INTEGRATED CIRCUITS

DATA SH EET

TDA3602

Multiple output voltage regulator

Product specification

File under Integrated Circuits, IC01

July 1994

Philips Semiconductors Product specification

Multiple output voltage regulator TDA3602

FEATURES

• Two VP state controlled regulators (REG1 and REG2)

• Regulator 3 operates during load dump or thermal

shutdown

• Multi-function control pin

• A back-up circuit for Regulator 3 via a single capacitor

• Supply voltage of −6 V to 50 V (a voltage of −3 V on V

does not discharge capacitor Cbu)

• Low reverse current Regulator 3

• Low quiescent current in coma mode

• HOLD output

• RESET output (LOW at load dump)

• High ripple rejection.

PROTECTIONS

• Foldback current limit protection (Regulators 1 and 2)

• Load dump protection

• Thermal protection

• DC short-circuit safe to ground and V

of all regulator

P

outputs

• Reverse polarity safe of pin 1 (VP). No high currents are

flowing which can damage the IC

• Capable of handling high energy on the regulator

outputs.

GENERAL DESCRIPTION

The TDA3602 is a multiple output voltage regulator,

intended for use in car radios with or without a

microprocessor. It contains two fixed voltage regulators

with foldback current protection (Regulators 1 and 2), and

one fixed voltage regulator that also operates during load

dump and thermal shutdown. This regulator can be used

to supply a microprocessor.

P

A back-up circuit supplies Regulator 3 during a short

period after the power is cut off (negative field decay or

engine start procedure). A state control pin (pin 4) controls

the device, which can be switched through four stages

using the information at this pin. The switching levels at

this pin contain hysteresis.

RESET and HOLD outputs can be used to interface with a

microprocessor. The RESET signal can be used to call up

or initialize a microprocessor (power-on reset). The HOLD

signal can be used to control the power stages (mute

signal in a low end application), or to generate a HOLD

interrupt (microprocessor application).

An internal Zener diode on the back-up pin allows this pin

to withstand a load dump when supplied by the pin using a

100 Ω series resistor.

The supply pin can withstand load dump pulses and

negative supply voltages.

July 1994 2

Philips Semiconductors Product specification

Multiple output voltage regulator TDA3602

QUICK REFERENCE DATA

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supply

V

P

I

P

T

vj

Voltage regulators

V

R1

V

R2

V

R3

positive supply voltage

operating 9.2 14.4 18 V

Regulator 3 on 6.0 14.4 18 V

jump start −−30 V

load dump; Regulator 3 on −−50 V

operating note 1 6.5 − 30 V

load dump; Regulator 3 on note 1 −−50 V

total quiescent current coma mode − 290 −µA

virtual junction temperature −−150 °C

output voltage Regulator 1 0.5 mA ≤ IR1≤ 250 mA 8.2 8.5 8.8 V

output voltage Regulator 2 0.5 mA ≤ IR2≤ 140 mA 4.8 5.0 5.2 V

output voltage Regulator 3 0.5 mA ≤ IR3≤ 50 mA 4.8 5 5.2 V

Note

1. Vbu (pin 8) supplied by VP2 with a 100 Ω series resistor and I

ORDERING INFORMATION

EXTENDED TYPE

NUMBER

TDA3602

(1)

PINS PIN POSITION MATERIAL CODE

9 SIL plastic SOT110

Note

1. SOT110-1; 1996 August 21.

REG3

PACKAGE

< 10 mA.

July 1994 3

Philips Semiconductors Product specification

Multiple output voltage regulator TDA3602

handbook, full pagewidth

2

TDA3602

REG1

V 8.5 V

REGULATOR 1

&

REG2

V 5 V

9

REGULATOR 2

Q

REG3

V 5 V

7

REGULATOR 3

RS

hold

5

&

CONTROL

HOLD CIRCUIT

reset

3

MCD346 - 1

6

ground

Fig.1 Block diagram.

P

V

1

P

V

SCHMITT

TRIGGER

POLARITY

bu

LOADDUMP /

PROTECTION

V REVERSE

July 1994 4

bu

V

SCHMITT

TRIGGER

8

bu

V

(back up)

5 V switched

bu

V

Zener

(21 V)

> 2 V

sc

V

R1,R2 on

STATE

4

V

L / H current

reset

CIRCUIT

CONTROL

sc

(state control)

Philips Semiconductors Product specification

Multiple output voltage regulator TDA3602

PINNING

SYMBOL PIN DESCRIPTION

V

P

1 positive supply voltage

REG1 2 Regulator 1 output

RESET 3 reset output

V

sc

4 state control input

HOLD 5 hold output

GND 6 ground

REG3 7 Regulator 3 output

V

bu

8 back-up

REG2 9 Regulator 2 output

handbook, halfpage

V

1

P

2

REG1

RESET

V

HOLD

GND

REG3

V

bu

REG2

3

4

sc

TDA3602

5

6

7

8

9

MCD345

Fig.2 Pin configuration.

FUNCTIONAL DESCRIPTION

This multiple output voltage regulator contains three fixed

voltage regulators, numbered 1, 2 and 3. Two of these can

be switched between the on and off states using the state

control pin (pin 4). The third (Regulator 3), which is

continuously in, can be switched by the state control pin

between a low and a high current mode.

In addition to Regulators 1 and 2, the device is supplied by

an internal switch that is open when the supply voltage

falls below the back-up voltage (negative field decay or

engine start procedure), or during a load dump. (During

this load dump, Regulators 1 and 2 are switched off and

RESET is switched LOW). This switched supply voltage

(the so-called back-up voltage (Vbu), is available at pin 8.

An electrolytic capacitor can be connected to this pin, and

the charge on this capacitor can be used to supply the

device for a short period after the supply voltage is

removed.

Three pins are provided for interfacing with a

microprocessor:

• state control pin

• hold output pin

• reset output pin.

When the supply voltage (VP) is connected to the device,

Vbu will rise. When Vbu reaches 7.9 V, the device is in the

power-on mode. The RESET output goes HIGH and

Regulator 3 is switched on. In a microprocessor

application, the RESET output can be used to call up the

CPU and to initialize the program.

What follows depends on the voltage at the state control

pin (V

). In most applications, when the supply voltage is

sc

connected, Vsc will rise slowly (e.g. by charging a

capacitor).The device will leave the power-on mode and

enter the reset mode when Vsc rises above 2.2 V. In both

the power-on and reset modes, Regulator 3 will be in the

high current mode, Regulators 1 and 2 will be switched off

and the RESET output will be HIGH.

The device will enter the wake mode when Vsc reaches 2.8

V. The RESET pin will go LOW and the CPU must be

switched to the sleep mode. Regulator 3 is still in the high

current mode.

As Vsc continues rising and the voltage reaches 3.6 V, the

stabilizer will be switched into the sleep mode. It will be in

a coma mode when Vsc is greater than 3.8 V. In this mode,

only the relevant circuits remain operating; this is to keep

the power consumption as low as possible i.e. typically 290

µA.

If the device is switched on with Vsc already higher than 3.8

V, the device will be switched directly from the power-on

mode into the coma mode.

When Vsc is lowered gradually from 3.6 V (or higher) to 2

V, the device will go from sleep to reset again.

Vsc must be lower than 1.1 V to bring the device into the on

mode; note that this is not the same as the power-on

mode. In this condition, Regulator 3 is in the high current

mode, both Regulators 1 and 2 are switched on and the

HOLD output will be HIGH (depending on the state of V

and the in-regulation condition of Regulators 1 and 2).

P

July 1994 5

Philips Semiconductors Product specification

Multiple output voltage regulator TDA3602

When the device is in the on mode, it will switch back to the reset mode when Vsc rises to 2 V, or when the supply voltage

drops below 7.3 V.

When V

drops below 3 V, the device will return to the power off mode, regardless of the condition the device was in.

REG3

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 134).

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

P

supply voltage

operating − 18 V

jump start t ≤ 10 min − 30 V

load dump t ≤ 50 ms; t

Regulator 3 on V

> −3 V; note 1 − 30 V

P

load dump t ≤50 ms; t

≥ 2.5 ms − 50 V

r

≥ 2.5 ms; note 1 − 50 V

r

reverse battery voltage −6 − V

T

stg

T

vj

V

pr

P

tot

storage temperature non-operating −55 +150 °C

virtual junction temperature operating −40 +150 °C

reverse polarity non-operating − 6V

total power dissipation − 15 W

Note

1. V

(pin 8) supplied by VP2 with a 100 Ω series resistor and I

bu

REG3

< 10 mA.

THERMAL RESISTANCE

SYMBOL PARAMETER THERMAL RESISTANCE

R

R

th j-a

th j-c

from junction to ambient in free air 50 K/W

from junction to case (see Fig.6) 12 K/W

CHARACTERISTICS

= 14.4 V; T

V

P

= 25 °C; measured in Fig.6; unless otherwise specified.

amb

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supply

V

P

supply voltage

operating 9.2 14.4 18 V

Regulator 3 on note 1 6.0 14.4 18 V

jump start t ≤ 10 min −− 30 V

load dump t ≤ 50 ms; t

I

P

quiescent current Vsc > 4V; note 2

= 12.4 V − 280 360 µA

V

P

= 14.4 V − 290 −µA

V

P

≥ 2.5 ms −− 50 V

r

July 1994 6

Philips Semiconductors Product specification

Multiple output voltage regulator TDA3602

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Schmitt triggers

VP2SCHMITT TRIGGER (FOR HOLD AND REGULATORS 1 AND 2)

V

thr

V

thf

V

hy

REGULATOR 1SCHMITT TRIGGER (FOR HOLD)

V

thr

V

thf

V

hy

REGULATOR 2SCHMITT TRIGGER (FOR HOLD)

V

thr

V

thf

V

hy

VBU SCHMITT TRIGGER (REGULATOR 3)

V

thr

V

thf

V

hy

State control pin

V

th

V

thr1

V

thf1

V

hy1

V

thr2

V

thf2

V

hy2

V

thr3

V

thf3

V

hy3

I

scl

rising voltage threshold 7.3 7.6 8.0 V

falling voltage threshold 6.8 7.1 7.5 V

hysteresis − 0.5 − V

rising voltage threshold − VR1 − 0.2 − V

falling voltage threshold − VR1 − 0.3 − V

hysteresis − 0.1 − V

rising voltage threshold − VR2 − 0.2 − V

falling voltage threshold − VR2 − 0.3 − V

hysteresis − 0.1 − V

rising voltage threshold V

falling voltage threshold V

bu

REG3

7.3 7.9 8.4 V

2.5 3 3.5 V

hysteresis − 4.9 − V

voltage threshold between note 2 − V

+ 0.2 − V

thr1

sleep and coma

voltage threshold wake to 3.35 3.6 3.85 V

sleep

voltage threshold sleep to 2.5 2.7 2.9 V

wake

hysteresis wake/sleep 0.85 0.92 1.0 V

voltage threshold reset to 2.6 2.8 3.0 V

wake

] voltage threshold wake to 1.75 1.9 2.05 V

reset

hysteresis reset/wake 0.85 0.92 1.0 V

voltage threshold on to reset 1.85 2.0 2.15 V

voltage threshold reset to on 1.0 1.1 1.2 V

hysteresis on/reset 0.85 0.92 1.0 V

input current

≤ 0.8 V −− −1µA

V

sc

≥ 4 V −− 1µA

V

sc

July 1994 7

Philips Semiconductors Product specification

Multiple output voltage regulator TDA3602

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Reset output

V

OL

V

OH

I

OL

I

OH

Hold output

V

OL

V

OH

I

OL

I

OH

Regulator 1 (I

V

REG1

V

REG1

∆V

REG1

∆V

REGL1

SVRR1 supply voltage ripple rejection f = 200 Hz;2 V (p-p) 60 −−dB

V

REGd1

I

REGm1

I

REGsc1

Regulator 2 (I

V

REG2

V

REG2

∆V

REG2

∆V

REGL2

SVRR2 supply voltage ripple rejection f = 200 Hz; 2 V (p-p) 60 −−dB

V

REGd2

I

REGm2

I

REGsc2

LOW level output voltage IOL = 0 0 0.2 0.8 V

HIGH level output voltage 2.0 5.0 5.25 V

LOW level output current VOL ≤ 0.8 V 0.3 0.8 − mA

HIGH level output current VOH > 3 V −0.3 −2.0 − mA

LOW level output voltage IOL = 0 0 0.2 0.8 V

HIGH level output voltage 2.0 5.0 5.25 V

LOW level output current VOL ≤ 0.8 V; note 3 0.3 1.0 − mA

HIGH level output current VOH > 3 V −1.5 −9.0 − mA

= 5 mA unless otherwise specified)

REG1

output voltage off Vsc > 2.1 V − 1 400 mV

output voltage

0.5 V ≤ I

10 V ≤ V

≤ 250 mA 8.2 8.5 8.8 V

REG1

≤ 18 V 8.2 8.5 8.8 V

P

line regulation 10 V ≤ VP ≤ 18 V −− 50 mV

load regulation 0.5 mA ≤ I

drop-out voltage I

current limit V

= 250 mA −− 0.4 V

REG1

> 7 V; note 4 0.4 − 1.2 A

REG1

≤ 250 mA −− 50 mV

REG1

short-circuit current RL ≤ 0.5 Ω; note 4 − 250 − mA

= 10 mA unless otherwise specified)

REG2

output voltage off Vsc >2.1 V − 1 400 mV

output voltage

0.5 V ≤ I

8 V ≤ V

≤ 140 mA 4.8 5.0 5.2 V

REG2

≤ 18 V 4.8 5.0 5.2 V

P

line regulation 8 V ≤ VP ≤ 18 V −− 50 mV

load regulation 0.5 mA ≤ I

drop-out voltage I

current limit V

= 140 mA − 1.2 − V

REG2

> 4.5 V; note 4 200 − 600 mA

REG2

≤ 140 mA −− 50 mV

REG2

short-circuit current RL ≤ 0.5 Ω; note 4 − 130 − mA

July 1994 8

Philips Semiconductors Product specification

Multiple output voltage regulator TDA3602

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Regulator 3 (I

V

∆V

REG3

REGL3

output voltage

output voltage sleep mode; I

= 5 mA unless otherwise specified)

REG3

0.5 mA ≤ I

7 V ≤ V

18 ≤ V

≤ 50 mA 4.8 5.0 5.2 V

REG3

≤ 18 V 4.8 5.0 5.2 V

P

≤ 50 V 4.8 5.0 5.2 V

P

≤ 10 mA; 4.5 5.0 5.5 V

REG3

note 2

I

LO1

∆V

REG3

∆V

REGL3

leakage output current VP = 0; Vbu = 6 V; V

line regulation 7 V ≤ VP ≤ 18 V −− 50 mV

load regulation 0.5 mA ≤ I

≤ 50 mA −− 50 mV

REG3

= 6 V −− −1µA

REG3

SVRR3 supply voltage ripple rejection f = 200 Hz; 2 V (p-p) 60 −−dB

V

REGd3

I

REGm3

drop-out voltage I

current limit V

= 50 mA; note 5 −− 0.4 V

REG3

> 4.5 V; note 6 140 − 500 mA

REG3

Switch

V

I

swm

swd

drop-out voltage Isw = 50 mA −− 0.45 V

maximum current 140 −−mA

Notes

1. Minimum operating voltage only if VP has exceeded 8 V.

2. In the sleep mode, Regulators 1 and 2 are off. In the coma mode, the state control circuit is also switched off, to make

the quiescent current as low as possible.

3. Hold circuit can sink this current in the RESET state and the ON state.

4. The foldback current protection limits the dissipated power at short-circuit (see Fig.5).

5. The drop-out voltage of Regulator 3 is measured between Vbu and V

6. At current limit, I

is held constant (behaviour in accordance with the broken line in Fig.5).

REGm

(pins 8 and 7).

REG3

July 1994 9

Philips Semiconductors Product specification

Multiple output voltage regulator TDA3602

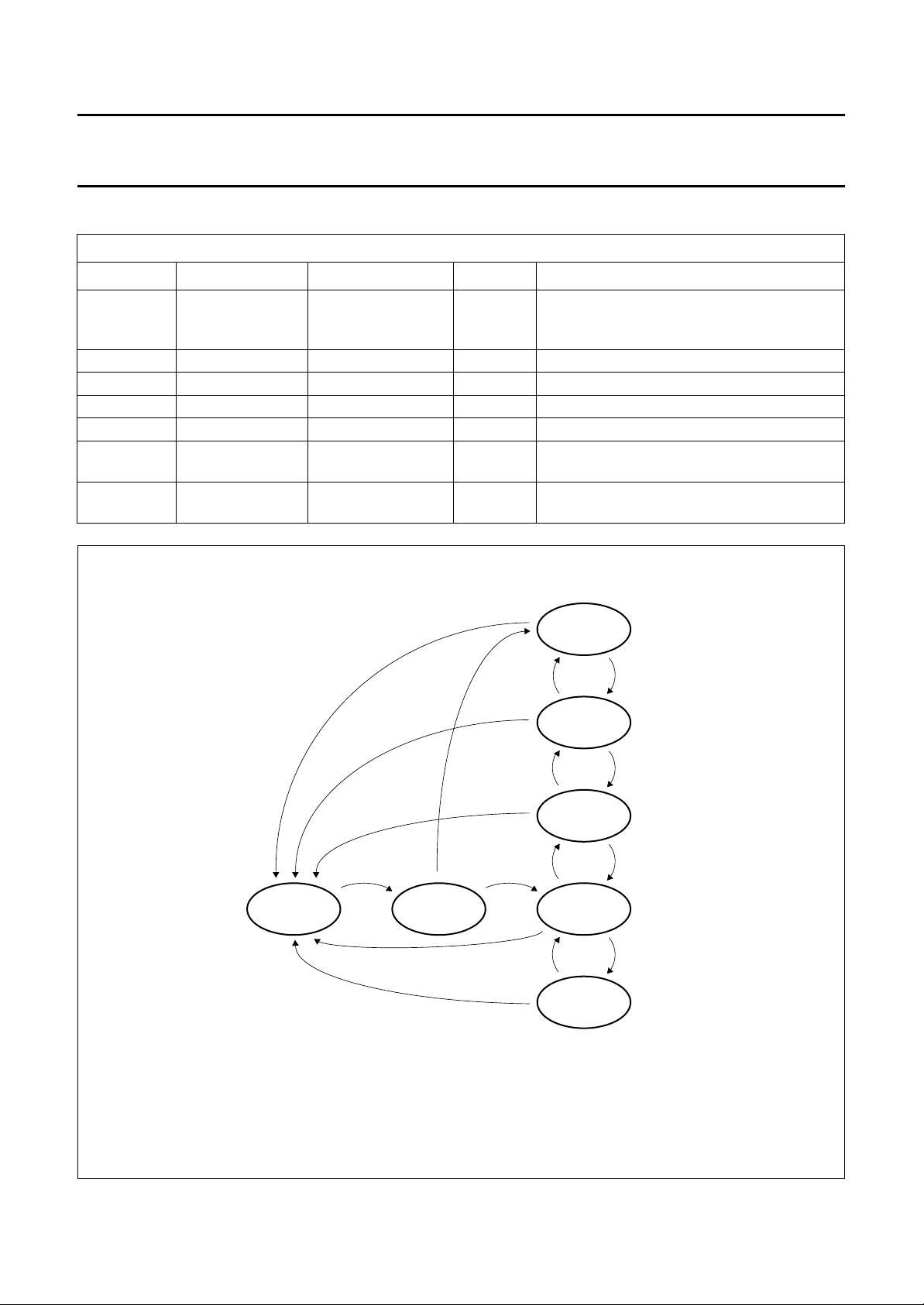

Table 1 State control pin.

VP1 SCHMITT TRIGGER IS TRUE

STATE REG3 (5 V) REG1 + REG2 RESET REMARKS

Coma LOW current off 0 stabilizer consumes low quiescent current;

state control circuit is switched off to lower the

quiescent current

Sleep LOW current off 0 state control circuit on

Wake HIGH current off 0 CPU in sleep mode

Reset HIGH current off 1 CPU called up

On HIGH current on 1 normal operation

Power on HIGH current off 1 V

Power off off off 0 V

rises from 0 to 8.5 V or higher

P1

(first start-up)

falls from VP to less than 3 V

P2

(V

= 2.5 V)

REG3

handbook, full pagewidth

REG3

REG3

bu

> 7.9 VV

bu

REG3

< 3 VV

< 3 VV

< 3 VV

REG3

COMA

> 3.8 VV

sc

SLEEP

> 3.6 VV

> 3.8 VV

sc

POWER ONPOWER OFF

< 3 VV

< 3 VV

sc

WAKE

> 2.8 VV

sc

> 2.2 VV

sc

RESET

> 2.0 VV

sc

or

< 7.1 VV

P

ON

< 3.8 VV

sc

< 2.7 VV

sc

< 1.9 VV

sc

< 1.1 VV

sc

and

> 7.6 VV

P

MCD347 - 1

Vbu = back-up voltage.

Vsc = state control voltage.

V

= Regulator 3 output voltage.

REG3

Fig.3 State diagram.

July 1994 10

Philips Semiconductors Product specification

Multiple output voltage regulator TDA3602

handbook, full pagewidth

REGULATOR 3

state control

REGULATORS

1 and 2

V

V

reset

hold

P

bu

MCD348

Fig.4 Timing diagram.

Table 2 Logic table HOLD function.

INPUTS FOR HOLD (note 1) OUTPUT

V

BU

VP SCHMITT

TRIGGER

ON STATE REG1 REG2 HOLD

10 X000

01 X000

1 1 0000

11 10X0

11 1X00

1 1 1111

Note

1. 0 = off; 1 = on; X = don't care.

July 1994 11

Philips Semiconductors Product specification

Multiple output voltage regulator TDA3602

QUALITY SPECIFICATION

Quality in accordance with UZW-BO/FQ-0601.

TEST INFORMATION

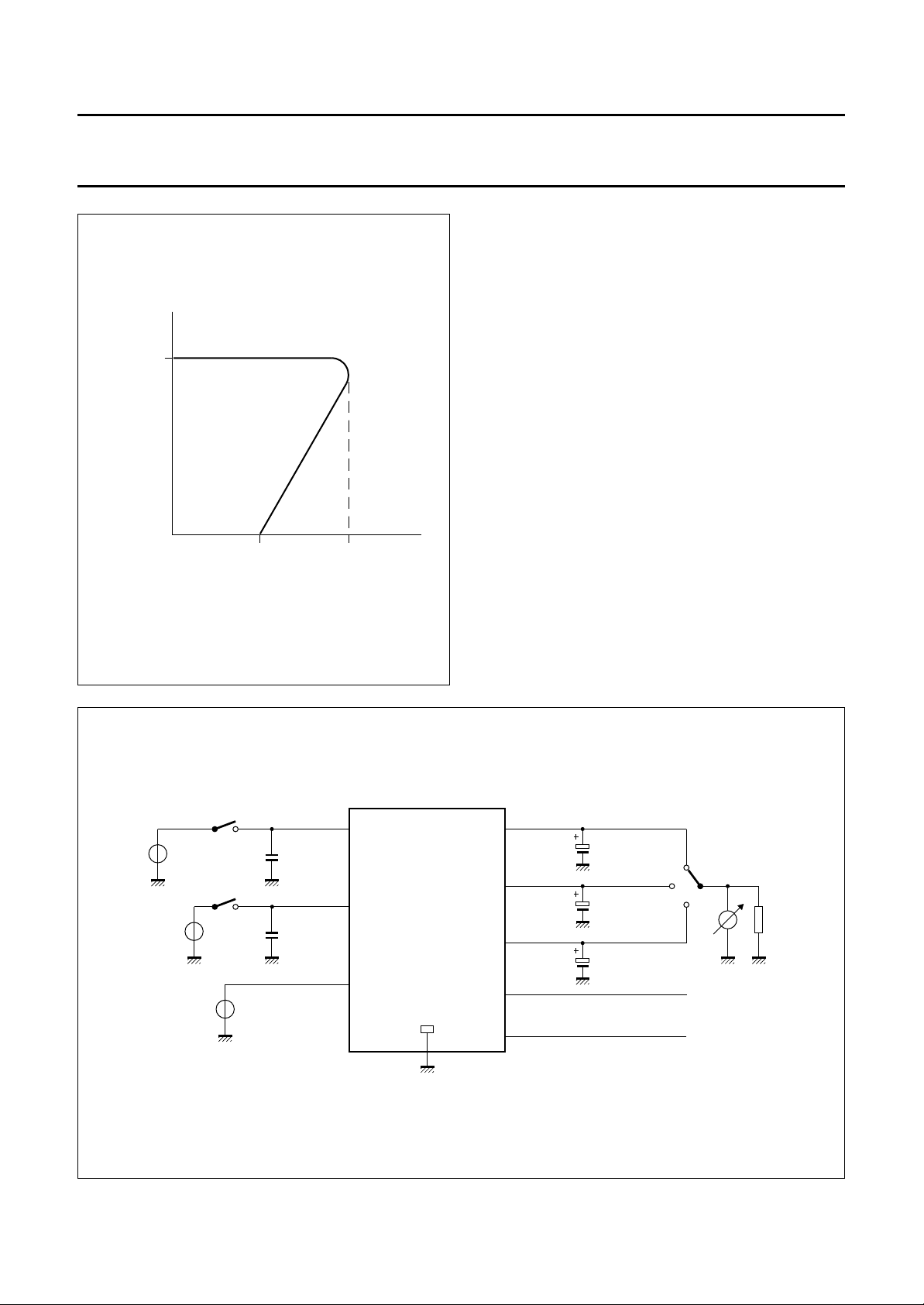

The outputs of the regulators are measured by means of a

handbook, halfpage

V

Rx

V

0

(Regulators

1 and 2)

selector switch (one by one). In addition, switch SW2 is

only closed when V

is greater than VP; then the internal

bu

switch of the TDA3602 is opened. Vbu (pin 8) can only

withstand a 50 V load dump pulse when switch SW2 is

kept open or when switch SW2 is replaced by a 100 Ω

resistor.

Fig.5 Foldback current protection.

handbook, full pagewidth

V

P

V

bu

V

on / off

sc

SW1

SW2

I

sc

C1

220 nF

C2

220 nF

state control

V

I

REGm

V

P

bu

1

8

4

MCD354 - 1

TDA3602

6

ground

Regulator 1

2

Regulator 2

9

Regulator 3

7

hold

5

reset

3

8.5 V

C3

10 µF

5 V

C4

10 µF

5 V continuous

C5

10µF

MCD351 - 1

R

V

L

2 W

Fig.6 Test circuit.

July 1994 12

Philips Semiconductors Product specification

Multiple output voltage regulator TDA3602

APPLICATION INFORMATION

Noise

Table 3 Noise at regulator outputs dependent on

capacitive load (C

REGULA TOR

(NOTE 1)

REG I

L

).

L

C

L

10 µF47µF 220 µF

1 150 mA 800 µV 220 µV 160 µV

2 100 mA 500 µV115 µV

3 50 mA 350 µV 190 µV

Note

1. Regulators loaded with 100mA; noise in µV RMS

(B = 10 Hz to 1 MHz).

The available noise at the output of the regulators depends

on the bandwidth of the regulators, which can be adjusted

by means of the load capacitors. The noise figures are

given in Table 3.

Although stability is guarenteed when C

is higher than

L

10 µF (over temperature range) with tan (φ) = 1 in the

frequency range 1 kHz to 20 kHz, it is recommended to

use a 47 µF load capacitor for Regulators 1 and 2. When

a microprocessor is supplied by Regulator 3 much noise

can be produced by this microprocessor. This noise is not

influenced by increasing the load capacitor of Regulator 3.

The noise on the supply line depends on the supply

capacitor. When a high frequency capacitor of 220 nF with

an electrolytic capacitor of 100 µF in parallel is placed

directly over pin 1 (VP) and pin 6 (ground) the noise is

minimized.

The stabilizer is in 'power on' after the supply is

reconnected (Vbu> 7.9 V) and 0.1 < Vsc < 2.2 V.

STABILIZER WITHOUT MICROPROCESSOR 2

Fig.8 illustrates the application circuit for a low end radio

set with push switches when no microprocessor is used.

The stabilizer can be switched to the on mode by pressing

switch SW1. In this mode, Regulators 1 and 2 are switched

on, so transistor T1 takes over from switch SW1. The

stabilizer can only be switched off by connecting the base

of T1 to ground (SW1 not pressed). This can be achieved

by pressing switch SW2.

The hold signal is only HIGH when the device is in the on

mode and both VP and the regulators are available, so that

this signal can be used to control the power stages (mute).

During a fault condition, this signal turns LOW

immediately.

When the stabilizer is connected to the supply for the first

time, the initial state will be the power-on stage, so

Regulators 1 and 2 are not switched on.

TABILIZER USED WITH MICROPROCESSOR

S

For a good understanding of the high end application,

shown in Fig.10, consult the flow chart of Fig.9.

When the set is off, a reset can be generated by

connecting the set to the supply for the first time (stabilizer

in power-on), or by pressing any key on the key matrix

(stabilizer in reset mode). When the reset is generated, the

stabilizer is held in the reset mode for a short period by T1.

The microprocessor has to take over control by making

reset mode equal to 0. The microprocessor can then

proceed with the initializing process. After this action, the

microprocessor has to check if the correct key has been

pressed. If so, the radio can be switched on by making on

equal to 0; if not, the microprocessor must switch the

device to the coma mode again, by making reset mode

and on both equal to 1; (wake mode is entered after a short

time constant, determined by R1 × C7 × constant), and

switch itself to sleep mode.

Application circuits

STABILIZER WITHOUT MICROPROCESSOR 1

The low end application is illustrated in Fig.7. When switch

SW1 is closed, a pulse is generated at the state control

input by C5 and R1, and the regulator is switched from

power off to the on mode (all three regulators are on). The

HOLD signal can be used to control the mute signal for the

power amplifiers. This signal is HIGH when all the

regulators are in regulation and VP1 Schmitt trigger is true.

July 1994 13

When the reset is generated for the first time (power-on

mode), the mode of the device can be detected by the hold

signal. If on = 0 and hold remains LOW, then the

microprocessor is in the power-on mode. In this event, the

microprocessor must go to the switch-off routine (making

on and reset mode both equal to 1).

Philips Semiconductors Product specification

Multiple output voltage regulator TDA3602

retro - rack

andbook, full pagewidth

retro - rack

andbook, full pagewidth

on / off

SW1

battery

> 220 µF

> 220 µF

C1

C1

R1

100 kΩ

R2

2.2 kΩ

V

P

V

bu

reset

1

8

3

4

C5

68 nF

47 kΩ

R1

C8

220 nF

C8

220 nF

state control

Fig.7 Low end application circuit.

V

P

V

C5

3.3 µF

C6

100 nF

1

bu

8

TDA3602

4

6

C8

220 nF

state control

TDA3602

6

ground

Regulator 1

Regulator 2

9

Regulator 3

7

hold

5

reset

3

Regulator 1

Regulator 2

Regulator 3

7

hold

C2

10 µF

C3

10 µF

C4

10 µF

C2

10 µF

C3

10 µF

C4

10 µF

MCD349 - 1

8.5 V2

5 V9

5 V continuous

mute5

8.5 V2

5 V

5 V continuous

mute

on

SW1

off

SW2

T1

R3

47 kΩ

Fig.8 Application circuit 2.

July 1994 14

ground

MCD350 - 1

Philips Semiconductors Product specification

Multiple output voltage regulator TDA3602

handbook, full pagewidth

SET OFF

RESET- MODE = 0

READ KEY

KEY = SET ON

Reset - pulse

by pressing any key

yesno

ON = 0

RESET- MODE = 1

SET ON

READ KEY

yes no

KEY = SET OFF

RESET

ON = 1

RESET- MODE = 1

SET OFF

Fig.9 Flow chart for high end application.

July 1994 15

MCD353 - 1

Philips Semiconductors Product specification

Multiple output voltage regulator TDA3602

handbook, full pagewidth

8.5 V2

C2

Regulator 1

1

P

V

C8

0.68 µF

C1

220µ F

5 V

10 µF

Regulator 2

9

V

bu

C3

8

10 µF

Regulator 3

TDA3602

F

µ

C6

220

R1

5 V continuous

C4

10 µF

hold

5

7

4

C7

state control

39 Ωk

reset

3

6

100 nF

C5

1 µF

ground

R2

15 Ωk

R6

82 Ωk

R4

120 Ωk

MCD352 - 1

R3

120 Ωk

T1

stabilizer on

battery

retro - rack

infrared

ir in

V

P

rows

columns

July 1994 16

on

open

collector

hold

reset-mode

Fig.10 High end application circuit.

I / O ports

reset

security in

ground

80C51 CPU

security

Philips Semiconductors Product specification

Multiple output voltage regulator TDA3602

Example of a modern car radio design with the

TDA3602

ESIGN CONSIDERATIONS

D

A modern car radio set meets the following design

considerations:

1. Semi on/off logic. The radio set has to switch on/off by

pressing the on/off key or by switching the ignition

2. Security code check

3. Low quiescent current in standby (this means that the

microprocessor is off when the set is off)

4. The set must recover the state it had before an engine

start or load dump

5. Apart from HOLD, RESET and VP only two more I/O

lines are used for full on/off logic

6. Supply by 1 or 2 supply lines

7. Radio Data System (RDS) should be implemented in

the set, but this is not a regulator problem

8. Lights must switch off during load dump

Although the TDA3602 is designed only to be supplied by

a continuous supply (battery), it is also possible to use both

a continuous and a switchable supply (ignition). The

ignition can be used to supply also the TDA3602, although

in this event additional circuitry is needed.

PPLICATION CIRCUIT WITH (SEMI-)FULL ON/OFF LOGIC

A

The application circuit of Fig.11 will meet all the above

mentioned design considerations. Three circuit parts can

be distinguished:

Reset circuitry

A reset is required to call-up the microprocessor when it is

switched to the sleep mode or the power-on reset (first

initialization of the microprocessor). To achieve this, three

different types of resets should be generated:

1. When the set has been disconnected from the supply,

the microprocessor must be initialized at connection to

the supply for the first time. The output ports of the

microprocessor are in a random state. To ensure

correct initialization, a reset has to be generated. This

is accomplished by the power-on state of the

TDA3602. In this state the reset output is HIGH and

Regulators 1 and 2 are disabled (despite the voltage

on the state control pin V

being below 1.1 V). Only

sc

after the voltage on the state control pin has risen

above 2.2 V can Regulators 1 and 2 be switched on

again by pulling the state control pin below 1.1 V.

2. In the sleep mode the microprocessor should be called

up by pressing the on/off key (normal off condition).

Now the reset is also generated by the RESET output

of the TDA3602. This reset output will go HIGH when

Vsc decreases from the value V

to below 1.9 V.

REG3

3. At fault conditions

(VP below 7.1 V, V

REG1

< V

nominal −0.3 V or

REG1

VP > 1 8 V), HOLD drops to logic 0 and the

microprocessor switches off the set. In accordance

with the design considerations is that the mode of

operation must switch to the state it was in before an

engine start or load dump occurred. To achieve this

the HOLD output of the TDA3602 can be used to

generate a reset pulse (only when Vsc remains below

1.1 V).

The RESET and HOLD outputs of the TDA3602 are

combined to generate the reset pulses. The pulses are

created by differentiating the outputs, using capacitors

C8 and C9. The reset pulses are added by means of the

diodes D2 and D3. The time constants are:

• tres

= 3 × R7 × C8 = 3 × 10 kΩ × 1uF = 30 ms

res(rise)

on/off button S1 should be pressed for at least 30ms,

before the microprocessor will see this

• tres

• tres

• tres

hold(rise)

(dis)

hold(disl)

= 3 × R7 × C9 = 5.4 ms

= 3 × R8 × C8 = 140 ms

= 3 × R9 × C9 = 25 ms

the microprocessor has to wait and check if HOLD

remains LOW for at least 25 ms before it switches off;

now it is certain that a correct reset will occur to wake up

the microprocessor again.

July 1994 17

Philips Semiconductors Product specification

Multiple output voltage regulator TDA3602

C11

C11

47 nF

47 nF

TR2

TR3

TR4

BULB UNIT

R10

47 Ωk

XTAL1

handbook, full pagewidth

C2

C1

220

220µF

nF

16 V

mute

power

S1

stage

Ωk

II

reset hold

Ωk

P

V

S2

S3

I/O I O O

P1.1 P1.2 P0.1 P0.2

P1.0P0.0

open-drain outputs

47 µF

C12

REG2

P

V

TDA3602SC

bu

V

µF

220

C3

R1

D4

Ω

ex1

R

100

C6

R4

1 Ωk

C11

REG1

47

nF

Ωk

100

TR1

47 µF

REG3

C7

R6

R5

GND HOLD

RESET

F

µ

10

Ωk

47

Ωk

100

C9

C8

47

C10

180 nF

1 µF

R7

nF

47

R9

D3

D2

47

R8

10 Ωk

D1

MSA723

mP 80C51

Fig.11 Application with all features of semi on/off logic.

R3

180 Ωk

Ωk

R2

390

L1

retrack

x1

xc1

A4

x2

xc2

ignition

A7

battery

14.4 V

x3xc3

July 1994 18

on/off security key matrix

x4

xc4

Philips Semiconductors Product specification

Multiple output voltage regulator TDA3602

A reset by the hold function can only be created when the

state control pin remains LOW. This is accomplished by

means of transistor T1 when Port P0,0 is high ohmic.

Because of resistors R2, R3 and R5 the transistor will

switch off when V

an engine start, when V

falls below a level of 5.0 V. During

ignition

reaches voltages as low as

ignition

5 V, the transistor will switch off. Regulators 1 and 2 are

already switched of by means of the VP Schmitt-trigger,

causing the HOLD output to go LOW. When V

ignition

again

increases the transistor will be switched on again (Port

P0,0 has to be open = logic 1), thereby switching the state

control pin to 0 V. As V

7.6 V (V

of the VP1 Schmitt-trigger) Regulators 1 and 2

rise

continues to increase above

ignition

will again switch on causing the HOLD output to go HIGH,

creating a new reset pulse.

The set can also be switched off by opening the ignition

key, causing transistor T1 to switch off. When the ignition

key is closed again, the set will restart to the original

situation that existed before the ignition key was opened.

The charge time of C6 equals 3× R4× C6 = 14ms. This is

less than the reset time tres

. To avoid the TDA3602

res(rise)

switching to coma mode before the microprocessor is

awakened, a double function has been given to T1. During

a reset pulse T1 is on (because of resistor R7), thus Vsc will

remain 0 V provided a reset occurs. After the reset pulse

has disappeared, the microprocessor is able to fully

control Vsc by mean of Port P0,0 or Port P1,1.

Security code circuitry

When the set is off and it is pulled out of RETRACK,×3 and

×4 are disconnected thereby switching the base of

transistor T1 to the output voltage of Regulator 3 (using

resistors R5 and R6). Transistor T1 is starting to conduct

and a RESET pulse is generated. The microprocessor is

activated and checks if Port P1,0 = logic 1. If this is so, the

microprocessor knows that the set is pulled out of

RETRACK and that time is limited to finish the program

correctly (because the microprocessor is operating on the

charge of capacitor C3). The security flag has to be set in

an EEPROM and the microprocessor can switch to

power-down before Regulator 3 switches to power-off.

Another possibility is that the set was running and pulled

out of RETRACK. Now a hold is generated, and the hold

interrupt routine has to check the security in Port P1,0.

R6 is an internal resistor in the microprocessor. An

external resistor limits however the spread.

Bulb circuitry

The lights are switched on provided the RESET output of

the TDA3602 is HIGH. This normally occurs when the set

is switched on. Only at first connection (power-off) will the

RESET output be HIGH when the set is off. In this event

the lights are also switched on. This is not a problem

because the required time for initializing the

microprocessor will be very short.

When a load dump occurs, the RESET output will go LOW,

disabling the lights. With the aid of this feature it is possible

to prevent the light bulbs being damaged at load dump.

Noise.

Regulators 1 and 2 are loaded with a 47 µF/16 V load

capacitor because of output noise. With this value the

output noise will be lower than 220 µV for Regulator 1 and

lower than 120 µV for Regulator 2 (see Table 3 and

associated text).

To minimize the noise on the supply line, capacitors C1

and C2 should be placed as close as possible across the

supply and ground pins of the TDA3602.

Timing diagram

In the timing diagram all of the situations which can occur

are shown (see Fig.12). A HIGH of switch S1 indicates that

S1 is pressed. A HIGH on Port P0,0 indicates that Port

P0,0 is high ohmic (Port P0 is an open-collector output). If

no open-collector output is available another port can be

used, but an extra diode has to be added in series with this

port to prevent T1 being switched on by this port. A HIGH

for the microprocessor indicates that the microprocessor is

operating, a LOW indicates that the microprocessor is in

standby mode.

The following situations are covered in the timing diagram:

1. Initialization of the microprocessor (TDA3602 in

power-off mode)

2. Switching the ignition with the set off (Port P0,0 =

logic 0)

3. Switching the set on/off/on by pressing S1 sequentially

(ignition available)

4. Switching behaviour at engine start and load dump

(set on)

5. Switching the set off and on again by switching the

ignition.

July 1994 19

Philips Semiconductors Product specification

Multiple output voltage regulator TDA3602

The timing diagram can only be understood after a

thorough investigation of the flow charts (see section Flow

chart semi on/off logic with security code). Furthermore

short and long RESET pulses can be seen (see Fig.12).

handbook, full pagewidth

V

battery

ignition

V

REG3

A4

A7

Flowchart semi on/off logic with security code

This section describes the software for controlling the

TDA3602 (semi on/off logic). A “o” in the flowchart flow

diagram Fig.13, indicates that the port mentioned is

switched as an output. A “1” indicates that the port

mentioned is switched as an input (temporarily).

The flowchart of figure 13 can be used for semi on/off logic.

reset

microprocessor

reset

V

SC

S1

microprocessor

REGULATORS

1 and 2

hold

P0. 0

initialization on

off on engine start load dump off by ignition

switch 1

MSA724

Fig.12 Timing of the applications.

July 1994 20

Philips Semiconductors Product specification

Multiple output voltage regulator TDA3602

handbook, full pagewidth

WAIT 25 ms

HOLD ?

= 0

SET

FLAG ?

= 1

P0, 0 (in)

= 1

P0, 0 = 0 (o)

= 1

= 0

= 0

START

P1, 0 ?

= 0

P1, 0 ?

SET FLAG = 1

= 1 set disconnected

= 1 first connection

SET FLAG = 1

SET ON

S

PRESSED

?

Po, 2 = 0

SEC FLAG = 0

SET FLAG = 0

P0, 0 = 0 (o)

µP: POWER DOWN

noyes

= 1

STOP

INTERUPT

HOLD = 0

HOLD ?

WAIT 10 ms

P0, 0 = 1 (o) P0, 0 = 0 (o)

P0, 0 = 1 (o)

µ

P

POWER DOWN

STOP

hold LOW because of:

Fig.13 Interfacing flow chart TDA3602.

July 1994 21

RTI

set pulled out

(1)

of RETRACK

SEC FLAG = 1

regulator fault

ignition = 0

= 1

= 0

P1, 0 ?

= 0

TIME OUT

= 25 ms ?

noyes

MSA728

Philips Semiconductors Product specification

Multiple output voltage regulator TDA3602

C11

C11

47 nF

47 nF

TR2

TR3

TR4

BULB UNIT

R10

47 Ωk

XTAL1

handbook, full pagewidth

C2

C1

220 nF

16 V

220µF

mute

power

S1

stage

Ωk

II

reset hold

Ωk

P

V

S2

S3

I/O I O O

P1.1 P1.2 P0.1 P0.2

P1.0P0.0

open-drain outputs

47 µF

C12

REG2

P

V

TDA3602SC

bu

V

220 µF

C3

R1

1 Ωk

C6

R4

C11

REG1

47 nF

Ωk

100

TR1

47 µF

REG3

C7

R6

R5

GND HOLD

RESET

F

µ

10

Ωk

47

Ωk

100

C9

C8

47

C10

180 nF

1 µF

R7

nF

47

R9

D3

D2

47

R8

10 Ωk

D1

MSA725

mP 80C51

Fig.14 Application with all features of full on/off logic.

R3

180 Ωk

Ωk

R2

x2

xc2

ignition

A7

390

battery

14.4 V

x3xc3

L1

retrack

x1

xc1

A4

July 1994 22

on/off security key matrix

C6

47 nF

x4

xc4

Philips Semiconductors Product specification

Multiple output voltage regulator TDA3602

FULL ON/OFF LOGIC

Using application circuit Fig.14, full on/off logic can be

achieved. Also extra software loops are required to enable

the set when ignition is off. The set can be controlled by

halfpage

START

P1, 1 = 1 (i)

X = Sx

X Sx + 4 ?

yes

P0, X = 0

Y = Sy

Y Sy + 4 ?

yes

input P1, Y

Y = Y + 1

P0, X = 1

X = X + 1

P1, 1 = 0 (o)

no

no

t R4 x C6 x in (5/3)

t 2.4 ms

Port P1,1 if the ignition is off (thus no extra I/O ports of the

microprocessor are required for full on/off logic).

Because Port P1,1 is a part of the key matrix the complete

key-scan loop must be finished within less than 0.5 × R4 ×

C6 = 2.4 ms, otherwise the TDA3602 will enter the reset

state and Regulators 1 and 2 are switched off during this

key-scan loop. When the time of the complete loop is

within 2.4 ms the Vsc will remain below 2 V (thus

Regulators 1 and 2 remain on).

It is also possible to switch Port P1,1 during the key-scan

loop sequentially from output (logic 0) to input. If this is

achieved within a time period of 1 ms, Vsc cannot become

HIGH long enough to switch Regulators 1 and 2 off.

When ignition is available, transistor T1 overrules Port

P1,1. In this event no variation on Vsc is seen during the

key-scan loop.

The flow chart presented in Fig.15 is only required for the

full on/off logic application of Fig.14.

The complete key-scan routine must be finished within 2.4

ms (when ignition is off) and that the key-scan routine has

to end with a statement P1,1 = logic 0. In the flow chart of

the key-scan routine, Sx is the start value of the rows and

Sy the start value of the columns. With Sx = 1 and

Sy = 1, one '0' is shifted on the output ports P0,1 to P0,5

and the input ports P1,1 to P1,5 are being read

sequentially per shift action.

Connections between microprocessor and Regulator 2

supplied

STOP

MSA727

Fig.15 Software key matrix with loops.

July 1994 23

When digital ICs, supplied by Regulator 2, are connected

to I/O ports (especially Ports 1 and 2), special attention in

the software has to be taken to avoid currents flowing from

Regulator 3 to Regulator 2. Because of ESD diodes in

digital ICs a current can flow from an output port (which is

in a high state) through the ESD diode into Regulator 2.

This will cause an increase in the quiescent current of the

set. The recommended action to avoid this problem is to

switch the specific I/O ports to logic 0.

Philips Semiconductors Product specification

Multiple output voltage regulator TDA3602

handbook, full pagewidth

REGULATORS

1 and 2

V

SC

S1

P1. 1

P0. 1

P0. 2

ignition switch = open (set was on with ignition off)

2 V

t 2.4 V

0

key scan cycle

S1 pushed to switch-off S1 pushed to switch-on

Fig.16 Timing key matrix.

open

MSA726

July 1994 24

Philips Semiconductors Product specification

Multiple output voltage regulator TDA3602

PACKAGE OUTLINE

SIL9MPF: plastic single in-line medium power package with fin; 9 leads

D

D

1

q

P

pin 1 index

P

1

q

2

q

1

SOT110-1

A

2

A

3

A

A

4

E

seating plane

19

Z

b

e

2

b

b

1

0 5 10 mm

scale

DIMENSIONS (mm are the original dimensions)

UNIT

mm

A

18.5

17.8

2

max.

3.7

A

8.7

8.0

b

0.67

0.50

b

1

2

1.40

1.14

bcD

A

3

4

15.8

1.40

15.4

1.14

0.48

0.38

21.8

21.4

(1)

D

1

21.4

20.7

A

Note

1. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

OUTLINE

VERSION

IEC JEDEC EIAJ

REFERENCES

SOT110-1

w M

(1)

E

eLPP

6.48

6.20

2.54

3.9

3.4

L

c

Q

(1)

w

0.25

Z

max.

1.0

2.75

2.50

1

3.4

3.2

q

Q

1.75

15.1

1.55

14.9

EUROPEAN

PROJECTION

q1q

2

5.9

4.4

5.7

4.2

ISSUE DATE

92-11-17

95-02-25

July 1994 25

Philips Semiconductors Product specification

Multiple output voltage regulator TDA3602

SOLDERING

Introduction

There is no soldering method that is ideal for all IC

packages. Wave soldering is often preferred when

through-hole and surface mounted components are mixed

on one printed-circuit board. However, wave soldering is

not always suitable for surface mounted ICs, or for

printed-circuits with high population densities. In these

situations reflow soldering is often used.

This text gives a very brief insight to a complex technology.

A more in-depth account of soldering ICs can be found in

“IC Package Databook”

our

Soldering by dipping or by wave

The maximum permissible temperature of the solder is

260 °C; solder at this temperature must not be in contact

with the joint for more than 5 seconds. The total contact

time of successive solder waves must not exceed

5 seconds.

DEFINITIONS

(order code 9398 652 90011).

The device may be mounted up to the seating plane, but

the temperature of the plastic body must not exceed the

specified maximum storage temperature (T

printed-circuit board has been pre-heated, forced cooling

may be necessary immediately after soldering to keep the

temperature within the permissible limit.

Repairing soldered joints

Apply a low voltage soldering iron (less than 24 V) to the

lead(s) of the package, below the seating plane or not

more than 2 mm above it. If the temperature of the

soldering iron bit is less than 300 °C it may remain in

contact for up to 10 seconds. If the bit temperature is

between 300 and 400 °C, contact may be up to 5 seconds.

stg max

). If the

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

July 1994 26

Loading...

Loading...