suppressor) if the

load dump peak voltage exceeds VCC max DC rating. The

same applies if the device will be subject to transients on

the VCC line that are grea ter tha n the ones sh own in the

ISO T/R 7637/1 table.

C I/Os PROTECTION:

µ

If a ground protection network is used and negative

transient are p resent on the VCC line, the control pins will

be pulled negative. ST suggests to insert a resistor (R

in lin e to prevent the µC I/Os pins to latch-up.

The value of these resistors is a compromise between the

leakage c urrent of µC an d the current required by the

HSD I/Os ( Input le vels comp atibilit y) wi th the lat ch-up li mit

of µC I/Os.

≤ R

-V

CCpeak/Ilatchup

Calculation example:

CCpeak

prot

= - 100V an d I

≤ 65kΩ.

prot

For V

5kΩ ≤ R

Recommended R

≤ (V

prot

OHµC-VIH-VGND

≥ 20mA; V

latchup

value is 10kΩ.

) / I

OHµC

ld

IHmax

≥ 4.5V

prot

)

8/17

1

VN920DSP

Off State Output Current

IL(off1) (u A)

9

8

7

6

5

4

3

2

1

0

-50 -25 0 25 50 75 100 125 150 175

Tc (°C)

Input Clamp Voltage

Vicl (V)

8

7.8

7.6

7.4

7.2

7

6.8

6.6

6.4

6.2

6

Iin=1mA

-50 -25 0 25 50 75 100 125 150 175

Tc (°C)

High Level Input Current

Iih (uA)

5

4.5

3.5

2.5

1.5

0.5

Vin=3.25V

4

3

2

1

0

-50 -25 0 25 50 75 100 125 150 175

Input High Level

Vih (V)

3.6

3.4

3.2

3

2.8

2.6

2.4

2.2

2

-50 -25 0 25 50 75 100 125 150 175

Input Hysteresis VoltageInput Low Level

Tc (°C)

Tc (°C)

Vil (V)

2.6

2.4

2.2

2

1.8

1.6

1.4

1.2

1

-50 -25 0 25 50 75 100 125 150 175

Tc (°C)

Vhyst (V)

1.5

1.4

1.3

1.2

1.1

1

0.9

0.8

0.7

0.6

0.5

-50 -25 0 25 50 75 100 125 150 175

Tc (°C)

9/17

11

VN920DSP

Overvoltage Shutdown

I

LIM

Vs T

case

Vov (V)

50

48

46

44

42

40

38

36

34

32

30

-50 -25 0 25 50 75 100 125 150 175

Ilim (A)

100

90

80

70

60

50

40

30

20

10

Vcc=13 V

0

-50 -25 0 25 50 75 100 125 150 175

Tc (°C)

Turn-on Voltage Slope Turn-off Voltage Slope

dVout/dt(on) (V/ms)

700

650

600

550

500

450

400

350

300

250

-50 -25 0 25 50 75 100 125 150 175

Vcc=13V

Rl=1.3Ohm

Tc (ºC)

dVout/dt(off) (V/ms)

550

500

450

400

350

300

250

200

150

100

50

Vcc=13V

Rl=1.3Ohm

0

-50 -25 0 25 50 75 100 125 150 175

Tc (°C)

Tc (°C)

On State Resistance Vs T

case

Ron (mOhm)

50

45

40

35

30

25

20

15

10

5

0

-50 -25 0 25 50 75 100 125 150 175

Iout=10A

Vcc=8V; 36V

Tc (ºC)

10/17

On State Resistance Vs V

CC

Ron (mOhm)

50

45

40

35

30

25

20

15

10

5

0

5 10152025303540

Tc= 150ºC

Tc= 25ºC

Tc= - 40ºC

Vcc (V)

VN920DSP

Status Leakage Current

Ilstat(µA)

0.05

0.045

0.04

0.035

0.03

0.025

0.02

0.015

0.01

0.005

Vstat=5V

0

-50 -25 0 25 50 75 100 125 150 175

Tc (ºC )

Status Low Output Voltage

Vstat (V)

0.8

0.7

0.6

0.5

Istat=1.6mA

Status Clamp Voltage

Vscl (V)

8

7.8

7.6

7.4

7.2

6.8

6.6

6.4

6.2

Istat=1mA

7

6

-50 -25 0 25 50 75 100 125 150 175

Tc (ºC)

0.4

0.3

0.2

0.1

0

-50 -25 0 25 50 75 100 125 150 175

Tc (ºC)

11/17

VN920DSP

Maximum turn off current versus load inductance

LMAX (A)

I

100

A

B

10

C

1

0.1 1 10 100

L(mH)

A = Single Pulse at T

B= Repetitive pulse at T

C= Repetitive Pulse at T

Jstart

=150ºC

Jstart

Jstart

=100ºC

=125ºC

Conditions:

VCC=13.5V

Values are generated with RL=0Ω

In case of repetitive pulses, T

(at beginning of each demagnetization) of every pulse must not exceed

jstart

the temperature specified above for curves B and C.

VIN, I

L

Demagnetization

Demagnetization

Demagnetization

t

12/17

PowerSO-10™ PC Board

VN920DSP

PowerSO-10™ THERMAL DATA

R

thj-amb

Layout conditio n of Rth and Zth measurements (PCB FR4 area= 58mm x 58mm, PCB thickness=2mm,

Cu thickness=35µm, Copper areas: from minimum pad lay-out to 8cm

Vs PCB copper area in open box free air condition

2

).

RTHj_amb (°C/W)

55

Tj-Tamb=50°C

50

45

40

35

30

0246810

PCB Cu heatsink area (cm^2)

13/17

VN920DSP

PowerSO-10 Thermal Impedance Junction Ambient Single Pulse

ZTH (°C /W)

100

10

1

0.1

Footprint

2

6 cm

0.01

0.0001 0.001 0.01 0.1 1 10 100 1000

Time (s)

Thermal fitting model of a single channel HSD

in PowerSO-10

Tj

C1

R1 R2

Pd

C2

C3

R3

T_amb

C4

R4

C5

R5

C6

R6

Pulse calculation formula

Z

THδ

where

R

δ tpT⁄=

TH

δ Z

THtp

Thermal Parameter

Area/island (cm2) Footprint 6

R1 (°C/W) 0.02

R2 (°C/W) 0.1

R3( °C/W) 0.2

R4 (°C/W) 0.8

R5 (°C/W) 12

R6 (°C/W) 37 22

C1 (W.s/°C) 0.0015

C2 (W.s/°C) 7.00E-03

C3 (W.s/°C) 0.015

C4 (W.s/°C) 0.3

C5 (W.s/°C) 0.75

C6 (W.s/°C) 3 5

1 δ–()+⋅=

14/17

PowerSO-10™ MECHANICAL DATA

VN920DSP

DIM.

MIN. TYP MAX. MIN. TYP. MAX.

mm. inch

A 3.35 3.65 0.132 0.144

A (*) 3.4 3.6 0.134 0.142

A1 0.00 0.10 0.000 0.004

B 0.40 0.60 0.016 0.024

B (*) 0.37 0.53 0.014 0.021

C 0.35 0.55 0.013 0.022

C (*) 0.23 0.32 0.009 0.0126

D 9.40 9.60 0.370 0.378

D1 7.40 7.60 0.291 0.300

E 9.30 9.50 0.366 0.374

E2 7.20 7.60 0.283 300

E2 (*) 7.30 7.50 0.287 0.295

E4 5.90 6.10 0.232 0.240

E4 (*) 5.90 6.30 0.232 0.248

e 1.27 0.050

F 1.25 1.35 0.049 0.053

F (*) 1.20 1.40 0.047 0.055

H 13.80 14.40 0.543 0.567

H (*) 13.85 14.35 0.545 0.565

h 0.50 0.002

L 1.20 1.80 0.047 0.070

L (*) 0.80 1.10 0.031 0.043

α 0º 8º 0º 8º

α (*) 2º 8º 2º 8º

(*) Muar only POA P013P

HE

h

A

F

A1

10

1

eB

0.25

D

= =

D1

= =

E2

DETAIL "A"

DETAIL "A"

B

0.10 A

E

SEATING

PLANE

A

C

α

B

E4

SEATING

PLANE

A1

L

P095A

15/17

11

1

1

1

VN920DSP

PowerSO-10™ SUGGESTED PAD LAYOUT

14.6 - 14.9

10.8 - 11

6.30

0.67 - 0.73

1

2

3

9.5

4

5

10

0.54 - 0.6

9

8

7

1.27

6

TAPE AND REEL SHIPMENT (suffix “13TR”)

TUBE SHIPMENT (no suffix)

C

A

B

A

All dimensi ons ar e in mm.

Base Q.ty Bulk Q.ty Tube length (± 0.5) A B C (± 0.1)

Casablanca 50 1000 532 10.4 16.4 0.8

Muar 50 1000 532 4.9 17. 2 0.8

MUARCASABLANCA

B

REEL DIMENSIONS

Base Q.ty 600

Bulk Q.ty 600

A (max) 330

B (min) 1.5

C (± 0.2) 13

F 20.2

G (+ 2 / -0) 24.4

N (min) 60

T (max) 30.4

C

TAPE DIMENSIONS

According to Electronic Industries Association

(EIA) Standard 481 rev. A, Feb 1986

Tape width W 24

Tape Hole Spacing P0 (± 0.1) 4

Component Spacin g P 24

Hole Diameter D (± 0.1/-0) 1.5

Hole Diameter D1 (min) 1.5

Hole Position F (± 0.05) 11.5

Compartm ent Depth K (max) 6.5

Hole Spacing P1 (± 0.1) 2

All dimensions are in mm.

Top

cover

tape

End

500mm min

All dimensions are in mm.

Empty components pockets

saled with cover tape.

User direction of feed

500mm min

Start

No componentsNo components Components

16/17

1

1

1

VN920DSP

Information furnished is believed to be accurate and reliable. Ho wev er, STMicroelectr onics assumes no r es ponsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may results from its use. No license is

granted by implication or otherwise under any patent or patent r ights of STMicr oelectronics . Specifications mentioned in this publication are

subject to c hange withou t notice. This publicatio n s upersedes an d r eplaces all information p r ev iously supplied. STMic r oelectroni c s pr oducts

are not authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

Australia - Brazil - Canada - Ch ina - Finland - France - Germany - Hong K ong - India - Isra el - Italy - Japan - M alaysia -

Malta - Moro c c o - S ingapore - Spain - Sweden - Switz er land - United Kingdom - U.S.A.

The ST logo is a trademark of ST M ic r oelectronic s

2002 STMicroelectronics - Printed in ITALY- All Rights Reserved.

STMicroelectronics GROUP OF COMPANIES

http://www.st.com

17/17

Loading...

Loading...