Datasheet TSI62B1, TSI265B1, TSI200B1, TSI220B1, TSI180B1 Datasheet (SGS Thomson Microelectronics)

TSIxxB1

®

Telecom equipment requiring combin ed

protection against transient overvoltages and

rectification by diode bridge :

Telephone set

Base station for cordless s et

Fax machine

Modem

Caller Id equipment

Set top box

MAIN APPLICATION

SO8

The TSIxxB1 provides the diode bridge and the

crowbar protection function that can be found in

most of telecom terminal equipment.

Integrated monolithically within a SO8 package,

this ASD device allows space saving on the

board and greater reliability.

DESCRIPTION

CCITT K17 - K20

10/700µs 1.5 kV

5/310µs 38A

VDE 0433

10/700µs2 kV

5/310µs 40A(*)

CNET

0.5/700µs 1.5 kV

0.2/310µs 38A

Bellcore

TR-NWT-000974

: 10/1000µs1 kV

10/1000µs 30A(*)

FCC Part 68

2/10µs 2.5 kV

2/10µs 75A (*)

MIL STD883C Method 3015-6

(*) with series resistor or PTC.

IN ACCORDANCE WITH THE FOLLOWING

STANDARDS :

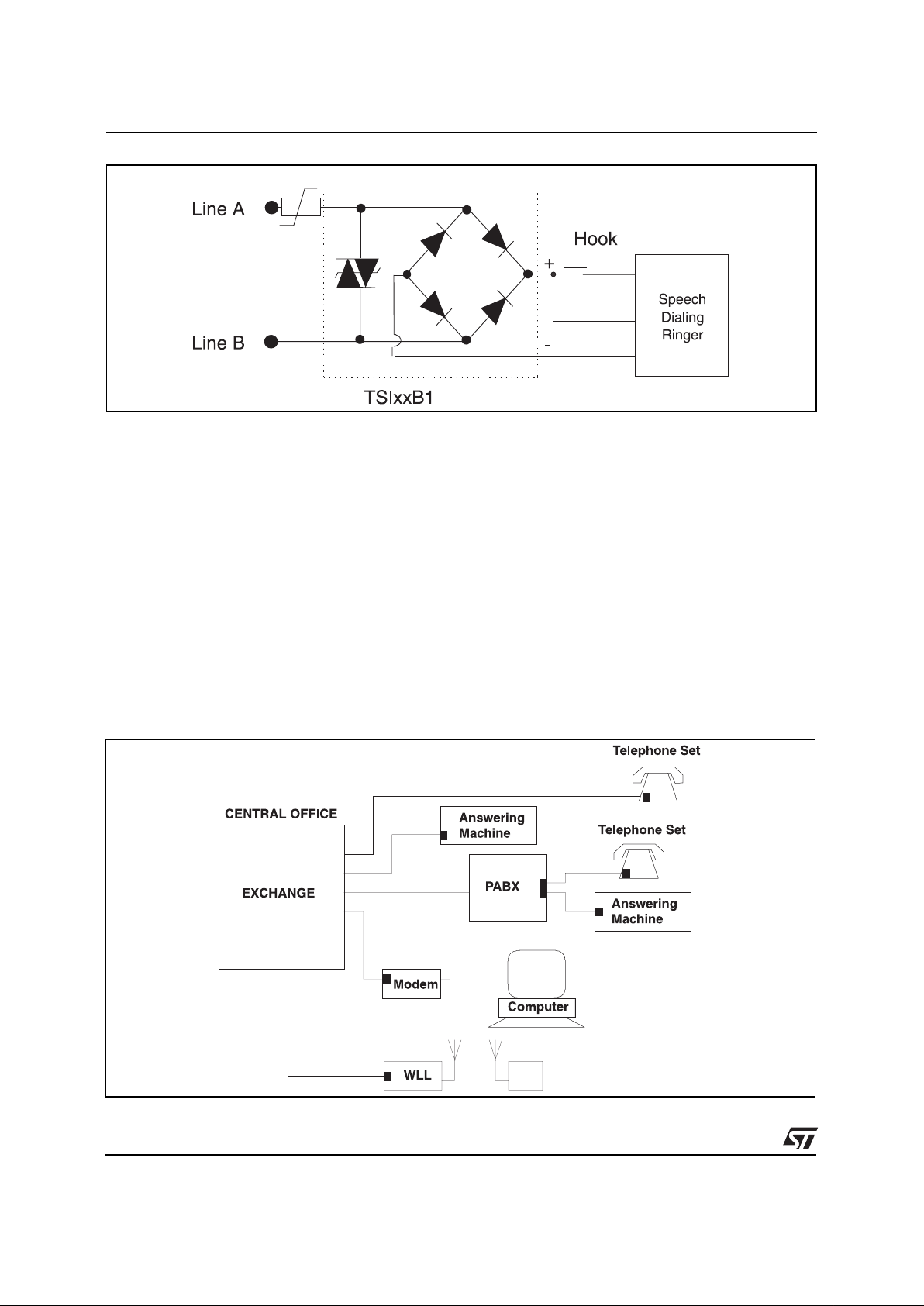

SCHEMATIC DIAGRAM

TERMINAL SET INTERFACE

PROTECTION AND DIODE BRIDGE

January 1998 - Ed: 3

Diode bridge for polarity guard and crowbar

protection within one device.

Single chip for greater reliability

Reduces component count versus discrete

solution

Saves space on the board

BENEFITS

STAND-OFF VOLTAGE FROM 62V TO 265V

PEAK PULSE CURRENT : 30 A (10/1000 µs)

MAXIMUM DC CURRENT : IF = 0.2 A

HOLDING CURRENT :150 mA

FEATURES

Application Specific Discretes

A.S.D.

TM: ASD is trademarks of SGS-THOMSON Microelectronics.

2

3

1

4

7

6

8

5

1/9

PTC

TYPICAL APPLICATION

Telecom terminals have a diode bridge for polarity

guard, located at the line interface stage. They also

have above this diode bridge one crowbar

protection device that is mandatory to prevent

atmospheric effects and AC mains disturbances

from damaging the electronic circuitry that follows

the diode bridge.

SGS-THOMSON proposes a one chip device that

includes both protection and diode bridge. This is

the concept of the T SIxxB1 dev ices.

Fig. 1 : The various uses of the TSIxxB1 in a conventional telecom network

TSIxxB1

2/9

The VRM value corresponds to the maximum

voltage of the application in normal operation. For

instance, if the maximum line voltage is ranging

between ±100V

RMS

of ringing plus 48V of battery

voltage, then the protection chosen for this application shall have a V

RM

close to 200V.

The V

BO

is the triggering voltage. This indicates the

voltage limit for which the component

short-circuits. Passing this V

BO

makes the device

turn on.

The I

BO

is the current that makes the device t urn

on. Indeed, if we want a Trisil to be turned on not

only the voltage across it shall pass the V

BO

value

but the current through it shall also pass the I

BO

value.

In other words, if a voltage surge occurring on the

line is higher than the V

BO

value of a Trisil, whereas

the line surge current is limited to a value that does

not exceed the Trisil’s I

BO

value, then the Trisil will

never turn into short circuit. At this time the surge

will be

clamped by the Trisil.

Anyhow the electronic circuitry located after the

Trisil will always be protected whatever the Trisil

state is (crowbar or clamping mode).

The I

H

stands for the holding current. When the

Trisil is turned on, as soon as the crossing current

surge gets lower than this I

H

value, the Trisil

protection device turns back in its idle state.

Remark : for this r eason the Trisil ’s IH value shall

be chosen higher than what the maximum t elecom

line current can be.

TSIxxB1 BEHAVIOUR WITH REGARD TO

SURGE STANDARD :

The TSIxxB1 is able to replac e both diode bridge

and usual discrete protection on telecom

terminals. Furthermore it complies with the CCITT

K17 recommendations :

10/700 µs waveform surge test, ± 1.5kV

AC power induction test

AC power contact test

ELECTR ICAL PAR AME TERS

Ω

Fig. 2 : Test circuit for the CCITT K17 recommendations

TSIxxB1

3/9

This test concerns the 10/700 µs waveform surge,

± 1.5 kV.

The surge generator used for the test has the

following circuitry (fig.2).

TEST # 1

LIGHTNING SIMULATION

Ω

Ω

Ω

Fig. 2 : 10/700 µs waveform surge generator circuit

The behaviour of the TSI200B1 to this lightning surge is given below (fig. 3).

Fig. 3 : Voltage across the TSI200B1 at the + and - terminations and current throught it

for a 1.5 kV positive surge (fig.3a) and negative surge (fig. 3b)

These curves show the peak voltage the surge

generates across the TSI200B1 + and terminations. This lasts a short time (≈ 2 µs) and

after, as the internal protection gehaves like a short

circuit. The voltage drop across the TSIxxB1

becomes a few volts. In the meanwhile all the

surge current flows in the protection.

As far as the 10/700 µs waveform surge test is

concerned,the TSIxxB1 withstand the ± 1.5 kV

test.

TSIxxB1

4/9

This test simulates the induction phenomena that

can happen between telecom lines and AC mains

lines (fig. 4).

TEST # 2

AC POWE R INDUCTION TEST

Fig. 4 : AC power induction test circuit

Part #1

test conditions : V

RMS

= 240 V

R = 600 Ω

t = 0.2 s

Part #2

test conditions : V

RMS

= 600 V

R = 600 Ω

t = 0.2 s

Fig. 5 : Voltage at the + and - terminations of the

TSI200B1, and current through it

while test part 1 is applied.

The TSIxxB1 withstand the AC power induction

test in both cases.

This test simulates the direct contact between the

telecom lines and the AC mains lines.

The AC power contact test consists in applying

240V

RMS

through a 10Ω PTC during 15 minutes

long on the device under test. The CCITT K17

recommendation specifies an internal generator

impedance allowing 10 A

RMS

when in short circuit.

The behavior of the TSI200B1 with respect to this

surge is given in figure 6.

TEST #3

AC POWER CONTACT TEST

Fig. 6 : Voltage at the TSI200B1 + & - terminations

and the current through it.

The figure 6 shows that after 250ms there is no

current anymore flowing through the TSI200B1

device. This is due to the action of the serial PTC

that limits the current through the line. This PTC is

mandatory for this test. It can also be replaced by a

fuse or any other serial protection that "opens" the

line loop under AC contact test.

TSIxxB1

5/9

Symbol Parameter Value Unit

I

PP

Non repetitive peak on-sate current (see note 1)

10/1000 µs (open circuit voltage wave shape 10/100 µs)

5/310 µs (open circuit voltage wave shape 10/700 µs)

2/10 µs (open circuit voltage wave shape 2/10 µs)

30

40

75

A

I

F

Maximu m DC cur rent

0.2 A

I

TSM

Non repetitive surge peak on-state current tp = 20 ms

t = 1s

5

3.5

A

T

stg

T

j

Storage temperature range

Maximum junction temperature

- 55 to +150

150

°C

T

L

Maximum lead temperature for soldering during 10 s 260 ° C

ABSOL UTE M AXIMU M RA TIN GS (T

amb

= 25°C)

Note 1 :

Pulse wa vef orm :

10/1000µstr=10µst

p

=1000µs

5/310µst

r

=5µst

p

=310µs

2/10µst

r

=2µst

p

=10µs

100

50

%I

PP

t

t

r

p

0

t

Symbol Parameter Value Unit

R

th(j -a )

Junction to ambient 170 °C/ W

THERMAL RE SISTA NC E

Symbol Parameter

V

RM

Stand-off voltage

V

BO

Breakover voltage

V

BR

Breakdown voltage

I

H

Holding current

I

BO

Breakover current

I

RM

Leakage current at V

RM

I

PP

Peak pulse current

C Capacitance

αT Temperature coefficient

ELECTRICAL CHARACTERI STICS (T

amb

=25°C )

V

I

V

RM

BO

V

RM

I

H

I

BO

PP

I

I

TSIxxB1

6/9

Type

I

RM

@ V

RM

VBO @ I

BO

I

H

I

BO

C

note1 note2 note1 note3

µAV V mA mAmApF

max. max. min. min. max. typ.

TSI6 2B 1

1

5

50

62

90 150 50 400 200

TSI180B1

1

5

50

180

250 150 50 400 200

TSI200B1

1

5

50

200

290 150 50 400 200

TSI220B1

1

5

50

220

330 150 50 400 200

TSI265B1

1

5

50

265

380 150 50 400 200

Note 1 :

Measured at 50 Hz, one cycle

Note 2 :

See test cricuit

Note 3 :

VR = 0V, F = 1MHz, between pins 1 and 8.

ELECTRICAL CHARACTERI STICS (T

amb

= 25 °C)

1 - PROTECTION DEVICES PARAMETERS

Symbol Test condition Value Unit

V

F

(for one diode)

I

F

= 20 mA

I

F

= 100 mA

0.9

1.1

V

V

2 - DIODE BRIDGE PARAMETERS

FUNCTIONAL HOLDING CURRENT (IH) TEST CIRCUIT : GO - NO GO TEST

This is a GO-NOGO Test which allows to confirm the holding current (I

H

) level in a functional

test ci rc u it.

TEST PROCEDURE :

1) Adjust the current level at the IH value by short circuiting the D.U.T.

2) Fire the D.U.T with a surge Current : Ipp = 10A , 10/1000 µs.

3) The D.U.T will come back off-state within a duration of 50 ms max.

R

-V

P

V

BAT

=-48V

Surge generator

D.U.T.

TSIxxB1

7/9

Type Marking

TSI62B1 TSI62

TSI180B1 TSI180

TSI200B1 TSI200

TSI220B1 TSI220

TSI265B1 TSI265

MARKING

ORDER CODE

RL = tape& reel ( 2500 pc s) .

= tube (100 pcs).

SO8 Package

TSI

265

B

1

RL

V

BR min.

Terminal

Set

Interface

TSIxxB1

8/9

Packagin g : prod uct su pplie d in tap e and ree l or anti stat ic tube s.

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the conseq ue nces o f

use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted by

implication or otherw ise under any pa tent or patent ri ghts of STMi croelec tronics. Spec ifications mentione d in this pub lication are su bject to

change without notice. This publication supersedes and replaces all information previously supplied.

STMicroelectr oni cs products are n ot au thorized for use as critical components in life support devi ces or systems wi t hout express written approval of STMicroelectronics.

© 1998 STMicroelectronics - Printed in Italy - All rights reserved.

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China - France - Germany - Italy - Japan - Korea - Malaysia - Malta - Mexico - Morocco - The

Netherlands - Singapore - Spain - Sweden - Switzerland - Taiwan - Thailand - United Kingdom - U.S.A.

PACKAGE MECHANICAL DAT A

SO8

REF. DIMENSIONS

Millimetres Inches

Min. Typ. Max. Min. Typ. Max.

A 1.75 0.069

a1 0.1 0.25 0.004 0.010

a2 1.65 0.065

b 0.35 0.48 0.014 0.019

b1 0.19 0.25 0.007 0.010

C 0.50 0.020

c1 45° (typ )

D 4.8 5.0 0.189 0.197

E 5.8 6.2 0.228 0.244

e 1.27 0.050

e3 3.81 0.150

F 3.8 4.0 0.15 0.157

TSIxxB1

9/9

Loading...

Loading...