SGS Thomson Microelectronics TD340ID, TD340 Datasheet

H-BRIDGE QUAD POWER MOSFET DRIVER

■ QUAD N-CHANNEL MOSFET DRIVE

■ INTEGRATED CHARGE PUMPFOR HIGH

SIDE MOSFET DRIVING

■ VERY LOW GROUND EMI NOISE

■ MOTOR SPEED AND DIRECTION CON-

TROL (LOW SIDE PWM)

■ INTERNAL OR EXTERNAL PWM SOURCE

■ 25kHz SWITCHING FREQUENCY ABILITY

■ SYNCHRONOUS HIGH SIDE RECTIFICA-

TION

■ REVERSED BATTERY ACTIVE PROTEC-

TION ABILITY

■ INTEGRATED 5V POWER SUPPLY FOR

MICROCONTROLLER

■ INTEGRATED SECURITY CIRCUITS:

UVLO, OVLO, WATCHDOG

■ 60V MAX RATING

DESCRIPTION

The TD340 integrated circuit allows N-Channel

Power Mosfets driving in a full H-bridge

configuration and is best suited for DC Motor

Control Applications. The four drivers outputs are

designed to allow 25kHz MOSFET switching.

The speedand direction of the motor are to be set

by twopins. Voltage across the motor is controlled

by low side Pulse Width Modulation (PWM). This

PWM feature can be made internally when the

input pinis connectedto an analog signal, or it can

be given directly from a digital source.

An internal charge pump allows proper upper

MOS driving for fullstatic operation (100% PWM).

TD340 achieves very low EMI noise thanks to its

balanced charge pump structure and its drivers

moderate slew rate.

To avoid excessive heating due to free wheeling,

appropriate synchronous rectification is achieved

on the corresponding High Side MOSFET.

Moreover, TD340 integrates a 5V voltage

regulator suitable as a power supply output forthe

microcontroller, a Reset circuit and a Watchdog

circuit.

Security functions disable the TD340 (MOS off)

when abnormal conditions occur like overvoltage,

undervoltage or CPU loss of control (watchdog).

TD340 withstands transients as met in automotive

field without special protection devices thanks to

its 60V BCD technology.

TD340

FOR DC MOTOR CONTROL

PRELIMINARY DATA

D

SO20

(Plastic Micropackage)

ORDER CODE

20

19

18

17

16

15

14

13

12

11

Package

D

OSC

CB1

H1

S1

CB2

H2

S2

L2

L1

Part Number Temperature Range

TD340ID -40°C, +125°C •

D=Small Outline Package (SO) - also available in Tape & Reel (DT)

PIN CONNECTIONS (top view)

VBATT

VOUT

RESET

CWD

WD

STBY

TEMP

IN1

IN2

1

2

3

4

5

6

7

8

9

CF GND

10

May 2000

This is preliminary information on anew product now in development or undergoing evaluation. Details are subject to change without notice.

1/21

SYSTEM AND INTERNAL BLOCK DIAGRAM

TD340

BATT+

5V

µCONTROLLER

0V

VBATT

VOUT

SUPPLY

UVLO

OVLO

RESET

CWD

RESET

WATCHDOG

WD

STBY

TEMP

IN1

T°

PWM

LOGIC

PWM

IN2

CF GND

TD340

OSC

CB1

H1

S1

CB2

H2

S2

L2

L1

Q2H

Q2L

Q1H

M

Q1L

BATT-

PIN DESCRIPTION

Name Pin Type Function

VBATT 1 Power Input Power Supply

GND 11 Ground Ground

L1 12 Push Pull Output Low Side Drive - Gate 1

L2 13 Push Pull Output Low Side Drive - Gate 2

H1 18 Push Pull Output High Side Drive - Gate 1

H2 15 Push Pull Output High Side Drive - Gate 2

S1 17 Analog Input High Side Drive - Source 1

S2 17 Analog Input High Side Drive - Source 2

CB1 19 Analog Input High Side Drive - Bootstrap Capacitor 1

CB2 16 Analog Input High Side Drive - Bootstrap Capacitor 2

CF 10 Analog Input External Capacitor to set the PWM Switching Frequency

IN1 8 Analog or Digital Input

IN2 9 Digital Input Direction to the Motor’s Rotation

STBY 6 Digital Input Standby Mode

TEMP 7 Analog Output Analog Indicator of Temperature

VOUT 2 Power Output Regulated Power Supply Output for the Microcontroller - 5V

RESET 3 Open Drain Output Reset Signal for the Microcontroller

WD 5 Digital Input Watchdog Signal from the Μicrocontroller

CWD 4 Analog Input External Capacitor to set Watchdog Timeout

OSC 20 Digital Output Oscillator Output

Analog Level of PWM (0 to 100%) if CF connected to a capacitor,

or PWM Signal if CF connected to ground

2/21

TD340

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

V

Batt

P

T

stg

ESD Electrostatic Discharge 2 kV

V

digital

V

lowgate

V

power

V

osc

T

R

hja

Notes:

1. The duration of the 60V voltage must be limited to 1 second if current is drained from the Vout regulator. Supply voltage in steady state

must be limited to ensure that dissipation rating is not exceeded.

2. The magnitude of input and output voltages must never exceed Vbatt+0.3V or 60V, whichever is less, except for H1 and H2: Vbatt+15V

or 60V, whichever is less.

OPERATING CONDITIONS

Positive Supply Voltage - Note 1 60 V

Power Dissipation 500 mW

d

Storage Temperature -55 to +150

Voltage on pins: IN1, IN2, STBY,WD, CWD, CF,TEMP,VOUT,

RESET

-0.3 to 7 V

Voltage on pins: L1, L2 -0.3 to 15 V

Voltage on pins: H1, H2, S1, S2, CB1, CB2 - Note 2 -0.3 to 60 V

Voltage on pin OSC Vbatt-6.5 to Vbatt V

Maximum Junction Temperature 150 °C

j

Thermal Resistance Junction-Ambient 85 °C/W

o

C

Symbol Parameter Value Unit

V

T

Positive Supply Voltage 6.5 to 18.5 V

batt

Operating Free Air Temperature Range -40 to +125 °C

oper

3/21

TD340

ELECTRICAL CHARACTERISTICS

Vbatt= 12V, Tamb=-40°C to 125°C (unless otherwise specified)

Symbol Parameter Test Condition Min. Typ. Max. Unit

TotalSupply Current

I

CC

T

min.<Tamb<Tmax.

I

stdby

Standby

Standby

UVLO

OVLO

Supply Current in Standby Mode

STDBY Pin Voltage for Standby OFF 0.8 V

H

STDBY Pin Voltage for Standby ON 2 V

L

Under Voltage Lockout - when

Vbatt<UVLO all buffer outputs are low

Under Voltage Lockout - when

Vbatt>OVLO all buffer outputs are low

DRIVERS - Cbootstrap=47nF

V

V

Freq Switching Frequency of PWM Cf = 270pF 20 25 30 kHz

I

I

Static Gate-Source High Side Mosfet Volt-

gs

age (charge pump)

Dynamic Gate-Source High Side Mosfet

gsd

Voltage (bootstrap)

Dead Time for secure Synchronous

t

d

Rectification

Output Current Capability - Low Side

Source

outl

Sink

Output Current Capability - High Side

Source

outh

Sink

OSCILLATOR - Rosc=5.6k - Note 1

F

V

Frequency of internal Step up converter

osc

Oscillator

Oscillator Swing - note 7

osc

T=25°C

-40°C < T < 125°C

T=25°C

-40°C < T < 125°C

Vbatt decreasing

Hyst. = 100mV typ.

Vbatt decreasing

Hyst. = 300mV

5.8 6.2 6.5 V

18.5 20 21.5 V

4.557

10mAmA

180 300

350µAµA

No Bootstrap Cap 8 11 15 V

9V

Cf=270nF,IN1=2.4V

No Load

Cload=4nF

T=25°C

40°C < T < 125°C

T=25°C

40°C < T < 125°C

T=25°C

40°C < T < 125°C

T=25°C

40°C < T < 125°C

T=25°C

40°C < T < 125°C

Vbatt = 12V

Vbatt = 9V

Vbatt > UVLO

2.1 2.8

30

25

60

50

30

25

60

50

0.6

0.5

6.25

6.25

5.1

1.5

50

50

100

100

50

50

100

100

111.4

3.5 µs

100

100

150

150

100

100

150

150

1.5

12

12

12.5

µs

mA

mA

mA

mA

mA

mA

mA

mA

MHz

MHz

V

V

V

4/21

TD340

ELECTRICAL CHARACTERISTICS (continued)

Vbatt= 12V, Tamb=-40°C to 125°C (unless otherwise specified)

Symbol Parameter Test Condition Min. Typ. Max. Unit

VOLTAGE REGULATOR - Co=220nF - note 2

V

Line

Reg

Load

Reg

Output Voltage

out

Line Regulation

Load Regulation

I

Maximum Output Current

o

I

Output Current Short Circuit Vout=0 100 200 mA

os

RESET SUPERVISORY CIRCUIT - note 3

Vt

V

V

Threshold Voltage Vout Increasing

hi

Threshold Voltage Vout Decreasing

thd

k

Linearity coefficient (Vthi = ki Vout) 0.86

i

k

Linearity coefficient (Vthd = kd Vout) 0.84

d

Hysteresis Threshold Voltage 50 100 200 mV

hys

t

Response Time High to Low 5 µs

phl

WATCHDOG CIRCUIT

t

Watchdog Time Out Period

wd

t

t

reset

Watchdog Input Pulse Width for Proper

ipw

Retrigger

Watchdog Input Rise Time for Proper

t

ipr

Retrigger

Reset Pulse Width 10 20 40 µs

TEMPERATURE OUTPUT

V

Output Voltage

T

∆V

Notes :

1. For proper operation, a 5.6k resistor needs to be connected between OSC and GND.

2. 220nF is the optimized value for the voltage regulator

3. The reset thresholds (Vout increasing and decreasing) are proportional to Vout, (coefficients kiand kd). ki and kd vary in the same direction with temperature.

4. Watchdog capacitor Cwd should be placed as close as possible to CWD pin.

Output Temperature Drift -7 -7.5 -7.8

T

Io=20mA

T=25°C

40°C < T < 125°C

6V < Vbatt < 16V,Io=20mA

T=25°C

40°C < T < 125°C

0 ≤ Io ≤ 40mA

T=25°C

40°C < T < 125°C

Vbatt = 12V

6V < Vbatt < 16V

T=25°C

40°C < T < 125°C

T=25°C

40°C < T < 125°C

No ext. capacitor

Cwd = 47nF - note 4

o

T= 25

C

4.6

4.5

5

5

5.4

5.5

100

150mVmV

2040mV

mV

40

20

4.0

3.9

3.9

3.8

0.5

0.7

4.3 4.5

4.2 4.4

1

1

4.6

4.5

2

1.5

mA

mA

ms

0.1 µs

0.1 µs

2.58 2.68 2.78 V

mV/oC

V

V

V

V

V

V

s

5/21

INTERNAL ELECTRICAL SCHEMATIC AND APPLICATION ENVIRONMENT

TD340

BATT +

S1

H1

CB1

OSC

CB2

Q1H

Q2H

H2

Q1L

+

A

M

-

Q2L

L1

L2

S2

BATT -

GND

UVLO/ OVLO

OSC

filter

-

+

TD340

6/21

5V REGULATOR

VOUT

VBATT

5V

RESET

RESET

WATCHDOG

WD

CWD

STBY

STBY

T°

TEMP

1.2V

IN1

µCONTROLLER

+

-

3.6V

CF

IN2

0V

TD340

FUNCTIONAL DESCRIPTION

Speed and Direction Control:

The TD340 IC provides the necessary interface between anH-Bridge DC-Motor Control configuration and

a micro controller. The speed and direction are given by two input signals coming from the

microprocessor.

Speed Control:

Speed control is achieved by Pulse Width Modulation (PWM).

The TD340 provides an internal PWM generator, but can accept an external PWM waveform.

IN1 can accept two different types of inputs:

- an analog input between 0 and 5V (CF must be connected to set the PWM frequency) gives an analog

value of the Internal PWM duty cycle

- a digital input (CF must be grounded) gives directly the PWM

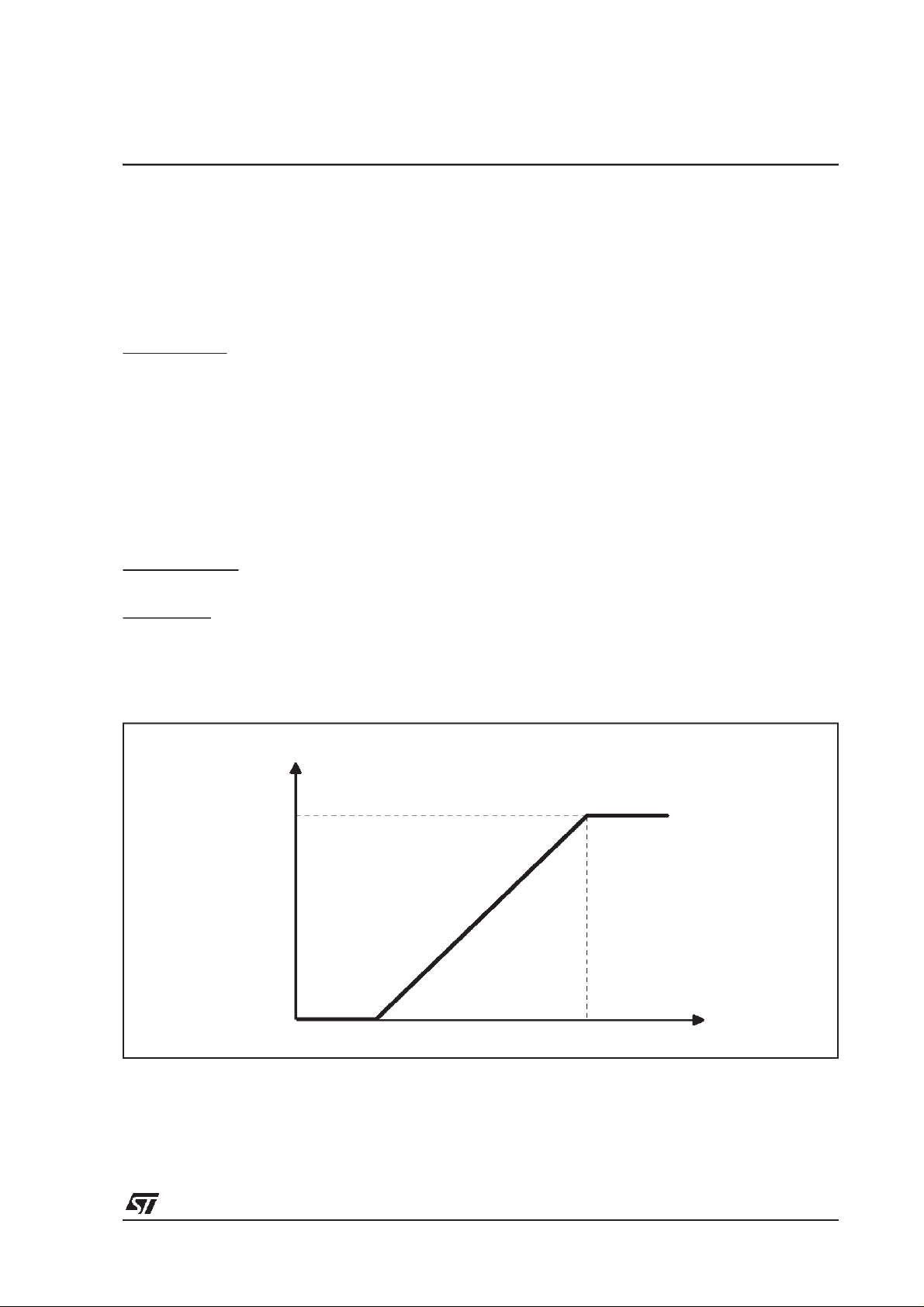

Figure 1 represents the Duty Cycle curve versus the IN1 analog voltage.

Figure 2 shows how to use the TD340 with an analog input or a digital input.

The speed control (or duty cycle) is achieved by the Low Side Drivers which impose the PWM function

while the cross-corresponding High Side MOSFETS is kept fully ON.

Direction Control:

IN2 accepts a digital value of the rotation direction.

Brake mode:

Brake mode is achieved by a zero level on the IN1 input.

The IN2 input selects low side or high side braking.

Brake mode is activated when the IN1 is at zero volt level for more than 200 us.

Figure 1 : Duty Cycle versus IN1 voltage

Duty Cycle

100%

0%

1.2V 3.6V IN1

Voltage

7/21

Loading...

Loading...